Grace Company Sure Stitch User Manual

Table of Contents

Wooden Quilting Frames

Display Console Attachment. . . . . . . . .

Top Plate Encoder Attachment . . . . . . .

Bottom Plate Encoder Attachment . . . .

Encoder Wheel Attachment . . . . . . . . .

Controller Attachment . . . . . . . . . . . . .

Wire Attachment. . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . .

Operating the SureStitch . . . . . . . . . . .

Limited 1 Year Warranty. . . . . . . . . . . .

Jumper Settings . . . . . . . . . . . . . . . . .

Pinnacle Quilting Frames

Display Console Attachment. . . . . . . . .

Top Plate Encoder Attachment . . . . . . .

Bottom Plate Encoder Attachment . . . .

Encoder Wheel Attachment . . . . . . . . .

Controller Attachment . . . . . . . . . . . . .

Wire Attachment. . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . .

Operating the SureStitch . . . . . . . . . . .

Limited 1 Year Warranty. . . . . . . . . . . .

Jumper Settings . . . . . . . . . . . . . . . . .

User Manual

Pg. 3

Pg. 3

Pg. 4

Pg. 4

Pg. 5

Pg. 5

Pg. 6

Pg. 7

Pg. 7

Pg. 8

Pg. 10

Pg. 10

Pg. 11

Pg. 11

Pg. 12

Pg. 12

Pg. 13

Pg. 14

Pg. 14

Pg. 15

Accessory for other quilting frames

Uiversal Adaptor . . . . . . . . . . . . . . . . .

Pg. 16 - 19

Pg. 1

Table of Contents

User Manual for installation

on Wooden Quilting Frames

Display Console Attachment. . . . . . . . .

Top Plate Encoder Attachment . . . . . . .

Bottom Plate Encoder Attachment . . . .

Encoder Wheel Attachment . . . . . . . . .

Controller Attachment . . . . . . . . . . . . .

Wire Attachment. . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . .

Operating the SureStitch . . . . . . . . . . .

Limited 1 Year Warranty. . . . . . . . . . . .

Jumper Settings . . . . . . . . . . . . . . . . .

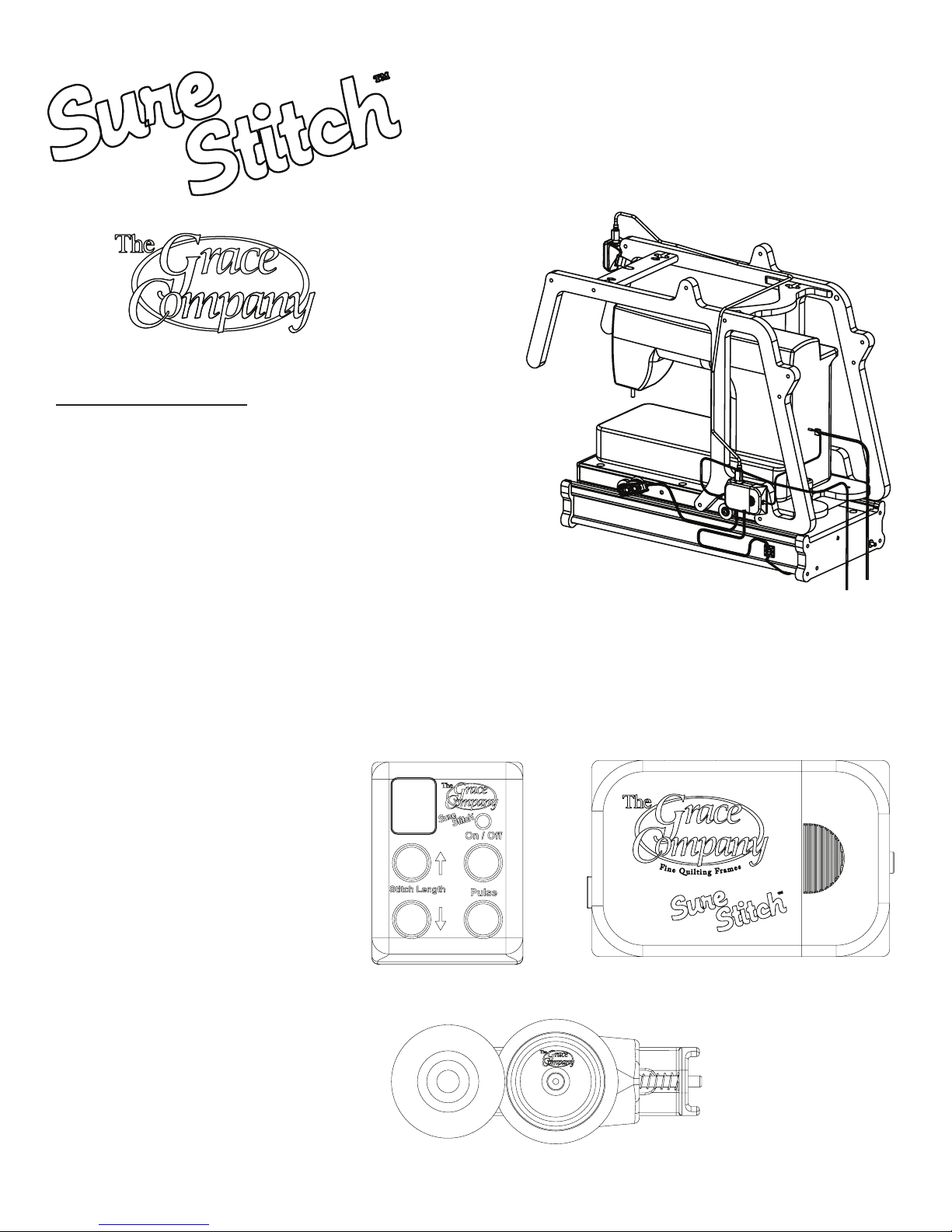

Parts Included:

1: Display Console

1: Control Box

2: Encoder (Wires attached)

(Not Shown)

1: 5v Power Supply

1: Display Cable

1: Sewing Machine Control Cable

6: Velcro - Cable Ties

2: Self Adhesive - Tie Mount

2: Zip Tie

Pg. 3

Pg. 3

Pg. 4

Pg. 4

Pg. 5

Pg. 5

Pg. 6

Pg. 7

Pg. 7

Pg. 8

Display Console

Control Box

Encoder

Pg. 2

SureStitch - Assembly

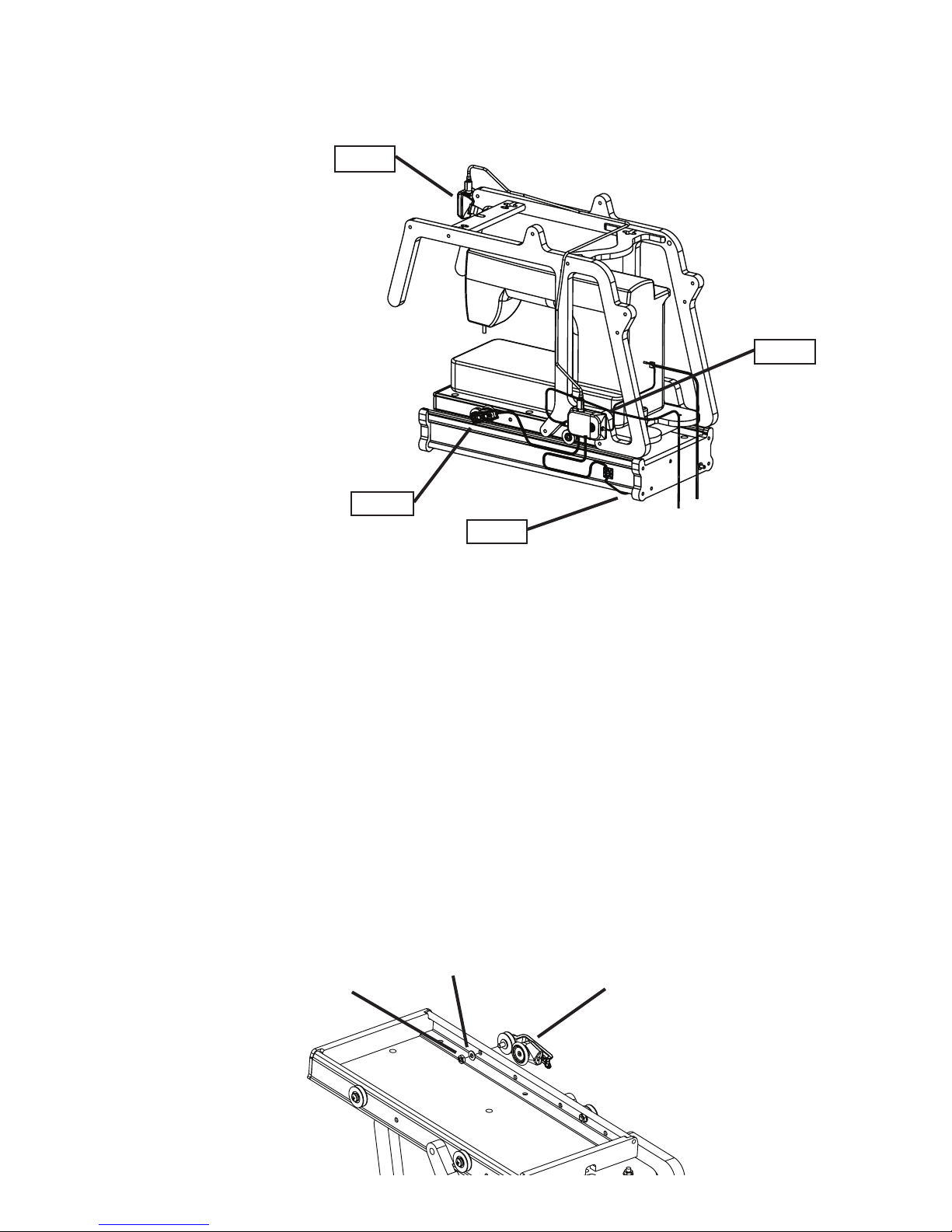

Display Console Attachment

Step 1: Secure the Display Console to your quilting frame with the included velcro strap.

Place the Display Console so that it’s controls will be easily accessible while you are quilting.

(NOTE: Wait to attach all wires until Step 5.)

Step 1: Display Console

Step 2: Top Plate Encoder

Step 3: Bottom Plate Encoder

Step 4: Controller

Step 1

Step 4

Fig. 1

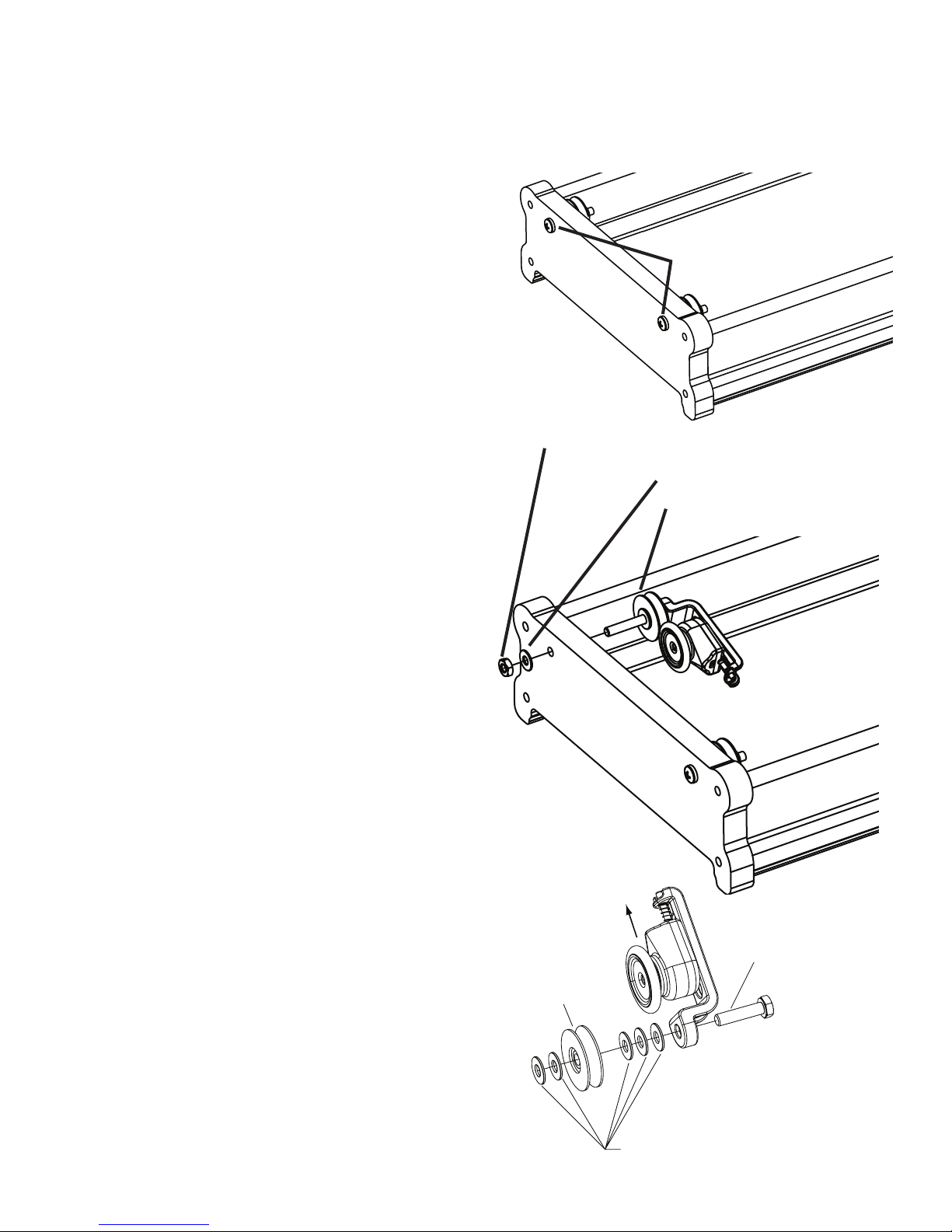

Top Plate Encoder Attachment

Step 2-1: If your sewing machine is in place on the carriage, remove it before continuing.

You will also need to turn the top plate up-side down, to be able to access the supporting

hardware.

2-2: Remove one of the front wheels from the top plate before attaching the encoder.

(Attach this encoder to the same side of the carriage that you will attach the Controller, in Step

4, to keep wires more organized.)

2-3: Remove the 6mm Hex nut, and the rst washer from the encoder with the shorter bolt

through the wheel (25mm).

2-4: Place the exposed end of the bolt on the Encoder through the hole that the wheel that

you just removed, was in.

2-5: Apply the Washer, and 6mm nut back onto the bolt. Tighten the nut securely. When

you tighten the nut, make sure that the encoders moving parts don’t contact any part of the

carriage. When the top plate is sitting upright, the encoder should be angled up slightly, so

that the encoder’s wheel doesn’t touch the track on the Bottom Plate. (See Fig. 1).

Step 2

Step 3

6mm Hex nut

Washer

Encoder with 25mm bolt

Fig. 2

Pg. 3

Bottom Plate Encoder Attachment

NOTE: THE WHEELS ON ONE END OF THE BOTTOM PLATE ARE

ATTACHED AS SHOWN IN Fig. 3-1. REMOVE ONE OF THESE

WHEELS IN STEP 3-1. The wheels attached to the other end of the Bottom Plate can’t be

used to attach an encoder.

Step 3-1: Remove one of the wheels from

the bottom plate before attaching the encoder.

(Attach this encoder to the opposite side of the

carriage as you attached the encoder on the

top plate.)

3-2: Remove the 6mm Hex nut, and the rst

washer from the remaining encoder. This

encoder should have the longer bolt through

the wheel (40mm).

3-3: Place the exposed end of the bolt on the

Encoder through the hole that the wheel that

you just removed, was in. Fig. 3-2

3-4: Apply the Washer, and 6mm nut back

onto the bolt. Tighten the nut securely.

When you tighten the nut make sure that the

encoders moving parts don’t contact any part of

the carriage. When the bottom plate is sitting

upright, the encoder should be angled up

slightly, so that the encoder wheel won’t touch

the Table Track..

Phillips Head Screw

Fig. 3-1

6mm Hex Nut

Washer

Encoder with 40mm bolt

Fig. 3-2

Encoder Wheel Attachment

This section is provided so you can

properly attach a wheel to your

encoder, if you ever need to put

a wheel onto the encoder. The

process is identical for any bolt

used.

Slide Encoder up, to allow

Encoder Wheel to t into

Carriage Wheel

6mm Hex Bolt

CarriageWheel

Washer

Pg. 4

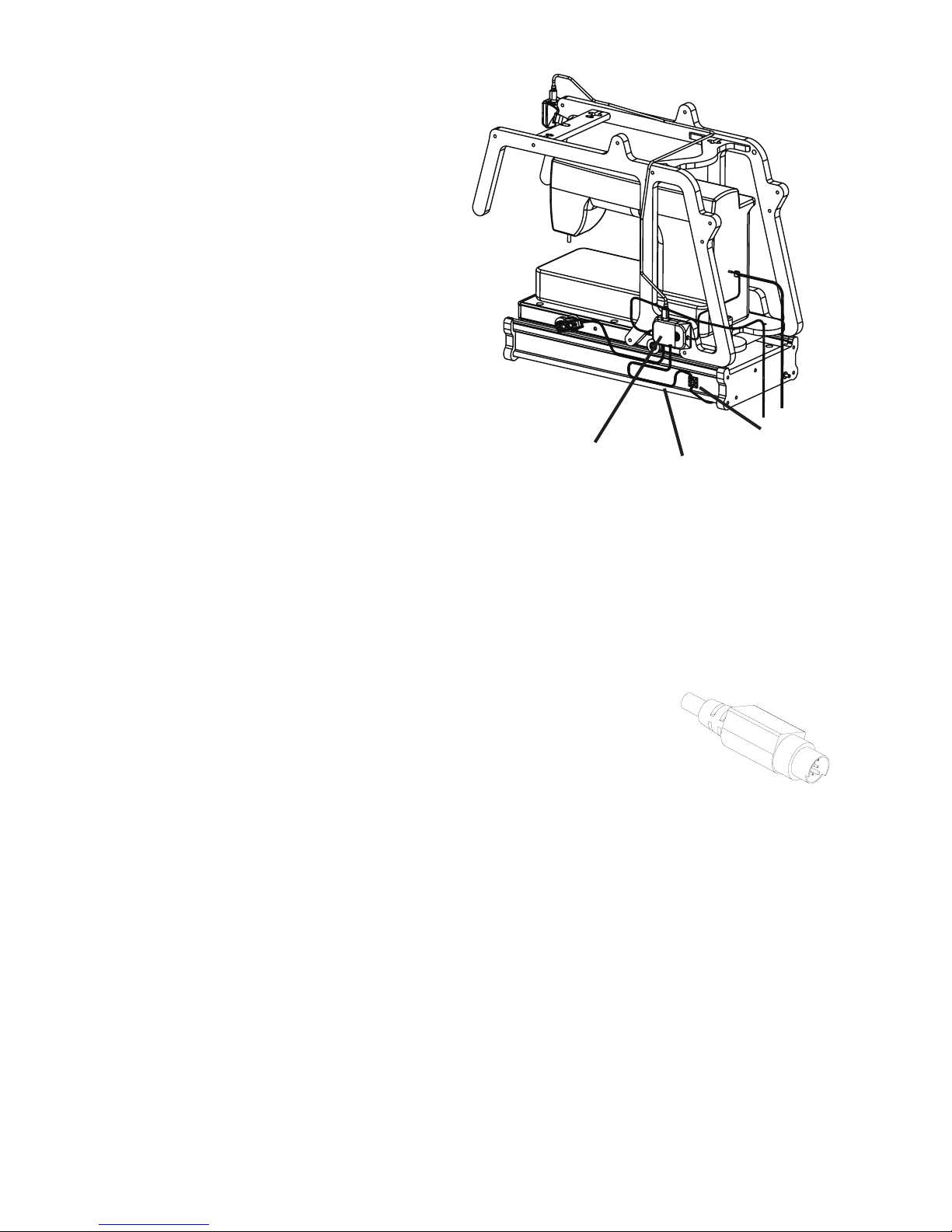

Controller Attachment

Step 4-1: Place your bottom, and top plates back onto your quilting machine. Also, Place your

sewing machine back onto the carriage.

NOTE: One end of all SureStitch wires are

attached to the Controller. Determine a place

to mount the Controller where it, or the wires

attached to it do not obstruct other features on

your quilting frame, or sewing machine. (Ideal

locations to mount the Controller are on the

lower portion of one of the carriage handles (see

Fig. 4), or directly to the back of your sewing

machine, other locations may also work better for

you.)

4-2: Remove the backing from the adhesive on

the back of the Controller.

Fig. 4

4-3: Adhere the Controller to the location that

you have determined to be the most convenient.

Controller

Bottom Plate

Tie Mount

Encoder Wire

Wire Attachment

NOTE:

• When wiring the SureStitch make sure that your sewing machine is turned off, and unplugged from

power, (this will ensure that when your sewing machine is turned on and accept the SureStitch as it’s

speed control).

• Leave a little slack in the wires near the wire connectors, to prevent the connector from being

pulled out, or damaged.

• Secure wires to carriage with the included velcro straps, tie mounts,

and zip ties. Keep wires taut between the velcro straps, and keep the

wires neat.

• When there is more wire than you need, coil up the extra wire,

and secure it to the carriage out of the way.

Display Wire Connector

Fig. 5-1

Step 5-1: Attach the Display wire (See Fig. 5-1, and Fig 5-2) to the Display Console, and to the

Controller. Be sure to line up the pins in the connectors to prevent bending them. Secure the wire to

the carriage to keep the wire neat.

5-2: Attach the wires from each of the encoders to the controller. It doesn’t matter which wire goes

into either of the (Telephone Type) connectors. Secure the encoder wires to the carriage using Tie

Mounts, and Zip Ties to keep the wires neat.

NOTE: When securing the wires for the bottom plate encoder, be sure to include enough slack to

allow your top plate to travel it’s entire available distance. This will prevent damage to the encoder

wire. Also, use a tie mount to secure the encoder wire to the bottom plate to prevent the wire from

rubbing on the quilting machine table when the carriage is being moved.

Pg. 5

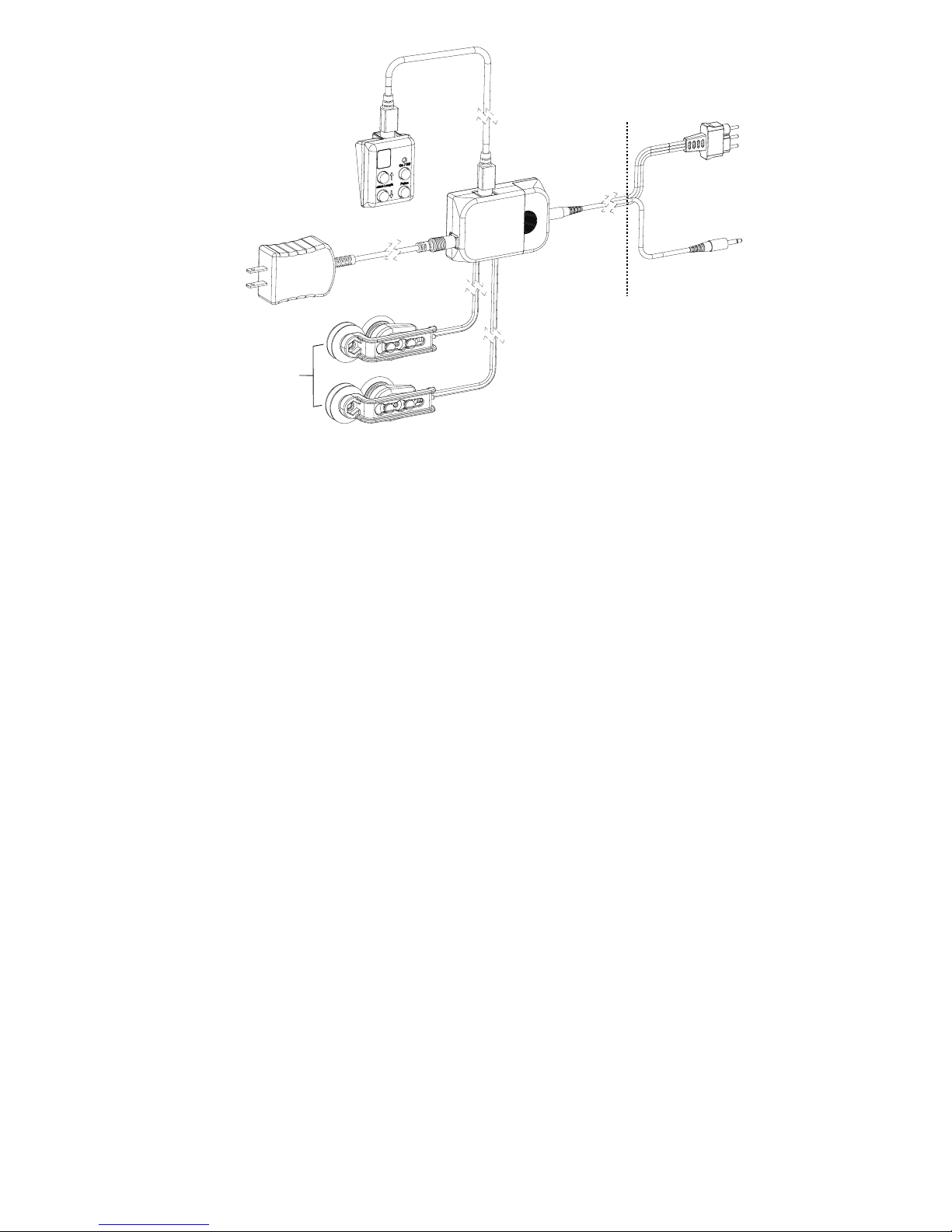

Wiring Diagram

To Sewing Machine

Display

Power Supply

(Appearance may vary)

Control Box

Note: You will recieve one (1) of the cords

shown above depending on the model of

sewing machine that your have.

Encoders

3 Prong Plug

Viking, PFAFF,

Janomi 1600

1 Prong Plug

All other compatible

Sewing Machines

Fig. 5-2

5-3: Connect the sewing machine control wire to the Controller, and also to the location on

your sewing machine where the foot pedal attaches.

5-4: Plug your sewing machine into an available power outlet, but do not turn on your sewing

machine. Connect the 5 volt power supply to the Controller. Plug the 5 volt power supply

into an available power outlet. (The power supply needs to be connected to a cord that is

long enough to allow the carriage to travel the entire length of the quilting frame.) It is OK to

leave the SureStitch connected to a power source, when not in use. If you do disconnect the

SureStitch from power, be sure to re-attach the unit to power before turning on your sewing

machine.

5-5: Verify that all wires are correctly attached. When the SureStitch is rst connected to

power, the LED panel on the display should show a number 5.

Troubleshooting

If you are experiencing problems.

T-1: Turn the sewing machine off.

T-2: Pull power cord out of SureStitch control box.

T-3: Plug power cord back into SureStitch.

T-4: Turn sewing machine on.

Because of your sewing machine’s built-in safety features, sometimes the machine will not

respond to your movement of the carriage and needs to be reset.

If your machine is running at an unusually slow speed, reset your machine and SureStitch

using the following steps.

T2-1: Turn sewing machine off.

T2-2: Unplug sewing machine from the wall, wait 5 seconds, and plug back in.

T2-3: Pull power cord out of SureStitch control box.

T2-4: Plug power cord back into SureStitch.

T2-5: Turn sewing machine back on.

Pg. 6

Loading...

Loading...