Grace Company Rotary Blade Sharpener User Manual

Rotary Blade Sharpener

The rotary sharpener is a safe, convenient and effective way

to extend the life of your rotary blades.

Basic Usage

* IMPORTANT: Do not sharpen newly out-of-the package blades! The Rotary Blade Sharpener is

used to hone a dull blade to a near factory-sharp edge. You will not be able to achieve a factorymachined edge. Damage and nicks on blades caused by pins, etc. are generally irreparable.

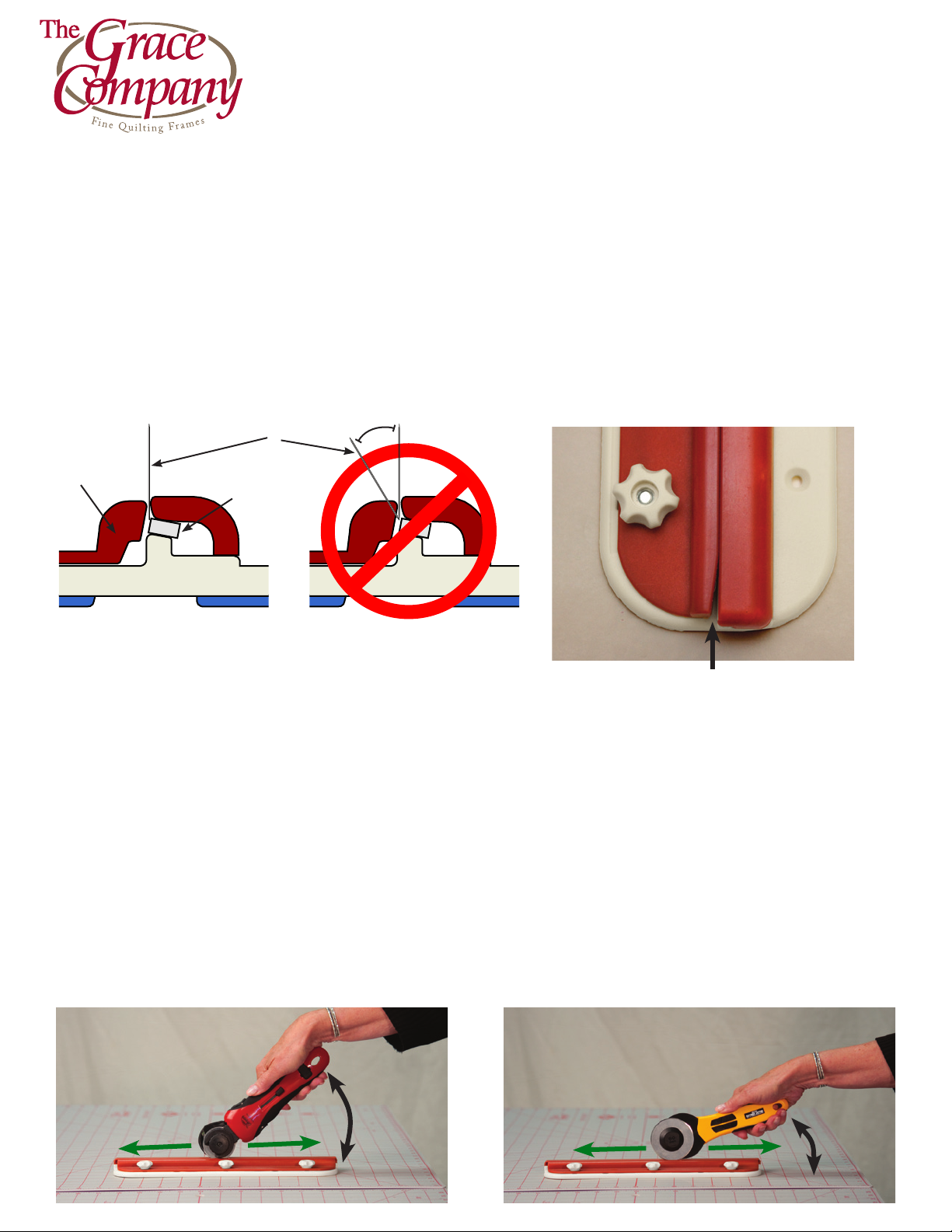

To use your sharpener, make sure that the Blade Guide is secured against the sharpening stone.

Insert the blade of your rotary cutter through the blade entrance at either end. When using your

sharpener make sure that your rotary cutter blade remains vertical at a 90° angle during the whole

process. Never angle your blade to cut in towards the sharpening stone as this may damage the

stone and dull your blade.

Blade

Blade Guide

To sharpen your blade

• Hold your cutter at roughly a 45° angle to the sharpener. Cutters with larger blades (60mm) may need

to decrease this angle to ensure that bottom of the blade aligns with the stone.

• Start at one end of sharpener track (not in the middle) and roll your cutter back and forth.

• Conrm that the blade is actually rotating as it travels through the slot.

• Pass the blade back and forth around 20 times (The number of times the blade will need to pass

back and forth will depend on the dullness of the blade. Fewer strokes may be required in the

sharpening process depending on the sharpness of the blade).

• Rotate the sharpener 180° and repeat the sharpening process for the other side of your blade.

• Repeat this process on both sides, decreasing the number of passes by half.

• Repeat again decreasing by half.

• Test the sharpness of your blade by cutting a piece of fabric.

Sharpening

Stone

Blade Entrance

Depending on sharpness of the blade, the sharpening process may need to be repeated.

30°

45°

Most Blades

60mm Blades

Adjustment and Maintenance

Cleaning

To prevent the build-up of metal residue on the abrasive stone, periodically clean the surface of the

stone. If the metal residue is not removed it may damage the abrasive stone surface, and the stone

will no longer easily sharpen blades.

To clean the stone, loosen the blade guide by unscrewing the knobs, and slide the blade guide away

from the stone. Clean the surface of the stone with a clean, dry rag. When you feel that you have

sufciently cleaned the abrasive stone, return the blade guide and knobs to their proper positions.

When securing the blade guide, adjust it so that your rotary cutter blade will easily roll in the slot, but

not so loose that the guide doesn’t force the blade against the abrasive stone.

Knobs

Blade Guide

Turning and replacing the stone

The abrasive stone in your sharpener has four

sides that can be used for sharpening blades.

After extensive use, the used side may wear

and become thinner in spots.

To turn your stone for use on a new side, rst

use the Allen Wrench located on the bottom of the sharpener to remove the 3 screws also found on

the bottom of the sharpener. Next, remove the stone bracket. You may now turn the stone so that a

new surface can be used for sharpening. Flipping the stone lengthwise may also increase the life of

the stone. Secure the stone and stone bracket onto the base again by turning each of the 3 screws

until they are all tight. Use this same process for replacing your stone with a new one when you feel it

becomes time to do so.

Stone Bracket

Important Notes

Keep your free hand clear of the

sharpener and blade while in use.

Do not attempt to hold the sharpener while in use.

With it’s non-skid bottom pads, the sharpener is

designed for hands-free use.

Loading...

Loading...