Grace Company Q'nique 21 Service Manual

Service Manual

21

|Table of Contents Q’nique 21: Service Manual

Bobbin Winder ............................................................................................................................ 1

Display Board Box ....................................................................................................................... 2

Needle Bar Height ....................................................................................................................... 3

Hopping Foot Height .................................................................................................................... 4

Hook Holder ............................................................................................................................... 5

Needle Plate ............................................................................................................................... 6

Handle Bars ................................................................................................................................ 6

Timing ........................................................................................................................................ 7

Thread Tensioner ........................................................................................................................ 9

Adjusting Thread Tensioner .........................................................................................................10

Extrusions Cover ........................................................................................................................11

Front Cover ................................................................................................................................12

Needle Rod Holders ....................................................................................................................13

Upper Shaft ...............................................................................................................................14

Pulley and Optical Encoding Wheel ..............................................................................................15

LED Assembly ............................................................................................................................15

Lower Shaft ...............................................................................................................................16

Bushing Block ............................................................................................................................17

Bushing Block ............................................................................................................................18

Main Board ................................................................................................................................19

Power Supply .............................................................................................................................20

Motor Driver Board ....................................................................................................................21

Grounding Wire ..........................................................................................................................21

Idler Pulley Tension ....................................................................................................................22

MCU Board Update .....................................................................................................................23

Motor Driver Board .....................................................................................................................26

Motor Driver Board Plugs ............................................................................................................26

Self Calibration Instructions ........................................................................................................27

Window Offset Adjustment Instructions .......................................................................................28

Encoder Test ..............................................................................................................................29

Button Test ................................................................................................................................29

Sensor Test ................................................................................................................................30

i

Tools Needed:

9mm Crescent Wrench

1.5mm Allen Wrench

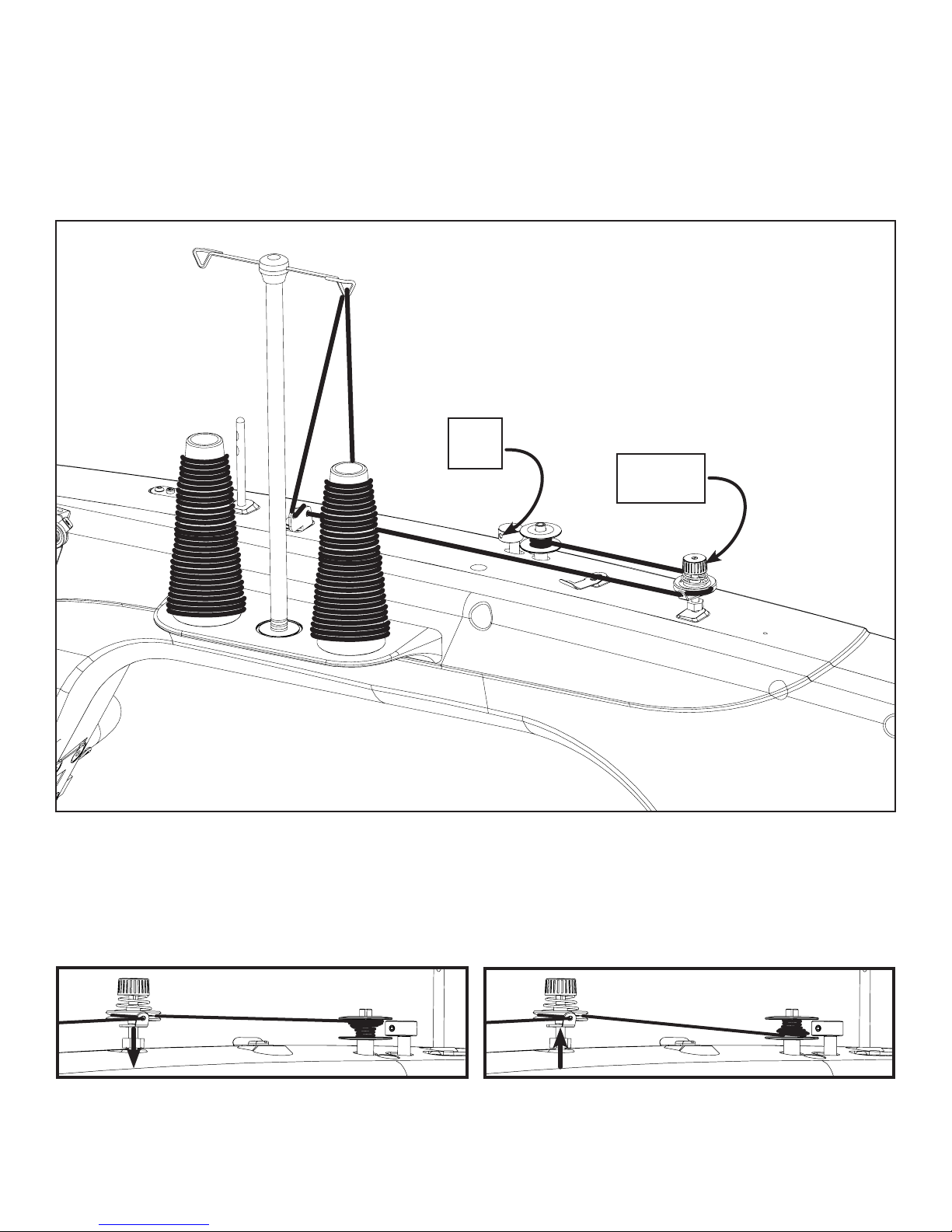

|Bobbin Winder Q’nique 21: Service Manual

Set

Screw

Tension

Disc Post

1. Adjust the Bobbin Winder Cam to be centered to the Bobbin without touching it by loosening the

Set Screw with the 1.5 mm Allen Wrench, adjusting the Cam, and retightening the Set Screw. If

thread winds mostly on the top of the bobbin, the Tension Discs Post will need to be lowered by

twisting the Tension Disc Post clockwise and retightening the hex nut.

2. If thread winds mostly on the top of the

bobbin, the Tension Disc Post will need to be

heightened by twisting the Tension Disc Post

clockwise and retightening the hex nut.

3. If thread winds mostly on the bottom of the

bobbin, the Tension Disc Post will need to be

heightened by twisting it counter clockwise and

retightening the hex nut.

1

2

Tools Needed:

3mm Allen Wrench

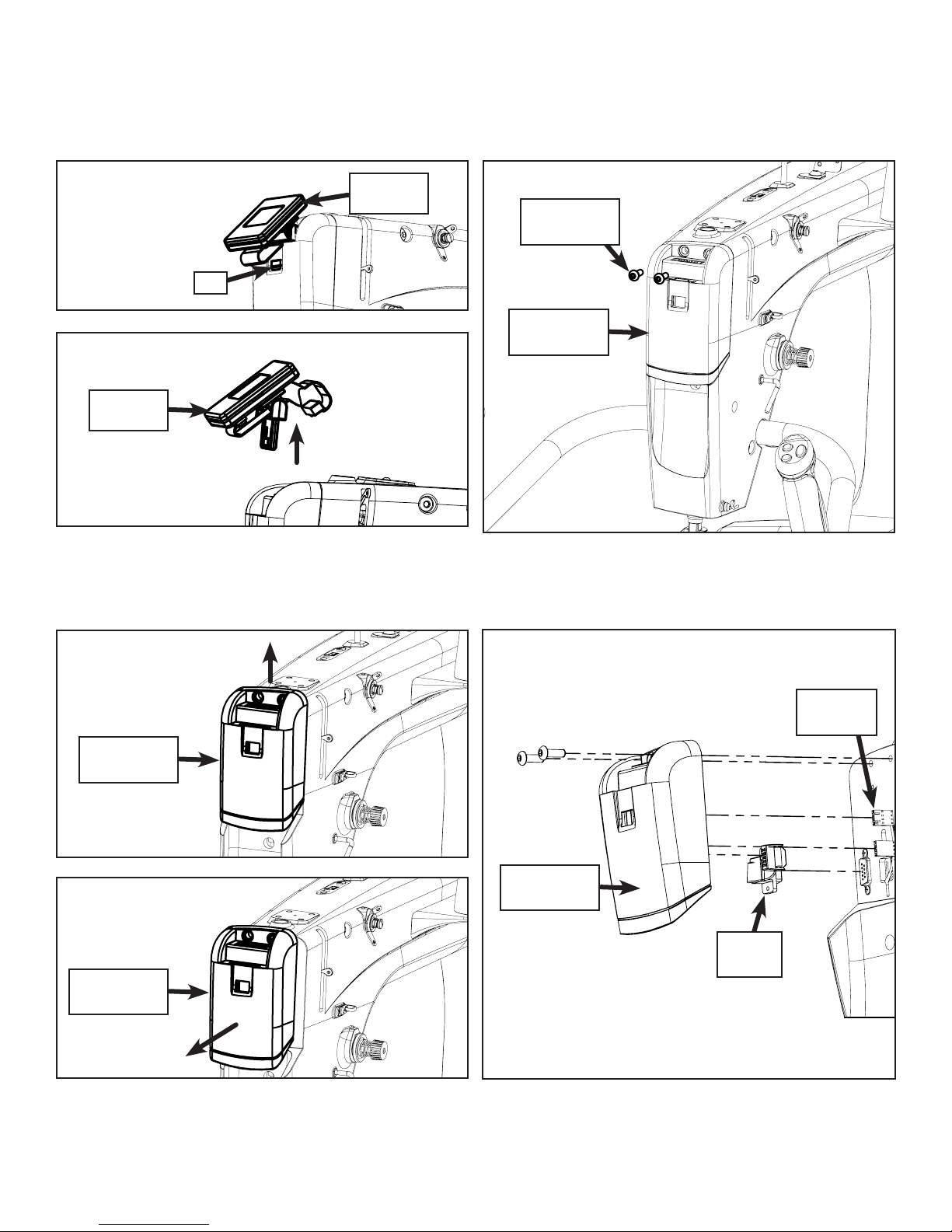

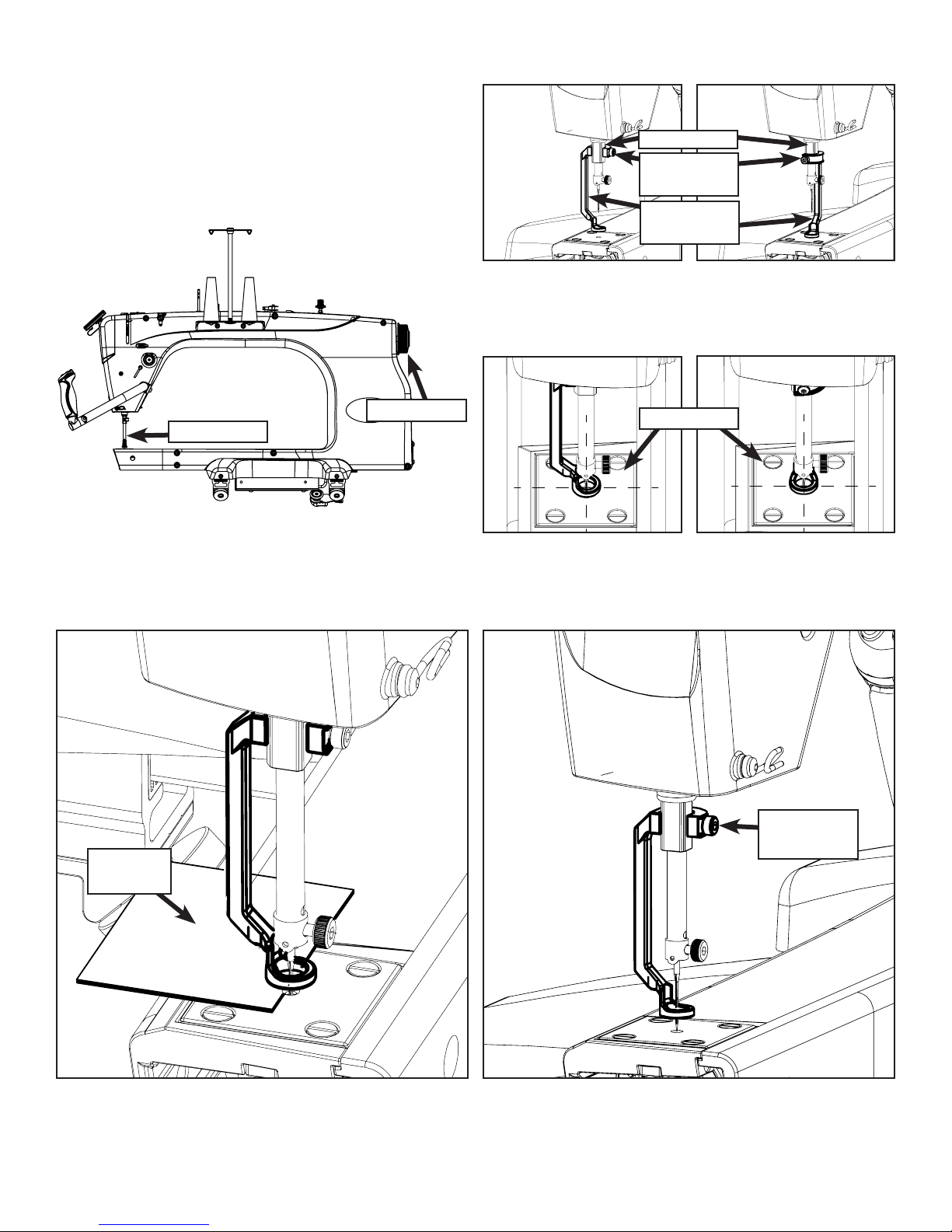

Screen

Assembly

Tab

|Display Board Box Q’nique 21: Service Manual

Screen

Assembly

M5 x 16mm

Board Box

SBHCS

Display

1. Press the Tab inward and pull the Screen

Assembly up and unplug the LCD Cable.

Display

Board Box

Display

Board Box

2. Remove the (2) M5 x 16mm SBHCS holding the

Display Board Box.

Handle

Cables (2)

Display

Board Box

Display

Cable

3. Pull the Display Board Box up and out.

4. Unplug the Handle Cables and Display Cable

and remove.

2

Tools Needed:

Flat Head Screwdriver

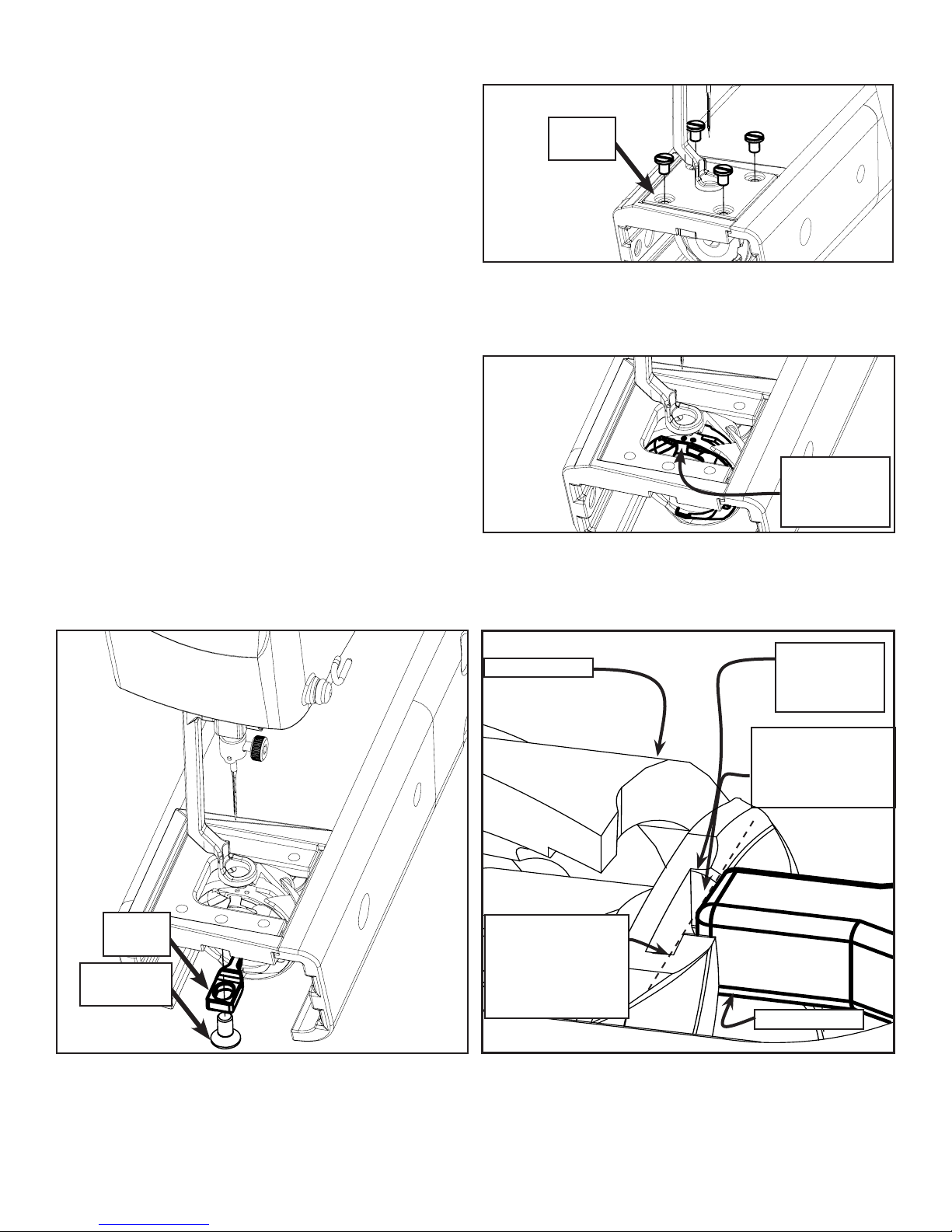

Needle Bar Height Spacer

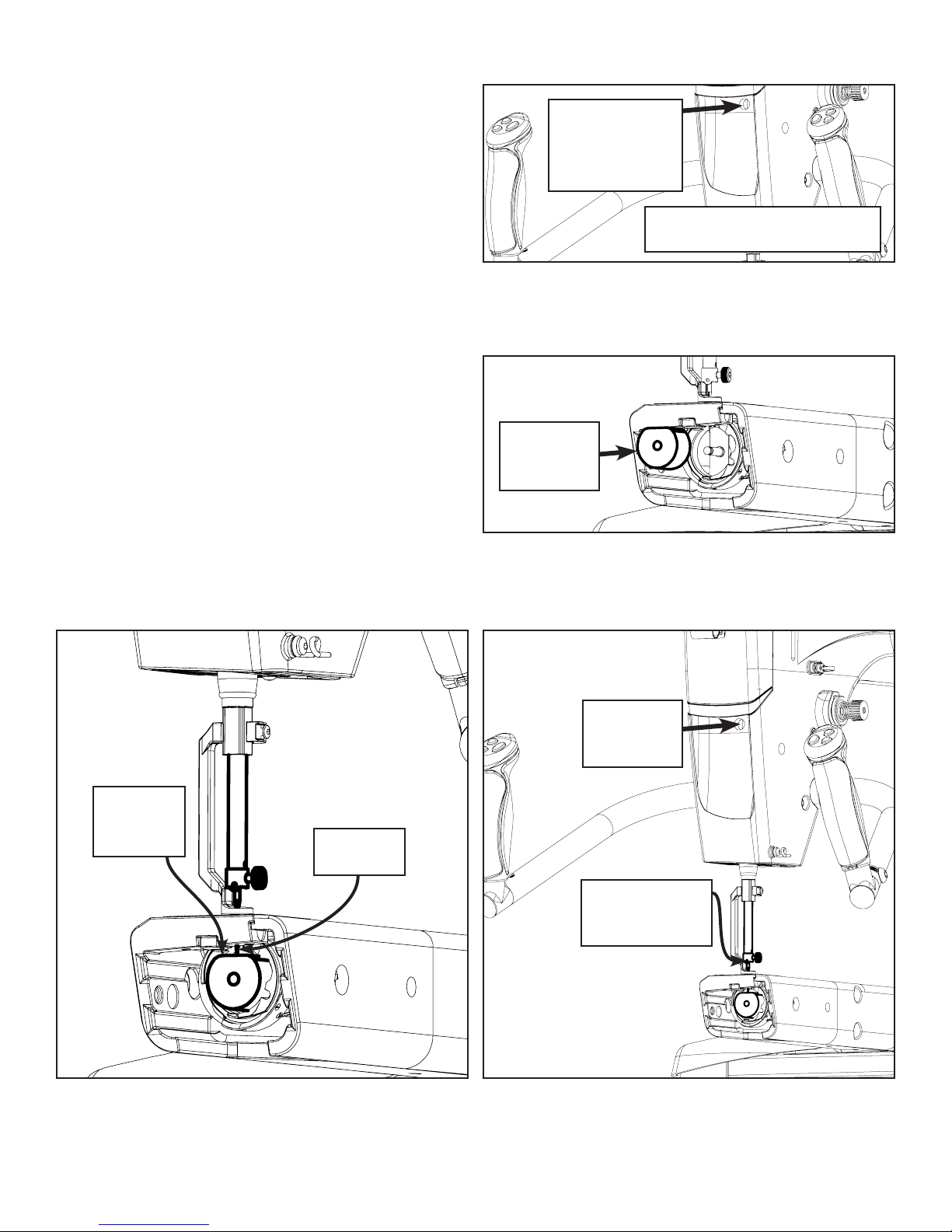

|Needle Bar Height Q’nique 21: Service Manual

Adjust Needle

Bar height with a

Flat Head Screw

Driver here.

*Note: Display Board Box may

have to be removed to access.

1. Rotate the hand wheel in the back of the

machine until the Needle Bar is in the lowest

position. Loosen screw inside sewing machine

head using a flat head screw driver.

Needle

Bar Height

Spacer

Height

Spacer

Flat Spot

2. Place the Needle Bar Height Spacer into the

Bobbin Case area.

Tighten

Screw inside

this hole

Tip of

Needle

Thread Guide

faces front

of machine

3. Using a Needle Bar Height Spacer bring the

Needle Bar down till the tip of the Needle is

resting on the flat surface of the Needle Bar

Height Spacer.

4. Tighten the screw inside the head of your

machine with a flat head screw driver, make

sure the Needle Bar is facing forward so the

thread guide is in the front of your machine.

3

Tools Needed:

|Hopping Foot Height Q’nique 21: Service Manual

3mm Allen Wrench

Hand Wheel

Needle Bar

2. Using the Hand Wheel in the back of your

machine, rotate your machine until the Needle

Bar is in the lowest position.

Press Bar

M3 Socket

Head Screw

Hopping

Foot

1. Attach your Hopping Foot to the press bar

using a M3 Socket Head Screw (don’t tighten

during this step) in either of the configurations

shown.

Needle Plate

3. Using the hole in the Needle Plate, align the

Hopping Foot so that it is centered.

.5mm Gap

Gauge

4. Place 2-6 sheets of paper under the foot and

lower the Hopping Foot to the top of the

surface depending on the thickness of your

project.

M3 Socket

Head Screw

5. Tighten the M3 socket head screw using the 3

mm Allen wrench.

*Note: Do not over tighten, this will

cause sewing machine to bind.

4

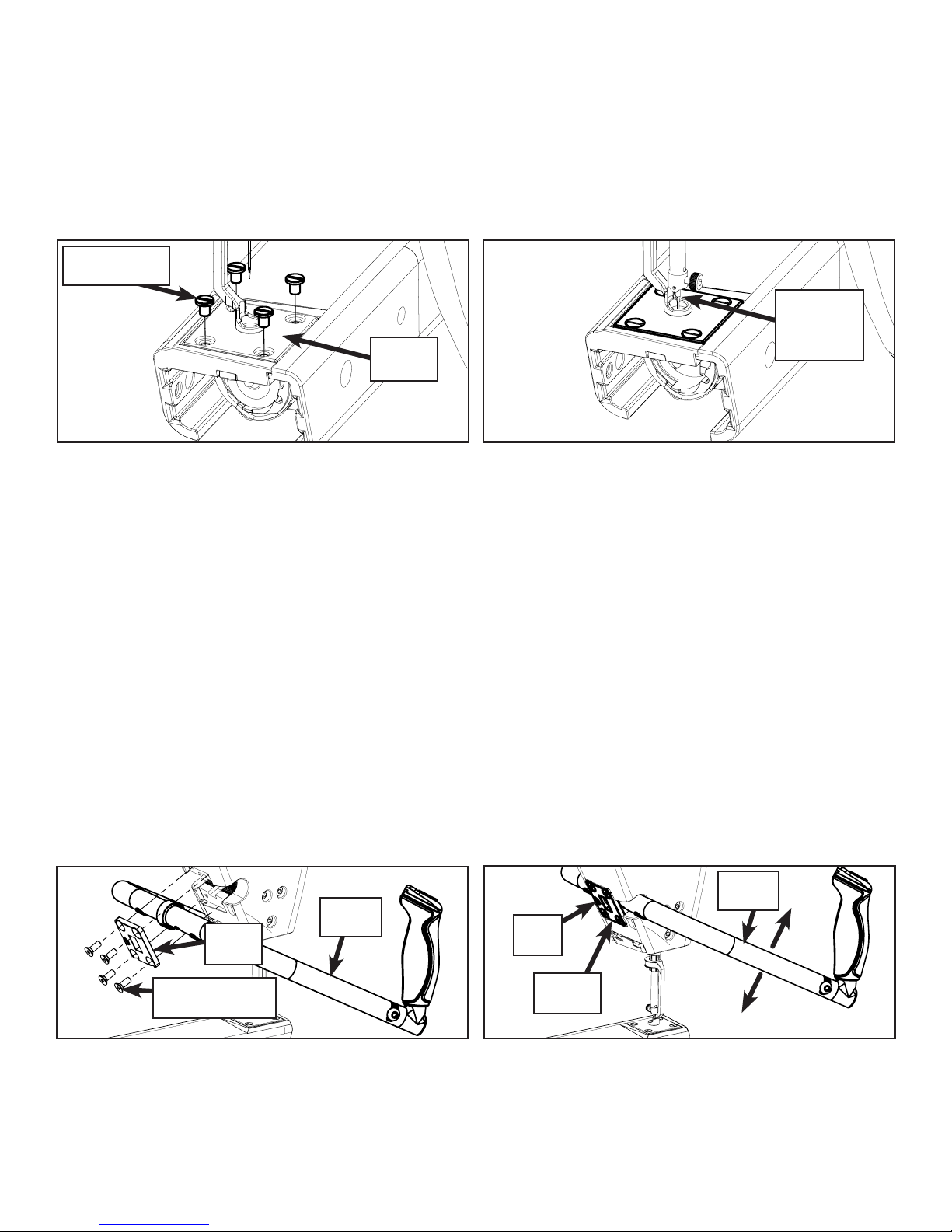

Tools Needed:

|Hook Holder Q’nique 21: Service Manual

3mm Allen Wrench

Flat Head Screwdriver

Needle

Plate

1. Remove the Needle Plate.

Hook Assembly

Positioning

Guide

2. Rotate your Hook Assembly so that the

positioning guide is at the highest point during

rotation.

Hook

Holder

M5 x 10mm

FHCS

3. Attach your Hook Holder to your sewing

machine with a M5 X 10mm FHCS (don’t

tighten the screw during this step) with the

Hook Holder’s finger in the middle of the Hook

Assembly’s positioning guide.

Hook Assembly

It’s hard to measure

so just make it so

tip of Hook Holder is

ush with Positioning

Guide Finger

Hook Assembly

Positioning

Guide

0.75mm Gap

between Hook

Holder and Hook

Assembly

Hook Holder

4. Slide your Hook Holder away from the Hook

Assembly so there is about a 0.75mm gap

between the Hook Holder and the Hook

Assembly, and tighten the M5 X 10mm FHCS.

5

Tools Needed:

Flat Head Screwdriver

Needle Plate

Screws (4)

|Needle Plate Q’nique 21: Service Manual

Needle

Plate

Needle in

Lowest

Position

1. Attach your Needle Plate using (4) Needle Plate

Screws, don’t tighten the screws during this

step.

2. Rotate Hand Wheel until the Needle is in the

lowest position. Move the Needle Plate until it

is centered around the Needle and tighten all

(4) Needle Plate Screws.

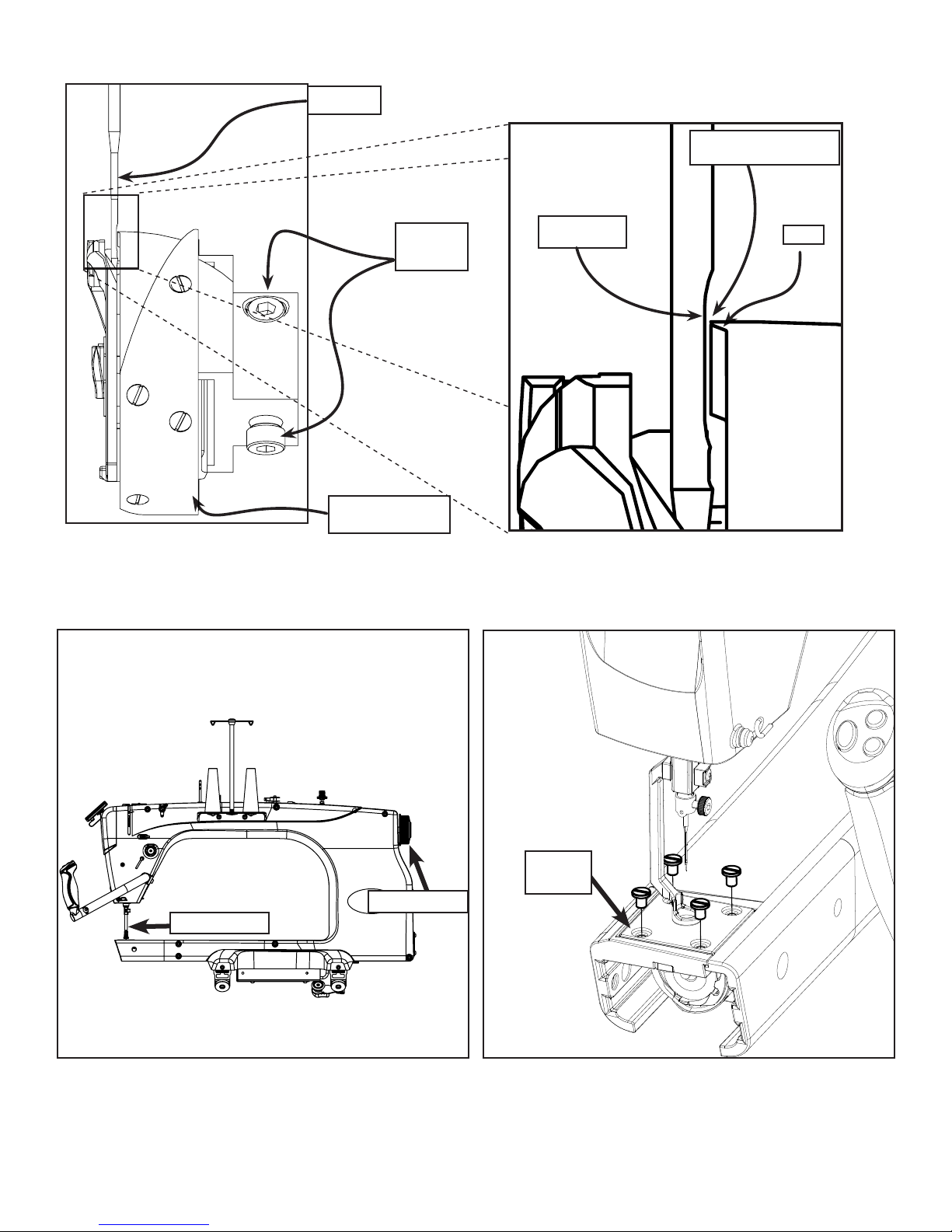

Handle Bars

Tools Needed:

5mm Allen Wrench

4mm Allen Wrench

To Remove: To Adjust:

Handle

Handle

Plate

Bars

Set

Screw

Handle

Bars

M6 x 16mm

Socket FCHS (4)

1. Using the 4mm Allen Wrench, remove the (4)

Screws from the Handle Plate. Remove the

Handle Plate and the Handle Bars

Handle

Plate

1. Adjust the Handles up and down by tightening

and loosening the Set Screw on the back of the

Handle Plate using the 5mm Allen Wrench.

6

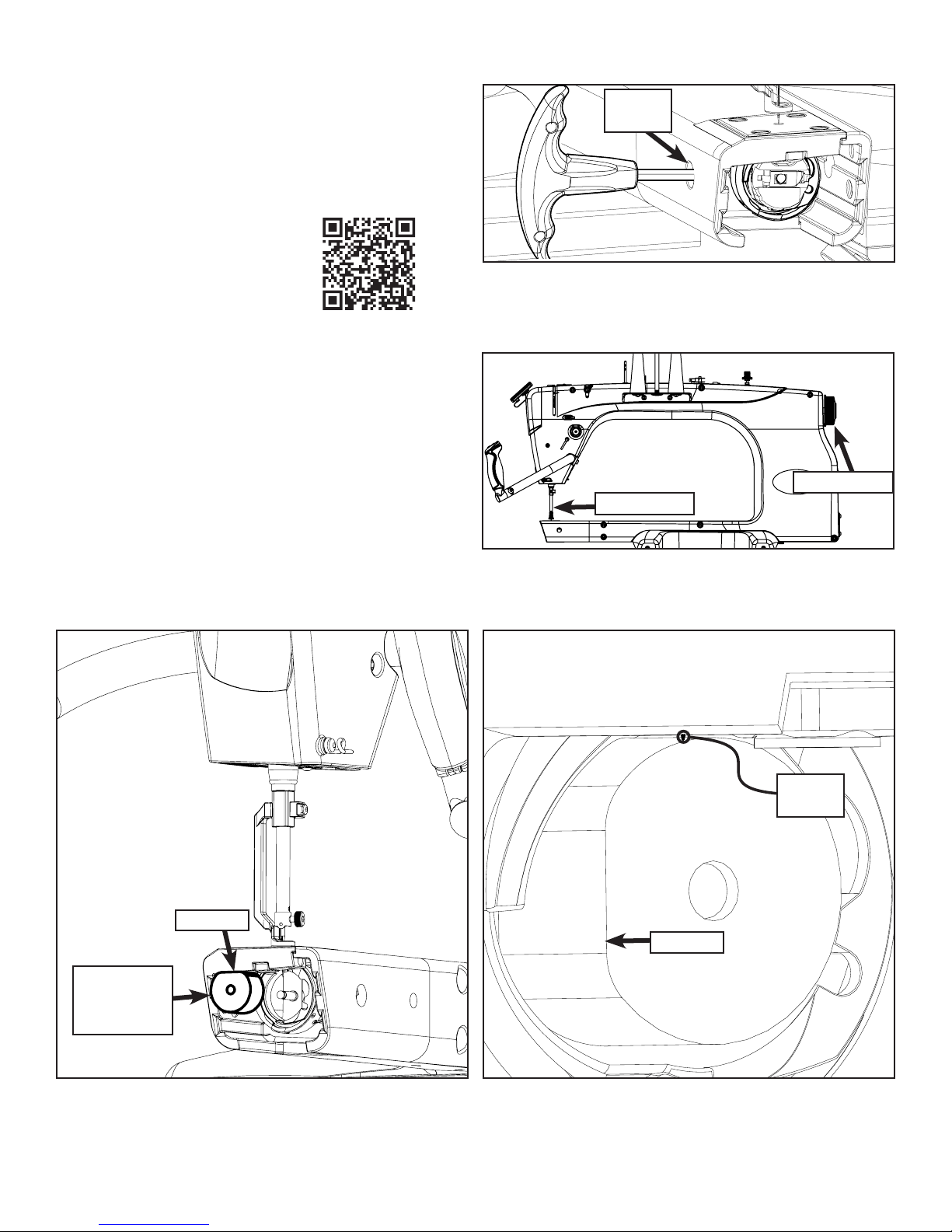

|Timing Q’nique 21: Service Manual

Tools Needed:

2mm Allen Wrench

Timing Spacer

Flat Head Screwdriver

A timing tutorial is available on

our website at:

http://www.qniquequilter.com/

videos/tutorials/

Timing

Hole

1. Loosen all 3 Hook Assembly Set Screws with a

2mm Allen Wrench by inserting the wrench into

the Timing Hole when each Set Screw aligns

with the hole.

Hand Wheel

Needle Bar

Needle

Bar Height

Spacer

2. Rotate the hand wheel clockwise from the front

of the machine so needle is rising out of the

Hook Assembly.

Tip Of

Needle

Flat Side

Flat Side

3. Place the Needle Bar Height Spacer into the

Bobbin Case area and twist so that flat side is

vertical.

4. Bring the Needle so it rests on the top of the

Needle Bar Height Spacer, so the groove in the

needle aligns in the middle of the hook on the

Hook Assembly.

7

Needle

0.02-0.75mm Gap

Set

Screws

Hook Assembly

Scarf

Hook

5. The Needle should be as close as possible to the Hook Assembly without touching, roughly between

0.02mm and 0.075mm. Tighten the Set Screw which is currently aligned with the Timing Hole on

the left side of the machine.

Needle Bar

6. Rotate the hand wheel a full rotation. If the

needle hits the Hook Assembly anywhere,

the needle will bend or there will be a clicking

noise. Adjust the needle height closer or

farther off from the hook.

Needle

Plate

Hand Wheel

7. Tighten the two remaining set screws and

reattach the Needle Plate.

8

Loading...

Loading...