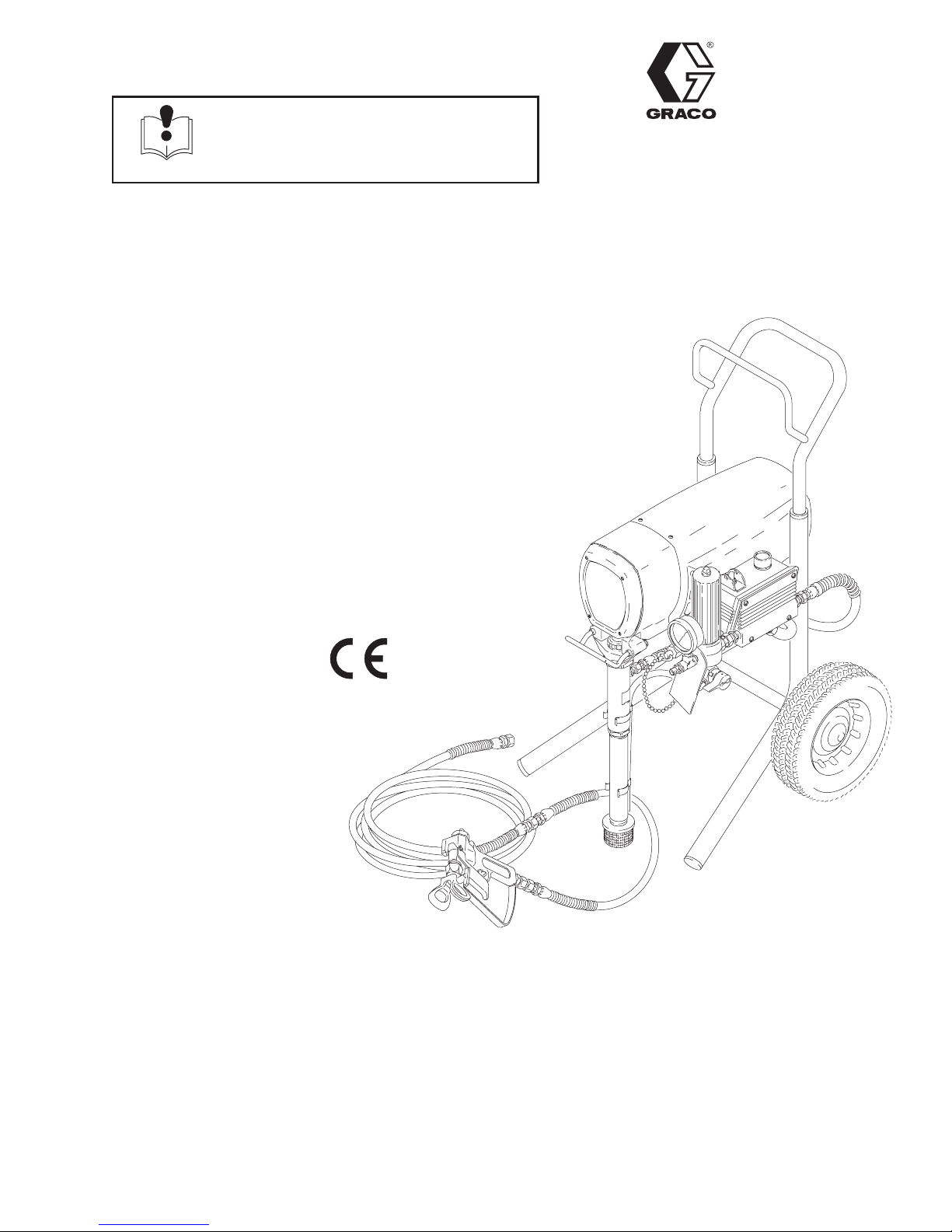

Page 1

INSTRUCTIONS-PARTS LIST

308–560

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

220/240 VAC, 8 AMP

ULTRAr

PLUS+

1000

AIRLESS PAINT SPRAYER

210 bar (3000 psi) Maximum Working Pressure

Model 231–350 Series A

Complete sprayer on Upright cart with hose,

gun, RAC IVt DripLesst Tip Guard

and SwitchTipt

Rev. D

Supersedes Rev. B

and unreleased Rev. C

U.S. PATENT NO. 4,323,741; 4,397,610

PATENTED 1983, CANADA

AND OTHER PATENTS PENDING

04794

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1995, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown and Care 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spin Test 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Repair Information 18. . . . . . . . . . . . . . . . . . . . .

Motor Brush Replacement 19. . . . . . . . . . . . . . . . . . . . .

Power Supply Cord Replacement 20. . . . . . . . . . . . . . .

On/Off Switch Replacement 21. . . . . . . . . . . . . . . . . . . .

Pressure Control Replacement 22. . . . . . . . . . . . . . . . .

Filter Board Replacement 23. . . . . . . . . . . . . . . . . . . . . .

Bearing Housing & Connecting Rod Replacement 24.

Symbols

Warning Symbol

Drive Housing Replacement 25. . . . . . . . . . . . . . . . . . . .

Motor Replacement 27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump Repair 29. . . . . . . . . . . . . . . . . . . . .

Parts Drawing – Sprayer 34. . . . . . . . . . . . . . . . . . . . . . .

Parts List – Sprayer 35. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing and List – Displacement Pump 36. . . . .

Parts Drawing – Pressure Control 37. . . . . . . . . . . . . . .

Parts List – Pressure Control 37. . . . . . . . . . . . . . . . . . . .

Wiring Diagram 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Numbers 40. . . . . . . . . . . . . . . . . . . . . . . . .

The Graco Warranty And Disclaimers 40. . . . . . . . . . . .

Caution Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

If there is any static sparking or you feel an electric shock while using this equipment, stop

spraying immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not operate a gasoline engine in the spray area.

2 308-560

Page 3

INSTRUCTIONS

WARNINGWARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call Graco Technical Assis-

tance at 1–800–543–0339.

Do not alter or modify this equipment.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. Refer to

the Technical Data on page 39 for the maximum working pressure of this equipment.

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not ex-

pose Graco hoses to temperatures above 82C (180F) or below –40C (–40F).

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

Wear hearing protection when operating this equipment.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid

and solvent manufacturer.

MOVING PARTS HAZARD

Moving parts, such as the air motor piston, can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the Pressure Relief Procedure on page 12 to prevent the

equipment from starting unexpectedly.

Page 4

WARNINGWARNING

INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin

can also cause serious injury.

Fluid injected into the skin is a serious injury. The injury may look like just a cut, but it is a serious

injury. Get immediate medical attention.

Do not point the gun at anyone or at any part of the body.

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body, glove or rag.

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun diffuser operation weekly. Refer to the gun manual.

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the Pressure Relief Procedure on page 12 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

Tighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do

not repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

NOTE: This is an example of the DANGER label on your sprayer. This label is available in other languages,

free of charge. See page 39 to order.

FIRE AND

EXPLOSION HAZARD

Spray painting, flushing or cleaning equipment with flammable liquids in

confined areas can result in fire or explosion.

Use outdoors or in extremely well ventilated areas. Ground equipment,

hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic drop

cloths, open flames such as pilot lights, hot objects such as cigarettes,

arcs from connecting or disconnecting power cords or turning light

switches on and off.

Failure to follow this warning can result in death or serious injury.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Liquids can be injected into the body by high pressure airless spray or

leaks – especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body. Drain all pressure before removing parts.Avoid accidental triggering of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical Treatment”.

Failure to follow this warning can result in amputation or serious

injury.

SKIN INJECTION

HAZARD

4 308-560

Page 5

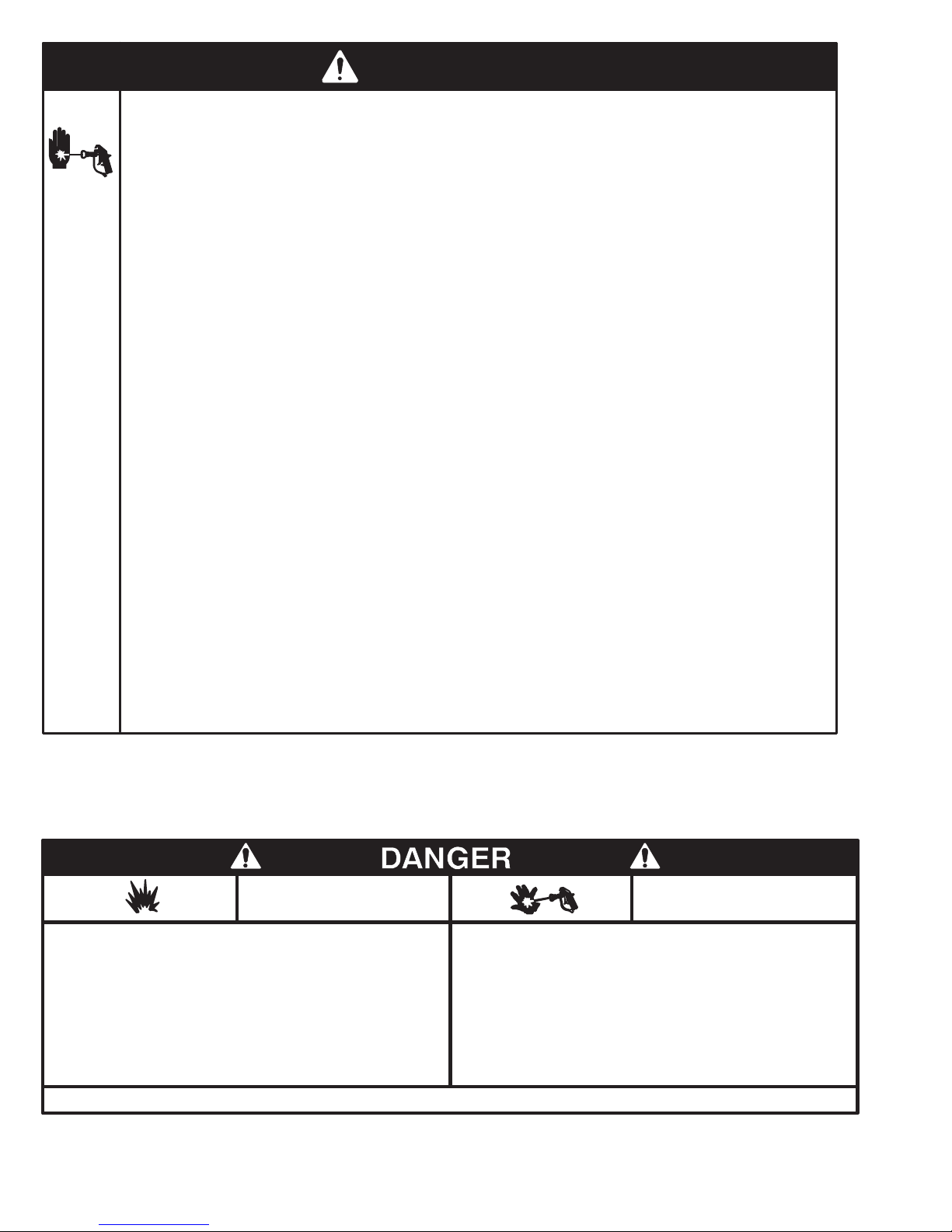

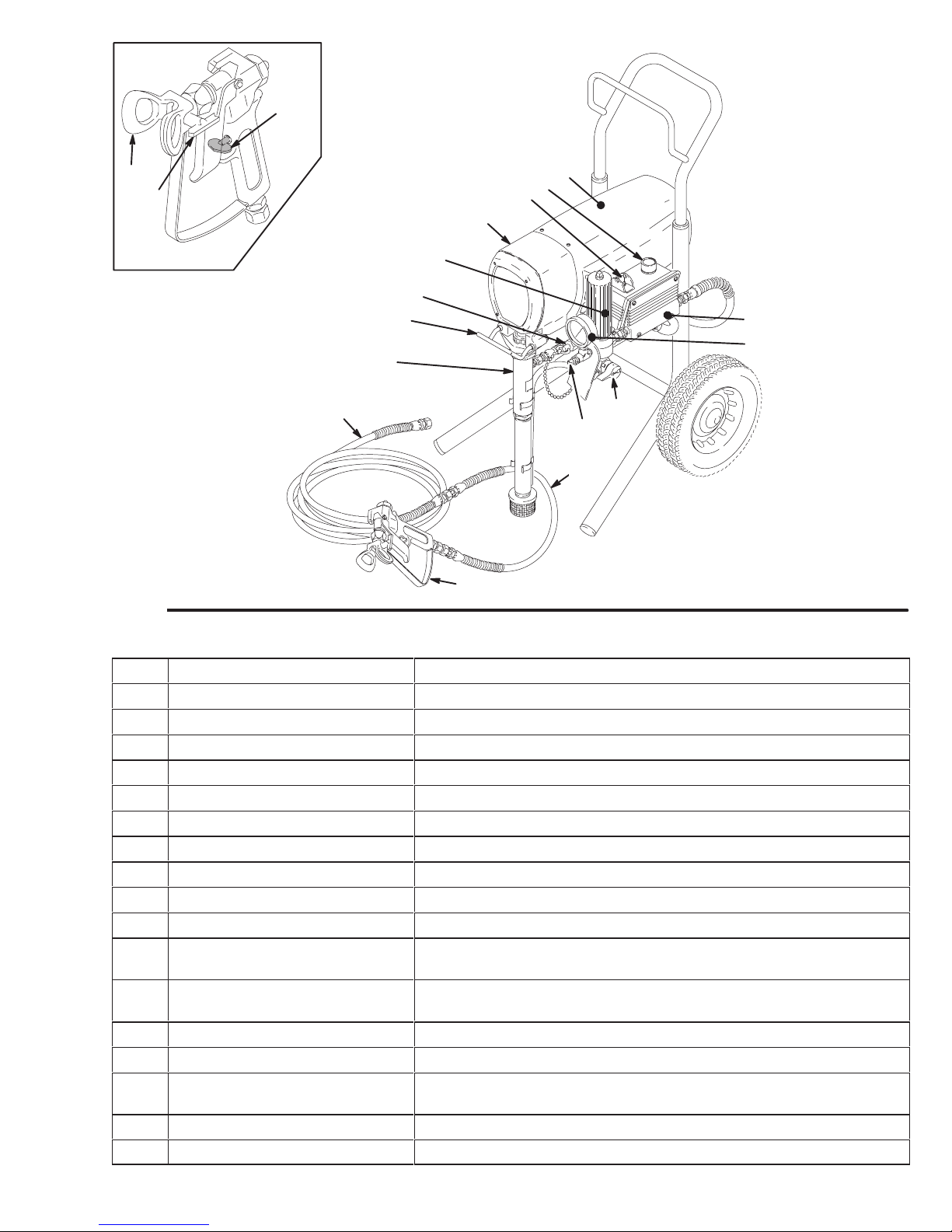

Major Components

T

K

M

0137

Fig. 1

A

B

C

D

E

F

G

S

U

H

J

R

P

N

L

04794

A Motor DC motor, 220/240 Vac, 50 Hz, 8A, 1 phase

B Pressure Adjusting Knob Controls fluid outlet pressure

C ON/OFF Switch Power switch that controls 220/240 Vac main power to sprayer

D Drive Assembly Transfers power from DC motor to the displacement pump

E Fluid Filter Final filter of fluid between source and spray gun

F Secondary Fluid Outlet Second spray gun operation is connected here

G Pail Hanger Container for fluid to be sprayed may be hung here

H Displacement Pump Transfers fluid to be sprayed from source through spray gun

J 50 ft (15 m) Main Hose 1/4 in. ID, grounded, nylon hose with spring guards on both ends

K RAC IV Tip Guard Reverse-A-Clean (RAC) tip guard reduces risk of injection injury

L Contractor Gun High pressure spray gun with gun safety latch

M RAC IV Switch Tip RAC switch tip uses high pressure fluid to remove clogs from spray

tip without removing tip from spray gun

N 3 ft (0.9 m) Hose 3/16 in. ID, grounded, nylon hose used between 50 ft hose and

spray gun to allow more flexibility when spraying

P Primary Fluid Outlet Single spray gun operation is connected here

R Pressure Drain Valve Relieves fluid outlet pressure when open

S Pressure Control Controls motor speed to maintain fluid outlet pressure at displace-

ment pump oulet. Works with pressure adjusting knob.

T Spray Gun Safety Latch Gun safety latch inhibits accidental triggering of spray gun

U Pressure Gauge Fluid pressure reference

Page 6

Setup

WARNING

To reduce the risk of serious injury from static

sparking, injection, or over pressurization and

rupture of the hose or gun, all hoses must be electrically conductive, the gun must have a tip guard, and

each part must be rated for at least 210 bar (3000 psi)

Maximum Working Pressure.

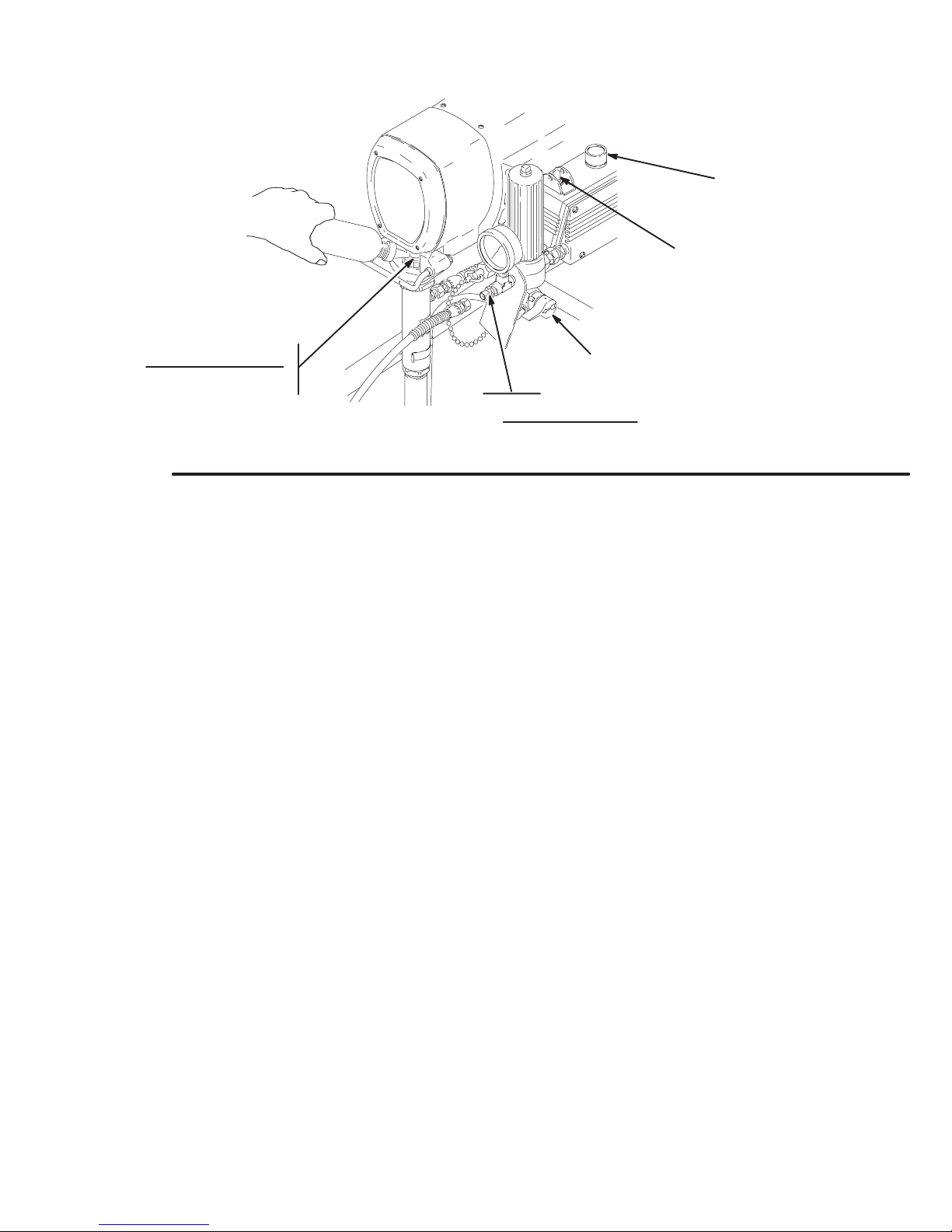

NOTE: See Fig. 2 while doing the setup.

1. Fill the packing nut/wet-cup 1/3 full with Graco

Throat Seal Liquid (TSL), supplied.

2. Connect the gun, 0.9 m (3 ft) hose and 15.1 m

(50 ft) hose. Screw the assembly onto the outlet

nipple. Don’t use thread sealant and don’t install

the spray tip yet!

3. Two gun hookup. Unscrew the cap from the 1/4

npsm(m) secondary hose outlet. Connect a hose

and gun to the outlet. Use a 1/4 in. ID, 15.1 m (50

ft) long (minimum) main hose. For more flexible

gun movement, install a 3/16 in. ID, 0.9 m (3 ft)

hose between the main hose and the gun.

CAUTION

To avoid damaging the pressure control, which may

result in poor equipment performance and component damage, follow these precautions:

1. Always use grounded, flexible spray hose at

least 50 ft. (15 m) long.

2. Never use a wire braid hose as it is too rigid to act

as a pulsation dampener.

3. Never install any shutoff device between the filter

and the main hose. See Fig. 2.

4. Always use the main filter outlet for one gun operation. Never plug this outlet.

WARNING

FIRE AND EXPLOSION HAZARD

Proper electrical grounding is essential

to reduce the risk of fire or explosion

which can result in serious injury and

property damage. Read the warning section FIRE OR EXPLOSION HAZARD on

page 2 for more detailed grounding

instructions.

4. Check the Electrical Service.

Two gun hookup. Unscrew the cap from the 1/4

npsm(m) secondary hose outlet. Connect a hose

and gun to the outlet. Use a 1/4 in. ID, 15.1 m (50 ft)

long (minimum) main hose. For more flexible gun

movement, install a 3/16 in. ID, 0.9 m (3 ft) hose between the main hose and the gun.

a. Electrical requirements: 220/240 V AC, 50 Hz,

8A (minimum).

b. Use a grounded electrical outlet located at least

6 m (20 ft) from the spray area.

b. Do not remove the grounding prong of the power

supply cord and do not use an adapter.

c. Extension cord specifications: 10A, 3-wire,

grounding type. (Long lengths reduce sprayer

performance.)

5. Plug in the sprayer. Turn the ON/OFF switch

OFF. Plug the cord into a grounded electrical

outlet.

6. Flush the pump to remove the oil left in to protect

pump parts after factory testing. See Flushing

on page 11.

7. Prepare the paint according to the manufacturer’s

recommendations. Remove any paint skin. Stir the

paint thoroughly. Strain the paint through a fine

nylon mesh bag (available at most paint dealers)

to remove particles that could clog the filter or

spray tip. This is an important step for trouble-free

paint spraying.

Page 7

Setup

PRESSURE ADJUSTING KNOB

ON/OFF SWITCH

PACKING NUT/ WET–CUP

FILL 1/3 FULL WITH TSL

Fig. 2

PRESSURE

DRAIN

VALV E

1/4 npsm(m) FLUID OUTLET NIPPLE

DO NOT INSTALL ANY SHUTOFF

DEVICE HERE

04787

7308-560

Page 8

Startup

Use this procedure each time you start the sprayer to

help ensure the sprayer is ready to operate and that you

start it safely.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Flush the sprayer if this is a first-time startup.

See page 11.

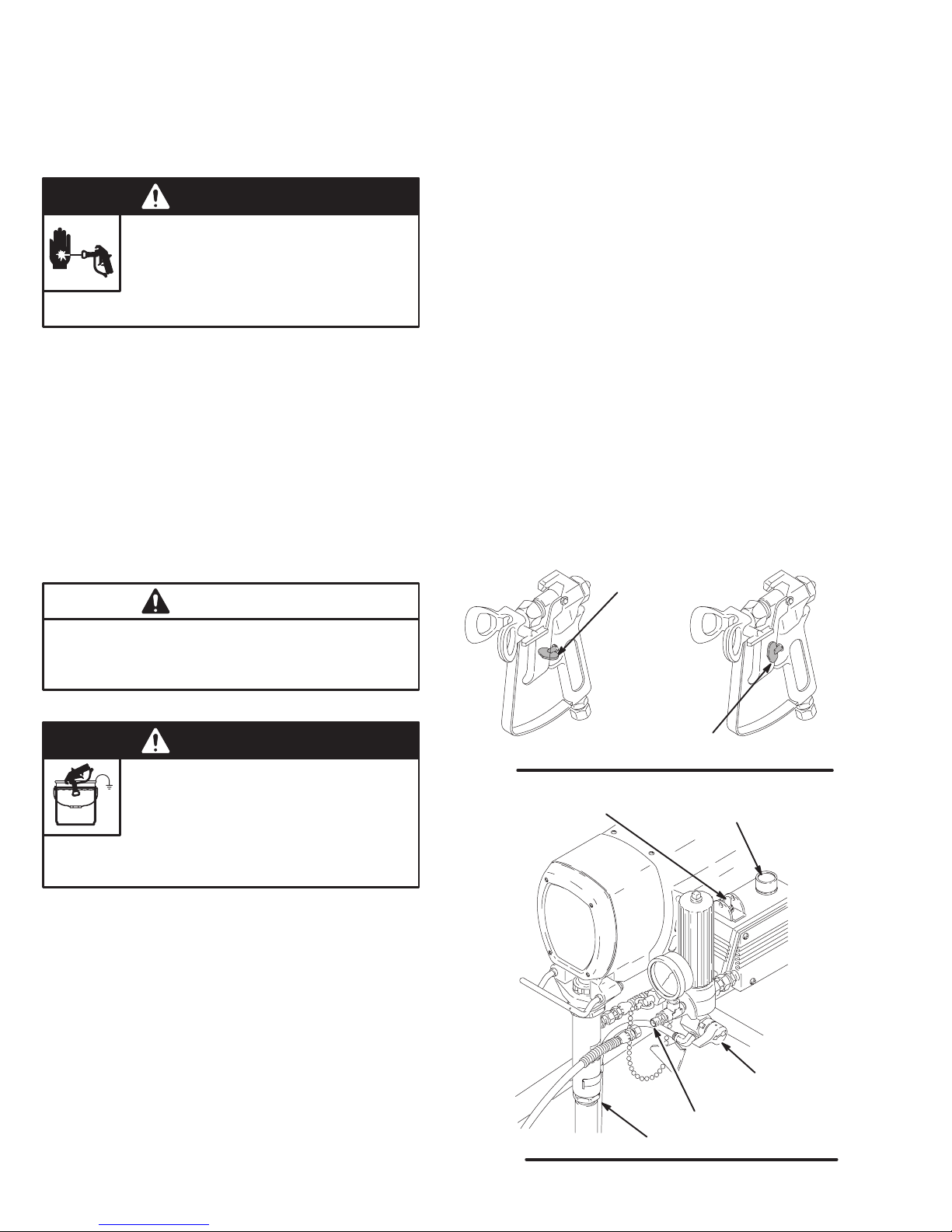

NOTE: See Fig. 4 except where noted.

1. Put the suction tube into the paint container .

2. Turn the pressure adjusting knob fully coun-

terclockwise to zero pressure.

3. Plug in the sprayer.

CAUTION

c. Release the trigger. Engage the gun safety latch.

5. Check all fluid connections for leaks . Relieve

the fluid pressure before tightening connections.

6. Install the spray tip and tip guard. Engage the

gun safety latch. See Fig. 3. Install the spray tip

according to the instructions supplied with it.

7. Adjust the spray pattern.

a. Increase the pressure just until spray from the

gun is completely atomized. Use the lowest

pressure needed to get the desired results. This

reduces overspray and fogging, decreases tip

wear and extends the life of the sprayer.

b. If more coverage is needed, use a larger tip

rather than increasing the pressure.

c. Test the spray pattern. T o adjust the pattern,

engage the gun safety latch, loosen the retaining

nut. Position the tip guard horizontally for a horizontal pattern or vertically for a vertical pattern.

Then tighten the retaining nut.

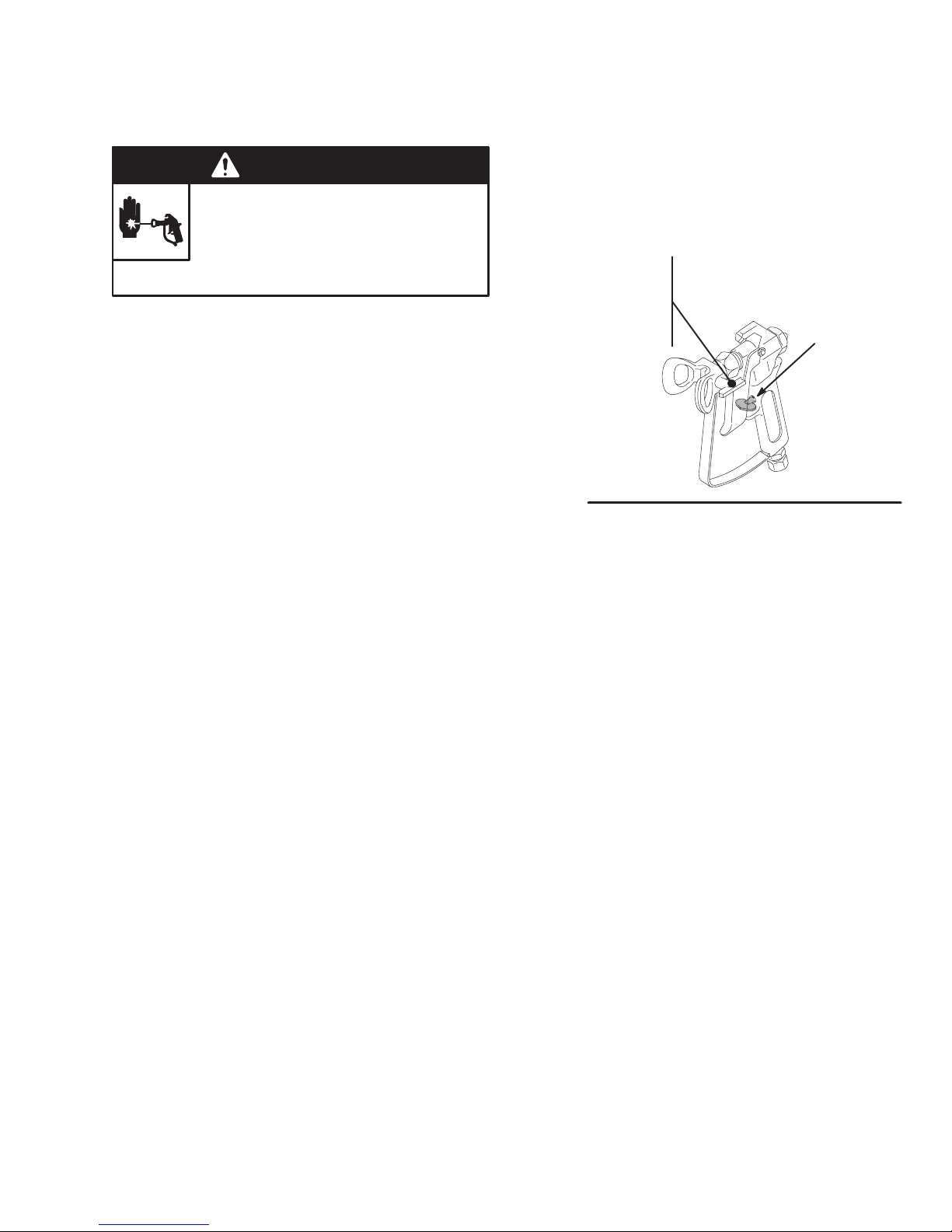

GUN SAFETY

LATCH SHOWN

ENGAGED

Do not run the pump without fluid in it for more than

30 seconds to avoid damage to the displacement

pump packings.

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking and

splashing when flushing, always remove

the spray tip from the gun and hold a

metal part of the gun firmly to the side of a

grounded metal pail.

4. Prime the pump.

a. Open the pressure drain valve (handle in down-

ward position). If you did not install a secondary

hose, be sure the nipple is tightly plugged with

the cap provided. Turn the ON/OFF switch to

ON. Slowly turn the pressure adjusting knob

clockwise until the sprayer starts. When fluid

comes from the drain hose, close the valve (handle in forward position).

b. Disengage the gun safety latch. See Fig. 3.

Following the warning, above, trigger the gun

until all air is forced out of the system and the

paint flows freely from the gun.

Fig. 3

ON/OFF SWITCH

Fig. 4

GUN SAFETY LATCH

SHOWN DISENGAGED

PRESSURE ADJUSTING KNOB

OUTLET NIPPLE

DRAIN HOSE

0137

PRESSURE

DRAIN

VALV E

04788

Page 9

Startup

Cleaning a Clogged Tip

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

1. Clean the front of the tip frequently during the day’s

operation. First, relieve pressure.

2. If the spray tip does clog, release the gun trigger, engage the gun safety latch, and rotate the RAC IV

handle 180. See Fig. 5.

3. Disengage the gun safety latch and trigger the gun

into a waste container. Engage the gun safety latch

again.

4. Return the handle to the original position, disengage

the gun safety latch, and resume spraying.

5. If the tip is still clogged, engage the gun safety latch,

shut off and unplug the sprayer, and open the pressure drain valve to relieve pressure. Clean the spray

tip as shown on the RAC IV package.

TIP GUARD HANDLE

SHOWN IN SPRAYING

TURN HANDLE 180,

DISENGAGE SAFETY

LATCH AND TRIGGER

GUN TO CLEAR CLOG

Fig. 5

POSITION

GUN SAFETY

LATCH SHOWN

ENGAGED

0137

9308-560

Page 10

Shutdown and Care

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

1. Check the packing nut/wet-cup daily. First relieve

pressure. Keep the wet-cup 1/3 full of TSL at all times

to help prevent fluid buildup on the piston rod and

premature wear of packings.

Tighten the packing nut just enough to stop leakage.

Over tightening causes binding and excessive packing wear. Use a round punch or brass rod and light

hammer to adjust the nut. Refer to Fig. 6.

6. Coil the hose and hang it on the hose rack when

storing it, even for overnight, to help protect the hose

from kinking, abrasion, coupling damage, etc.

PACKING NUT/

WET–CUP

TIGHTEN

2. Clean the fluid filter often and whenever the spray-

er is stored. Follow the Flushing Guidelines on page

11 or refer to manual 307–273, supplied, for the

cleaning procedure.

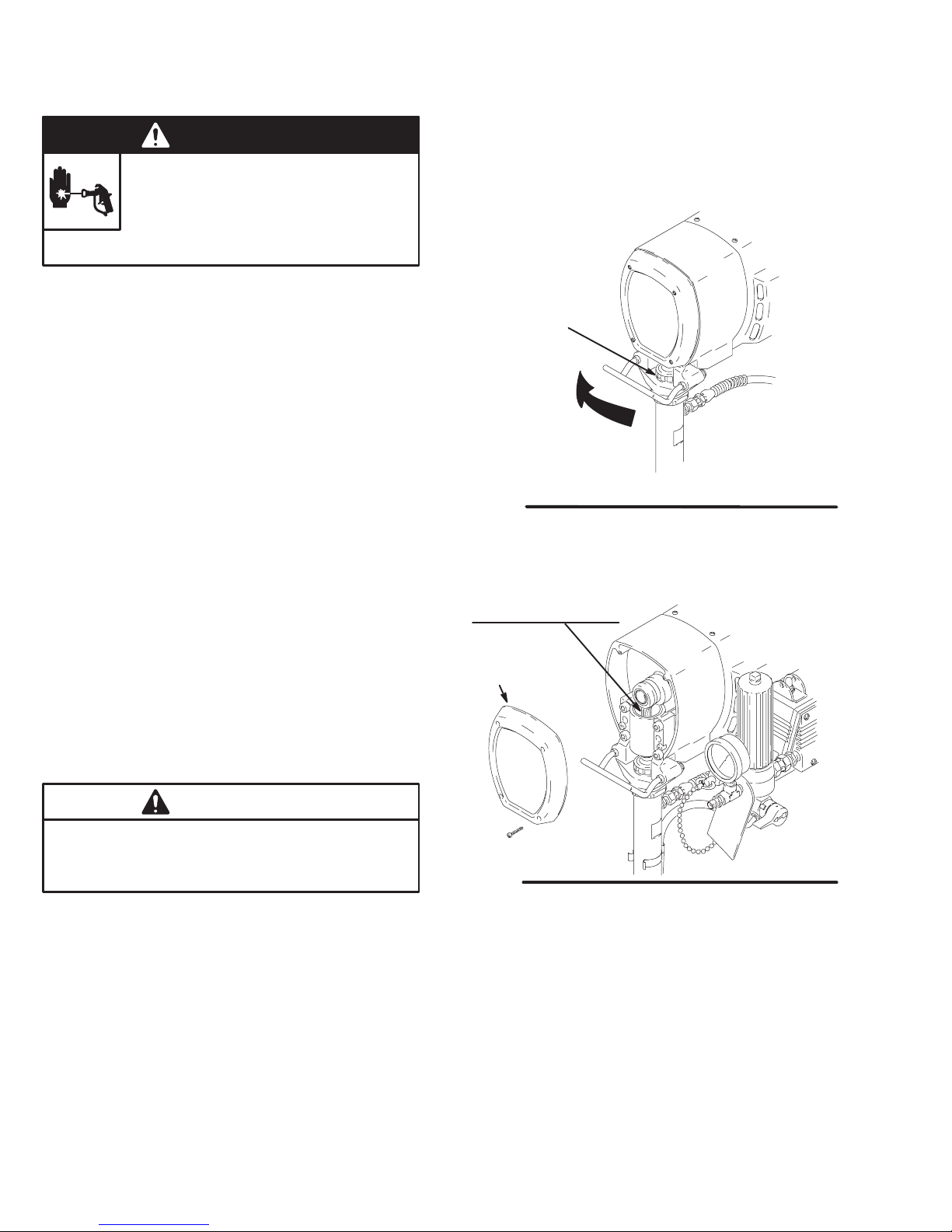

3. Lubricate the bearing housing after every 100

hours of operation. First relieve pressure. Remove

the front cover . Fill the bearing housing cavity with

SAE 10 non-detergent oil. See Fig. 7.

4. For very short shutoff periods, leave the suction

tube in the paint, relieve pressure, and clean the

spray tip.

5. Flush the sprayer at the end of each work day and

fill it with mineral spirits to help prevent pump corrosion and freezing. See page 11.

CAUTION

To prevent pump corrosion, never leave water or any

type of paint in the sprayer when it is not in use. Pump

water or paint out with mineral spirits.

Fig. 6

FILL BEARING HOUSING

CAVITY WITH SAE 10

NON-DETERGENT OIL

AFTER EVERY 100

HOURS OF OPERATION

FRONT

COVER

Fig. 7

01218A

04797

10 308-560

Page 11

Flushing

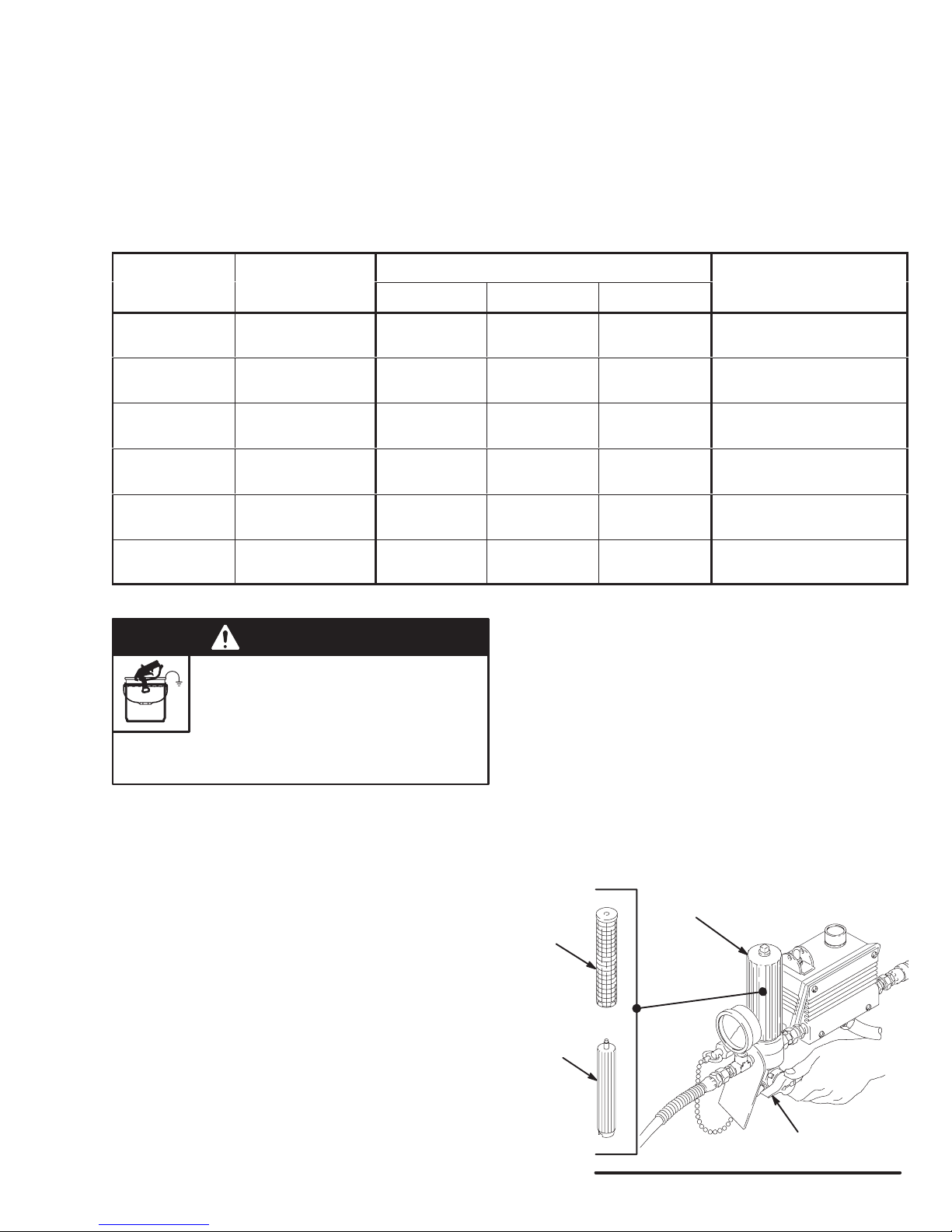

NOTE: Several flushes are often required to thoroughly clean the system and prepare it for the next fluid to be

sprayed, or to store the sprayer. Use this chart to determine the required flushing order for the fluid you are

using, and then follow the procedure below for flushing.

*Use this category for flushing a brand new sprayer and flushing after storage.

System has

this fluid in it: sprayed.

*Oil-based

solvent or paint

Oil-based

solvent or paint

Oil-based

solvent or paint

Water or waterbased paint

Water or waterbased paint

Water or waterbased paint

Next fluid to be

p

Oil-based paint –

new color

Water-based paint Mineral spirits Warm soapy

Prepare for

storage

Water-based paint

– new color

Oil-based paint Warm soapy

Prepare for

storage

Flush 1 Flush 2 Flush 3

Mineral spirits none none Prime with oil-based paint

Mineral spirits none none Relieve pressure,

Warm soapy

water

water

Warm soapy

water

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking and

splashing when flushing, always remove

the spray tip from the gun and hold a

metal part of the gun firmly to the side of a

grounded metal pail.

Flushing order:

Clean water Prime with water-based

water

Clean water none Prime with water

Clean water Mineral spirits Prime with oil

Clean water Mineral spirits Relieve pressure,

6. Do not run the pump dry for more than 30 seconds

to avoid damaging the pump packings!

7. Follow the illustrated Pressure Relief Procedure

on page 12. Engage the gun safety latch.

8. Unscrew the filter bowl and reinstall the clean

screen. Install the bowl and hand tighten.

Before you spray or store

p

sprayer:

paint

Leave drain valve open

Leave drain valve open

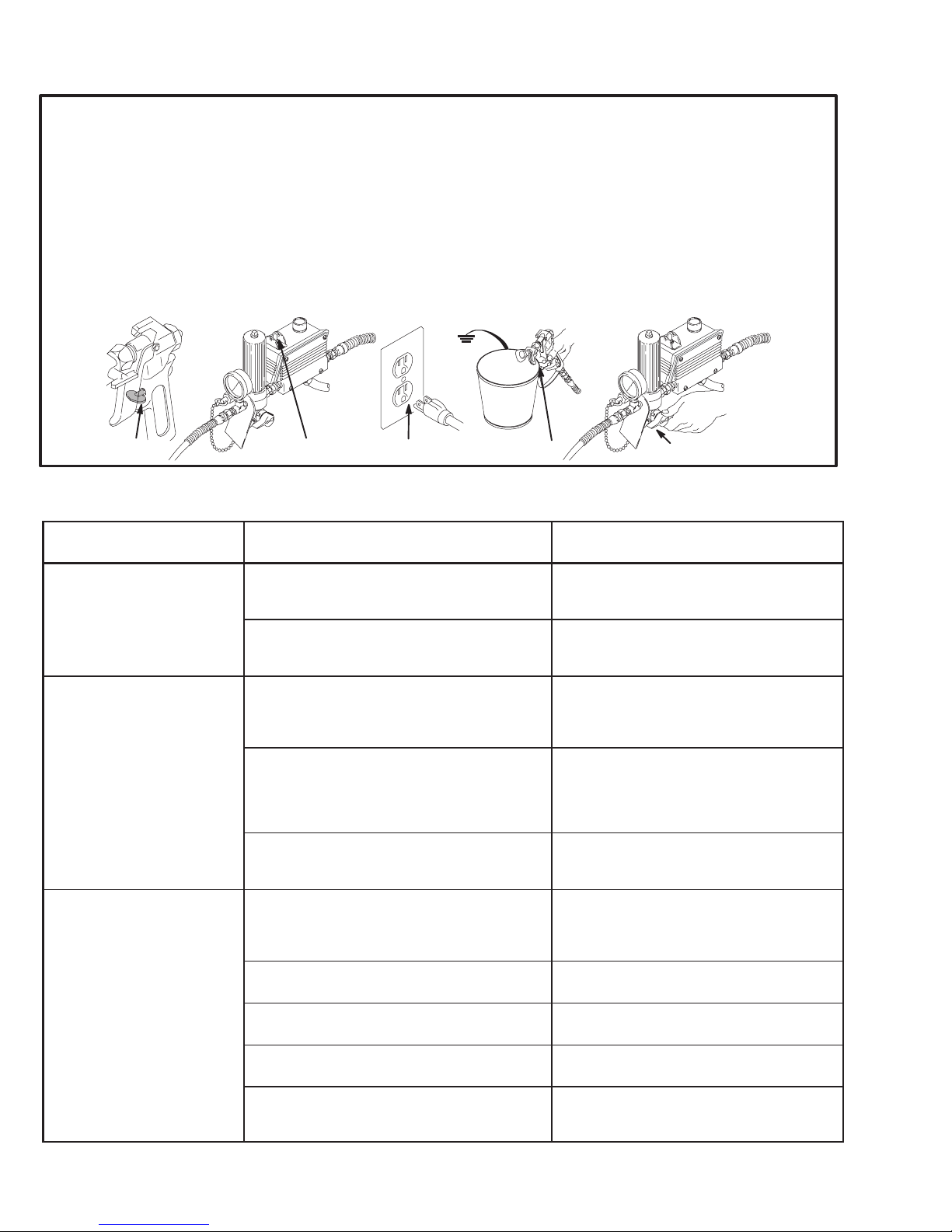

1. Follow the illustrated Pressure Relief Procedure

on page 12. Engage the gun safety latch.

2. Turn the pressure adjusting knob fully counterclockwise to zero pressure.

3. Remove the spray tip from the gun. Remove the

filter bowl and screen; see manual 307–273. Clean

the screen separately and install the bowl without

the screen to flush it. See Fig. 8.

4. Put the suction tube into a grounded metal pail

with 1/2 gallon of compatible solvent.

5. Start the sprayer. See page 8. To save the fluid

still in the sprayer, trigger the gun into another

container until the next fluid appears, then trigger

the gun back into the fluid you are pumping. Circulate the flushing fluid a couple of minutes to thoroughly clean the system.

9. Remove the suction tube and screen and clean

them separately.

FILTER

BOWL

SCREEN

FILTER

SUPPORT

PRESSURE

DRAIN VALVE

Fig. 8

04789

11308-560

Page 12

Troubleshooting

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including fluid injection, splashing fluid or solvent in the eyes or on the skin,

or injury from moving parts or electric shock, always follow

this procedure whenever you shut of f the sprayer, when

checking or servicing any part of the spray system, when installing, cleaning or changing spray tips, and whenever you

stop spraying.

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Unplug the power supply cord.

1,5 2 4

Perform all Troubleshooting procedures before disassembling the sprayer.

MOTOR WON’T OPERATE

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

4. Disengage the gun safety latch. Hold a metal part of the

gun firmly to the side of a grounded metal pail, and trigger the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the pressure drain valve, having a container

ready to catch the drainage. Leave the valve open until

you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved after following the steps above,

retaining nut or hose coupling to relieve pressure gradually,

then loosen completely. Now clear the tip or hose.

3

VERY SLOWLY loosen the tip guard

6

WHAT TO DO

When check is not OK refer to this column

04793

Basic Fluid Pressure Problems

Basic Mechanical Problems 1. Check for frozen or hardened paint in the

Basic Electrical Problems

1. Check the pressure control knob setting. The

motor will not run if it is at the minimum setting

(fully counterclockwise).

2. Check for a clogged spray tip or fluid filter. Refer to the separate gun, tip, or fluid filter instruction manual.

pump (76) and/or pressure control tube. Using

a screwdriver, carefully try to rotate fan at back

of motor by hand. See page 17.

2. Check displacement pump connecting rod pin

(43). It must be completely pushed into connecting rod (68) and retaining spring (42) must

be firmly in groove of connecting rod. See Fig.

32.

3. Check for motor damage. Remove drive

housing assembly (67). See page 25. T ry to

rotate fan by hand.

1. Check pressure control safety circuit. 2. Turn pressure control ON/OFF switch to

2. Check electrical supply with volt meter. Meter

should read 200–250 VAC.

3. Check extension cord fordamage. Check extension cord continuity with a volt meter.

1. Slowly increase the pressure setting to see

if the motor starts.

2. Relieve pressure, refer to the separate gun,

tip, or fluid filter instruction manual for

cleaning.

1. Thaw. Plug in sprayer and turn on. Slowly

increase pressure setting to see if motor

starts. If it doesn’t, see NOTE 1, below.

2. Push pin into place and secure with spring

retainer.

3. Replace motor (73) if fan won’t turn. See

page 27.

OFF to RESET. If the pressure control safety continues to trip, see ELECTRICAL

SHORT on page 16.

2. Reset building circuit breaker; replace

building fuse. Try another outlet.

3. Replace extension cord.

4. Check sprayer power supply cord (314) for

damage such as broken insulation or wires.

5. Check motor brush leads, terminals and brush

length. Brush length should be 1/2” (12 mm)

minimum. See page 19.

NOTE 1: Thaw the sprayer if water or water-based paint has frozen in it, due to exposure to low temperatures, by placing it in a warm

area. Do not try to start the sprayer until it has thawed completely. If paint hardened (dried) in the sprayer, the pump packings and/or

pressure control must be replaced. See page 29 (Displacement Pump) or 22 (Pressure Control).

4. Replace power supply cord. See page 20.

5. Tighten terminal screws; replace brushes.

See page 19.

12 308-560

Page 13

MOTOR WON’T OPERATE (Continued)

TYPE OF PROBLEM

Follow Pressure Relief Procedure on page 13. Remove gun

from hose. Remove pressure

control.

WHAT TO CHECK

If check is OK, go to next check

1.Check leads from motor to be sure they are

securely fastened and properly mated.

2. Check for loose motor brush lead connections

and terminals. See page 19.

3. Check brush length which should be 12 mm

(1/2 in.) minimum. See page 19.

NOTE: The brushes do not wear at the same

rate on both sides of the motor . Check both

brushes.

4. Check for broken or misaligned motor brush

springs. Rolled portion of spring must rest

squarely on top of brush. See page 19.

5. Check motor brushes for binding in brush

holders. See page 19.

6. Check motor armature commutator for burn

spots, gouges and extreme roughness. Remove motor cover and brush inspection

plates to check. See page 19.

WHAT TO DO

When check is not OK refer to this column

1. Replace loose terminals; crimp to leads. Be

sure male terminal blades are straight and

firmly connected to mating part.

Clean circuit board male terminals. Replace loose or damaged terminals. Securely reconnect leads.

2. Tighten terminal screws. Replace brushes

if leads are damaged. See page 19.

3. Replace brushes. See page 19.

4. Replace spring if broken. Realign spring

with brush. See page 19.

5. Clean brush holders. Remove carbon with

small cleaning brush. Align brush leads

with slot in brush holder to assure free vertical brush movement.

6. Remove motor and have motor shop resurface commutator if possible. See page 27.

Refer to the wiring diagram on

page 38 to identify test points

(TP).

7. Check motor armature for shorts using armature tester (growler) or perform spin test. See

page 17.

8. Check pressure control board (301) by substituting with a good pressure control board. See

page 22.

1. Check filter board. Connect volt meter to TP7

and ON/Off switch TP3.Connect a jumper

from TP4 to TP8. Plug in sprayer . Meter

should read 200 to 250 VAC. Unplug sprayer.

Remove jumper.

2. Check power supply cord (314). Disconnect

TP1 female (neutral) and TP2 female and

connect volt meter to these leads. Plug in

sprayer. Meter should read 200 to 250 VAC.

Unplug sprayer. Reconnect TP2.

3. Check ON/OFF switch (307). Disconnect TP3

and TP4 and connect volt meter to TP3 and

TP4 terminal on the ON/OFF switch. Plug in

sprayer and turn ON. Meter should read 200

to 250 VAC. Turn off and unplug sprayer. Reconnect TP3.

4. Check motor terminal cutoff switch. Connect

volt meter to TP1 female and TP6 female.

Plug in sprayer and turn on. Meter should read

200 to 250 VAC. Turn off and unplug sprayer.

5. Check all terminals for damage or loose fit.

Reconnect TP1, TP2, TP3, TP4, TP5, and

TP6 connectors.

7. Replace motor. See page 27.

8. Replace with new pressure control board

(301). See page 22.

1. Temporary bypass to check (Replace filter

board?)

2. Replace power supply cord. See page 20.

3. Replace ON/OFF switch. See page 21.

4. Allow motor to cool. Correct cause of overheating. If switch remains open after motor

cools, check continuity between TP4 female and TP5 female with ohmmeter . If

open, replace motor.

5. Replace damaged terminals and reconnect securely.

13308-560

Page 14

LOW OUTPUT

TYPE OF PROBLEM

Low Output

WHAT TO CHECK

If check is OK, go to next check

1. Check for worn spray tip. 1. Follow Pressure Relief Procedure Warn-

2. Check to see that pump does not continue to

stroke when gun trigger is released. Plug in

and turn on sprayer. Prime with paint. Trigger

gun momentarily, then release and engage

safety latch. Relieve pressure, turn off and unplug sprayer.

3. Check electrical supply with volt meter. Meter

should read 200–250 VAC.

4. Check extension cord size and length; must

be at least 1.5 mm

longer than 100m (300 ft).

5. Check +, –, M+ and M– leads from motor to

pressure control circuit board (B1) for damaged or loose wires or connectors. Inspect

wiring insulation and terminals for signs of

overheating. See page 27.

6. Check for loose motor brush leads and terminals. See page 19.

7. Check for worn motor brushes which should

be 12 mm (1/2 in.) minimum. See page 19.

2

(12 AWG) wire and no

WHAT TO DO

When check is not OK refer to this column

ing then replace tip. See your separate gun

or tip manual.

2. Service pump. See pages 29–33.

3. Reset building circuit breaker; replace

building fuse. Repair electrical outlet or try

another outlet.

4. Replace with a correct, grounded extension cord.

5. Be sure male terminal blades are centered

and firmly connected to female terminals.

Replace any loose terminal or damaged

wiring. Securely reconnect terminals.

6. Tighten terminal screws. Replace brushes

if leads are damaged. See page 19.

7. Replace brushes. See page 19.

8. Check for broken and misaligned motor brush

springs. Rolled portion of spring must rest

squarely on top of brush.

9. Check motor brushes for binding in brush

holders. See page 19.

10.Check stall pressure. Gauge should read 170

bar (2500 psi) minimum.

11. Check pressure control board (301) by substituting with a good pressure control board. See

page 22.

12.Check motor armature for shorts by using an

armature tester (growler) or perform spin test.

See page 17.

8. Replace spring if broken. Realign spring

with brush. See page 19.

9. Clean brush holders, remove carbon dust

with small cleaning brush. Align brush lead

with slot in brush holder to assure free vertical brush movement.

10.Replace with new pressure control board

(301). See page 22.

11. Replace with new pressure control board

(301). See page 22.

12.Replace motor. See page 27.

14 308-560

Page 15

NO OUTPUT

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

Motor runs and pump strokes 1. Check paint supply. 1. Refill and reprime pump.

2. Check for clogged intake strainer. 2. Remove and clean, then reinstall.

3. Check for loose suction tube or fittings. 3. Tighten; use thread sealant or sealing tape

4. Check to see if intake valve ball and piston ball

are seating properly. See page 29.

5. Check for leaking around throat packing nut

which may indicate worn or damaged packings. See page 29.

Motor runs but pump does not

stroke

1. Check displacement pump connecting rod pin

(43). See page 32.

2. Check connecting rod assembly (68) for damage. See page 24.

3. Be sure crank in drive housing rotates; plug in

sprayer and turn on briefly to check. Turn off

and unplug sprayer. See page 25.

WHAT TO DO

When check is not OK refer to this column

on threads if necessary.

4. Remove intake valve and clean. Check

balls and seats for nicks; replace if necessary. See page 29. Strain paint before using to remove particles that could clog the

pump.

5. Replace packings. See pages 29–33. Also

check piston valve seat for hardened paint

or nicks and replace if necessary. Tighten

the packing nut/wet-cup.

1. Replace pin if missing. Be sure retainer

spring (42) is fully in groove all around connecting rod. See page 32.

2. Replace connecting rod assembly . See

page 24.

3. Check drive housing assembly for damage

and replace if necessary. See page 25.

EXCESSIVE PRESSURE FLUCTUATIONS

TYPE OF PROBLEM

Spray pattern variations. 1. Be sure leads to pressure control circuit board

WHAT TO CHECK

If check is OK, go to next check

(B1) are firmly connected. Be sure all male terminals blades are centered and firmly connected to female terminals. See Fig. 33.

2. Check maximum working pressure. 2. Replace with a new pressure control board

3. Check pressure control board (301) by substituting with a good pressure control board. See

page 22.

4. Check LOW OUTPUT section, page 14.

WHAT TO DO

When check is not OK refer to this column

1. Reconnect securely. See Fig. 33.

(301). See page 22.

3. Replace with a new pressure control board

(301). See page 22.

15308-560

Page 16

MOTOR IS HOT AND RUNS INTERMITTENTLY

TYPE OF PROBLEM

Motor is hot and runs intermittently.

ELECTRICAL SHORT

TYPE OF PROBLEM

Building circuit breaker opens

as soon as sprayer switch is

turned on.

WHAT TO CHECK

If check is OK, go to next check

1. Determine if sprayer was operated at high

pressure with small tips, which causes low

motor RPM and excessive heat build up.

2. Be sure ambient temperature where sprayer

is located is no more than 32

sprayer is not located in direct sun.

3. Determine if sprayer was turned on, pressurized, but not operating for long periods of time.

WHAT TO CHECK

C(90F) and

If check is OK, go to next check

1. Check all electrical wiring for damaged insulation, and all terminals for loose fit or damage.

Also check wires between pressure control

and motor which are encased in conduit (1).

See page 27.

2. Check for missing inspection plate gasket

(see page 27), bent terminal forks or other

metal to metal contact points which could

cause a short.

3. Check motor armature for shorts. Use an armature tester (growler) or perform spin test.

See page 17. Inspect windings for burns.

WHAT TO DO

When check is not OK refer to this column

1. Decrease pressure setting or increase tip

size.

2. Move sprayer to shaded, cooler area if possible.

3 Turn off sprayer whenever you stop spray-

ing for a while and relieve fluid pressure.

WHAT TO DO

When check is not OK refer to this column

1. Repair or replace any damaged wiring or

terminals. Securely reconnect all wires.

2. Correct faulty conditions.

3. Replace motor. See page 27.

Sprayer quits after sprayer operates for 5 to 10 minutes.

4. Check pressure control board (301) by substituting with a good control board. See page 22.

1. Check Basic Electrical Problems on page 12. 1. Perform necessary procedures.

2. Check ON/OFF switch (307) See page 21.

sure the sprayer is unplugged!

wires from switch. Check switch with ohmmeter. The reading should be infinity with the ON/

OFF switch OFF, and zero with the switch ON.

3. Check for damaged or pinched wires in the

pressure control. See page 22.

1. Check Basic Electrical Problems on page 12. 1. Perform necessary procedures.

2. Check electrical supply with volt meter. Meter

should read 200 to 250 VAC.

3. Check tightness of pump packing nut. Overtightening tightens packings on rod, restricts

pump action, and damages packings.

Disconnect

4. Replace with a new pressure control board

(301). See page 22.

Be

2. Replace ON/OFF switch. See page 21.

3. Replace damaged parts. See page 22.

2. If voltage is too high, do not operate

sprayer until corrected.

3. Loosen packing nut. Check for leaking

around throat. Replace pump packings, if

necessary. See page 29.

16 308-560

Page 17

WARNING

ELECTRIC SHOCK HAZARD

Do not touch the brushes, leads, springs

or brush holders while the sprayer is

plugged in to reduce the risk of electric

shock and serious bodily injury.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

Spin Test

lutions before coming to a complete stop. If the motor

does not spin freely, the armature is shorted and the motor must be replaced. See page 27.

59

F

For checking armature, motor winding and brush electrical continuity.

Setup

Relieve pressure. Remove the drive housing. See page

25.

Remove the motor shield (59), the fan cover (F) and the

inspection covers (J). See Fig. 9.

Remove the pressure control/cover(301). Disconnect

the – and + leads from the motor to the pressure control/

cover terminals M–, and M+. See Fig. 10.

Armature Short Circuit Test

Relieve pressure. Quickly turn the motor fan by hand. If

there are no shorts, the motor will coast two or three revo-

301

Fig. 9

J

01224A

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

Relieve pressure. Connect the two black motor leads together with a test lead. Turn the motor fan by hand at

about two revolutions per second.

If there is uneven or no turning resistance, check the following: broken brush springs, brush leads, motor leads;

loose brush terminal screws, motor lead terminals; worn

brushes. Repair parts as needed. See page 19.

If there is still uneven or no turning resistance, replace the

motor. See page 27.

Fig. 10

M–

–

M+

+

04790

Page 18

General Repair Information

CAUTION

To reduce the risk of a pressure control malfunction:

Always use needle nose pliers to disconnect a

wire. Never pull on the wire, pull on the connector.

Mate wire connectors properly. Be sure the flat

blade of the insulated male connector is centered

in the wrap-around blade of the female connector.

Route wires carefully to avoid interference with

the other connections of the pressure control. Be

sure the wires are not pinched between the cover

and the control box.

Tool List

Phillips screwdriver

Small flat blade

screwdriver

Needle nose pliers

Plastic mallet

Adjustable wrench

Adjustable, open-end

wrench

Torque wrench

1/4 in. hex key wrench

3/16 in. hex key wrench

5/8 in. socket wrench

3/8 in. open end wrench

1/2 in. open end wrench

3/4 in. open end wrench

7/8 in. open end wrench

High quality motor oil

Bearing grease

WARNING

ELECTRIC SHOCK HAZARD

To reduce the risk of serious injury, including electric shock, DO NOT touch

any moving parts or electrical parts with

your fingers or a tool while inspecting the repair.

Shut off the sprayer and unplug it as soon as you

complete the inspection. Reinstall all covers, gaskets, screws and washers before operating the

sprayer.

3. If the sprayer does not operate properly, review

the repair procedure again to verify that everything

was done correctly. If necessary, see the

Troubleshooting Guide, pages 12 – 16, to help

identify other possible problems and solutions.

CAUTION

Do not run the sprayer dry for more than 30 seconds to avoid damaging the pump packings.

4. Reinstall the motor shield before regular op-

eration of the sprayer and replace it if it is damaged. The cover directs cooling air around the

motor to help prevent overheating. It can also help

reduce the risk of burns, fire or explosion; see the

WARNING, below.

1. Keep all screws, nuts, washers, gaskets, and

electrical fittings removed during repair procedures. These parts are not normally provided with

replacement assemblies.

2. Test your repair before regular operation of the

sprayer to be sure the problem is corrected.

WARNING

FIRE AND EXPLOSION HAZARD

During operation, the motor and drive

housing become very hot and could

burn your skin if touched. Flammable

materials spilled on the hot, bare motor could

cause a fire or explosion. Always have the motor

shield in place during regular operation to reduce

the risk of burns, fire or explosion.

18 308-560

Page 19

Motor Brush Replacement

NOTE: Replace the brushes when they have worn to

less than 12 mm (1/2 in). Note that the brushes

wear differently on each side of the motor , so

check them both. Brush Repair Kit 222–157 is

available. A new spring clip, P/N 1 10–816 may

be purchased separately.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

1. Relieve pressure.

2. Remove the motor shield (59). Remove the inspection covers (J) and gaskets (K) on each side

of the motor. See Fig. 11.

5. Inspect the commutator for excessive pitting,

burning or gouging. A black color on the commutator is normal. Have the commutator resurfaced by

a qualified motor repair shop if the brushes seem

to wear too fast.

CAUTION

When installing the brushes, follow all steps carefully to avoid damaging the parts.

6. Install a new brush so the lead is in the long slot of

the holder. See Fig. 13.

BRUSH HOLDER

SHORT SLOT

LONG SLOT

BRUSH

SPRING

CLIP

59

F

Fig. 11

J

01224A

3. Push in the spring clip to release its hooks from

the brush holder. Pull out the spring clip. See Fig.

12.

SPRING

HOOK

BRUSH

SPRING CLIP

P/N 110–816

Fig. 12

4. Loosen the brush lead terminal screw. Pull the

brush lead away, leaving the motor lead terminal in

place. Remove brush and spring. See Fig. 14.

01227

NOTE: SPRING MUST COIL

IN THIS DIRECTION

Fig. 13

01227

7. Slide the terminal under the terminal screw washer

and tighten the screw. Be sure the motor lead is

still connected at the screw. See Fig. 14.

SPRING

BRUSH

Fig. 14

TERMINAL SCREW

MOTOR LEAD

TERMINAL

SPRING CLIP

BRUSH LEAD

01227

8. Place the spring on the brush as shown in Fig. 13.

9. Install the spring clip and push it down to hook the

short slots in the housing. See Fig. 13.

10. Repeat for the other side.

Page 20

11. Test the brushes.

a. Remove the pump connecting rod pin.

b. With the sprayer OFF, turn the pressure con-

trol knob fully counterclockwise to minimum

pressure. Plug in the sprayer.

c. Turn the sprayer ON. Slowly increase the

pressure until the motor is at full speed.

d. Inspect the brush and commutator contact

area for excessive arcing. Arcs should not

“trail” or circle around the commutator surface.

WARNING

ELECTRIC SHOCK HAZARD

Do not touch the brushes, leads, springs

or brush holders while the sprayer is

plugged in to reduce the risk of electric

shock and serious bodily injury.

CAUTION

Do not run the sprayer dry for more than 30

seconds while checking the brushes to avoid

damaging the displacement pump packings.

12. Install the brush inspection covers and gaskets.

13. Break in the brushes. Operate the sprayer for at

least one hour with no load. Install the connecting

rod pin.

Power Supply Cord Replacement (Fig. 15)

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Read the GENERAL REPAIR INFORMATION

on page 18 before doing this procedure.

1. Relieve pressure.

2. Remove the pressure control board/cover (301).

3. Disconnect the power supply cord (314),

both leads from the ON/OFF switch (307), and

the green wire to the grounding screw (317).

4. Loosen the strain relief bushing (315) and remove

the power supply cord (314).

5. Install the new power supply cord in the reverse

order.

301

307

317

315

6. Install the proper plug on the other end of the

power supply cord. Follow all local codes to select

the proper plug.

Fig. 15

20 308-560

314

04791

Page 21

On/Off Switch Replacement (Fig. 16)

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

1. Relieve pressure.

2. Remove the pressure control board/cover (301).

3. Disconnect the two wires from the ON/OFF switch

(307). See Fig. 15.

8. Powder the inside of the rubber boot (309) with

talcum powder, then shake the excess out of the

boot.

9. Install the nut and rubber boot and tighten.

10. Reconnect all wires.

309

308

4. Using a 5/8 in. socket wrench, remove the nut and

rubber boot (309). Remove the switch guard (308).

See Fig. 16.

5. Remove the ON/OFF switch (307).

6. Install the new switch so the internal tab of the

pressure control housing (D) engages with the

vertical groove in the threads of the switch.

7. Install the switch guard (308), aligning the internal

tab with the groove in the threads.

Fig. 16

D

307

04795

21308-560

Page 22

Pressure Control Replacement

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

3. Remove the four mounting screws and washers

(302, 303, 304) from the pressure control board/

cover (301). See Fig. 18.

4. Carefully remove the pressure control board/cover

(301) so as not to stress the cables.

5. Remove the potentiometer cable (310) from the

pressure control board/cover (301).

1. Relieve pressure.

2. Disconnect the filter/drain valve assembly and the

pump supply hose at the pressure control while

holding the pressure control fitting (A) firmly. See

the CAUTION, below. See Fig. 17.

CAUTION

Do not allow the fittings (A) to turn when removing

or connecting the hose and filter/drain assembly.

Do not over tighten the screws when attaching the

pressure control board/cover. Turning the fittings or

over tightening the screws may shift the calibration

of the pressure control.

6. Disconnect the pressure control board/cover

black/white M+ and black M– leads from the motor

+ and– leads.

7. Disconnect the red motor leads from the TS leads

on the pressure control board/cover (301).

8. Disconnect the brown power lead (L1) from the

filter board.

9. Disconnect the blue lead (L2) from the filter board.

10. Loosen the ground terminal screw (317) and

disconnect the ground lead (C).

11. Pull off the pressure control board/cover.

TO PUMP

TO GUN

Fig. 17

22 308-560

A

301

A

FILTER/DRAIN

VALVE ASSEMBLY

04792

Page 23

Pressure Control Replacement

WARNING

Do not attempt to adjust or calibrate the pressure

control. If the pressure control is faulty, replace it.

301

12. Reassemble in the reverse order; attach ground

wire (C), power leads (L1 and L2), the red leads to

the TS terminals on the circuit board (B1), the M+

and M– leads, and the potentiometer cable to the

connector on B1. Carefully route the wires away

from the filter board. Attach the pressure control

board/cover (301) using the four mounting screws

and washers (302, 303, 304),

304

Fig. 18

303

302

304

310

TS

L2

L1

B1

C

317

04790

Filter Board Replacement

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

1. Relieve pressure.

2. Perform the Pressure Control Replacement

procedure steps 2 through 11.

3. Remove the three screws holding the filter board in

place and remove the filter board.

4. Reassemble in the reverse order; replace filter

board, attach ground wire (C), power leads (L1

and L2), the red leads to the TS terminals on the

circuit board (B1), the M+ and M– leads, and the

potentiometer cable to the connector on B1. Carefully route the wires away from the filter board.

Attach the pressure control board/cover (301)

using the four mounting screws and washers (302,

303, 304),

23308-560

Page 24

Bearing Housing and Connecting Rod

Replacement (Fig. 19)

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

NOTE: Stop the sprayer at the bottom of its stroke to get

the crank (E) in its lowest position.To lower the

crank manually, carefully rotate the blades of the

fan with a screwdriver.

11. Align the connecting rod (68) with the crank (E)

and the drive housing locating pins (G) with the

bearing housing (69) holes. Push the bearing

housing onto the drive housing or tap it into place

with a plastic mallet.

CAUTION

DO NOT use the bearing housing screws (25) to try

to align or seat the bearing housing; the bearing and

drive housing will not align properly and will result in

premature bearing wear.

12. Install the screws and lockwashers (25,23). Tighten the screws evenly to 175 in-lb (19 N.m).

1. Relieve pressure.

2. Remove the front cover (49). Unclip the drain hose

(36) from the pump. Hold a wrench on the pump

intake valve (223) and unscrew the pump suction

tube. Disconnect the pump hose (70).

3. Push up the retaining spring (42). Push the pin

(43) out the rear.

4. Loosen the locknut (47). Unscrew the displacement pump (76).

5. Remove the four screws and lockwashers (25,23).

6. Lightly tap the lower rear of the bearing housing

(69) with a plastic mallet to loosen it from the drive

housing (67). Pull the bearing housing and the

connecting rod assembly (68) straight off the drive

housing.

7. Remove the pail bracket assembly (F) and install it

on the new bearing housing.

13. Install the pump. See page 32.

14. Install the remaining parts. See Fig. 19

67

PACK WITH

BEARING GREASE

B

OIL

25,23

TORQUE TO

175 in-lb (19 N.m)

49

F

C

68

42

47

43

E

40

.

G

69

70

8. Inspect the crank (E) for excessive wear and

replace parts as needed. Evenly lubricate the

inside of the bronze bearing (B) with high quality

motor oil. Liberally pack the roller bearing (C) with

bearing grease.

9. Assemble the connecting rod (68) and bearing

housing (69).

10. Clean the mating surfaces of the bearing and drive

housings (69,67).

24 308-560

Fig. 19

76

223

36

04486

Page 25

Drive Housing Replacement (Fig. 20)

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

CAUTION

4. Lightly tap the lower rear of the bearing housing

(69) with a plastic mallet to loosen it from the drive

housing (67). Pull the assembled bearing housing

and connecting rod straight off the drive housing.

5. Remove the two drive housing screws (26) and

lockwashers (20).

6. Remove the two lower screws (13) and lockwashers (20) and then the two upper screws (16) and

lockwashers (20) from the front of the motor (73).

DO NOT drop the gear cluster (51) when removing

the drive housing (67). The gear cluster may stay engaged in the motor front end bell or the drive housing.

DO NOT lose the thrust balls (9) located at each end

of the gear cluster (51) or drop them between gears.

The balls, which are heavily covered with grease,

usually stay in the shaft recesses, but could be dislodged. If caught between gears and not removed,

the balls will seriously damage the drive housing. If

the balls are not in place, the bearings will wear prematurely.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

1. Relieve pressure.

2. Remove the front cover (49) and the motor shield

(59). Unclip the drain hose (36) from the pump.

3. Remove the four bearing housing screws (25) and

lockwashers (23).

7. Tap the drive housing (67) with a plastic mallet to

loosen it from the front of the motor (73), and then

pull the drive housing straight off.

8. Liberally apply bearing grease to the gear cluster

(51). The gear area should have approximately 4

total ounces of grease. Grease is supplied with

the drive housing replacement kit. Be sure the

thrust balls (9) are in place.

9. Place the bronze-colored washer (67b) THEN the

silver-colored washer (67a) on the shaft protruding

from the big gear in the drive housing (67).

10. Align the gears and push the new drive housing

straight onto the front of the motor and locating

pins.

11. Continue reassembling the sprayer.

25308-560

Page 26

Drive Housing Replacement

34

16

20

25,23

TORQUE TO

175 in-lb (19 N.m)

49

LIBERALLY APPLY GREASE

67b

67

69

36

9

59

67a

51

13

20

9

20

26

ig. 20

26 308-560

03752

Page 27

Motor Replacement (Fig. 21 and 22)

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

12. Remove the two lower screws (13) and lockwashers (20) and then the two upper screws (16) and

lockwashers (20) from the front of the motor (73).

13. Tap the drive housing (67) with a plastic mallet to

loosen it from the front of the motor (73), and then

pull the drive housing straight off.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

1. Relieve pressure.

2. Remove the motor shield (59).

3. Remove the pressure control board/cover (301).

Disconnect the four motor leads. See figure 21.

4. Loosen the conduit connector nut on the conduit

connector (318) at the pressure control.

5. Swing the conduit (1) away from the conduit

connector (318).

6. Remove the conduit seal (29) from around the

conduit elbow coming into the pressure control.

Pull the motor leads through the elbow, one at a

time.

CAUTION

Always pull the motor leads one at a time to avoid

loosening the terminals, which could result in a bad

connection and poor sprayer performance.

CAUTION

DO NOT drop the gear cluster (51) when removing

the drive housing (67). The gear cluster may stay engaged in the motor front end bell or the drive housing.

DO NOT lose the thrust balls (9) located at each end

of the gear cluster (51) or drop them between gears.

The balls, which are heavily covered with grease,

usually stay in the shaft recesses, but could be dislodged. If caught between gears and not removed,

the balls will seriously damage the drive housing. If

the balls are not in place, the bearings will wear prematurely.

14. While supporting the motor (73) to keep the

sprayer from tipping, remove the four motor

mounting screws (8). Lift off the motor.

15. Install the new motor (73).

16. Liberally apply bearing grease to the gear cluster

(51). The gear area should have approximately 4

total ounces of grease, Grease is supplied with

the drive housing replacement kit. Be sure the

thrust balls (9) are in place.

7. Loosen the connector nut on the connector elbow

(31) at the motor and pull the conduit (1) away

from the motor. Pull the leads through the conduit,

one at a time.

8. Unscrew the connector elbow (31) from the

motor.

9. Pull the wires through the elbow, one at a time.

10. Remove the front cover (49).

11. Remove the two drive housing screws (26).

17. Place the bronze-colored washer (67b) and then

the silver-colored washer (67a) on the shaft protruding from the big gear in the drive housing (67).

18. Align the gears and push the drive housing (67)

straight onto the front of the motor (73) and locating pins.

19. Continue reassembling the sprayer. Use a turning

motion on the conduit (1) when feeding wires

through it. Install the conduit seal (29) around the

wires in the conduit elbow (318) at the pressure

control to keep contaminants from entering the

motor conduit. See the Detail in Fig. 22.

Page 28

B1

Motor Replacement

DETAIL

Shows position of

conduit seal (29) in

conduit connector (345)

Fig. 21

POWER CORD

LIBERALLY APPLY GREASE

67b

51

67a

M+

M–

MOTOR

73

9

29

+

–

04772

318

01232

34

59

16

20

49

Fig. 22

26

69

20

67

36

31

8

13

20

9

11

70

10

1

318

70

40

301

04804

28 308-560

Page 29

Displacement Pump Repair (Fig. 23, 24, 25

and 26)

WARNING

FLUID INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated Pressure Relief

Procedure warning on page 12 when-

ever you are instructed to relieve pressure.

NOTE: Read the GENERAL REP AIR INFORMATION

on page 18 before doing this procedure.

NOTE: Use Packing Repair Kit 222–588. An asterisk

following a reference number, i.e., (210*), indicate that the part included in the kit. For the best

results, use all the new parts in the kit even if the

old ones still look good.

NOTE: Clean and inspect parts after disassembling the

pump. Replace worn or damaged parts.

Disassembling the Pump

1. See page 32 to remove the pump.

2. Unscrew the intake valve (223) from the cylinder

(219). Remove all parts. See Fig. 23.

205

216

224

219

Fig. 23

3. If no further service is needed, reassemble the

intake valve. Be sure you use a new o-ring (202*).

220

221*

204*

202*

223

INTAKE

VALV E

04230

4. Remove the packing nut (216) and plug (205). See

Fig. 23.

5. Use a plastic mallet to tap the piston rod (224)

down, then pull the rod out through the bottom of

the cylinder (219). See Fig. 23.

6. Remove the throat packings and glands. See Fig.

24.

*209

*213

THROAT

PACKINGS

*208

207*

219

Fig. 24

04231

Page 30

Displacement Pump Repair

7. Clamp the flats of the piston rod in a vise. Loosen

the retaining nut (211). Unscrew the piston valve

(222) from the rod. Remove all parts from the

piston valve (222). See. Fig 25.

210*

WARNING

Always use the special sleeve removal tool to remove the sleeve. Other removal methods could

cause the pump to rupture, resulting in serious bodily

injury. If the sleeve cannot be removed easily using

the tool, return the sleeve and cylinder to your Graco

distributor for removal.

9. Screw the large nut (B) of the tool into the top of

the cylinder (19). Screw down the rod (A) to push

the sleeve out. Remove the tool. See Fig. 26

.

224

*225

211

Fig. 25

8. Remove and clean the sleeve (218). Use ONLY

the special sleeve removal tool, P/N 222–586.

*206

212*

PISTON

ASSEMBLY

215*

203*

214*

222

04332

Fig. 26

A

B

218

219

0028

Page 31

Displacement Pump Repair

Reassembling the Pump

NOTE: Alternate leather and plastic packings as shown

in Fig. 27. The lips of the throat “V” packings

must face down. The lips of the piston “V” packings must face up. The lips of the U–cup seal

(203*) face down. Incorrect installation damages

the packings and results in pump leaking.

NOTE: Soak leather packings in oil before using them.

1. Check the outside of the piston rod (224) and the

inside of the sleeve (218) for scoring or scratches.

If these parts are damaged, new packings will not

seal properly. Replace these parts if needed.

2. Stack the backup washer (214), seal (203*),

female gland (215*), alternate packings

(212*,206*), and then male gland (210*) onto the

piston valve (222). See Fig. 25.

224

TORQUE TO

10.5 in-lb (1.2 N.m)

to seat the packing,

and then back off and

tighten finger tight.

211

225*

APPLY ONE DROP

OF SEALANT TO

THESE THREADS

*210

206* LEATHER

POLY *212

LIPS FACE UP

LIPS FACE UP

215*

203*

222

LIPS FACE DOWN

214*

ig. 27

6. Place the flats at the top of the rod in a vise.

0029

3. Tighten the packing retaining nut (211) against the

piston valve (222) to 10.5 in-lb (1.24 N.m).

Note the alignment of the piston (222) to the

packing retainer nut (211). Maintain this alignment

through Steps 5, 6 and 7.

4. Place the ball (225) on the piston valve (222). See

Fig. 27.

CAUTION

Step 5 is critical. Follow the procedure carefully to

avoid damaging the packings by overtightening.

5. Apply one drop of adhesive, supplied, to the piston

valve threads. Then hand tighten the valve assembly into the piston rod just until the nut (211) contacts the rod. See Fig. 27.

7. Use a wrench to CAREFULLY tighten the nut

(211) onto the piston rod to 19 ft-lbs (25 N.m). See

Fig. 28.

Use two wrenches to maintain the alignment

mentioned in Step 7, above.

224

211

TORQUE NUT

AGAINST ROD TO

19 ft–lb (27 N.m)

DO NOT ALLOW NUT

(211) TO MOVE WHEN

INSTALLING PISTON

ONTO ROD

Fig. 28

8. Stack the male gland (208*), alternate packings

(213*,207*), and female gland (9) into the top of

the cylinder (219). See Fig. 29.

9. Install the packing nut (216) and plug (205), but

leave loose for now. See Fig. 29.

01238

31308-560

Page 32

Displacement Pump Repair

10. Coat the piston rod and packings with oil. Carefully

slide the assembly INTO THE TOP OF THE

SLEEVE.

NOTE: The tapered end of the sleeve is the bottom of it.

See Fig. 30.

11. Place a new o-ring (202*) firmly in the cylinder

groove. See Fig. 29

205

216

*209

47

*207

LEATHER

LIPS MUST

FACE DOWN

213*

POLY

LIPS MUST

FACE

DOWN

*208

219

218

PISTON

ASSEMBLY

Fig. 30

12. Slide the sleeve/piston rod assembly INTO THE

BOTTOM OF THE CYLINDER . This is to prevent

packing damage during reassembly. See Fig. 30.

13. Screw down the cylinder locknut (47) until it is

finger tight at the bottom of the external cylinder

threads.

14. Place the flats of the intake valve (223) in a vise.

Install a new o-ring (202*). Screw the pump cylinder into the valve. Torque to 67 ft-lb (90 N.m). See

Fig. 29.

15. Install the pump.

TAPERED END

0030

*202

219

218

*210

*206

LEATHER

LIPS MUST

FACE UP

*203

U–CUP SEAL

LIPS MUST

FACE DOWN

*202

Fig. 29

212*

POLY

LIPS MUST

FACE UP

215*

214*

211

TORQUE TO:

67 ft-lb

(90 N.m)

01197

32 308-560

Page 33

Displacement Pump Repair

REMOVING AND INSTALLING PUMP

Remove the pump

1. Flush the pump. Relieve pressure. Stop the pump

with the piston rod (224) in its lowest position or

carefully rotate the blades of the fan with a screwdriver to lower the rod.

2. While holding the pump intake valve (223) steady

with a wrench, unscrew the suction tube (71).

3. Disconnect the hose (70).

4. Push the retaining spring (42) up. Push out the pin

(43).

5. Loosen the locknut (47) and unscrew the pump

from the bearing housing (69).

69

(

Fig. 31).

3. Push the retaining spring (42) into the groove all

the way around the connecting rod.

4. Tighten the locknut (47) very tight–about 70 ft-lb

(97 N.m)–with a 2 in. open–end wrench and a light

hammer.

WARNING

Be sure the retaining spring (42) is firmly in the

groove of the connecting rod, all the way around, to

prevent it from working loose due to vibration. Refer

to Fig. 32.

If the pin works loose, parts could break off due to the

force of the pumping action. These parts could be

projected through the air and result in serious bodily

injury, sprayer damage or property damage.

CAUTION

If the locknut (47) loosens during operation, the

threads of the bearing housing (69) will be damaged.

Be sure to tighten the locknut firmly.

42

224

216

43

47

223

71

Fig. 31

40

70

03749A

Install the pump ( Fig. 32).

1. Screw the displacement pump 3/4 of the way into

the bearing housing (69).

2. Hold the pin (43) up to the pin hole in the connecting rod assembly (68) and continue screwing in the

pump until the pin slides easily into the hole. Back

off the pump until the top threads of the pump

cylinder are flush with the face of the bearing

housing and the outlet nipple (40) is straight back.

5. Tighten the packing nut (216) just enough to stop

leakage, but no tighter. Fill the wet-cup/packing nut

1/3 full with Graco TSL (65).

68

43

FACE OF

BEARING

HOUSING

Fig. 32

216

47 TORQUE TO

42

69

70 ft–lb

(95 N.m)

03750

Page 34

Parts Drawing – Sprayer

Ultra

PLUS+

Model 231–350, Series A

Includes items 1 – 102

Complete Sprayer

25

49

58

LABEL

61

24

1000 Sprayers

67

68

69

23

42

47

43

9

40

67b

32

70

51

26

67a

12

9

20

73

LABEL

LABEL

20

LABEL

73C*LABEL

16

57

56

41*

34

77

59

34

83

44

34

27

REF

77

31

62

48

52

8

8

13

20

11

10

37

35

REF

78

78

76

36

71

90

102

53

100

101

34 308-560

72

38

40

66b

65

50

89

Ref 36

45

33

66

74a

88

66a

39

21

63

1

SEE PARTS ON PAGE 37

74

14

19

Ref 70

64

29

04773

Page 35

Parts List – Sprayer

Ultra

PLUS+

1000 Sprayers

Model 231–350, Series A

Includes items 1 – 102

Complete Sprayer

REF

NO. PART NO. DESCRIPTION QTY

1 065–312 CONDUIT,

s

pecify length when ordering

8 110–963 SCREW, serrated flange, hex hd, 4

9 100–069 BALL,

5/16–18 x 3/4”

10 100–188 NUT ,

11 100–214 LOCKW ASHER,

12 186–494 CLIP, large 1

13 100–643 SCREW,

14 101–242 RING, retaining 2

16 100–644 SCREW,

19 104–811 HUBCAP 2

20 105–510 LOCKWASHER,

21 106–062 WHEEL,

23 106–115 LOCKWASHER,

24 107–209 SCREW,

25 107–210 CAPSCREW,

26 107–218 CAPSCREW,

27 100–020 WASHER 2

29 107–447 SEAL,

31 108–460 CONNECTOR,

32 112–746 NUT,

33 108–691 PLUG, tubing 2

34 108–865 SCREW,

35 109–032 SCREW,

36 190–091 HOSE, drain 1

37 110–243 RING,

38 181–102 CLIP,

39 109–046

ADAPTER, female, ORS 3/8–18 npt(f) 1

11/16–16 UN thread

40 162–453 NIPPLE, 1/4 npt(m) x 1/4 npsm 2

41 185–952* LABEL,

42 176–817 SPRING,

43 176–818 PIN,

44 110–240 SPEED NUT 2

45 178–034* T AG,

47 178–941 NUT,

48 111–590 BUTTON, snap 2

49 179–899 COVER,

50 100–840 ADAPTER,

51 179–961 GEAR REDUCER 1

52 183–350 WASHER 2

53 181–072 STRAINER 1

56 290–031 LABEL,

57 290–032 LABEL,

58 290–030 LABEL,

59 237–692 SHIELD,

61 189–918 HANGER, pail 1

includes items 34, 41, 56, 57

62 192–027 SLEEVE 2

electrical 0.7 ft

steel, 1/4” dia. 2

heavy hex, 5/16–18 unc–2a 4

socket head, 1/4–20 x 0.75” 2

filh, no. 8–32 x1” 4

conduit,

hex 2

pan head, no. 8 x 3/8” 10

pnhd, 10–32 x 1/4” 4

retaining 2

small 1

DANGER, English 1

straight, hdls, 0.3125” dia x 1.023” 1

WARNING 1

hex 1

ID, motor cover, left 1

ID, motor cover, right 1

ID, front cover 1

motor

spring, 5/16” 4

socket head, 1/4–20 x 1” 2

spring, 1/4” 6

semi–pneumatic 2

spring, 3/8” 4

sch, 3/8–16 x 1–1/2” 4

sch, 1/4–20 x 2.75” 2

see page 28

conduit, 45 1

retaining 1

housing 1

elbow, 1/4–18 npt (m x f) 1

REF

NO. PART NO. DESCRIPTION QTY

63 290–024 LABEL, ID, control, top 1

64 290–033 LABEL, ID, control, bottom 1

65 206–994 THROAT SEAL LIQUID,

66 214–570 FLUID FILTER 1

Includes 66a and 66b

see manual 307–273 for parts

66a 100–040 .PLUG 1

66b 162–453 NIPPLE,

1/4 npt(m) x 1/4 npsm 1

67 218–032 DRIVE HOUSING 1

67a 178–967 .WASHER, silver–colored 1

includes replaceable items 67a and 67b

67b 107–089 .WASHER,

bronze–colored 1

68 218–034 CONNECTING ROD 1

69 218–035 BEARING HOUSING 1

70 223–766 HOSE,

cpld 1/4 npsm (f), 29” (715 mm),

spring guards both ends

grounded, nylon,1/4” ID 1

71 185–386 TUBE, suction 1

72 220–285 CAP,

73 222–397** MOT OR, ELECTRIC 1

2

73a 107–267 .TERMINAL, female

73b 107–264 .TERMINAL,

73c 185–951* .LABEL,

74 237–677 V ALVE,

74a 111–225 CONNECTOR,

for secondary outlet 1

includes replaceable items 73a to 73d

(which are shown on page 38

and one of item 9

DANGER, English 1

pressure drain

, Fig. 33

male

, Fig. 33

Includes 74a

tube, 90 1

76 222–580 DISPLACEMENT PUMP

77 222–554 HANDLE,

78 222–555 FRAME,

see page 36 for parts

cart 1

sprayer 1

83 185–384 BRACKET 2

88 102–814 GAUGE 1

89 106–228 TEE 1

90 220–422 GUARD, tip, RAC IV 1

100 223–541 HOSE,

101 214–701 HOSE,

grounded, nylon, 1/4” ID,

cpld 1/4 npsm(f), 50 ft (15 m)

spring guards both ends 1

grounded, nylon, 3/16” ID,

cpld 1/4 npsm(f), 3 ft (.9 m),

spring guards both ends 1

102 222–667 SPRAY GUN

see manual 307–614 for parts

*Extra Danger and Warning tags and labels available free.

1

**Motor Brush Repair Kit 222–157 is available.

Order separately.

8 OZ 1

2

2

1

1

1

Page 36

Parts Drawing & List – Displacement Pump

PTFEPTFEPTFE

Model 222–580, Series A

Sleeved Displacement Pump

Includes items 202 to 225

REF

NO. PART NO. DESCRIPTION QTY