Page 1

1

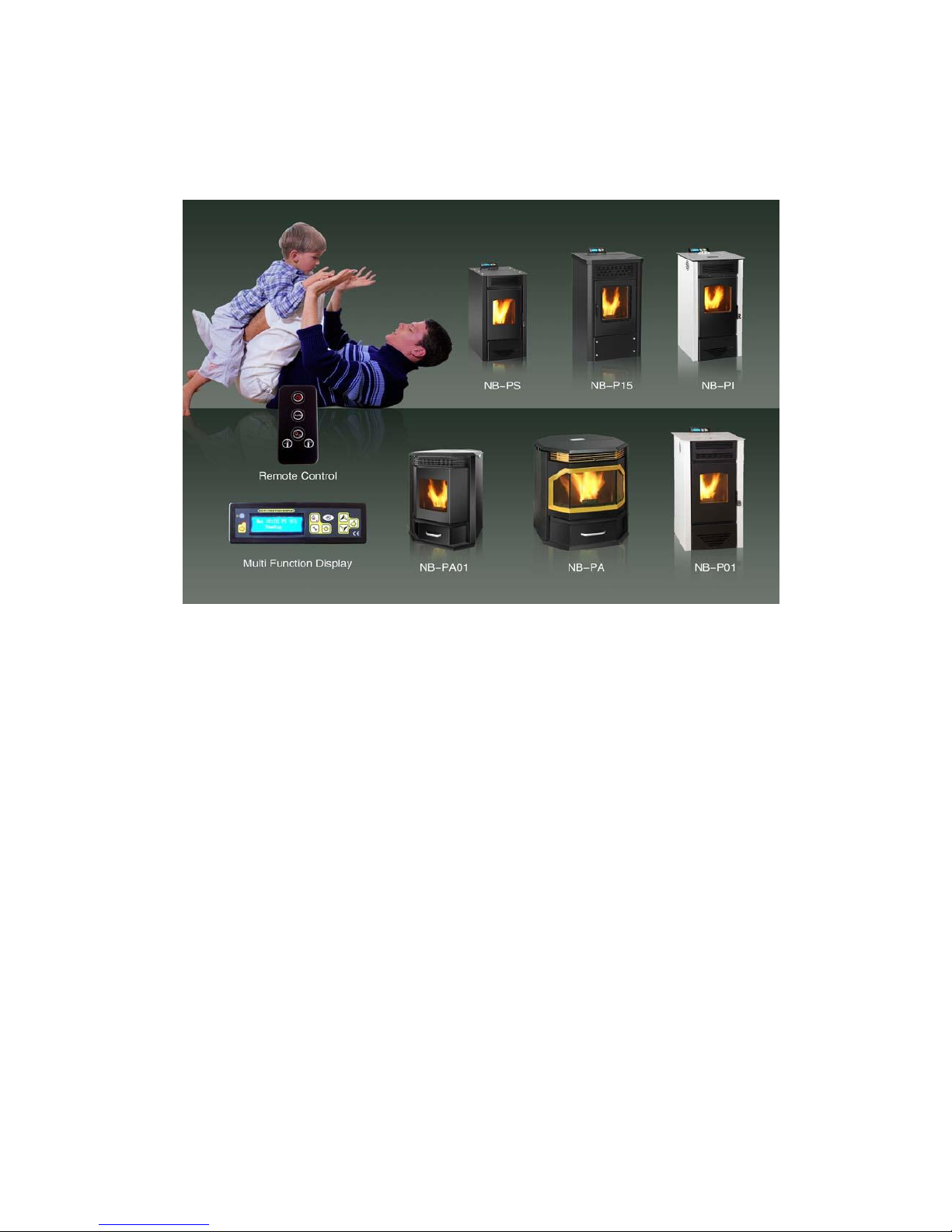

FREESTANDING PELLET STOVE

(PLEASE KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE)

A LIFETIME OF WARMTH

*Please read this entire manual before installation and use of

this pellet fuel burning room heater. Failure to follow these

instructions could result in property damage, bodily injury, or

even death.

*Save these instructions!

INSTALLER: THIS MANUAL MUST STAY WITH APPLIANCE!

MANUFACTURED BY:

NINGBO GRACE MACHINE CO., LTD

PO BOX 315400

Add. Lanshi Bridge Village, LanJiang Street, Yuyao ,Ningbo City,CHINA

Email: info@nbpelletstove.com

Web: www.nbpelletstove.com

Tel. /Fax: 0086-574-62511234/0086-574-62511112

Page 2

2

Table of Contents

1. Fuel Requirement------------------------------------------------3

2. Stove Features -----------------------------------------------------7

3. Structure instruction----------------------------------------------10

4. Installation and Caution ------------------------------------------12

5. Operation ----------------------------------------------------------21

6. Maintenance--------------------------------------------------------34

7. Troubleshooting----------------------------------------------------38

8. Warranty------------------------------------------------------------42

9. Electronic Plan---------------------------------------------------- 43

Page 3

3

1. Fuel Requirement

Before introducing how the stove can be operated, the fuel of

stove should be briefly introduced since it is related to the

performance of the stove. (Your pellet stove has been designed to burn wood

pellets only. Do not use any other type of fuel, as this will void any warranties stated in

this manual.)

Pellet quality is important, please read the following:

The performance of your pellet stove is greatly affected by the type and quality of wood

pellets being burned. As the heat output of various quality wood pellets differs, so will

the performance and heat output of the pellet stove.

The Pellet Fuel Industries (P.F.I.) has established standards for wood pellet manufacturers.

We recommend the use of pellets that meet or exceed these standards. Please use a

recommended pellet type.

P.F.I. PELLET STANDARDS:

Fines (fine particles)......1% maximum through a 1/8‖ screen

Bulk Density..................40 pound per cubic foot minimum

Size..............................1⁄4‖ to 5/16‖ diameter 1⁄2 – 11⁄2‖ long maximum

Ash Content..................1% maximum (Premium grade)

..................3% maximum (Standard grade)

Moisture Content...........8% maximum

Heat Content.................approximately 8200 Btu per pound minimum

CAUTION:

Page 4

4

It is important to select and use only pellets that are dry and free of dirt or any impurities such

as high salt content. Dirty fuel will adversely affect the operation and performance of the unit

and will void the warranty.

ASH: The ash content of the fuel and operation of your stove will directly determine the

frequency of cleaning. The use of high ash fuels may result in the stove needing to be cleaned

daily. A low ash fuel may allow longer intervals between cleaning.

CLINKERING: [clinkers are silica (sand) or other impurities in the fuel that will form a hard

mass during the burning process]. This hard mass will block the air flow through the Burn Pot

Liner and affect the performance of the stove. Any fuel, even approved types, may tend to

clinker. Check the Burn-Pot Liner daily to ensure that the holes are not blocked with clinkers.

If they become blocked, remove the liner (when the unit is cold) and clean/scrape the clinkers

out. Clean the holes with a small pointed object if required.

Refer to the section Routine Cleaning and Maintenance.

PELLET FEED RATES: Due to different fuel densities and sizes, pellet feed rates may vary.

This may require an adjustment to combustion fan‘s speed or to the auger feed trim setting on

low. Since stove supplier has no control over the quality of pellets that you use, we assume no

liability for your choice in wood pellets.

Size of wood pellet

This stove uses wood pellet fuel. It is small column pellet with cleaning surface. Pellets are

either 1\4‖(6MM) or 5\16‖8(MM)in diameter and vary in length. The stove will burn either

diameter pellets. The length is no more than 30mm for¢6mm, 25mm for ¢8mm, and their

humidity is no more than 10%. Ash is no more than 1%. Take care of the pellet. Do not damp

Page 5

5

or crush it. Or, it will affect the efficiency and the dust will be collected on the door glass.

Pellet fuel is made from sawdust and scrap wood from many different species of wood. Pellets

made from hardwoods contain more ash than those made from softwoods. Minerals from ash and

sand in the pellets clinker under the extreme temperatures in the burn pot. Try burning various

brands of pellets until you find one that burns with minimum ash and clinkers. Once you find a

pellet brand that burns well, continue using this brand. High ash fuel increases the frequency of

stove cleaning. Fuel with excessive moisture content may jam the auger assembly.

Store pellets at least 36” (1m) away from the pellet stove

SAFETY WARNINGS AND RECOMMENDATIONS:

Caution: Do not connect to any air distribution duct or system. Do not burn garbage or

flammable fluids such as gasoline, naphtha or engine oil. When unit in operation, Keep

children, clothing and furniture away. Contact may cause skin burns.

FUEL: This pellet stove is designed and approved to only burn wood pellet fuel with up to

3% ash content. Dirty fuel will adversely affect the operation and performance of the unit and

may void the warranty. Check with your dealer for fuel recommendations.

THE USE OF CORDWOOD IS PROHIBITED BY LAW.

SOOT: Operation of the stove with insufficient combustion air will result in the formation of

soot which will collect on the glass, the heat exchanger, the exhaust vent system, and may

stain the outside of the house.

This is a dangerous situation and is inefficient. Frequently check your stove and remove the

dust inside of stove ensure proper combustion. If it is necessary, call your dealer to adjust the

Page 6

6

speed of fan or feeding speed.

CLEANING: There will be some of fly ash and small amounts of creosote built up in the

exhaust. This will vary due to the ash content of the fuel used and the operation of the stove.

It is advisable to inspect and clean the exhaust vent semi-annually or every two tons of

pellets.

Page 7

7

2. STOVE FEATURES

Pellet stove is advanced designed and has individual fresh air input and venting system.

Negative pressure burning technology causes high efficiency and little ash outlet during

burning. It will be shut off automatically by wrong burning or out of fuel. Large BTU, quick

heating and low fuel cost are its advantages.

1. Main performance

Model NP-P15

Dimension (WxHxD) MM 529x1025x512

Weight KG 115

Air inlet Pipe MM 40x80

Air outlet Pipe MM 76

Heat Area M2 120

Automatic Burning Time (Min-Max.) H 16/40

Fuel Wood Pellet

Consumption for Pellet (Min-Max) KG/H 0.8/2.0

Efficiency % 86%

Hopper Capacity KG 32

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60

Rating Power KW 11

Model NP-P01

Dimension (WxHxD) MM 510x1029x527

Weight KG 106

Air inlet Pipe MM 50

Air outlet Pipe MM 76/80

Heat Area M2 100

Automatic Burning Time (Min-Max.) H 20/40

Fuel Wood Pellet

Consumption for Pellet (Min-Max) 0.7/1.6

Efficiency % 85%

Hopper Capacity KG 30

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60

Rating Power KW 9

Page 8

8

Model NP-PS

Dimension (WxHxD) MM 439x900x487

Weight KG 80

Air inlet Pipe MM 50

Air outlet Pipe MM 80

Heat Area M2 60

Automatic Burning Time (Min-Max.) H 20/50

Fuel Wood Pellet

Consumption for Pellet (Min-Max) 0.4/0.9

Efficiency % 82%

Hopper Capacity KG 20

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60

Rating Power KW 5

Model NP-PI

Dimension (WxHxD) MM 471x993x470

Weight KG 110

Air inlet Pipe MM 50

Air outlet Pipe MM 80

Heat Area M2 90

Automatic Burning Time (Min-Max.) H 18/34

Fuel Wood Pellet

Consumption for Pellet (Min-Max) 0.7/1.4

Efficiency % 85%

Hopper Capacity KG 25

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60

Rating Power KW 8.0

Page 9

9

Model NP-PA

Dimension (WxHxD) MM 665x787x610

Weight KG 120

Air inlet Pipe MM 76

Air outlet Pipe MM 76

Heat Area M2 140

Automatic Burning Time (Min-Max.) H 13/33

Fuel Wood Pellet

Consumption for Pellet (Min-Max) 0.8/2.1

Efficiency % 83%

Hopper Capacity KG 27

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60

Rating Power KW 13

Model NP-PA-01

Dimension (WxHxD) MM 490x680x450

Weight KG 80

Air inlet Pipe MM 50

Air outlet Pipe MM 60

Heat Area M2 50

Automatic Burning Time (Min-Max.) H 15/24

Fuel Wood Pellet

Consumption for Pellet (Min-Max) KG/H 0.5/0.9

Efficiency % 80%

Hopper Capacity KG 12

Electronic consumption W/H 100-400

Rating Voltage and Frequency V/HZ 230/50-115/60-100/50

Rating Power KW 6

Thickness of steel, inside: MM 3

Thickness of steel, outside: MM 1.5-2

APPEARANCE CHOICES

The STOVE can be ordered with the following sides and doors color:

Black Red Beige

Page 10

10

3.Structure instruction

The stove is mainly made up of following items: (NB-P15 AS

EXAMPLE)

1. Hopper covers 2.hopper 3.auger 5.convertion blower 4. Auger motor 6.venting pipe 7. Exhaust

blower 8.front cover 9.ash drawer 10.fire shield board 11.stove door 12.heat exchanger 13.

Control board

The following is a list of main components and their functions

IGNITER

The STOVE comes equipped with an automatic igniter for lighting the fuel when the stove is in

lighting mode. There are two ways to light the wood pellet for our models. One is the igniter heats

wood pellet directly through the burn pot and then lighted by the combustion blower. The other

one is that the igniter lights the pellet directly. The igniter remains energized for the first eight

minutes of the lighting sequence.

VACCUM SWITCH

Page 11

11

The STOVE has s vacuum switch located behind the left door, fastened to the base. If a low

pressure is created in the firebox by a leak, opening the front door, a blocked flue, or unsealed ash

drawer, the vacuum switch will sense it and cause the stove to go into a shutdown mode.

AUGER AND AUGER MOTOR

The 5 RPM auger motor turns the auger, lifting pellets up the auger tube. The pellets are then

dropped down a tube and into the firepot. The auger is controlled by the control board.

OVER TEMPERATURE SNAP SWITCH

This switch is installed on the bottom of hopper and shut off the stove if it senses excessive

temperatures(70 degrees). This snap switch can be changed by resetting programs in the chip!

CONVECTION BLOWER SNAP SWITCH

This switch is installed on the vent pipe and turns the convection blower on when the stove gets up

to temperature (30 degrees). Besides, switch off the stove when the temperature goes below 30

degrees

Page 12

12

4. Pellet Stove installation

Deciding Where to Locate your Pellet Appliance and CLEARANCES TO COMBUSTIBLES:

When installing this unit on a combustible floor (for example linoleum, hardwood flooring) a

noncombustible hearth pad (15mm thickness) must be under the unit. The pad must extend at least

the width of the appliance [22‖ (558 mm)] and at least the depth of the appliance plus 6‖ (153 mm)

in front of the appliance [29 3⁄4‖ (756 mm)].

The clearance between the walls or to the top is no less than the

size of 50mm.

1. Electrical:

The unit must be grounded. The grounded electrical cord should be connected to a standard

230V, 50Hz (4.5 Amps), (115 volts (4.5 Amps), 60 hertz) electrical outlet. Be careful

that the electrical cord is not trapped under the appliance and that it is clear of any hot

surfaces or sharp edges and also must be accessible. If this power cord should become

damaged, a replacement power cord must be purchased from the manufacturer or a qualified

dealer.

2. Air input and venting pipe Installation

Several examples, taken by NB-P15, are the following

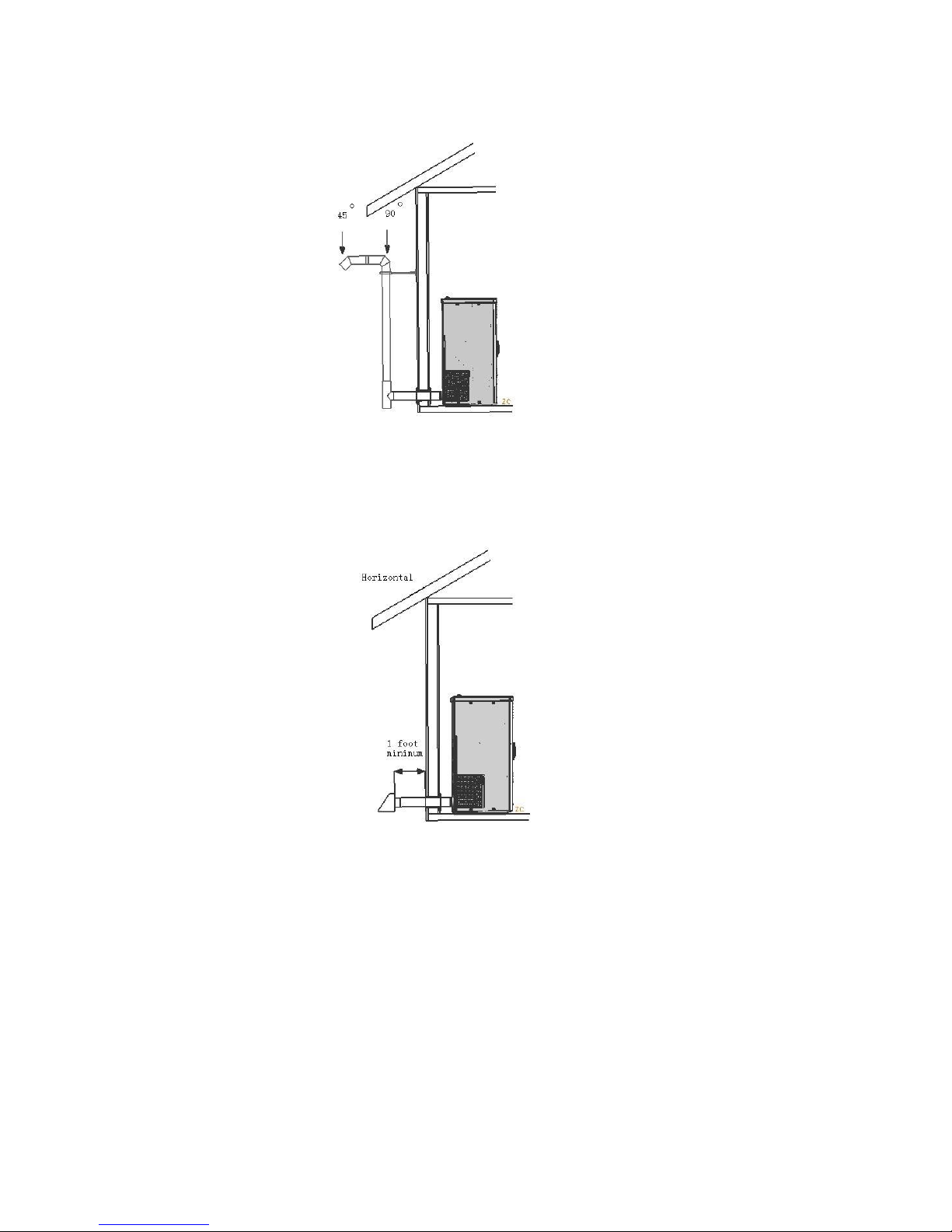

Horizontal and Up,

Page 13

13

Horizontal

Horizontal and Up through the eave

Page 14

14

The Distance between wall and stove when it is installed in the

house (MM)

Page 15

15

The stove of NB-P15'S air input pipe diameter is 40X80 mm, venting pipe diameter is ¢76

mm. The total length of pipes is no longer than 3m and elbows are not available. Indoor

venting pipe joint should be sealed by silicone sealant to prevent exhaust leaking into the

room. Venting pipe and termination should be waterproof and avoid being blocked. Or, the

stove can not work properly. When the installation is limited by space or the owner‘s special

requirements and the pipes‘ length should be longer than 3m and need elbows, the diameters

of the air input pipe and venting pipe must be increased properly for smooth convection. If

not, it will influence the burning and the stove can not work properly. The owner should

connect with the local seller for the right installation. When pellet stove is normal working,

the temperature on venting pipe surface can reach 200˚C, so the combustible things, clothes

and furniture should be away from the venting pipe. To prevent scald, don‘t touch the heating

surface!

Vent Termination Requirements

Page 16

16

(1)Do not terminate the vent in any enclosed or semi enclosed areas such as a carport, garage, attic,

crawlspace, narrow walkway, closely fenced area, under a sundeck or porch, or any location that

can build up a concentration of fumes such as stairwells, covered breezeway,etc.

(2)Vent surfaces can become hot enough to cause burns if touched. Noncombustible shielding or

guards may be required.

(3)Termination must exhaust above the inlet elevation. It is recommended that at least five feet of

vertical pipe be installed outside when the stove is vented directly through a wall. This will create

a natural draft to prevent the possibility of smoke or odor during appliance shut down or power

failure and avoids exposing people or shrubs to high temperatures.

(4)The vent should terminate no less than four feet below, no less than four feet horizontally

from ,and no less than one foot above doors and windows, or gravity /ventilation air inlets into the

building.

(5)The distance between the bottom of termination and grade should be a minimum of 12‖.The

distance between the bottom of the terminate and a public walkway should be a minimum of seven

feet.

(6)Locate the vent terminatation at least two feet away from combustible material such as shrubs,

plants, grass, fences, roof overhangs, and adjacent buildings.

Pellet pipe type PL or L must be used to vent the STOVE. Single wall pipe cannot be used with

this pellet stove. The stove‘s flue collar is 3‖in diameter. An approved wall thimble or approved

ceiling firestop must be used when the pellet pipe passes through a combustible wall ceiling.

The stove‘s combustion blower pressurizes and pushes flue gases out the pellet pipe .As a result,

all pipe joints should be locked together or screwed with three screws if the pipe does not have a

Page 17

17

locking system and sealed with high temperature silicone.

The pipe should be siliconed and fastened with three screws to the stove‘s flue collar.

The longer the run of pipe and the more elbows used, the greater the resistance to the flow of flue

gases. Four inch diameter pellet pipe is recommended for pipe runs greater than 15 feet or when a

number of elbows are used.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYS TEM OF

THIS UNIT. FO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

Here are some examples of installation in different situation

Horizontal installations that terminate without any vertical sections of pipe are approved;

However, wind may direct flue gases towed the house causing discoloring problems. For this

reason, horizontal and up 5 feet or horizontal and through the eave installations are recommended.

To aid in cleaning, wherever possible, the venting system should include a tee with clean out

attached to the flue collar on the stove.

Masonry Chimney

When venting into a masonry chimney, the pellet pipe can terminate just inside the chimney

.However, it is recommended to run the pellet pipe to the top of the chimney.

Fireplace

When venting into a fireplace chimney, the pellet pipe can terminate just above the damper.

However, it is recommended to run the pellet pipe to the top of the chimney.

Vertical

If the length of pipe exceeds 15 feet, 4 inch pipe rather than 3 inch vent pipe should be used.

Page 18

18

Mobile Home Installations

The following are required for installation of the STOVE in mobile homes.

1) Connecting the STOVE to outside combustion air is optional, except in mobile home

installations and when required by local building codes. The stove‘s air intake will accept 3‖ ID

pipe to accommodate outside air installations. The air intake on the exterior of the home should

always be located substantially below the flue termination and terminate with a cover to keep out

weather and pests

2) The stove must be fastened to the floor using lag screws. The screws can be inserted through

the holes in the pedestal located behind the side doors

3) The stove must be grounded with a #8 or larger copper wire.

WARNING:

DO NOT INSTALL THIS STOVE IN A SLEEPING ROOM IN A MANUFACTURED HOME.

CAUTION:

THE STRUCTURAL INTEGRITY OF THE MANUFACTURED HOME FLOOR, WALL ,AND

CEILING/ROOF MUST BE MAINTAINED.

SURGE PROTECTORS

A surge protector is recommended to ensure the stove‘s electrical components are not damaged

due to a surge in the electrical supply. Only high quality protector should be used—cheap ones do

not provide the protection needed.

OUTSIDE AIR INSTAKKATIONS

Connecting the STOVE to outside combustion air is optional, except in mobile home installation

and when required by local building codes. The stove‘s air intake will accept 3‖ID pipe to

Page 19

19

accommodate outside air installation. The air intake on the exterior of the home should always be

located substantially below the flue termination and terminate with a cover to keep out weather

and pests.

THERMOSTAT INSTALLATION

The stove comes from the factory wired to operate manually see control board operation on the

following page. A low voltage thermostat can be installed on the stove.

CAUTIONS INSTALLATION AND REPAIR SHOULD ONLY BE PERFORMAED BY A

QUALIFIED SERVICE TECHNICIAN. DO NOT ATTEMPT TO SERVICE THE

APPLIANCE YOURSELF.

Avoid over firing the stave do not hand feed pellets to the appliance. Never use gasoline, gasoline

type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids to start or flesh up a fire in this

heater. Keep all such liquids well away from the heater while it is in use. For your safety, do not

install or operate your stove without first reading and understanding this manual.

Any installation or operation of the appliance deviating from that which is stated in this instruction

manual WILL void the warranty and may be hazardous.

Due to high temperature, the stove should be located out of traffic areas and away from furniture

and draperies. Children and adults should be alert to the hazards of high surface temperature and

should stay away to avoid burns or clothing ignition. Young children should be carefully

supervised when they are in the same room as the STOVE. Clothing or any other flammable

material should not be placed on or near the stove. Any grille, panel, or glass removed for service

MUST be replaced prior to operating the stove.

Do not operate appliance with the glass front removed, cracked, or broken. Replacement of the

Page 20

20

glass should be done by a qualified service technician. Country Stoves, its employees, or any of its

representatives assume no responsibility for any damages caused by an inoperable, inadequate, or

unsafe condition as a result of any improper operation, service, or installation procedures. Whether

direct or indirect. The appliance when installed must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the National Electrical Code. ANSI\NFPA 70

Page 21

21

5. Operation

1. The first ignition

When first time‘s running, the paint can be get rid of by burning. So some unpleasant Smell might

come out. Please open the window and door to vent the smell.

Note: If the new stove, when its first time using, it is necessary to put a handful of wood pellet to

the fire pot before hand.

Put wood pellet fuel into the hopper, connect the power. Then On/Off Light is Lighting (It means

that power is on). Operate as the instruction on section 2―start and operation‖

2. Start and operation

Please operate the stove as following (refer to stove structure figure and electrical control figure):

Check the box, pellet grate bar,air mate board and ash pan then adjust to proper position.

Push On/Off button UP to 3mins, the light is off and the combustion fan starts to work for 20

seconds to clean the fire pot, then feeding Light is On, meanwhile Convection Blower Lights and

Feel Intake Quantity Lights will be automatically selected to some level, ignitor is working as well.

After less than one Min‘s Feeding, it stops for a while, some smoke will come out, meanwhile, the

combustion fan starts. After Less than one min., it forms the stable flame.

Note: If the new stove, when its first time using, it is necessary to put some pellet to the fire

pot before hand.

Depending on the heating desire, fuel intake quantity can be adjusted from few to large by the fuel

intake Button. At the same time adjust the convention Button to blow the heat to the room to

reach the best combustion. (According to the various quality of wood pellet, please select right

feeding speed, in order to burn properly)

Page 22

22

Note: if the ignition is failure, the thermal control will shut off the stove automatically. If want to

restart it again, Please Switch off the power for a while and then switch on the power (In order to

shut down the previous process of program), follow the above process to ignite and start again.

3. Turning Pellet Stove Off

Please turn off the stove as the following:

Press On/Off button up to 2 seconds; the auger motor will be stopped, the other motors are

working continuously, meanwhile the ON/OFF light flashes, until the temperature decreases to

somewhere (30 Degree), it will stop completely.

4. Safety

(1) The stove will power off and the fire will be put out since the stove decreases to the safety

temperature

(2) The stove will be shut down, when thermodisc (for the hopper)T2≥70˚C

(3) When vent pipe is blocked, the vent pipe indicator light will be on and the stove will shut

down. Then please check it or call your dealer!

Caution

1. It is important to select and use only pellets that are dry and free of dirt or any impurities

such as high salt content. Dirty fuel will adversely affect the operation and performance of the

unit and will void the warranty. The Pellet Fuel Industries (P.F.I.) has established standards

for wood pellet manufacturers. We recommend the use of pellets that meet or exceed these

standards. Ask your dealer for a recommended pellet type.

2. Please keep the door closing and sealing during burning for good effect and preventing hot

ash flying out.

Page 23

23

3. The burning features ---bright yellow flame, the pellet burning with a little jumping in the

grate bar. No pile pellet and no smoke venting. If it becomes a little dark glow and lazy flame,

smoke appears from the venting terminal, speed up the combustion blower to add the air

input.

4. For reducing the heat output, its better to reduce the pellet feed by selecting lower power

level.

5. Venting pipe and air input pipe should keep unblocked.

FOR MORE INFORMATION ABOUT THE

OPERATION PLEASE READ FOLLOWING:

Page 24

24

Switching on / switching off

The heater switching on and switching off is performed through the ON/OFF key

At the switching on the message, CLEANING will be shown on first,

Cleaning’ is displayed for 20 second, in order to clean the fire pot.

In the same way at the switching off the message

After the temperature in the stove is lower than 30degree, finally, the phrase

‘GOODBYE’ is displayed.

!! ATTENTION !!

During the flame switching off phase and exchanger cooling, it isn’t

possible to switch on again the heater up to the operation end; this

state is highlighted from the message

‘SWITCHING OFF’

5.OperationSwitching on\off

Page 25

25

At the switching on the flame isn’t started immediately, depends from the selected functioning

formality. Two formalities are settable: AUTOMATIC or MANUAL, for further details see the

appropriate section.

The switching on Stage, which has the duration of about 15-20 minutes, are necessary to the

resistence to carry the pellets at the switching on temperature, (depends from the heater). The

switching on procedure is showed from a passages set showed in the display. Before starting the

switching on, the heater performs the brazier cleaning and displays the following wording:

Firstly,

Secondly,

Thirdly,

The starting first phase is showed from the message ‘FEED’. In this phase are performed the

chimney verification operations and the pellets will be loaded in the melting pot. The successive

phase will be showed from the inscription ―Lighting”. In this phase there will be the appearance of

the first breeding grounds. This state remains up to when the smokes temperature doesn‘t exceed

the planned threshold.

!! ATTENTION !!

From the appearance of the first breeding grounds, some minutes can spend before the end of the

switching on phase.

Page 26

26

When the switching on phase is finished, some minutes will spend necessary for the flame

stabilization. This phase is showed from the message ‘STABILIZATION” which finishes

after some minutes going up at the work phase

When the switching on phases are finished the heater will show the own state on the

display..

It is possible to switch off the heater in every functioning phase, except that during the

programming. The switching off performs pressing the key ON/OFF for two seconds, as

previously described.

!! ATTENTION !!

If the heater is switched off, the flame will continue to be present up to the fuel

exhaustion contained in the melting pot, this phase will manage in automatic

way both fans and it will have the duration up to 5 minutes.

The switching off phase is displayed from the message ‗SWITCHING OFF” present up to

the end of the operation.

Whether the heater is switched or not, on the display will display the hour, the power, and

the planned set temperature.

Switching on

/off

Page 27

27

FLAME POWER VARIATION

Pressing the key the feed quantity can be changed, the display shows the

selected power.

MINIMUM POWER P4

LOW POWER P3

MEDIUM POWER P2

MAXIMUM POWER P1

Flame variation

Page 28

28

ECO STAGE

If the room temperature exceeds the set out temperature, automatically the stove is stopped in

order to save energy, It shows like following:

After the room temperature drops down, and below the set out temperature, it automatically,

switching on again.

Automatic and manual SELECTING

Pressing the keys , The light shown on the following, will be

on/off.

If the light is on, it shows that automatic programme is selected.

Otherwise it is manual.

ECO Stage

Manual/Automatic

Page 29

29

DESIRED TEMPERATURES SETTING

Pressing the keys , on the display The temperature is selecting.

Desired temperatures

Setting

Page 30

30

CLOCK SETTING

Pressing the keys up to 2 sconds, on the display Clock is selecting:

You can choose week by keys , keeping press the key

The time can by select, Also using , to select the right one.

CLEANING SETTING

After keeping pressing the key, , you can adjust every X mins, last Y seconds to

cleaning the burning pot by the key

COMBUSTION FAN SETTING

Again by keeping pressing the key, , you can change the speed of combustion

fan

Clock Setting

Page 31

31

from P1 to P4, BY PRESSING

For example P1:

It should be noted, P5 is the speed of combustion fan when it is cleaning.

P6 is the speed of combustion fan during the lighting stage.

TIMER SETTING

On the display the following wording will appear

With this function you program the heater for a weekly programming, associating the

switching on and the switching off at the pre fixed timetables. You can program daily

switching on and switching off for the whole week.

By keeping pressing the key , you will found the attached instruction above,

Then you can press to choose week days

By pressing , to select hours, then press to decide the hour on or Off.

Page 32

32

On the superior line it is showed the day which is programming, the hour with the

functioning state.

On the below line the programmed hour are displayed.

Lower one means off, taller on means on, which also shows on superior line

Pressing the key the programming will finish.

*******************************************************

If showing following words, such as:

It means that there are some problem with vacuum Switch.

Such as door has not been closed properly

Combustion fan's speed should be up.

There is some leakage about the stove and so on.

It means that the high temperature sensor has some problem,

Such as: the switch is broken,

The temperature is too high that the stove runs not properly

Page 33

33

!! ATTENTION !!

You can press to exit the program state. Otherwise, keep pressing

REMOTE CONTROL

Min remote control

Page 34

34

6. Maintenance

Unplug and let the STOVE cool before performing any maintenance or cleaning. Some brands of

pellets produce more ash and clinkers than others. Therefore the frequency of performing the

following cleaning procedures depends to a great degree on the quality of the pellets burned. Not

cleaning this unit will cause it to burn poorly and will avoid your stove’s warranty.

BURN POT CLEANING

The combustion fan comes on at high speed once an hour to blow the byproducts of combustion

out of the burn pot. However, the burn pot should be cleaned more thoroughly after burning about

10 bags of pellets. The burn pot has a number of gaps in the bottom and sides that provide

combustion air to the pellets. The extreme temperatures in the burn pot can cause the impurities in

the pellets to form ash and clinkers.

When the stove is cool, open the front door and lift out the iron burn pot. Scrape the inner bottom

and sides of the pot with a screwdriver to remove all ash and clinkers from these surfaces.

Besides, please also clear the bars of the igniter carefully, although it was made of ceramic, it can

be easily broken by smash them with some hard stuffs. Make sure all the gaps in the bottom of pot

are open. Place the burn pot in the hole from which it was removed. Make sure the high side of the

pot is rotated toward the front of the stove. Push the burn pot down so surface A is tight against

the steel supporting the pot. Do not substitute any other grate or pot for use in this stove.

CLEANING GLASS

Caution: Do not open the front door when the stove is hot. To open the door, follow the first two

steps listed in Front Door Removal. Clean the glass using a soft cloth or paper towel and Windex

Page 35

35

or wood stove window cleaner. A damp cloth with small amount of ash from the firebox can also

be used to clean the glass.

ASH DRAWER REMOVAL AND CLEANING

Caution: Do not remove the ash drawer when the stove is hot. Pull the ash drawer forward and

away from the stove.

Caution:

Disposal of Ashes should be placed in a metal container with a tight fitting lid. The closed

container should be placed on a noncombustible floor or the ground well away from all

combustible materials, pending final disposal. If the ashes are disposed of by burial in soil or

otherwise locally dispersed, they should be retained in the closed container until all cinders have

been thoroughly cooled. Reinstall the ash drawer by inserting the drawer in the stove and

refastening the left and right latches securely. Note that if the ash drawer does not seal tightly to

the stove, the control board may detect a leak and shut the stove down.

CLEANING THE COMBUSTION BLOWER

To clean the combustion blower, remove the four nuts labeled. A in the drawing to the right with

an 11/32‘‘wrench.After removing these nuts, the motor with fan attached can be pulled from the

fan housing. The fan blades and the fan housing can be vacuumed once the motor is removed.

When reinstalling the motor, a new gasket may need to be installed between the motor and the fan

housing. To complete the reinstallation, place the motor back on the fan housing and reinstall the

six nuts. Make sure the motor‘s green ground wire is secured under one of the nuts.

CLEANING THE FLUE GAS PASSAGE WAYS

Cleaning the flue passageways should be done at least once a year. Burning high ash pellets may

Page 36

36

require this cleaning to be done more often. Clean these passageways only when the stove and ash

are cold do not start a fire in the vacuum cleaner by vacuuming up hot ash. On each side of the

stove there are two access covers (see B and C on the drawing to the right) that can be removed by

unscrewing the two 5/32‘‘ allen head screws. Insert a cleaning brush in the openings to loosen any

ash buildup and use a vacuum cleaner to remove the loosed ash. Reinstall the covers when

cleaning is complete. There are also two more access holes located behind the ash drawer.

Remove the ash drawer (see the previous page) and loosen the two 5/32‘‘ allen head screws shown

as D in the drawing below. Rotate the covers over the access holes and use a brush and vacuum to

clean the ash. Rotate the covers back over the holes and tighten the screws. Front View Looking

into the Ash Drawer Cavity with the Ash Drawer Removed.

CLEANING THE CONVECTION BLOWER

To clean the convention blower, remove the right side door (see the following page). Disconnect

the stove power cord from the electrical outlet. Remove the two screws (A in the drawing to the

right) securing the blower to the blower duct. Slide the blower to the rear disengaging it from the

blower duct. A vacuum can be used to remove any dust accumulation on the blower‘s blades or

inside the blower duct. Caution should be used not to damage the blower‘s blades during cleaning.

Note that future models of the stove may be built so that the screws A may just need to be

loosened rather than removed to remove the blower. To reinstall the blower, slide the blower back

into the retaining lip B and reinstall screws A.

CLEANING THE VENT PIPE

Soot and Fly ash: Formation and Need for Removal

The products of combustion will contain small particles of fly ash will collect in the exhaust

Page 37

37

venting system and restrict the flow of the flue gases. Incomplete combustion, such as occurs

during start up, shutdown, or incorrect operation of the room heater will lead to some soot

formation which will collect in the exhaust venting system. The exhaust venting system should be

inspected at least once every year to determine if cleaning is necessary. Sweep the pipe as needed.

A tee and the cleanout in the vent system attached to the stove‘s flue collar will facilitate this

cleaning.

Required Cleaning Schedule after Number of Bags Burned

Burn Pot=10 bags

Ash Drawer=50 bags

Flue Fan=100 bags

Blower=100 bags

NOTE: Cleaning schedule will vary depending on quality of pellets used. Burned high ash

pellets used. Burned high ash pellets will require more frequent cleaning

CHANGE THE HEAT RESISTOR EVERY TWO OR THREE MONTHS

Normally, we have a spare set off heat resistor with a new stove!

Page 38

38

7. Troubleshooting

The control panel of the stove has trouble examine sensors. When the sensor detect the

abnormal work temperature (below 30˚C), or the other sensor‘s temperature is above 70˚C the

auto-control temperature switches will react accordingly. When temperature is below 30˚C,

the safety control system will stop the stove automatically; when the other sensor, fixed into

the hopper, detect the temperature is above 70˚C, the stove will be shut down.

The general troubles, the possible reasons and the solutions are as following, after solving

problems, start the stove again:

problems

reason

solution

1. The start light does not

light when power is on

No power in stove or in the

control panel.

Check the power and wires.

2. The blower doesn‘t

work after pressing the

start bottom.

If after 15 mins, it doest

work, there must be

wrong

It is normal.

It will start automatically

when the temperature is

above 30 degrees on the

venting pipe.

Please wait

No power in stove or in the

control panel.

Or Unplugged on the mother

board

The low temperature sensor is

broken

Check the power and wires.

Plug it

Replace it

3. No feeding after 20 seconds of starting.

There are three stages for the feeding process.

One is during the several minutes, feeding is constantly. "Feeding" is showing on the LCD

display

Page 39

39

Two is the following couple minutes, the feeding light is off.:"Light" showing on the Display

The last stage is that feeding Every several seconds all the time after previous stages.

A. For the first stage

(during first several

minutes)

Feed unit is blocked.

Check the auger is blocked or not.

There is the problem

about the connection

between motor and auger

Check the fasten screw between

auger and motor loose or not.

Or the auger might jump out

No fuel in the hopper.

Fill the fuel into the hopper.

B. For the second stage

It is normal

Please be patient

C. Regarding to the last

stage

Feed unit is blocked.

Check the auger is blocked or not.

There is the problem

about the connection

between motor and auger

Check the fasten screw between

auger and motor loose or not.

Or the auger might jump out

No fuel in the hopper.

Fill the fuel into the hopper.

4. Feeding not properly

A. too much wood pellet

and cannot burned in time

The level of feeding

speed is too high

Adjust the combustion fan's speed

up

B. The fire is off due to

little wood pellet can be

burned

The level of feeding

speed is too low

Adjust the combustion fan's speed

Down

5 After ignition the power

is off 15min later.

Pellet feeder unit is off or

pellet is too little.

30˚C temperature switch

breaks or the connection

wires of switch loose.

Not enough pressure in

the stove

Check the pellet feeder unit and

restart.

Check the connection wires or

change the 30˚C temperature switch.

Adjust the combustion fan's speed

up

6 orange and lazy fire,

piled pellet, carbon on the

glass

Lack of air intake for

burning.

Clean the block in gate bar.

Check the door and window glass

gasket sealed or not.

Page 40

40

Check the air intake pipe and

venting pipe blocked or not, and

clean it. Change to the big diameter

pipes if pipes are too long to affect

combustion.

Adjust the combustion fan's speed

up

Call the dealer to reset the program

7 The fire put out and

power is off

automatically.

The hopper is empty.

No fuel feed.

The fuel feed is too little.

low temperature switch

(30˚C) is wrong.

Set temperature is

reached

Put fuel into the hopper. refer to (2)

Lower the speed of combustion fan

Cool the stove at least 1 hour then

operate again or change the low

temperature switch (30˚C).

"ECO" its normal, waiting, after the

temperature is blow set on, it will

automatically switch on again

8 The blower still works

after the stove is cool and

fuel feed stops.

The low temperature

switch (30˚C) is broken.

Change this switch.

9 no enough heat wind

Unqualified fuel

Blower speed is too high.

Heat exchange tubes are

dirty.

Use the standard specially pellet.

Use higher power

Clean the heat exchange tubes.

10. Showing "Pressure

Erro" on the display

Vent pipe is blocked

The door is opening

The are some leakages

Shut down the stove, check the

venting pipe

Close the door and unplugged then

restart

Check it and repair it.

Page 41

41

Adjust the combustion fan's speed

up to offer more pressure in the

stove

ELECTRICAL GENERATOR OPERATION

Your stove can be powered with a gas driven electrical generator.

However, the generator’s electrical regulator may not be compatible with the stove’s

electronics. The higher the quality of the generator, the greater the chance that it is

compatible with the stove.

Page 42

42

8. Warranty

1. If the owner follows the operation of this manual, it is guaranteed the stove can well work

normally within one year after selling. If the stove be destroyed by the poor quantity or the

stove works abnormally within the guarantee period, it will be repaired or changed parts with

free charge.

2. The problems caused by the owner‘s improperly operation are not our guarantee. We can

supply payment service. It‘s a lifetime product.

Page 43

43

9.Electronic Plan

Loading...

Loading...