Page 1

GR871

14" (355 mm) Heavy Duty Chop Saw

Scie fendeuse de 355 mm (14 po) et de service intensif

Cortadora de metales de 355 mm (14")

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

GRABBER

®

Page 2

Page 3

1

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY GRABBER TOOL, CALL US TOLL FREE AT:

1-800-477-

TURN (1-800-477-8876)

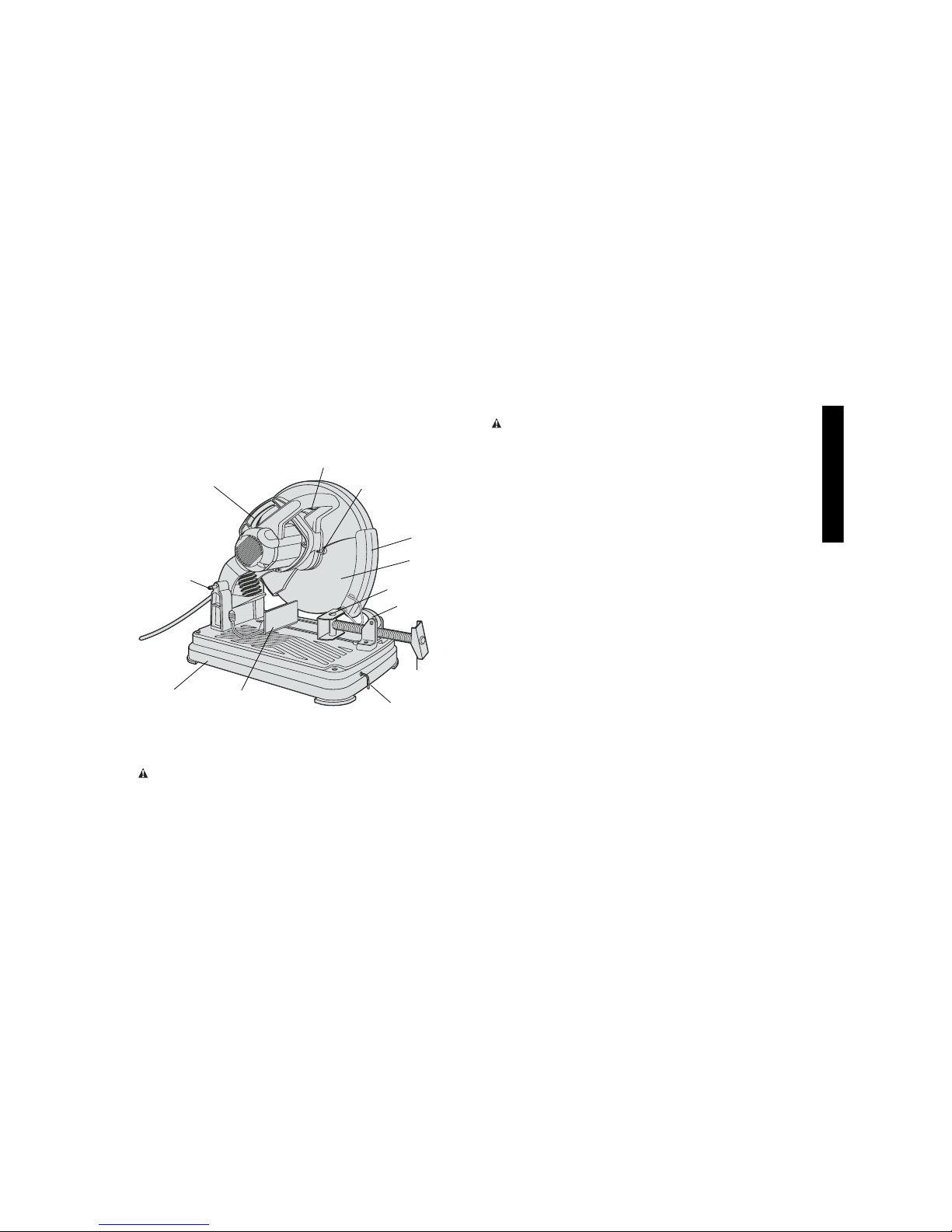

TRIGGER SWITCH

FENCE

VISE LEVER

CRANK

WHEEL

GUARD

WHEEL

VISE

CARRY

HANDLE

LOCK

DOWN PIN

WHEEL LOCK LEVER

BASE

HEX

WRENCH

WARNING: FOR YOUR OWN SAFETY READ INSTRUCTION

MANUAL BEFORE OPERATING CHOP SAW.

Important Safety Instructions

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe dis-

tance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches,

or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and safer at the rate

for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for

which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using and extension cord, be sure

to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The following table shows the

correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

Page 4

2

English

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not moreAmerican Wire Gage

Than Than

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing, neckties,

rings, bracelets, or other jewelry which may get caught in moving

parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cut-

ting operation is dusty. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

• SECURE WORK. Use clamps or a vise to hold work when practical.

It’s safer than using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best

and safest performance. Follow instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories,

such as blades, bits, cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in off position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction man-

ual for recommended accessories. The use of improper accessories

may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine that

it will operate properly and perform its intended function — check for

alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard

or other part that is damaged should be properly repaired or replaced.

• DIRECTION OF FEED. Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER

OFF. Don’t leave tool until it comes to a complete stop.

• REPLACEMENT PARTS.

When servicing

use only identical

replacement parts.

• TO REDUCE THE RISK OF ELECTRIC SHOCK, this equipment has a

polarized plug (one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit, contact a qualified

electrician to install the proper outlet. DO NOT CHANGE THE PLUG IN

ANY WAY.

Additional Safety Rules for Chop Saw

• Always wear safety goggles or other eye protection when using this tool.

• Before using, inspect each cutting wheel for cracks or flaws. If a crack

or flaw is evident—discard the wheel! The wheel should also be

inspected whenever you think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed)

place the tool in a well protected area. If the wheel has an undetected

crack or flaw, it should burst in less than one minute. Never start the

tool with a person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment.

If this occurs, stop the tool and inspect the wheel.

• Clean your chop saw periodically following the procedure in this manual.

• Do not remove wheel guard.

• Always use the vise or special fixturing to clamp work.

• Use only 14" type 1 wheels rated at 4100 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

Page 5

3

English

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• NEVER USE A CIRCULAR SAW BLADE IN THIS CHOP SAW. DO

NOT USE TOOTHED BLADES.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE LIQUIDS,

GASES OR DUST. Sparks from cutting or motor may ignite dust

and fumes.

SAVE THESE INSTRUCTIONS

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, saw-

ing, grinding, drilling, and other construction activities. Wear

protective clothing and wash exposed areas with soap and

water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

Power Supply

Be sure your power supply agrees with the nameplate marking. 120

volts, “60 Hz” means alternating current (normal 120 volt, 60 Hz house

current). A voltage decrease of more than 10% will cause a loss of

power and overheating.

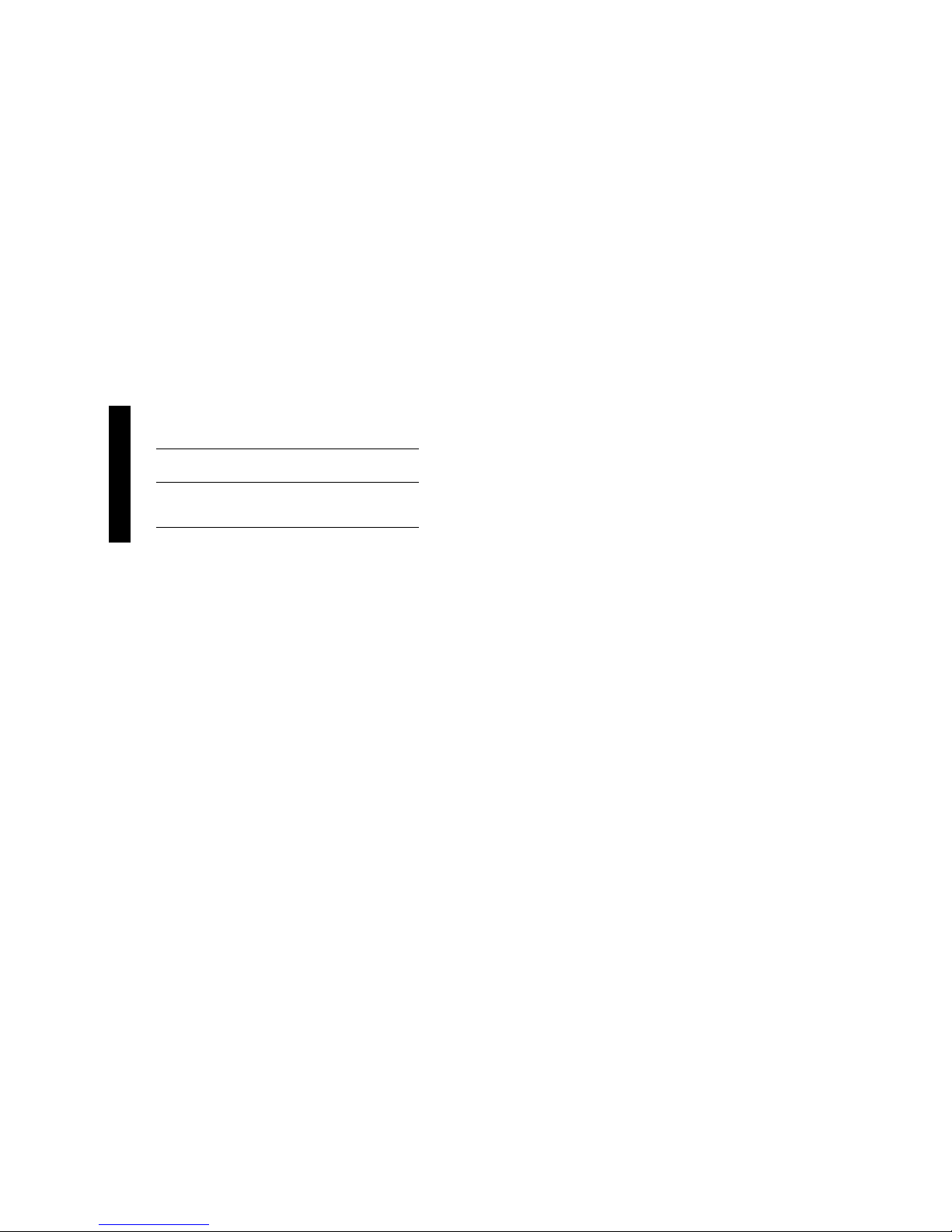

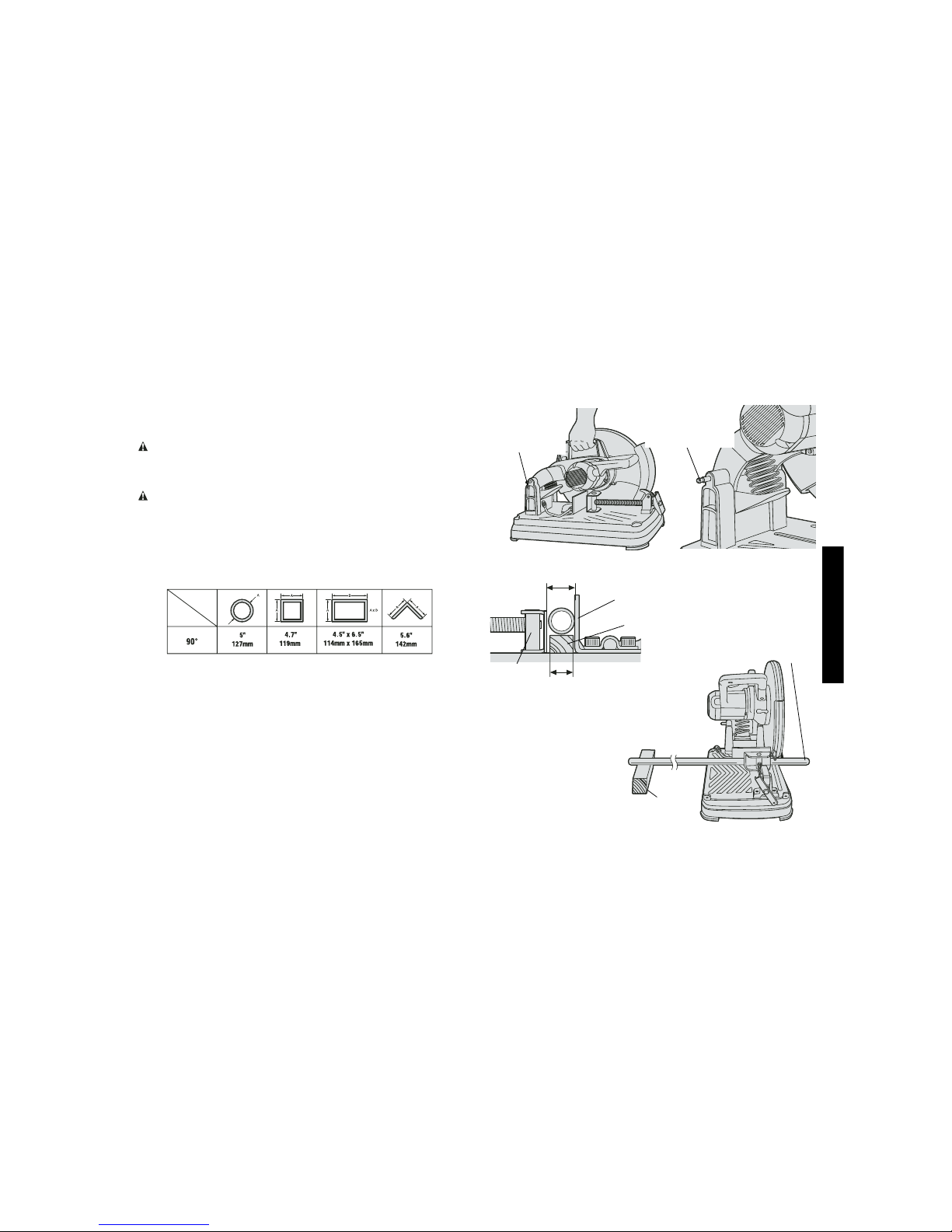

Cutting Capacity

The wide vise opening and high pivot point provide cutting capacity for

many large pieces. Use the cutting capacity chart to determine total

maximum size of cuts that can be made with a new wheel.

CAUTION: CERTAIN LARGE, CIRCULAR OR IRREGULARLY

SHAPED OBJECTS MAY REQUIRE ADDITIONAL HOLDING

MEANS IF THEY CANNOT BE HELD SECURELY IN VISE.

CAUTION: DO NOT CUT MAGNESIUM WITH THIS TOOL.

Maximum Cutting Capacity

NOTE: CAPACITY SHOWN ON CHART ASSUMES NO WHEEL WEAR

AND OPTIMUM FENCE POSITION.

Standard Equipment

1 14" (355mm) Metal Cutting Abrasive Wheel. Use only high strength

Type 1 organic bonded wheels rated 4,100 rpm or higher.

(Aluminum Oxide)

1 Wheel Wrench

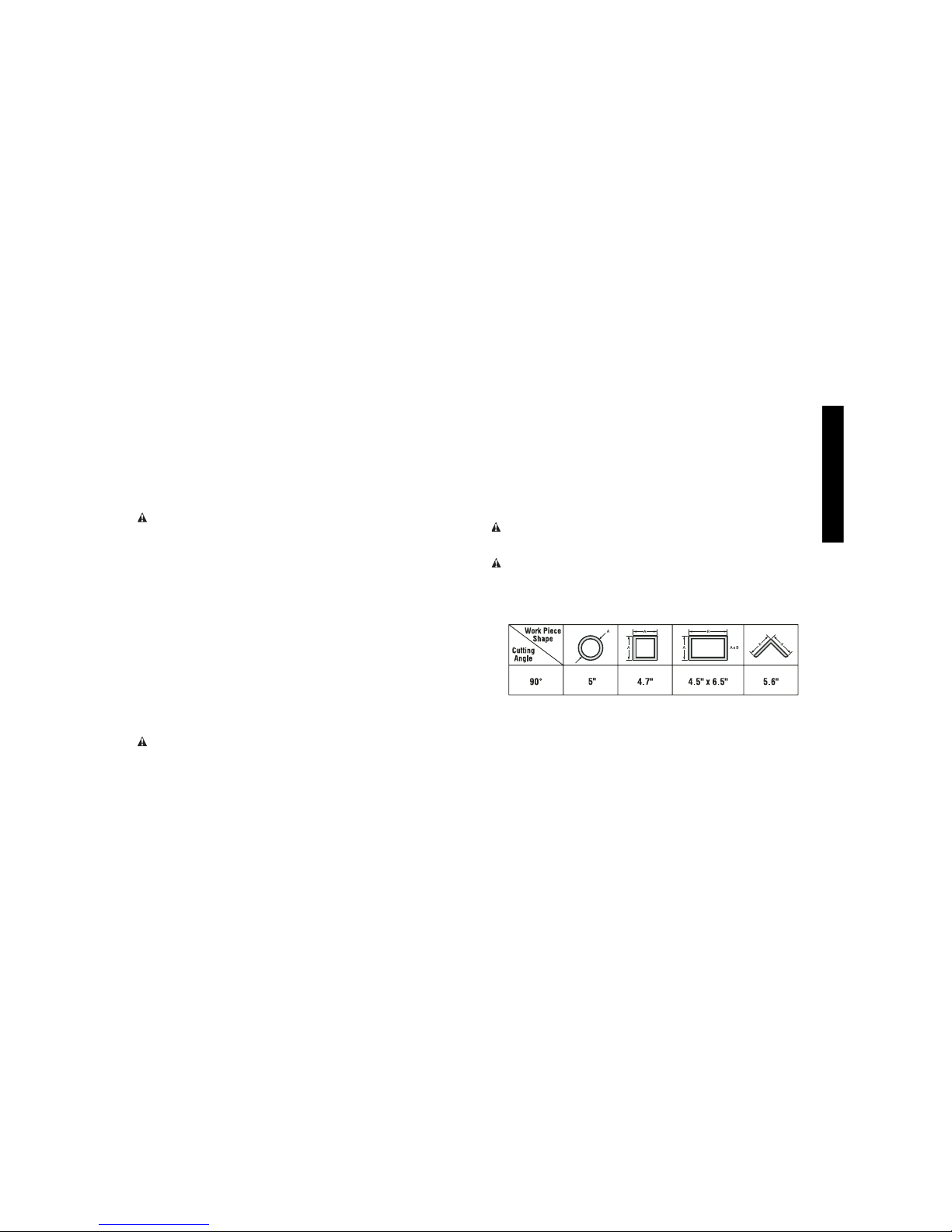

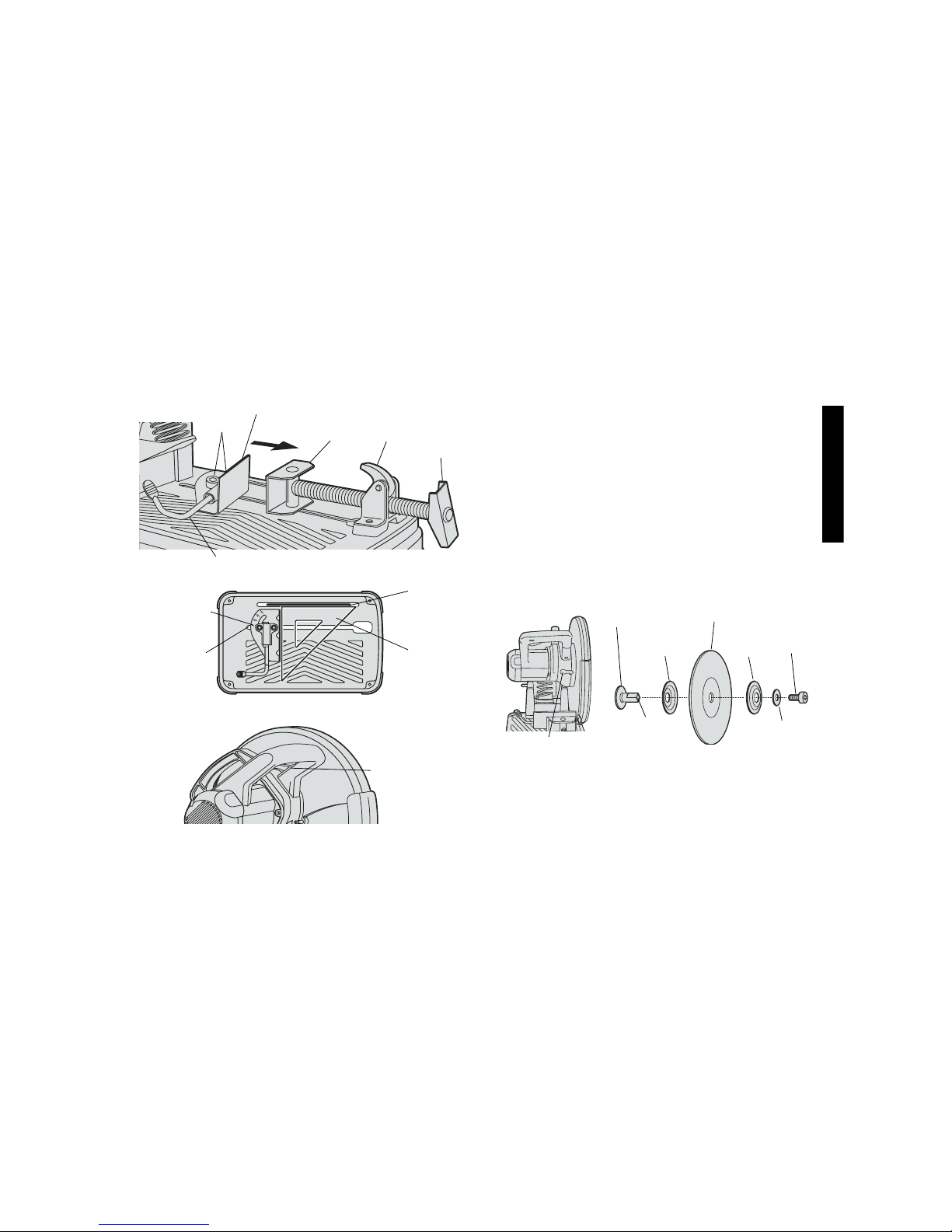

To Carry

Fold down unit to position where you can carry the saw. Push in lock

pin (Figure 1) to lock arm down.

Page 6

4

English

Unlocking

To unlock tool and raise head, depress motor arm slightly and pull lock

pin out. Motor arm will then pivot upward (see Figure 2).

Material Clamping and Supporting

• Angles are best clamped and

cut with both legs resting

against base.

• A spacer block slightly narrower than the work space

(see Figure 3) can be used to

increase wheel utilization.

• Long workpieces must be supported by a block so it will be

level with top of base (see

Figure 4). The cut off end

should be free to fall downward

to avoid wheel binding.

VISE

DIAMETER OF

WORK PIECE

FENCE

SPACER

BLOCK

WIDTH OF

SPACER BLOCK

FIG. 3

LOCK PIN

FIG. 1

LOCK

PIN

FIG. 2

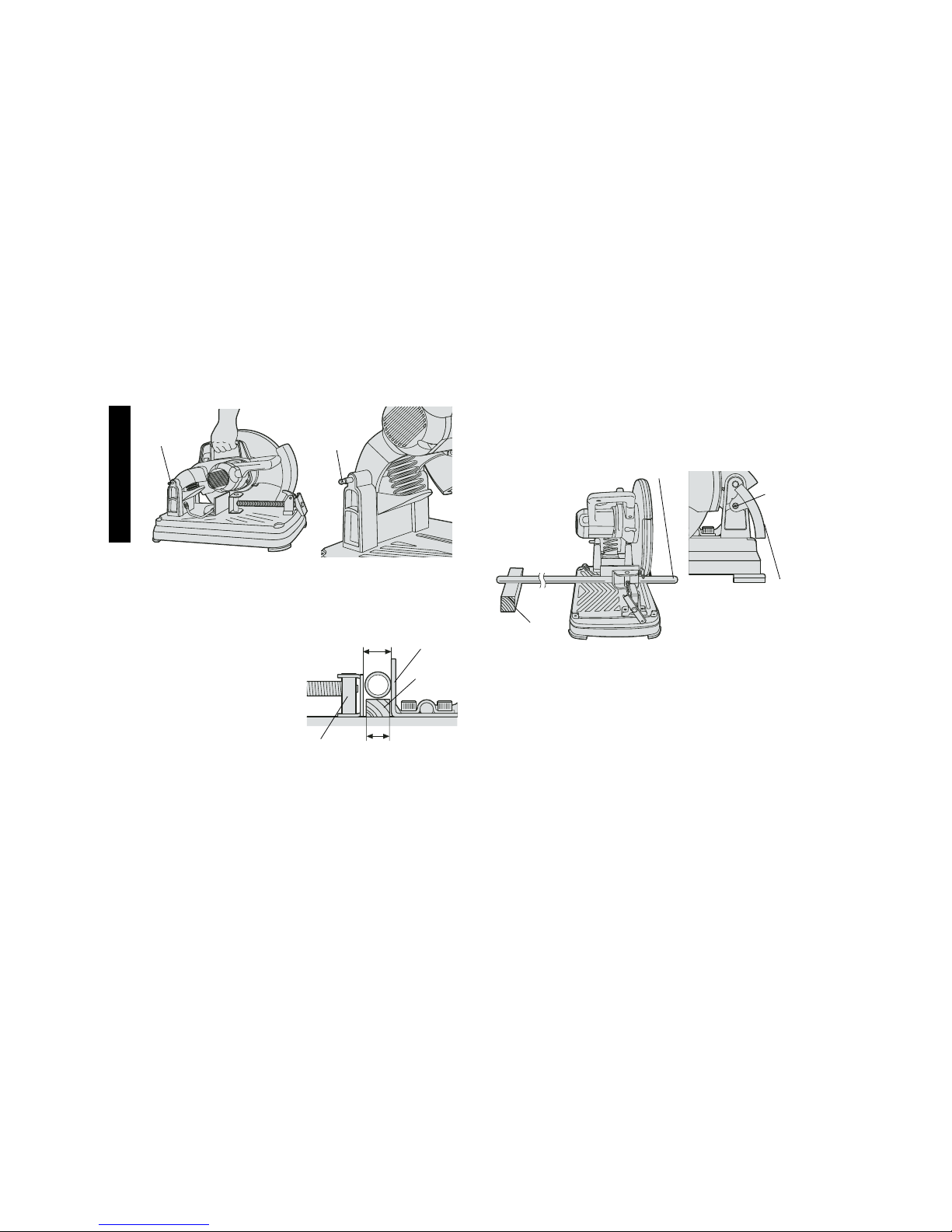

Spark Deflector Adjustment

To best deflect sparks away from surrounding persons and materials, loosen the screw, adjust the spark deflector and then retighten

screw (see Figure 5).

Vise Operation

Vise has a quick travel feature. To release the vise when it is clamped

tightly, turn the crank counterclockwise one or two times to remove

clamping pressure. Lift vise lever up. Pull crank assembly out as far

as desired. Vise may be shoved into work without cranking. Lower

vise lever then tighten vise on work by using crank (see Figure 6).

Fence Operation

Fence requires no wrenches to adjust. The quick release clamp lever

unlocks and locks the fence. When the lever is rotated fully forward,

the fence is unlocked. The fence can then be freely moved forward,

backward or rotated to allow for the best cutting position for a new

wheel and as the wheel wears.

Rotating the lever fully to the rear locks the fence in position selected. If

the bottom leg of the lever is not horizontal (parallel to the base), the

BLOCK

FIG. 4

CUT OFF

END

FIG. 5

SCREW

SPARK

DEFLECTOR

Page 7

5

English

fence is not locked. Lever will only lock fence when there is strong

resistance to moving it to rear. If resistance is light, adjust clamping

force by tightening slightly the two bolts holding the fence to the base.

Test by reclamping and attempt to move fence (see Figure 6).

Fence Angle Adjustment

Angle adjustment indicator is part of fence clamping system. Align

desired angle indicator line with edge of slot in base (see Figure 7). For

a more accurate square cut (Figure 7), disconnect power supply, unlock

fence, push arm down until wheel extends into base, place a square

against wheel, adjust fence against square, then lock fence into

position.

Switch

To start the tool, depress the trigger switch shown in Figure 8. To turn

the tool off, release the trigger switch. Keep hands and material from

wheel until it has coasted to a stop.

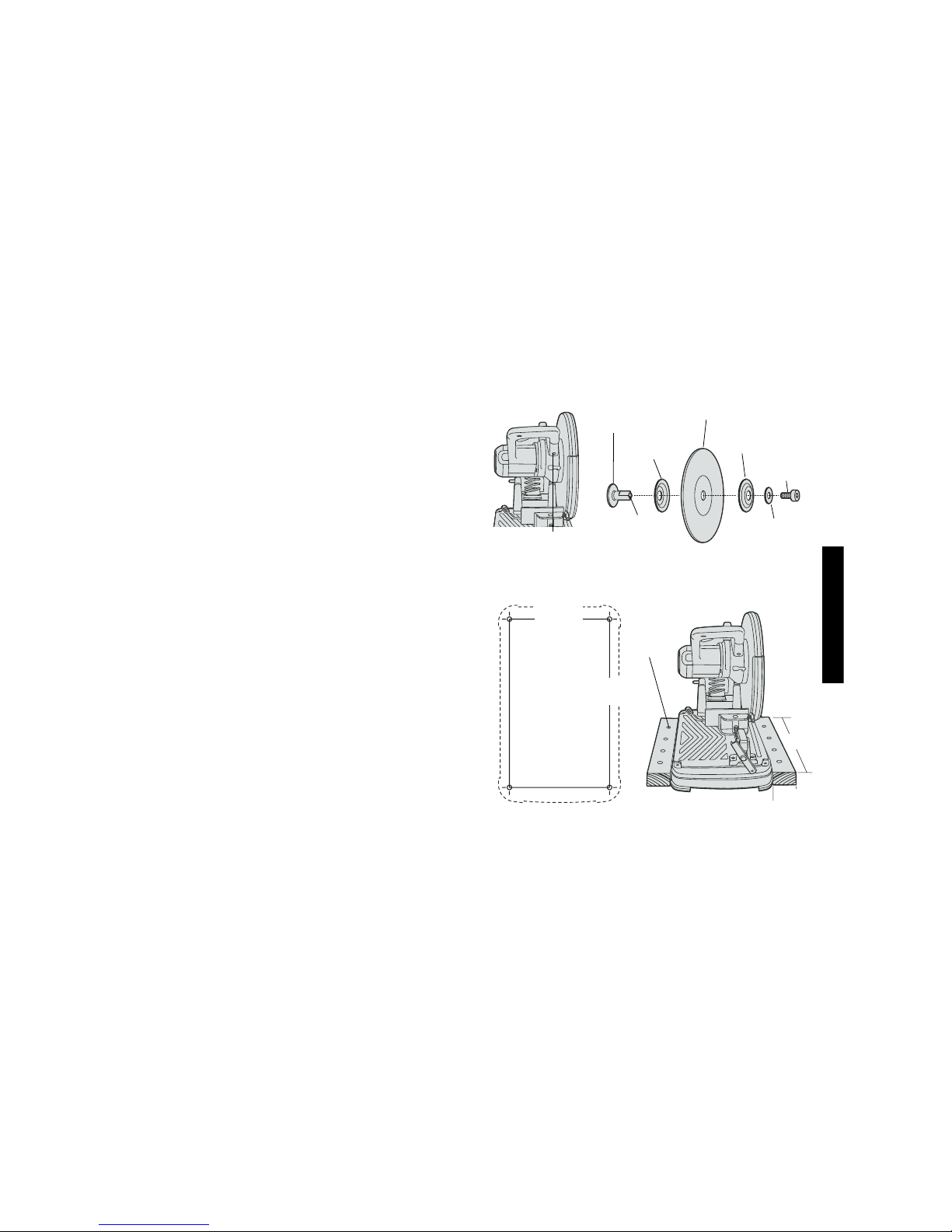

Removal and Installation of Wheels

1. Be sure tool is disconnected from power supply.

2. Push in wheel lock lever (Figure 9) and rotate wheel by hand until

wheel lock lever engages slot in inside flange to lock wheel. Loosen

SPINDLE SHAFT

FLANGE,

INSIDE

FLAT

WASHER

FLANGE,

OUTSIDE

WHEEL

FIG. 10

M10

BOLT

INTERNAL

THREAD

FIG. 9

WHEEL LOCK LEVER

TRIGGER

SWITCH

FIG. 8

WHEEL

FIG. 7

SQUARE

ANGLE

ADJUSTMENT

INDICATOR

SLOT

EDGE

VISE

LEVER

CRANK

FIG. 6

VISE

FENCE

FENCE

BOLTS

CLAMP LEVER

FORWARD

Page 8

6

English

the bolt counterclockwise in the center of the abrasive wheel with

the 8 mm hex wrench found in the holder in the base. Bolt has right

hand thread.

3. Remove the bolt, washer, outside flange, and old wheel (Fig. 10).

4. Install the new abrasive wheel by reversing the above steps.

5. Do not over tighten bolt.

DO NOT MAKE ANY ADJUSTMENT WHILE THE WHEEL IS IN MOTION.

DO NOT MAKE ANY ADJUSTMENT WHILE CHOP SAW IS PLUGGED

INTO POWER SUPPLY.

WARNING: CHECK THE WORK SURFACE THAT THE CHOP

SAW RESTS ON WHEN REPLACING WITH A NEW ABRASIVE

WHEEL. IT IS POSSIBLE THAT THE WHEEL MAY CONTACT ANY

ITEMS OR STRUCTURE THAT EXTENDS ABOVE WORK SURFACE

(UNDER THE BASE) WHEN THE ARM IS FULLY LOWERED.

NAIL

FIG. 12

17-3/8"

(441 MM)

10-1/8"

(257 MM)

FIG. 11

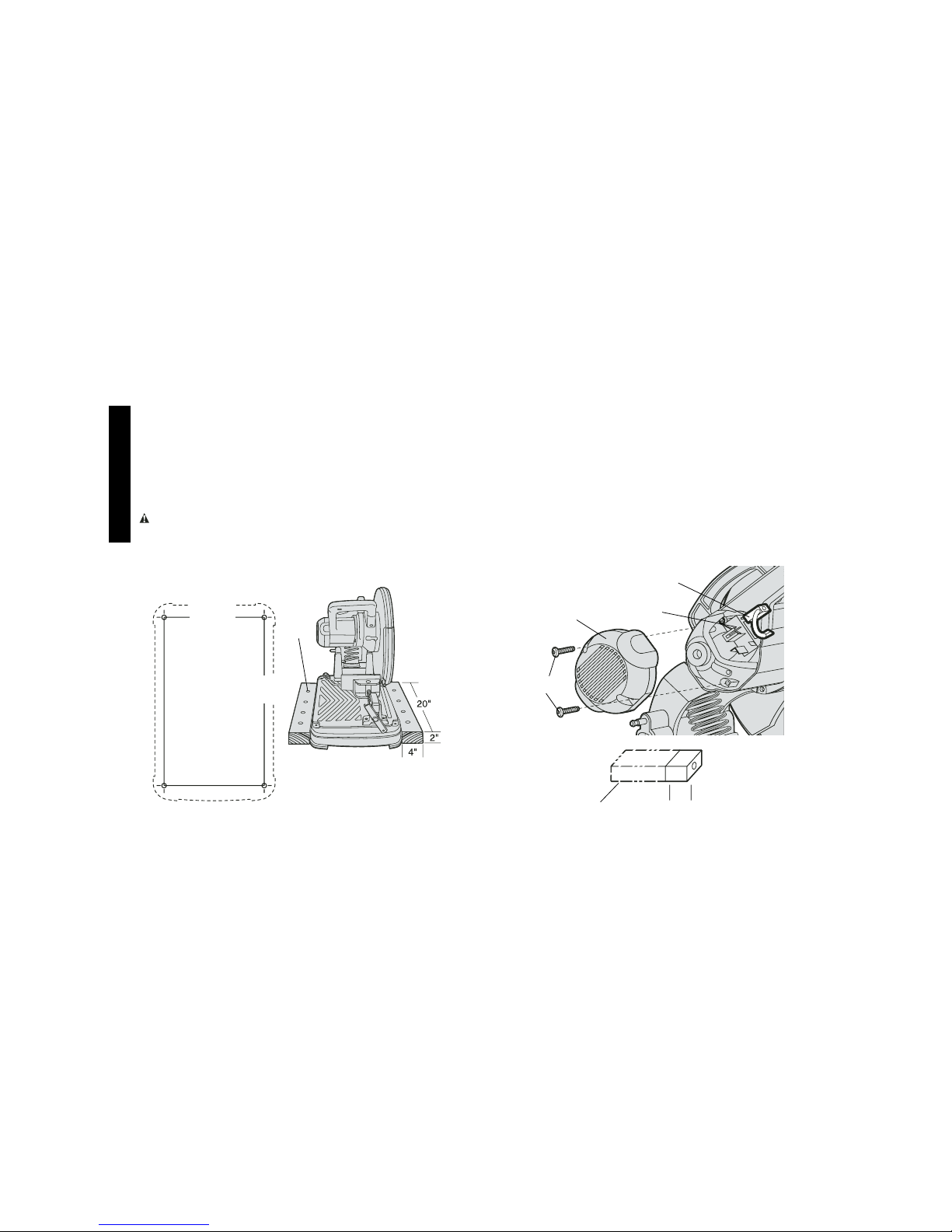

Mounting

PROCEDURE FOR PERMANENT MOUNTING

1. Drill four holes 5/16" through the work surface (Figure 11).

2. Insert 1/4-20 screws down through the holes in the base and

through holes in mounting surface. The approximant length of the

screws should be the thickness of the mounting surface plus 4".

CRADLE MOUNTING

1. Cut two boards approximately 20" long x 2" high x 4" wide (508mm

x 50mm x 100mm).

2. Place chop saw at desired work location.

3. Place boards tightly along side, and nail to work surface,

(Figure 12).

.3"

(8 MM)

FIG. 14

BRUSH

BRUSH

FIG. 13

SCREWS

END CAP

SPRING

Page 9

7

English

Motor Brush Inspection and

Replacement

Be sure tool is unplugged before inspecting brushes. Brushes should

be regularly inspected for wear. To inspect brushes, unscrew the two

end cap screws and remove end cap (see Figure 13). To remove each

brush, first unplug the shunt wire terminal connection. Then carefully

back the brush spring out of the brush box and remove brush (see

Figure 13). Brushes should slide freely in brush box. If brushes are

worn down to .3” (see Figure 14) they should be replaced. To reinstall

each brush carefully back the spring out of the brush box, insert the

brush and return the spring making sure it is pressing on the brush

and not touching the brush box. Then replace the end cap and two

screws.

Operation Tips for More Accurate Cuts

• Allow the wheel to do the cutting. Excessive force will cause the

wheel to glaze reducing cutting efficiency and/or to deflect causing inaccurate cuts.

• Adjust fence angle (Figure 7).

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and vibration.

Cleaning

Blowing dust and grit out of the main housing by means of an air hose

is recommended and may be done as often as dirt is seen collecting in

and around the air vents.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local service center. If you need any assistance

in locating any accessory, please contact GRABBER Construction

Products, 205 Mason Circle, Concord, CA 94520 or call 1-800-477TURN (1-800-477-8876).

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers or

other qualified service organizations, always using identical replacement parts. ALWAYS WEAR SAFETY GLASSES. ALWAYS

SECURE WORK IN VISE. DISCONNECT TOOL FROM POWER

SUPPLY BEFORE CHANGING WHEEL.

Lubrication

Closed-type, grease-sealed ball bearings are used throughout. These

bearings have sufficient lubrication packed in them at the factory to last

the life of the chop saw.

Gears should be relubricated every 60 to 90 days, depending upon

use. This lubrication should only be attempted by experienced power

tool repair persons like the mechanics at GRABBER service centers.

The gear case should be wiped clean and 1/2 oz. (16 grams) of

GRABBER Lubricant Part No. 790206 (6 oz. tube) placed in the gear

case.

Full Warranty

GRABBER heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-477-TURN (1-800-477-8876). This warranty does not apply to

accessories or damage caused where repairs have been made or

attempted by others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states or provinces.

Page 10

8

Français

Importantes mesures de sécurité

AVERTISSEMENT! Lire et comprendre toutes les mesures de

sécurité suivantes afin d'éviter les risques de secousses électriques,

d'incendie ou de blessures graves.

CONSERVER CES MESURES.

• MAINTENIR LES PROTECTEURS EN PLACE et en bon état.

•

RETIRER LES CLÉS DE RÉGLAGE; prendre l’habitude de s’assurer

que les clés de réglage soient retirées de l’outil avant de démarrer ce

dernier.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s'en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l'écart de l'aire de travail.

• S'ASSURER QUE L'ATELIER EST À L'ÉPREUVE DES

ENFANTS. Utiliser des cadenas, un interrupteur principal et retirer

les clés servant au démarrage.

• NE JAMAIS FORCER L'OUTIL. Afin d'obtenir un rendement sûr et

efficace, utiliser l'outil à son rendement nominal.

• UTILISER L'OUTIL APPROPRIÉ. Ne jamais exiger d'un petit outil

ou d'un accessoire le rendement d'un outil de fabrication plus

robuste.

• CORDONS DE RALLONGE. S'assurer que le cordon de rallonge

est en bon état. Lorsqu'on se sert d'un cordon de rallonge, s'assurer qu'il est de calibre approprié pour la tension nécessaire au

fonctionnement de l'outil. L'utilisation d'un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l'outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chiffre indiquant le calibre est inversement proportionnel au calibre du cordon.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL GRABBER, COMPOSEZ SANS FRAIS LE :

1-800-477-TURN (1-800-477-8876).

INTERRUPTEUR Á DÉTENTE

GUIDE

LEVIER DE LA

BRIDE DE

SERRAGE

MANIVELLE

PROTECTEUR

LAME

BRIDE DE

SERRAGE

POIGNÉE

POUR LE

TRANSPORT

TIGE DE

VERROUILLAGE

EN POSITION

ABAISSÉE

LEVIER DE VERROUILLAGE

DE LA LAME

SOCLE

CLÉ

HEXAGONALE

AVERTISSEMENT : PAR MESURE DE SÉCURITÉ PERSONNELLE, LIRE LE GUIDE D'UTILISATION AVANT D'UTILISER LA

SCIE FENDEUSE.

Page 11

9

Français

• UTILISER DES ACCESSOIRES RECOMMANDÉS. Consulter le

guide d'utilisation pour connaître la liste des accessoires recommandés. L'utilisation de tout autre accessoire présente des risques

de blessures.

• NE JAMAIS SE TENIR DEBOUT SUR L'OUTIL. Cela présente

des risques de blessures si l'outil bascule ou si on entre en contact

avec le tranchant par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l'outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l'alignement et les attaches des pièces mobiles, le degré

d'usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l'outil. Faire réparer ou remplacer tout protecteur ou toute autre pièce endommagée.

• SENS DE COUPE. Alimenter la pièce dans la lame seulement

dans le sens opposé à celui de rotation de la lame.

• NE JAMAIS LAISSER L'OUTIL SANS SURVEILLANCE, METTRE L'OUTIL HORS TENSION. Attendre l'immobilisation com-

plète de l'outil avant de s'en éloigner.

• POUR RÉPARER L'OUTIL, n'utiliser que des pièces de rechange

identiques.

• AFIN DE RÉDUIRE LES RISQUES DE SECOUSSES ÉLEC-

TRIQUES, l'outil est muni d'une fiche polarisée (une lame plus

large que l'autre). Ce genre de fiche n'entre que d'une façon dans

une prise polarisée. Lorsqu'on ne peut insérer la fiche à fond dans

la prise, il faut communiquer avec un électricien certifié afin de faire

installer une prise appropriée. Il ne faut pas modifier la fiche.

Mesures de sécurité relatives aux scies

fendeuses

• Toujours porter des lunettes de sécurité ou tout autre dispositif de

protection pour les yeux en utilisant l'outil.

• Avant d'utiliser l'outil, vérifier si la lame comporte des fissures ou

des défectuosités. Le cas échéant, jeter la lame. Il faut également

vérifier la lame lorsqu'on croit que l'outil est tombé.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples, des cravates, des bagues, des bracelets ou

d'autres bijoux qui peuvent être happés par les pièces en mouvement. Il est conseillé de porter des chaussures à semelle antidérapante. Protéger la chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter

également un masque respiratoire si le travail de coupe produit de

la poussière. Les lentilles des verres correcteurs ordinaires résistent seulement aux chocs; il ne s'agit pas de lunettes de sécurité.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l'aide de brides ou

d'un étau. On peut alors se servir des deux mains pour faire fonctionner l'outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et

affûtés pour qu'ils donnent un rendement supérieur et sûr. Suivre

les directives concernant la lubrification et le remplacement des

accessoires.

• DÉBRANCHER LES OUTILS lorsqu'on doit réparer l'outil ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ÉVITER LES DÉMARRAGES ACCIDENTELS. S'assurer que l'in-

terrupteur est à la position hors circuit lorsqu'on branche l'outil.

Page 12

10

Français

congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la

fréquence avec laquelle on effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien ventilé et

utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements de

protection et nettoyer les parties exposées du corps avec de

l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la pous-

sière susceptible de causer des dommages sérieux et permanents au

système respiratoire. Toujours utiliser un appareil respiratoire antipoussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps

.

Alimentation

Veiller à ce que la tension d'alimentation soit conforme aux exigences

de la plaque signalétique de l'outil. La mention «120 volts, 60 Hz»

signifie courant alternatif (courant domestique normal de 120 volts,

60 Hz).

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe.

Capacité de coupe

La grande ouverture de la bride de serrage ainsi que l'articulation

exceptionnelle de la scie permettent de couper de nombreuses pièces

• Lorsqu'on met l'outil en marche (avec une lame neuve ou de

rechange), il faut le tenir dans un endroit à l'écart. Si la lame comporte une fissure ou une défectuosité non décelée, elle éclate en

moins de une minute. Ne jamais mettre l'outil en marche lorsqu'une

personne (y compris l'utilisateur) se trouve devant la scie.

• Éviter de faire faire un rebond à la lame ou de la manipuler rudement. Le cas échéant, mettre l’outil hors circuit et inspecter la lame.

• Nettoyer l’outil régulièrement conformément aux directives

d’entretien du présent guide.

• Ne jamais enlever le protecteur.

• Toujours utiliser la bride de serrage pour fixer la pièce à découper.

• Utiliser seulement des lames Type 1, 355 mm ayant une vitesse

nominale d'au moins 4 100 trs/min.

• Laisser refroidir les pièces découpées avant de les manipuler.

• Ne pas tenter de couper du bois ni de la maçonnerie avec l'outil.

• NE JAMAIS DÉCOUPER DU MAGNÉSIUM AVEC L'OUTIL.

• Utiliser la scie fendeuse seulement dans une pièce bien aérée.

• Mettre la scie fendeuse hors circuit avant de retirer les pièces qui

se trouvent dans le socle de l'outil.

• NE JAMAIS UTILISER UNE LAME DE SCIE CIRCULAIRE

AVEC LA SCIE FENDEUSE. Ne pas utiliser de lame ayant des

dents.

• NE PAS UTILISER L'OUTIL DANS DES ENDROITS OU L'AT-

MOSPHERE CONTIENT DES LIQUIDES, DES VAPEURS OU

DES POUSSIERES INFLAMMABLES. Les étincelles que pro-

duit le moteur en marche ou la coupe pourraient enflammer ces

produits.

CONSERVER CES MESURES

AVERTISSEMENT : Certains outils, tels que les sableuses élec-

triques, les scies, les meules, les perceuses ou certains autres outils

de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

Page 13

11

Français

BLOC-

SUPPORT

BRIDE DE

SERRAGE

DIAMÉTRE DE LA

PIÈCE À OUVRER

GUIDE

BLOC-

SUPPORT

LARGEUR DU

BLOC-SUPPORT

FIG. 3

FIG. 4

BOUT DÉCOUPÉ

de grandes dimensions. Consulter le tableau sur la capacité de coupe

afin de déterminer la dimension maximale totale de coupe de la nouvelle lame.

MISE EN GARDE : IL PEUT ÊTRE NÉCESSAIRE DE FIXER

CERTAINS OBJETS DE DIMENSIONS EXTRAORDINAIRES, CIRCULAIRES OU DE FORMES IRRÉGULIÈRES QUI NE PEUVENT

PAS ETRE RETENUS DANS LA BRIDE.

MISE EN GARDE : NE PAS COUPER DU MAGNÉSIUM AVEC

l'outil.

Capacité de coupe maximale

NOTE : LES CAPACITÉS INDIQUÉES SUR lE TABLEAU NE

TIENNENT PAS COMPTE DE L'USURE DE LA LAME ni de

la position optimale du guide.

CONSERVER CES MESURES.

Équipement standard

1 355 mm (14") lame abrasive à métaux – Utiliser seulement des

lames Type 1 à haute résistance à liant organique ayant une

vitesse nominale d’au moins 4 100 trs/min. (oxyde d'aluminium).

1 clé pour la lame

Transport

Plier l'outil de façon à pouvoir le transporter. Enfoncer la tige de

verrouillage (fig. 1) afin de verrouiller le bras en position abaissée.

Forme de

la pièce à

travailler

Angle

de coupe

Capacités de coupe maximales

TIGE DE

VERROUILLAGE

FIG. 1

TIGE DE

VERROUILLAGE

FIG. 2

Page 14

12

Français

Déverrouillage

Pour déverrouiller l'outil et en soulever la tête, enfoncer légèrement le

bras du moteur et retirer la tige de verrouillage. Le bras du moteur

pivote alors vers le haut (fig. 2).

Fixation et soutien du matériau

• Les angles sont mieux fixés et coupés lorsque les deux extrémités

reposent contre le socle.

• On peut se servir d'un bloc-support légèrement plus étroit que l'espace de travail (fig. 3) afin d'augmenter la capacité d'utilisation de

la lame.

• Les pièces à ouvrer longues doivent être soutenues par un bloc

afin d'être au même niveau que le dessus du socle (fig. 4). La

partie coupée devrait pouvoir tomber librement afin de ne pas

coincer la lame.

Réglage du

pare-étincelles

Afin de diriger les étincelles loin des

personnes et des choses qui se

trouvent près de l'outil, desserrer la

vis, régler le pare-étincelles et

resserrer la vis (fig. 5).

Fonctionnement de

la bride de serrage

La bride de serrage comporte une fonction de déplacement rapide.

Pour dégager la bride lorsqu'elle est bien serrée, faire tourner la

manivelle dans le sens antihoraire de un ou deux tours afin de

dégager la pression de serrage. Soulever le levier de la bride. Retirer

à l'emplacement voulu la manivelle. On peut installer la bride sans se

servir de la manivelle. Abaisser le levier de la bride puis serrer la bride

sur le matériau à l'aide de la manivelle (fig. 6).

FIG. 5

VIS

PARE-

ÉTINCELLES

LEVIER DE

LA BRIDE DE

SERRAGE

MANIVELLE

FIG. 6

BRIDE DE

SERRAGE

GUIDE

BOULONS

DU GUIDE

DÉVERROUILLER LE GUIDE

VERS L´AVANT

INTERRUPTEUR

À DÉTENTE

FIG. 8

LAME

FIG. 7

ÉQUERRE

INDICATEUR

DE RÉGLAGE

DE L´ANGLE

REBORD DE

LA FENTE

Page 15

13

Français

CLOU

FIG. 12

17-3/8PO

(441 MM)

10-1/8 PO

(257 MM)

FIG. 11

20 po

4 po

Fonctionnement du guide

On n'a pas besoin de clé pour régler le guide. Le levier de serrage à

dégagement rapide sert à verrouiller et à déverrouiller le guide.

Lorsqu'on fait tourner le levier complètement vers l'avant, le guide est

déverrouillé. On peut alors le déplacer librement vers l'avant, vers l'arrière ou le faire tourner afin d'obtenir la position de coupe optimale

pour la nouvelle lame et à mesure que la lame s'use.

Lorsqu'on fait tourner le levier complètement vers l'arrière, le guide est

verrouillé dans la position voulue. Lorsque la patte inférieure du levier

n'est pas à l'horizontale (parallèle au socle), le guide n'est pas

verrouillé. Le levier bloque le guide seulement lorsqu'il y a une forte

résistance lorsqu'on tente de le déplacer vers l'arrière. Lorsqu'il y a

peu de résistance, régler la force de serrage en serrant légèrement les

deux boulons retenant le guide au socle. Vérifier en utilisant de nouveau le levier et en tentant de déplacer le guide (fig. 6).

Réglage de l'angle du guide

L'indicateur de réglage de l'angle fait partie du système de serrage du

guide. Aligner la ligne voulue de l'indicateur sur le rebord de la fente

dans le socle (fig. 7). Pour obtenir une coupe carrée des plus précises (fig. 7), débrancher l'outil, déverrouiller le guide, abaisser le bras

jusqu'à ce que la lame soit dans le socle, placer une équerre contre la

lame et régler le guide contre l'équerre, puis verrouiller le guide en

place.

Interrupteur

Enfoncer la détente illustrée à la figure 8 pour mettre le moteur en

marche et la relâcher pour arrêter le moteur. Éloigner les mains et le

matériau de la lame jusqu'à son immobilisation complète.

RETRAIT ET INSTALLATION DE LA LAME

1. S'assurer que l'outil est débranché.

2. Enfoncer le levier de verrouillage de la lame (fig. 9) et faire tourner la lame à la main jusqu'à ce que le levier de verrouillage de la

lame s'enclenche dans la fente de la bride intérieure afin de

verrouiller la lame. Desserrer dans le sens antihoraire le boulon

ARBRE

BRIDE

INTÉRIEURE

RONDELLE

PLATE

LAME

FIG. 10

BOULON

M 10

FILET

INTERNE

FIG. 9

LEVIER DE

VERROUILLAGE

DE LA LAME

2 po

BRIDE

EXTÉRIEURE

Page 16

14

Français

AVERTISSEMENT : VÉRIFIER LA SURFACE SUR LAQUELLE

REPOSE LA SCIE FENDEUSE LORSQU'ON EN REMPLACE LA

LAME ABRASIVE. CETTE DERNIERE POURRAIT ENTRER EN

CONTACT AVEC DES ARTICLES OU DES STRUCTURES QUI

DÉPASSENT DE LA SURFACE DE TRAVAIL (SOUS LE SOCLE)

LORSQU'ON ABAISSE LE BRAS DE LA SCIE.

Montage

DIRECTIVES DE MONTAGE PERMANENT

1. Percer quatre trous d'un diamètre de 7 mm (5/16 po) dans la surface de travail (fig. 11).

2. Insérer des vis nº 20 de 1/4 po dans les trous du socle et de la surface de travail. La longueur approximative de la vis correspond à

l'épaisseur de la surface de travail plus 100 mm (4 po).

MONTAGE SUR CHEVALET

1. Découper deux planches d'une longueur de 508 mm (20 po) sur

une hauteur de 50 mm (2 po), sur une largeur de 100 mm

(4 po).

2. Placer la scie fendeuse à l'emplacement voulu.

3. Placer les deux planches tout contre chaque côté de la scie et les

clouer dans la surface de travail (fig. 12).

Inspection et remplacement des balais

du moteur

S'assurer que l'outil est débranché avant d'en vérifier les balais. Il faut

examiner ces derniers régulièrement afin d'en observer le degré

d'usure. Pour ce faire, dévisser les deux vis du bouchon et retirer ce

dernier (fig. 13). Pour retirer chaque balai, il faut d'abord débrancher

la borne montée en dérivation. Puis, il faut repousser délicatement le

ressort de balai hors de la boîte de balais et retirer le balai (fig. 13).

Les balais devraient glisser librement dans la boîte de balais. Lorsque

l'usure des balais atteint 6 mm (0,3 po) (fig. 14), il faut les remplacer.

Pour remettre les balais en place, il faut repousser délicatement le

ressort hors de la boîte de balais, insérer le balai et replacer le ressort

qui se trouve au centre de la lame abrasive à l'aide de la clé

hexagonale de 8 mm qui se trouve dans la case du socle. Le

boulon est fileté à droite.

3. Retirer le boulon, la rondelle, la bride extérieure et l'ancienne lame

(fig. 10).

4. Installer la nouvelle lame abrasive en se conformant aux étapes

précédentes dans le sens inverse.

5. Éviter de trop serrer le boulon.

N'EFFECTUER AUCUN RÉGLAGE LORSQUE LA LAME TOURNE.

N'EFFECTUER AUCUN RÉGLAGE LORSQUE LA SCIE FENDEUSE EST BRANCHÉE.

.3 PO

(8 MM)

BALAI

FIG. 14

FIG. 13

VIS

RESSORT

BALAI

BOUCHON

Page 17

15

Français

Lubrification

L'outil est entièrement monté sur des roulements à billes scellés et

graissés. Ces derniers sont lubrifiés en permanence à l'usine afin de

servir pour la durée de l'outil.

Il faut lubrifier les engrenages aux 60 à 90 jours, selon le degré

d'utilisation de l'outil. Il faut confier ces travaux aux techniciens

qualifiés des centres de service de produits GRABBER. Il faut

nettoyer le boîtier des engrenages en l'essuyant et y verser 16

grammes (1/2 oz) de lubrifiant GRABBER (pièce n° 790206 - tube de

192 g (6 oz)).

Garantie complète

Les outils industriels de service intensif GRABBER sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

GRABBER qui s’avérait défectueuse en raison d’un vice de matière

ou de fabrication sera réparée sans frais. Pour obtenir de plus amples

renseignements sur les réparations couvertes para la garantie, composer e 1 (800) 477-8876. La présente garantie ne couvre pas les

accessoires ni les avaries dues aux réparations tentées ou effectuées

par des tiers. Les modalités de la présente garantie donnent des droits

légaux spécifiques. L'utilisateur peut également se prévaloir d'autres

droits selon l'état ou la province qu'il habite.

en s'assurant qu'il est appuyé contre le balai et qu'il ne touche pas à

la boîte de balais. Il faut ensuite remettre en place le bouchon et les

deux vis.

Conseils afin d'optimiser la précision de

la coupe

• Laisser la lame découper. Lorsqu'on exerce une pression excessive sur l'outil, on risque de bloquer la lame et d'en minimiser

l'efficacité ou de la dévier et de procurer une coupe imprécise.

• Régler l'angle du guide (fig. 7).

• S'assurer que le matériau repose à plat contre le socle.

• Bien fixer le matériau afin d'en empêcher le mouvement et les

vibrations.

Nettoyage

Il faut nettoyer le boîtier principal de l'outil en y soufflant de l'air

comprimé pour en chasser la poussière et les charpies dès qu'il y a

accumulation de poussière dans les évents et autour de ceux-ci.

Accessoires

Les accessoires recommandés pour chaque outil sont vendus chez

les dépositaires locaux ou les centres de service autorisés. Pour

obtenir plus d’information sur les accessoires, communiquer avec

GRABBER Construction Products, 205 Mason Circle, Concord, CA

94520 ou composer le 1-800-477-TURN (1-800-477-8876).

MISE EN GARDE : L'utilisation de tout autre accessoire non

recommandé pour l'outil peut être dangereuse.

Réparations

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service GRABBER ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Page 18

16

Español

¡ADVERTENCIA! Lea y asegúrese de entender todas las

instrucciones. El no hacerlo puede originar riesgos de choque eléc-

trico, incendio y/o lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

Instrucciones importantes de seguridad

• CONSERVE LAS GUARDAS EN SU SITIO y listas para trabajar.

• RETIRE LAS LLAVES DE AJUSTE O PRESIÓN. Desarrolle el

hábito de verificar que las llaves, incluyendo las llaves de

ajuste, hayan sido retiradas del eje antes de poner en marcha la

herramienta.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Las áreas y bancos

con objetos acumulados en desorden propician los accidentes.

• NO SE EMPLEE EN AMBIENTES PELIGROSOS. No utilice

herramientas eléctricas en ligares inundados o mojados, ni las

exponga a la lluvia. Conserve bien iluminada el área de trabajo.

• CONSERVE APARTADOS A LOS NIÑOS. Todos los visitantes

deben permanencer a distancia segura de la zona de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados, inter-

ruptores maestros y retirando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá mejor con su tra-

bajo y de manera más segura bajo las especificaciones para las

que se diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce una her-

ramienta o sus dispositivos en una tarea para los que no han sido

diseñados.

• UTILICE UN CABLE DE EXTENSION ADECUADO. Asegúrese

que su extensión esté en buenas condiciones. Cuando utilice una

extensión, asegúrese de emplear una que soporte la corriente que

su herramienta necesita. Una extensión con calibre insuficiente

provocará una caída en el voltaje de la línea, ocasionando pérdida

de potencia y sobrecalentamiento. El cuadro siguiente muestra el

calibre correcto a utilizarse de acuerdo con la longitud y el amper-

GATILLO INTERRUPTOR

GUIA

PALANCA DE

LA PRENSA

MANIVELA

GUARDA

DEL DISCO

PRENSA

ASA DE

ACARREO

PERNO DE

SEGURIDAD

PALANCA DEL

SEGURO

DEL DISCO

BASE

LLAVE

ALLEN

DISCO

Epecificaciones

Tensión de alimentación: 120 V

Potencia nominal: 1650 W

Frecuencia de operación: 50/60 Hz

Consumo de corriente: 15 A

¡ADVERTENCIA! PARA SU PROPIA SEGURIDAD

LEA ESTE MANUAL DE INSTRUCCIONES ANTES DE

UTILIZAR LA CORTADORA DE METALES.

Page 19

17

Español

aje indicado en la placa de identificación. Si tiene dudas, utilice el

calibrte siguiente. Mientras más pequeño sea el número del calibre, mayor será su capacidad.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No recomendado

• VISTA LAS PRENDAS ADECUADAS. No utilice prendas de vestir

flojas, guantes, corbatas, anillos, brazaletes ni otras piezas de

joyería que pudiesen quedar atrapadas en las partes móviles. Se

recomienda el empleo de calzado antiderrapante. Cúbrase el

cabello si lo tiene largo.

• SIEMPRE UTILICE GAFAS DE SEGURIDAD. También utilice una

máscara contra polvo si la operación a efectuar lo produce. Los

anteojos de uso diario solamente tienen lentes resistentes al

impacto, NO SON anteojos de seguridad.

• SUJETE BIEN LA PIEZA DE TRABAJO. Sujete la pieza de

trabajo con abrazaderas o en las mordazas de un torno de banco

cuando sea práctico hacerlo. Es más seguro que sujetarla con la

mano y le permite usar ambas manos para manejar la

herramienta.

• NO SE SOBREEXTIENDA. Conserve siempre bien apoyados los

pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

afiladas y limpias para que funcionen mejor y de manera más

segura. Siga las instrucciones de cambio de accesorios.

• DESCONECTE LA HERRAMIENTAS antes de efectuarles

servicio y cuando les cambie acesorios, como cuchillas, brocas y

similares.

• REDUZCA EL RIESGO DE ENCENDIDO ACCIDENTAL.

Asegúrese que el interruptor esté en posición de apagado antes de

conectar la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Busque en el

manual de instrucciones los accesorios recomendados. El uso de

accesorios inadecuados puede causar riesgos de lesiones.

• NUNCA SE PARE EN LA HERRAMIENTA. Puede provocarse

lesiones graves si la herramienta se vuelca o si hace contacto

accidental con la herramienta de corte.

• REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando la

herramienta, debe revisar cuidadosamente una guarda o cualquier

otra pieza que esté dañada para determinar si cumplirá

adecuadamente con su función; revise la alineación de las piezas

móviles, sus montajes, ruptura de partes y cualesquiera otras

condiciones que pudiesen afectar su operación. Repare o

reemplace las piezas dañadas.

•

DIRECCIÓN DE ALIMENTACIÓN. Introduzca la pieza que desea

cortar únicamente contra la dirección de rotación el disco de corte o

de la sierra.

• NUNCA DEJE LA HERRAMIENTA EN FUNCIONAMIENTO Y

DESATENDIDA. APAGUELA. No deje la herramienta hasta que

se haya detenido por completo.

•

REPUESTOS. Utilice solamente piezas de repuesto idénticas..

•

PARA REDUCIR EL RIESGO DE CHOQUES ELÉCTRICOS,

este

equipo tiene un enchufe polarizado (donde una clavija es más

ancha que la otra). Este enchufe entra en un tomacorrientes polarizado solamente en una posición. Si el enchufe no entra en el

receptáculo, contacte un electricista calificado para que le instale el

tomacorrientes adecuado. NO CAMBIE EL ENCHUFE DE NINGUNA

MANERA.

CONSERVE ESTAS INSTRUCCIONES

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler

o perforar con máquina, así como al realizar otras actividades de la

construcción, contiene substancias químicas que se sabe producen

Page 20

18

Español

cáncer, defectos congénitos u otras afecciones reproductivas.

Algunos ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia

en que se haga este tipo de trabajo. Para reducir la exposición a esas

substancias químicas: trabaje en un área bien ventilada, y trabaje con

equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar,

aserrar, esmerilar, taladrar y otras actividades constructivas.

Vista ropas protectoras y lave las áreas expuestas con agua y

jabón. Permitir que el polvo se introduzca en su boca, ojos, o

dejarlo sobre la piel promueve la absorción de químicos dañinos.

ADVERTENCIA: Toda persona que entre al área de trabajo

deberá usar una máscara antipolvo o protección respiratoria. El filtro

debería ser reemplazado a diario o cuando el usuario tenga dificultad

para respirar. Puede encontrar la máscara antipolvo apropiada

aprobada por NIOSH/OSHA en su ferretería local.

Instrucciones de seguridad para

cortadoras de metales

• Siempre utilice anteojos de seguridad cuando emplee esta

herramienta.

• Antes de usar la unidad, revise los discos de corte en busca de

cuarteaduras. Si hay cuarteaduras, deseche el disco. También

debe revisarse el disco si usted piensa que se ha golpeado.

• Cuando encienda la herramienta (con un disco nuevo, o después

de haberlo cambiado), colóquela en un área protegida. Si el disco

se cuartea, puede estallar en menos de un minuto. Nunca encienda la unidad si hay personas en línea con la herramienta, incluyendo al operador.

• Durante la operación, evite que el disco rebote. Si esto ocurre,

detenga la unidad y revise el disco.

• Limpie su sierra para metales periódicamente siguiendo los procedimientos mencionados en la sección relativa al mantenimiento.

• No quite la guarda del disco.

• Utilice la prensa para asegurar la pieza de trabajo.

• Unicamente utilice discos de 355 mm, Tipo 1 fabricados para 4100

o más rpm.

• Permita que las piezas cortadas se enfríen antes de manipularlas.

• No intente cortar madera o mampostería con esta herramienta.

• NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

• Utilice la cortadora de metales en un área bien ventilada.

• Apague la sierra antes de quitar cualquier pieza de la base.

• NO CORTE MATERIAL ELECTRICAMENTE VIVO.

• NUNCA UTILICE DISCOS PARA SIERRA CIRCULAR EN ESTA

SIERRA. NO EMPLEE DISCOS DENTADOS.

• NO EMPLEE ESTA HERRAMIENTA CERCA DE LIQUIDOS,

GASES, O POLVOS INFLAMABLES. Las chispas originadas en

el corte o en el motor pueden originar la ignición de estos polvos y

vapores.

Alimentación

Asegúrese que su toma de corriente concuerda con la marca de la

placa de identificación. 120 volts, 60 Hz significa corriente alterna

(corriente doméstica normal a 120 volts y 60 Hz).

Una disminución de más del 10% en la intensidad causará pérdida de

potencia y sobrecalentamiento.

Capacidad de corte

La gran capacidad de abertura de la prensa y el alto punto de pivoteo

proporcionan capacidad para cortar piezas muy grandes. Use la tabla

que sigue para determinar el tamaño máximo de los cortes que podrá

hacer con un disco nuevo.

Page 21

19

Español

PRECAUCION: ALGUNOS OBJETOS GRANDES, O DE

FORMA IRREGULAR PUEDEN REQUERIR ALGUN MEDIO DE

SUJECION ADICIONAL AL NO PODERSE SUJETAR CON LA

PRENSA.

PRECAUCION: NO CORTE MAGNESIO CON ESTA

HERRAMIENTA.

Capacidad máxima de corte

NOTA: LA CAPACIDAD MOSTRADA EN LA TABLA ASUME QUE

NO HAY DESGASTE EN EL DISCO.

Equipo estándar

1 Disco abrasivo dec 355 mm para corte de metales. Utilice única-

mente discos con ligaduras orgánicas de alta resistencia fabricados para 4100 o más rpm. (Oxido de aluminio)

1 Llave para el disco

Para transportar la unidad

Pliegue la unidad de manera que pueda transportarla. Empuje el

perno de seguridad (figura 1) para asegurar el brazo en la posición

baja.

Para desasegurar

Para desasegurar y elevar la cabeza, oprima el brazo del motor ligeramente y tire del perno de seguridad hacia afuera. El brazo del

motor subirá (observe la figura 2).

PERNO DE

SEGURIDAD

FIG. 1

PERNO DE

SEGURIDAD

FIG. 2

BLOQUE

PRENSA

DIAMETRO DE LA

PIEZA DE DE TRABJO

BLOQUE

ESPACIADOR

ANCHO DEL BLOQUE

ESPACIADOR

FIG. 3

FIG. 4

EEMO QUE SE

DESPRENDE

GUIA

Page 22

20

Español

PALANCA DE

LA PRENSA

MANVELA

PRENSA

GUIA

TORNILLOS

DE LA GUIA

PALANCA DE PRENSADO

ADELANTE

DISCO

FIG. 7

ESCUADRA

INDICADOR DE

AJUSTE DE

ANGULOS

BORDE DE

RANURA

Sujeción y soporte de material

• Los ángulos se sujetan y cortan mejor con ambas patas apoyadas

contra la base.

• Puede emplearse un bloque espaciador ligeramente más angosto que el espacio de trabajo (figura 3) para aumentar la utilización

del disco.

• Las piezas grandes deben apoyarse por un bloque de manera

que queden a nivel con la superficie de la base (figura 4). El

extremo que se desprende debe quedar libre para caer para evitar que el disco se atore.

Ajuste del deflector de chispas

Para alejar las chispas de las personas y materiales a su alrededor de

la mejor manera posible, afloje el tornillo, ajuste el deflector y apriete

el tornillo (observe la figura 5).

Operación de la prensa

La prensa cuenta con un sistema de movimiento rápido. Para liberar

la prensa cuando esté apretada, gire la manivela en sentido contrario

a las manecillas del reloj una o dos veces para relajar la presión. Suba

la palanca de la prensa. Tire del montaje de la manivela hacia fuera

cuanto desee. La prensa puede utilizarse sin usar la manivela. Sin

embargo, termine de apretarla siempre utilizando la manivela

(observe la figura 6).

Ajuste del ángulo de la guía

El indicador del ángulo de ajuste es parte del sistema de prensado a

la guía. Haga coincidir la línea deseada en el indicador de ángulos

con el borde de la ranura en la base (figura 7). Para un corte a

escuadra más preciso (figura 7), desconecte la alimentación de corriente, desasegure la guía, empuje el brazo hacia abajo hasta que el

disco traspase la base, coloque una escuadra contra el disco, ajuste

la guía contra la escuadra y asegure la guía en su posición.

FIG. 5

SCREW

DEFLECTOR

DE CHIDPAS

FIG. 6

Page 23

21

Español

Interruptor

Para encender la herramienta, oprima el gatillo interruptor ilustrado en

la figura 8. Para apagarla, libere el gatillo. Conserve las manos y el

material alejados del disco hasta que este se haya detenido completamente.

Remoción e instalación de discos

1. Asegúrese que la herramienta está desconectada de la toma de

corriente.

2. Asegure el disco con la palanca del seguro del disco (fig. 9) y gire

el disco a mano hasta que la palanca del seguro se trabe en la

ranura correspondiente para asegurar el disco. Afloje el tornillo

que se encuentra al centro de la rueda abrasiva en sentido contrario a las manecillas del reloj con la llave hexagonal de 8 mm

que se está en el porta llaves de la base. El tornillo es de cuerda

derecha.

3. Quite el tornillo, la roldana, la arandela exterior y el disco abrasivo

usado (fig. 10).

4. Instale el nuevo disco abrasivo invirtiendo los pasos anteriores.

5. No apriete demasiado el tornillo.

NO REALICE NINGÚN AUSTE MIENTRAS QUE EL DISCO SE

ENCUENTRE EN MOVIMIENTO.

NO REALICE NINGÚN AUSTE MIENTRAS QUE LA CORTADORA

DE METALES SE ENCUENTRE CONECTADA A UNA TOMA DE

CORRIENTE.

INTERRUPTOR

DE GATILLO

FIG. 8

FLECHA

ARANDELA

INTERIOR

ROLDANA

PLANA

ARANDELA

EXTERIOR

DISCO

FIG. 10

M10

TORNILLO

ROSCA

INTERIOR

FIG. 9

PALANCA DE

SEGURO DEL DISCO

CLAVO

FIG. 12

17-3/8"

(441 MM)

10-1/8"

(257 MM)

FIG. 11

Page 24

22

Español

ADVERTENCIA: VERIFIQUE LA SUPERFICIE DE TRABAJO

SOBRE LA QUE DESCANSA LA CORTADORA CUANDO REEMPLACE UN DISCO ABRASIVO, ES POSIBLE QUE EL DISCO

HAGA CONTACTO CON LA SUPERFICIE DE TRABAJO (A

TRAVES DE LA BASE) CUANDO EL BRAZO SE HA BAJADO

COMPLETAMENTE.

Montaje

Procedimiento para montaje permanente

1. Perfore cuatro barrenos de 7,9 mm (5/16") en la superficie de

trabajo (fig. 11).

2. Inserte tornillos de 6 mm (1/4-20) a través de la parte inferior de

la superficie de trabajo, hasta las patas, en la base de la

herramienta. La longitud del tornillo debe ser igual al espesor de

la superficie de trabajo más 100 mm (4").

MONTAJE DE CUNA

1. Corte dos tablas de 50 cm (20") de longitud por 5 cm (2") de alto

por 10 cm (4") de ancho.

2. Coloque la sierra en el lugar deseado.

3. Coloque los tableros apretados contra los lados, y clávelos a la

superficie de trabajo (fig. 12).

Carbones del motor

Asegúrese que la herramienta esté desconectada antes de revisar los

carbones. Los carbones deben revisarse frecuentemente en busca de

desgaste. Para revisarlos, afloje los tornillo y quite la tapa del extremo

(observe la figura 13). Para quitar cada carbón, desconecte primero

la conexión terminal del cable de derivación. A continuación, saque

cuidadosamente el resorte y el carbón de la caja del carbón (observe

la figura 13). Los carbones deben deslizarse libremente en la caja. Si

los carbones se desgastan hasta una longitud de 0,76 cm (0,3”) (figura 14) deberán reemplazarse. Para reinstalar los carbones, saque

cuidadosamente el resorte de la caja, inserte el carbón y coloque de

.3"

(8 MM)

CARBONE

FIG. 13

FIG. 14

TORNILLOS

TAPA

CARBONE

RESORTE

nuevo el resorte, asegurándose que éste esté oprimiendo al carbón y

no haga contacto con la caja. A continuación, coloque de nuevo la

tapa del extremo y los dos tornillos.

Recomendaciones para obtener cortes

más precisos

• Permita que el disco haga el corte. Excesiva fuerza ocasionará

que el disco se cristalice, reduciendo la eficiencia del corte y (o)

se desvíe haciendo cortes no rectos.

Page 25

23

Español

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero No.831 - Col. Centro (81) 8375 2313

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. Madero 139 Pte. - Col. Centro (442) 214 1660

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: _____________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:_____________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como en

materiales y mano de obra empleados para su fabricación. Nuestra

• Ajuste el ángulo de la guía (figura 7).

• Asegúrese que el material quede plano sobre la base.

• Sujete el material apropiadamente para evitar movimientos y

vibraciones.

Limpieza

Debe sopletearse la carcaza con una manguera con aire comprimido,

tan a menudo como vea que se acumula mugre alrededor de las

tomas de aire.

Lubricación

Se han empleado baleros de bolas sellados de tipo cerrado. Estos

baleros cuentan con la lubricación suficiente para soportar durante

toda la vida de la cortadora de metales.

Los engranes deben relubricarse cada 60 a 90 días, dependiendo del

uso. Esta lubricación deberá ser efectuada por personal capacitado,

como los mecánicos de los centros de servicio autorizados

GRABBER. La caja de engranes debe limpiarse y deben añadirse

16 gramos (1/2 oz.) de lubricante GRABBER (parte No. 790206).

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán hacerse reparaciones, mantenimiento y ajustes de esta herramienta en

los centros autorizados de servicio GRABBER u otras organizaciones

autorizadas. Estas organizaciones prestan servicio a las herramientas

GRABBER y emplean siempre refacciones legitimas GRABBER.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELÉCTRICAS, FAVOR DE DIRIGIRSE AL CENTRO

DE SERVICIO MAS CERCANO

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur - Col. Industrial Bravo (667) 7 12 42 11

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

Page 26

24

Español

garantía incluye la reparación o reposición del producto y/o componentes sin cargo alguno para el cliente, incluyendo mano de obra, así

como los gastos de transportación razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta

y esta póliza sellada por el establecimiento comercial donde se

adquirió el producto, de no contar con ésta, bastará la factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas

a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales GRABBER están garantizadas durante

un año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos. Por favor

regrese la unidad completa, con el transporte pagado, a cualquier

Centro de Servicio para Herramientas Industriales de D

EWALT o a las

estaciones de servicio autorizado enlistadas bajo “Herramientas

Eléctricas” en la Sección Amarilla. Esta garantía no se aplica a los

accesorios ni a daños causados por reparaciones efectuadas por

terceras personas. Esta garantía le otorga derechos legales

específicos, y usted puede tener otros derechos que pueden variar de

estado a estado.

IMPORTADOR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

BOSQUES DE LAS LOMAS C.P., 05120 MEXICO, D.F.

TEL 3-26-71-00

Page 27

Page 28

GRABBER Construction Products, 205 Mason Circle, Concord, CA 94520

Copyright © 2005

Form# 634668-00

Loading...

Loading...