GP Systems BioSmart PV-WTC-EM, BioSmart PV-WTC-MF, BioSmart PV-WTC-HD, BioSmart PV-WTC-LG Installation Manual

1

BioSmart PV-WTC

Terminal

Installation guide

2

3

TABLE OF CONTENTS

GENERAL PRODUCT INFORMATION ..................................................................4

1. SPECIFICATIONS .................................................................................................5

1.1 BioSmart PV-WTC models .........................................................................5

1.2 Basic specifications ...................................................................................5

1.3 Factory settings .........................................................................................6

1.4 Package contents .......................................................................................6

2. USE, TRANSPORTATION AND STORAGE CONDITIONS .......................................6

3. SAFETY REQUIREMENTS ....................................................................................6

4. DISPOSAL ............................................................................................................7

5. MANUFACTURER’S GUARANTEE ........................................................................7

6. INSPECTION CERTIFICATE ..................................................................................7

7. TERMINAL DESCRIPTION ....................................................................................8

7.1 Description of terminal’s front panel ..........................................................8

7.2 Description of connection ports ................................................................10

7.3 Description of indicators and circuit board jumpers..................................11

8. INSTALLATION .....................................................................................................11

8.1 Installation notes ........................................................................................11

8.2 Installation procedure ................................................................................12

8.3 Connecting the terminal’s power supply ....................................................14

8.4 Connecting the terminal to an Ethernet network .......................................15

8.5 Connecting an electromechanical lock to the terminal’s circuit board......17

8.6 Connecting an electromagnetic lock through the BioSmart BCR ..............18

8.7 Connecting an entry sensor and control buttons ......................................19

8.8 Connecting to an external controller through Wiegand .............................20

9. CONFIGURING NETWORK PARAMETERS ............................................................21

10. ENSURING OF THE OPERATION ..........................................................................22

4

Dear customers!

Thank you for purchasing our product. With proper installation and use, this device will

bring you many years of reliable service.

GENERAL PRODUCT INFORMATION

The BioSmart PV-WTC work and attendance terminal is designed for use as part of the

BioSmart biometric access monitoring and control system. The terminal provides a means

to track working hours and attendance by identifying users through the unique biometric

characteristics of subcutaneous palm veins and RFID proximity cards. It can also be used

for access monitoring and control.

Compatible with BioSmart-Studio software version V5.0.3.269 and above.

Four models of this terminal are available:

- With Em-Marin (EM) card format scanner;

- With Mifare (MF) card format scanner;

- With HID iClass and HID Prox (HD) card format scanner;

- With Legic (LG) card format scanner.

5

1. SPECIFICATIONS

1.1 BioSmart PV-WTC models

Designation Device serial number

BioSmart PV-WTC-EM

BioSmart PV-WTC-MF

BioSmart PV-WTC-HD

BioSmart PV-WTC-LG

1.2 Basic specifications

Palm vein scanner type Optical, infrared

Maximum number of users* 1,000,000

Maximum number of card codes 1,000,000

Maximum number of palms

300,000

Maximum number of events

10,000,000

1:1000 vein matching identification time, sec

not longer than 2

False acceptance rate, % **

0.00008

Integrated RFID card scanner

Yes

Card scanning range, mm

up to 100

Display

TFT 3.5” 320х240

Keyboard

keypad, 12 buttons

BioSmart relay module support

Yes

Connection interface with computer

Ethernet

USB interface for configuration

USB 2.0

Web interface for configuration

Yes

Wiegand 26-40 bit output interface

Yes

On-board relay

12 VDC, 1 А

Number of discrete inputs, pcs

1

Power supply specifications

12 VDC±15%, 1 A

Outer dimensions (L x W x H), mm

215х150х117

Net weight, g

820

Gross weight, g

1270

Operating temperature range, °С

from 0 to plus 50

Operating relative air humidity, %

not higher than 90

Design

Detachable plastic body

6

1.3 Factory settings

Terminal’s IP address 175.25.110.71

Terminal’s network address Serial number

Administrator password

No password

1.4 Package contents

Item Number, pcs.

BioSmart PV-WTC Terminal 1

Product certificate 1

Installation instructions 1

Mounting kit (two 6х35 dowels, two

3.5х38 self-tapping screws)

1

2. USE, TRANSPORTATION AND STORAGE

CONDITIONS

Abrasive or chemically active materials should not be used to clean the outer surfaces of the device

or the palm vein scanner.

The terminal may be stored in the following environmental conditions:

- ambient air temperature from minus 40 to plus 50 °С;

- relative air humidity (without condensation) up to 98%.

Water, dust and other foreign substances should be prevented from entering the inside of the

terminal during transportation and storage. Following storage of the terminal in low temperature or

high humidity conditions, it must be kept in a dry environment at a temperature of (20±5) °С for no

less than 30 minutes before being turned on.

3. SAFETY REQUIREMENTS

To avoid malfunctions in the terminal, it must be disconnected from its power source before any

work is carried out with its case open.

Only specialists authorized by the manufacturers of this terminal should carry out the repair and

replacement of terminal parts.

7

4. DISPOSAL

The BioSmart PV-WTC terminal does not contain materials hazardous to the health of users or the

environment. No special ecological safety measures are required when disposing of this unit at the

end of its operational lifespan.

5. MANUFACTURER’S GUARANTEE

The manufacturer guarantees successful performance and correspondence to the stated product

characteristics on the condition that the consumer complies with the rules of its use, installation,

connection, transportation and storage.

The manufacturer provides a warranty on the BioSmart PV-WTC terminal for the period of 60

months from the day of sale indicated in its certificate.

If notes on the date of the product’s sale are absent from the certificate, the warranty period is

calculated from its manufacturing date.

The Manufacturer’s Warranty does not extend to BioSmart PV-WTC terminals that have broken

down due to the Customer failing to comply with its rules of operation.

6. INSPECTION CERTIFICATE

BioSmart PV-WTC- terminal, assembly no.

has been classified as fit for use.

Issue date

P r o d u c t i o n M a n a g e r

(signature)

(print full name)

Manufacturer:

GP Systems GmbH

Ochshäuser Str. 45

34123 Kassel Germany

e-mail: info@gp-systems.com

Tel. +49 151 100 41 701

8

7. TERMINAL DESCRIPTION

7.1 Description of terminal’s front panel

An exterior view of the terminal is shown on figure 1.

Figure 1. Exterior view of BioSmart PV-WTC terminal

1. Smart card reader

2. LCD screen

3. Keypad

4. Palm vein scanner

9

The terminal’s status panel is displayed at the top of the screen with the following symbols:

The instrument’s factory serial number is displayed in the top right corner of the status panel.

The screen displays the current date, time and day of the week.

The screen also features two buttons: “Menu” and “Info”. The “Info” menu displays all the information you need about the device’s state. The “Menu” button opens the device’s options.

The keypad buttons (fig. 2) are used to navigate through the on-screen menu:

2 – moves up the list;

6 – moves to the right or switches from list to

function buttons. Used for page navigation in

the “Users” menu;

4 – moves to the left or switches from func-

tion buttons to list. Used for page navigation in

the “Users” menu;

8 – moves down the list.

– used for selection and confirmation

С – used to return to the previous menu sec-

tion or delete the last digit entered.

Figure 2. Keypad

Operating mode indication

blue flashing symbol – terminal is ready to identify users

yellow flashing symbol – terminal is undergoing administration, identification is temporarily disabled

Output relay status Status of connection to BioSmart-Studio server

closed connection established

open no connection

Other indicators

connection with identification server established

free access mode enabled

terminal locked

there is an error in the terminal’s operation (error status indicated in the terminal’s “Info” menu)

The keypad is also used to enter all numeric settings.

10

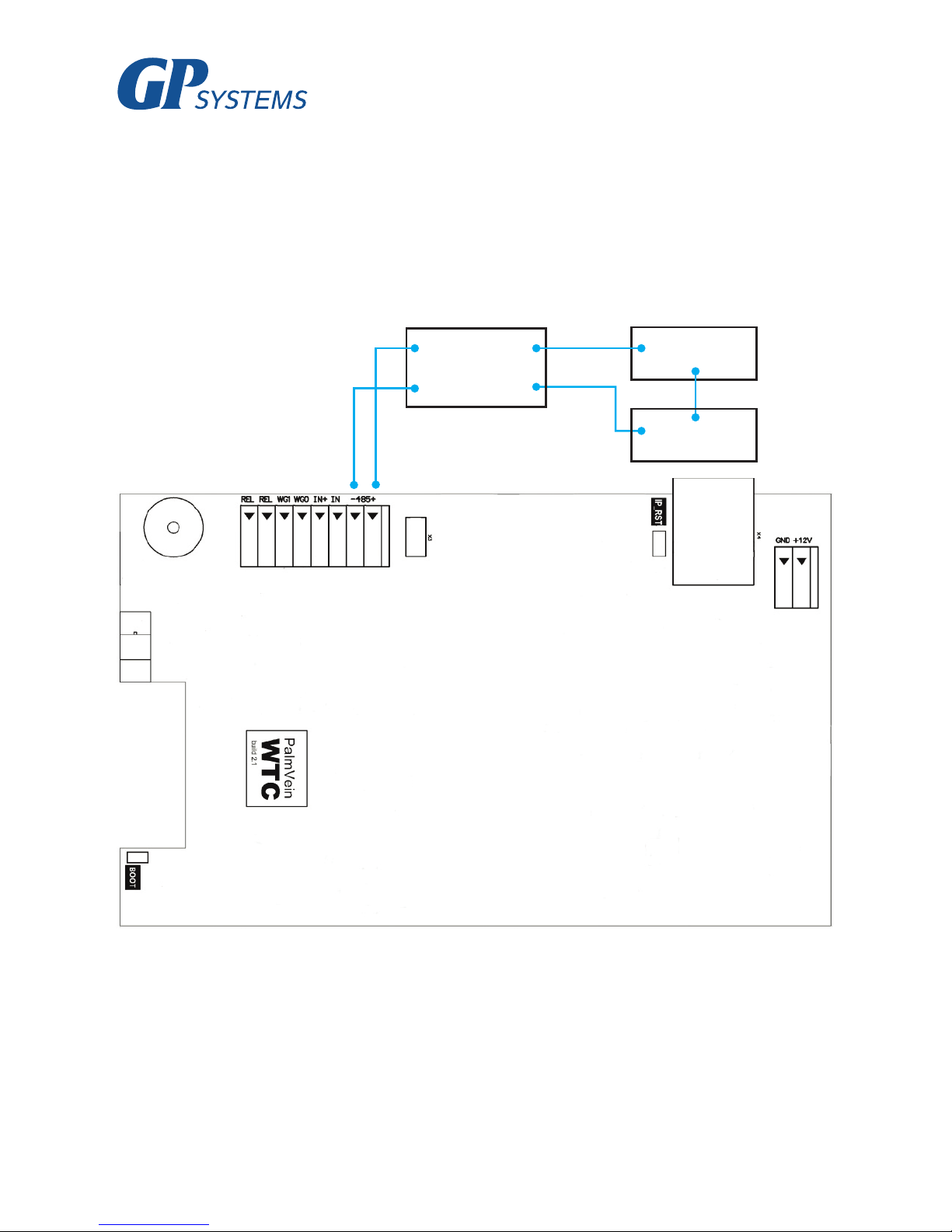

7.2 Description of connection ports

A view of the terminal’s circuit board is shown in fig. 3. The circuit board’s contacts are described

in table 1.

Figure 3. Exterior view of terminal’s circuit board

1 2 3 4 5 6 7 8 9

11 12

10

Table 1. Circuit board connectors

No.

Label Description Connection purpose

1

REL 1st relay normally-open contact output (DC 1A, 12V) Actuator control input

2

REL 2nd relay normally-open contact output (DC 1A, 12V) Actuator power supply output

3

WG1 Wiegand interface DATA1 output

Wiegand external controller interface

DATA 1 intput

4

WG0 Wiegand interface DATA0 output

Wiegand external controller interface

DATA0 intput

5

IN+ +12V output for discrete input Relay control button

6

IN Discrete input Door sensor output, relay control button

7

485- - interface of RS485 connection with BCR -485 BCR contact

8

485+ + interface of RS485 connection with BCR +485 BCR contact

9

X3

Mini USB connector for terminal configuration using

the BioSmart Manager program.

Computer USB port

10

X4 RJ45(8P8C) port for Ethernet network connector Ethernet network interface

11

GND Power, ground Ground of 12V power supply

12

+12 V Power, +12V +12V power supply

11

7.3 Description of indicators and circuit board jumpers

The LEDs located on the Ethernet port indicate the physical connection’s state (Link, green) and

transfer activity (Activity, red).

The IPRST jumper is used to reset the network configuration to factory settings. To do this, you

must close the jumper contacts and wait for the Link and Activity LEDs to go out. Afterwards, the

jumper must be opened again.

The BOOT jumper is used to put the terminal into bootloader mode. This mode allows you to

restore the terminal to normal function if its firmware becomes corrupted. To enable bootloader

mode, you must close the BOOT jumper with the power off and then power on the terminal. After

the terminal is powered on, the contacts must be opened. The terminal’s display should show the

message “BOOT”. The process of loading the terminal’s firmware is described in more detail in the

terminal’s Operating Manual.

8. INSTALLATION

8.1 Installation notes

When deciding where to install the terminal, the following should be taken into account:

- The recommended height for the terminal is 120-150 cm from the floor, for reasons of convenience in positioning the palm on the scanner, presenting a card and viewing events on the LCD screen.

Access to the terminal should be free and unobstructed to allow for convenient positioning of the

palm.

- If installing multiple terminals, they must be placed no closer than 80 cm away from each other in

order to minimize mutual interference from their in-built RFID card readers.

- Installing a terminal within 1 m of any external RFID readers or other sources of electromagnetic

interference is not recommended. Nearby sources of electromagnetic interference may negatively

affect the operation of the built-in RFID card reader.

- It is recommended to leave some length in the cables attached to the terminal, enough to remove

the terminal from the wall and access its jumpers.

- If the device is installed on a metal surface, the range of its RFID card reader may be reduced.

When installing cables, please observe the following recommendations:

- Cables must be installed in accordance with the operational code for electrical installations;

- Do not lay cables within 30 cm of sources of electromagnetic interference;

- All cables must only intersect power cables at a right angle;

- Any cable extensions must be soldered.

12

Before installation:

- Carefully check for mechanical damage on the surface of the terminal’s palm scanner, circuit

board and housing;

- In order to avoid short circuits, the protected ends of cables used to connect the terminal must

not exceed 5 mm.

Cab. no.

Cable connection Max. length Type

1 Ethernet (IEEE 802.3) – terminal 100 m

Four twisted pair cables of no lower than

category five with a wire size of no less

than 0.2 mm

2

2 Power source – terminal power 2 m

Duplex cable with a wire size of no

less than 0.75 mm2 (for example, 3192Y)

3 Terminal – lock, BCR - lock 2 m

Duplex cable with a wire size of no

less than 0.75 mm2 (for example, 3192Y)

4

Terminal – BioSmart BCR

2 m

Four twisted pair cables of no lower than

category five with a wire size of no less

than 0.2 mm

2

5 IN, IN+ terminal contacts – external devices 2 m CQR-6 or RAMCRO-6 cable

6

WO0, WO1 terminal contacts – external

devices

2 m

Four twisted pair cables of no lower than

category five with a wire size of no less

than 0.2 mm

2

Table 2. Types of cables used:

8.2 Installation procedure

The terminal must be installed using the following procedure:

1. Open the box and verify that all the terminal’s parts are present.

2. Decide where you will install the terminal.

3. Unscrew the screws located in the lower part of the terminal housing which secure the housing

to the rear panel. Remove the rear panel.

4. Place the rear panel of the terminal on the wall and mark out the fixture points for the terminal

(fig. 4).

5. Lay and feed through all the required cables. The cables used must correspond to table 2, or

have similar technical characteristics. Ensure that there are no tears, breaks or mechanical defects in

the cables. Ensure that the power is off before connecting any cables.

6. Feed the cables through the hole for cable insertion in the terminal’s rear panel.

13

7. Fix the terminal’s rear panel onto the installation surface using the fixings included in the pack-

aging.

8. Connect the terminal’s power according to p. 4.3

9. Connect the terminal’s network cable according to p. 4.4

10. If necessary, connect the lock and external sensors according to p. 4.5 – 4.8 if using the termi-

nal for access monitoring and control or with external equipment through the Wiegand interface.

11. After connecting all the necessary cables, attach the terminal to the rear panel and screw in the

fastening screws located on the base.

Figure 4. Marking attachment points

Hole for cable

insertion

14

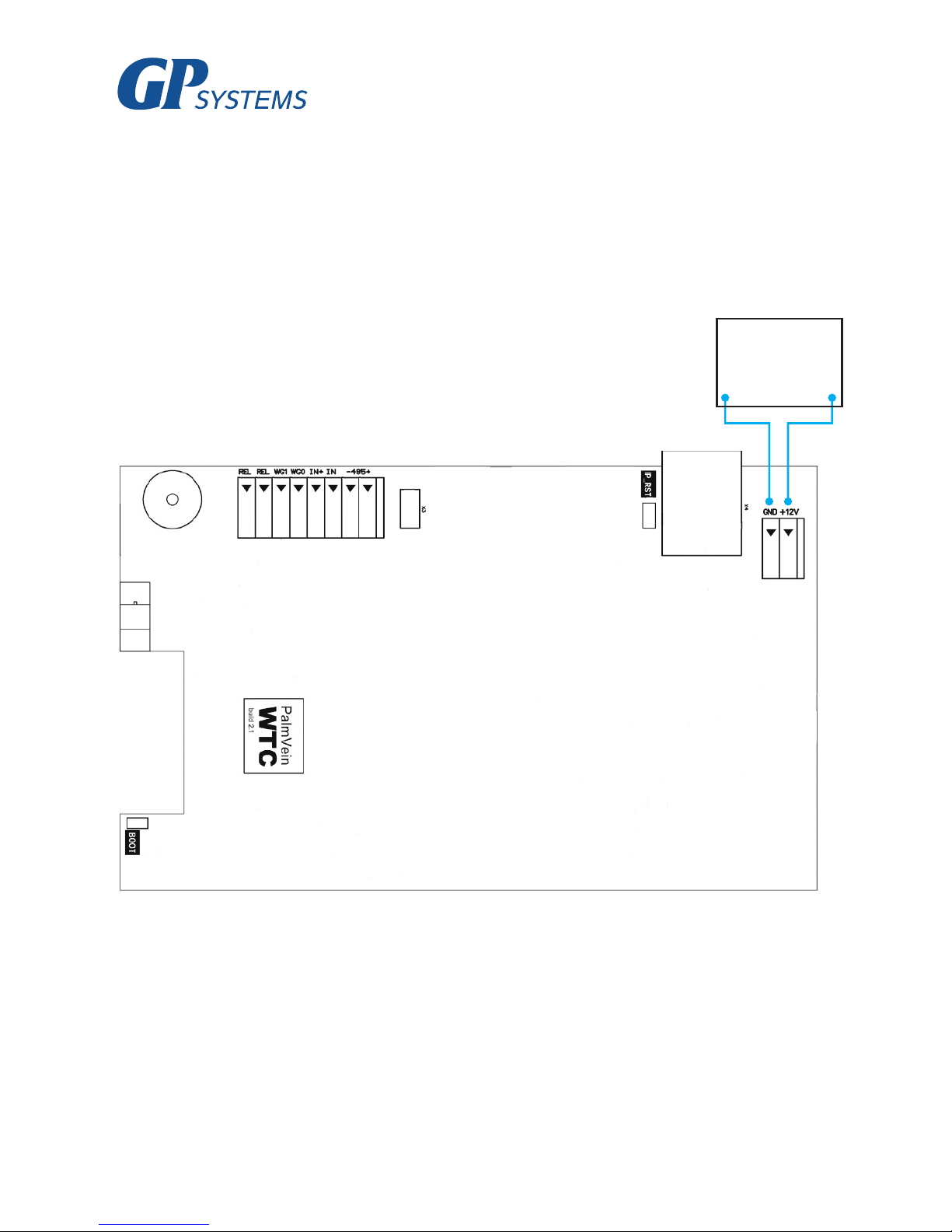

8.3 Connecting the terminal’s power supply

Use cable 2 (see table 2) to connect the power supply according to the connection diagram in

figure 6.

DC 12V

power

supply

GND +12V

Figure 6. Connecting the terminal’s power supply

15

8.4 Connecting the terminal to an Ethernet network

Connect the terminal to an Ethernet network according to figure 7.

Figure 7. Connecting to an Ethernet network

Network

interface

16

Use cable 1 (see table 2) to connect the terminal (via the Ethernet port) to a computer, network

switch or router. The order of connections in the cable’s modular connector must correspond to the

TIA/EIA-568-B standard, in accordance with figure 8.

17

8.5 Connecting an electromechanical lock to the terminal’s circuit

board

Figure 9 describes how to connect an electromechanical lock to the terminal. Use cable 3 (see table

2) to connect the electromechanical lock.

Figure 9. Connecting an electromechanical lock

Lock

Power

supply

+

-

18

8.6 Connecting an electromagnetic lock through the BioSmart BCR

An electromagnetic lock is connected in conjunction with the BioSmart BCR in accordance with

figure 10.

Use cables 3 and 4 to connect it (see table 2).

Figure 10. Connecting an electromagnetic lock

The connection and configuration of the BioSmart BCR is described in detail in the BioSmart BCR

Operating Manual.

+485 NC1

BCR

-485 C1

Lock

PSU

19

8.7 Connecting an entry sensor and control buttons

An entry sensor or a control button for exiting the premises can be connected directly to the BioS-

mart PV-WTC terminal’s on-board discrete input.

Figure 11. Connecting a door sensor or button

to the on-board discrete input

Use cable 5 for this connection (see table 2).

If your access monitoring and control system requires the simultaneous use of an entry sensor and

button for exiting the premises, you must connect them using the BioSmart BCR.

Door sensor

or button

20

Figure 12. Connecting a door sensor and button

using the BioSmart BCR

Use cables 4 and 5 for this connection (see table 2).

The connection and configuration of the BioSmart BCR is described in detail in the BioSmart BCR

Operating Manual.

8.8 Connecting to an external controller through Wiegand

Figure 13 describes how to connect the terminal to an external AMCS controller through the Wie-

gand interface.

Use cable 6 for this connection (see table 2).

+485

BCR

-485

21

Figure 13. Connecting the terminal to an external

controller through the Wiegand interface

D0 (IN)

D1 (IN)

GND

9. CONFIGURING NETWORK PARAMETERS

Connect the terminal’s power supply. Wait for the screen to turn on.

Navigate through the on-screen menu using the corresponding keypad buttons (p. 3.1).

Press “Menu”. A prompt will appear on the display requesting the terminal’s configuration pass-

word. To log in, press .

The factory default password is an empty password.

22

When you log in to configuration mode for the first time, it is recommended that you set a new

password to avoid future unsanctioned access to the terminal’s options.

Go to the “Options” section, choose “Reset options” and press .

Warning! The “Reset options” button in this menu resets all the terminal’s settings to factory

default settings, and removes all user and event data saved in the terminal’s memory.

To change the terminal’s network settings, go to the “Network” section.

Choose the “New IP address” option from the list and press .

Enter the required IP address using the keypad and press .

Enter the required network mask and gateway options in the same way.

Navigate to the “Apply” button and press .

After this, the new network settings will go into effect.

The device is ready for use. Further configuration of the device should be carried out using the

BioSmart-Studio or BioSmart Manager programs.

The BioSmart PV-WTC Operating Manual and all necessary drivers and software can be found at

the address www.gp-systems.com in the “Technical Support” section.

10. ENSURING OF THE OPERATION

Go to the “Info” menu and confirm that the physical Ethernet network connection is established

and that there are no errors in the device’s operation.

If the device is connected correctly and its network options are configured correctly, the following

parameters should be displayed:

Next, a hardware test must be performed on the terminal.

To do this, press the “Menu” button. A prompt will appear on the display requesting the terminal’s

configuration password. To log in, press .

Select “Self-diagnostics” and press . Wait for the device’s diagnostic test results to appear on

the screen.

If there are no operational errors in the terminal, the message “Success” will be displayed on all

the tests. If this is not the case, you must contact the manufacturer to arrange for servicing works to

be carried out.

Network connection

Yes

IP conflict

No

Hardware errors

None

23

Thank you for purchasing our product!

24

GP Systems GmbH

Ochshäuser Str. 45

34123 Kassel Germany

Tel. +49 151 100 41 701

Loading...

Loading...