GPRINTER GP-9034T, GP-9035T User Manual

Thermal Transfer Barcode Printer

User's Manual

GP-9034T/9035T

Customer service hotline : 400 611 3828

CONTENTS

The printer

Introduction

Application Field

Product features

Specifications

Optional accessories

Standard equipment

Specification

Printer Introduction

Installation

LED Indicator and Function

Maintenance

Open and check

Cable connection

LED indicator

Printer components

Ribbon installation

Button Function

Paper installation

Power on Function

17

Printing specification

Ribbon specification

Paper specification

2.5

2.4

2.3

2.2

2.1

1.1

4.1

5.1

6.1

4.2

5.2

6.2

5.3

6.3

7.

02

02

03

03

03

03

04

04

04

05

06

06

07

09

09

09

10

11

11

12

12

The printer

Introduction

Thanks for choosing GP-9034T, GP-9035T series direct thermal and thermal transfer label printer.

This series printer is built with 2 sets of gear to drive motor, with capability of handling 300

meters long ribbon and large label roll. Printer inner volume is fit for 5" OD (Outer Diameter)

paper roll, if using external paper holder, you can install 8.4"OD industrial grade label roll.

This printer is designed for real-time and batch label printing, with serial, parallel, USB and

Ethernet in connection port. Direct thermal printing and thermal transfer printing modes are all

one printer body, so you can choose various kinds of printing materials, for example: thermal

paper, plain paper, coated paper, silver paper, plastic paper etc.

Common 1D barcode and 2D barcode fonts are built inside printer, also it support 4 direction

printing, characters can be enlarged from 1 to 10 times. Besides, it supports 5 different size

bitmap fonts, OCR-A and OCR-B fonts, together with 300dpi higher print resolution, this series

printer are your best choice among the same class.

Declaration: This is a class A product fit for Non Tropic regions installation . This product ,

may cause radio interference in life environment users may need to take adequate preven

-tive

,

measures.

Application Field

Manufacturing & Warehousing logistic industry

Healthcare

Parcel Post

Office & Studio

Retail

Product labeling and marking

Warehouse management label

Category marking label

Operation instruction marking label

Distributing instruction marking label

Patients marking

Medicine marking

Specimen marking

Mailing label

Price Label marking

Product item marking

Jewelry product marking

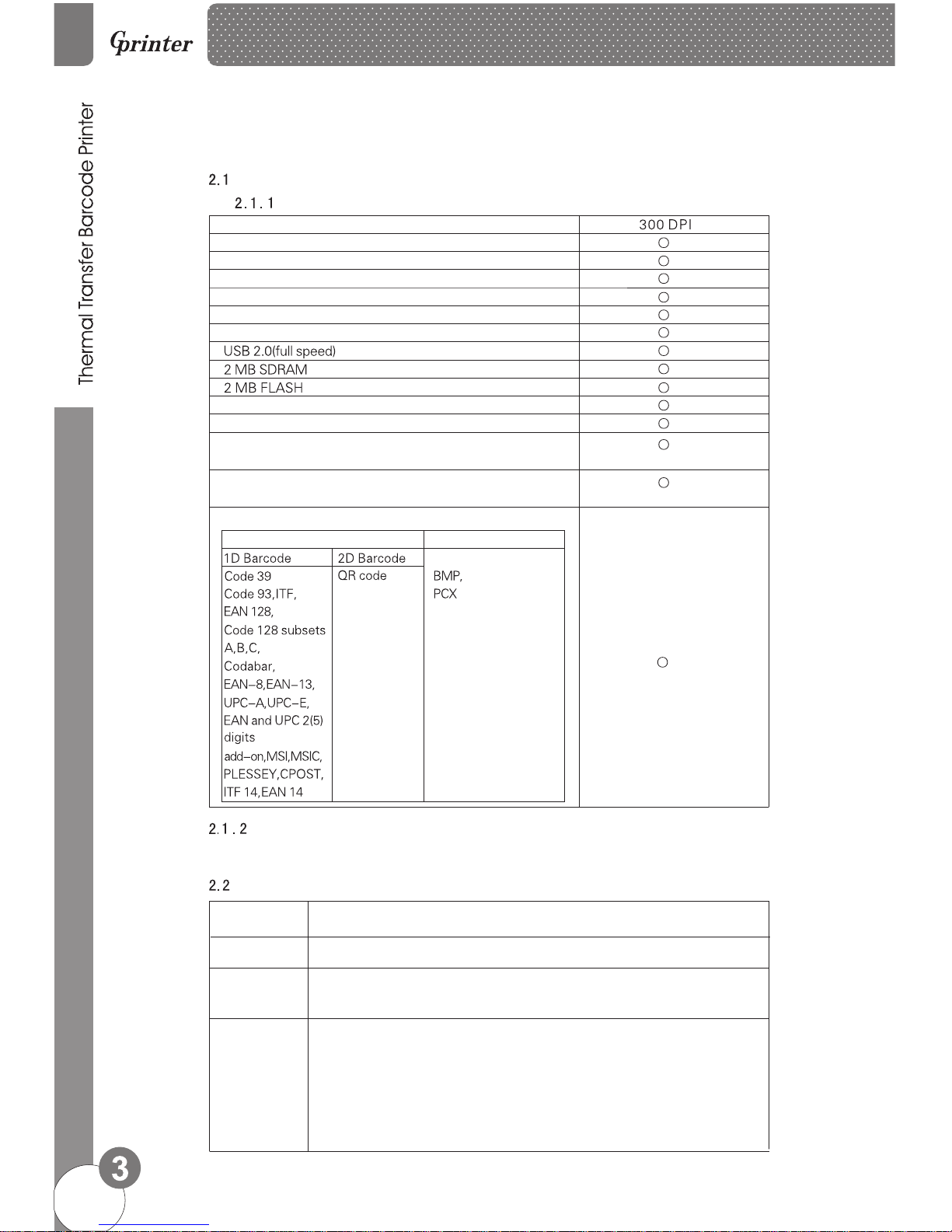

2.

Product features

Standard equipment

Optional accessories

Specifications

Support bar code

Support picture

Power Supply

Printer weight

Printer size

External stand is standard accessory for GP-9035T, optional for GP-9034T.

Can print text, bar code, pictures

Product standard

Ribbon printing

Direct Thermal printing

ABS plastic housing

Gap sensor

Ribbon sensor

The print head open sensor

Communication interface

Memory

Memory

Feed button & LED indicator

Built-in 8 kinds of dot matrix fonts

The character and the bar code can be printed in four directions

(0,90,180,270 degree).

Built in simplified Chinese, traditional Chinese and

Korean font for programming.

Environment

186(W)x180(H)x2 90 (D)

2.4KG

Input: AC 100-240V Output: DC 24V 2A

Storage Environment: -10~50℃ (-10~140℃),

Humidity:10~90%,no condensation

Operation Environment:5~45℃(41~104℃),

Humidity:25~85%,no condensation

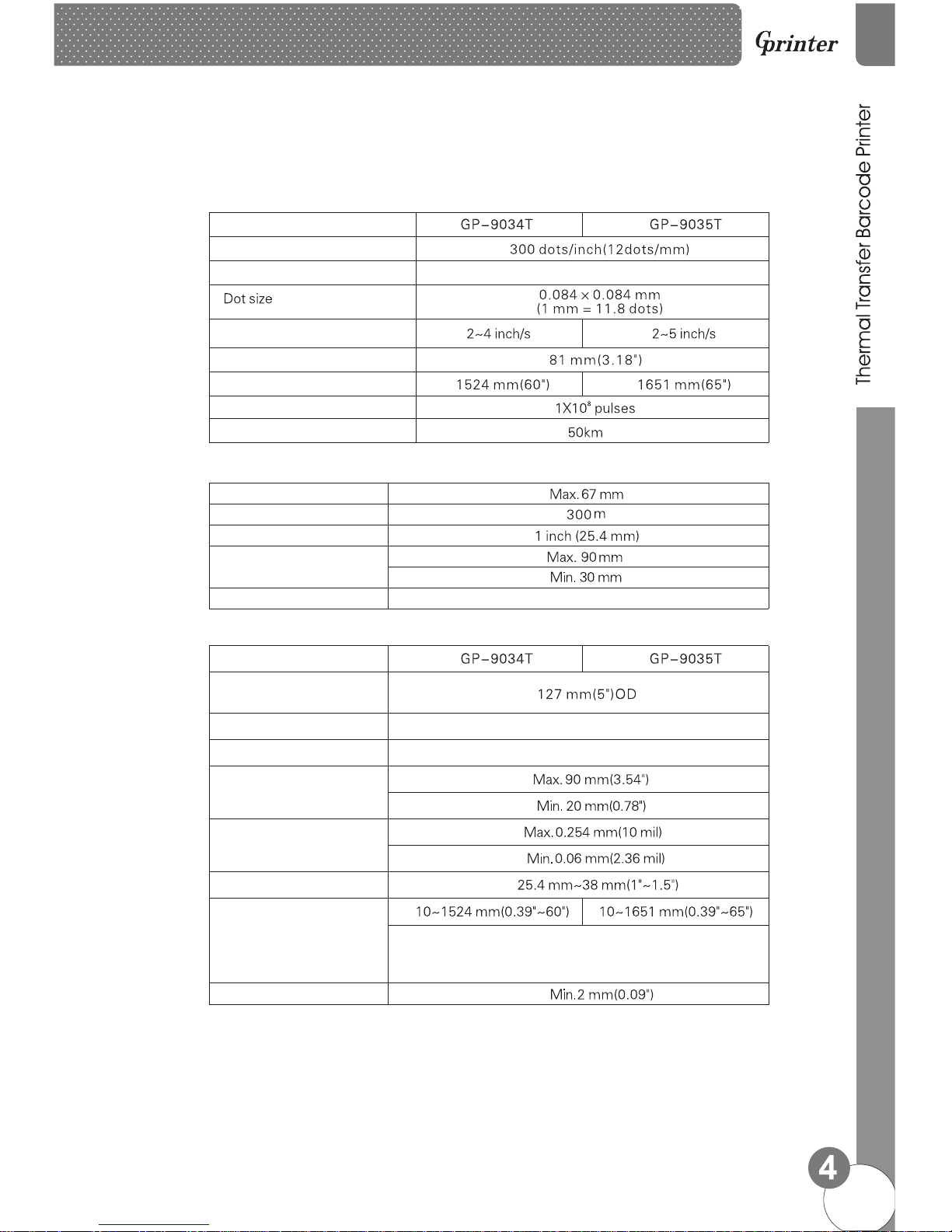

Printing specification

Model

Model

The print head

Print mode

Ribbon / thermal

Ribbon specification

Paper specification

Outward winding

Pulse excitation

(widthxlength)

Print speed (inches per second)

Maximum print width

Maximum print length

Thermal print head reliability

Ribbon diameter

The ribbon length

The ribbon axis size

The ribbon width

Ribbon winding way

Label length

Gap size

Roll axis size

The thickness of the paper

(upper & bottom paper)

The width of the paper

(upper & bottom paper)

The paper winding way

Paper type

The maximum capacity of

internal paper roll diameter

Printing side outward or inward winding

Continuous paper , paper with interspaces , folding paper ,sprocket paper

Note : If label length less than 25.4mm(1 inch),label paper with

perforations are recommended, labels can be torn off easily.

2.3

2.4

2.5

Res olution

Pri nt spee d

Dot d ensit y

Pri nt meth od

Dot s ize

Int erf ace

Pri nt widt h(max .)

Pri nt leng th(ma x.)

Rib bon dia meter

Rib bon len gth

Rib bon cor e size

Rib bon wid th

Rib bon rol ling up method

Paper roll dia meter (Max.)

Paper type

Paper rollin g up method

GP-9034T GP-9035T

300 d pi

2~4 i nch/s

300 d ots/i nch(1 2dots /mm)

Rib bon/D irect t hermal line

0.0 84×0. 084 mm (1 m m = 11.8 dots)

USB +Seri al+Parallel

81m m(3.1 8")

152 4mm(6 0")

Max . 67mm

300 m

1 inc h (25.4 m m)

Max .90mm , M in.30 mm

Out ward rolling

127 m m(5") OD

Con tinuo us, gap , folde d, punc hed

Pri nting s ide out ward rolling / inw ard rolling

)

Paper width

(La bel+b acking sheet)

Max .90 mm( 3.54" ) Min.2 0 mm(0. 78")

Max .0.25 4 mm(10 m il) Min .0.06 m m(2.36 mil)

Paper thickn ess

(La bel+b acking sheet)

Paper roll core siza

Paper gap

Lab el leng th

25. 4 mm~38 m m(1"~ 1.5")

2 mm( 0.09" ) min.

10~ 1651 mm (0.39 "~65" )

Rem ark : If label lengt h less than 25 .4mm(1 inch) , label p aper with perforatio ns are reco mmended, lab els can b e torn of f easil y.

Dim ensio n

Weight

Work environment

Storage environment

Power

186 (W)*1 80(H) *290( D)

2.4 KG

Temperature 5~45℃ ; Humidi ty 25~8 5%

Inp ut: AC 10 0V/240V ,Outp ut: DC 24V/2A

Temperature -10~50℃ ; Hu midity 10~90 %

Acc essor ies

Ext enal-holder as op tion

Mec hanis m Relia bility

50k m

Max .90 mm( 3.54" ) Min.2 0 mm(0. 78")

Max .0.25 4 mm(10 m il) Min .0.06 m m(2.36 mil)

165 1mm(6 5")

Max . 67mm

300 m

1 inc h (25.4 m m)

Max .90mm , M in.30 mm

Out ward rolling

127 m m(5") OD

Con tinuo us, gap , folde d, punc hed

Pri nting s ide out ward rolling / inw ard rolling

10~ 1524 mm (0.39 "~60" )

Eth ernet +USB+ Seria l+Parallel

300 d pi

2~5 i nch/s

300 d ots/i nch(1 2dots /mm)

Rib bon/D irect t hermal line

0.0 84×0. 084 mm (1 m m = 11.8 dots)

Ext enal-holder as st andard ac cesso ry

25. 4 mm~38 m m(1"~ 1.5")

2 mm( 0.09" ) min.

81m m(3.1 8")

★ 300dpi High , 5 inch/sec high print speed.

90mm width paper exit design for more label options.

★ Completely new motherboard with 4 interfaces to meet different connection need.

★ Newly added thermal transfer printing method, comsumer option more flexible, storage period more longer.

★ Separate mechanism structure, compact and practical, support Thermal transfer and direct thermal line printing.

★ Large gear in mechanism and newly designed transmission system, enable paper roll to feed more smoothly.

★ External paper holder are optional for Φ8.4" industral-grade large roll.

★ Built with 2-motor gear-driven engine,GP-9035T is able to handle 300 meters long ribbon and big label roll.

resolution

★

Specification:

3.

Loading...

Loading...