SAVE THESE INSTRUCTIONS

Industrial Grade

PVDF

TURBINE HOUSING

Owner’s Manual

Turbine shown here with Computer

Electronics which are sold separately.

921915-02 Rev. E 02/16

To the owner . . .

Congratulations on receiving your

GPI Industrial Grade Turbine. We are

pleased to provide you with a product

designed to give you maximum reli‑

ability and efciency.

Our business is the design, manufac‑

ture, and marketing of liquid handling,

agricultural, and recreational prod‑

ucts. We succeed because we provide

customers with innovative, reliable,

safe, timely, and competitively‑priced

products. We pride ourselves in con‑

ducting our business with integrity and

professionalism.

We are proud to provide you with a

quality product and the support you

need to obtain years of safe, depend‑

able service.

Victor Lukic, President

Great Plains Industries, Inc.

TABLE OF CONTENTS

General Information ...................... 2

Installation .................................... 4

Operation ...................................... 5

Maintenance ................................. 5

Troubleshooting ............................ 7

Model Number Chart .................... 7

Specications ............................... 8

Parts ............................................. 9

Service........................................ 10

GENERAL INFORMATION

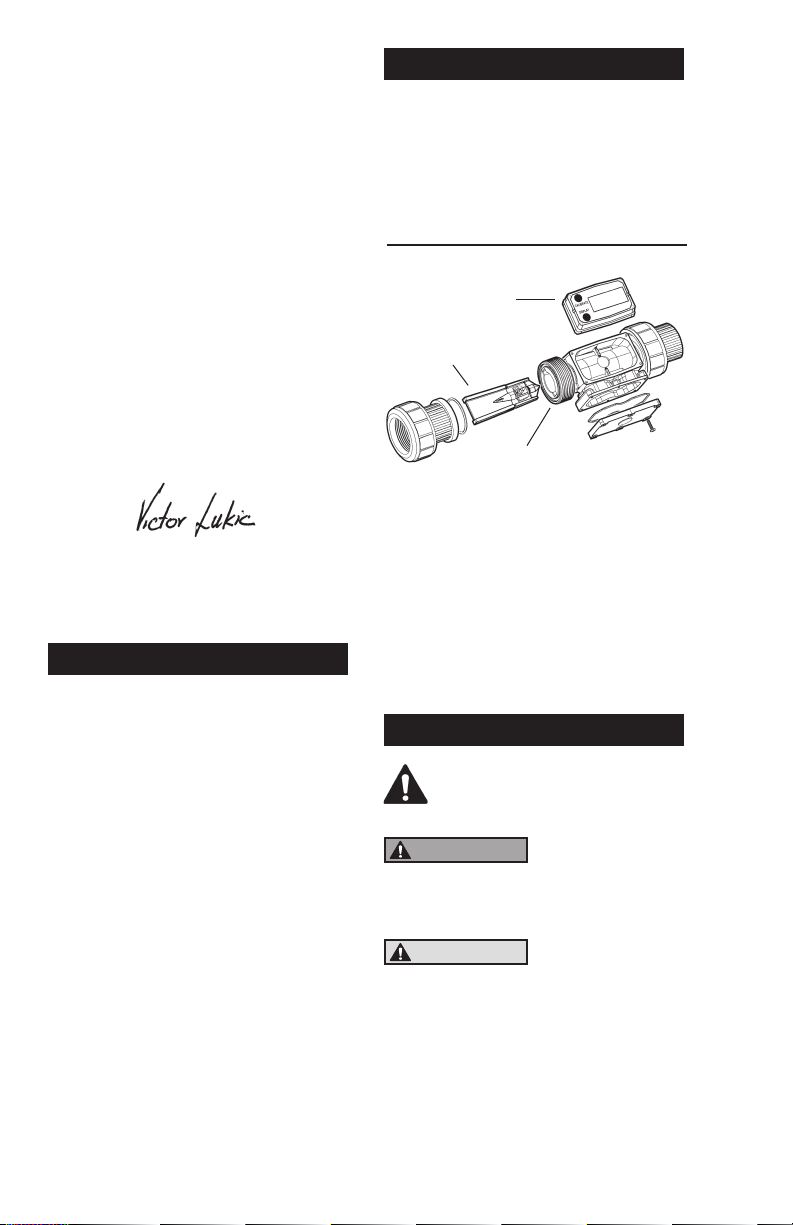

This manual will assist you in installing

and maintaining your PVDF turbine

housing. (See Figure 1) Information

on computer electronics and acces‑

sory modules are contained in other

manuals. Please reference those as

necessary.

Figure 1

Computer Electronics

(sold separately)

Rotor Assembly

Turbine Housing

For best results, take the time to fully

acquaint yourself with all information

about all components of your GPI

Electronic Digital Metering System

prior to installation and use. If you

need assistance, contact the distribu‑

tor from whom you purchased your

turbine.

SAFETY INSTRUCTIONS

This symbol is used throughout

the manual to call your attention

to safety messages.

WARNING

WARNINGS

you to the poten‑

alert

tial for personal

injury.

CAUTION

CAUTIONS call

your attention to

practices or pro

‑

cedures which

may damage your

equipment.

NOTES give information that can

improve efciency of operations.

2 921915-02 Rev. E

It is your responsibility to make sure

that all operators have access to

adequate instructions about safe op‑

erating and maintenance procedures.

Read Me!

For your safety, review the major

warnings and cautions below before

operating your equipment.

WARNING

The apparatus enclosure may contain

aluminum and is considered to

constitute a potential risk of ignition

by impact or friction. Care must be

taken into account during installation

and use to prevent impact or friction.

WARNING

Part of the enclosure is constructed

from plastic. To prevent the risk of

electrostatic sparking the plastic

surface should only be cleaned with

a damp cloth.

1. This equipment is approved

to handle only uids that are

compatible with all materials of

construction.

2. When measuring ammable liq‑

uids, observe precautions against

re or explosion.

3. When handling hazardous liquids,

always follow the liquid manufac‑

turer’s safety precautions.

4. When working in hazardous

environments, always exercise

appropriate safety precautions.

5. Always dispose of used cleaning

solvents in a safe manner accord‑

ing to the solvent manufacturer’s

instructions.

6. During turbine removal, liquid

may spill. Follow the liquid manu‑

facturer’s safety precautions for

clean up of minor spills.

7. Do not blow compressed air

through the turbine.

8. Do not allow liquids to dry inside

the turbine.

9. Handle the rotor carefully. Even

small scratches or nicks can affect

accuracy.

10. When tightening the turbine, do

not use a wrench or pliers to

tighten the turbine. Hand tighten

only.

11. For best results, always verify

accuracy before use.

Product Description

GPI Industrial Meter Turbines are

identied by the internal diameter of

the inlet and outlet.

Model 05 ‑ 1/2 inch

Model 10 ‑ 1 inch

Each turbine is designed to work with

on‑board computer electronics and/or

with one of several accessory mod‑

ules that can interface to a wide variety

of reporting and collecting devices.

Liquid ows through the turbine hous‑

ing causing an internal rotor to spin.

As the rotor spins, an electrical signal

is generated in the pickup coil. The

electrical signal provides the output

necessary to operate the on‑board

computer electronics for local indica‑

tion directly on the turbine or one of

several accessory modules that trans‑

mit the signal to external equipment.

Upon receipt, examine your meter

for visible damage. The turbine is a

precision measuring instrument and

should be handled as such. Remove

the protective plugs and caps for a

thorough inspection. If any items are

damaged or missing, contact your

distributor.

Make sure the turbine model meets

your specic needs. Refer to the

Specications Section and conrm

the following:

3921915-02 Rev. E

1. The owrate is within the limits of

your model.

2. The liquid is compatible with the

turbine’s wetted components.

3. The system’s pressure does not

exceed the turbine’s maximum

pressure rating.

Each GPI Turbine has a unique iden‑

tication number that includes the

Serial Number, K‑Factor and Manu‑

facturing Date. This identication

number is etched into the surface of

the turbine. Record this identication

number in the back of the Owner’s

Manual in the space provided.

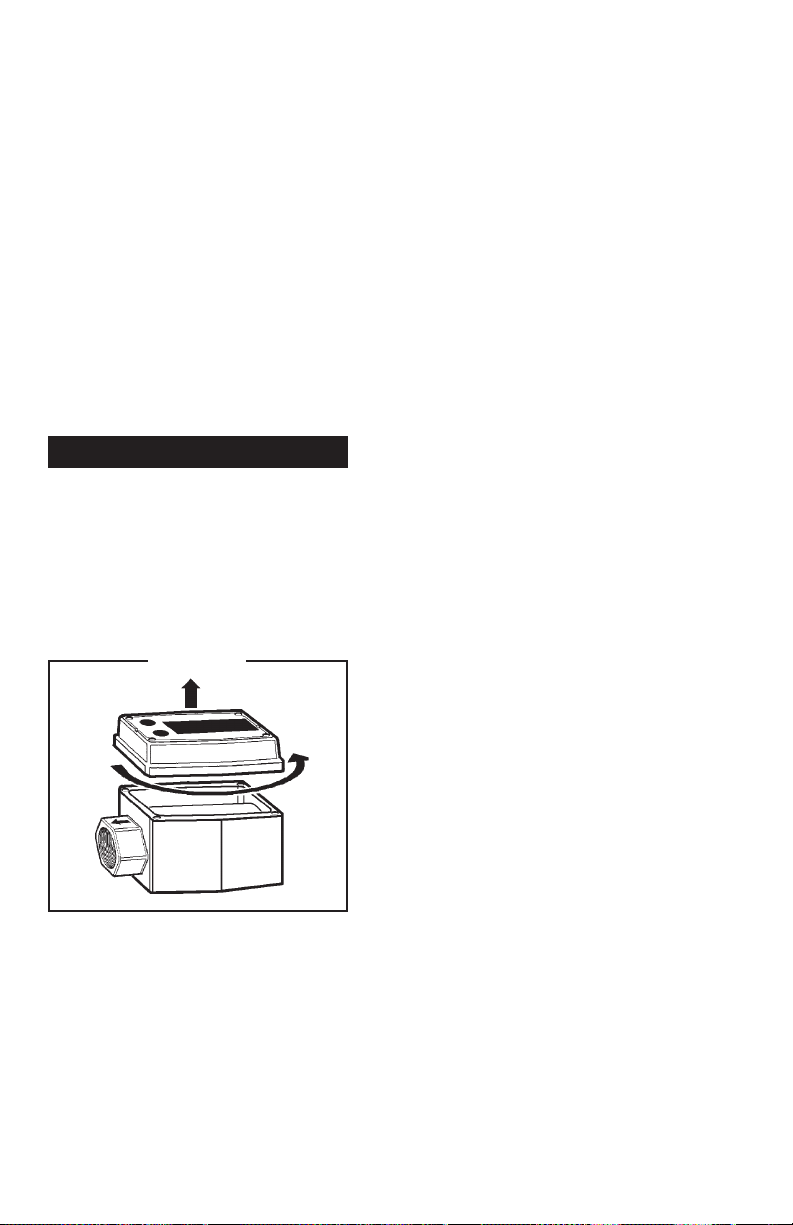

INSTALLATION

All GPI turbines are designed to

measure ow in only one direction.

The direction is indicated by the arrow

cast‑molded in the turbine outlet. If the

opposite direction is desired, and you

are using on‑board computer electron‑

ics, rotate the computer electronics

180 degrees prior to installation.

Diagram 1

Flow altering devices such as elbows,

valves, and reducers can affect ac‑

curacy. The following recommended

guidelines are given to enhance ac‑

curacy and maximize performance.

Distances given here are minimum

requirements; double them for desired

straight pipe lengths.

Upstream from the turbine, allow

a minimum straight pipe length at

least 10 times the internal diameter

of the turbine. For example, with

the 1 inch turbine, there should be

10 inches (25.4 cm) of straight pipe

immediately upstream. The desired

upstream straight pipe length is 20

inches (50.8 cm).

Downstream from the turbine, allow

a minimum straight pipe length at

least 5 times the internal diameter

of your turbine. For example, with

the 1 inch turbine, there should be 5

inches (12.7 cm) of straight pipe im‑

mediately downstream. The desired

downstream distance is 10 inches

(25.4 cm).

A typical back pressure of 5 to 50 PSI

(0.34 to 3.4 bar) will prevent cavitation.

Create back pressure by installing a

control valve on the downstream side

of the meter at the proper distance

detailed above.

Foreign material in the liquid being

measured can clog the turbine’s rotor

and adversely affect accuracy. If this

problem is anticipated or experienced,

install screens to lter impurities from

incoming liquids.

Model 05

Maximum Particulate Size

Inches: 0.005

Microns: 125

Mesh: 120

Standard Sieve: 125 µm

Alternative Sieve: No. 120

Model 10

Maximum Particulate Size

Inches: 0.018

Microns: 500

Mesh: 35

Standard Sieve: 500 µm

Alternative Sieve: No. 35

To ensure accurate measurement,

remove all air from the system before

use. To purge the system of air:

1. Ensure some back pressure ex‑

ists on the turbine in the line.

2. Open the discharge valve or

4 921915-02 Rev. E

Loading...

Loading...