GPI - Great Plains Industries FLOMEC QSE Mag Series Catalog Page

PRODUCT CONFIGURATION

QSE MAG FLOWMETER

The QSE Mag Series is a dependable highly accurate

electromagnetic owmeter designed for ow and usage

monitoring in commercial applications.

The Noryl

TM

housing and ow tube offer a lightweight, easyto-install Mag Meter that is resistant to heat (210°F [99°C])

and compatible with many water-based liquid solutions.

The QSE Mag Meter monitors ow rate and total ow in a

wide variety of applications including: HVAC, Turf/ Irrigation

and other water reclamation applications.

FEATURES / BENEFITS

• Low investment and operating costs

• ± 0.5% Accuracy of Reading (from 0.25 fps to 15 fps

[0.08 to 4.6 m/s])

• Wide turndown ratio of 60:1

• Non-intrusive, no moving parts to wear out,

maintenance, repair costs low and tolerates high flows

without damage

• The slightly modified bore permits unobstructed flow

and minimizes flow disturbances and straight pipe

requirements

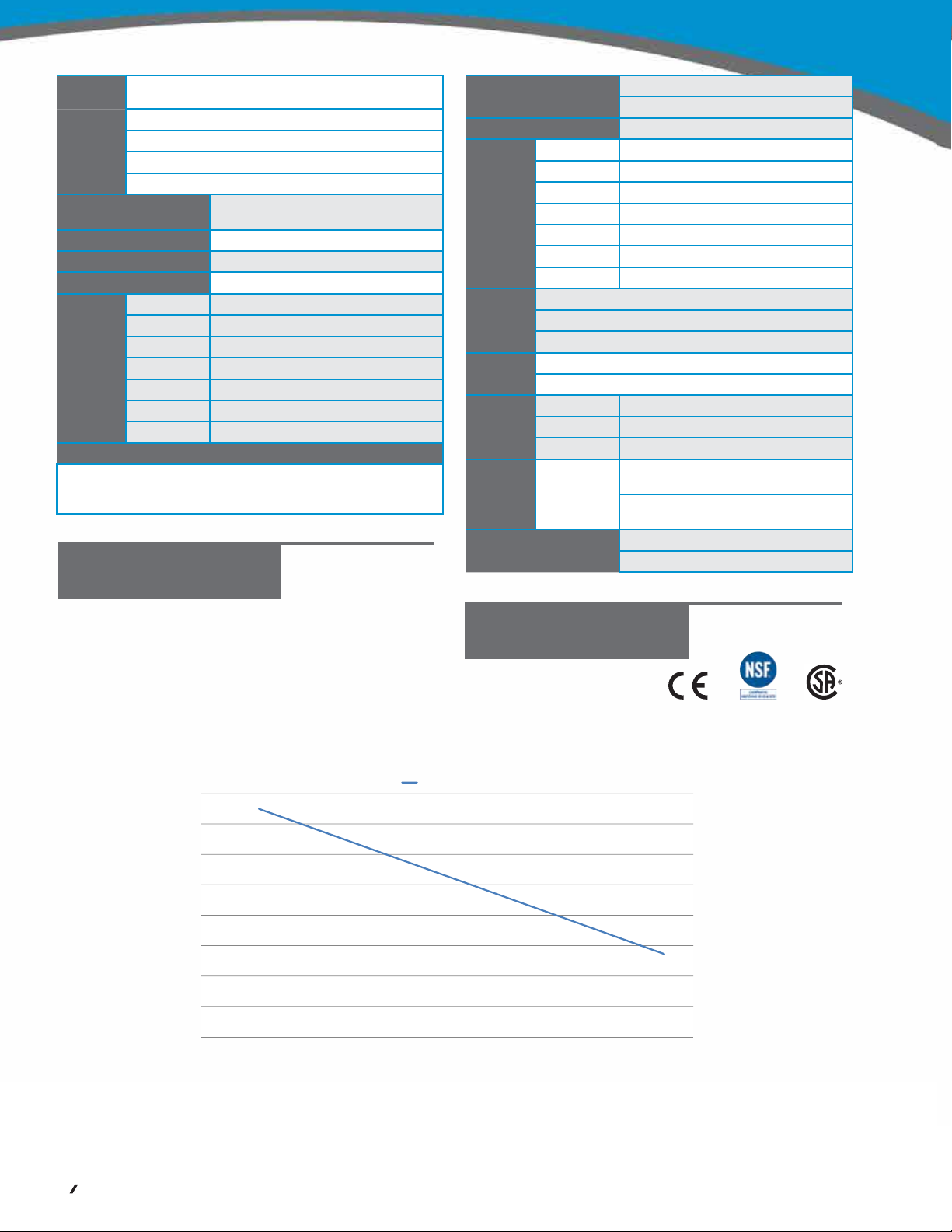

PRODUCT IDENTIFIER

QSE = Electro-Magnetic Flow Meter

SIZE

FITTING

2

05 = 1/2” (15 mm)

07 = 3/4” (20 mm)

10 = 1” (25 mm)

15 = 1-1/2” (40 mm)

20 = 2” (50 mm)

30 = 3” (80 mm) (Flange only)

40 = 4” (100 mm) (Flange only)

3

NPT = NPT (Male) (½” to 2” Only)

BSP = BSPP (Male) (ISO 228) (½” to 2” Only)

FAP = ANSI Flange - Polymer (3” & 4” Only)

FAS = ANSI Flange - Steel (3” & 4” Only)

FDS = DIN Flange - Steel (3” & 4” Only)

ELECTRONIC CHOICE

09 = 2-Button Integral Display, Field Congurable (Cumulative,

Batch & Rate) and Integral Pulse Transmitter (Open Collector

Square Wave), Includes Four Strain Reliefs

QB = Integral Pulse Transmitter (Open Collector Square Wave),

Includes Four Strain Reliefs

COMMUNICATION CHOICE

Q1 = Integrates with Any Electronic Choice QSI Module:

Blue Tooth®, Coil/Digital Pulse Input, Pulse Output (Flow or

Energy & Scalable), RS485 (MODbus RTU), Temperature Inputs,

BTU Calculator. Energy Use Computation Note: Energy Use

Computation Requires Temperature Sensor Probes (Select

Probes Below)

Q2 = Integrates with Any Electronic Choice QSI Module:

Blue Tooth®, Coil/Digital Pulse Input, Pulse Output (Flow or

Energy & Scalable), Data Logger, Temperature Inputs, BTU

(Heat) Calculator. Energy Use Computation Note: Energy Use

Computation Requires Temperature Sensor Probes (Select

Probes Below)

Q3 = Integrates with Any Electronic Choice QSI Module:

Blue Tooth®, Coil/Digital Pulse Input, Pulse Output (Scalable),

Data Logger, 4-20mA.

XX = No Communication Suite

TEMPERATURE SENSOR PROBES

1 = Integrates with QSI Communications Choice for Energy

Use Computation (2ea) 1" (25 mm) Long Temperature Sensor

Probes w/Cables (10 ft. [3 m]) (Customer Installed), Used with

1/2" through 2" Meters

2 = Integrates with QSI Communications Choice for Energy

Use Computation (2ea) 2" (50 mm) Long Temperature Sensor

Probes w/Cables (10 ft. [3 m]) (Customer Installed), Used with

3" and 4" Meters

X = No Temperature Probes

1

4

5

6

ELECTROMAGNETIC FLOWMETERS

• 7 line sizes (½” to 4”) ½”, ¾”, 1”, 1-½”, 2”, 3", & 4”

• Housing ported with “Thermal Well Supports” for

sensors (Energy Management)

• Compatible with GPI 09 Electronics Display or

FLOMEC QSI I/O Board

PACKAGING (Auto Select)

A = 1/2" - 2" Meters

B = 3" Meter

C = 4" Meter

1 2 3 4 5 6 7

>>>> QSE 30 FAP 09 Q1 2 B

7

3

SPECIFICATIONS

QS200 INSERTION ULTRASONIC FLOWMETER

The QS200 Insertion Ultrasonic Flowmeter provides an accurate

reading of liquid ow rate and accumulated ow. Designed to

support commercial irrigation applications, the QS200 is available

in ve pipe sizes, 1 to 4 in.

The QS200 ultrasonic insert is available with a PVC tee or as an

“insert retrot” for replacement of existing paddlewheel ow sensors.

FEATURES / BENEFITS

• Low-cost, effective and easy installation

• No moving mechanical parts (low-maintenance)

• Simple two-wire connector (for power and pulse)

• Compatible with irrigation controllers (common name brands)

• High accuracy: ± 2.0% of reading (compared to full scale

accuracy)

• Provides extended leak detection down to

0.1 fps (0.03 m/s)

• LED light indicators: (green for power and amber for pulse)

• Patented design

• Ideal for clean water ow measurement

• External wiring: (direct burial wire)

INSERT DESCRIPTION

Designed for above and below grade applications, such as irriga-

tion, municipal and underground monitoring where the ow rates

are between 0.1 to 15 fps (0.03 to 4.57 m/s) and temperatures are

below 140° F (60° C). QS200 inserts are supplied with two single

conductors, 18 AWG solid copper wire leads that are 36 inches

(914.4 mm) in length with UL Style 116666 direct burial insulation.

SPECIFICATIONS

Tee Housing

Material:

Schedule 80 PVC

Insert Wetted

Materials:

Body: PPS (Ryton R-4)

Sensor: PEI (Ultem 1000)

O-Ring: EPDM

Temperature Rating:

Operating:

32° F to 140° F (0° C to 60° C)

Storage:

-20° F to +160° F (-29° C to +71° C)

Flow Range:

0.1 to 15 fps (0.03 to 4.57 m/s)

Accuracy:

Typically ±2% of reading

Operating

Pressure:

150 psi @ 73° F (10 bar @ 23° C)

100 psi @ 140° F (7 bar @ 60° C)

Transducer

Excitation:

Supply Voltage: 7.5V (dc) min. to 36V (dc) max

Quiescent Current: 200 μA (typical)

Output

Frequency:

0 to 100 Hz

Output Pulse

Width:

4 ms

Electrical

Cable for Insert

Electronics:

36 inches (914.4 mm) of 18 AWG, solid cop-

per, “Direct Burial” (UL 493 & 83)

APPROVALS

APPLICATIONS

• Agriculture Irrigation

• Turf / Landscape Irrigation

Systems

• Micro Irrigation Systems

• Groundwater Monitoring

• Sub-Metering Applications:

» High Rise Tenant Buildings

» Apartment Complex

» Universities

» Commercial Businesses

» Processing Facilities

IP68

Fitting

Type:

Recommeded Plastic

Flange Bolt Torque:

Pipe Sizes: 1/2”, 3/4”, 1”, 1-1/2”, 2”, 3”, 4”

Pressure Rating: 150 psi @ 73 F (10 bar @ 23 C)

Velocity: 0.25 to 15 fps (0.08 to 4.57 m/s)

Flow: 1/2” (05) 0.16 - 10 GPM (0.63 - 38 L/min)

Accuracy

±0.5% of Reading between 0.25 fps and 15 fps (0.08 m/s and 4.57 m/s)

(Reference Owner's Manual for complete accuracy and

uncertainty specications)

NPT, BSP, ANSI Flanged, DIN Flanged

1/2” to 2” - NPT (Male), BSPP (Male) (ISO 228)

3” & 4” 150# ANSI Flanged - Polymer Flange

3” & 4” ANSI Flanged - Steel Flange

3” & 4” DIN Flanged - Steel Flange

25 ft.-lbs. (33.9 Nm)

3/4” (07) 0.3 - 20 GPM (1.27 - 76 L/min)

1” (10) 0.6 - 40 GPM (2.52 - 151 L/min)

1-1/2” (15) 1.3 - 80 GPM (5.05 - 303 L/min)

2” (20) 2.5 - 150 GPM (9.47 - 568 L/min)

3” (30) 5 - 300 GPM (19 - 1136 L/min)

4” (40) 10 - 600 GPM (38 - 2271 L/min)

APPLICATIONS

• Agriculture Irrigation

• Turf Irrigation Systems

• Micro Irrigation Systems

• HVAC

• EMS (Energy Management

Systems)

• BAS (Building Automation

Systems)

160.0

140.0

120.0

100.0

80.0

Pressure PSIG

60.0

40.0

20.0

0.0

50 70 90 110 130 150 170 190 210

(10) (21) (32) (43) (54) (66) (77) (88) (99)

• Chilled water

• Domestic water (hot and cold

• Energy sub-metering

(BTU hot and cold)

• Process (blow down,

make up, boiler feed, etc.)

Derated Pressure Curve for QSE (Pressure vs Temperature)

Derated Pressure

Temperature °F (°C)

Operating Temperature

Range:

Ambient Temperature Range: 0 F to 140 F (-18 C to 60 C)

Typical

K-Factor:

Power

Supply:

Consumption:

Wetted

Materials:

Frequency

Range:

1/2” (05) 4347 PPG (1158.5 Pulses/L)

3/4” (07) 1937 PPG (511.8 Pulses/L)

1” (10) 1089 PPG (287.7 Pulses/L)

1-1/2” (15) 484.1 PPG (127.9 Pulses/L)

2” (20) 400 PPG (105.7 Pulses/L)

3” (30) 121 PPG (32.0 Pulses/L)

4” (40) 68.1 PPG (18.0 Pulses/L)

Externally Powered

Voltage Supply (Min): 12V (dc or ac)

Voltage Supply (Max): 30V (dc or ac)

Max current consumption (QSE with QSB): 75mA

Max current consumption (QSE with QSI): 150mA

Body Noryl

Electrodes 316L SS

Seals EPDM O-Rings

All Sizes

Calibration Report: Standard

1/2"-2": 32 F to 210 F (0 C to 99 C)

3"-4": 32 F to 180 F (0 C to 82 C)

TM

10 Hz Minimum - 1,000 Hz Maximum

(with 09 Display)

10 Hz Minimum - 3,000 Hz Maximum

(with Blind Pulse Out)

N.I.S.T. Available

APPROVALS

NEMA 6P

(pending)

IP67

11.0

9.7

8.3

6.9

5.5

ressure bar

P

4.1

2.8

1.4

0.0

4

Loading...

Loading...