Page 1

Q09 Display

Owner’s Manual

(Shown on 1 inch NPT QSE Meter)

Q09 Display

TABLE OF CONTENTS

INTRODUCTION ..................................... 1

IMPORTANT NOTICE ....................... 2

SAFETY ............................................ 2

INSTALLATION ....................................... 2

OPERATION ........................................... 4

Display .............................................. 4

Batch And Cumulative Totals ........... 4

CALIBRATION ........................................ 4

Factory Calibration ........................... 4

Field Calibration ............................... 5

USER CONFIGURATION ........................ 6

Changing Conguration Settings ..... 6

K-Factor Entry Field Calibration ....... 6

MAINTENANCE ...................................... 6

SPECIFICATIONS ................................... 7

SERVICE ................................................. 8

Returning Parts ................................ 8

LIMITED WARRANTY ........................... 12

INTRODUCTION

The Q09 display is specically

designed to operate with the

electronics housed within the cover

plate. The display is mounted on a

specialized cover plate containing

other electronics and together they

make up the total Q09 electronics

package. The electronics in the

cover plate (QSB [not available

as adapter kit]) or (QSI1, QSI2 or

QSI3) when externally powered,

provides correctly adjusted power

to the display via a 10 pin bridge

connector. Information on the

operation, capabilities and wiring of

the electronics within the cover plate

that is mated to your Q09 display

is contained in its own dedicated

manual (QSB, QSI1, QSI2, QSI3).

920896-03 Rev B03/2018

Page 2

The display microprocessor

electronics have extremely low power

requirements and high data retention

capabilities in both RAM and ROM.

Information is clearly displayed on

a large 6-digit LCD readout with

two-point oating decimal for totals

from .01 to 999,999. All operations

are easily accessed with the two

buttons on the front panel.

The Q09 display is available mounted

to the meter you ordered or as a

kit that adapts the electronics to

other GPI meters. The electronics

inside the cover plate converts

the voltage (or pulses) from the

meter into usable information. This

information, along with power, is

supplied to the display that translates

the information into calibrated ow

units shown on the display’s readout.

The display is a precision measuring

instrument and should be handled

as such. Refer to the Specications

Section to conrm required features.

IMPORTANT NOTICE

Q09 displays are very sensitive to

electric noise if operated within 6

inches of some electric motors,

relays, transformers or other

sources of electronic noise.

If the Q09 Display is used in

a manner not specied by the

manufacturer, the protection provided

by the equipment may be impaired.

SAFETY

• This product is not approved

for use in hazardous locations.

• Be sure O-rings and seals

are kept in good repair.

• When applying power, adhere to

specications in this manual.

• Disconnect external power

before attaching or detaching

input or output wires.

WARNING: Product should

never be operated outside its

published specications for

temperature or pressure. See

specications for your model.

CAUTION: Installation near

high electromagnetic elds

and high current elds is not

recommended and may result

in inaccurate readings.

INSTALLATION

If you ordered your Q09 display

with a meter, it is installed at the

factory. If you ordered your Q09

display separately from a meter (i.e.

repair part), follow the instructions

below to install on a QSE meter. If

you ordered your Q09 display with

one of our several types of meter

adapter kits, follow the separate

instructions enclosed with the kit to

install the unit. In every case, please

review and thoroughly understand

all manuals and installation

instructions before proceeding.

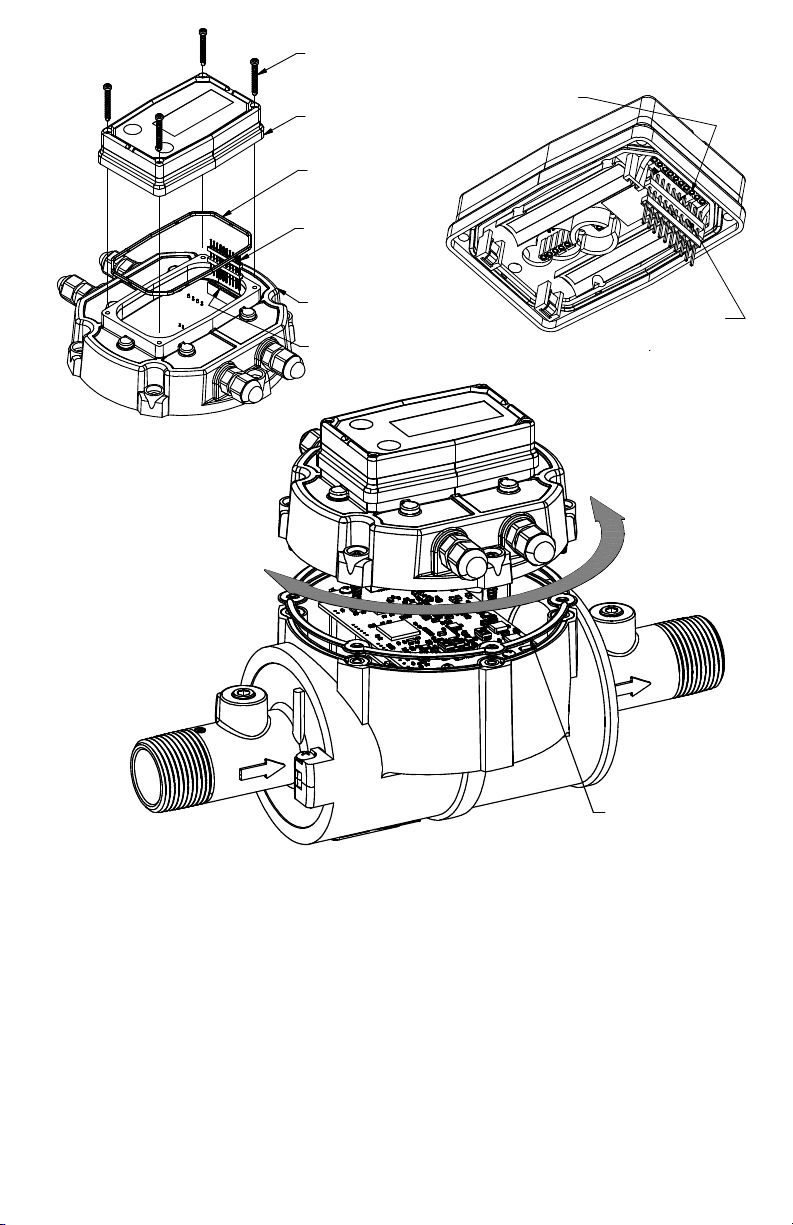

• Make sure the seal is seated

in its groove on the bottom of

the display (see Figure 1).

• Insert the long pins of the

10 pin bridge connector

about half-way into the 10

pin PC board connector.

• Then, align the 10 pin connector

on the display with the short pins

on the 10 pin bridge connector

and engage pins using gentle

force until the display is seated

on the cover plate (see Figure 2).

2

Page 3

(4) SCREWS

10 PIN SOCKET

Figure 1

DISPLAY

SEAL

10 PIN BRIDGE

CONNECTOR,

SHORT PINS UP

COVER PLATE

10 PIN PC BOARD

CONNECTOR

CONNECTER

10 PIN BRIDGE

CONNECTOR

Figure 2

• When the display is seated

Figure 3

on the cover plate, the pins

are fully engaged. Secure the

display to the cover plate with

the four screws at the corners

of the faceplate. Make sure

the seal is fully seated before

tightening the screws.

COVER PLATE

SEAL

QSE meters are designed to

measure ow in only one direction.

If the display is upside down in

your installation, remove the six

screws retaining the cover plate to

the meter, turn the cover plate with

display as required and reinstall the

screws. A ribbon cable connects the

electronics within the cover plate to

electronics within the meter body

and allows 180 degrees of movement

in either direction. Make sure the

cover plate seal is fully seated before

tightening the screws (see Figure 3).

3

Page 4

DISPLAY

OPERATION

When uid is owing through

the meter, a small propeller

icon is highlighted.

All operations are reected in the

LCD readout. The large center

digits indicate amounts, where

smaller words or “icons” located

above and below indicate specic

information regarding totals, ow,

calibration and units of measure.

Activate the Meter: When power is

supplied to the meter, the display

automatically becomes active, is

on continuously and always ready

to perform. It remains active until

meter power is disconnected.

BATCH AND CUMULATIVE TOTALS

The display maintains two totals.

The Cumulative Total provides

continuous measurement and

cannot be manually reset. The Batch

Total can be reset to measure ow

during a single use. The Cumulative

Total is labeled TOTAL 1, Batch

Total is labeled TOTAL 2 BATCH.

When the Cumulative Total reaches

a display reading of 999,999 the

display will highlight an X10 icon.

This indicates to the operator that a

zero must be added to the 6 digits

shown. When the next rollover

occurs, the display will highlight

an X100 icon. This indicates to

the operator that two zeros must

be added to the 6 digits shown.

Press the DISPLAY button

briey to switch between the

TOTAL 1, TOTAL 2 BATCH and

FLOWRATE. When TOTAL 2 BATCH

is displayed, you can hold the

DISPLAY button for 3 seconds to

reset the Batch Total to zero.

4

Flowrate Feature: To use this feature,

press and release DISPLAY button

until FLOWRATE icon appears.

The factory set time base will be

highlighted to the right of FLOWRATE

(M = minutes, H = hours, D = days).

When FLOWRATE is invoked, the

display will be indicating rate of ow.

CALIBRATION

FACTORY CALIBRATION

All Q09 Displays

All calibration units are visible to the

user as icons on the top line of the

display, above the numeric digits.

All units are congured with a

“factory” calibration. Both gallons

and litres are available (“GL” or “LT”

will be displayed). While holding

the CALIBRATE button, briey

press DISPLAY to toggle between

gallons and litres. This factory

calibration (indicated with FAC) is

permanently programmed into the

display and is not user adjustable.

NOTE: Your display may have other

units of measure programmed into

it. If so, holding the CALIBRATE

button and momentarily pressing the

DISPLAY button will toggle through

all factory set units. Other possible

units are: IGL (imperial gallon), QT

(quart), CF (cubic feet), CM (cubic

meter), BL (42 gal. barrel), CC

(cubic centimeter) or OZ (ounce).

Switching between different units will

not corrupt the Total’s contents. For

example, in GL mode, the display

totalizes 10.00 gallons, if the user

switches to LT mode, the display will

Page 5

read 37.85 litres (the same volume,

different unit). The “eld” calibration

may be set by the user, and can be

changed or modied at any time

using the calibration procedure

described in the Field Calibration

Section. Totals or owrate derived

from the eld calibration are invoked

when the FAC icon is no longer

visible on the top line of the display.

Factory calibration settings are

programmed into each display

during manufacturing, using water

at 70° F (21° C). Readings using

the Factory Calibration (FAC) may

not be accurate in some situations.

For example: Under extreme

temperature conditions, nonstandard plumbing congurations

or with uids other than water.

FIELD CALIBRATION

If the meter is suspected of being

incorrect, eld calibration is a method

of adjusting the meter K-factor to

compensate for error causing factors.

The method of eld calibration is

dependent on the electronics that

is mated with your Q09 display.

NOTE: Q09 displays not mated to

QSI electronics will use the manual

entry Correction Factor Method

outlined below.

The manual entry method of eld

calibration outlined below is disabled

when the Q09 display is mated with

QSI electronics. The QSI electronics

becomes the controlling element

that manages the manual calibration

entries for the display. This eld

calibration method is available in

the QSI Android Application noted

in the QSI owner’s manual.

Q09 Displays Not Mated

to QSI Electronics

A manual entry method using the

buttons on the Q09 display is used.

This method adjusts the K-factor by

percentages to match the display

volume with actual volume.

Calibration Using Display

(Correction Factor Method)

Field Calibration and Factory

Calibration were outlined previously

in the Calibration Section.

1. To eld calibrate, press and

hold the CALIBRATE and

DISPLAY buttons for about 3

seconds until you see FLdCAL.

Release both buttons and you

will see CF - 00.0. You are now

in the eld calibration mode

and values from -99.9% to

+99.9% can be entered.

2. The +/– position appears either

as an “underscore” character

for positive, or as a “hyphen”

character for negative. The

DISPLAY button selects the

position and the CALIBRATE

button toggles this character.

3. The DISPLAY button can then

be pushed to select the numeric

positions. Press the CALIBRATE

button to scroll from 0 to 9. Enter

the percentage of change you

want the display to correct. When

satised with the value, press

both CALIBRATE and DISPLAY

buttons simultaneously. CALEnd

will be displayed and unit will go

back to normal operation, less

the FAC (factory calibration) icon.

4. All enabled units-of-measure

remain visible and selectable –

the entered correction will be

applied to all enabled units.

5. To return to factory calibration

(FAC), press and hold both

CALIBRATE and DISPLAY

buttons for about 3 seconds

until FAcCAL is displayed. Then

release buttons. The unit should

return to normal operation

and FAC icon is visible.

5

Page 6

USER CONFIGURATION

The Q09 display has been

programmed with many features,

most of which can be enabled by the

end user by way of a conguration

process. By disabling “unnecessary”

features, day-to-day owmeter

operation can be greatly simplied,

making the unit easier to use.

There are several features that are

disabled by default when shipping

standard meters. (For example,

K-Factor Entry Field Calibration,

described below.) For more

advanced users, it may be desirable

to enable ALL possible features.

User congurable features include:

• Totalizers/Modes Enabled

(Cumulative Total, Batch 2

Total, Flowrate Mode).

• Flowrate Timebase

(Minute, Hour, Day).

• Factory Calibration Curve Units

Enabled – Gallons, Litres, Imperial

Gallons, Quarts, Ounces, Cubic

Feet, Cubic Centimeters, Cubic

Meters or Barrels (42 Gal).

• Dispense/Display or K-Factor

Entry Calibration.

CHANGING CONFIGURATION SETTINGS

Q09 Displays Not Mated

to QSI Electronics

NOTE: Q09 displays not mated to

QSI electronics can use the manual

entry method outlined below.

The manual entry method of

changing conguration settings

outlined below is disabled when

the Q09 display is mated with QSI

electronics. The QSI electronics

becomes the controlling element that

manages the manual conguration

entries. This conguration setting

method is available in the QSI

Android Application noted in

the QSI owner’s manual.

Access to the conguration process

is restricted for security until a

“password” is entered. Contact

your distributor or GPI to get the

password and instructions to unlock

and reset conguration settings.

This information is also available at

www.FLOMEC.net. Congurations

are entered and stored as six-digit

“codes” where each digit represents

a setting for one of the conguration

options. New conguration settings

are stored in the display’s long-term

memory and will not be lost either in

OFF mode or during electrical failure.

K-FACTOR ENTRY FIELD CALIBRATION

Presently all displays are

programmed with three different

eld calibration methods, only one

of which is active, the “correction

factor” calibration procedure

described above. It is possible

to activate “K-Factor entry” or

“dispense/display” eld calibration

by changing conguration settings.

Contact your distributor or GPI to get

the correct password, conguration

code and instructions for this

calibration method. This information

is also available on the GPI Web site.

MAINTENANCE

The display is virtually maintenancefree. However, it is important

to keep the display clean and

free of contaminants.

6

Page 7

SPECIFICATIONS

STANDARD FEATURES

• 2 Totalizing Registers

• 1 Factory Calibration Curve

• 1 Field Calibration Curve

• Rate of Flow Feature

• Flowrate Time Base in Minutes

INPUT PULSE RATE

Minimum Pulse In: DC

Minimum

Coil Input:

Maximum Raw: 1,000 Hz

Minimum: .01 pulses/unit

Maximum:

FIELD CALIBRATION

Minimum: -99.9%

Maximum: +99.9%

READOUT TOTALS

Min. Display: 0.01

Max. Display: 999,999 (x100)

TEMPERATURES

Operational:

Storage:

Ambient Air

Operation

Temperature

10 Hz

K-FACTOR

999,999

pulses/unit

CORRECTION

+0° to +140° F

(-18° to +60° C)

-40° to +158° F

(-40° to +70° C)

0°F to +140°F

(-18°C to +60°C)

INTERNAL POWER

SUPPLY TO DISPLAY

5 VDC provided

by a 10 pin

bridge connector

from cover plate

Voltage

Requirement:

Pollution

Degree

Installation

Category

electronics.

External power to

meter is required

to provide

necessary internal

power to display.

ELECTRICAL

2

1

Altitude 2000m Max.

Indoor use only

7

Page 8

SERVICE

The Waste Electrical and Electronic

Equipment (WEEE) directive

(2002/96/EC) was approved by the

European Parliament and the Council

of the European Union in 2003. This

symbol indicates that this product

contains electrical and electronic

equipment that may include bat-

teries, printed circuit boards, liquid

crystal displays or other components that may be subject

to local disposal regulations at your location. Please

understand those regulations and dispose of this product

in a responsible manner.

For warranty consideration, contact

your local distributor. If you need

further assistance, contact the GPI

Customer Service Department at:

o obtain prompt, efcient

T

service, always be prepared with

the following information:

1. The model number of

your display electronics.

2. The serial number and

manufacturing date code

of the FLOMEC® meter the

display is attached to.

3. Specic information about part

numbers and descriptions.

For warranty work always be

prepared with your original sales slip

or other evidence of purchase date.

RETURNING PARTS

Please contact the factory before

returning any parts. It may be

possible to diagnose the trouble

and identify needed parts in a

telephone call. GPI can also

inform you of any special handling

requirements you will need to

follow covering the transportation

and handling of equipment

which has been used to transfer

hazardous or ammable liquids.

RoHS Compliant (2011/65/EU)

This product is in compliance with

the RoHS Directive of the European

Parliament and of the Council on

the Restriction of the Use of Certain

Hazardous Substances in Electrical

and Electronic Equipment.

CAUTION: Do not return equipment

without specic authority from the

GPI Customer Service Department.

Due to strict regulations governing

transportation, handling, and

disposal of hazardous or ammable

liquids, GPI will not accept

equipment for rework unless it is

completely free of liquid residue..

8

Page 9

91011

Page 10

Page 11

Page 12

© 2018 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc.

920896-03 Rev B03/2018

Loading...

Loading...