Page 1

PRODUCT CONFIGURATION

OM SERIES SMALL CAPACITY (OVAL GEAR METERS)

The FLOMEC® OM Small Capacity Oval Gear Meters have a

large ow range and offer the ability to handle a wide range of uid

viscosities with exceptional levels of repeatability.

FEATURES / BENEFITS

• High accuracy and repeatability, direct volumetric reading

• Measures high and low viscosity liquids

• No requirement for ow conditioning (straight pipe runs)

• Stainless Steel rotors (Optional PPS rotor for OM008 meter only)

• Quadrature pulse output option and bi-directional ow

• Optional Exd I/IIB approval (ATEX, IECEx)

• Only two moving parts

PRODUCT IDENTIFIER

OM = Oval Gear Meter

METER SIZE

004 = 1/8" (4 mm), 0.26-9.5 GPH (1.0-36 L/hr)

006 = 1/4" (6 mm), 0.5-27 GPH (2-100 L/hr)

008 = 3/8" (8 mm), 4-145 GPH (15-550 L/hr)

BODY MATERIAL

A = Aluminum

S = 316 Stainless Steel

N = Intermediate Pressure 316L SS (1450 PSI / 100 bar)

ROTOR MATERIAL / BEARING TYPE

00 = PPS (Not available for 300º F (150º C) meters) / No bearing

(Available for OM008 only)

51 = Stainless Steel / Carbon Ceramic (Standard on OM004 &

OM006, optional for OM008)

71 = Keishi cut Stainless Steel (For high viscosity liquids) / Carbon

Ceramic (Available for OM008 only)

O-RING MATERIAL

1 = FKM (Viton™) -5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™) 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-2 = 250º F (120º C) max.

-3 = 300º F (150º C) max. (Hall Effect)(Includes Stainless Steel

terminal cover)

-5 = 250º F (120º C) max. (includes integral cooling n)

-8 = 176º F (80º C) max. (meters with integral instruments, OM008

with PPS rotors)

PROCESS CONNECTIONS

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

B = Bottom entry manifold (SS body only)

CABLE ENTRIES

1 = M20 x 1.5 mm (M16 x 1.5 mm for R4 options)

2 = 1/2" NPT

6 = 3 x 16mm drilled holes (for F instruments only)

2

1

3

4

5

6

7

8

INTEGRAL OPTIONS

__ = Combination Reed Switch and Hall Effect Sensor

SS = Stainless Steel terminal cover

RS = Reed Switch only - to suit Intrinsically safe installations

E1 = Explosion proof Exd IIB T3...T6 (Aluminum & Stainless Steel

meters) [IECEx & ATEX approved]

E2 = Explosion proof Exd I/IIB T3...T6 (Stainless Steel meters only)

[IECEx & ATEX mines approved]

QP = Quadrature pulse (2 NPN phased outputs)

Q1 = Explosion proof ~ Exd (with quadrature pulse) [IECEx & ATEX

approved]

HR = High Resolution Hall Effect output (004 – 006 only)

H1 =

Explosion proof ~ Exd with HR Hi-Res. Hall option (004-006 only)

R3 = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved]*#

R3G = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved] (with gallons calibration)*#

R4 = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia)*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy hous

ings with facia) (with gallons calibration)*#

R5

= RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing)

(with gallons calibration)*#

E18 = E018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, aluminium body [IECEx & ATEX approved]#

E19 = E018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, stainless steel body [IECEx & ATEX approved]#

F18 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART#

F19 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, Intrinsically safe# [IECEx & ATEX approved]

F31 = Intrinsically safe F130 2 stage batch controller# [IECEx &

ATEX approved]

9

-

*Temp code 5 required for integral instruments between 176F (80C) & 250F (120C)

#Temp code 8 required for integral instruments below 176F (80C)

1 2 3 4 5 6 7 8 9

--->>>> OM 006 A 51 2 -8 2 1 R5

Page 2

© 2019 Great Plains Industries, Inc. All Rights Reserved.

SPECIFICATIONS

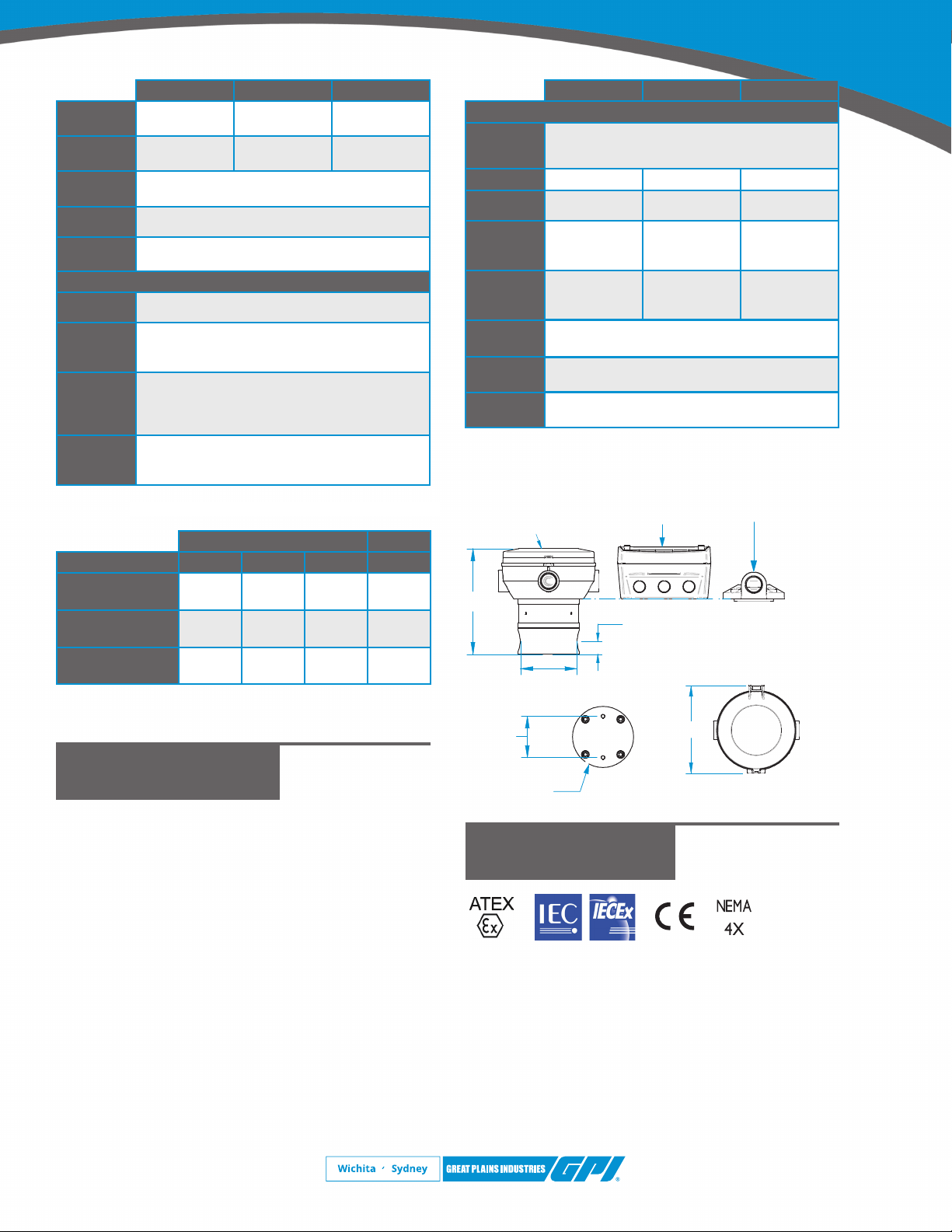

B

C

RT12 / RT14

GRN HOUSING

RT40

COVER

OM008: 5/8" (16 mm)

OM004 & OM006: 7/16" (12.5 mm)

MOUNTING

FOOTPRINT

1.97”

(50 mm)

2.68” (68 mm)

OM004 OM006 OM008

Nominal

Size:

Flow*

Range:

Accuracy

3cp:

Repeatability:

Temperature

Range:

Pressure Rating (Threaded Meter):

Aluminum 220 psi (15 bar)

316

Stainless

Steel

Intermediate

Pressure

Stainless

Steel

Recommended

Filtration:

+

@

1/8"

(4 mm)

0.26-9.5 GPH

(1.0-36 L/hr)

± 1.0% of reading (accuracy is ± 0.2% of reading with

optional RT14 with non-linearity correction)

Typically ± 0.03% of reading

-40° F to +300° F (-40° C to +150° C)

1/4"

(6 mm)

0.5-27 GPH

(2-100 L/hr)

495 psi (34 bar)

1450 psi (100 bar)

200 mesh (75 µm)

3/8"

(8 mm)

4-145 GPH

(15-550 L/hr)

OM004 OM006 OM008

Electrical:

Output

Pulse

Resolution:

Reed Switch 10600 (2800) 3975 (1050) 1345 (355)

Hall Effect 10600 (2800) 3975 (1050) 2690 (710)

QP Quadrature

Hall option

HR - High

Resolution

Hall Effect

Reed Switch

Output

Hall Effect

Output (NPN)

Optional

Outputs

*Maximum ow is to be reduced as viscosity increases, see ow de-rating

guide. Max recommended pressure drop is 14.5 psi (1 bar).

+

When used to meter rate, at very low ow rates, the rate can jump, due to

resolution (not accuracy).

Pulses / gallon (Pulses / L) - Nominal

10600 (2800) 3975 (1050) 2690 (710)

42400 (11200) 15900 (4200) n/a

30V (dc) x 200mA max. [maximum thermal shock 18 F

(10 C) / minute]

3 wire open collector, 5-24V (dc) max., 20mA max.

4-20mA, scaled pulse, quadrature pulse, ow alarms or

two stage batch control

DIMENSIONS

B C

OPTION OM004 OM006 OM008 —

RT12 / RT14 GRN

HOUSING

RT40

COVER

4.8"

(122 mm)

4.9"

(125 mm)

3.6"

(92 mm)

4.8"

(122 mm)

4.9"

(125 mm)

3.6"

(92 mm)

*All dimensions are ± .079” (±2mm)

5.0"

(129 mm)

5.2"

(132 mm)

3.9"

(99 mm)

APPLICATIONS

• Oils

• Fuel

• Diesel

• Truck Metering

• Chemical Additive Injection

• Batching

• Molasses

• Clean Fluids

• Bunker C Fuel Oil

• Oil-Based Paints

• Industrial Fluids

• Chemical Feed Lines

4.9"

(124 mm)

3.8"

(96 mm)

2.8"

(72 mm)

C

APPROVALS

IP66/67

03/19 IND-1043_OM_SMALL

Loading...

Loading...