GPI - Great Plains Industries FLOMEC OM Series Catalog Page

PRODUCT CONFIGURATION

OM SERIES MECHANICAL FLOWMETER

Volumetric ow measurement of clean liquids. Suitable for

applications for safe area metering of fuel oils, lubricants, and

other non-ammable viscous chemicals.

FEATURES / BENEFITS

• High accuracy oval gear technology with low pressure

drop can be used in gravity-fed applications

• No requirement for ow conditioning or straight pipe

runs makes them ideal for compact installations with

limited space

• Robust aluminum mechanical registers

• Optional air eliminator/strainers

POSITIVE DISPLACEMENT FLOWMETERS (OVAL GEAR)

PRODUCT IDENTIFIER

OM = Oval Gear Meter

METER SIZE

015 = 1/2” (15 mm), 0.26-10.6 GPM (1-40 L/min)

025 = 1” (25 mm), 2.6-40 GPM (10-150 L/min)

040 = 1 1/2” (40 mm), 4-66 GPM (15-250 L/min)

050 = 2” (50 mm), 8-130 GPM (30-500 L/min) (PPS rotors)

080 = 3” (80 mm), 10-200 GPM (35-750 L/min)

080E = 3” Extended ow (80 mm), 13-260 GPM (50-1000 L/min)

100 = 4” (100 mm), 20-400 GPM (75-1550 L/min)

100E = 4” Extended Flow (100 mm), 40-660 GPM (150-2500 L/

2

min) (only available with Aluminum Rotors)

BODY MATERIAL

A = Aluminum

E = Extended ow Aluminum (OM080E & OM100E)

S = 316L Stainless Steel (OM015 -OM080)

ROTOR MATERIAL / BEARING TYPE

00 = PPS / No Bearing

10 = Keishi cut PPS / No Bearing

44 = Aluminum / hardened steel roller bearing (OM100E only)

51 = Stainless Steel / Carbon Ceramic (OM015-OM080)

71 = Keishi cut, Stainless Steel / Carbon Ceramic (OM015-OM080)

(for high viscosity liquids)

O-RING MATERIAL

1 = Viton™ 5º F minimum (-15º C)

3 = Teon encapsulated Viton™ (includes KALREZ shaft seals on

080 - 100E sizes) 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

1

3

4

5

PROCESS CONNECTIONS

00 = No ttings (025-100E)

10 = BSPP (G) female threaded (ISO 228)

20 = NPT female threaded

40 = ANSI-150 RF Flanged

50 = ANSI-300 RF Flanged (015-050)

60 = PN16 DIN Flanged

MECHANICAL REGISTERS

M3 = 4 digit mechanical totalizer - litre

Totalizer capacity

(OM015-OM040) 9999.9 litre

(OM050-OM100E) 99999 litre

M4 = 4 digit mechanical totalizer - US gallons

Totalizer capacity

(OM015-OM040) 9999.9 gallon

(OM050-OM100E) 99999 gallon

V1 = 5 digit mechanical reset register - litre

Total capacity

(OM50-OM100E) 999999 litre

7

8

1 2 3 4 5 6 7 8

--->>>> OM 100 A 51 1 -8 10 M3

APPLICATIONS

MAXIMUM TEMPERATURE LIMIT

-8 = 176º F (80º C) maximum

6

• Automotive

• Aviation

• Mining

• Power

• Chemical

• Pharmaceutical

• Food

• Paint

• Petroleum Industries

• Environmental Applications

19

SPECIFICATIONS

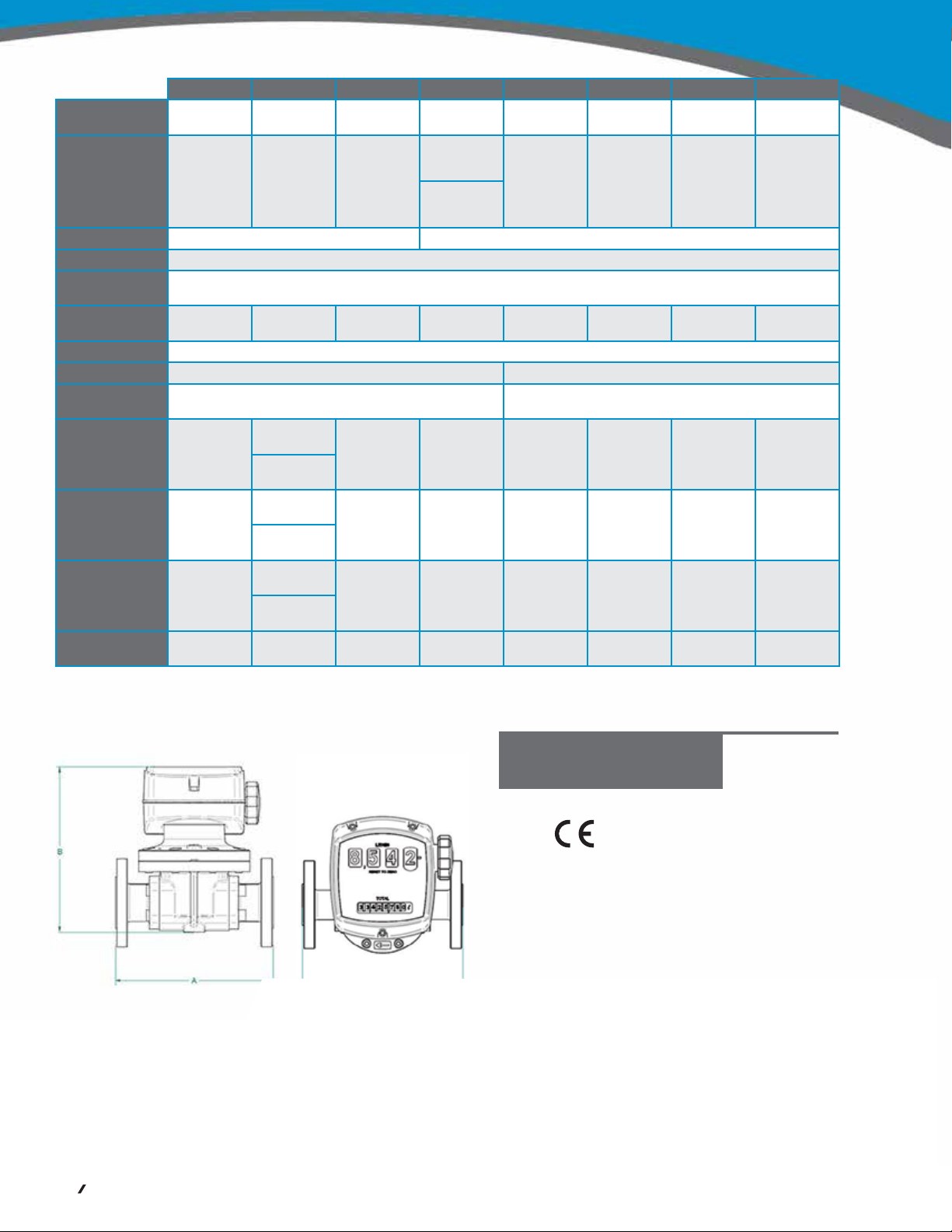

DIMENSIONS

OM015 OM025 OM040 OM050 OM080 OM80E OM100 OM100E

Nominal Size: 1/2” (15 mm) 1” (25 mm)

1-1/2” (40

mm)

2” (50 mm) 3” (80 mm) 3” (80 mm) 4” (100 mm) 4” (100 mm)

Nominal Flow

Range* @ 3cP:

0.26-10.6

GPM

(1 - 40

L/min)

2.6-40

GPM

(10-150

L/min)

4-66

GPM

(15-250

L/min)

8-118 GPM

(30-450 L/min)

(SS rotors)

10-200

GPM

(35-750

L/min)

13-260

GPM

(50-1000

L/min)

20-400

GPM

(75-1500

L/min)

40-660

GPM

(150-2500

L/min)

8-130 GPM

(30-500 L/min)

(PPS rotors)

Accuracy: ±1% of reading for M registers ±1% of reading for M registers (±0.5% for V registers)

Repeatability: Typically ± 0.03% of reading

Ambient Temp.

Range

5 F - 176 F (-15 C - 80 C)

Max. Pressure

(threaded)

580 psi

(40 bar)

580 psi

(40 bar)

435 psi

(30 bar)

285 psi

(20 bar)

175 psi

(12 bar)

175 psi

(12 bar)

145 psi

(10 bar)

145 psi

(10 bar)

M Register 4 digit resettable & NEMA 4 (IP65)

V Register n/a 5 digit resettable & NEMA 3S (IP54)

Recommended

Filtration:

100 mesh (150 m) 40 mesh (400 m)

Face-to-Face

Dimension A Threaded

4.33”

(110 mm)

5.39”

(137 mm) AL

7.4”

(188 mm)

8.35”

(212 mm)

10.5”

(266 mm)

11.6”

(294 mm)

11.6”

(294 mm)

12.6”

(320 mm)

6.93”

(176 mm) SS

Face-to-Face

Dimension A Flanged

7.44”

(189 mm)

7.8”

(198 mm) AL

9.92”

(252 mm)

10.91”

(277 mm)

13.93”

(354 mm)

15.04”

(382 mm)

15.28”

(388 mm)

16.3”

(414 mm)

9.33”

(237 mm) SS

Meter Base-toRegister Top Dimension B

7.01”

(178 mm)

7.4”

(188 mm) AL

8.94”

(227 mm)

9.33”

(237 mm)

10.63”

(270 mm)

11.34”

(288 mm)

13.11”

(333 mm)

16.4”

(416 mm)

8.43”

(214 mm) SS

Meter Cap Width

4.33”

(110 mm)

4.72”

(120 mm)

6.23”

(160 mm)

7.09”

(180 mm)

9.53”

(242 mm)

11.5”

(292 mm)

11.5”

(292 mm)

13.1”

(332 mm)

*Maximum ow reduces as viscosity increases, see ow de-rating guide.

Max recommended Pressure drop is 14.5 psi (1 bar).

APPROVALS

IP54/65

NEMA

3S / 4

PRODUCT IDENTIFIER

OM = Oval Gear Meter

METER SIZE

025 = 1" (25 mm), 2.6 - 40 GPM (10-150 L/min)

BODY MATERIAL

P = PPS

ROTOR MATERIAL / BEARING TYPE

00 = PPS / No bearing

10 = Keishi cut PPS / No bearing

O-RING MATERIAL

1 = FKM (Viton™) 5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™) 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-8 = 176º F (80º C) max.

PROCESS CONNECTIONS

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

CABLE ENTRIES

1 = M20 x 1.5 mm (M16 x 1.5 mm for R4 option)

2 = 1/2 in. NPT

6 = 3 x 16 mm drilled holes (for F instruments only)

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

QP = Quadrature pulse (2 NPN phased outputs)

QPN = Quadrature pulse (2 NPN phased outputs) with Australian NMI

& NZ approval for trade sale

R4 = RT40 rate totalizer with backlit large digit LCD [scalable pulse

output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing) (with

gallons calibration)*#

F18 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART#

OM SERIES CHEMICAL FLOW METER

The FLOMEC® Chemical Flow Meter provides precise volumetric

ow measurement of a broad range of clean water based products

and aggressive chemicals and is also suitable for most fuels, fuel

oils and lubricating liquids. Applications include batching, dosing

or packaging of various corrosive chemicals as a more economical

alternative to a complete 316 stainless steel meter for liquids such

as Diesel Exhaust Fluid (Adblue).

FEATURES / BENEFITS

• High accuracy & repeatability, direct reading ow meter

• No requirement for ow conditioning (straight pipe runs)

• Measures high & low viscosity liquids

• Quadrature pulse output option & bi-directional ow

• Optional NMI Pattern Approval (Australia Only)

PRODUCT CONFIGURATION

2

1

8

9

3

4

5

6

7

METER SELECTION

• PPS meters are used for non-aromatic/non-halogenated organic

chemicals, water based liquids, Diesel Exhaust Fluid and petro-

leum products including oils and grease, fuels and fuel oils. It is

unsuitable for strong acids and oxidizers.

• PPS meters with standard ceramic rotor pins are suitable for ap-

plications where stainless steel is not suited or permitted.

• Blind pulse meters are available with Reed Switch and Hall Ef-

fect outputs. Quadrature pulse and integral 4-20mA outputs are

optional.

1 2 3 4 5 6 7 8 9

--->>>> OM 025 P 10 1 -8 1 1 R5

20

Loading...

Loading...