Page 1

1 2 3 4 5 6 7 8 9

OM SERIES MEDIUM CAPACITY (OVAL GEAR METERS)

The FLOMEC® OM Medium Capacity Meters are great for medium

ow ranges and have the ability to handle a wide range of uid

viscosities.

FEATURES / BENEFITS

• High accuracy and repeatability, direct volumetric reading

• Measures high and low viscosity liquids

• Quadrature pulse output option and bi-directional ow

• Optional Exd I/IIB approval (ATEX, IECEx)

• No requirement for ow conditioning (straight pipe runs)

• Only two moving parts

PRODUCT IDENTIFIER

OM

= Oval Gear Meter

METER SIZE

015

= 1/2” (15 mm), 0.26-10.6 GPM (1-40 L/min)

025 = 1” (25 mm), 2.6-40 GPM (10-150 L/min)

040 = 1-1/2” (40 mm), 4-66 GPM (15-250 L/min)

050 = 2” (50 mm), 8-118 GPM (30-450 L/min) with SS Rotors

050 = 2” (50 mm), 8-130 GPM (30-500 L/min) with PPS Rotors

BODY MATERIAL

A

= Aluminum

M = Intermediate pressure aluminum meter (2000 psi [138 bar]

max.) (OM025 only)

S = 316L Stainless Steel

N = Intermediate Pressure 316L SS (OM015-OM025N = 1450 psi

[100 bar]) (OM040N-OM050N = 725 psi / 50 bar)

ROTOR MATERIAL / BEARING TYPE

00 =

PPS (not available for 300º F [150º C] meters) / No bearing

10 = Keishi cut PPS (for high viscosity liquids) (not available for

300º F [150º C] meters) / No bearing

51 = Stainless Steel / Carbon Ceramic

71 = Keishi cut Stainless Steel (for high viscosity liquids) / Carbon

Ceramic

O-RING MATERIAL

1

= FKM (Viton™) (standard for Alum.) 5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-2

= 250º F (120º C) max.

-3 = 300º F (150º C) max. (Hall Effect) (Includes Stainless Steel

terminal cover)

-5 = 250º F (120º C) max. (includes integral cooling n)

-8 = 176º F (80º C) max. (meters with integral instruments)

PROCESS CONNECTIONS

0

= No ttings (Not available on 015 size)

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

3 = Sanitary Fittings (are 1/2” (13 mm) larger than meter size)

4

= ANSI-150 RF Flanged

5 = ANSI-300 RF Flanged

6 = PN16 DIN Flanged

CABLE ENTRIES

1

= M20 x 1.5 mm (M16 x 1.5 mm for R4 option)

2 = 1/2 in. NPT

6 = 3 x 16 mm drilled holes (for F instruments only)

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

SS = Stainless Steel terminal cover

RS = Reed Switch only - to suit Intrinsically safe installations

E1 = Explosion proof Exd IIB T3...T6 (Aluminum & Stainless meters)

[IECEx & ATEX approved]

E2 = Explosion proof Exd I/IIB T3...T6 (stainless meters only) [IECEx

& ATEX mines approved]

QP = Quadrature pulse (2 NPN phased outputs)

QPN = Quadrature pulse (2 NPN phased outputs) with Australian

NZNMI approval for trade sale

Q1 = Explosion proof Exd (with quadrature pulse) [IECEx & ATEX

approved]

Q1N =

Explosion proof Exd (IECEx & ATEX) with Quadrature pulse with

Australian NMI & NZ approval for trade sale (Not available on 015 size)

R3 = Intrinsically safe RT12 with all outputs (GRN housing) [IECEx &

ATEX approved]*#

R3G = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved] (with gallons calibration)*#

R4 = RT40 rate totalizer with backlit large digit LCD [scalable pulse

output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy hous

-

ings with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing)

(with gallons calibration)*#

E18 = E018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, aluminium body [IECEx & ATEX approved] (Not available

with 015 size)#

E19 = E018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, stainless steel body [IECEx & ATEX approved] (Not avail

-

able with 015 size)#

F18 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART#

F19 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART, Intrinsically safe [IECEx & ATEX approved]#

F31 = Intrinsically safe F130 2 stage batch controller [IECEx & ATEX

approved]#

2

1

8

9

3

4

5

6

7

PRODUCT CONFIGURATION

--->>>> OM 025 A 51 2 -5 2 1 R4

*Temp code 5 required for integral instruments between 176F (80C) & 250F (120C)

#Temp code 8 required for integral instruments below 176F (80C) by 20%

POSITIVE DISPLACEMENT FLOWMETERS (OVAL GEAR)

11

Page 2

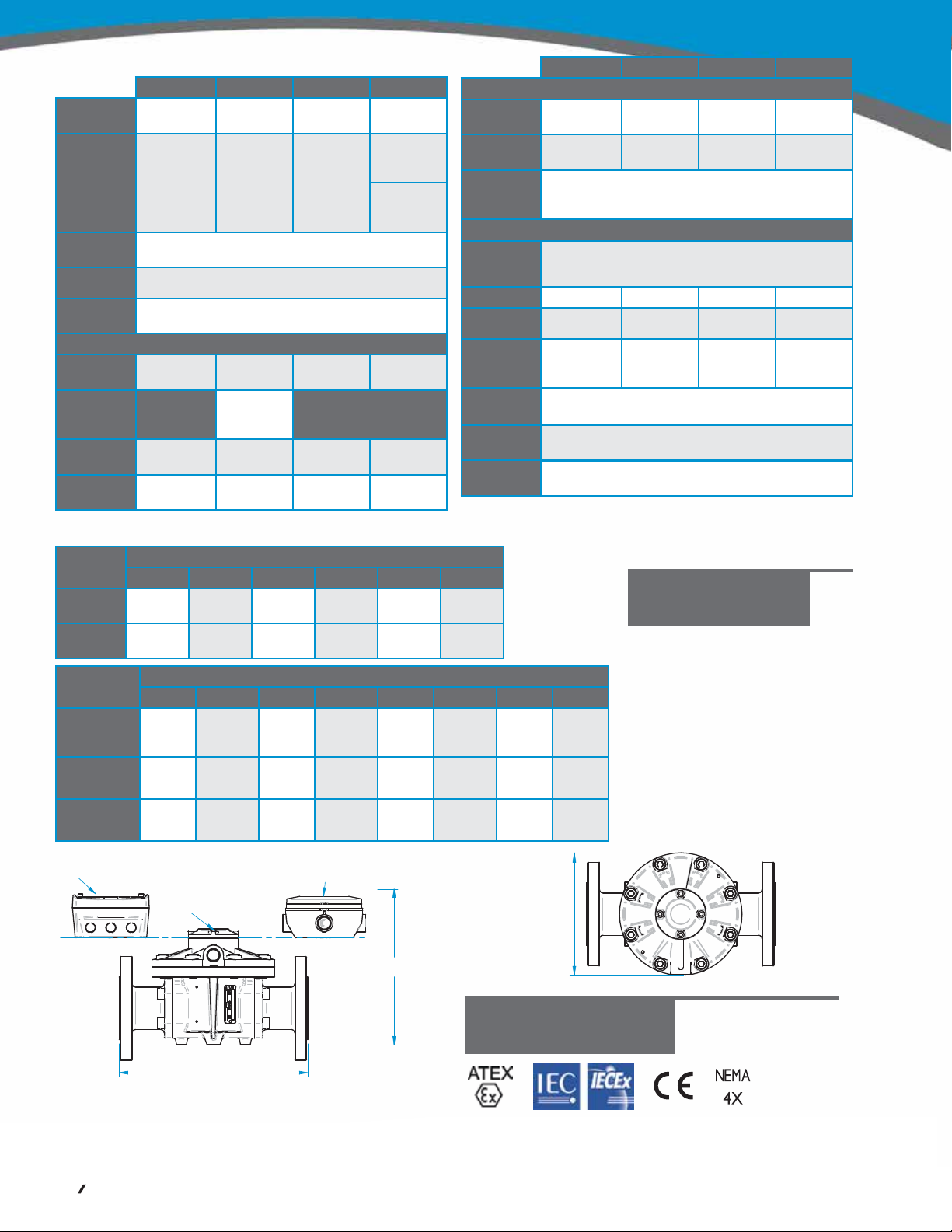

SPECIFICATIONS

A

RT40

RT12 / RT14

GRN HOUSING

COVER

B

*Maximum ow is to be reduced as viscosity increases, see ow de-rating guide.

Max recommended pressure drop is 14.5 psi (1 bar).

Modular

Fitting

A

OM015 OM025A

OM025S/N

OM040 OM050 OM050E

A.N.S.I. 150

DIN16

7.4”

(189 mm)

7.8”

(198 mm)

9.3”

(237 mm)

9.9”

(252 mm)

10.9”

(277 mm)

10.9”

(277 mm)

B.S.P

N.P.T.

4.3”

(110 mm)

5.4”

(137 mm)

6.9”

(176 mm)

7.4”

(188 mm)

8.3”

(212 mm)

8.3”

(212 mm)

DIMENSIONS

All dimensions are ± .079 (±2 mm)

APPLICATIONS

• Oils

• Fuel

• Diesel

• Truck Metering

• Bunker C Fuel

Oil

• Chemical Addi

-

tive Injection

• Batching

• Molasses

• Clean Fluids

• Oil-Based

Paints

• Industrial Fluids

• Chemical Feed

Lines

OM015 OM025 OM040 OM050

Nominal

Size:

1/2"

(13 mm)

1"

(25 mm)

1 1/2"

(38 mm)

2”

(51 mm)

*Flow

Range:

0.26-10.6

GPM

(1-40 L/min)

2.6-40

GPM

(10-150 L/min)

4-66

GPM

(15-250 L/

min)

8-118 GPM

(30-450 L/

min) (SS)

8-130 GPM

(30-500 L/

min) (PPS)

Accuracy

@3cp:

± 0.5% of reading (accuracy is ± 0.2% of reading with

optional RT14 with non-linearity correction)

Repeatability:

Typically ± 0.03% of reading

Temperature

Range:

-40° F to +300° F (-40° C to +150° C) refer to factory for

lower temperature

Pressure Rating (Threaded Meter):

Aluminum

990 psi

(68 bar)

990 psi

(68 bar)

435 psi

(30 bar)

285 psi

(20 bar)

Intermediate

Pressure

Aluminum

2000 psi

(138 bar)

316 Stainless

Steel

990 psi

(68 bar)

990 psi

(68 bar)

435 psi

(30 bar)

550 psi

(38 bar)

Intermediate

Pressure SS

1450 psi

(100 bar)

1450 psi

(100 bar)

725 psi

(50 bar)

725 psi

(50 bar)

OM015 OM025 OM040 OM050

Pressure Rating (Mechanical Meter):

Aluminum

580 psi

(40 bar)

580 psi

(40 bar)

435 psi

(30 bar)

285 psi

(20 bar)

316 Stainless

Steel

580 psi

(40 bar)

580 psi

(40 bar)

435 psi

(30 bar)

285 psi

(20 bar)

Recommended

Filtration

100 mesh (150 m)

Electrical:

Output

Pulse

Resolution:

Pulses / gallon (Pulses / L) - Nominal

Reed Switch 318 (84) 120 (27) 53 (14) 25 (6.5)

Hall Effect 636 (168) 405 (107) 212 (56) 99 (26)

QP Quadrature

Hall Option

636 (168) 204 (54) 106 (28) 49 (13)

Reed Switch

Output

30V (dc) x 200mA max. [maximum thermal shock 18 F

(10 C) / minute]

Hall Effect

Output (NPN)

3 wire open collector, 5-24V (dc) max., 20mA max.

Optional

Outputs

4-20mA, scaled pulse, quadrature pulse, ow alarms or

two stage batch control

Conguration

B

OM015A

OM015S/N OM025A OM025S/N

OM040A

OM040S/N

OM050 OM050E

RT12 / RT14

GRN Housing

6.0”

(154 mm)

5.8”

(148 mm)

6.6”

(168 mm)

6.5”

(165 mm)

7.9”

(203 mm)

7.6”

(194 mm)

8.6”

(218 mm)

10.5”

(268 mm)

RT40 Alloy

Housing

6.2”

(157 mm)

5.9”

(151 mm)

6.7”

(171 mm)

6.6”

(168 mm)

8.1”

(206 mm)

7.8”

(197 mm)

8.7”

(221 mm)

10.7”

(271 mm)

Cover

4.2”

(106 mm)

3.9”

(100 mm)

4.7”

(123 mm)

4.6”

(117 mm)

6.1”

(155 mm)

5.7”

(146 mm)

6.7”

(170 mm)

8.6”

(220 mm)

A

OM040: Ø6.3” (160 mm)

OM050: Ø7.1” (180 mm)

OM015: Ø4.3” (110 mm)

OM025: Ø4.7” (120 mm)

RT40

RT12 / RT14

GRN HOUSING

COVER

B

APPROVALS

IP66/67

OM SERIES LARGE CAPACITY(OVAL GEAR METERS)

The FLOMEC® OM Large Capacity Oval Gear Meters have tting

sizes of 3 inches and 4 inches, and handle volumetric ow measure-

ment of clean liquids used in a wide range of applications.

FEATURES / BENEFITS

• High accuracy and repeatability, direct volumetric reading

• Measures high and low viscosity liquids

• Quadrature pulse output option and bi-directional ow

• Optional Exd I/IIB approval (ATEX, IECEx)

• No requirement for ow conditioning (straight pipe runs)

• Only two moving parts

PRODUCT CONFIGURATION

PRODUCT IDENTIFIER

OM

= Oval Gear Meter

METER SIZE

080

= 3 inch (80mm), 10-200 GPM (35-750 L/min)

080E

= 3 inch Extended Flow (80mm), 13-260 GPM (50-1000 L/min)

100

= 4 inch (100mm), 20-400 GPM (75-1500 L/min)

100E = 4 inch Extended Flow (100mm), 40-660 GPM (150-2500 L/min)

(Only available with Aluminum Rotors)

BODY MATERIAL

A = Aluminum

E = Extended ow Aluminum version

S = 316L Stainless Steel (OM080 only)

ROTOR MATERIAL / BEARING TYPE

00

= PPS (not available for 300ºF (150ºC)) / No bearing

10 = Keishi cut PPS (for high viscosity liquids) (not available for 300ºF

(150ºC)) / No bearing

44 = Aluminum/Hardened Steel Roller (100E only)

51 = Stainless Steel / Carbon Ceramic (080 only)

71 = Keishi cut Stainless Steel rotors (for high viscosity liquids) /

Carbon Ceramic (080 only)

O-RING MATERIAL

1

= FKM (Viton™) -5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™) (included KALREZ shaft seals)

5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-2

= 250º F (120º C) max.

-3 = 300º F (150º C) max. (OM080 only) (Hall Effect output only)

-5 = 250º F (120º C) max. (includes integral cooling n)

-8 = 176º F (80º C) max. (meters with integral instruments)

PROCESS CONNECTIONS

0

= No ttings

1

= BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

4

= ANSI-150 RF Flanged

6 = PN16 DIN Flanged

CABLE ENTRIES

1

= M20 x 1.5 mm

2 = 1/2 in. NPT

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

SS = Stainless Steel terminal cover

RS = Reed Switch only - to suit Intrinsically safe installations

E1 = Explosion proof Exd IIB T3...T6 (aluminum & stainless meters)

[IECEx & ATEX approved]

E2 = Explosion proof Exd I/IIB T3...T6 (stainless meters only) [IECEx &

ATEX mines approved]

QP = Quadrature pulse (2 NPN phased outputs)

QPN = Quadrature pulse (2 NPN phased outputs) with Australian NMI

& NZ approval for trade sale

Q1 = Explosion proof Exd (with quadrature pulse) [IECEx & ATEX ap

-

proved]

Q1N = Explosion proof Exd (IECEx & ATEX) with Quadrature pulse with

Australian NMI & NZ approval for trade sale

R3 = Intrinsically safe RT12 with all outputs (GRN housing) [IECEx &

ATEX approved]*#

R3G = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved] (with gallons calibration)*#

R4 = RT40 rate totalizer with backlit large digit LCD [scalable pulse

output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing) (with

gallons calibration)*#

F18 = F018 backlit rate/tot. pulse out, 4-20mA, 10 pt lin, HART#

F19 = F018 Intrinisic Safe, backlit rate/tot. pulse out, 4-20mA, 10 pt

lin, HART [IECEx & ATEX approved]#

F31 = Intrinsically safe F130 2 stage batch controller [IECEx & ATEX

approved]#

2

1

8

9

3

4

5

6

7

*Temp code 5 required for integral instruments between 176F (80C) & 250F (120C)

#Temp code 8 required for integral instruments below 176F (80C)

--->>>> OM 025 A 51 2 -5 2 1 R5

1 2 3 4 5 6 7 8 9

12

Loading...

Loading...