GPI - Great Plains Industries FLOMEC OM Medium Capacity High Pressure Flow Meters Catalog Page

PRODUCT CONFIGURATION

OM SERIES MEDIUM CAPACITY HIGH PRESSURE

FLOMEC® OM Medium Capacity High Pressure Flow Meters

provide volumetric measurement of clean liquids for high pressure.

Suitable for applications including metering lubricants, chemicals,

grease, additives, and other high viscosity uids.

FEATURES / BENEFITS

• High accuracy and repeatability, direct volumetric reading

• No requirement for ow conditioning (straight pipe runs)

• Measures both high and low viscosity liquids

• Optional Exd I/IIB approval (ATEX, IECEx)

• High Pressure rated up to 5580 psi (400 bar) (4350 psi [300

bar] on 2 “ meter)

PRODUCT IDENTIFIER

OM

= Oval Gear Meter

METER SIZE

015

= 1/2” (15 mm), 0.26-10.6 GPM (1-40 L/min)

025

= 1” (25 mm), 2.6-40 GPM (10-150 L/min)

040

= 1.5” (40 mm), 4-66 GPM (15-250 L/min)

050 =

BODY MATERIAL

H

= High Pressure 316L SS

(5800 PSI / 400 bar)

(4350 PSI / 300 bar, 050 size)

ROTOR MATERIAL / BEARING TYPE

00 = PPS (Not available for 300ºF (150ºC) meters) / No bearing

10 = Keishi Cut PPS (for high viscosity liquids) (Not available for

300ºF (150ºC) meters) / No bearing

51 = Stainless Steel / Carbon Ceramic

71 = Keishi cut Stainless Steel (for high viscosity liquids) / Carbon

Ceramic

O-RING MATERIAL

1

= Viton™ 5º F minimum (-15º C)

3 = Teon encapsulated Viton™ 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-2

= 250º F (120º C) max.

-3+ = 300º F (150º C) max. (Hall Only) (includes SS terminal cover)

-5

= 250º F (120º C) max. (includes integral cooling n)

-8 = 176º F (80º C) max. (meters with integral instruments, OM008

with PPS rotors)

PROCESS CONNECTIONS

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

CABLE ENTRIES

1

= M20 x 1.5 mm (M16 x 1.5mm for R4 options)

2

= 1/2 “ NPT

6 = 3 x 16 mm drilled holes (for F instruments only)

2

2” (50 mm), 8-130 GPM (30-500 L/min) (PPS rotors)

1 9

3

4

5

6

7

8

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

SS = Stainless steel terminal cover]

RS = Reed Switch only - to suit Intrinsically Safe installations

E1 = Explosion proof Exd IIB T3...T6 [IECEx & ATEX approved]

E2 = Explosion proof Exd I/IIB T3...T6 [IECEx & ATEX mines approved]

R3 = Intrinsically Safe rate totalizer with all outputs (GRN housing)

[IECEx & ATEX approved]*#

R3G = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved] (with gallons calibration)*#

R4 = RT40 backlit rate totalizer with all outputs (Alloy housing with

facia protector) [scalable pulse output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN housing)

[scaled pulse, alarms, 4-20mA, backlight]*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing)

(with gallons calibration)*#

E18 = ATEX/IECEx EXd E018 backlit rate/tot, pulse, 4-20mA, lin,

HART (Al), Incl. Line Bushing [IECEx & ATEX approved]#

E19 =ATEX/IECEx EXd E018 backlit rate/tot, pulse, 4-20mA, lin, HART

(SS), Incl. Line Bushing [IECEx & ATEX approved]#

F18 = F018 backlit rate/tot, pulse out, 4-20mA, 10 pt lin, HART#

F19 = F018 Intrinsically Safe backlit rate/tot, pulse out, 4-20mA, 10

pt lin, HART#

F31 = F130 Intrinsically Safe 2 stage batch controller#

1 2 3 4 5 6 7 8 9

--->>>> OM 025 H 00 1 -5 1 1 R5

*Temp code 5 required for integral instruments between 176F (80C) & 250F (120C)

#Temp code 8 required for integral instruments below 176F (80C)

+

Option will de-rate meter pressure ratings by 20%

POSITIVE DISPLACEMENT FLOWMETERS (OVAL GEAR)

17

SPECIFICATIONS

PRODUCT IDENTIFIER

OM = Oval Gear Meter

METER SIZE

015 = 1/2” (15 mm), 0.26-10.6 GPM (1-40 L/min)

025 = 1” (25 mm), 2.6-40 GPM (10-150 L/min)

040 = 1 1/2” (40 mm), 4-66 GPM (15-250 L/min)

050 = 2” (50 mm), 8-130 GPM (30-500 L/min) (PPS rotors)

080 = 3” (80 mm), 10-200 GPM (35-750 L/min)

080E = 3” Extended ow (80 mm), 13-260 GPM (50-1000 L/min)

100 = 4” (100 mm), 20-400 GPM (75-1550 L/min)

100E = 4” Extended Flow (100 mm), 40-660 GPM (150-2500 L/

min) (only available with Aluminum Rotors)

BODY MATERIAL

A = Aluminum

E = Extended ow Aluminum (OM080E & OM100E)

S = 316L Stainless Steel (OM015 -OM080)

ROTOR MATERIAL / BEARING TYPE

00 = PPS / No Bearing

10 = Keishi cut PPS / No Bearing

44 = Aluminum / hardened steel roller bearing (OM100E only)

51 = Stainless Steel / Carbon Ceramic (OM015-OM080)

71 = Keishi cut, Stainless Steel / Carbon Ceramic (OM015-OM080)

(for high viscosity liquids)

O-RING MATERIAL

1 = Viton™ 5º F minimum (-15º C)

3 = Teon encapsulated Viton™ (includes KALREZ shaft seals on

080 - 100E sizes) 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-8 = 176º F (80º C) maximum

PROCESS CONNECTIONS

00 = No ttings (025-100E)

10 = BSPP (G) female threaded (ISO 228)

20 = NPT female threaded

40 = ANSI-150 RF Flanged

50 = ANSI-300 RF Flanged (015-050)

60 = PN16 DIN Flanged

MECHANICAL REGISTERS

M3 = 4 digit mechanical totalizer - litre

Totalizer capacity

(OM015-OM040) 9999.9 litre

(OM050-OM100E) 99999 litre

M4 = 4 digit mechanical totalizer - US gallons

Totalizer capacity

(OM015-OM040) 9999.9 gallon

(OM050-OM100E) 99999 gallon

V1 = 5 digit mechanical reset register - litre

Total capacity

(OM50-OM100E) 999999 litre

OM SERIES MECHANICAL FLOWMETER

Volumetric ow measurement of clean liquids. Suitable for

applications for safe area metering of fuel oils, lubricants, and

other non-ammable viscous chemicals.

FEATURES / BENEFITS

• High accuracy oval gear technology with low pressure

drop can be used in gravity-fed applications

• No requirement for ow conditioning or straight pipe

runs makes them ideal for compact installations with

limited space

• Robust aluminum mechanical registers

• Optional air eliminator/strainers

PRODUCT CONFIGURATION

2

1

3

4

5

6

7

8

APPLICATIONS

• Automotive

• Aviation

• Mining

• Power

• Chemical

• Pharmaceutical

• Food

• Paint

• Petroleum Industries

• Environmental Applications

1 2 3 4 5 6 7 8

--->>>> OM 100 A 51 1 -8 10 M3

Nominal Size: 1/2” (15 mm) 1” (25 mm) 1.5” (40 mm) 2” (50 mm)

Nominal Flow* Range @

3cP:

Accuracy:

Repeatability:

Max. Pressure - High

Pressure meter Bar [psi]

(threaded)

Protection Class:

Recommended

Filtration:

Electrical:

Output Pulse Resolution:

Reed Switch: 318 (84) 102 (27) 53 (14) 25 (6.5)

Hall Effect: 636 (168) 405 (107) 212 (56) 99 (26)

High Resolution Hall Effect:

Reed Switch Output:

Hall Effect Output:

OM015 OM025 OM040 OM050

8-118 GPM

0.26-10.6

GPM

(1 - 40 L/min)

± 0.5% of reading (± 0.2% of reading with optional RT14)

2.6-40

GPM

(10-150 L/min)

Typically ± 0.03% of reading

5800 psi (400 bar)

(15-250 L/min)

4-66

GPM

(30-450 L/min)

(SS Rotors)

8-130 GPM

(30-500 L/min)

(PPS Rotors)

4350 psi

(300 bar)

IP66/67 (NEMA 4X) optional EX-d I/IIB T4/T6, Integral ancillaries can

be supplied with I.S. (Intrinsically Safe)

100 mesh (150 μm)

Pulses / gallon (Pulses / L) - Nominal

636 (168) 204 (54) 106 (28) 49 (13)

30V (dc) x 200mA Max (Maximum thermal shock 18°F [10°C] /min)

3 wire open collector, 5 - 24V (dc) max, 20mA max.

APPLICATIONS

• Aviation

• Mining

• Power

• Chemical

• Pharmaceutical

• Food

• Paint

• Petroleum Industries

• Environmental

APPROVALS

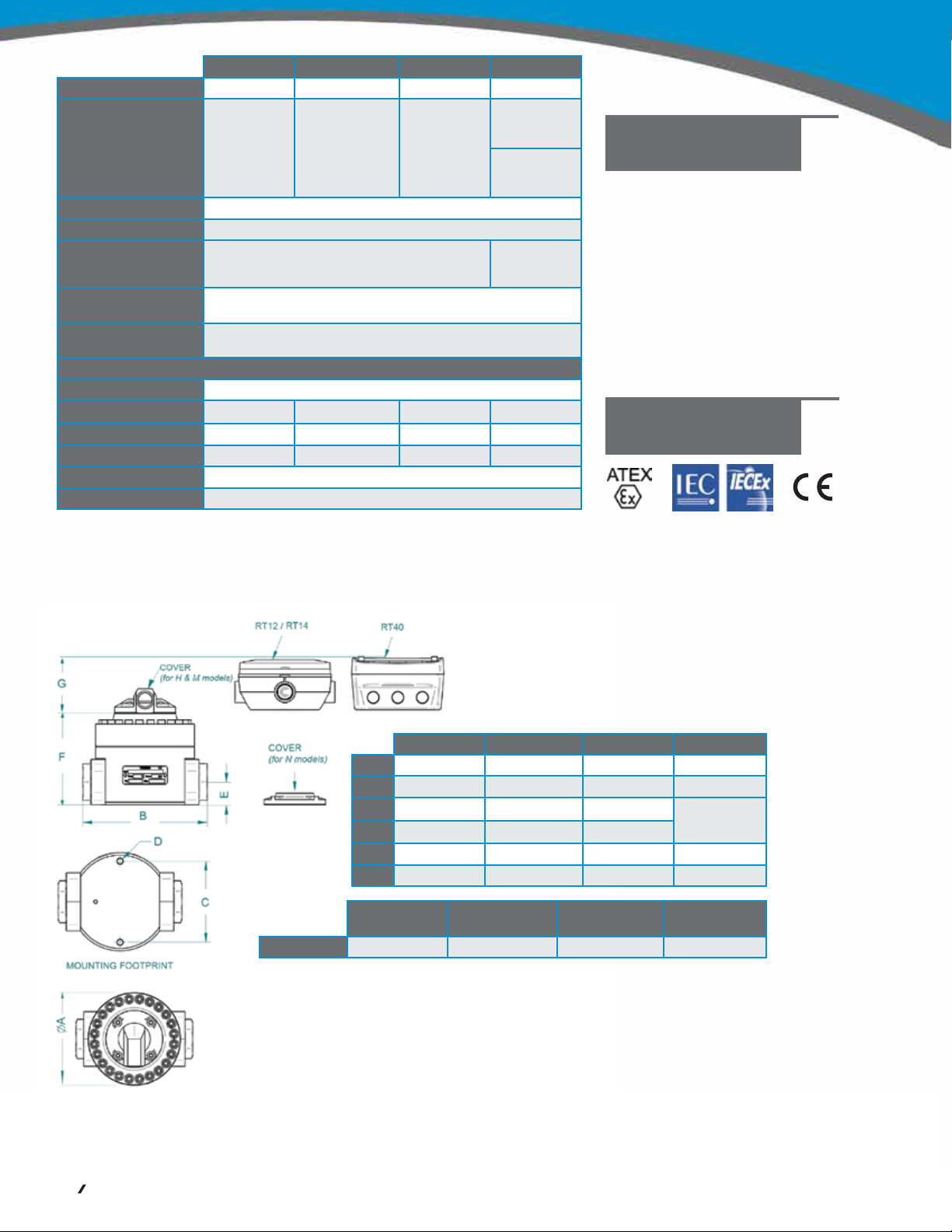

DIMENSIONS

All dimensions are ± .079” (±2 mm)

*Maximum ow reduces as viscosity increases,

see ow de-rating guide. Max recommended

Pressure drop is 14.5 psi (1 bar).

OM015H OM025H OM040H OM050H

4.72” (120 mm)

A

4.41” (112 mm) 6.03” (152 mm) 8.54” (217 mm)

B

C

3.62” (92 mm) 3.90” (99 mm) 5.28” (134 mm)

D M10 x 13 M8 x 16

E

1.02” (26 mm) 1.08” (27.5 mm) 1.54” (39 mm)

4.62” (92 mm) 4.41” (112 mm) 6.18” (157 mm

F

RT12 / RT14 RT40

G 2.41” (61 mm) 2.48” (63 mm) 0.51” (13 mm) 1.26” (32 mm)

4.72” (120 mm)

6.30” (160 mm)

M10 x 16

COVER

(N Meters)

7.09” (180 mm)

9.29” (236 mm)

consult distributor for mounting

footprint

2.01” (51 mm)

) 6.77” (172 mm)

COVER

(H & M Meters)

18

Loading...

Loading...