Page 1

PRODUCT CONFIGURATION

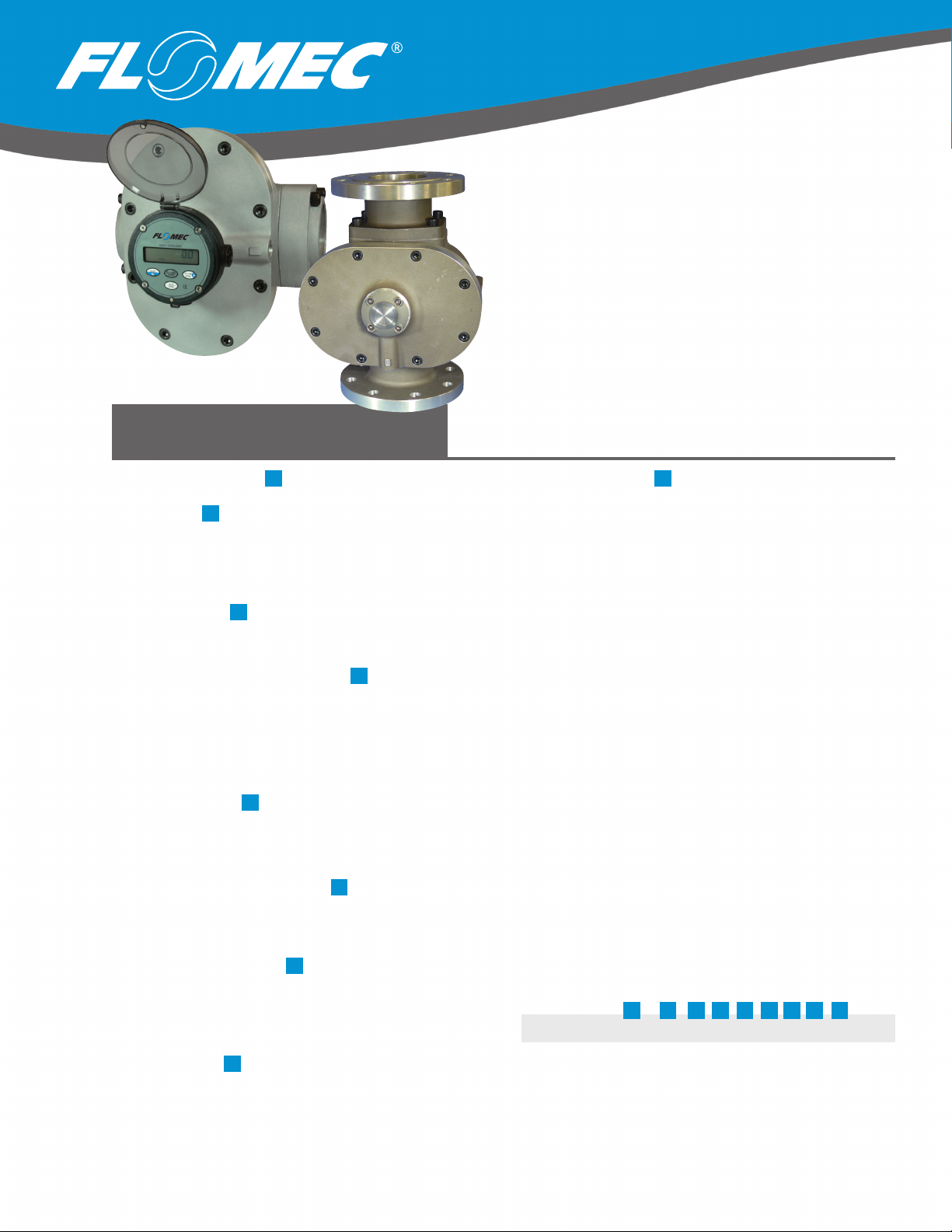

OM SERIES LARGE CAPACITY (OVAL GEAR METERS)

The FLOMEC® OM Large Capacity Oval Gear Meters have tting

sizes of 3 inches and 4 inches, and handle volumetric ow measurement of clean liquids used in a wide range of applications.

FEATURES / BENEFITS

• High accuracy and repeatability, direct volumetric reading

• Measures high and low viscosity liquids

• Quadrature pulse output option and bi-directional ow

• Optional Exd I/IIB approval (ATEX, IECEx)

• No requirement for ow conditioning (straight pipe runs)

• Only two moving parts

PRODUCT IDENTIFIER

OM

= Oval Gear Meter

METER SIZE

080

= 3 inch (80mm), 10-200 GPM (35-750 L/min)

080E

= 3 inch Extended Flow (80mm), 13-260 GPM (50-1000 L/min)

100

= 4 inch (100mm), 20-400 GPM (75-1500 L/min)

100E = 4 inch Extended Flow (100mm), 40-660 GPM (150-2500 L/min)

BODY MATERIAL

A = Aluminum

E = Extended ow Aluminum version

S = 316L Stainless Steel (OM080 only)

ROTOR MATERIAL / BEARING TYPE

00

= PPS (not available for 300ºF (150ºC)) / No bearing

10 = Keishi cut PPS (for high viscosity liquids) (not available for 300ºF

(150ºC)) / No bearing

44 = Aluminum/Hardened Steel Roller (100E only)

51 = Stainless Steel / Carbon Ceramic (080 only)

71 = Keishi cut Stainless Steel rotors (for high viscosity liquids) /

Carbon Ceramic (080 only)

O-RING MATERIAL

1

= FKM (Viton™) -5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™) (included KALREZ shaft seals)

5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-2

= 250º F (120º C) max.

-3 = 300º F (150º C) max. (OM080 only)

-5 = 250º F (120º C) max. (includes integral cooling n)

-8

= 176º F (80º C) max. (meters with integral instruments)

PROCESS CONNECTIONS

0

= No ttings

1

= BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

4

= ANSI-150 RF Flanged

6 = PN16 DIN Flanged

CABLE ENTRIES

1

= M20 x 1.5 mm

2 = 1/2 in. NPT

2

(Only available with Aluminum Rotors)

1

3

4

5

6

(Hall Effect output only)

7

8

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

SS = Stainless Steel terminal cover

RS = Reed Switch only - to suit Intrinsically safe installations

E1 = Explosion proof Exd IIB T3...T6 (aluminum & stainless meters)

[IECEx & ATEX approved]

E2 = Explosion proof Exd I/IIB T3...T6 (stainless meters only) [IECEx &

ATEX mines approved]

QP = Quadrature pulse (2 NPN phased outputs)

QPN = Quadrature pulse (2 NPN phased outputs) with Australian NMI

& NZ approval for trade sale

Q1 = Explosion proof Exd (with quadrature pulse) [IECEx & ATEX ap

proved]

Q1N

= Explosion proof Exd (IECEx & ATEX) with Quadrature pulse with

Australian NMI & NZ approval for trade sale

R3 = Intrinsically safe RT12 with all outputs (GRN housing) [IECEx &

ATEX approved]*#

R3G = RT12 Intrinsically Safe rate totalizer with all outputs (GRN

Housing) [IECEx & ATEX approved] (with gallons calibration)*#

R4 = RT40 rate totalizer with backlit large digit LCD [scalable pulse

output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing) (with

gallons calibration)*#

F18 = F018 backlit rate/tot. pulse out, 4-20mA, 10 pt lin, HART#

F19 = F018 Intrinisic Safe, backlit rate/tot. pulse out, 4-20mA, 10 pt

lin, HART [IECEx & ATEX approved]#

F31 = Intrinsically safe F130 2 stage batch controller [IECEx & ATEX

approved]#

9

-

1 2 3 4 5 6 7 8 9

--->>>> OM 025 A 51 2 -5 2 1 R5

*Temp code 5 required for integral instruments between 176F (80C) & 250F (120C)

#Temp code 8 required for integral instruments below 176F (80C)

Page 2

© 2019 Great Plains Industries, Inc. All Rights Reserved.

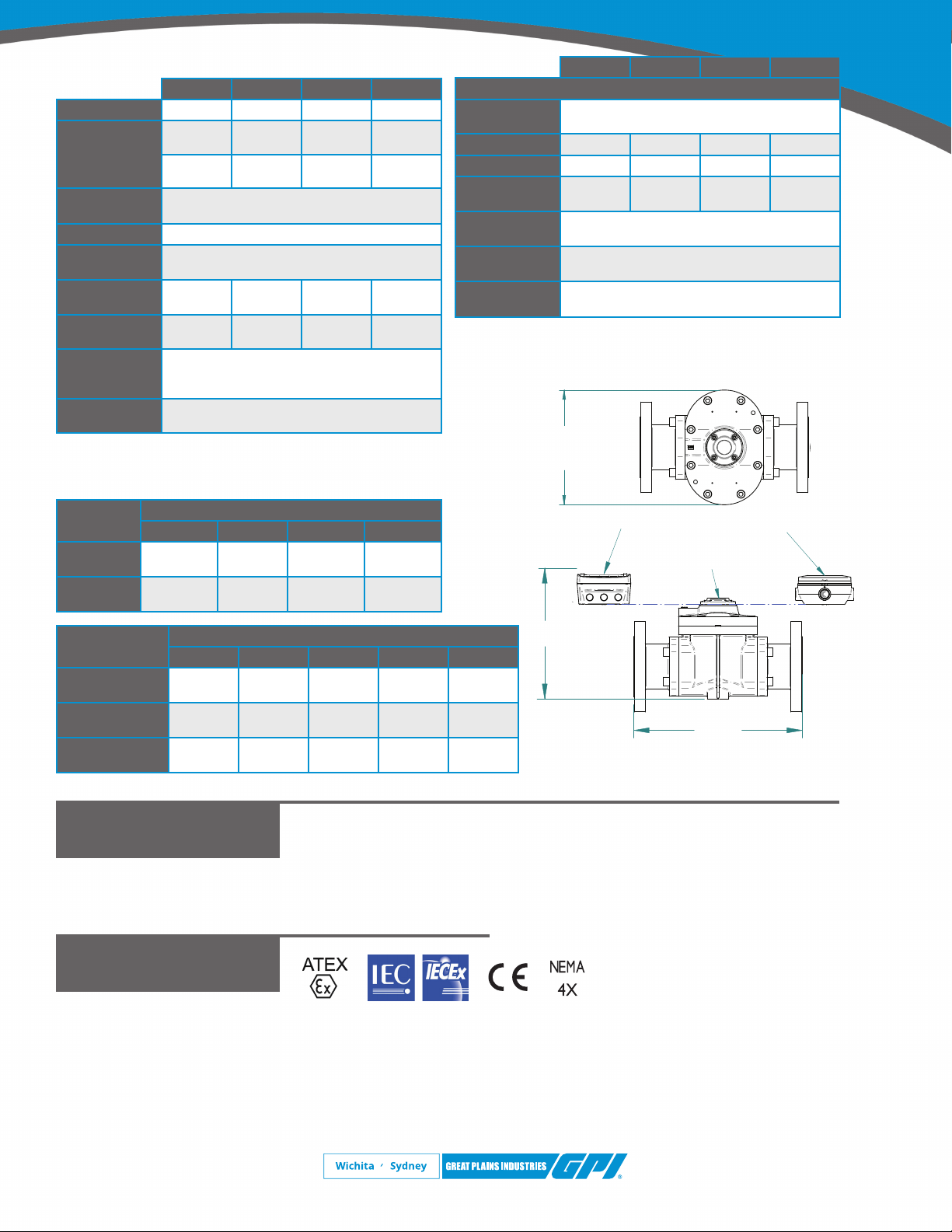

SPECIFICATIONS

OM080 OM080E OM100 OM100E

Nominal Size: 3” (80 mm) 3” (80 mm) 4”(100 mm) 4”(100 mm)

Nominal Flow*

Range @ 3cP:

Accuracy:

Repeatability: Typically ± 0.03% of reading

Temperature

Range:

Max. Pressure

(Aluminum)

Max. Pressure

(Stainless Steel)

Protection Class:

Recommended

Filtration:

:

10-200

GPM

35-750

L/min

±0.5% of reading (±0.2% of reading with optional

175 psi

(12 bar)

175 psi

:

(12 bar)

IP66/67 (NEMA 4X) Optional EXd I/IIB T3...T6,

integral ancillaries can be supplied I.S.

13-260

GPM

50-1000

L/min

-40˚F - +300˚F (-40˚C - +150˚C)

175 psi

(12 bar)

n/a n/a n/a

(Intrinsically Safe)

40 Mesh (400 μm)

20-400

GPM

75-1500

L/min

RT14)

145 psi

(10 bar)

40-600

GPM

150-2500

L/min

145 psi

(10 bar)

DIMENSIONS

All dimensions are ± .079” (±2 mm)

MODULAR

FITTING

Flanged

Threaded

OM080 OM080E OM0100 OM0100E

13.9”

(354 mm)

10.5”

(266 mm)

15.0”

(382 mm)

11.6”

(294 mm)

A

15.3”

(388 mm)

11.6”

(294 mm)

16.3”

(414 mm)

12.6”

(320 mm)

OM080 OM080E OM100 OM100E

Electrical:

Output Pulse

Resolution:

Reed Switch: 10.0 (2.65) 5.68 (1.55) 4.15 (1.10) 2.1 (0.56)

Hall Effect: 40.5 (10.7) 22.7 (6.00) 16.6 (4.40) 8.5 (2.24)

QP Quadrature

Hall Effect:

Read Switch

Output:

Hall Effect

Output:

Optional

Outputs:

*Maximum ow is to be reduced as viscosity increases, see ow de-rating

guide. Max recommended pressure drop is 14.5 psi (1 bar).

Pulses / gallon (Pulses / L) - Nominal

20.0 (5.33) 11.4 (3.00) 8.3 (2.20) 4.24 (1.12)

30V (dc) x 200 mA max. (maximum thermal shock

18º F [10º C] / minute)

3 wire open collector. 5-24V (dc) max., 20 mA

max.

4-20 mA, scaled pulse, quadrature pulse, ow

alarms or two stage batch control

9.53” (242 mm)(080)

11.5” (292 mm)(080E, 100)

13.07” (332 mm)(100E)

RT40

RT12 / RT14

COVER

CONFIGURATION

RT12 / RT14 GRN

HOUSING

RT40

COVER

APPLICATIONS

APPROVALS

B

OM080A OM080S OM080E OM0100 OM0100E

10.2”

(260 mm)

10.3”

(264 mm)

8.4”

(213 mm)

10.1”

(257 mm)

10.2”

(260 mm)

8.1”

(206 mm)

10.9”

(277 mm)

11.0”

(281 mm)

9.0”

(229 mm)

12.7”

(322 mm)

12.8”

(326 mm)

10.7”

(274 mm)

15.7”

(399 mm)

15.9”

(403 mm)

13.9”

(352 mm)

• Oils

• Fuel

• Diesel

• Truck Metering

B

• Bunker C Fuel Oil

• Chemical Additive Injection

• Batching

• Molasses

IP66/67

A

• Clean Fluids

• Oil-Based Paints

• Industrial Fluids

• Chemical Feed Lines

03/19 IND-1043-OM-LARGE

Loading...

Loading...