Page 1

PRODUCT IDENTIFIER

OM = Oval Gear Meter

METER SIZE

025 = 1" (25 mm), 2.6 - 40 GPM (10-150 L/min)

BODY MATERIAL

P = PPS

ROTOR MATERIAL / BEARING TYPE

00 = PPS / No bearing

10 = Keishi cut PPS / No bearing

O-RING MATERIAL

1 = FKM (Viton™) 5º F minimum (-15º C)

3 = PTFE encapsulated FKM (Viton™) 5º F minimum (-15º C)

4 = Buna-N (Nitrile), -40º F minimum (-40º C)

MAXIMUM TEMPERATURE LIMIT

-8 = 176º F (80º C) max.

PROCESS CONNECTIONS

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

CABLE ENTRIES

1 = M20 x 1.5 mm (M16 x 1.5 mm for R4 option)

2 = 1/2 in. NPT

6 = 3 x 16 mm drilled holes (for F instruments only)

INTEGRAL OPTIONS

___ = Combination Reed Switch and Hall Effect Sensor

QP = Quadrature pulse (2 NPN phased outputs)

QPN = Quadrature pulse (2 NPN phased outputs) with Australian NMI

& NZ approval for trade sale

R4 = RT40 rate totalizer with backlit large digit LCD [scalable pulse

output, backlight]*#

R4G = RT40 rate totalizer with backlit large digit LCD (Alloy housings

with facia) (with gallons calibration)*#

R5 = RT14 backlit rate totalizer with all outputs (GRN Housing)*#

R5G = RT14 backlit rate totalizer with all outputs (GRN Housing) (with

gallons calibration)*#

F18 = F018 backlit rate/tot, pulse, 4-20mA, 10 point linearization,

HART#

OM SERIES CHEMICAL FLOW METER

The FLOMEC® Chemical Flow Meter provides precise volumetric

ow measurement of a broad range of clean water based products

and aggressive chemicals and is also suitable for most fuels, fuel

oils and lubricating liquids. Applications include batching, dosing

or packaging of various corrosive chemicals as a more economical

alternative to a complete 316 stainless steel meter for liquids such

as Diesel Exhaust Fluid (Adblue).

FEATURES / BENEFITS

• High accuracy & repeatability, direct reading ow meter

• No requirement for ow conditioning (straight pipe runs)

• Measures high & low viscosity liquids

• Quadrature pulse output option & bi-directional ow

• Optional NMI Pattern Approval (Australia Only)

PRODUCT CONFIGURATION

2

1

8

9

3

4

5

6

7

METER SELECTION

• PPS meters are used for non-aromatic/non-halogenated organic

chemicals, water based liquids, Diesel Exhaust Fluid and petroleum products including oils and grease, fuels and fuel oils. It is

unsuitable for strong acids and oxidizers.

• PPS meters with standard ceramic rotor pins are suitable for applications where stainless steel is not suited or permitted.

• Blind pulse meters are available with Reed Switch and Hall Effect outputs. Quadrature pulse and integral 4-20mA outputs are

optional.

1 2 3 4 5 6 7 8 9

--->>>> OM 025 P 10 1 -8 1 1 R5

POSITIVE DISPLACEMENT FLOWMETERS (OVAL GEAR)

21

Page 2

Housing Material: OM025

PRODUCT IDENTIFIER

EGM004 = 1/8" (4 mm) 0.26 - 9.6 GPH (1-36 L/hr)

EGM006 = 1/4" (6 mm) 0.5 - 27 GPH (2-100 L/hr)

EGM008 = 3/8" (8 mm) 4 - 145 GPH (15-550 L/hr)

EGM015 = 1/2" (15 mm) 0.26 - 10.6 GPM (1-40 L/min)

EGM020 = 3/4" (20 mm) 0.5 - 21 GPM (3-80 L/min)

MATERIALS

A00 = Aluminum / PPS / No bearing (EGM008-020)

A51 = Aluminum / Stainless Steel / Carbon Ceramic (EGM004-015)

A52 = Aluminum / Stainless Steel / Bronze

(EGM004-015)

S00 = 316 Stainless Steel / PPS / No bearing (EGM008-020)

S51 = 316 Stainless Steel / Stainless Steel / Carbon Ceramic

(EGM004-015)

O-RING MATERIALS

1 = Viton (5°F min. [-15°C])

3 = Teon encapsulated Viton (5°F min. [-15°C])

4 = Nitrile, (-40°F min. [-40°C])

TEMPERATURE

8 = 176°F (80°C) max

PROCESS CONNECTION

1 = BSPP (G) female threaded (ISO 228)

2 = NPT female threaded

INTEGRAL OPTIONS

0 = Hall effect output (no calibration) (2 m cable)

1 = Hall effect output with one point calibration and K-Factor (2 m

cable)^*

2 = Fuel consumption (Pulsating ow, PT100 temp. sensor, one pt

Cal & K-factor) (2 m cable)^*

EGM-SERIES ELECTRONIC FLOWMETER

All EGM-Series pulse meters are designed for volumetric

ow measurement of clean liquids across a broad range of

applications in the automotive, aviation, mining, power, chemical,

pharmaceutical, and petroleum industries. The EGM-Series will

produce accurate and reliable measurements of almost all clean

liquids, including but not limited to; alcohols, fuels and oils,

water based salts and solutions, corrosion inhibitors, brake and

transmission uids, greases, emulsiers, adhesives, insecticides,

and some aggressive chemicals.

FEATURES / BENEFITS

• Oval Gear technology for high accuracy and repeatability

• Direct volumetric measurement of flow

• Accuracy of reading is not affected by temperature and

viscosity changes

• Measures high and low viscosity liquids

• Only two moving parts

• "Fuel Consumption" option can tolerate ow pulsations

and has a built-in temperature sensor to correct for the fuel

density changes

GENERAL SPECIFICATIONS

• Flow rates:0.26 GPH - 21.1GPM (1 L/hr - 80 L/min)

• Sizes: 1/8" - 3/4" (4 mm - 20 mm)

• Temperature range: 5°F - +176°F (-15°C - +80°C)

CALIBRATION

EGM-Series owmeters are available with factory calibrations or

can be calibrated in the eld as an economical option.

FUEL CONSUMPTION

EGM-Series owmeters with the Fuel Consumption option (Integral

Option 2) are equipped with an integral PT100 temperature sensor

which allows for accurate measurement of fuel consumption on

combustion engines by correcting for temperature differences from

the inlet to outlet of the engine. It also includes the Pulsating Flow

electronics that eliminate the effect of pulsations in the ow.

PRODUCT CONFIGURATION

2

1

3

4

5

APPLICATIONS

• Aluminum meters with PPS rotors are suitable for petroleum

products including: oils, greases, fuels and fuel oils.

• Aluminum meters with stainless steel rotors and bronze

bearings are suitable for petroleum products including: fuels

with high Benzene content, automotive brake uid, and some

solvents such as turpentine.

• Stainless steel meters are suitable for alcohols, water based

liquids, some aggressive liquids, AdBlue (DEF, Urea) as well as

fuel and oil applications in saline marine environments.

6

51 2 3 4

6

--->>>> EGM008 A00 1 8 1 2

^Statement of conformance K-Factor printed on meter

*Calibration sheet can be ordered

Nominal Size: 1" (25 mm)

Nominal Flow

Range* @ 3cP:

Accuracy:

Repeatability: Typically ± 0.03% of reading

Temperature

Range:

Max. Pressure 70 psi (5 bar)

Electrical:

Output Pulse

Resolution:

Reed Switch: 102 (27)

Hall Effect: 405 (107)

QP Quadrature

Pulse

Reed Switch

Output:

Hall Effect Output:

Recommended

Filtration

±0.5% of reading (±0.2% of reading with optional

Pulses / gallon (Pulses / L) - Nominal

30V (dc) x 200mA max. (maximum thermal shock

3 wire open collector. 5-24V (dc) max., 20mA

2.6 - 40 GPM

(10-150 L/min)

RT14)

-40˚C - +80˚C (-40˚F - +180˚F)

204 (54)

18°F [10°C] / minute)

max.

200 mesh [75 μm]

*Maximum ow is to be reduced as viscosity increases, see ow de-rating guide.

Maximum recommended pressure drop is 14.5psi [1 Bar]

APPROVALS

IP65

22

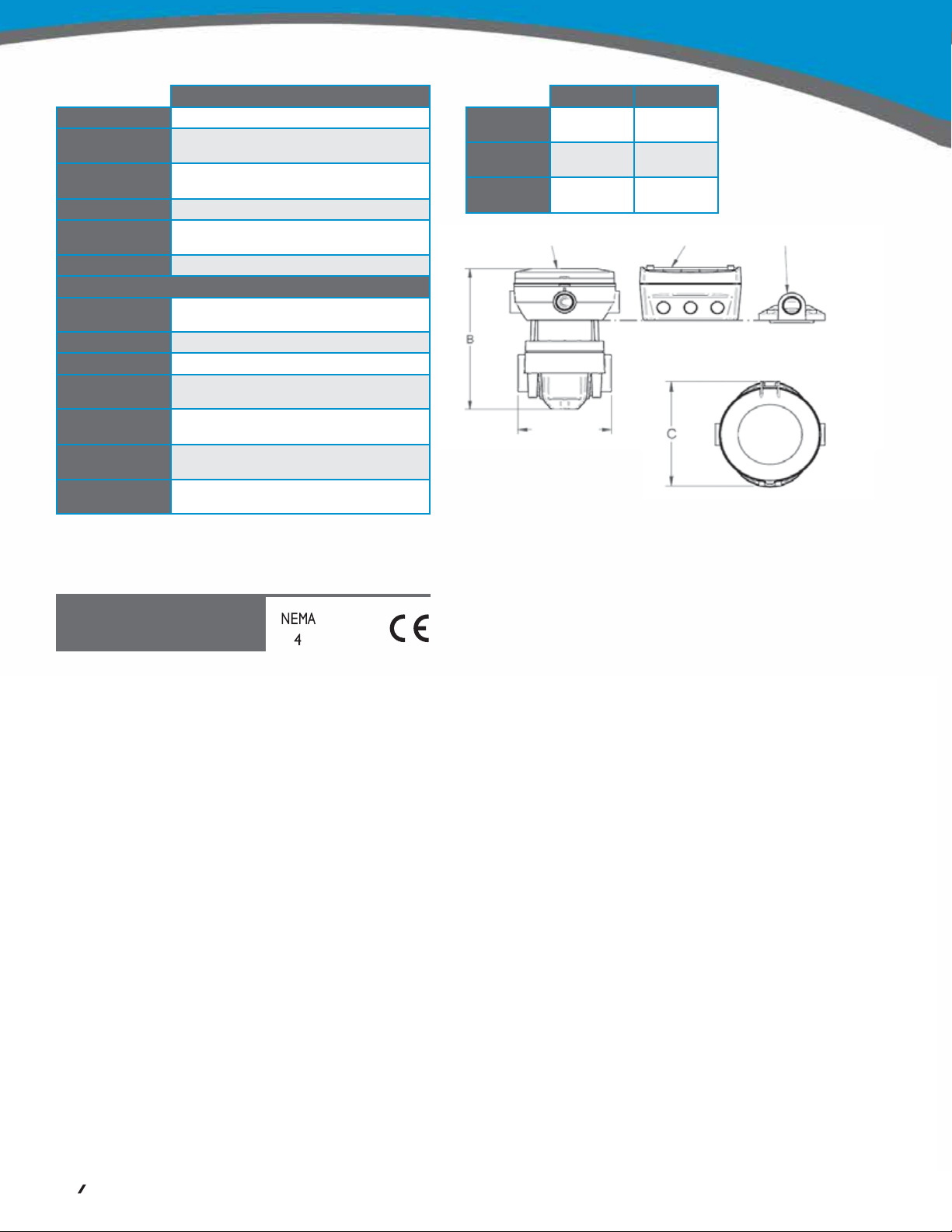

DIMENSIONSSPECIFICATIONS

RT12 / RT14

RT40

COVER

B C

6.57"

(167 mm)

6.69"

(170 mm)

4.84"

(123 mm)

RT12 / RT14 RT40 COVER

4.09"

[104 mm]

F/F

4.88"

(124 mm)

3.78"

(96 mm)

2.91"

(74 mm)

Loading...

Loading...