GPI - Great Plains Industries 02 Series Owners Manual

SAVE THESE INSTRUCTIONS

Owner's Manual

02 Series Electronic Flowmeter

with Scaled Pulse Output

IMPORTANT NOTICE

This meter is not approved for use with ammable liquids.

Do not use with liquids or chemicals that are not compatible with the wetted materials found in the Specications

section.

This meter is not legal for trade applications.

This meter is sensitive to electrical "noise" and may not operate correctly if located near certain electrical equipment.

CALIBRATION

This meter has a permanent factory calibration for light

viscosity uids. If installed and used correctly, accuracies of

no greater than ±5% will be obtained.

INSTALLATION

This meter may be installed in-line either horizontally or

vertically, or at the end of the hose adjacent to the nozzle

if present. For best accuracy, provide 10 inches of pipe

upstream and 5 inches of pipe downstream. The use of pipe

sealant or PTFE tape is acceptable. Review your application

for suitability. Attach meter with arrow on outlet port pointed

in the direction of ow.

For Aluminum Housings: Using a wrench, tighten meter at

the ends.

For Nylon Housings: Hand tighten only. Avoid using metal

connections, as this could damage the housing.

OPERATION

Batch and Cumulative Totals

This meter maintains two totals: Batch and Cumulative.

The Batch total may be reset to measure ow during a

single use. The Cumulative total provides continuous measurement and may not be manually reset. The Batch total is

labeled TTL1. The Cumulative total is labeled TTL2. When

the Cumulative total reaches a maximum reading of 9999,

it will automatically reset to zero. Press the DISPLAY button

briey to switch between Batch and Cumulative totals.

Batteries Included

Activate the Meter

Turn the meter ON by starting uid ow or briey pressing

the DISPLAY button. The meter will display the batch or

cumulative total from last use.

Press DISPLAY briey to display the batch total. Hold the

DISPLAY button down for three seconds to reset that batch

total to zero.

This meter is programmed to turn off automatically if not

used for approximately one minute.

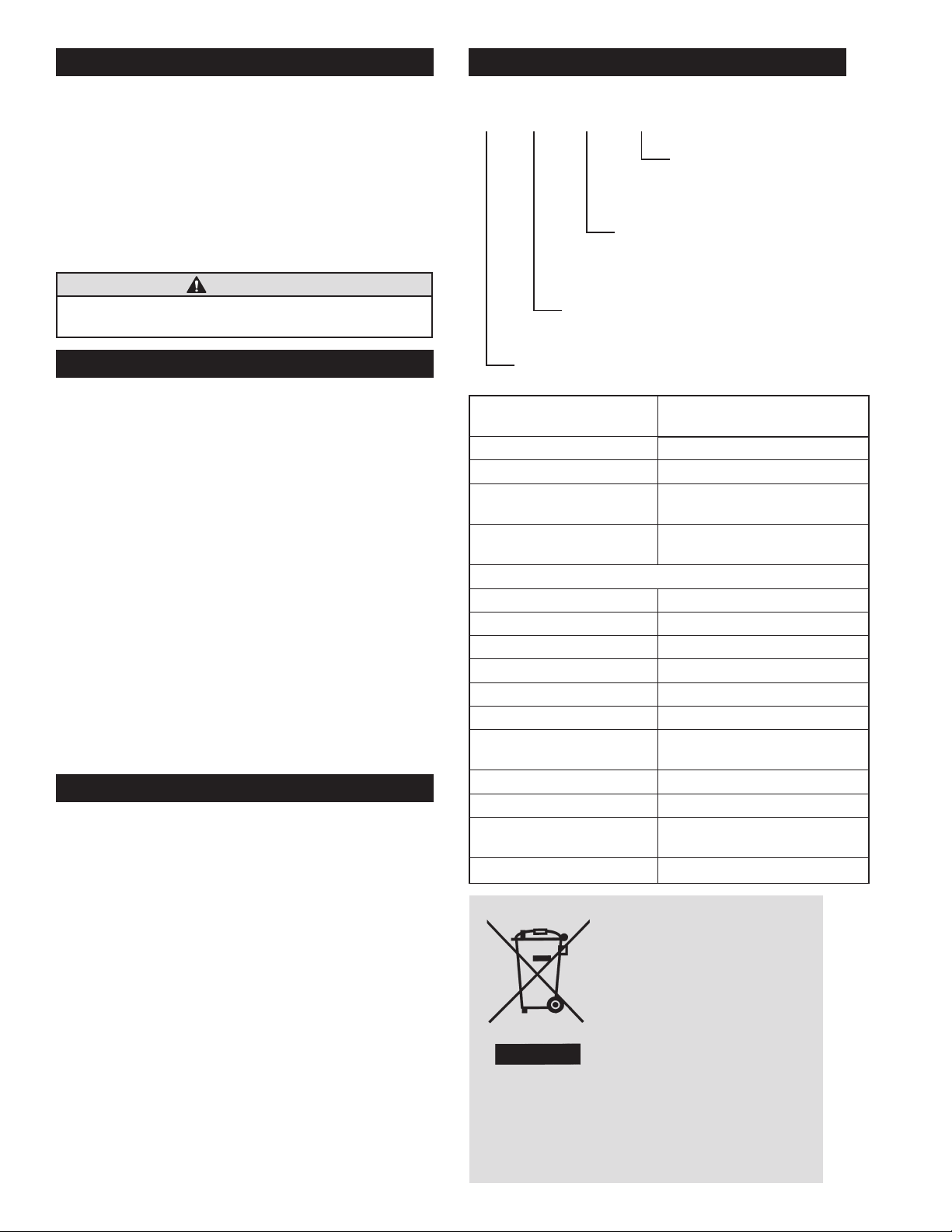

Scaled Output Pulse

For every whole unit (Gallon or Litre) that passes through the

meter's Batch Total (TTL1), a single pulse is transmitted via

the attach cable. The White wire is signal and the Black wire

is common (GND) (See Specications).

Note: Some interface devices may not have an internal pullup resistor. Use a minimum 820 ohms resistor if necessary

(See Figure 1).

Figure 1

PULL-UP

RESISTOR

WHITE

- PULSE

BLACK - COMMON

5-30 VDC

V+

CUSTOMER

INTERFACE

EQUIPMENT

INPUT

GND

920894-01 Rev. C09/15

MAINTENANCE

Proper handling and care will extend the life and service of

this meter.

Turbine Rotor

This meter is virtually maintenance-free. However, it is

important for the rotor to move freely. Keep the meter clean

and clear of contaminants.

Remove debris or deposits from the rotor using a soft brush

or small probe. Be careful not to damage the turbine rotor or

supports.

CAUTION

Blowing compressed air through the turbine assembly

could damage the rotor.

SPECIFICATIONS

02 N 31 GM

GM - Gallons

LM - Litres

12 - 1” BSPT (Female)

31 - 1” NPT (Female)

52 - 1” BSPP (Female)

A - Aluminum Housing

N- Nylon Housing

BATTERY REPLACEMENT

The meter is powered by two AAA alkaline batteries which

may be replaced while the meter is installed. When batteries

are removed or lose power, the batch and cumulative totals

reset to zero but the factory calibration is retained.

If the meter display becomes dim or blank, replace the batteries as follows:

1. Remove the four Phillips-head screws from the face of

the meter and lift the faceplate from the turbine.

2. Remove the old batteries and clean any corrosion from

the terminals.

3. Install new batteries. Make sure the positive post is in

the correct position.

4. When the batteries are replaced, the faceplate will power

ON. Check the display to ensure normal functions have

resumed before assembling again.

5. Re-seat batteries, if necessary, and position the faceplate on the turbine housing. To avoid moisture damage, make sure the seal is fully seated. Tighten the four

screws on the faceplate.

SERVICE

For technical assistance, warranty replacement or repair

contact your FLOMEC® distributor:

02 - Series Flowmeter

Flowrate:

Working Pressure (MAX.): 150 PSIG (10.3 bar) Nylon

300 PSIG (21 bar) Aluminum

Operating Temperature:

Storage Temperature:

Wetted Materials:

Housing:

Bearings:

Shaft:

Rotor / Supports:

Rings:

Signal Generator:

Pulse Out Description:

Pulse Duration: 250 msec

Pulse Amplitutde: 5 to 30 VDC

Scaling:

Cable Length: 5 ft. / 1.5 meters

Open Collector (a.k.a. npn

3 to 30 GPM

(11 to 113 LPM)

+14F to +130F

(-10C to 55C)

-40F to +158F

(-40C to 70C)

Noted above

Ceramic

Tungsten Carbide

Nylon

316 Stainless Steel

Ferrite

or current sinking)

One pulse per

Gallon or Litre

To obtain prompt, efficient service, always be prepared

with the following information:

• The model number

• The manufacturing date code (located under the

coverplate)

For warranty work, always be prepared with your original sales

slip or other evidence of purchase date.

Please contact your FLOMEC® distributor before returning

any part. It may be possible to diagnose the trouble and nd

a solution with a telephone call. You may also be informed of

any special requirements you will need to follow for shipping.

2

The Waste Electrical and Electronic

Equipment (WEEE) directive

(2002/96/EC) was approved by the

European Parliament and the Council

of the European Union in 2003. This

symbol indicates that this product

contains electrical and electronic

equipment that may include

batteries, printed circuit boards,

liquid crystal displays or other components that may be

subject to local disposal regulations at your location.

Please understand those regulations and dispose of this

product in a responsible manner.

920894-01 Rev. C

Loading...

Loading...