GPI RP-10 Owner's Manual

5252 East 36th Street North

Wichita, KS USA 672 20- 320 5

TEL: 316-686-7361

FAX: 316 -68 6-6 746

“A Gr ea t P la ins Ve nt ure s Sub si dia ry ”

www.gpi.net

1-800-835-0113

SAVE THESE INSTRUCTIONS

RP-10 Rotary Hand Pump

for Fuel and Petroleum

Owner’s Manual

GENERAL INFORMATION

The RP-10 Rotary Hand pump is designed for use with gasoline

(up to 15% alcohol blends such as E15), diesel fuel (up to 20%

bio-diesel blends such as B20), kerosene and up to medium

weight oils. These self-priming pumps deliver up to 10 gallons

(38 litres) per 100 revolutions and are designed for use on a tank

with a 2-inch bung. They are equipped with an anti-siphon vent

to prevent possible tank siphoning. Do not use the RP-10 pump

with chemicals.

Safety Instructions

Observe standard safety precautions when handling fuel.

• Keep away from open flame or spark.

• Do not refuel vehicles or equipment with engines running or

while equipment engine is hot.

•

Do not smoke while refueling.

Before installation, clean the tank interior of dirt and foreign material. Wrap all threads that are exposed to liquids with 3 to 4 turns of

Teflon

petroleum fuels. Remove protective covers and plugs.

04/08

®

tape or a thread-sealing compound approved for use with

INSTALLATION

1. Hand-tighten the riser on to the tank bung.

2. Assemble the crank and handle. Then snugly tighten the crank onto the shaft. Reference the Illustrated Parts Drawing for details.

. Screw the suction pipe into the pump inlet.

3

4. Extend the suction pipe to its full length. Insert it through the

riser and into the tank. Adjust the suction pipe to the length

needed to rest on the tank bottom. If tank debris is a potential

problem, raise the end of the suction pipe 2 to 3 inches.

5

. Secure the pump onto the riser with the two set screws. Tighten

until snug.

To install the hose and nozzle, thread the elbow fitting into the

pump outlet and tighten until snug. Hand-tighten the hose into the

elbow until snug. Tighten the nozzle onto the hose fitting. Insert

the nozzle into the hanger.

OPERATIONS

To dispense fuel, remove the nozzle from its hanger and insert into

a tank. Pump fuel by rotating the crank in the direction of the arrow on the housing. After dispensing fuel, drain the hose

and replace the nozzle in the

hanger.

During daily use, this pump is

essentially maintenance free.

However, the pump should be

inspected periodically for signs

of leakage. If leaks are present or

other problems occur, refer to the

Troubleshooting Section.

Rev. C 921462-06

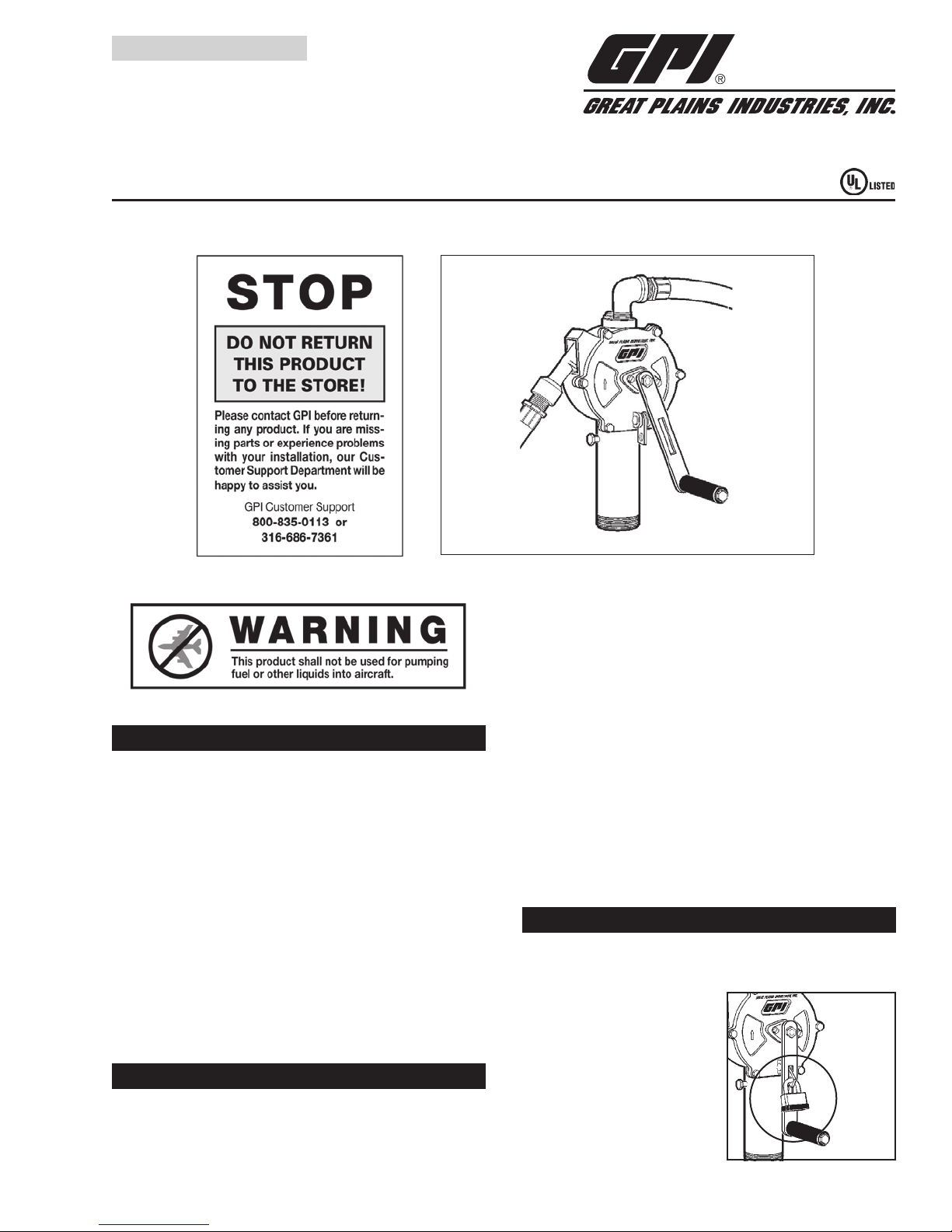

Use

standard

padlock

to secure

handle.

SPECIFICATIONS

PARTS AND SERVICE

The Rotary Hand Pump is compatible with gasoline (up to 15%

alcohol blends such as E15), diesel fuel (up to 20% biodiesel blends

such as B20), kerosene and up to medium weight oils.

Construction: L

ightweight, die-cast aluminum housing.

Stainless steel shaft. Fluorocarbon

seals. Cast iron rotor and carbon vanes.

Built-in anti-siphon vent.

Pumping Capacity: U

p to 10 gallons (38 litres) per 100

revolutions

Inlet: 1

Outlet: 3

Shipping Weight: 1

Hose and Nozzle: 3

-inch NPT female

/4-inch NPT female

7 lbs. (7.7 kg)

/4-inch x 8 foot (2.4m) Buna-N

statically grounded hose.

Aluminum Alloy unleaded nozzle

Suction Pipe: P

lastic, adjustable from 22 to 40 inches

(55 to 102cm)

For warranty consideration, parts or other service information,

please contact your local distributor or the GPI Customer Service

Department, during normal business hours at:

1-800-835-0113

To obtain prompt, efficient service, be prepared with:

he model number of your pump

• t

• the serial number or manufacturing date code of your pump,

and

• p

arts descriptions and numbers

Reference the Illustrated Parts List for specifics on parts. For warranty service, be prepared with your original sales slip or other

evidence of purchase date.

CAUTION

Do not return the pump without specific authority from the

GPI Customer Service Department. Due to strict regulations governing transportation, handling, and disposal

of hazardous or flammable liquids, GPI will not accept

pumps for rework unless they are completely free of

liquid residue.

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

A. FLUID LEAKS AROUND 1. Retainer loose Tighten retainer screws.

SHAFT

if necessary.

B. FLUID LEAKS AT ANTI- 1. Anti-siphon vent or Remove vent cap. Loosen vent by turning counterclockwise. Remove

SIPHON VENT O-ring damaged vent and O-ring. Clean. To replace, seat O-ring on vent and screw vent

into place until bottomed out. Replace vent cap.

C. LOW FLOWRATE 1. Internal parts worn or Remove coverplate and inspect for wear on vanes, coverplate, and all

debris in vane cavity inside housing surfaces. Replace any scored parts.

2. Vanes cracked Remove coverplate and inspect for chips or cracks on vanes. If

necessary, replace vanes.

D. PUMP FAILS TO PUMP 1. Suction pipe leak Remove pump from tank and riser. Inspect the spacer and suction pipe

for wear or damage. Replace, as necessary, and install pump on tank.

2. Internal parts worn or Remove coverplate and inspect for wear on vanes, coverplate, and all

debris in vane cavity inside housing surfaces. Replace any scored parts.

3. Vanes cracked Remove coverplate and inspect for chips or cracks on vanes. If

necessary, install Overhaul Kit or replace vanes.

E. HANDLE TURNS HARD 1. Debris in vane cavity Remove pump from tank. Remove coverplate and inspect for debris in

OR PUMP SEIZED cavity. Clean cavity, vanes, and rotor. Flush contamination from tank.

Assemble and install pump.

2. Internal parts worn Remove pump from tank. Remove coverplate and inspect for damaged

necessary, install Overhaul Kit or replace vanes.

F. VANES STICKING 1. Debris in vane cavity Remove coverplate. Use emery cloth to remove debris or corrosion in

vane slots. Apply lubricant (WD-40

2.

O-ring worn Check shaft O-ring for excessive wear. Replace Shaft Seal O-ring,

®

) if needed.

Loading...

Loading...