GPI QME10, QMF05, QME05, QMF10, QME20 Owner's Manual

...

SAVE THESE INSTRUCTIONS

Fixed and Portable

Ultrasonic Flowmeter (UFM)

Owner’s Manual

TABLE OF CONTENTS

Key Aspects of QStar UFM..........................................3

Fixed

Approvals/CE...............................................................3

Measuring Principle ..................................................... 3

QStar Fixed UFM and Components ............................ 4

QStar Portable UFM and Components........................ 8

Operating ................................................................... 10

Getting Started .......................................................... 10

Preparing for Measurement ....................................... 13

Measuring with UFM.................................................. 15

Setup Parameters......................................................15

Measuring Windows .................................................. 31

Calibration ................................................................. 44

System Settings.........................................................44

Troubleshooting ......................................................... 46

Software Update ........................................................ 53

Fluid Properties ......................................................... 54

Specications ............................................................ 56

Portable

920222-0105/13

QSTAR FIXED AND PORTABLE UFM OWNER’S MANUAL

Text identied with an exclamation mark contains important information that relates to the basic data

and operation of the device.

Text identied with the letter “i” contain supplementary and helpful information.

i

FIXED UFM

Text contained within this box applies specically

to the QStar FIXED UFM. If you have a PORTABLE

UFM, skip this section and go to the text with no

border, or the text in the PORTABLE UFM box.

FIXED UFM

PACKAGE INCLUDES:

• Transmitter

• Ultrasonic transducers

• Spacer bar for the ultrasonic transducers

(for types F10/F21)

• Stainless steel mounting belts

• Getting Started (“Quick-start”) manual

• USB drive with Owner’s Manual

• Ultrasonic coupling grease

Other ultrasonic transducers for smaller or larger pipe

dimensions, as well as clamp-on temperature sensors, are available on separate order. Contact GPI at

www.GPImeters.net or toll-free (888) 996-3837.

PORTABLE UFM

Text contained within this box applies specically

to the QStar PORTABLE UFM. For a FIXED

UFM, skip this section and go to the text with

no border, or the text in the FIXED UFM box.

PORTABLE UFM

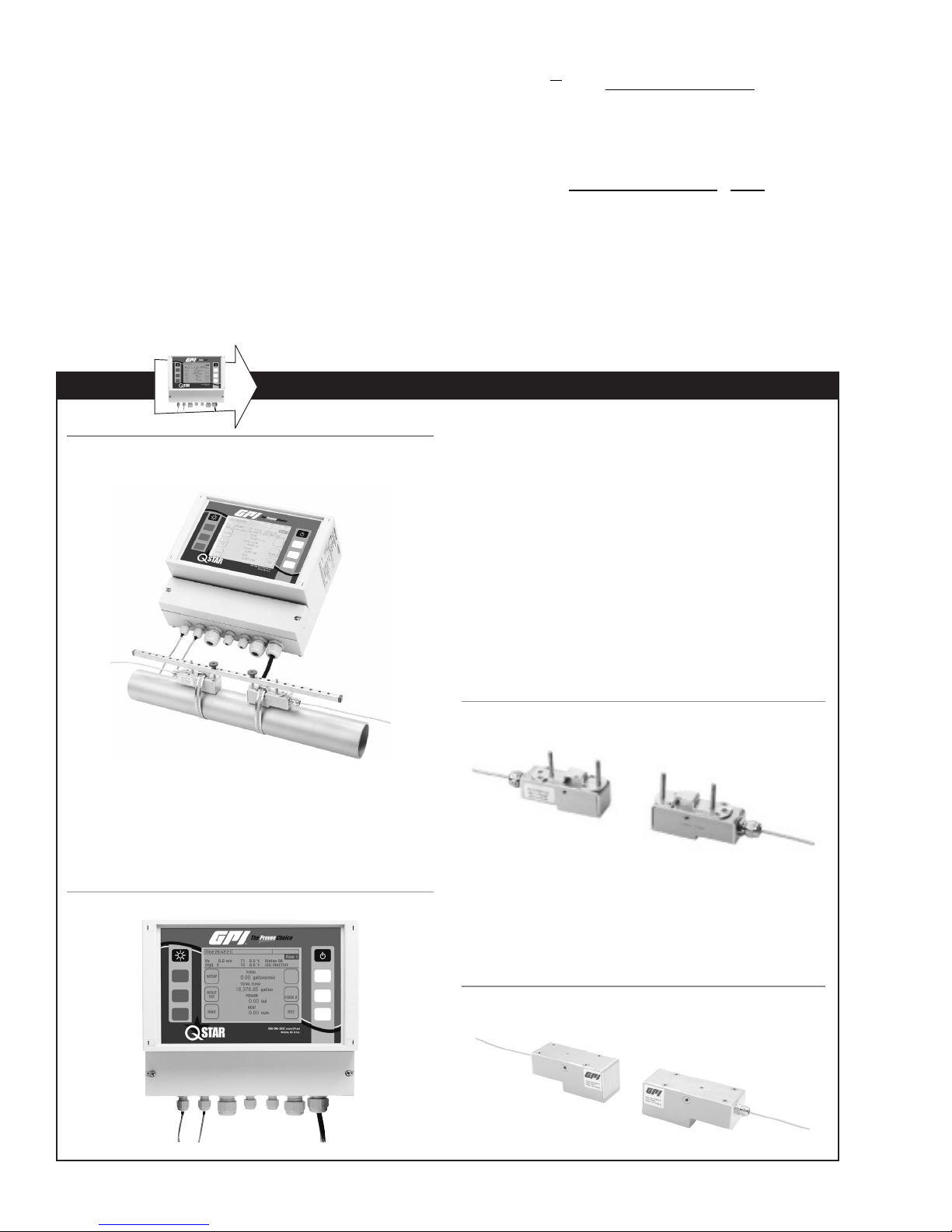

PACKAGE INCLUDES:

• Hard-shell case

• QStar Portable ow transmitter

• Plug-in power adapter, plus IEC appliance power

cable

• Transducer cables

• Ultrasonic transducers

• Spacer bar for the ultrasonic transducers

• Cable for the 4 mA to 20 mA analog output (Mini

DIN, alligator clips)

• Digital output cable for the relay/pulse output

(Mini DIN, alligator clips)

2

TEL: 888-722-3569 • 973-940-1684 • FAX: 1-973-940-1651 • www.GPImeters.com

• USB cable

• Stainless steel mounting chains (up to 16 in.)

• Getting Started (“Quick-start”) manual

• USB drive with operating instructions

• Ultrasonic coupling grease

• Measuring tape

Other ultrasonic transducers for smaller

or larger pipe dimensions and clamp-on

temperature sensors, are available

on separate order. Contact GPI

at www.GPImeters.net or

toll-free (888) 996-3837.

KEY ASPECTS OF QSTAR UFM:

APPROVALS/CE

• Fixed or Portable system for measuring liquids in lled

piping systems.

• Uses the ultrasonic transit-time differential method.

• Heat measurement is included as standard application.

Clamp-on Fixed and Portable temperature sensors

are optional.

• Portable UFM can be operated in battery-powered

mode and on a power adapter for operation with 100%

duty cycle. Fixed UFM can be operated on a power

adapter.

• Supports measurements on piping with diameters

from 1/2" to 240" (depending on the sensor used).

• The uid to measure may have a temperature range

from -40° F to +300° F (depending on the transducer

used).

• You can save the measuring data to the internal

SD card, read the data via USB port and export this

data using Microsoft® ofce software such as Excel

(Portable UFM only).

• The device is equipped with an electrically isolated

relay output and two 4mA to 20mA current outputs

that can be operated in active and passive mode.

QStar UFM is compliant with the following

European Directives and Standards

Test Specications

DIN EN 55011 B (11/2007)

DIN EN 61000-4-2 (09/2008)

DIN EN 61000-4-3 (06/2008)

DIN EN 61000-4-4 (07/2005)

DIN EN 61000-4-5 (06/2007)

DIN EN 61000-4-6 (10/2008)

DIN EN 61000-4-8 (12/2001)

DIN EN 61000-4-11 (02/2005)

Test Requirements

DIN EN 61000-6-1 (10/2007)

DIN EN 61000-6-3 (09/2007)

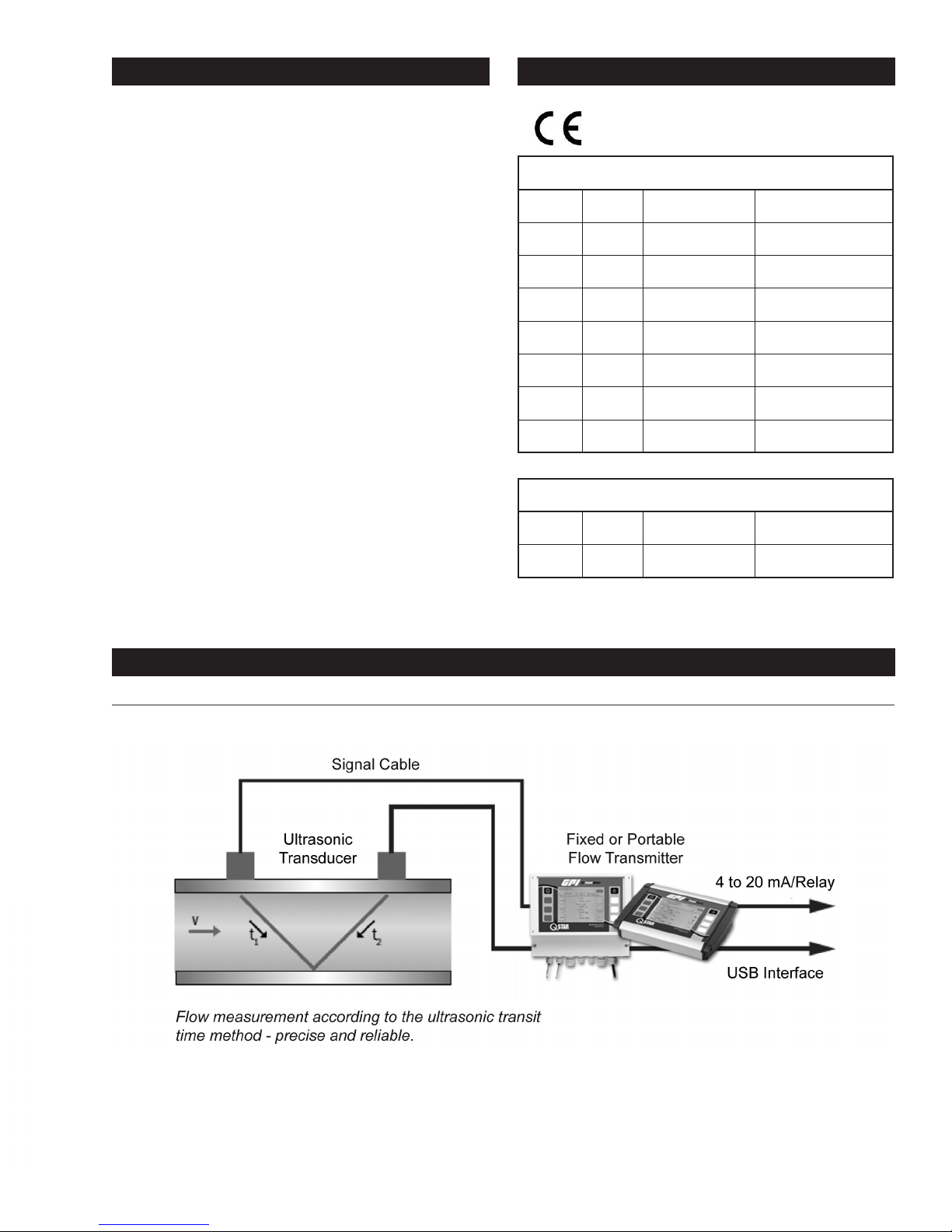

FIGURE 1: Measuring Principle

ULTRASONIC MEASURING PRINCIPAL

TEL: 888-722-3569 • 973-940-1684 • FAX: 1-973-940-1651 • www.GPImeters.com

3

The UFM employs precise, ultrasonic transit-time dif-

cos221

)12(

−

TT

TT

π

4cos221

TT

ferential method. This method involves installation of

two ultrasonic transducers on the surface of the piping

and their interconnection with the electronic evaluation

system. The ultrasonic transducers operate in alternating

mode as transmitter and receiver with cyclic exchange of

ultrasonic signals. Measurements cover the transit times

of the upstream and downstream signals (t1, t2). The UFM

measures the transit-time differential of the ultrasonic

signals t1 and t2 that travel upstream and downstream.

These signals are accelerated (t1) or retarded (t2). The

difference that develops between both signal transit times

is proportional to ow velocity and is used in combination

with the piping geometry data for precise calculation of

the volumetric owrate.

FIXED UFM AND COMPONENTS

=

Lv

α

α

D

2

⋅⋅

⋅⋅

Calculation of ow velocity [m/s]

)12(

TT

−

LQ

=

⋅⋅

Calculation of owrate [m3/s]

The ow transmitter uses a sophisticated cross-correlation

to detect signals. This ensures a reliable detection of

signals even in case of harsh circumstances like gas

and/or particle load.

FIGURE 2: UFM – with Mounted Ultrasonic Transducers (Bottom)

and Flow Transmitters

The UFM consists of the ultrasonic transducers and the

ow transmitter that are mounted onto piping.

FLOW TRANSMITTER

The ow transmitter processes the signals and makes

the measurement results available to the user.

ULTRASONIC TRANSDUCERS

The ultrasonic transducers are mounted onto the piping and transmit and receive the ultrasonic signals

that are used in the ow transmitter to calculate the

volumetric owrate.

Ultrasonic transducers:

QMF-F10 (1 MHz) for pipe diameters 1.25" to 16"

QMF-F21 (2 MHz) for pipe diameters 3/8" to 4"

Operating temperatures: -40° F to 300° F

FIGURE 4: Ultrasonic Transducers (F10/F21) typically

used with Spacer Bar (not shown)

FIGURE 3: Flow Transmitter

4

TEL: 888-722-3569 • 973-940-1684 • FAX: 1-973-940-1651 • www.GPImeters.com

Ultrasonic transducer:

QMF-F05 (0.5 MHz) for pipe diameters 8" to 240"

Operating temperatures: -40° F to 180° F

(300° F optional on request)

FIGURE 5: Ultrasonic Transducers (Type F05)

FIXED UFM AND COMPONENTS (Continued)

MOUNTING MATERIAL AND

ACCESSORIES

Signal cables

Signal cables are a part of the ultrasonic transducers

and cannot be separated from transducers.

Spacer bar for transducer mounting

For transducers F10 and F21 (Transducer QMF-F05

is mounted on pipes using textile tape rather than

spacer bar).

FIGURE 6: Spacer bar

Metal Mounting Belt for Transducer

Mounting

FIGURE 7: Mounting Belt (Stainless Steel)

QMF-PT100 Temperature sensors

The clamp-on temperature sensors collect temperature data in heating and cooling circuits.

This data is then used to calculate heating and cooling

quantities.

FIGURE 9: Clamp-on temperature sensors, QMF-PT100

(optional)

FIGURE 10: QMF-PT100 (optional) Temperature Sensor

Mounted with Metal Belt

FIGURE 8: Transducers Mounted with Spacer Bar and

Mounting Belts

Coupling grease

Apply the ultrasonic coupling gel between the ultra-

sonic transducer and the piping in order to optimize

signal input.

TEL: 888-722-3569 • 973-940-1684 • FAX: 1-973-940-1651 • www.GPImeters.com

Interfaces of UFM

Open the cover to access the connecting terminals.

FIGURE 11: Front view of transmitter showing cover

Cover

Remove

Screws

5

FIXED UFM AND COMPONENTS (Continued)

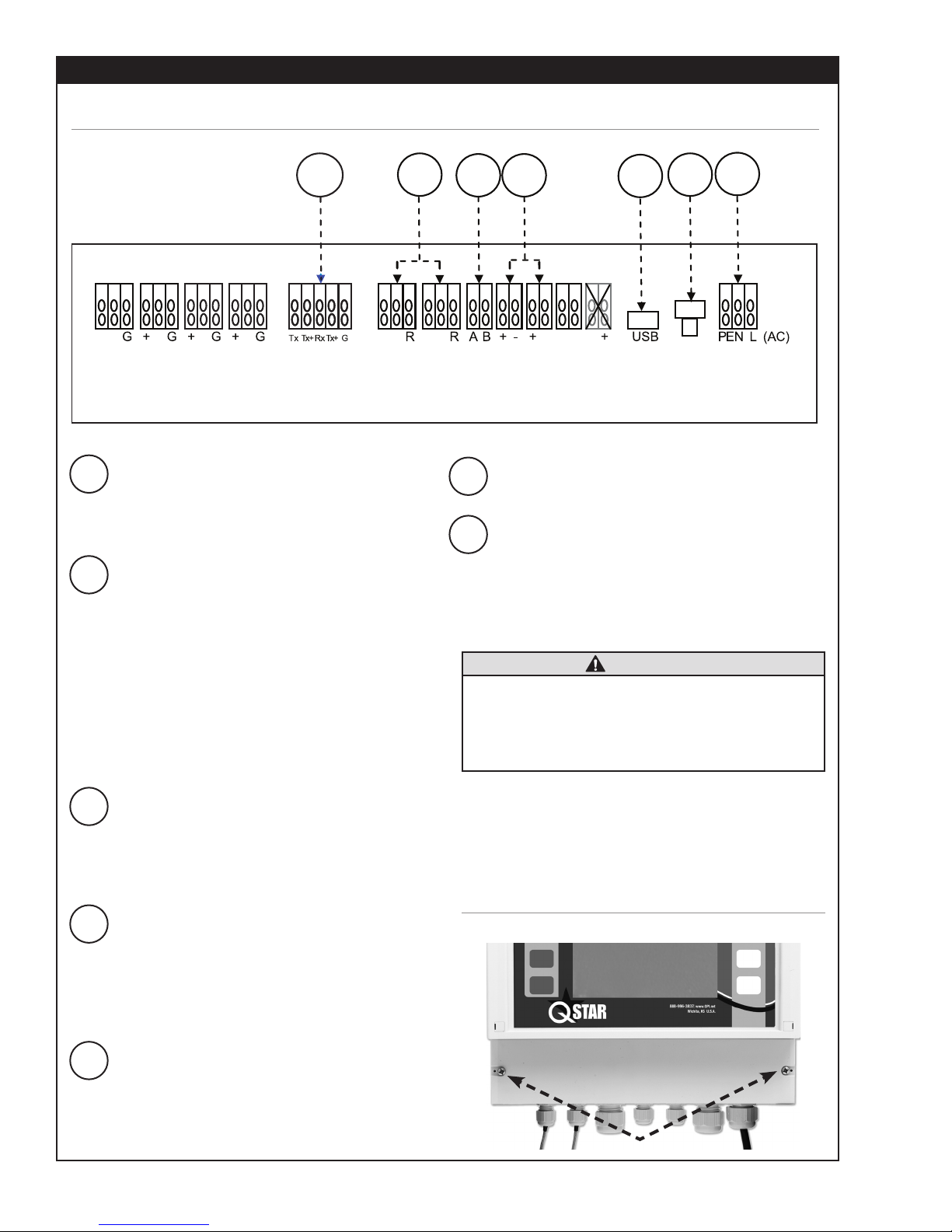

CONNECTOR BOARD

FIGURE 12: Connecting Terminals

1 2 3 4 5 6 7

+ - - - - - + --

UP1 DN1 UP2 DN2 RS232/ 485

1 RS232/RS485 Interface boards

Digital Interface boards RS232 or RS485 are

available as an option to provide digital communication via ASCI strings.

2 Input for temperature sensors

QMF-PT100 (3-wire)

The two temperature sensors (feed and return

pipe) can be connected in order to measure

heat/thermal output. The ow transmitter always

includes the capability for heat/thermal output

measurement. Note that (if required by customer)

the QMF-PT100 inputs can also be used to reset

the counters. If you use this reset function you

cannot measure heat/thermal output at same

time.

WW WW

QMF-

QMF-

PT100

PT100

Relay OUT2 OUT1 DO1 DO2 Reset Power

6 Hardware Reset

Used to reset unit (for hang-ups).

7 Power Supply

Location for connecting the supply voltage. QStar

UFM is available as AC (90-240VAC) and DC

(18-36VDC) version.

Always use the correct voltage for the UFM.

Improper supply voltage might seriously

damage the ow transmitter. Check the type

of power supply on the name plate (printed

on right side of enclosure of ow transmitter.

CAUTION

+ - (DC)

3 Relay output (potential-free)

This output is potential-free NO (normally open)

relay output. Use this output to establish an

alarm (for example, when exceeding a certain

ow speed).

4 Analog output 4-20mA (active)

The 4-20mA outputs can be used to submit

measurement data like ow, thermal output and

velocity to the Programmable Logic Controller

(PLC). These outputs are in active mode (supply

voltage provided internally by ow transmitter).

5 USB- Interface

Used for rmware updates. Standard USB (micro

USB)- cable required to connect to a PC.

6

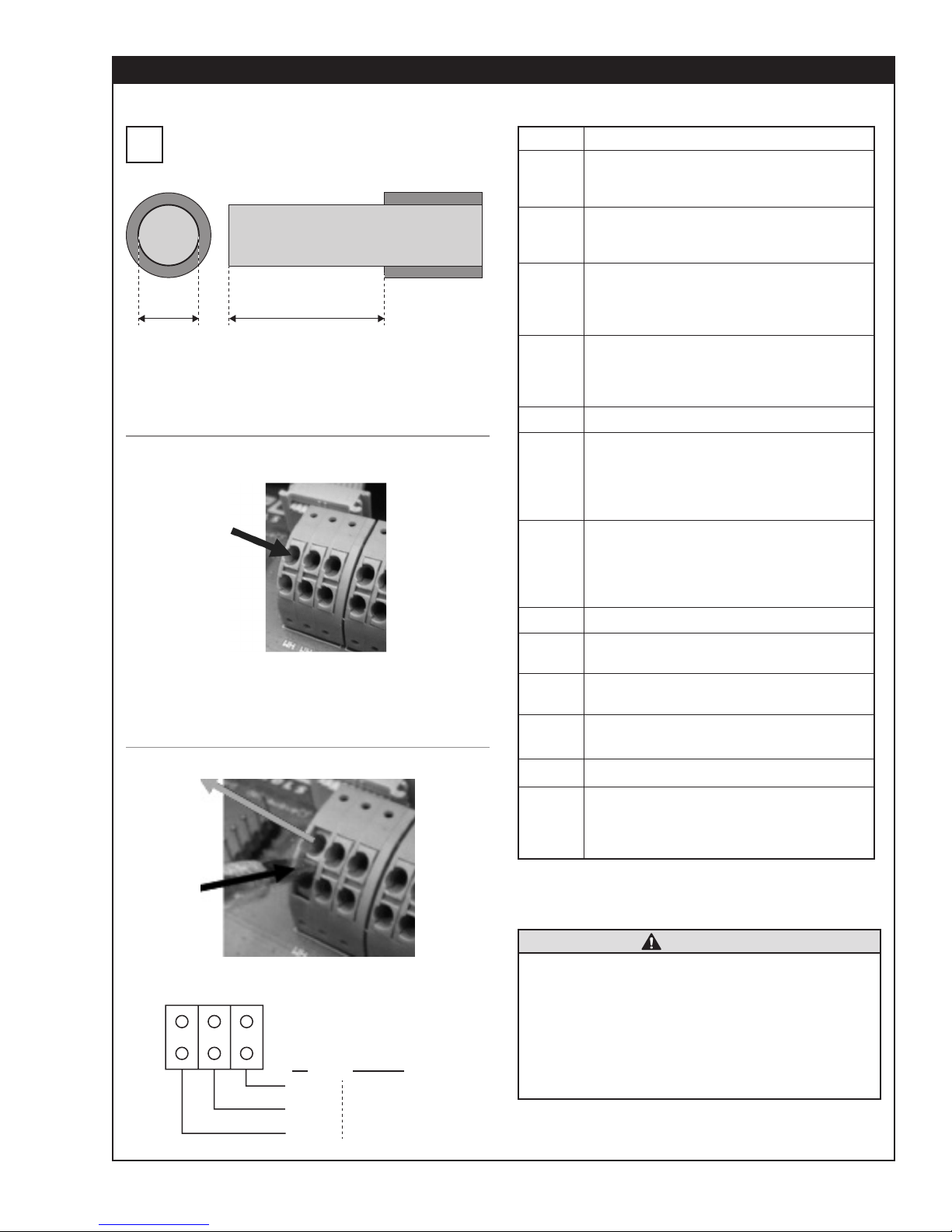

Wiring

The connection terminals are located under the lower

cover. Remove the two screws and plastic cover to

gain access to the connection terminals.

FIGURE 13: Accessing the Connection Terminals

FIXED UFM AND COMPONENTS (Continued)

.5".015" - .030"

AC TERMINAL BLOCK WIRING

Use cables with 16-26 AWG wires. Wires should

be stripped about .5 in. to allow proper contact

i

to terminals.

Put the stripped end of the related wire into the

related hole. Wires will be held by spring. It might

be helpful to use end sleeves or tin the wire ends.

FIGURE 14: Connection Terminals – Fasten Cables

Use a slotted screwdriver to unfasten wires, then press

middle part between the two holes as shown to loosen

the spring and remove the wires.

FIGURE 15: Connection Terminals - Unfasten Wires

Terminal Diagram

Terminals

UP1

DN1

UP2

DN2

RS485 Optional Interface board

QMF-

PT100

QMF-

PT100

Relay Relay output, external voltage required

OUT1

OUT2

DO1

DO2 Optional, Digital output 2

Designation

Connection of upstream transducer

Red wire to be connected to +

Black wire to be connected to -

Connection of downstream transducer

Red wire to be connected to +

Black wire to be connected to -

Connection of upstream transducer

(path2)

Red wire to be connected to +

Black wire to be connected to -

Connection of downstream transducer

(path2)

Red wire to be connected to +

Black wire to be connected to -

Connect temperature sensors

(measuring colder temperature) to left

QMF-PT100 terminal

WH = White wire from QMF-PT100

RD = Red wire from QMF-PT100

Connect temperature sensors

(measuring warmer temperature) to

right QMF-PT100 terminal

WH = White wire from QMF-PT100

RD = Red wire from QMF-PT100

Analog output1, 4…20mA, active, voltage provided internally

Analog output2, 4…20mA, active, voltage provided internally

Digital output (Transistor), passive

mode, external voltage required.

PE NL1

US EUROPE

BLACK

WHITE

GREEN

BROWN

BLUE

GREEN/YELLOW

Power

Supply

Either DC (18-36VDC) or AC (90-

240VAC). Check order conrmation

or name plate on ow transmitter for

operating voltage.

CAUTION

• The 4-20mA outputs are set in active mode.

That means the required voltage is provided

by ow transmitter internally. DO NOT USE

additional external voltage.

• The digital output is set in passive mode and

requires external voltage to be operated.

• Relay is rated to max. 45V, 0.25mA. These

values must not be exceeded.

7

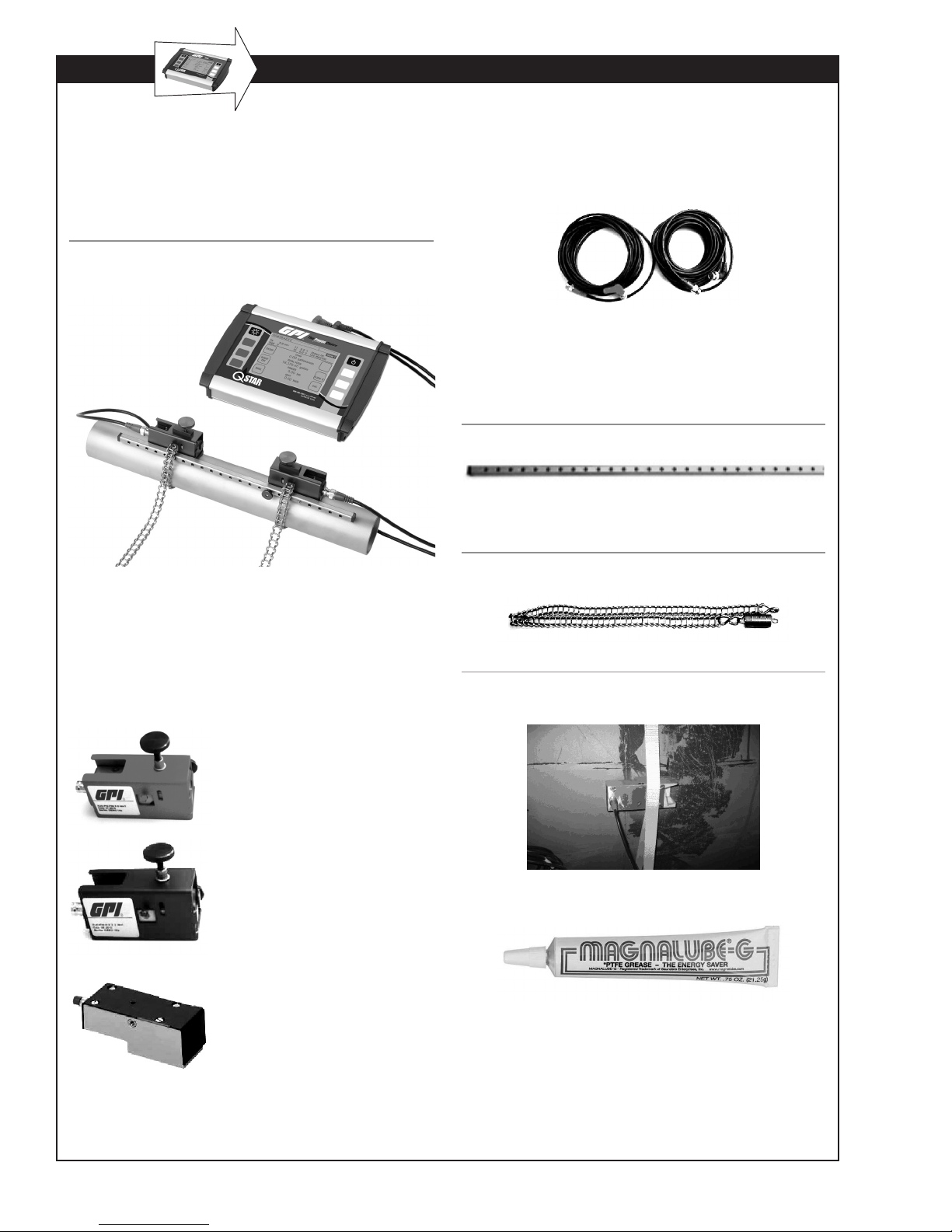

PORTABLE UFM AND COMPONENTS

PORTABLE FLOW TRANSMITTER

Your UFM consists of the ultrasonic transducers and

the ow transmitter that are mounted onto your piping.

The ow transmitter processes the signals and provides

the measurement results.

FIGURE 16: PORTABLE Flow Transmitter (Top) and

Mounted Ultrasonic Transducers (Bottom)

MOUNTING MATERIAL AND

ACCESSORIES

Signal cables

Spacer bar for transducer mounting

For QMP-F10 and QMP-F21 (QMP-F05 is mounted

on pipes using textile tape rather than spacer bar).

FIGURE 17: Spacer bar

Chains for Transducer Mounting

FIGURE 18: Mounting Chain (Stainless Steel)

ULTRASONIC TRANSDUCERS

The ultrasonic transducers mount onto the piping to

transmit and receive the ultrasonic signals used in the

ow transmitter to calculate the volumetric owrate.

Ultrasonic transducer QMP-F21

(2 MHz), RED housing, for pipe

diameters from 0.5 to 4.0 inches.

Operating temperatures: -40° F to

300° F

Ultrasonic transducer QMP-F10

(1 MHz), BLUE housing. Pipe diameters: 1.5 to 16 inches. Operating

temperatures: -40° F to 300° F

Ultrasonic transducer QMP-F05

(0.5 MHz), GREEN housing. For

pipe diameters from 8 to 240

inches. Operating temperatures:

-40° F to 176° F (300° F optional

on request)

FIGURE 19: Transducer QMP-F05 (500 kHZ) for large

pipes – Mounting with textile tape.

Coupling grease

Apply the ultrasonic coupling gel between the ultrasonic

transducer and the piping to optimize signal input.

8

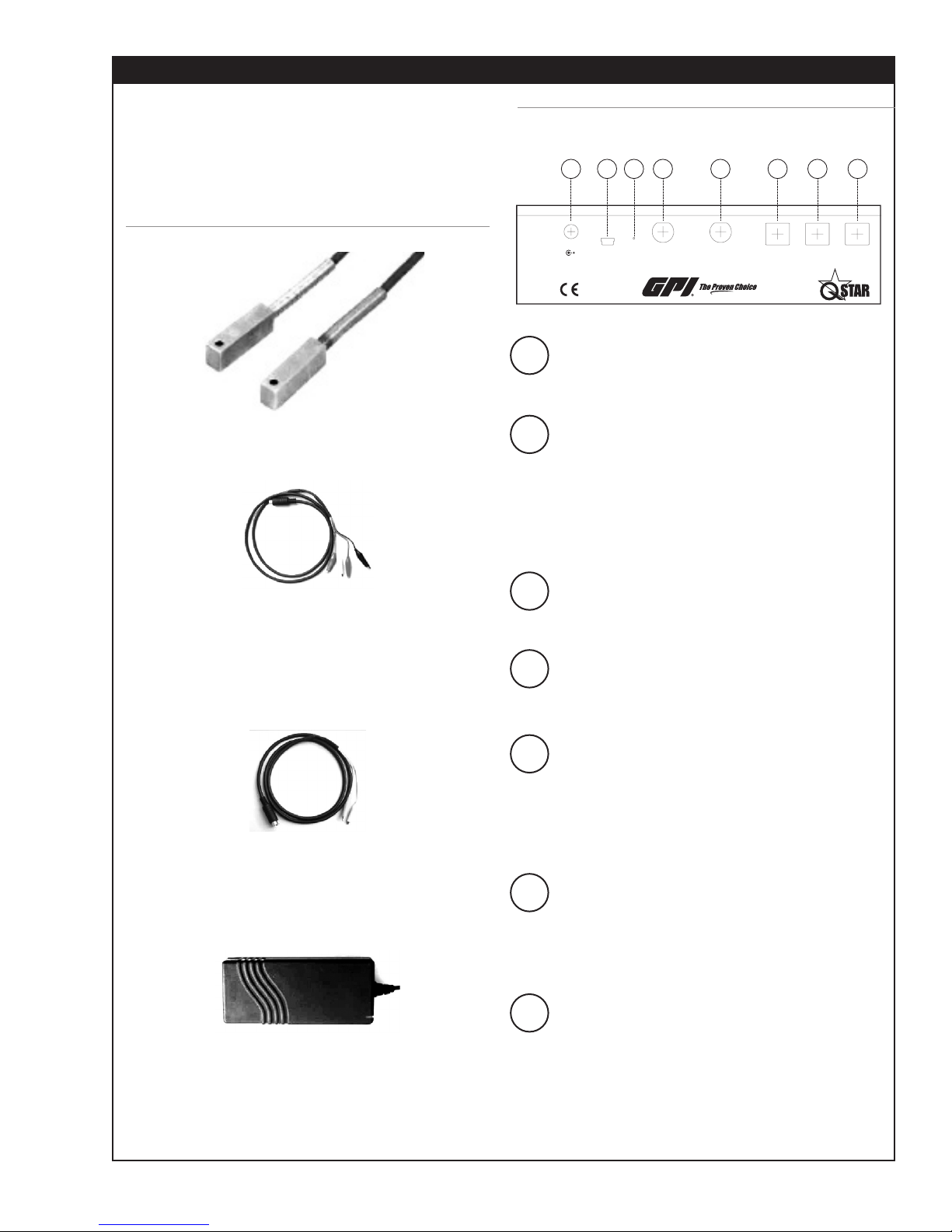

PORTABLE UFM AND COMPONENTS (Continued)

78

QMP-PT100 Temperature sensors

(Optional)

The clamp-on temperature sensors collect temperature data in heating and cooling circuits.

Use this data to calculate heating and cooling quantities.

FIGURE 20: QMP-PT100 clamp-on temperature sensors

4-20mA analog output cable

FIGURE 21: Back view of Portable UFM connections

1234 56

Reset Down Up Relays/ T1/T2Analog OutUSBPower

Impulse OUT

1 Power Input

This jack is used to connect the plug-in power

adapter that is included with the UFM package.

2 USB Interface (Mini.USB Type B)

Enables access to the integrated SD memory

card from a PC. This card is used to store data

logging information and measurement data (LOG

les). Windows XP or later versions detect the

internal SD Card as mass storage medium. No

need to install additional drivers.

QMP-001

The analog output cables can be used to connect an

external data logger or recorder to the ow transmitter for the transmission of measured values such as

owrates, or thermal output.

Cable for Relay/Pulse

The relay connecting cable can be used to trigger

alerts. For example, when exceeding a certain owrate.

Power adapter 100-240V, 47-63Hz, 1A

The power adapter is normally used to charge the

battery. Your UFM supports permanent operation by

using the power adapter.

3 Hardware Reset

Use a small screwdriver (or paper clip) to

press the reset button.

4/5 BNC Inputs for Ultrasonic

Transducers

Jacks for the ultrasonic transducers.

6 Relay/Pulse Output (4-Pol Mini DIN)

Electrically isolated output with NO (normally

open) contact. This internal NO contact is open

unless an actuating signal is generated. Allows

user to assign alarm or threshold limit functions

to this output.

7 Input for Temperature Sensors

QMP-PT100 (6-Pole Mini DIN)

Receptacle for the optional temperature sen-

sors that enable the use of the internal heat

measurement function of the UFM.

8 4-20mA Analog Output

(5-Pol Mini DIN)

These outputs can be assigned variables such

as the owrate and return a current that is

proportional to the value of the variables. The

outputs operate in active (power provided by

ow transmitter) 2-wire mode.

9

SAFETY INSTRUCTIONS

HOW TO NAVIGATE

• The ow transmitter cannot be operated outside the

temperature range from -4° F to 140° F.

• The ultrasonic transducers are sensitive to mechanical

stress such as impact and vibration. Always safeguard

the transducers against strong vibration or impact to

avoid damage or destruction.

• The plug-in power supply is suitable for in-door use

only.

• The plug-in power adapter or the power cable must

be replaced completely in the case of mechanical or

electrical damage.

• The ow transmitter is not approved for operation in

hazardous locations. The standard ultrasonic transducers are not approved for operation in hazardous

locations.

• The ultrasonic transducers may not be operated

outside their specied uid temperatures.

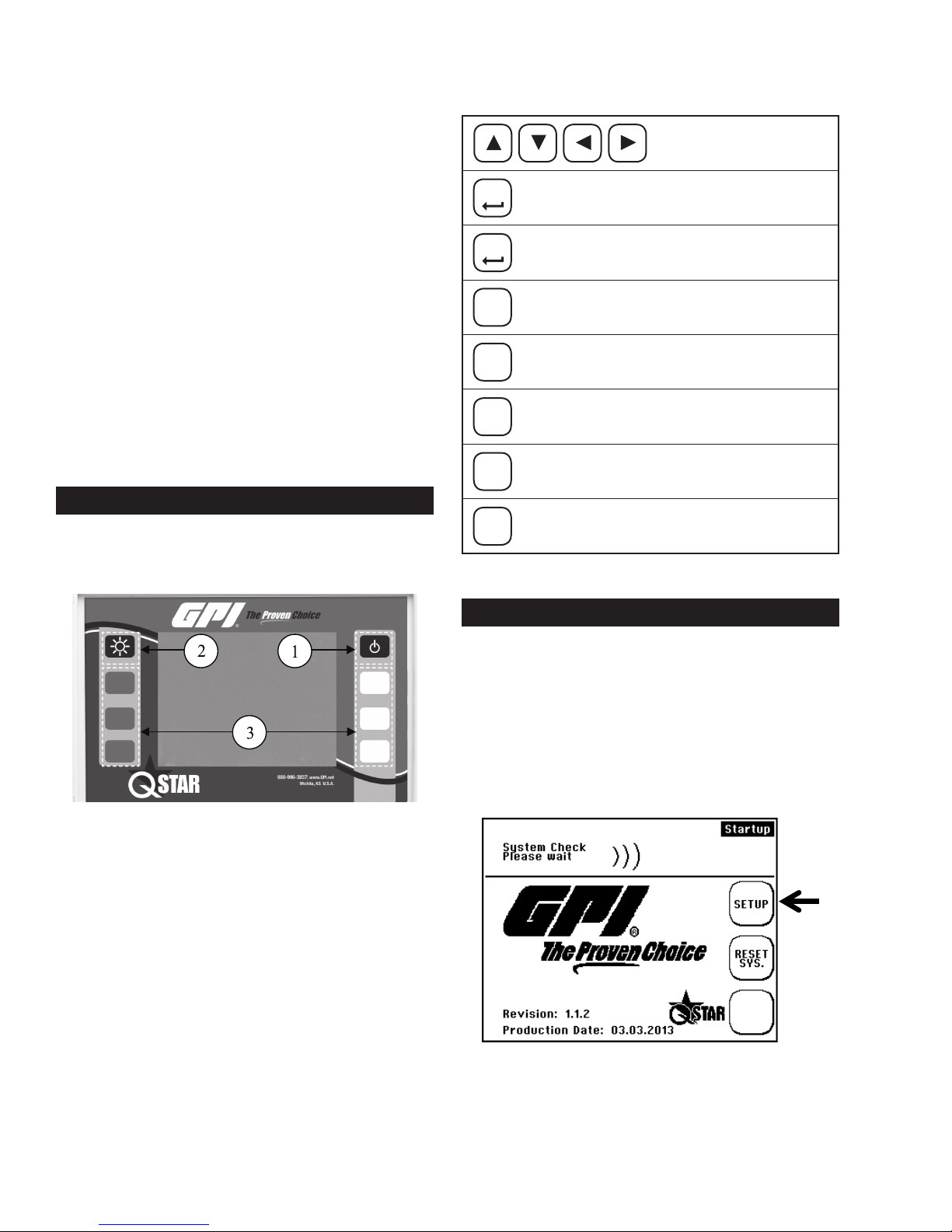

OPERATING

Use the corresponding multifunctional buttons:

Arrow buttons for

navigation

ENTER

NEXT

BACK

XYZ

Conrms entry

Conrms entries and opens the next window

Returns to the previous window

Increases the value

+

–

Reduces the value

Activates a certain function (depending on

chosen menu)

No function

CONTROL BUTTONS

1. Turns on Portable transmitter. Fixed transmitter will

automatically start when connected to voltage supply.

2. Switches the backlight On and Off.

3. Multifunctional buttons: Use this button to select the

function that is displayed next to it on the screen.

GETTING STARTED

BASIC SETTINGS, MAIN MENU,

NAVIGATION

Setting Language

1. Switch on the device. During the start sequence, press

the multifunctional button that is located next to the

“SETUP” eld.

10

2. Conrm the “SETUP LANG.” button

2. Select “COMPL Setup” when window appears.

3. Use the arrows in the next window to select the dialog

language. Conrm entry with “Enter”. Exit the menu

with “SETUP.”

CAUTION

The language setting selects the language used

in the menus. The language in the elds next to

the multifunctional button remains unchanged.

Navigation in Main Menu “Flow 1”

The “Flow 1” measuring window is automatically opened

with a delay of a few seconds after turning on the power.

The “Flow 1” measuring window provides an overview

of all data that is necessary for ow and optional heat

measurements.

You are now in the main menu. Select all necessary

functions of the device in this menu.

To return to the measuring window, proceed as follows:

Select “ESC” -> “MEAS” in the next window.

To accelerate access to the main menu after

power on, select the start sequence “SETUP.”

i

Select “COMPL SETUP” in the next window.

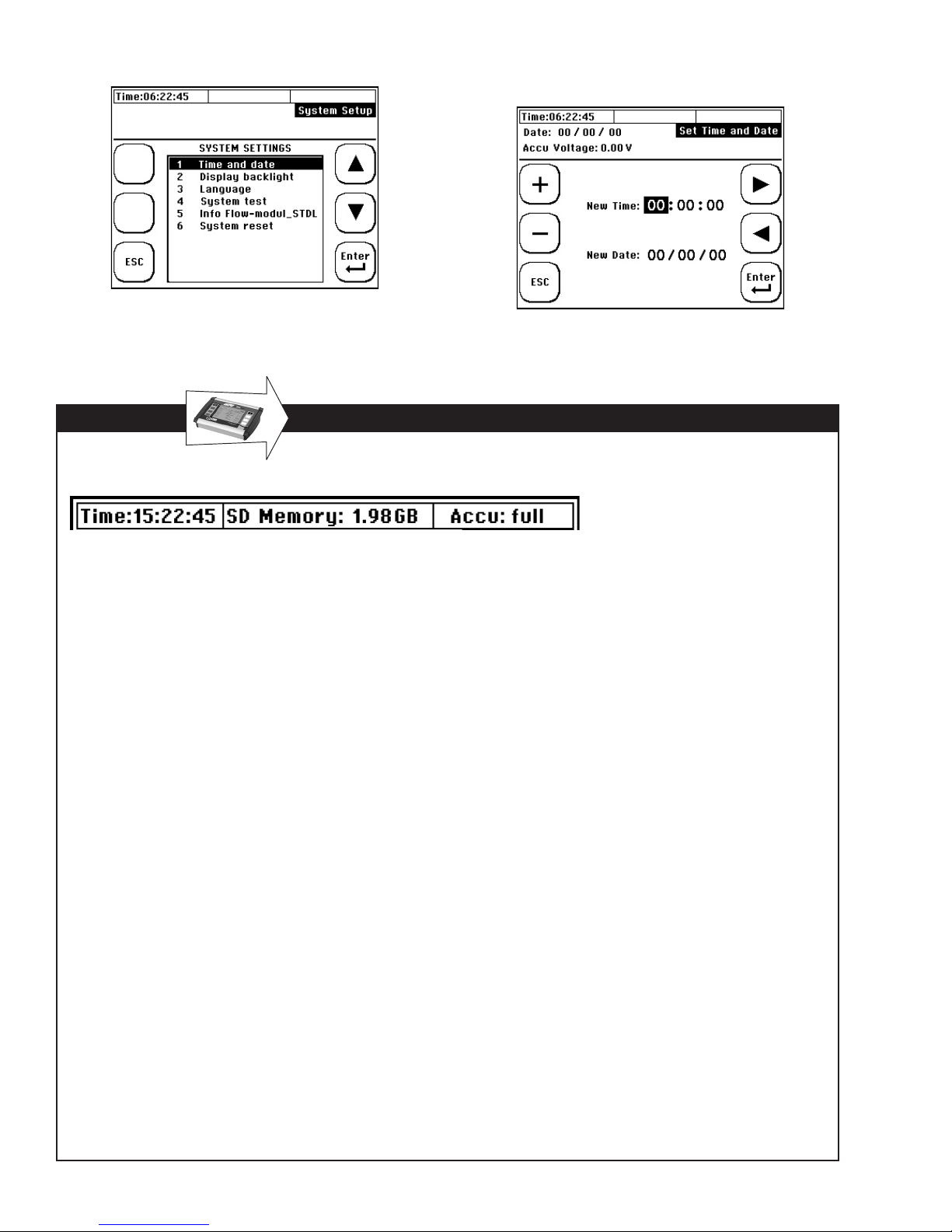

Setting the Time and Date

After selecting the dialog language, the setup menu opens.

1. Scroll the “System Setup” menu command using the

arrow keys.

1. Select “Setup”

11

2. Select the “Time and Date” menu command

APPLIES TO PORTABLE QSTAR

The status bar is located in the uppermost row of the display.

3. Enter the time as: Hour (hh): Minute (mm): Second (ss).

Enter the date as: Month (mm): Day (dd): Year (yy).

Time

Displays the current time (system time). The time stamp

that is derived from the system time will be applied to

the measurement data.

SD memory

Displays the free space on the internal SD memory

card of the device (standard is 2 GB).

Backup battery

Provides information about the status of the rechargeable battery.

• Load: The device is powered using the power

adapter while the battery is charged. The empty

battery needs a charging time of approximately ve

hours.

• Full: The battery is in a charged state. The device

may be operated for approximately ve hours when

the display backlight is switched off or for approxi-

mately three hours when it is switched on.

Percentage display

Displays the charging state of the battery.

The times specied applies to a new battery. The factual

operating/load cycles may deviate from the specied

time values.

12

PREPARING FOR MEASUREMENT

The following section elaborates on essential aspects that must be taken into account for successful

owrate measurements.

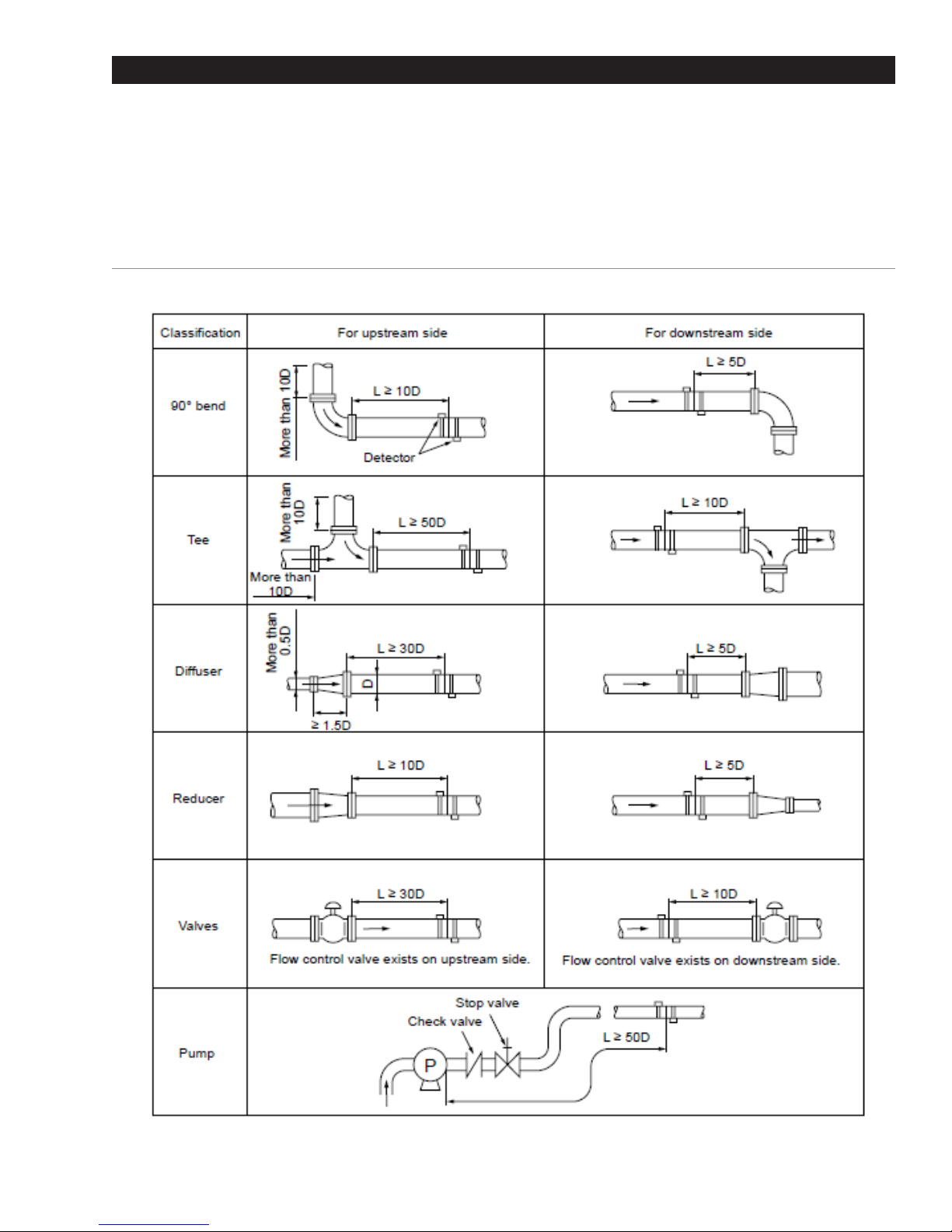

STRAIGHT RUN REQUIREMENTS

The selection of the mounting location has a signicant impact on measurement quality. The

charge and discharge areas listed in the following table should be taken into account.

FIGURE 22: Straight run requirements

13

TRANSDUCER MOUNTING POSITIONS

4cos221

TT

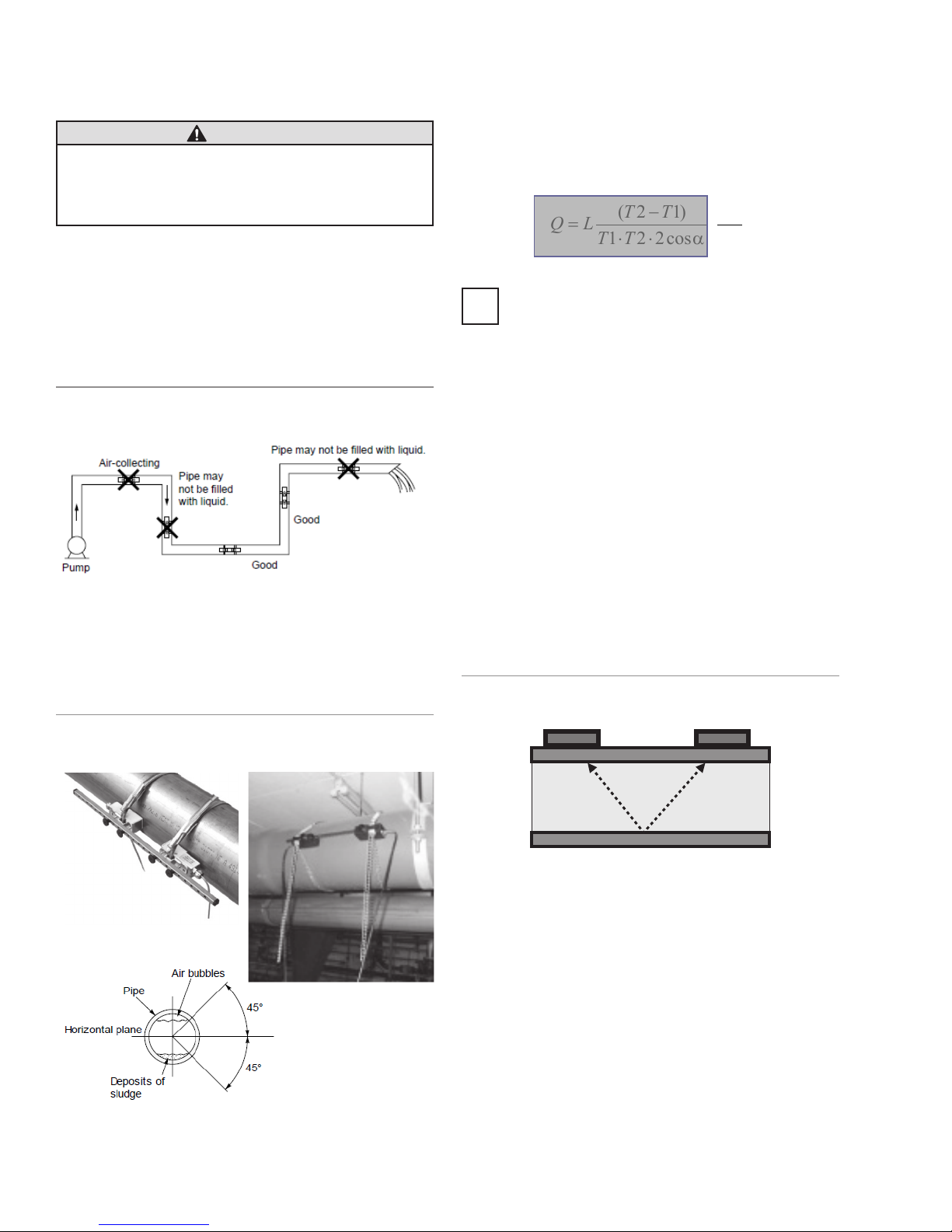

Mounting Ultrasonic Transducers

CAUTION

The pipe must always be lled completely

at the mounting positions of the ultrasonic

transducers. It is not possible to take

measurements on partially lled pipe.

The ultrasonic transducer can be operated in any mount-

ing position. However, conforming with the mounting

positions shown below is mandatory. The drawing shows

the side view of the piping.

Mounting Ultrasonic Transducers On

Horizontal Pipe

FIGURE 23: Preferable mounting positions for ultrasonic

transducers (1)

UFM uses the cross section of the pipe to calculate

the ow. The cross section is calculated from the inner

diameter setup (user setting). If there is sedimentation

in the pipe, which decreases the real inner diameter, a

small amount of uncertainty may result. The same hap-

pens when the inner diameter is not known/estimated.

D

2

πα⋅⋅

)12(

TT

LQ

=

−

⋅⋅

To measure pipes with unknown wall thicknesses

a wall thickness gauge is avaiable from GPI. Ask

i

GPI Customer Service Representative for more

information or visit www.GPImeters.net.

Ultrasonic Transducers On Non-Planar

Surface

Never mount the transducers on non-planar surfaces such

as welding seams or deformations. Always try to remove

thick and uneven protective paint coating from the piping

area where the ultrasonic transducers will be mounted.

On horizontal piping, mount the transducer with an offset

of about +/-45% to the horizontal plane. Otherwise, there

is a risk of the accumulation of bubbles in the upper sec-

tion and sedimentation in the lower section of the pipe.

FIGURE 24: Preferred mounting positions for ultrasonic

transducers (2)

Mounting Ultrasonic Transducers

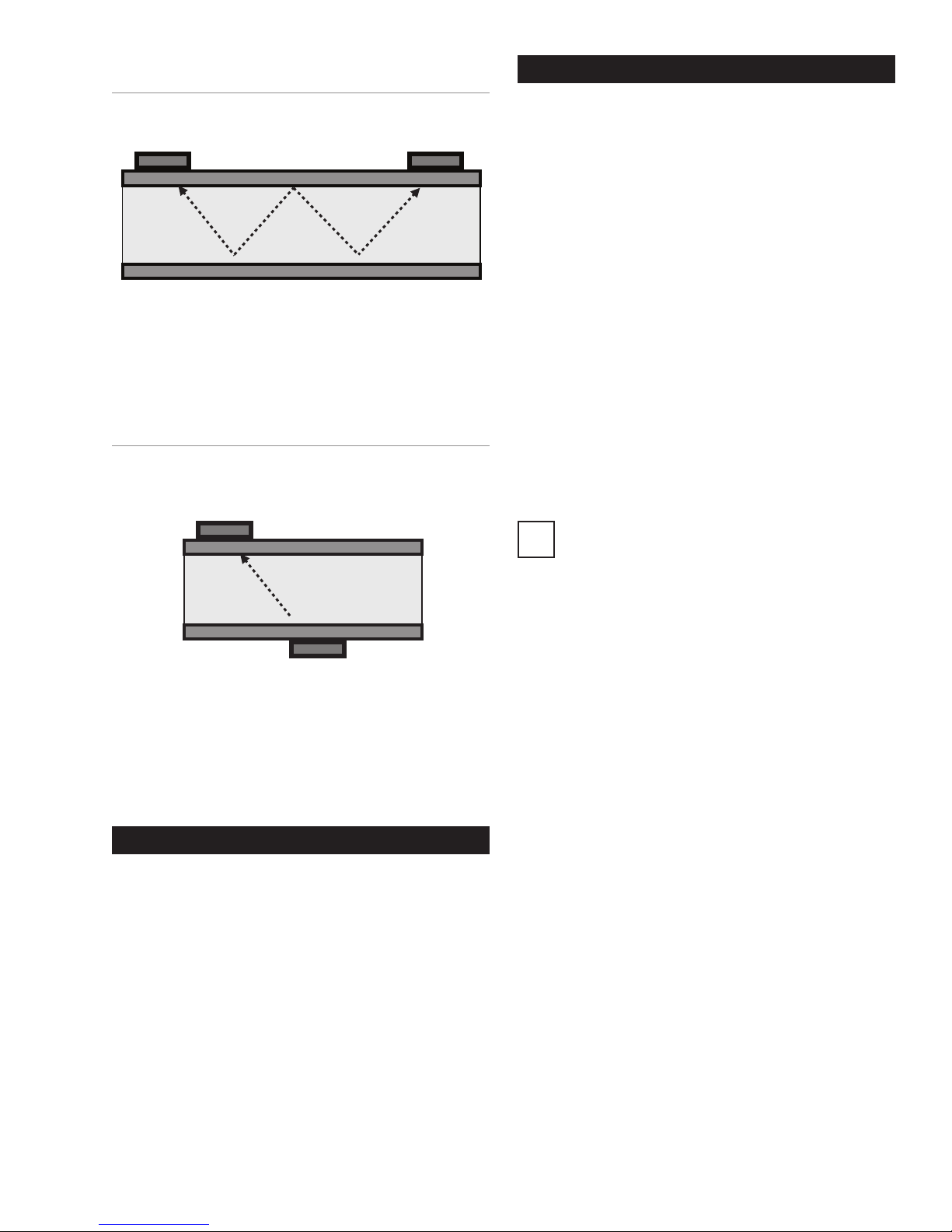

Following are the options for mounting the ultrasonic transducers. The V-mode is standard for most applications.

V-Mode

FIGURE 25: Mounting of transducers in V-mode

Transducer 1 Transducer 2

In the V-mode, both ultrasonic transducers are mounted

onto the same side of the pipe. This mode is the standard

for small and medium pipe dimensions. The ultrasonic

signals are reected from the pipe wall.

14

W-Mode

Transducer 1

SETUP PARAMETERS

FIGURE 26: Mounting of Transducers in W-Mode

Transducer 1 Transducer 2

The W-mode is a special method for mounting the ultrasonic transducers. This method is usually employed on

very small pipes.

Z-Mode

FIGURE 27: Mounting of Transducers in Z-Mode

Transducer 2

The Z-mode is a special method for mounting the ultrasonic transducers. The signal is transmitted across

a shorter distance with this installation method. Use for

measuring large-scale piping systems, or where the sys-

tem is lled with heavily contaminated or gas-loaded uid.

Ths section denes the input of all data that is necessary

for ow measurement.

• “QUICK SETUP”: The Quick Setup guide offers stepby-step instructions on the essential tasks required to

setup parameters.

• “COMPL SETUP”: The complete setup function

enables access to all options and expert settings.

WHAT NEEDS TO BE SETUP

• The pipe’s outer diameter or circumference.

• The wall thickness of the pipe. The material and thick-

ness of the pipe lining, if such lining exists.

• The pipe material

• The uid

• The type of ultrasonic transducers

• The mounting mode for the ultrasonic transducers

Ultrasonic measurement is based on the signal

transit time process. The ultrasonic signals

i

penetrate the piping and the uid. In order to

calculate the signal transit time, each uid, pip-

ing material and existing lining will be assigned a

sonic speed value, as well as the pipe diameter

or circumference value. The tabular database

species the sonic speed values for the materials

and uid. The sonic speed for materials not listed

in the tables must be entered manually. Tables

that list additional sonic speed parameters for

different materials are available in the back of

these operating instructions.

MEASURING WITH UFM

5 Steps to Flow Measurement:

• Select a suitable location for mounting the ultrasonic

transducers

• Setup the UFM pipe parameters

• Mount the ultrasonic transducers onto the piping

• Perform a zero calibration

• Start the ow measurement

15

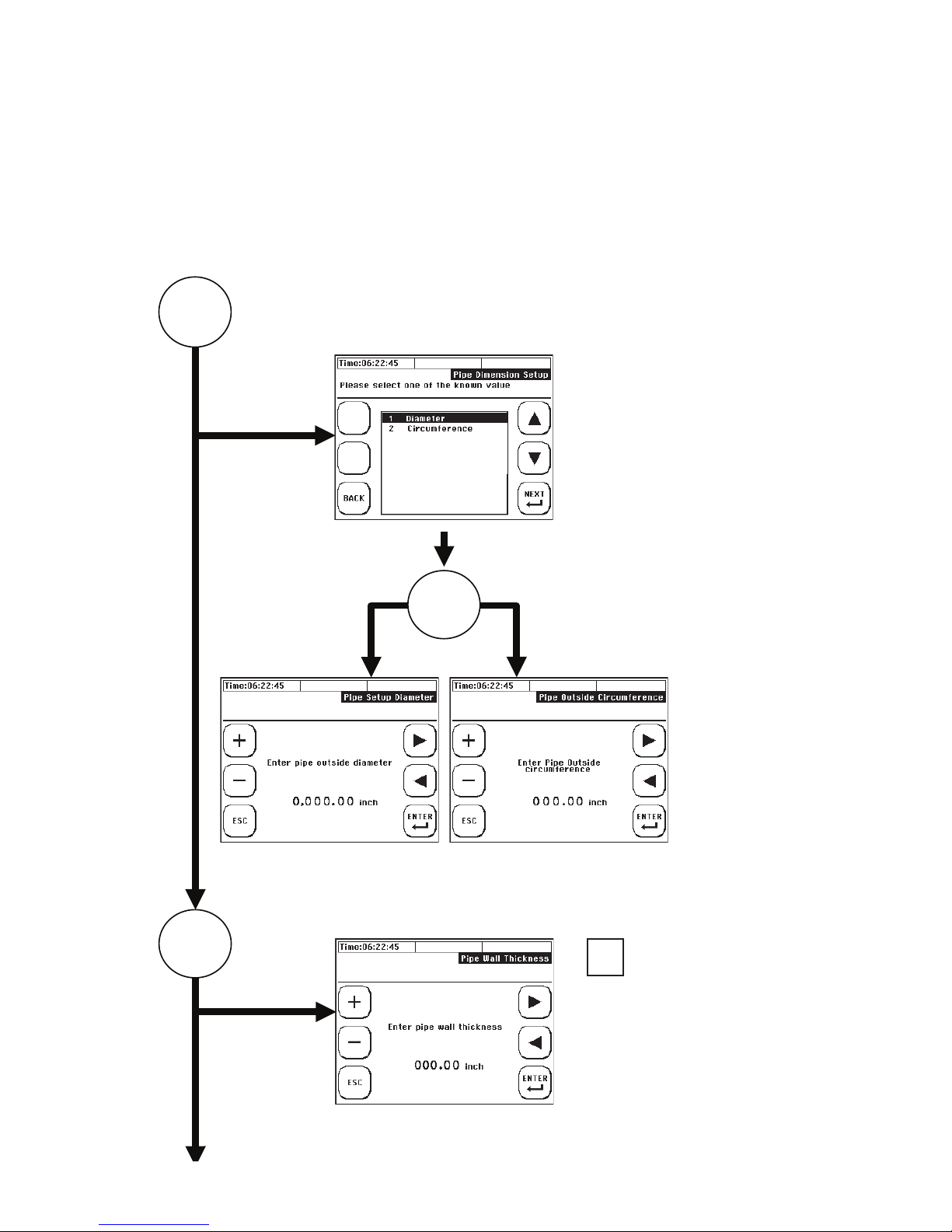

USING QUICK SETUP

START

Accessing the setup dialog:

After power on: Select “Setup” -> “Quick Setup” within the start sequence.

In the primary measuring window “Flow 1”: Select “Setup” -> “Quick “Setup.”

Enter the kinematic viscosity of the uid:

Specify whether to enter

the pipe circumference

or outer diameter.

1

2

Enter the outer diameter

OR

Enter the outside

circumference

i

Use a wall thickness

meter if wall thickness

is unknown, or

consult published

pipe standards.

16

Enter the pipe’s wall thickness

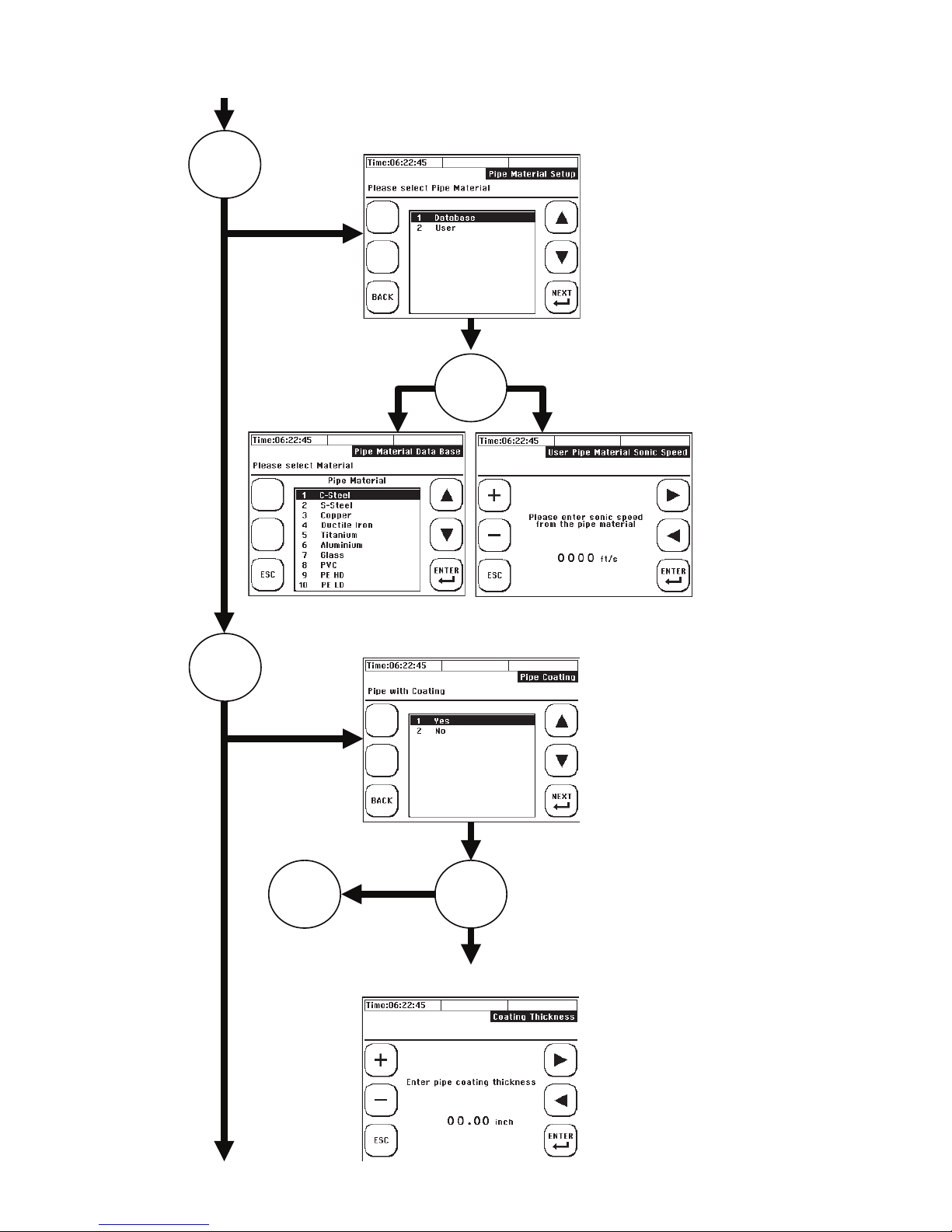

USING QUICK SETUP (CONTINUED)

Choose pipe material

3

OR

4

Does the pipe have a lining YES/NO?

NO

OR5

YES. Enter the thickness of the lining.

Select the database,

or user input if a

material is not listed

in the database.

17

USING QUICK SETUP (CONTINUED)

OR

Choose lining material from

the database.

5

Enter speed of sound of

user-dened coating.

Select the uid:

OR

18

Enter the kinematic

viscosity of the

medium:

Loading...

Loading...