Page 1

SAVE THESE INSTRUCTIONS

Commercial Grade

Q9 COMPUTER

ELECTRONICS

Owner’s Manual

920787-01 Rev H 11/02/2020

Page 2

To the owner . .

Congratulations on receiving your

GPI Commercial Grade Computer

Electronics. We are pleased to pro‑

vide you with a product designed

to give you maximum reliability and

eciency.

Our business is the design, manu‑

facture, and marketing of liquid han‑

dling, agricultural, and recreational

products. We succeed because we

provide customers with innovative,

reliable, safe, timely, and compet‑

itively‑priced products. We pride

ourselves in conducting our business

with integrity and professionalism.

We are proud to provide you with a

quality product and the support you

need to obtain years of safe, depend‑

able service.

Victor Lukic, President

Great Plains Industries, Inc.

TABLE OF CONTENTS

General Information .............................2

Meter Installation .................................3

Troubleshooting ...................................4

Specications ......................................5

Installation ...........................................8

Operation .............................................9

Parts ..................................................17

Service...............................................17

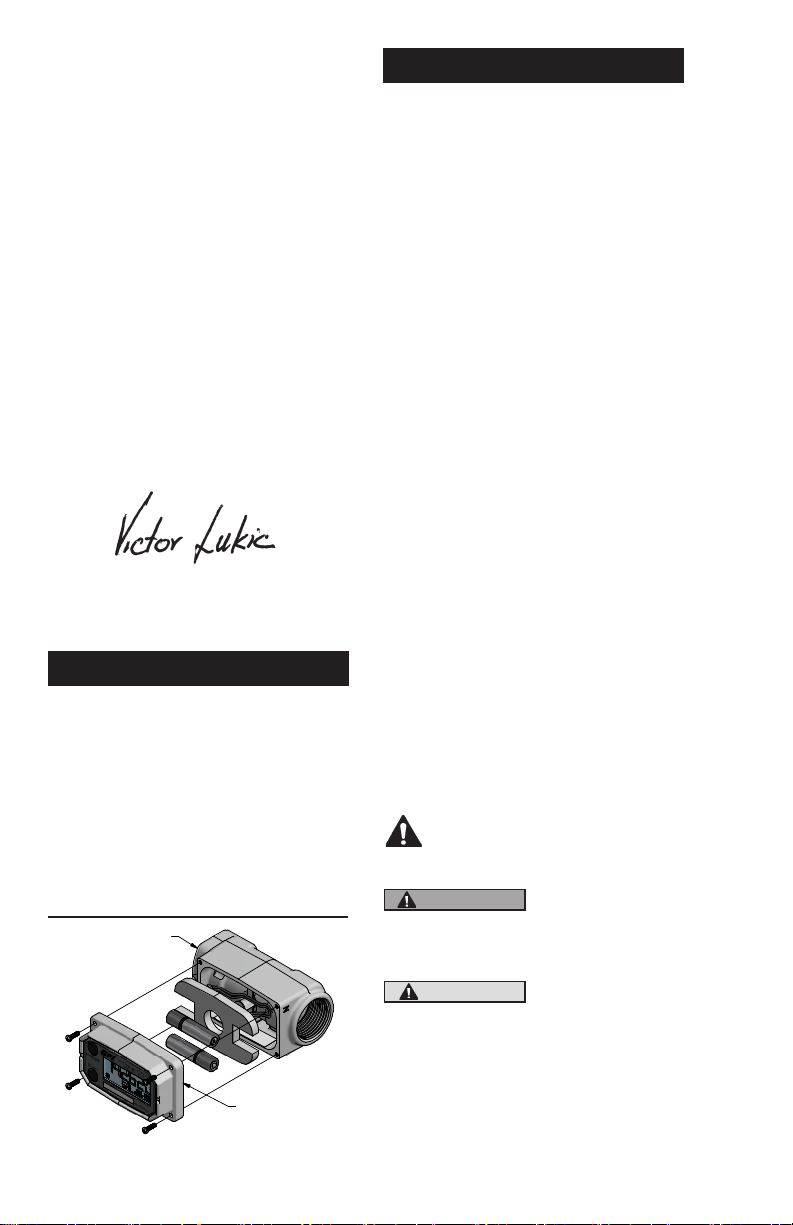

GENERAL INFORMATION

This manual will assist you in oper‑

ating and maintaining the Computer

Electronics of the GPI Commer‑

cial Grade Meters. (See Figure 1)

Calibration details are given in this

manual. Information on turbine hous‑

ings and accessory modules are

contained in other manuals. Please

reference those as necessary.

TURBINE HOUSIN G

2

Figure 1

COMPUTER

ELECTRONICS

Before Getting Started

Take the time to fully acquaint your‑

self with all information about the

components of your GPI Electronic

Digital Meter. If you need assistance,

contact the distributor from whom

you purchased your computer.

This symbol is used through‑

out the manual to call your

attention to safety messages.

WARNING

CAUTION

Notes give information that can

improveeciency ofoperations.

Warnings alert

you to the poten‑

tial for personal

injury.

Cautions call

your attention to

practices or pro‑

cedures which

may damage your

equipment.

Page 3

It is your responsibility to make sure

that all operators have access to ad‑

equate instructions about safe oper‑

ating and maintenance procedures.

Read Me!

For your safety, review the major

warnings and cautions below before

operating your equipment.

WARNING

The apparatus enclosure may

contain aluminum and is consid‑

ered to constitute a potential risk

of ignition by impact or friction.

Care must be taken into account

during installation and use to

prevent impact or friction.

WARNING

Part of the enclosure is con‑

structed from plastic. To prevent

the risk of electrostatic sparking

the plastic surface should only

be cleaned with a damp cloth.

1. This equipment is approved to

handleonly uidsthatarecom‑

patible with all wetted materials.

2. When measuring ammable liq‑

uids, observe precautions against

reorexplosion.

3. When handling hazardous liq‑

uids, always follow the liquid

manufacturer’s safety precau‑

tions.

4. When working in hazardous

environments, always exercise

appropriate safety precautions.

5. For best results, always verify

accuracy before use.

METER INSTALLATION

Avoid electronically “noisy”

environments. Install at least 6

inches (15.2 cm) away from motors,

relays, or transformers.

All GPI A1 Series meters are Factory

Mutual Approved and carry a Class

1, Division 1 Approval for hazardous

environments. In addition, GPI meters

have NEMA Type 4 enclosures.

They are tested and calibrated at

the factory using state‑of‑the‑art

calibration procedures and testing

equipment.

To ensure accurate measurement,

remove all air from the system before

use.

1. Ensure some back pressure on

the turbine.

2. Open the discharge valve

or nozzle and allow fluid to

completelyllthesystem.Make

sure the stream is full and steady.

3. Close the discharge valve or

nozzle.

4. Start normal operations.

It is strongly recommended that

accuracy be veried prior to use.

To do this, remove all air from the

system, measure an exact known

volume into an accurate container,

and verify the volume against the

readout or recording equipment. If

necessary, use a correction factor

to figure final volume. For best

results,accuracyshouldbeveried

periodically as part of a routine

maintenance schedule.

3

Page 4

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

A. METER IS NOT 1. Field Calibration not Field calibrate again or select

ACCURATE performed properly Factory Calibration.

2. Factory Calibration not Perform a Field Calibration accord‑

suitable for liquid being ing to Calibration Section.

measured

3.Meteroperatedbelow Increaseowrate.

minimumowrate

4. Meter partially clogged Remove meter. Clean carefully.

with dried liquid Make sure rotor spins freely.

5. Turbine bearings Remove meter. Clean carefully.

partially clogged with Make sure rotor spins freely.

dried liquid

6. Sealant material Remove meter. Make sure rotor

wrapped around rotor spins freely.

7. Installed too close to Install correctly.

ttings

8. Installed too close to Install correctly.

motors or electrically

“noisy” environment

B. READOUT 1. Batteries weak, dead Remove computer, check and

FADED OR or not connected replace batteries if necessary.

BLANK

2. Computer defective Contact the factory.

C. NORMAL 1. Field Calibration not Field Calibrate again or select

FLOWRATE performed correctly Factory Calibration.

BUT METER

2. Rotor stuck or damaged Remove meter. Make sure rotor

DOES NOT

spins freely.

COUNT

3. Sealant material Remove meter. Make sure rotor

wrapped around rotor spins freely.

4. Computer defective Contact the factory.

D. REDUCED 1. Meter clogged with Remove meter. Clean carefully.

FLOWRATE dried liquids Make sure rotor spins freely.

AND METER

2.Belowminimum Increaseow.

DOES NOT

owrate

COUNT

E. CANNOT GET 1. Wrong button sequence Proceed with calibration according

METER INTO to the Calibration Section.

FIELD CALI‑

2. Computer circuit board Replace computer. Contact the

BRATION

defective factory.

3. Button defective Replace computer. Contact the

factory.

4

Page 5

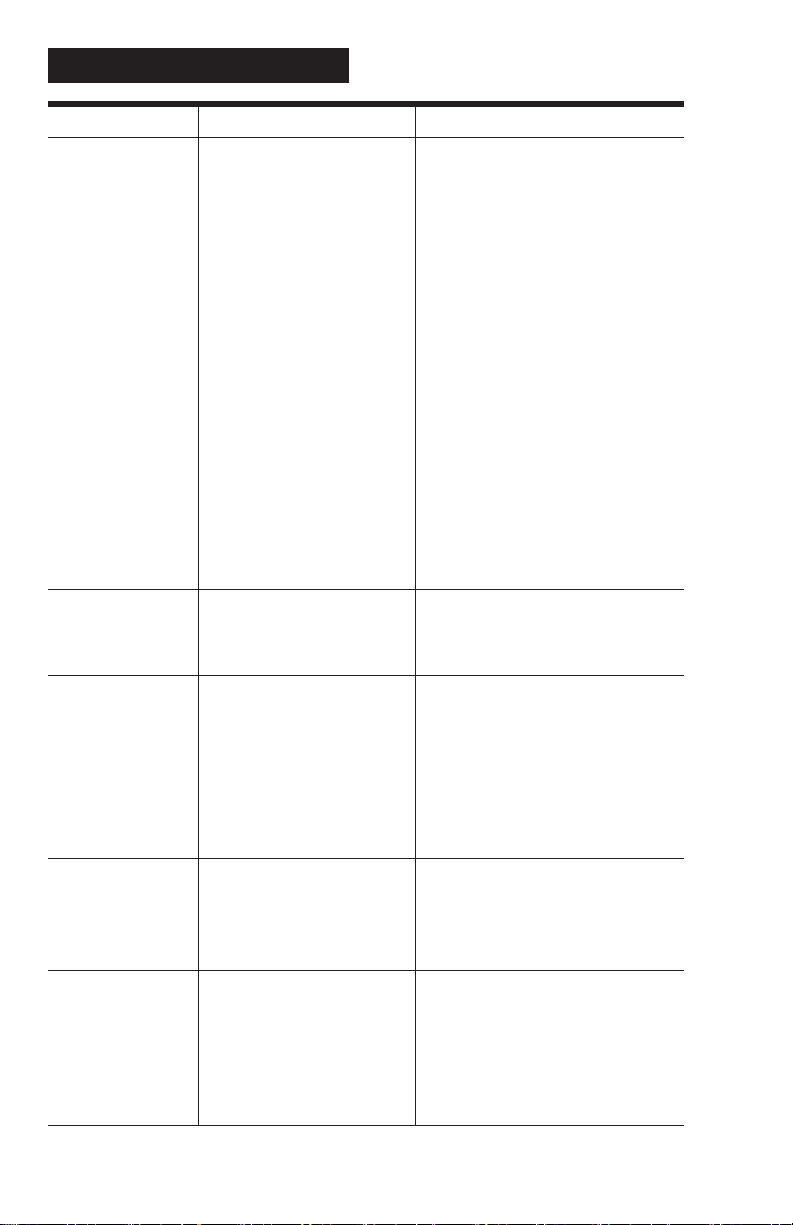

Q9 COMPUTER ELECTRONICS

MECHANICAL

Housing

Material

+0°F to +129°F (‑18°C to +54°C)

information on GPI® Remote Kits.

Storage

Temperature

ELECTRICAL

Input

Rate

Minimum: 0.001 pulses/unit

Maximum: 999,999 pulses/unit

Field

Correction

Readout

Totals

Minimum Display: 0.001

Maximum Display: 999,999 (x100)

Field

Calibration

Internal Power Supply: (2) Alkaline AAA batteries @ 1.5-volts each

Battery Life: 2+ years

STANDARD FEATURES INCLUDE

(2) Totalizing Registers

(1) Field Calibration Curve

COMPUTER ELECTRONICS TERMINAL CONNECTIONS

SPECIFICATIONS

Transparent Amorphous Nylon

Operating

Temperature

Pulse

K‑Factor

Calibration

Power

(1) Factory Calibration Curve

Figure 2

If wider operating temperature ranges are desired, reference

‑40°F to +158°F (‑40°C to +70°C)

Frequency Range: 0.25 Hz – 3kHz

Minimum: ‑99.999%

Maximum: +99.999%

Yes

5

Page 6

SPECIFICATIONS (CONTINUED)

DIMENSIOINS

Length

Height

Height

“C”

Width (Widest Point)

3.40 in.

(8.6 cm)

0.85 in.

(2.1 cm)

0.72 in.

(1.8 cm)

2.14 in.

(5.4 cm)

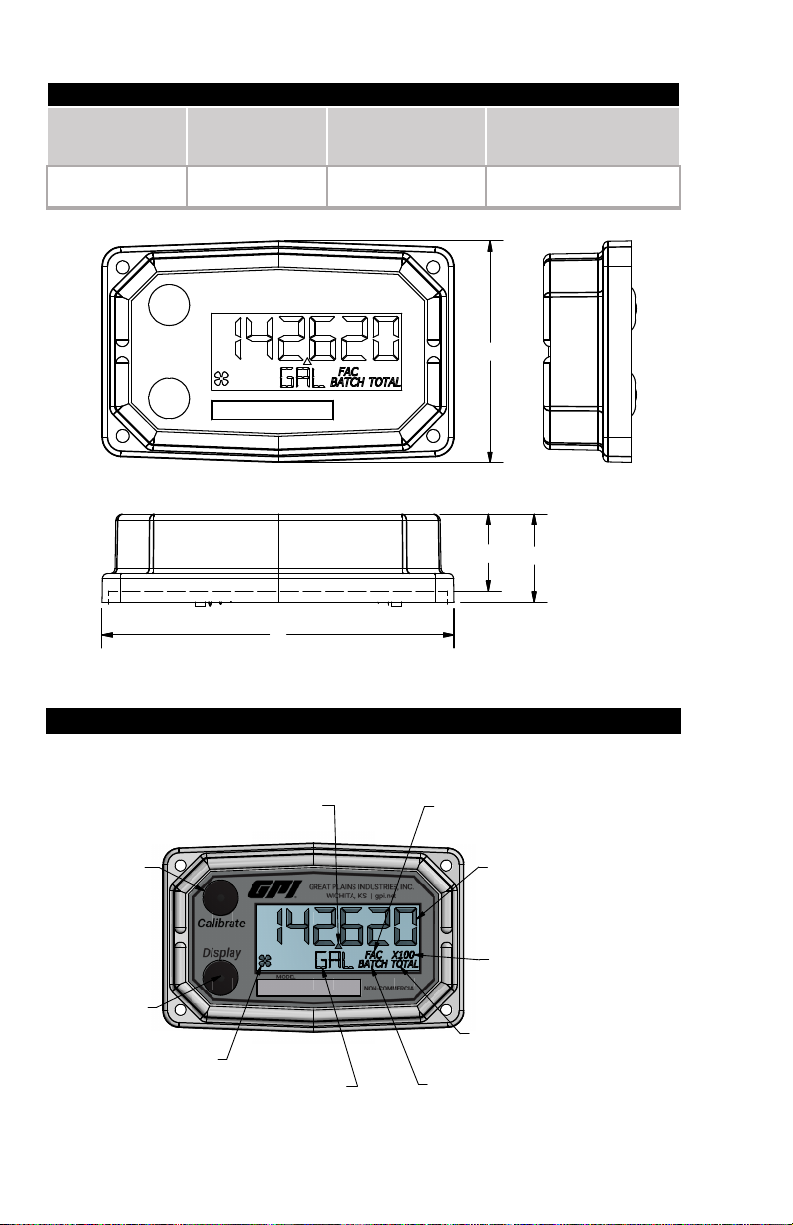

COMPUTER DISPLAY FEATURES

Figure 3

“A”

“B”

(Mounted)

“D”

D

C

B

A

Familiarize yourself with the computer features before installation and use.

CALIBRATE

BUTTON

FLOATING DECIMAL

POINT (3 PLACE)

FACTORY CALIBRATION

INDICATOR

BATCH TOTAL OR

ACCUMULATIVE TOTAL

DISPLAY

BUTTON

FLOW INDICATOR

INFORMATION ROW

BATCH INDICATOR

TOTALS SPILL-OVER

INDICATOR

(X10 OR X100)

TOTAL INDICATOR

(BATCH & ACCUMULATIVE)

Figure 4

6

Page 7

SPECIFICATIONS (CONTINUED)

AGENCY APPROVALS

Q9 Industrial Grade Computer Electronics

Intrinsically safe approval only applies when

used with a FLOMEC® FM Approved meter.

Q9 Industrial Grade Computer Electronics when installed on a

FLOMEC FM Approved meter.

IP65

NOTE: When a component with Approval Agency ratings is mated to another

SPECIFICATIONS (CONTINUED)

AGENCY APPROVALS

INTRINSICALLY SAFE FOR

CLASS I, II, III, DIV. 1,

GROUPS ABCDEFG,

T4 Ta= ‑40° to +54°C

NONINCENDIVE

FOR CLASS I, II, III, DIV. 2,

GROUPS ABCDFG, T4 Ta= ‑40° to +54°C

GREAT PLAINS INDUSTRIES, INC.,

5252 E. 36TH ST. NORTH,

WARNING:

See Owner’s

Manual for

Warnings and

Cautions Before

Installation.

WICHITA, KANSAS

67220 U.S.A

component with the same Approval Agency ratings, the combination may gain

environmental approvals.

When one of the components has lessor or no Approval Agency ratings, the resultant

combination assumes the ratings of the lessor rated component.

If one component has no ratings, the resultant combination has no ratings.

Specic Conditions of Use

1. All computer assemblies are to be used with GPI battery 902004‑02 except Q1, Q9, and R9

versions which use Energizer E92 / EN92, or Duracell MN2400 Alkaline batteries.

2. GPI remote kit assembly 113275‑1 may be used with the meter when installed in accordance

with GPI Manual No.920507‑01. GPI Remote Kit Assembly 113275‑10 may be used with the

meter when installed in accordance with GPI Manual No. 920507‑02.

3. The apparatus enclosure may contain aluminum which is considered to constitute a potential

risk of ignition by impact or friction. Care must be taken into account during installation and

use to prevent impact or friction.

REMOTE KIT ASSEMBLY (113275-10

)

4. Part of the enclosure is constructed from plastic. To prevent the risk of electrostatic sparking

the plastic surface should only be cleaned with a damp cloth.

7

Page 8

INSTALLATION

PRODUCT DESCRIPTION

INSTALLATION

This computer electronics is designed specifically for use on GPI Turbine Housings. It

is also designed to work with several accessory output modules.

The CMOS, microprocessor‑based electronics have extremely low power

requirements and data retention capabilities in both RAM and ROM. Information is

clearly displayed on a large 6‑digit LCD readout with three‑point floating decimal for

totals from .001 to 999,999 (x1), 9,999,990 (x10), or 99,999,900 (x100). All

operations are easily accessed with the two buttons on the front panel.

In a GPI turbine meter, liquid flows through the turbine housing causing an internal

rotor to spin. As the rotor spins, an electrical signal is generated in the pickup coil.

This pulse data from the turbine is translated into calibrated flow units shown on the

computer's display readout.

Before installation, ensure your computer model meets your specific needs. Refer to

the Specifications Section to confirm required features. The model number of your

computer is displayed on the outside wall of the computer housing and also inside the

computer housing on the floor of the battery holder.

If you ordered your computer electronics with a turbine body, the electronics are

installed at the factory.

If you ordered your computer separately as a replacement, simply mount the

computer on your turbine body with the four screws at the corners of the faceplate.

Make sure the seal is fully seated before tightening the screws.

If you ordered the computer with a turbine body and an accessory module, please

review and thoroughly understand all installation instructions before proceeding.

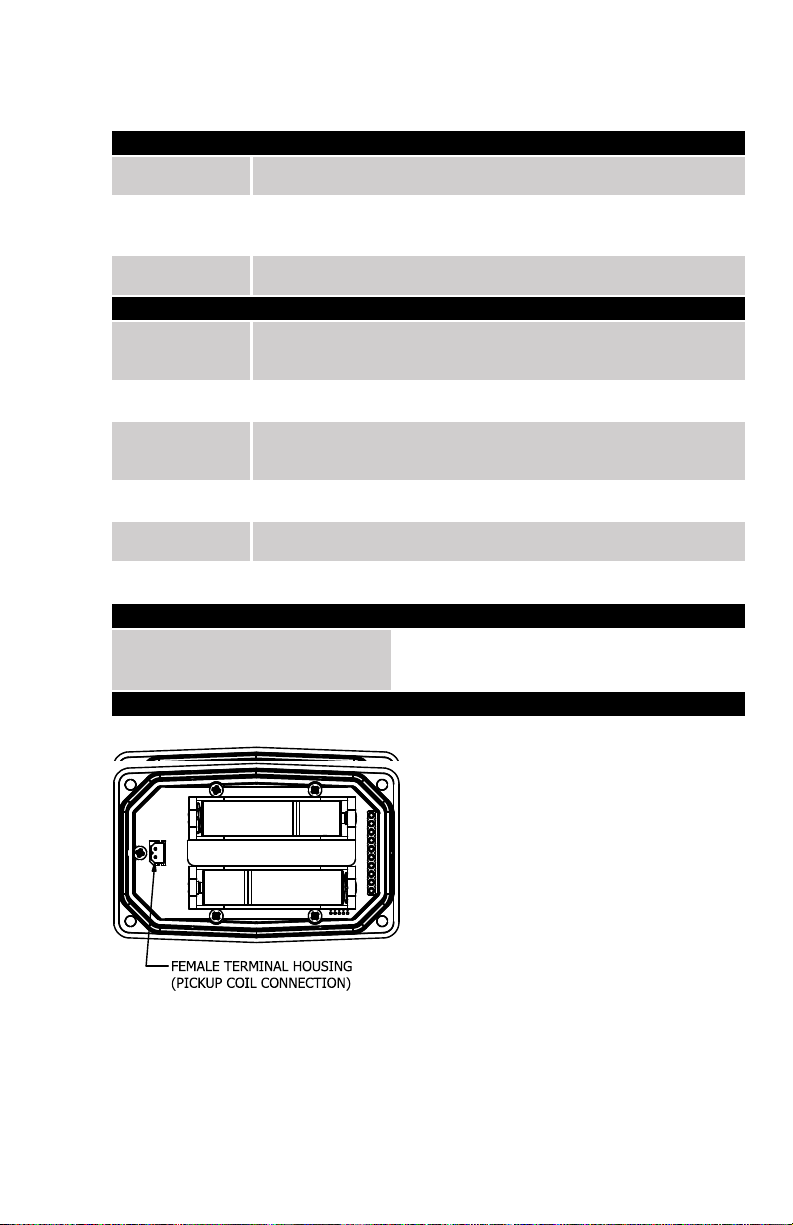

All GPI turbine meters are designed to measure flow in only one direction. The

direction is indicated by the arrow on the turbine outlet port. If the computer display is

upside down in your installation, remove the four screws, turn the display 180 degrees

and reinstall the screws. (See Figure 5)

PICKUP COIL

CONNECTOR

METER BODY

Figure 5

NOTE: When rotating the computer

display, it is not necessary to

disconnect the pickup coil connector,

however, care should be taken to

avoid inadvertent strain on the

connector wires.

8

Page 9

OPERATION

COMPUTER DISPLAY

ACTIVATE THE COMPUTER

All operations are revealed on the LCD using the large 6‑characters in the top row and

smaller characters and symbols in the second row. These characters and symbols

indicate information regarding totals, flow, calibration, units of measure and

operational messages.

Push button operation varies dependent upon the various modes of operation, i.e.

Normal Operation mode and Field Calibration mode. Their operation will be described

in their respective sections.

When batteries are installed, the computer is on continuously and always ready to

perform.

The computer is powered by field replaceable commercially available batteries.

Reference the computer maintenance section for battery replacement details.

Figure 6

Figure 7

When batteries are initially installed or

replaced, the initialization routine will start

the LCD display blank, then display

“HELLO” on the top row and “Q9Disp” on

the information row for one second. (See

Figure 6)

The LCD will then display “HELLO” on the

top row and “FW Vxx” on the information

row for one second. The Vxx will be the

version of the software installed on the

display. Example: “FW V03” indicates

firmware version 3 installed on the display.

(See Figure 7)

General

The computer maintains two totals; Batch total and accumulative total. The batch

total can be reset to measure flow during a single use. The accumulative total

provides continuous measurement and can only be reset by removing the batteries,

holding down the Display button, and replacing the batteries.

The button usage map on the next page is useful for understanding where the various

menus are located within the software programming and the route to get to a specific

menu. The map is followed by user instructions explaining each menu.

9

Page 10

OPERATION

NORMAL OPERATION MODE

Button Usage Map – Normal Operation Mode

BUTTON

Display

Display

Hold

Calibrate

Calibrate

Button Operation (Normal Operation Mode)

Toggles Between

When Batch Total

is Displayed

and

Press

Display

Hold for 3 Seconds to Enter

Field Calibration Mode

Hold for 3 Seconds

to Reset Batch Total

Toggles Between

Batch Total

Accumulative Total

Gallons

Litres

Display Button: Toggle between batch total and accumulative total.

When a total is displayed, momentarily pressing Display button toggles the top row of

large display digits between batch total and accumulative total. The information row

will change to the proper units and the corresponding icons will also be shown, i.e.

TOTAL or BATCH TOTAL. (See Figure 8)

(Batch Total‑Litres) (Accumulative Total‑Gallons)

Figure 8

10

Page 11

OPERATION (continued)

NORMAL OPERATION MODE (continued)

Display Button: Batch total reset.

When a batch total (see Figure 9‑1) is displayed, press and continue to hold Display

button for 3 seconds; the software will display a three second count down, then reset

the batch total to zero. (See Figures 9‑2 thru 9‑4)

NOTE: If Display button is released prior to

count down completion, the software returns to

Figure 9‑1

Figure 9‑2

Figure 9‑3

Figure 9‑4

NOTE: When the accumulative total is displayed in Normal Operation Mode, it cannot

be reset using the Display button. Accumulative total can only be reset by removing

Figure 9‑5

batch total screen. (See Figure 9‑1)

NOTE: After count down completes, display will

show 0.000 until user releases Display button.

(See Figure 9‑3)

NOTE: After Display button is released, the

display will return to Batch Total screen and will

increment the total if flow is detected. (See Figure

9‑4)

the batteries, holding down the Display button, and

replacing the batteries. If the user attempts to reset it

using the Display button, the software will display a

“Reset Denied” message on the LCD until the button

is released. (See Figure 9‑5).

11

Page 12

OPERATION (continued)

FIELD CALIBRATION MODE (continued)

Calibration Method Selection Menu

This menu is used to define which calibration method will be used in normal operation,

either factory calibration or field calibration. The calibration method last entered (by

the user or the factory) will be used to calculate volume.

Factory Calibration: All units are configured with a "factory" calibration. This factory

calibration (FAC icon displayed below 6-digit display) is permanently programmed into

the computer and is not user adjustable.

NOTE: The factory calibration stored in the unit will never be lost

Factory calibration is the typical use

method (see Figure 10-1). Prior to

shipping from the factory, the display will

be configured and calibrated to the meter

body on which it is installed (or going to be

installed).

When the user selects this option the FAC

icon will be “ON” to indicate that the display

is using its factory calibration table. This

method does not support field calibration.

Figure 10-1

Field Calibration: Field calibration is done using the dispense/display method.

Dispense/Display is a field calibration

method by which the user will dispense a

known volume of fluid and the software will

keep track of the pulse count during the

dispense operation. The user will then

enter the known volume into the display

and the software will calculate a K-factor

for the volume dispensed. (See Figure 10-

2)

Figure 10-2

General

The calibration method may be set by the user (either factory calibration or field

calibration). The field calibration can be modified at any time using the process

described in this section. Totals derived from the field calibration are being invoked

when the (FAC) icon is no longer visible below the 6-digit display.

Factory calibration settings are programmed into each computer during

manufacturing, using Stoddard test solvent at 70° F (21° C) for meters up to 1 inch.

Meters 1-1/2 inch and larger are factory calibrated using water at 70° F (21° C).

Settings are correct for light liquids such as water, gasoline or diesel. Readings using

the factory calibration (FAC) may not be accurate in some situations, for example,

"heavy" liquids such as motor oil, under extreme temperature conditions, non-

standard plumbing configurations or with fluids other than mentioned above.

For improved accuracy under such conditions, the computer allows for field

calibration, that is, user entry of custom calibration parameters.

12

Page 13

OPERATION (continued)

FIELD CALIBRATION MODE (continued)

Verify Accuracy before Beginning Field Calibration

For the most accurate results, dispense at a flowrate which best simulates your actual

operating conditions. Avoid "dribbling" more fluid or repeatedly starting and stopping

the flow. This can result in less accurate calibrations. Make sure you meet the

meter's minimum flowrate requirements.

Low Flow meter: 0.3 GPM (1.1 LPM or 0.25 IGPM)

1 inch meter: 3.0 GPM (11 LPM or 2.5 IGPM)

2 inch meter: 30 GPM (113 LPM or 25 IGPM)

The use of a uniformly dependable, accurate calibration container is recommended for

the most accurate results. A five gallon calibration container is available in the parts

section of this manual. For best results, the meter should be installed and purged of

air before field calibration.

Due to high flowrates on meters 2 inch and larger, it is strongly recommended that

field calibration be completed with a combination of volume and weight determined

with fine resolution scales.

Field Calibration Entry

At the beginning of the calibration entry menu, the software will allow the user to start

the calibration process or to exit back to normal operation. (See Figures 11‑1 & 11‑2)

Advance focus: Press and release the CALIBRATE button.

Advance to the next menu: Press and release the DISPLAY button.

The bottom row of characters will be in focus to indicate that the user can select

between either “Start” or “Exit” by advancing focus.

Figure 11‑1

Figure 11‑2

If “Start” is in focus when advancing to the

next menu, the software will automatically

advance to the dispense/display field

calibration menu

If “Exit” is in focus when advancing to the

next menu, the software will display a

“save” screen (see Figure 13‑3) to enter

“yes or no” to save your entries.

13

Page 14

OPERATION (continued)

FIELD CALIBRATION MODE (continued)

Dispense Display Method

Dispense/Display is a field calibration method by which the user will dispense a known

volume of fluid and the software will keep track of the pulse count during the dispense

operation. The user will then enter the known volume into the display and the

software will calculate a K-factor for the volume dispensed. (See Figure 12-1)

The software will allow the user to

dispense a known volume in order to

create a custom K-factor. This will not over

write the existing factory calibration table.

Figure 12-1

The first screen in this calibration method

will show “run 1” indicating that computer is

waiting for flow to start. (See Figure 12-2)

NOTE: Pressing any single button while

on this screen will not have any effect.

Pressing both buttons and holding will

allow the user to exit calibration mode.

Figure 12-2

Begin dispensing into a container of known

accurate volume. As soon as pulses are

detected by the software, the screen will

switch to display the volume being

dispensed on the top row and the volume

unit on the bottom row. (See Figure 12-3)

Figure 12-3

When the user is finished with the run, modify the volume on screen to be the actual

volume dispensed. To do this pressand hold the Display button until the left most

digit begins to flash indicating it is in focus, then release the Display button.

Pressing the Calibrate button will increment the digit in focus. Pressing the Display

button will advance focus to the next digit.

Holding Display and pressing Calibrate will lock in the entered volume.

The software will then calculate the K-factor for the volume entered based on the

pulse count for the run and the volume entered. The average frequency and the K-

factor will be entered into the custom user K-factor table for run 1.

14

Page 15

OPERATION (continued)

FIELD CALIBRATION MODE (continued)

Exit Dispense Display Method

This menu is used to indicate to the user they are exiting the field calibration mode

menu. The user can exit any of the calibration methods at any time. To exit, press

and hold the Display and Calibrate buttons simultaneously for 3 seconds; the

software will display a three second count down (see Figure 13-1), then reset to show

the exit display. (See Figure 13-2)

Figure 13-1

NOTE: After 3 seconds, “FldCAL” will then

be displayed on the top row and “Exit” on

the bottom row (see Figure 13-2) until the

user releases both buttons. The software

will store the sorted table of frequencies

and K-factors, then exit back to normal

mode.

Figure 13-2

COMPUTER MAINTENANCE

Batteries

The computer electronics are powered by alkaline batteries. Removing the batteries

before storing the meter will extend battery life since the computer is always on (either

standby or active) when the batteries are installed.

If the meter's readout should become dim, blank or the low battery message appears

(see below), the batteries should be replaced.

Note: If the battery life is sufficiently low,

“LOWBAT” will be displayed in the

message area on the bottom row of

characters. This low battery message will

be displayed automatically.

15

Page 16

OPERATION (continued)

COMPUTER MAINTENANCE (continued)

Battery Replacement Information

The computer is shipped with (2) alkaline AAA size batteries (1.5‑volts each) installed.

The installed batteries are Agency Approval rated for use with this electronic device.

Battery replacements are readily available as an off‑the‑shelf item. To maintain the

Agency Approvals of this device, and maintain the GPI warranty, the batteries listed

below are approved for use.

Alkaline (AAA size, 1.5‑volts each)

Energizer, Alkaline, E92 or En92

Duracell, Alkaline, Mn2400

Do not mix brands or technologies. Do not mix old and new batteries. Do not

use rechargeable batteries.

Open battery cells should be disposed of in accordance with local regulations.

When batteries are disconnected or fail, the computer memory will retain the batch

total, accumulative total, factory calibration curve, and field calibration curve

indefinitely.

It is strongly recommended that battery checks and terminal cleaning be a part of a

routine maintenance schedule. Battery terminals should be cleaned annually.

Batteries can be replaced without removing the meter from the piping system.

Replace Batteries

1. Remove the (4) corner screws attaching the computer electronics to the meter and

lift the computer electronics from the meter.

2. Remove the batteries.

3. Check the battery terminals and remove any corrosion.

4. Install the new batteries and make sure the positive posts are positioned correctly.

When the batteries are installed correctly, the computer powers on automatically

and the display will show information.

5. Make sure the seal is fully seated before placing the computer electronics back on

the turbine. Tighten the (4) screws previously removed.

6. Do not clean exterior of computer assembly with Isopropyl Alcohol.

16

Page 17

PARTS

The factory, when provided with

model number and serial number,

can replace your entire Computer

Electronics Assembly.

Order replacement kits, parts, and

accessories with the part numbers

given here.

Part No. Description

901002‑52 Seal

116000‑1 Large (5 gal.) Calibration

Container. Use for water

baseduids.Donotuse

with fuel products.

SERVICE

For warranty consideration, parts,

or other service information, please

contact your local distributor. If you

need further assistance, call the

GPI Customer Service Department

in Wichita, Kansas, during normal

business hours.

1‑888‑996‑3837

Toobtain prompt,ecient service,

always be prepared with the following

information:

1. The model number of your com‑

puter electronics.

2. The serial number or manufactur‑

ing date code of your computer

electronics.

3. Specicinformation aboutpart

numbers and descriptions.

For warranty work always be pre‑

pared with your original sales slip

or other evidence of purchase date.

Returning Parts

Please contact the factory before

returning any parts. It may be possible

to diagnose the trouble and identify

needed parts in a telephone call. GPI

can also inform you of any special

handling requirements you will need

to follow covering the transportation

and handling of equipment which has

been used to transfer hazardous or

ammableliquids.

CAUTION

Do not return computer

electronics or meters without

specic authority from the GPI

Customer Service Department.

Due to strict regulations

governing transportation,

handling, and disposal of

hazardous or ammable liquids,

GPI will not accept computer

electronics or meters for rework

unless they are completely free

of liquid residue.

CAUTION

Meters not flushed before

shipment can be refused and

returned to the sender.

17

Page 18

Declaration of Conformity

Product Name: Electronic Digital Meter

Model Numbers: 03*****

A1***********

A2***********

G2*****9***

We declare, that the product:

Model numbers include all combinations of an alpha-numeric series as illustrated above.

Conforms with the requirements of the Directives below by compliance with the Standards subsequently listed:

1. Council Directive 2004/108/EC (until April 19, 2016) and Directive 2014/30/EU (from April 20, 2016)

relating to Electro-Magnetic Compatibility.

EN 61000-6-2:2005

EN 61000-6-3:2007/A1:2011

2. Council Directive 94/9/EC (until April 19th, 2016) and Directive 2014/34/EU (from April 20th, 2016)

relating to equipment or protective systems intended for use in potentially explosive atmospheres.

EN 60079-0:2018

EN 60079-11:2012

EN 60529+A1:2000

3. Council Directive 2011/65/EU and 2002-95-EC as amended (RoHS Directive) relating to the restriction of

certain hazardous substances in electrical and electronic equipment.

Supplementary Information:

- is product meets an (Ingress Protection) IP65 rating.

- is product has insucient internal volume size or pressure ratings to meet a pressure directive.

- is product is not recommended for custody transfer or application where levying by consumption takes

place.

I the undersigned, hereby declare that the equipment specied above conforms to the above Directive(s) and

Standard(s).

Signature:

Full Name: Victor Lukic

Position: President

Great Plains Industries, Inc.

Place: Wichita, KS USA

March 2016

Notied Body: FM Approvals Europe Ltd.

One Georges Quay Plaza

Dublin, Ireland D02 E440

Identication No: 2809

EC-Type Examination Certicate No: FM13ATEX0016X

18

Page 19

Q9 Computer Electronics:

ATEX

Factory Mutual Approved

Intrinsically Safe for Class I, II, III, Division 1, All Groups

Intrinsically Safe approval only applies when used with GPI® FM Approved meter

Q9 Computer Electronics when installed on a GPI FM Approved meter

ATEX

IP65

Factory Mutual Approved

Intrinsically Safe for Class I, II, III, Division 1, All Groups

19

Page 20

Limited Warranty Policy

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220‑3205,

hereby provides a limited warranty against defects in material and workmanship on all

products manufactured by Great Plains Industries, Inc. This product includes a 2 year

warranty. Manufacturer’s sole obligation under the foregoing warranties will be limited

to either, at Manufacturer’s option, replacing or repairing defective Goods (subject

to limitations hereinafter provided) or refunding the purchase price for such Goods

theretofore paid by the Buyer, and Buyer’s exclusive remedy for breach of any such

warranties will be enforcement of such obligations of Manufacturer. The warranty shall

extend to the purchaser of this product and to any person to whom such product is

transferred during the warranty period.

The warranty period shall begin on the date of manufacture or on the date of purchase

with an original sales receipt. This warranty shall not apply if:

A. theproducthasbeenalteredormodiedoutsidethewarrantor’sdulyappointed

representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has

been installed or operated other than in accordance with the manufacturer’s

operating instructions.

To make a claim against this warranty, contact the GPI Customer Service Department

at 316‑686‑7361 or 888‑996‑3837. Or by mail at:

If you are outside North or South America contact:

The company shall, notify the customer to either send the product, transportation prepaid,

tothecompanyatitsoceinWichita,Kansas,ortoadulyauthorizedservicecenter.

The company shall perform all obligations imposed on it by the terms of this warranty

within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WAR‑

RANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES

INCURRED IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED

HEREUNDER.

Thecompanyherewithexpresslydisclaimsanywarrantyofmerchantabilityortness

for any particular purpose other than for which it was designed.

Thiswarrantygivesyouspecicrightsandyoumayalsohaveotherrightswhichvary

from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part

702 (governs the resale availability of the warranty terms).

Great Plains Industries, Inc.

5252 E. 36th St. North

Wichita, KS, USA 67220‑3205

Great Plains Industries – Australia

1/16 Atkinson Road,

Taren Point NSW 2229, Sydney, Australia

ATEX

920787-01 Rev H 11/02/2020

(IP65)

© 2020 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc. / 800-835-0113 / GPI.net

Loading...

Loading...