GPI MR 5-30 Owner's Manual

General Information ������������������ 2

Safety Instructions �������������������� 2

Installation �������������������������������� 2

Operation ���������������������������������� 3

Calibration �������������������������������� 4

Maintenance ����������������������������� 4

Troubleshooting ������������������������5

Specications ��������������������������� 5

Illustrated Parts List ������������������ 6

Parts and Service ��������������������� 7

TABLE OF CO NTENTS

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

SA VE THESE INSTRUCTIONS

MR 5-30 A viation

Fuel Meter

Owner’s Manual

To the owner…

Congratulations on receiving your GPI

MR 5-30 Meter� We are pleased to provide

you with a meter designed to give you

maximum reliability and efciency.

Our business is the design manufacture,

and marketing of liquid handling,

agricultural, and recreational products� We

succeed because we provide customers

with innovative, reliable, safe, timely, and

competitively-priced products� We pride

ourselves in conducting our business with

integrity and professionalism�

We are proud to provide you with a quality

product and the support you need to

obtain years of safe, dependable service�

President

Great Plains Industries, Inc

10/11 Rev� - 922092-09

GENERAL INFORMATION

The purpose of this manual is to assist

you in installing, operating and maintaining your mechanical fuel meter�

Please take a few moments to read

these instructions before installing and

operating your fuel meter�

The MR 5-30 Mechanical Fuel Meter is

designed for the eld measurement of

thin viscosity petroleum fuels only and

intended for use with pump systems

in the 5 to 30 GPM or 19 to 114 LPM

ow range (not intended for gravity

ow systems). Using mechanical gears,

these meters translate ow data from a

nutating disc into calibrated units which

are indicated on the face of the meter�

This meter is factory calibrated for kero-

sene grade (JET A). Field calibration

feature is available for other uids, see

Calibration section�

For ground-based refueling only.

Do not use in or on the aircraft.

Use this meter with aviation gasoline

(AVGAS 100LL) and kerosene grade

(JET A).

Do not use this equipment for dis-

pensing any uids other than those

for which it was designed. To do so

may damage the meter and will void

the warranty.

SAFETY INSTRUCTIONS

The following safety

alert symbols are used

in this manual.

DANGER

DANGER indicates a hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous

situation which, if not avoided, may

result in minor or moderate injury.

It is your responsibility to:

• know and follow applicable national, state and local safety codes

pertaining to installing and operating electrical equipment for use

with ammable liquids.

• know and follow all safety precau-

tions when handling petroleum

fuels

• ensure that all equipment operators have access to adequate instructions concerning

safe operation and maintenance�

1�

DANGER

Observe precau-

tions against re or explosion when

dispensing fuel� Do not operate

the meter in the presence of any

source of ignition including running or hot engines, lighted cigarettes, or gas or electric heaters�

2�

WARNING

Any components

such as hose, nozzle, or pump

added to your meter must be

statically grounded and approved

for use with petroleum fuels�

3�

WARNING

Avoid prolonged

skin contact with petroleum fuels�

Use protective goggles, gloves,

and aprons in case of accidental

splashing or spillage� Change

saturated clothing and wash skin

contact areas promptly with soap

and water�

2

WARNING

INSTALLATION

Before installing your meter , review the

safety instructions given above� Examine your meter to make sure there are

no visible signs of shipment damage�

Plan your meter installation by reviewing the following procedures� Your system must be mounted on a vented tank�

If the tank is unvented, your local dealer

or distributor can supply a pressure cap�

If the meter is located in a rigid piping

system where the uid is trapped (for

example, by gravity, valves or nozzles)

thermal expansion of the fluid can

create pressure spikes that can damage

a meter�

Install a thermal relief valve or otherwise

allow for thermal expansion of the uid.

Prior to installation, determine the tting

angle desired and whether horizontal or

vertical orientation is required�

Rotate Fittings

To rotate inlet and/or outlet fittings,

remove the two nuts and bolts that

secure each tting. Rotate the tting to

the desired orientation� Make sure the

O-ring is fully seated� Tighten the nuts

and bolts snugly�

C

hange Orientation

1� Pull the knob to remove from unit�

Remove screws that hold bezel in

place and set aside�

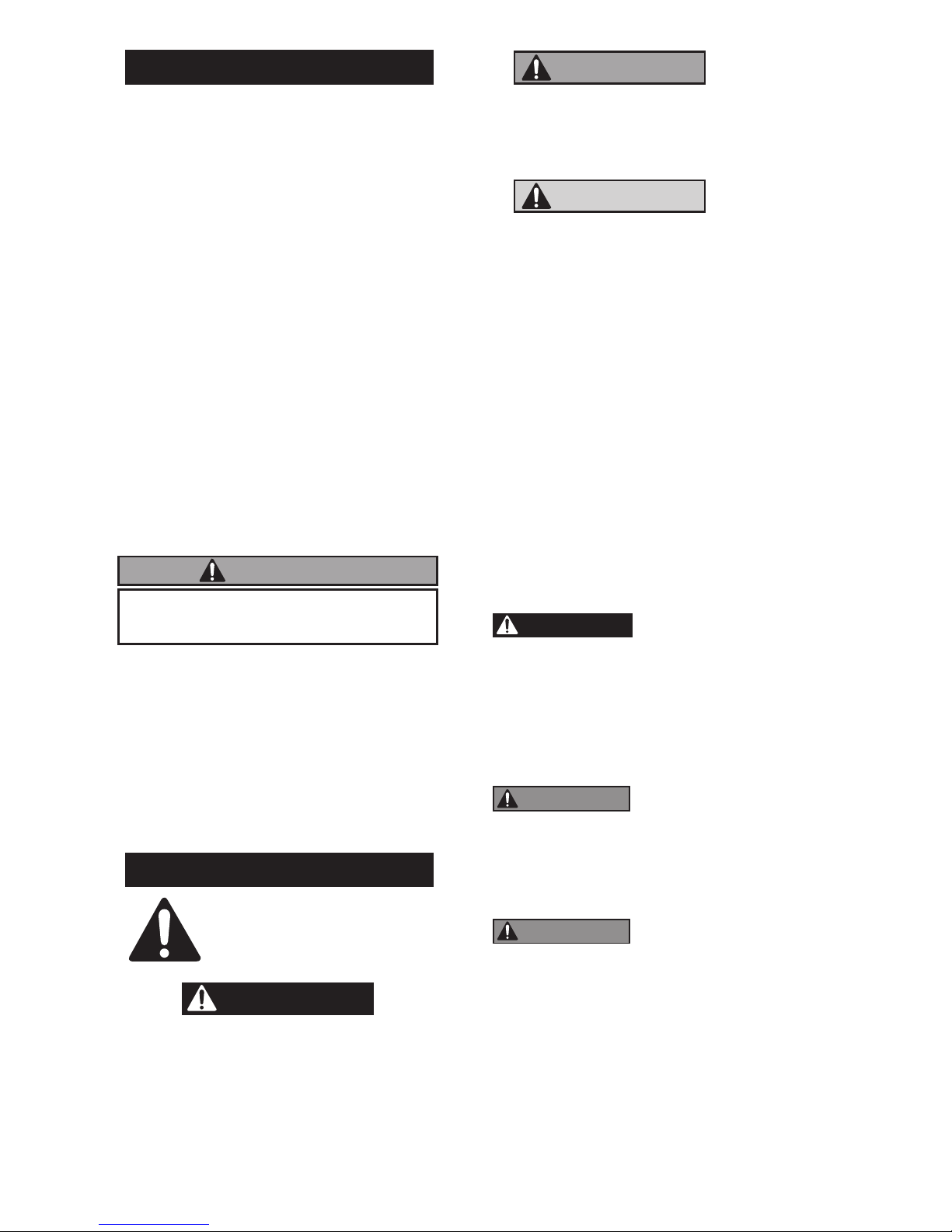

2� Remove the two screws that hold

the faceplate in place and remove

faceplate. (Figure 1)

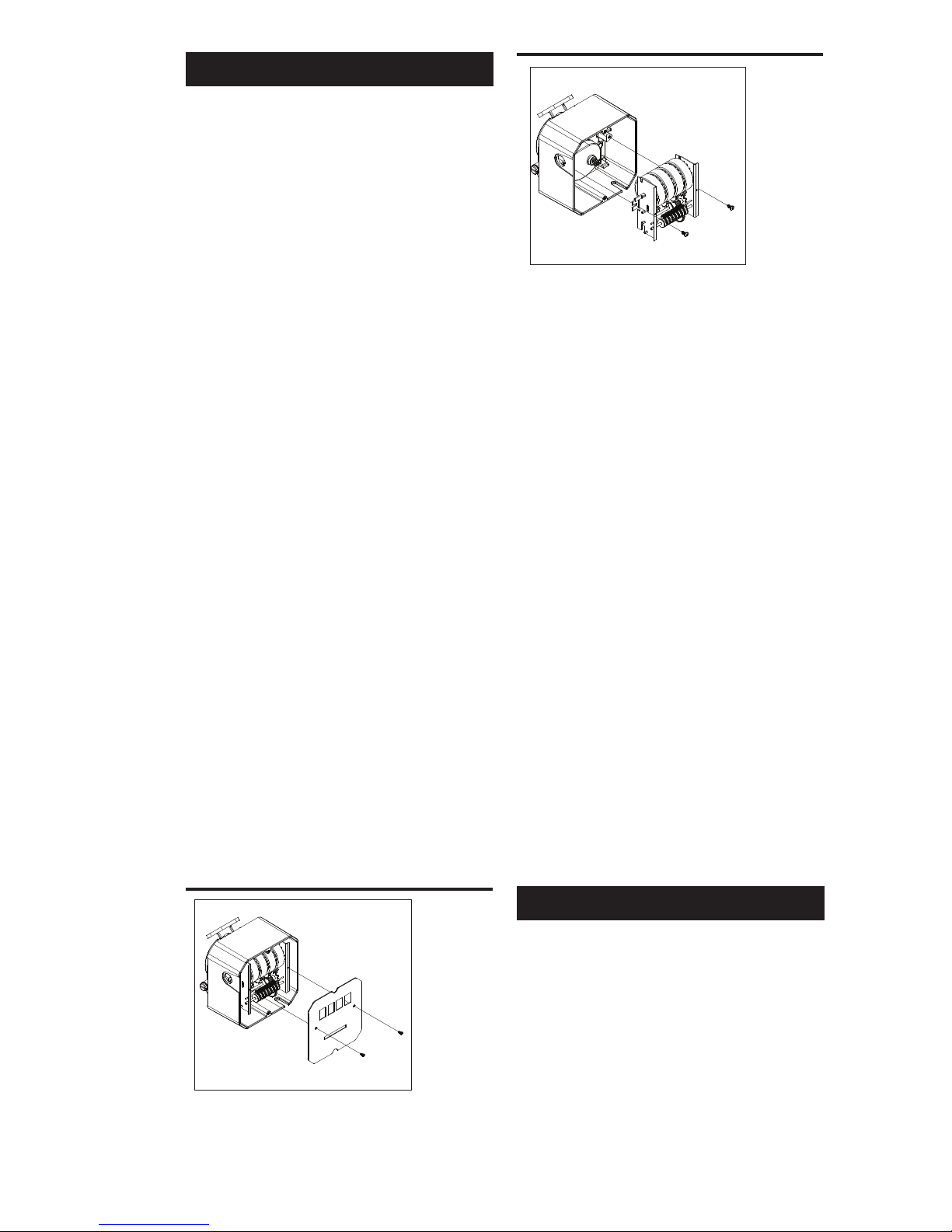

3� Remove two screws to release

the counter assembly. (Figure 2)

4� Remove the bevel gear from the

center of the coverplate� Remove

the eight pairs of nuts and bolts

that hold the coverplate assembly

in place�

5� Now you can rotate the coverplate

to the desired orientation�

Reassemble in reverse order,

making sure the O-ring is fully

seated� T orque eight nuts and bolts

to 60 - 72 in-lb�

Meter Installation

1� Remove protective plugs from the

meter inlet and outlet ports�

2� Wrap threaded male connections

with thread tape or use a pipe

sealant compound compatible with

petroleum fuels� We recommend

thread sealant at the inlet tting in

horizontal orientation�

3� Install the meter on the pump using

an appropriately sized nipple� The

meter’s ow path is marked on the

housing exterior with an arrow pointing toward the outlet port�

4� Install other system components on

the meter and tighten snugly�

OPERATION

ALWAYS FOLLOW SAFETY

PRECAUTIONS WHEN OPERATING

THIS EQUIPMENT. REVIEW THE

SAFETY INSTRUCTIONS. Before

each use, visually check the meter to

ensure it is securely connected to other

system components and there is no

leakage� Promptly wipe spilled fuel from

the meter’s exterior and other system

components�

3

Figure 1

Figure 2

Loading...

Loading...