GPI M30-G8N, M30-L8N Product Owners Manual

Product Owner’s Manual

EN

5-30 GPM

(19-114 L/min)

Fuel Meter

Models M30-G8N, M30-L8N

921529-01 Rev A6/2019

Thank you for choosing a Great Plains Industries product, and

congratulations on your purchase!

Headquartered in the heartland of the U.S., GPI strives

for integrity, innovation, continuous improvement, and

dependability—values you will immediately recognize when using

our products.

The maintenance policies and procedures outlined in this manual

emphasize our commitment to safety and our dedication to you

as a customer. By working together, we can ensure years of

reliable, quality service.

Please save these instructions for future reference. Read carefully before attempting

to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply

with instructions could result in personal injury and/or property damage.

Please refer to back cover for information regarding this product’s warranty and

other important information.

DO NOT RETURN THIS PRODUCT TO THE STORE!

Please contact Great Plains Industries, Inc. before returning any product. If you are

missing parts, or experience problems with your installation, contact our Customer

Support Department. We will be happy to assist you.

Call: 800-835-0113 or 316-686-7361

Email: gpisales@gplains.com

SAVE FOR YOUR RECORDS

Model #: ___________________

Serial #: ___________________

Purch. Date: _______________

tools.eps

Heavy_Hazard.eps

tools.eps

box.eps

Heavy_Hazard.eps

Hot_surface.eps

tools.eps

box.eps

magnify_2.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

BEFORE YOU BEGIN

Usage Requirements

• This manual covers fuel meter models M30-G8N and M30-L8N

• This fuel meter is designed, tested and approved for use with thin

viscosity petroleum fuels such as gasoline blends (up to E15), diesel

fuel blends (up to B20) and kerosene.

Please take all due precautions when handling these flammable liquids.

• Do not use this meter for measuring any fluids other than those for

which it was designed. To do so may damage the meters’ components

and will void the warranty.

• The M30 Mechanical Fuel Meter is designed for the field measurement

of thin viscosity petroleum fuels only and intended for use with pump

systems in the 5 to 30 GPM or 19 to 114 L/m flow range (not intended

for gravity flow systems). Using mechanical gears, these meters

translate flow data from a nutating disk into calibrated units which are

indicated on the face of the meter. This meter is factory calibrated for

diesel fuel. A field calibration feature is available for other fluids (see

Calibration section).

Tools Needed

• 10mm Open-end Wrench, Hex Wrenches (Hex Keys, 3mm & 5mm),

Thread Tape pr Pipe Thread Sealing Compound (approved for use with

flammable liquids)

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

UNPACKING

Contents

• (1) Nutating Disc Fuel Meter, U.S. Gallon or Litre Version

• (1) Register Knob

• (1) 1 in. NPT Inlet Fitting with O-ring and mounting screws

• (1) 1 in. NPT Outlet Fitting with O-ring and mounting screws

Inspect

• After unpacking the unit, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with carrier.

• Review General Safety Instructions and all Caution, Warning, and

Danger statements as shown.

MAINTENANCE /

REPAIR

3

GENERAL SAFETY INSTRUCTIONS

IMPORTANT: It is your responsibility to:

• Know and follow applicable national, state and local safety codes

pertaining to installing and operating electrical equipment for use with

flammable liquids.

• Know and follow all safety precautions when handling petroleum fuels.

• Ensure that all equipment operators have access to adequate

instructions concerning safe operating and maintenance procedures.

Observe all safety precautions concerning safe handling of petroleum fuels.

SAFETY /

ASSEMBLY /

SPECIFICATIONS

INSTALLATION

fuel. Do not operate the meter in the presence of any source of ignition including

running or hot engines, lighted tobacco products, gas or electric heaters, or any

type of electronic device. A spark can ignite fuel vapors.

splashing or spills. Change saturated clothing and wash skin promptly with

soap and water.

use with petroleum fuels.

To prevent physical injury or property damage, observe

precautions against fire or explosion when dispensing

Avoid prolonged skin contact with petroleum fuels. Use

protective goggles, gloves and aprons in case of

Any components such as hose, nozzle, or pump added to

your meter must be statically grounded and approved for

This product shall not be used for pumping fuel or other

liquids into aircraft.

TROUBLESHOOTING OPERATION GETTING STARTED

REPAIR

MAINTENANCE /

4

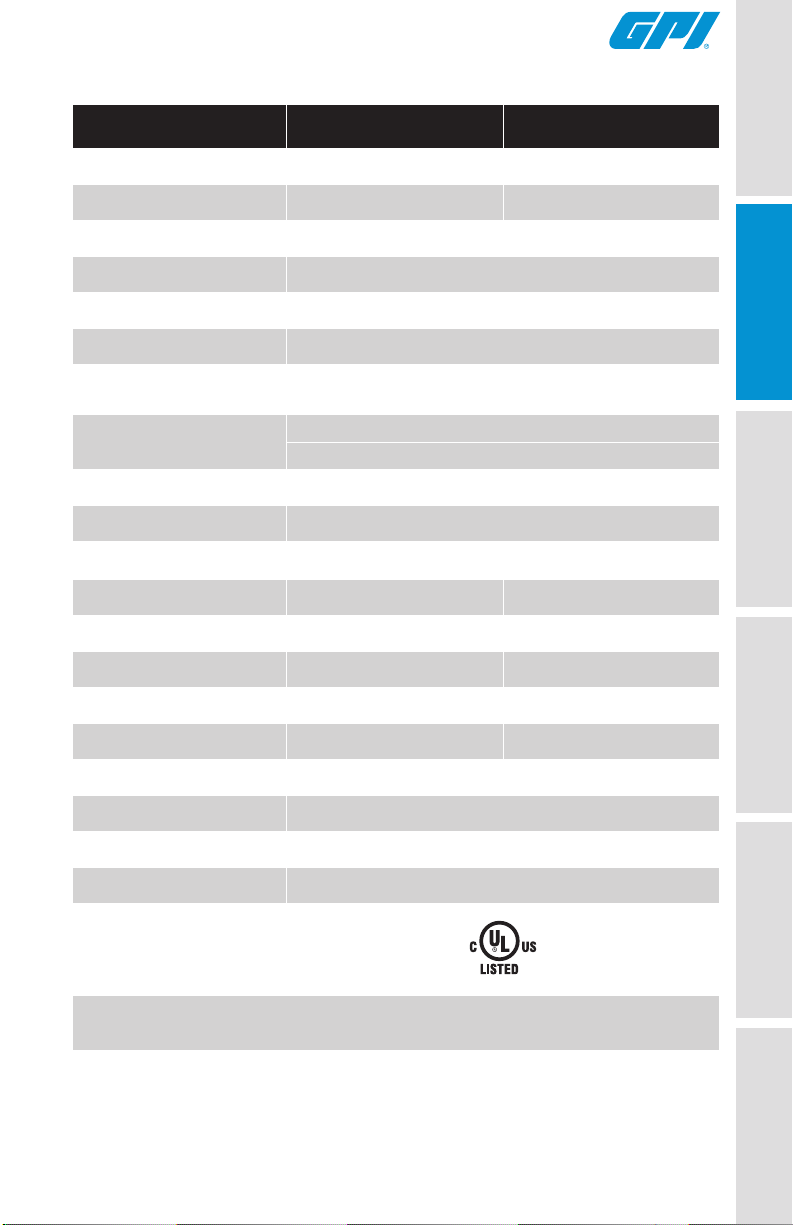

SPECIFICATIONS

M30-G8N

(GALLON MODEL)

Unit of Measure U.S. Gallon Litre

Flow Range 5 to 30 GPM 19 to 114 L/min

Operating Temperature -20° F to 125° F -29° C to 52° C

Typical Accuracy ± 2%

Technology Nutating Disc

Housing, Cover, Fittings Aluminum

Maximum Working

Pressure

Pressure Drop (at Max.

Flow)

Inlet/Outlet Threads 1 in. NPT

Maxium Batch Total 999.9

Maximum Cumulative Total 999,999.9

50 PSIG / 3.4 bar

Diesel: 7.0 PSI / 0.5 bar

Unleaded: 5.0 PSi / 0.3 bar

M30-L8N

(LITRE MODEL)

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Weight 8.1 lbs 3.7 kg

Maximum Dimensions

Width: 5.9 in. 15.0 cm

Height: 7.9 in. 20.0 cm

Depth: 5.3 in 13.3 cm

Wetted Materials

Nutator Assembly PBT (Polybutylene Terephthalate), Stainless Steel

Seals NBR (Nitrile Butadiene Rubber)

Mag-Drive Acetal, Stainless Steel, Neodymium (Nickel Plated)

Approvals

NOTE: Accuracy is factory calibrated using diesel fuel. Field calibration is available on

all models.

OPERATION TROUBLESHOOTING

MAINTENANCE /

REPAIR

5

Loading...

Loading...