Page 1

1

LM50DB / LM50DN (ELECTRONIC)

INSTRUCTION MANUAL

This meter is designed for in line use with Engine Oil & A TF

up to a maximum viscosity of SAE 140, Diesel & Water Glycol mixtures with a maximum water content of less than 50%.

Please read and retain this instruction manual to

assist you in the operation and maintenance of this

quality product.

GENERAL INFORMA TION

This manual assists you in operating and maintaining your

new positive displacement flowmeter. The information

contained will help you ensure many years of dependable

performance and trouble free operation.

Please take a few moments to read through this manual before

installing and operating your new meter. If you experience

problems with this product, refer to the Maintenance and

Trouble Shooting sections of this manual. If you require

further assistance please contact your local GPI

Distributor.

IMPORTANT INFORMA TION

The GPI quality Positive displacement flowmeter has

incorporated the oval rotor principal into its design. This has

proven to be a highly reliable and highly

accurate method of measuring flow, pr oviding exceptional

repeatability and high accuracy .

GPI recommends, that if you are using your meter as an inline application you should install a filter

before the inlet of the meter. Contact your local GPI distributor

for further details.

INSTALLATION

2) Do not over tighten connections.

0002

OPERATION

LM50DB or LM50DN ELECTRONIC REGISTER

DISPLA Y BUTT ON

Each press of the DISP button will allow you to scroll through

the meter options

Resetable Batch T otal

Resetable Accumulative T otal

Non Resetable Accumulative T otal

Flowrate

RESET BUTTON

The RESET button allows you to reset the Batch T otal or the

Resettable Acumulative T otal to zero.

To reset either the Batch total or Resetable Acumulative total.

Press the DISP button to scroll to either the Batch or Resetable

total . When the required total is displayed. Press reset to zero

the totalizer.

FLOWRATE

This display option shows the flowrate of the fluid

passing through the meter.

IM083

0106

POSITIVE DISPLACEMENT FLOWMETERS

Page 2

2

CAUTION

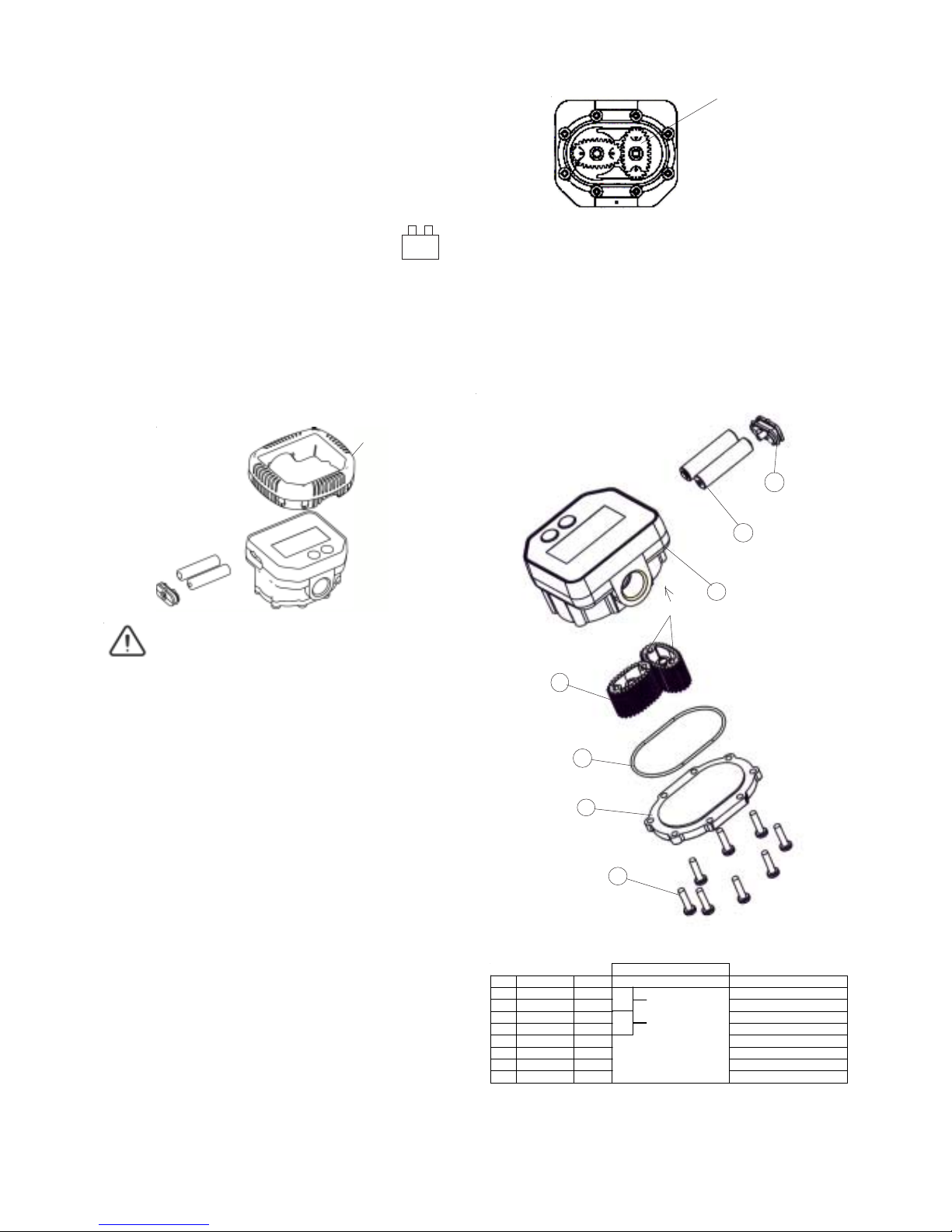

METER DISASSEMBLY

P A RTS DIAGRAM

Ensure the fluid supply to the meter is disconnected and

the line pressure is released befor e disassembly.

METER REASSEMBLY

1) Replace both rotors (4) so as they are at 90O to each other.

(see fig 2). Check the rotor rotation by turning either of the

rotors. If the rotors are not in mesh correctly or do not

rotate freely remove one of the rotors and replace it

correctly at 900 to the other rotor. Re-check the operation of

the rotors.

5) Test the meter by turning the rotors with a finger or by

applying low air pressure (No more than a good breath)

to the inlet port of the meter. This will confirm the meter

is operating correctly .

1

2

5

6

7

4

3

PARTS LIST

BA TTERY REPLACEMENT

1) Remove the plastic protector shroud from the meter

body. (fig 1)

3) Replace the 2 x (AAA) Alkaline batteries. (Refer to the

front of the meter for correct battery orientation).

Note: Only use Alkaline batteries.

If NO flow goes through the meter for 60 seconds the display

will go into sleep mode (Blank). The display will

automatically wake if the buttons are pressed or flow occurrs.

SLEEP MODE

Note: The electronic computer module is non-repairable. The

meter will need to be replaced if found to be damaged or faulty.

1) Remove the 8 x philips head screws (1) from the meter

cover.

2) Remove the meter cover (2) and o’ring (3).

3) Remove both rotors (4).

4) Clean and inspect all parts. Replace any suspect, worn or

damaged components.

NOTE: Ensure the rotor with the magnets is assembled on

the same side as the batteries. The magnets in the rotor must

face towards the electronic display .

The Rotor with Magnets

( fig 2)

(fig 1)

magnets

Note: Replace the batteries as soon as the battery

indicator on the LCD is displayed

+

-

2) Remove the battery cover.

4) Replace the battery cover and re-fit the plastic shroud.

All data will be saved when the batteries are removed.

2) Lightly grease the o’ring (3) and place it on the meter body.

3) Clean the meter cover plate (2) and place it on the body.

T ake care not to damage the o’ring (3).

4) Install the 8 screws (1) and tighten in a diagonal pattern to

1nm (0.73 ft.lb). Visual check the cap has been pulled down

evenly.

Protector Shroud

(fig 3)

ORDER FOR REPLACEMENT

ITEM PART NO No. of f PART/ SET DESCRIPTION

1 N65 8 LM50K02 SCREW SET

2 IM011 1 METER COV ER PLATE SET

3 BS035 1 LM50K01 O'RING SEAL

4IM020 2 ROTOR SET

5 1 N/A METER BODY

6 2 N/A BATTERY SET

7 1 N/A BATTERY COVER SET

8 IM070-BLUE 1 LM50K03 PROTECTOR SHROUD SET

Page 3

3

ELECTRONIC MODULE

PROGRAMING DETAILS

c) To access the programs and settings, hold down the RESET button for 5 seconds

d) T o scroll through the setting options press theDISP button.

The electronic module has been set up as follows:-

totL 2

rAtE 3

diSP 4

CALI 5

CONF 6

dIA 7

2. TOTALS

3. FLOWRATE

4. DISPLAY

5. CALIBRATION

6. CONFIGURATION

7. DIAGNOSTICS

NOTE: Details for changing individual options .

For example to change the units setting on the batch total turn to item 2 - 21

21 change batch total (units)

23 change resetable accumulative total (units)

24 change resetable accumulative total (decimal point)

25 change non-resetable accumulative total (units)

26 change non-reset accumulative total (decimal point)

22 change batch total (decimal point)

27 change “K” factor

31 change flowrate (units)

32 change flowrate (decimal point)

33 change flowrate (time base setting)

34 set the amount of signal pulses to calculate flowrate

35 set minimum flow rate

41 set sleep mode

43 set sleep time

42 change display (wake up default setting )

51 calibration adjustment

6 configuration details

71 diagnostic mode

a) Ensure the meter is awake before trying to enter the programming mode.

b) If the meter goes into sleep mode during programming, it will automatically

return to operating mode.

totL 2

Note: As the decimal point does not float we recommend that a maximum of 2 decimal

places be used, see below for details.

Page 4

4

e) Press and hold down RESET until “program” disappears

to accept setting.

2. TOTALS SETTINGS

totL2

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

21 BATCH TOTAL = unit 21 (set units)

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to scroll through the settings (ltr , gal, qrt) to

the desired units

b) Press RESET “ unit 21” will appear.

22 BA TCH T OTAL = dEC 22 (set decimal point)

b) Press RESET twice “ dEC 22” will appear.

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to set the decimal point to 1st, 2nd, 3rd or

no decimal place. (e.g 11111.1 = 1 decimal place)

23 RESETABLE ACCUM T OTAL = unit 23 (set units)

b) Press RESET 3 times “ unit 23” will appear.

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to scroll through the settings ( ltr, gal, qrt )

to the desired units

24 RESETABLE ACCUM T OTAL = dEC 24

( set decimal point )

b) Press RESET 4 times “ dEC 24” will appear.

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to set the decimal point to 1st, 2nd, 3rd or

no decimal place (e.g. 11111.1 = 1 decimal place).

25 NON-RESET ACCUM TOTAL = unit 25 (set units)

b) Press RESET 5 times “ unit 25” will appear .

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to scroll through the settings (ltr, gal, qrt) to

the desired units.

26 NON-RESET ACCUM TOT AL = dEC 26

(set decimal point)

b) Press RESET 6 times “ dEC 26” will appear.

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to set the decimal point to 1st, 2nd, 3rd or

no decimal place (e.g. 11111.1 = 1 decimal place).

27 “K” FACTOR = kFac 27

(normal setting is 112.00 pulses)

b) Press RESET 7 times “ kFac 27” will appear.

c) Press and hold down RESET for 2 seconds ( program will

appear)

T o change the ‘K’ factor , press RESET ( digit will flash),

to change digit press RESET.

Press DISP to scroll to the next number. Press RESET

to change the value

To change the decimal point, press DISP until it is

in the required position. Press RESET to set the decimal

point.

d)

e) Press and hold down RESET until “program” disappears

to accept setting.

e) Press and hold down RESET until “program” disappears

to accept setting.

e) Press and hold down RESET until “program” disappears

to accept setting.

e) Press and hold down RESET until “program” disappears

to accept setting.

e) Press and hold down RESET until “program” disappears

to accept setting.

e) Press and hold down RESET until “program” disappears

to accept setting.

f) Press RESET for five seconds to return the meter to the

operating mode.

f) Press RESET for five seconds to return the meter to the

operating mode.

f) Press RESET for five seconds to return the meter to the

operating mode.

f) Press RESET for five seconds to return the meter to the

operating mode.

f) Press RESET for five seconds to return the meter to the

operating mode.

f) Press “RESET” for five seconds to return the meter to the

operating mode.

f) Press RESET for five seconds to return the meter to the

operating mode.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

Page 5

34 NUMBER OF PULSES = nuM 34

(Number of pulses used to calculate flowrate)

3. FLOW RATE rAtE 3

b) Press the DISP button 1 time to reach “rAtE 3”

c) Press RESET “ unit 31” will appear.

31 UNITS = unit 31 (set units)

d) Press and hold down RESET for 2 seconds ( program will

appear)

e) Press RESET to scroll through the settings (ltr, gal, qrt) to

the desired units

32 DECIMAL POINT = dEC 32. (decimal point setting)

b) Press the DISP button 1 time to reach “rAtE 3”

c) Press RESET twice “ dEC 32” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear)

e) Press RESET to set the decimal point to 1st, 2nd, 3rd or

no decimal place (e.g. 11111.1 = 1 decimal place)

33 TIME = tiME 33 (rate time base)

b) Press the DISP button 1 time to reach “rAtE 3”

c) Press RESET 3 times “tiME 33” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear)

e) Press RESET to set time base (seconds, minutes, hours )

Note: When there is fluctuating flowrate present increasing

the number will give a more accurate flowrate reading.

(number range is 0 - 299)

b) Press the DISP button 1 time to reach “rAtE 3”

c) Press RESET 4 times “ NUM 34” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear and the digit will flash). To change press RESET

e) Press DISP to go to the next digit. To change press

RESET

35 FLOW = Cut 35 (Set minumum measurable flowrate)

b) Press the DISP button 1 time to reach “rAtE 3”

c) Press RESET 5 times “ Cut 35” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear and the digit will flash). To change press RESET

e) Press DISP to go to the next digit. T o change press RESET

Note : Total number 999.9

4. DISPLA Y diSP 4

41 SLEEP MODE = SLP 41 ( set sleep mode)

b) Press the DISP button 2 times to reach “diSP 4”

c) Press RESET “ SLP41” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear)

e) Press RESET to select sleep setting ( no sleep, sleep)

5

f) Press and hold down RESET until “program” disappears

to accept setting.

f) Press and hold down RESET until “program” disappears

to accept setting.

f) Press and hold down RESET until “program” disappears

to accept setting.

f) Press and hold down RESET until “program” disappears

to accept setting.

f) Press and hold down RESET until “program” disappears

to accept setting.

f) Press and hold down RESET until “program” disappears

to accept setting.

g) Press RESET for five seconds to return the meter to the

operating mode.

g) Press RESET for five seconds to return the meter to the

operating mode.

g) Press RESET for five seconds to return the meter to the

operating mode.

g) Press RESET for five seconds to return the meter to the

operating mode.

g) Press RESET for five seconds to return the meter to the

operating mode.

g) Press RESET for five seconds to return the meter to the

operating mode

42 UNIT = unit 42 (set default display)

Note: The display will reset to the default units after a time

which is set in time 43. If no units are set, the display will

remain as selected

b) Press RESET 2 times “ unit 42 ” will appear.

This value is the maximum time (sec) to measure the number

of pulses set in nuM34

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

c) Press and hold down RESET for 2 seconds ( program will

appear)

d) Press RESET to select required display (batch, reset total,

total, rate, blank)

e) Press and hold down RESET until “program” disappears

to accept setting.

f) Press RESET for five seconds to return the meter to the

operating mode.

Page 6

6

5. CALIBRATION

CALI 5

Note: Provides calibration adjustment up to +/- 5% of

reading. You will need to calculate the percentage

adjustment you require. If the meter is reading over you will

need to enter a minus figure. If the meter is reading under you

will need to enter a plus figure.

51 CALIBRA TION = CALI 51 ( adjust calibration +/- 5%)

b) Press the DISP button 3 times to reach “CALI 5”

c) Press RESET “CALI 51” will appear.

d) Press and hold down RESET for 2 seconds ( program will

appear and the first digit will flash)

e) Press RESET to change number.

Press DISP to change the decimal point position, or go

to the next number.

Press the RESET button to set the negative value.

f) Press and hold down RESET until “program” disappears

to accept setting.

g) Press RESET for five seconds to return the meter to the

operating mode.

6. CONFIGURATION

CONF 6

6 CONFIGURA TION = CONF 6 (configuration details)

b) Press the DISP button 4 times to reach “CONF 6”

c) Press RESET “MOD” plus model number will appear.

d) Press RESET “REL” plus hardwear release number will

appear.

e) Press RESET the screen will flash between “SOFT” and

the softwear release no’s (at 2 second intervals)

f) Press RESET the screen will flash between “SEr” and the 6

figure serial number (at 2 second intervals)

g) Press RESET “MAN” plus manufacturer number

h) Press RESET the screen will flash between “CONFIG”

and the configuration number (at 2 second intervals).

i) Press RESET for five seconds to return the meter to the

operating mode.

7. DIAGNOSTICS

dIA 7

a) Press and hold down RESET for 5 seconds until “MEtr 1”

appears.

71 DIAGNOSTICS = dIA 7 (diagnostic mode)

b) Press the DISP button 5 times to reach “dIA 7”

c) Press RESET “ dIA 71” will appear.

d) Press and hold down RESET for 2 seconds ( Program will

appear then all the segments should be displayed).

e) Press the DISP button “diSP” ( to check that the display

button is working properly).

f) Press the RESET button “RESEt” ( to check that the reset

button is working properly).

g) Press and hold down RESET for 2 seconds ( Program

will disappear (check the condition of the reed switch).

The condition of the reed switch can only be checked

when there is liquid flowing through the meter. The reed

switch should be reading between 50 - 80.

h) Press RESET for five seconds to return the meter to the

operating mode.

d) Press RESET to select default time (5-20 seconds)

e) Press and hold down RESET until “program” disappears

to accept setting.

f) Press RESET for five seconds to return the meter to the

operating mode.

Step 1. Reset the batch reading to zero.

Step 2. Dispence at least 5 liters, using a constant flow rate,

into a graduated calibrated container.

Step 3. Take the reading from the IM50.

Step 4. Calculate the % error as follows.

% error = (( container volume - IM50 volume) / container volume) * 100

Step 5. Enter the % error into the meter as calculated, if the

value is negative enter a negative number

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

c) Press and hold down RESET for 2 seconds ( program will

appear)

b) Press the DISP button 2 times to reach “tiME 43”

a) Press and hold down RESET for 5 seconds until “totL2”

appears.

43 TIME = tiME 43 (time to revert to default display)

Note: The display shows ( Hxx rYY ) when fluid flows through

the meter. YY is the sensitivity of the reed switch.

Page 7

7

NOTES:

Page 8

TROUBLE SHOOTING GUIDE

SPECIFICATIONS

TROUBLE CAUSE RE M EDY

No fl uid p assi ng through a) Dirt particles jam m i ng th e roto rs a) Remove ro to rs and rem o ve any dirt or cont am i nat ion

the meter

The meter is no t reg ist er ing fl ui d out put a) Flat b a tte ry a) Replace batte ry

b) No signal fro m ro to r t he magnets b) C heck m agnets and rep lace ro to rs if req u ired

c) Damaged com p uter ( r eed switc h un it )c) Replace meter

Meter not accurate a) Flow rate outside recom m end ed flow ra te a) Adjust flowrate to

b) "K " f act or incorr ect b) R e- set "K" fact or to fact ory setting (1 12 . 00 pulses)

8

A cc ur a cy + / - 0.5% of Reading

Type Oval Gear

Flow rate 1 Ltr -30 Ltr (0.26 - 7.8 US Gal) per minute

Maximum Working Pr essure 10350kPa / 1500psi / 103.5 Bar

Suitable for use w ith : Engine Oil, Diesel Oil, Automatic Transmission Fluid (Maximum Visc ocity SAE140),

Ethelene Glycol Based Anti-Freeze / Anti-Boil mixture (Max 50% w ater)

Wetted Materia ls Acetal, Aluminium, Steel, Nitrile Rubber

Battery Type 2 x AAA Alkaline

Resettable Totalizer 999999 ( ltr or gal )

Non-Resettable Totalizer 999999 ( ltr or gal )

Connec tions 1/2" BSPT or 1/2" NPT

Maximum Temperatur e 55 deg C (131 deg F)

Minimum Temper atur e 5 deg C ( 41 deg F )

G reat Plains Ind ustries, Inc. 5252 E. 36

th

Street N orth, W ichita, KS USA 67220-3205, hereby provides a limited

warranty against defects in m aterial and workmanship on all products manufactured b y Great Plains Industries, Inc.

This product includes a 1 year w arranty. M anufacturer’s sole obligation under the foregoing warranties will be

lim ite d to e ith e r, a t M a n u fa ctu r e r’s o p tio n , r ep la c in g o r re p a ir ing de fe c tiv e G o od s (s u b je c t to lim ita tio n s h e re in a fte r

provided) or refunding the purchase price for such Goods theretofore paid by the Buyer, and Buyer’s exclusive

remedy for breach of any such warranties w ill b e enforcem ent of such obligations of Manufacturer. The w arranty

shall extend to the purchaser of this produ ct and to any person to whom such product is transferred d uring the

w a rra nty pe rio d.

The warranty period shall begin on the date of manufacture or on the d ate of purchase with an original sales receipt.

T his w ar ra n ty sh a ll n o t a p p ly if:

A. th e p r o d u c t h a s b e e n a lte re d o r m o d ifie d o u ts id e th e w a rr a n to r ’s d u ly a p p oi n te d r e p r e s e n ta tiv e ;

B. the product has been subjected to neglect, misuse, ab use or dam age or has been installed or operated

oth e r th a n in a c c o rd a n c e w ith th e m a n u fa ctu r e r’s o p e ra tin g in s tru c tio n s.

To m ake a claim against this warranty , contact the GPI Custom er Service Departm ent at

316-686-7361 or 888-996-3837. O r by m ail at:

Great Plains Industries, Inc.

5252 E. 36

th

St. North

W ichita, KS, U SA 67220 -3205

The comp any shall, notify the customer to either send the product, transportation prepaid, to the comp any at its office

in Wichita, Kansas, or to a duly authorized service center. The com pa ny shall p erform all obligations im posed on it by

th e te r m s o f th is w a rr a n ty w ith in 6 0 d a y s o f re c e ip t o f th e d e fe c tiv e p ro d u c t.

GRE AT PLAINS IND USTRIES, INC., EXC LUDES LIABILITY UNDE R THIS W A RRAN TY FO R DIRECT, INDIRECT,

IN C ID E N T A L A N D C O N S E Q U E N T IA L D A M A G E S IN C U R R E D IN TH E U S E O R LO S S O F U SE O F TH E PR O D U C T

W A RRAN TED H EREU ND ER.

The comp any herew ith expressly disclaim s any warranty of merchantability or fitness for any particular purp ose

oth e r th a n fo r w h ic h it w as d e s ig n e d .

This warranty gives you specific rig hts and you may also have other rights w hich vary from U.S. state to U.S. state.

Note: In com pliance with M AG NU SO N M O SS CO NSU M ER W A RRAN TY AC T – Part 702 (governs the resale availability

of the w arranty term s).

Loading...

Loading...