Page 1

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

1- 888 -99 6-3 837

SAVE THESE INSTRUCTIONS

GPI 4-20 mA Out with Display

Owner’s Manual

Local Models

GX510

To the owner…

Congratulations on receiving your GPI 4-20 mA Out with

Display. We are pleased to provide you with a product

designed to give you maximum reliability and efficiency.

Our business is the design, manufacture, and marketing of

liquid handling, agricultural, and recreational products. We

succeed because we provide customers with innovative,

reliable, safe, timely, and competitively-priced products. We

pride ourselves in conducting our business with integrity and

professionalism.

We are proud to provide you with a quality product and the

support you need to obtain years of safe, dependable service.

President

Great Plains Industries, Inc.

Display information in this manual supersedes display information provided with your meter.

GM Series

(Shown here on GM001)

Remote Model

GX500

TABLE OF CONTENTS

General Information ............................................................. 2

Safety Instructions ............................................................... 2

Installation ........................................................................... 2

Wiring .................................................................................. 3

Configuration ....................................................................... 9

Operation ............................................................................. 9

Calibration ........................................................................... 9

K-Factor Method Calibration Procedures ........................... 9

Correction Factor Method Calibration Procedures ........... 10

Maintenance ...................................................................... 12

Troubleshooting ................................................................. 13

Dimensional Drawings ....................................................... 14

Illustrated Parts Drawing ................................................... 15

Specifications - Local ........................................................ 16

Specifications - Remote .................................................... 17

Service ............................................................................... 18

WEEE Directive .................................................................. 18

06/10

Rev. H 920765-05

1

Page 2

GENERAL INFORMATION

SAFETY INSTRUCTIONS

This manual will assist you in operating and maintaining

the GPI electronics supplied with your GPI meter or as an

accessory unit on both local and remote models. The GPI

Electronics can be used in indoor or outdoor applications

where occasional exposure to moisture is common.

• The 4-20 mA Out with Display is available in two versions. One indicates flowrate in units/minute and one

in units/hour. Both indicate flow totals in gallons and

litres.

• The 4-20 mA Out with Display can be used on all GPI

models, including the Precision G series, the Industrial

Grade G2 series, the Commercial Grade A1 series,

and the positive displacement GM series oval gear

meters.

Product differences in this manual are identified by either,

Local or Remote as necessary.

If the meter was purchased with this display, then it will come

calibrated from the factory for gallons “GAL” and litre “LTR”.

Field calibration is also available.

If the unit was purchased as an accessory or remote, the

calibration has not been entered and the end user will need

to configure and calibrate the display.

The GPI 4-20 mA Out with Display is a flow totalizer and rate

meter with industry standard current loop output. The unit is

loop powered, and provides a 4-20 mA analog output proportional to the frequency signal for communication with PLCs

and other customer equipment. The 4-20 mA (or 0-20 mA)

output is calibrated under actual flow conditions with simple

push-button calibration. Auxiliary output includes 0-5 VDC.

The microprocessor-based electronics have extremely low

power requirements and are completely powered by the

4-20 loop. The electronics provides the options of local (on

the meter) and/or remote (up to 5,000 feet) display. Flow total

and rate are displayed on a large 6-digit LCD readout with

two-point floating decimal for totals from .01 to 999,999. All

operations are easily accessed with the push buttons on the

display front panel.

CAUTION

This unit is not FM Approved. Therefore, use of this

transmitter with an approved metering system voids

FM Approval.

NOTE: This unit is loop powered, requiring an input power

supply of 8.5 to 35 volts (24 VDC is recommended).

NOTE: Setpoint calibration of the unit is required for the 4-20

mA, 0-20 mA, and 0-5 V output options.

• When measuring flammable liquids, observe precautions against fire or explosion.

• When working in hazardous environments, always

exercise appropriate safety precautions.

• When applying external power to the transmitter, use

DC power only.

• Disconnect external power to the transmitter before

detaching or attaching input or output wires.

• Ground loops between sensor and user equipment can

damage the transmitter and can be dangerous.

• If you cannot galvanically isolate the sensor from earth

ground, you may need to use the transmitter’s optically

isolated inputs.

• Be sure O-rings and seals are kept in good repair.

INSTALLATION

CAUTION

Installation should be performed only by qualified

personnel, and in accordance with local governing

regulations.

The following installation guidelines are separated by meter

series and mounting type.

Precision G Series:

• Local – The GX510 4-20 mA Out with Display mounts

directly to the 1 inch MNPT conduit connector.

• Remote – The GX500 4-20 mA Out with Display

connects via an output cable as shown in the Wiring

Diagram.

Industrial Grade G2 Series:

• Local – The GX510 4-20 mA Out with Display requires

the GPI Conduit Connector Kit (Part #113437-01) for

local mounting to the G2 series meter.

• Remote – The GX500 4-20 mA Out with Display

connects via an output cable as shown in the Wiring

Diagram.

Commercial Grade A1 Series:

• Local – The GX510 4-20 mA Out with Display requires

the GPI Conduit Connector Kit (Part #113437-01) for

local mounting to the A1 series meter.

• Remote – The GX500 4-20 mA Out with Display

connects via an output cable as shown in the Wiring

Diagram.

2

GM Oval Gear Series:

• Local – The 4-20 mA Out with Display is mounted

directly to the oval gear meter housing.

Page 3

• Remote – The GX500 4-20 mA Out with Display connects via an output cable as shown in the Wiring Diagram.

Mount the GPI 4-20 mA Out with Display using bolts, screws

or standard U-bolts for pipes. Mounting options include:

• Wall

• Pipe

• Meter (1 inch FNPT conduit connection required)

WIRING

This manual refers to various models of GPI flowmeters.

Determine what type of input the electronics will receive and

what type of output, if any, you require. Use the diagrams

found in the wiring diagrams section (if the unit is not already

wired) to correctly wire the system.

The display is externally powered by the loop.

NOTE: Totals will be lost with loss of power on loop.

Environmental

Choose a mounting location suitable for the 4-20 mA Out with

Display. The ideal mounting location is where the:

• flowmeter is as close as possible.

• mounting surface has minimal vibration.

• ambient temperature is +32°F to +140°F (0°C to

+60°C).

• cable lengths are minimal.

Avoid mounting locations where the 4-20 mA Out with Display is:

• subject to constant exposure to water or other liquids

(occasional low-pressure splashing will not harm unit

if cable entry points are well-sealed).

• subject to > 5g shock loading.

• facing the sun directly for long periods of time.

• close to high voltage/current runs, DC motors, internal

combustion engines, or frequency inverters.

Cable Guidelines

4-20 mA Current Loop:

• The current loop itself is very resistant to electrical noise

pickup and shielded cable is seldom needed except in

very “noisy” (electrical) locations and/or when very long

runs (thousands of feet) are used.

Sensor Cabling:

• Some products come with 20 ft. of shielded cable.

• If you require a longer cable, a 100 ft. cable kit is available from GPI, or use Belden 9363 cable. When wiring

longer lengths of cable, be sure to connect the shield

to LOCAL-COM ONLY! (Multiple shield connections

may cause ground-loop problems).

• Some trial and error may be needed because of the wide

variety of user conditions. Try to keep cable lengths

short!

CAUTION

Determine maximum power supply voltage after determining maximum allowable voltage of all electronic

devices in the system.

The 4-20 mA Out with Display may come with 20 ft. of cable

to connect to the meter. The customer must supply the communication loop cable. Although the unit is usually powered

through the communication loop, there are some circumstances that might require external power.

Connecting the Equipment:

• Remove the faceplate by removing the four (4) corner

screws.

• Attach wiring from your equipment according to the

following terminal connections and wiring diagrams,

depending on your circumstances.

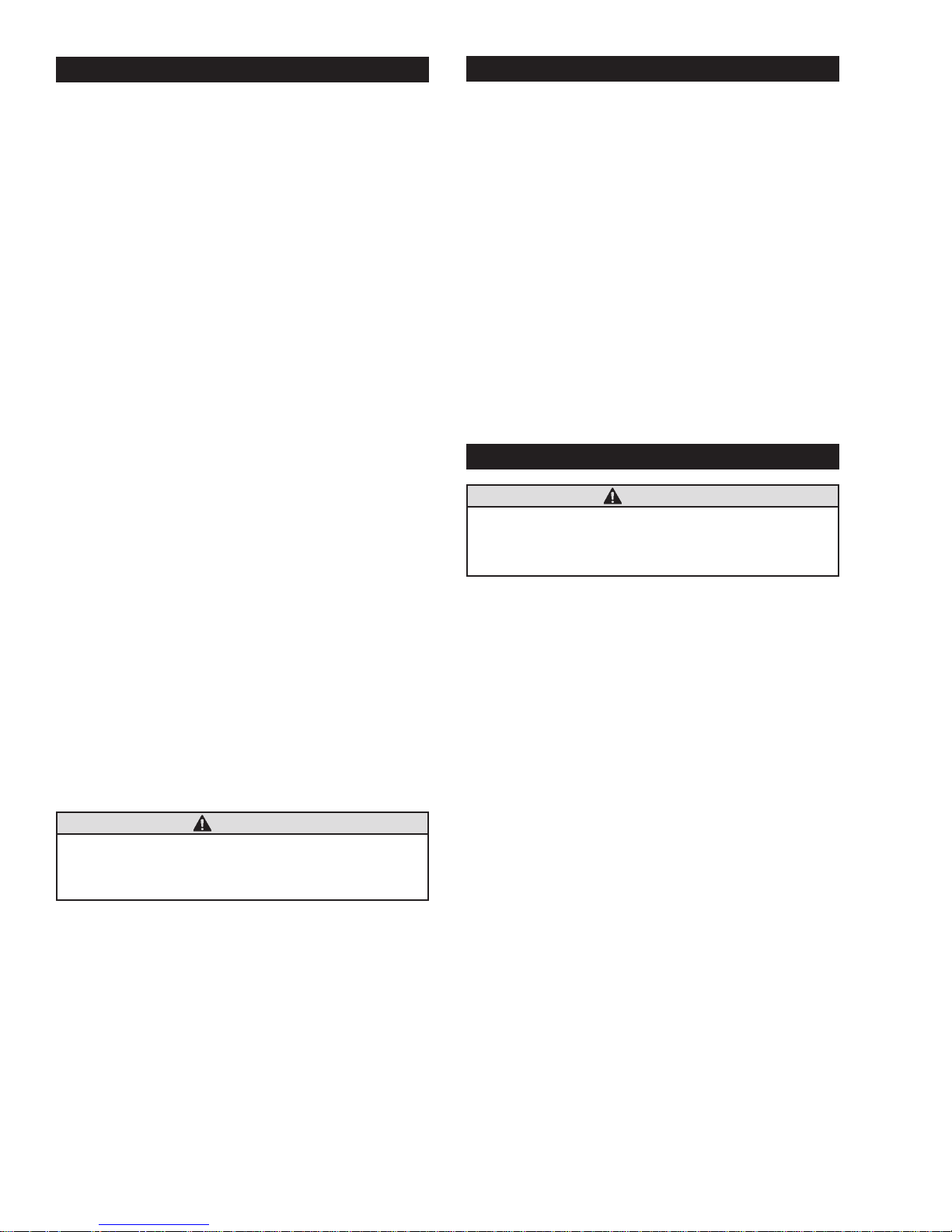

Terminal Connections

Remote Transmitter INPUTS / OUTPUTS

ISO-IN COM: Return for

isolated inputs

ISO-LF IN: Optically-Isolated

High-level Low-frequency

Input

ISO-HF IN: Optically-Isolated

High-level High-frequency

Input

HL-LF IN: High-level Low-

frequency Input. 150 Hz

maximum

COIL-A IN: Low-level

Sinewave Input

COIL-B IN: Low-level

Sinewave Input

HL-HF IN: High-level High-

frequency Input

EDM PWR: Local Vcc. Regu-

lated 5-VDC internal power.

This terminal can supply up

to approximately 2.5 mA,

continuously, to external

circuitry. Typical load/line regulation under ordinary conditions is about ± 10%

LOCAL COM: Local Common

0-5 V OUT: 0 to 5 V Voltage Output. Frequency to Analog Output.

PULSE OUT: Pulse-Out Frequency Output Signal. It is an “open-collector” output

(also known as “n-p-n” or “current-sinking”), referenced to transmitter Local-

Common

LOOP (–): 4 to 20 mA Current Loop – current into transmitter

LOOP (+): 4 to 20 mA Current Loop – current out of transmitter

ISO-IN COM

ISO-LF IN

ISO-HF IN

HL-LF IN

COIL-A IN

COIL-B IN

HL-HF IN

EDM PWR

LOCAL COM

LOCAL COM

0-5 V OUT

PULSE OUT

LOOP (–)

LOOP (+)

3

Page 4

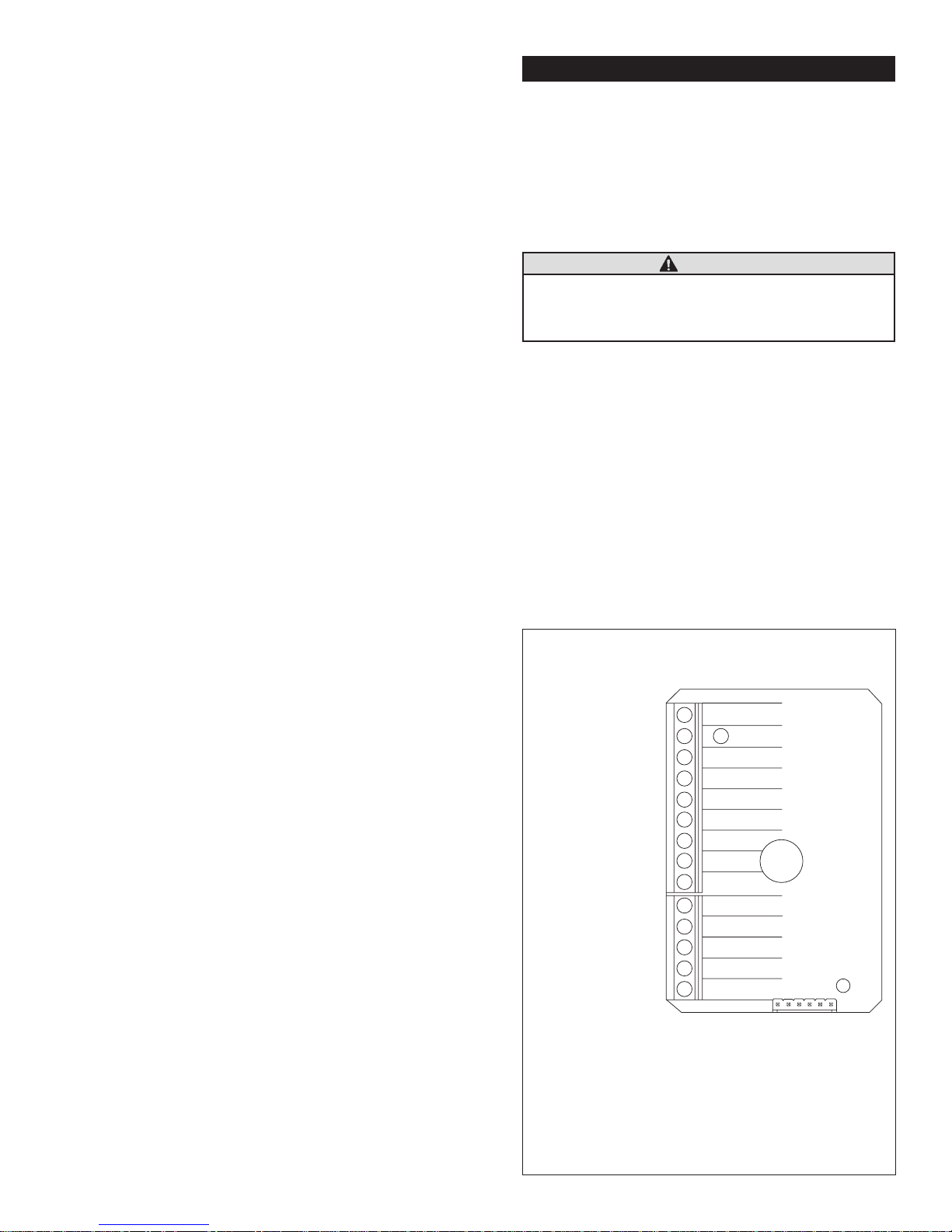

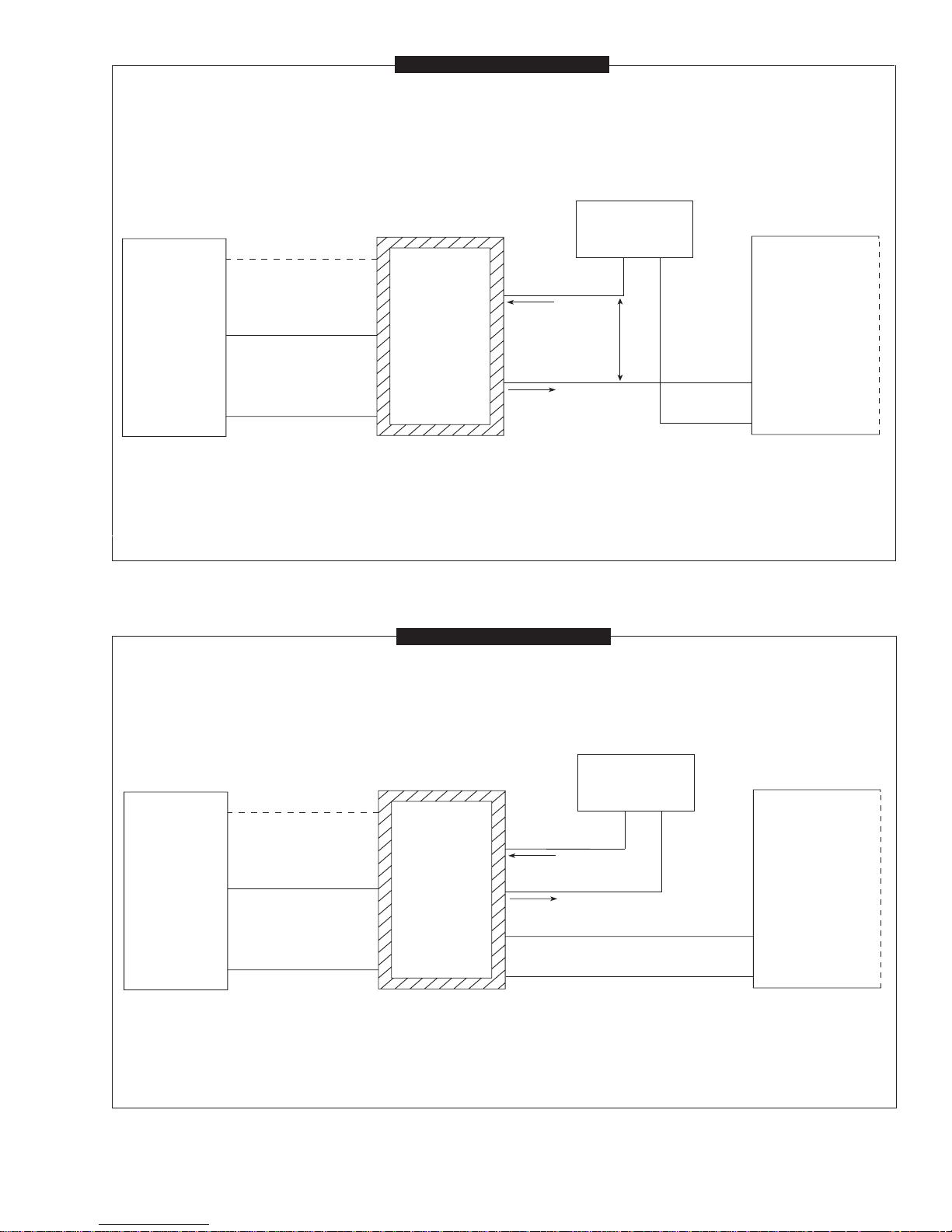

W I R I N G D I A G R A M 1

— 4-20 mA or 0-20 mA Output —

Customer Equipment with Built-in Power Supply

Input: Turbine Mounted Display or Conditioned Signal Sensor (Open Collector)

Output: Customer Equipment, 0-20 mA Sensing, Built-in Loop Power Supply

INPUTS OUTPUTS

Ext. Power

(Red)

GPI

Meter

Note Regarding Resistor “R”: R not generally required for distance up to 25 ft.

Use R = 10k (10000 ohms) for distance up to 50 ft.

Use R = 5.1k (5100 ohms) for distance up to 100 ft.

Use R = 2.7k (2700 ohms) for distance up to 250 ft.

Do not use R less than 2.4k (ohms)

Pulse Out

(White)

Common

(Black)

Shield recommended.

If used, connect to

transmitter’s local

com ONLY!

EDM Power

R

(See note)

HL-HF IN

Local Com

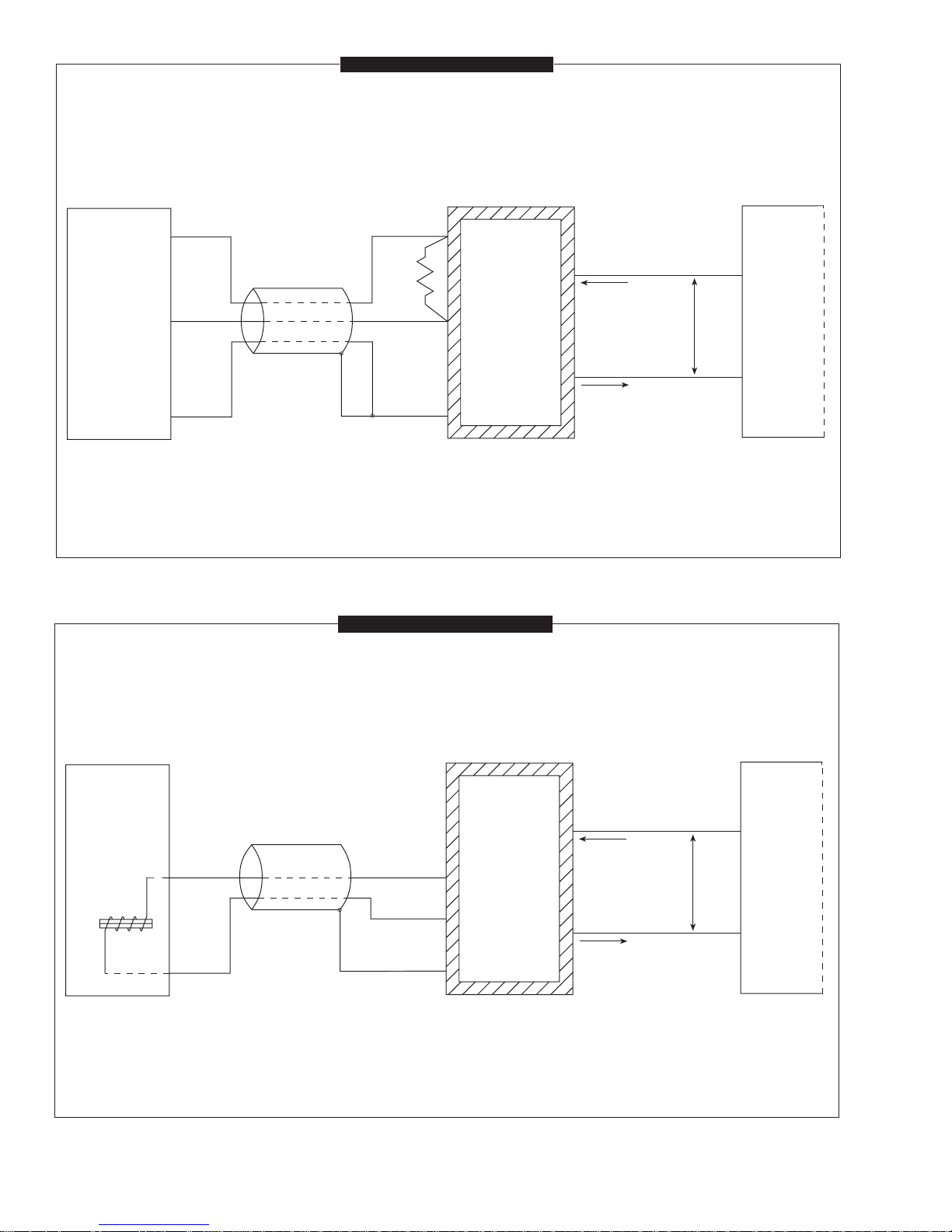

W I R I N G D I A G R A M 2

— 4-20 mA or 0-20 mA Output —

Customer Equipment With Built-in Power Supply – High Temp Applications

Input: Standard Remote Sensor (Variable Reluctance Pickup Coil)

Output: Customer Equipment, 0-20 mA Sensing, Built-in Loop Power Supply

4-20 mA Out

with Display

Loop (+)

(current)

Min. V = 8.5

Max. V = 35

Loop (–)

(current)

CAUTION: Whe n reassembling the f ac ep la te ,

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner screws (hand tighten only). Faceplate can be rotated 90°.

Customer

Equipment

GPI Meter

Unpowered

Pickup Coil

Only

➤ Minimum signal amplitude required for normal operation approx. 15 mV P-P

➤ Recommended cable type – twisted pair with shield

➤ Recommended maximum cable length – 20 ft.

Coil-A

Coil-B

Shield recommended.

Connect shield to

transmitter’s local

com ONLY!

4

INPUTS OUTPUTS

4-20 mA Out

with Display

Coil-A

Coil-B

Local Com

Loop (+)

(current)

Min. V = 8.5

Max. V = 35

Loop (–)

(current)

CAUTION: Whe n reassembling the f ac ep la te ,

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner screws (hand tighten only). Faceplate can be rotated 90°.

Customer

Equipment

Page 5

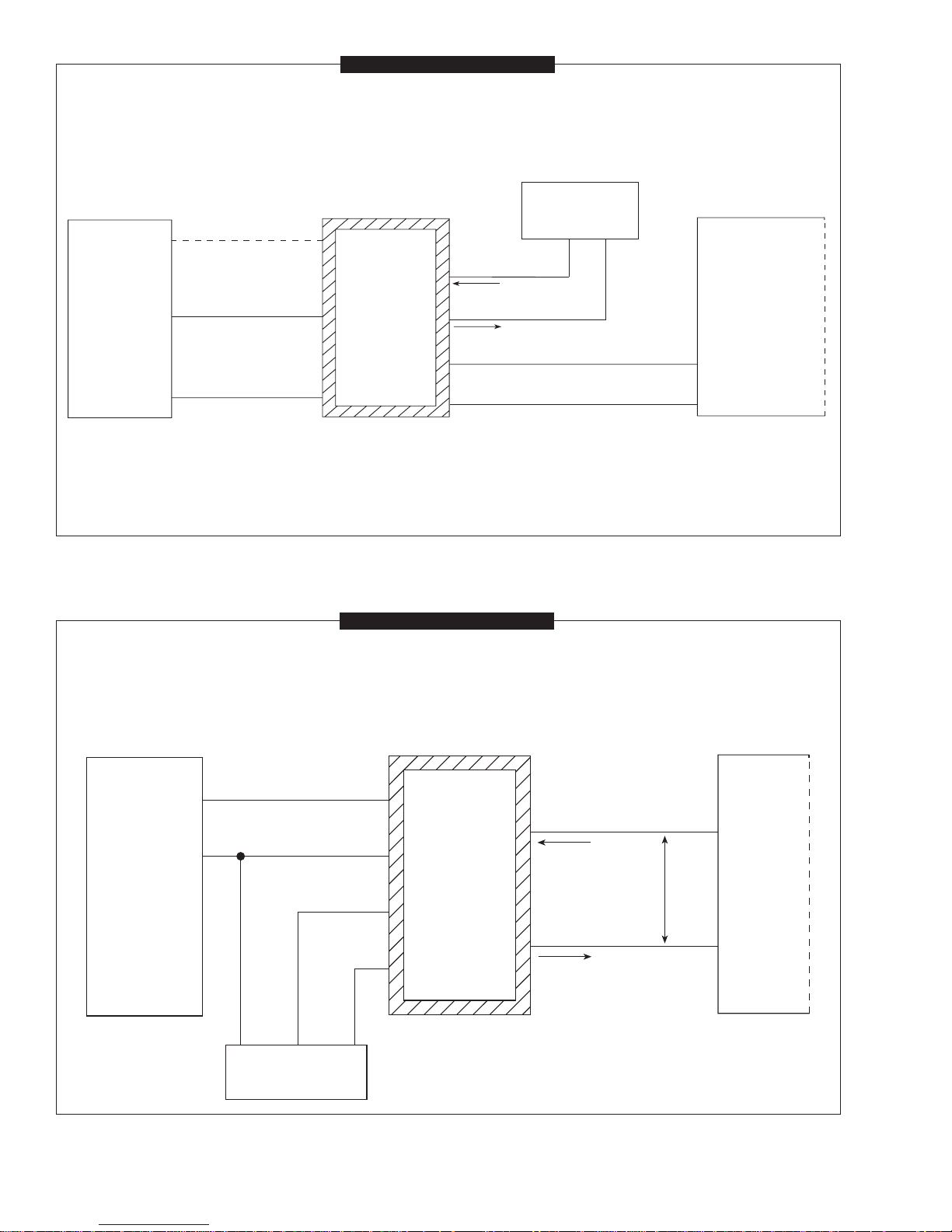

W I R I N G D I A G R A M 3

— 4-20 mA or 0-20 mA Output —

Customer Equipment Without Built-in Power Supply

Input: Turbine Mounted Display or Conditioned Signal Sensor (See inputs from Diagram 1) Standard Remote Sensor (See inputs from Diagram 2)

Output: Customer Equipment, 0-20 mA Sensing, Separate Power Supply

Loop Power Supply

Typ 12 – 24 VDC

(+)

(current)

Min. V = 8.5

Max. V = 35

(current)

(–)

CAUTION: Whe n reassembling the f ac ep la te ,

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner s crews (hand tighten only).

Faceplate can be rotated 90°.

Customer Equipment

Loop (+) Input

Loop (–) Input

Frequency-Generating

Input Device

NOTE: Minimum loop power supply voltage required:

8.5V + (Max - Customer - Equipment - Drop) +

(Wiring - IR - Drop)

INPUTS OUTPUTS

4-20 mA Out

with Display

W I R I N G D I A G R A M 4

Loop (+)

Loop (–)

— 0-5 V Output —

Customer Equipment Without Built-in Power Supply

Input: Turbine Mounted Display or Conditioned Signal Sensor (See inputs from Diagram 1) Standard Remote Sensor (See inputs from Diagram 2)

Output: Customer Equipment, 0-5 V Sensing, Separate Loop Power Supply

Frequency-Generating

Input Device

NOTE 1: Loop power supply electrically isolated

from customer equipment

NOTE 2: Actual value of loop current (mA) is

disregarded

INPUTS OUTPUTS

4-20 mA Out

with Display

Loop (+)

Loop (–)

0-5 V Output

Local Com

Loop Power Supply

Typ 12 – 24 VDC

(+)

(current)

(current)

(–)

CAUTION: Whe n reassembling the f ac ep la te ,

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner screws (hand tighten only). Faceplate can be rotated 90°.

Customer Equipment

0-5 V Analog Input (+)

Analog In Return (–)

5

Page 6

W I R I N G D I A G R A M 5

— Pulse Output —

Customer Equipment Without Built-in Power Supply

Input: Turbine Mounted Display or Conditioned Signal Sensor (See inputs from Diagram 1) Standard Remote Sensor (See inputs from Diagram 2)

Output: Customer Equipment, Frequency Sensing, Separate Loop Power Supply

INPUTS OUTPUTS

Frequency-Generating

Input Device

NOTE 1: Loop power supply electrically isolated

from customer equipment

NOTE 2: Actual value of loop current (mA) is

disregarded

Customer Equipment with Built-in Power Supply

Output: Customer Equipment, 0-20 mA Sensing, Built-in Loop Power Supply

Loop Power Supply

Typ 12 – 24 VDC

4-20 mA Out

with Display

W I R I N G D I A G R A M 6

Loop (+)

(current)

Loop (–)

(current)

Pulse Out

Local Com

(+)

(–)

CAUTION: Whe n reassembling the f ac ep la te ,

— 4-20 mA or 0-20 mA Output —

Input: Reed Switch

Customer Equipment

Open-Collector Pulse In

Pulse-In Return

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner screws (hand tighten only). Faceplate can be rotated 90°.

GPI

Meter

* Optional to use HL-HF IN

Signal

Common

Black Blue Red

PCB Assembly

INPUTS OUTPUTS

* HL-LF IN

Local Com

GPI

4-20 mA Out

Pulse Out

EDM Pwr

with Display

Loop (+)

Loop (–)

(current)

Min. V = 8.5

Max. V = 35

(current)

CAUTION: Whe n reassembling the f ac ep la te ,

make sure that the enclosure seal is not

crimped or twisted. Do not over-tighten

corner screws (hand tighten only). Faceplate can be rotated 90°.

Customer

Equipment

6

Page 7

Output: Customer Equipment, 0-20 mA Sensing, Built-in Loop Power Supply

HE Power Supply

4.5 - 24 VDC

(+) (–)

Supply (+)

W I R I N G D I A G R A M 7

— 4-20 mA or 0-20 mA Output —

Customer Equipment With Built-in Power Supply

Input: Hall Effect

INPUTS OUTPUTS

*

Signal

GPI

Meter

*

Note: Hall Effect requires dedicated power supply.

Common (–)

Black Blue Red

Input: Reed Switch (See inputs from Diagram 6) or Hall Effect* (See inputs from Diagram 7)

PCB Assembly

HL-HF IN

Local Com

Pulse Out

EDM Pwr

W I R I N G D I A G R A M 8

GPI

4-20 mA Out

with Display

Loop (+)

(current)

Customer

Min. V = 8.5

Max. V = 35

Loop (–)

(current)

CAUTION: When reassembling the faceplate, make sure that the enclosure

seal is not crimped or twisted. Do not over-tighten corner screws

(hand tighten only). Faceplate can be rotated 90°.

Equipment

— 4-20 mA or 0-20 mA Output —

Customer Equipment Without Built-in Power Supply

Output: Customer Equipment, 0-20 mA Sensing, Separate Loop Power Supply

GPI

Meter

*

Note: Hall Effect requires dedicated power supply.

INPUTS OUTPUTS

Loop (+)

GPI

4-20 mA Out

with Display

Loop (–)

Loop Power Supply

Typ 12 - 24 VDC

(+)

(current)

(current)

CAUTION: When reassembling the faceplate, make sure that the enclosure

(–)

Customer

Equipment

Loop (–) Input

Min. V = 8.5

Max. V = 35

Loop (+) Input

seal is not crimped or twisted. Do not over-tighten corner screws

(hand tighten only). Faceplate can be rotated 90°.

7

Page 8

W I R I N G D I A G R A M 9

— 0-5 V Output —

Customer Equipment Without Built-in Power Supply

Input: Reed Switch (See inputs from Diagram 6) or Hall Effect* (See inputs from Diagram 7)

Output: Customer Equipment, 0-5 V Sensing, Separate Loop Power Supply

INPUTS OUTPUTS

GPI

Meter

NOTE 1: Loop power supply electrically isolated from customer equipment

NOTE 2: Actual value of loop current (mA) is disregarded

*

Note: Hall Effect requires dedicated power supply.

4-20 mA Out

with Display

W I R I N G D I A G R A M 1 0

GPI

Loop (+)

(current)

Loop (–)

(current)

0-5 V Output

Local Com

Loop Power Supply

Typ 12 – 24 VDC

(+)

CAUTION: When reassembling the faceplate, make sure that the enclosure

(–)

Customer

Equipment

0-5 V Analog Input (+)

Analog In Return (–)

seal is not crimped or twisted. Do not over-tighten corner screws

(hand tighten only). Faceplate can be rotated 90°.

— 4-20 mA or 0-20 mA Output and Pulse Output —

Customer Equipment With Built-in Power Supply

Input: Reed Switch

Output: Customer Equipment, 0-20 mA Sensing, Frequency Sensing, Built-in Loop Power Supply

INPUTS OUTPUTS

Loop (+)

1

GPI

Meter

NOTE 1: Loop power supply electrically isolated from customer equipment

NOTE 2: Actual value of loop current (mA) is disregarded

NOTE 3: 4-20 mA and Pulse Output option available only with Reed Switch input

* Optional to use HL-HF IN

2

3

4

* HL-LF IN

Local Com

GPI

4-20 mA Out

with Display

Loop (–)

(current)

Min. V = 8.5

Max. V = 35

(current)

CAUTION: When reassembling the faceplate, make sure that the enclosure

seal is not crimped or twisted. Do not over-tighten corner screws

(hand tighten only). Faceplate can be rotated 90°.

Customer

Equipment

Common

Open Collector

Pulse-In

8

Page 9

CONFIGURATION

Configuration determines what information is present on the

LCD display. For instance, total, flowrate, type of calibration,

etc.

The Display has been programmed with many features, which

can be enabled by the end user through the configuration

process. By disabling unnecessary features, day-to-day

flowmeter operation can be greatly simplified, making the

unit easier to use. Alternately, there are several features not

found in the default configuration.

Available features include:

• 0 to 3 totals, either resettable (Batch) or non-resettable

(Cumulative).

• Flowrate or no flowrate. Available in units per minute, hour

or day.

• Three different field calibration methods: K-factor entry,

Dispense/Display or % Correction Factor.

• Various units of measure (some or all): GL (gallon), LT

(litre), IGL (imperial gallon), QT (quart), CF (cubic feet),

CM (cubic meter), BL (42 gal. barrel), CC (cubic centimeter) or OZ (ounce).

Changing Configuration Settings

Access to the configuration settings require a specific procedure and a pin code available through the GPI Website at

www.gpimeters.net or call GPI Customer Serivce at 888996-3837.

OPERATION

Computer Display

All operations are reflected in the LCD readout. The large center

digits indicate amounts, where smaller words or “icons” located

above and below indicate specific information regarding totals,

flow, calibration and units of measure.

Computer is on continuously while the loop is powered.

Press the DISPLAY button briefly to switch between the TOTAL

1, TOTAL 2 BATCH and FLOWRATE. Press DISPLAY briefly

to display the TOTAL 2 BATCH. Hold the DISPLAY button for

3 seconds to reset the Batch Total to zero.

When fluid is flowing through the meter, a small propeller

icon is highlighted.

Flowrate Feature

To use this feature, press and release DISPLAY until FLOWRATE

icon appears. The factory set time base will be highlighted to

the right of FLOWRATE (M = minutes, H = hours, D = days).

When FLOWRATE is invoked, the display will be indicating

rate of flow.

Factory and Field Calibration

All calibration information is visible to the user as icons on the

top line of the display, above the numeric digits.

All units are configured with a “factory” calibration. Both

gallons and liters are available (“GL” or “LT” will be displayed).

While holding the CALIBRATE button, briefly press DISPLAY

to toggle between gallons and litres. This factory calibration

(indicated with FAC) is permanently programmed into the

computer and is not user adjustable.

NOTE: Your computer may have other units of measure

programmed into it. If so, holding the CALIBRATE button and momentarily pressing the DISPLAY button will

toggle through all factory set units. Other possible units

are: IGL (imperial gallon), QT (quart), CF (cubic feet), CM

(cubic meter), BL (42 gal. barrel), CC (cubic centimeter)

or OZ (ounce).

Switching between different units will not corrupt the Total’s

contents. For example, in GL mode, the computer totalizes

10.00 gallons, if the user switches to LT mode, the display will

read 37.85 litres (the same volume, different unit).

The “field” calibration may be set by the user, and can be

changed or modified at any time using the calibration procedure

described in the Calibration Section. Totals derived from the

field calibration are invoked when the FAC icon is no longer

visible on the top line of the display.

Batch and Cumulative Totals

The computer maintains two totals. The Cumulative Total

provides continuous measurement and cannot be manually

reset. The Batch Total can be reset to measure flow during a

single use. The Cumulative Total is labeled TOTAL 1, Batch

Total is labeled TOTAL 2 BATCH.

When the Cumulative Total reaches a display reading of 999,999

the computer will highlight an X10 icon. This indicates to the

operator that a zero must be added to the 6 digits shown.

When the next rollover occurs, the computer will highlight an

X100 icon. This indicates to the operator that two zeros must

be added to the 6 digits shown.

CALIBRATION

Field Calibration Procedures

(K-Factor Method)

If the display was purchased as an accessory or remote,

then the field calibration method set at the factory is K-factor

Entry method.

This method allows the user to key in a single point K-factor

value that represents the meter it will be used with. K-factor

values for specific meters can be found on the meter itself,

in Table 1 or www.gpimeters.net.

1. To field calibrate, press and hold both CALIBRATE and

DISPLAY buttons for about 3 seconds until you see

FLdCAL. Release both buttons and you will see Kxxxx.x

(where “x” represents the current field-cal k-factor value).

You are now in the field calibration mode.

9

Page 10

2. The far left digit will be blinking. The DISPLAY button

can then be pressed to select the digit location and the

CALIBRATE button can be pressed to scroll the desired

value at the blinking position. Edit the K-factor shown to

the desired value. Acceptable K-factor range is 0000.1 to

9999.9.

3. After the new value has been entered, momentarily press

and release both buttons. “CALEND” will be momentarily

displayed. Unit is now ready for use.

4. Notice that the upper display line, the “FAC” icon and all

the units of measure have disappeared.

Alternate units of measure are not selectable when the meter

is operating with field calibration. This calibration is a unique

single-point calibration for the meter and/or application.

NOTE: To return to factory calibration (FAC), press and hold both

CALIBRATE and DISPLAY buttons for about 3 seconds,

until FAcCAL is displayed. Then release buttons. Unit

should return to normal operation and FAC icon is visible.

NOTE: If the field calibration mode is entered and NO fluid is

dispensed, then upon leaving, the computer will use data

from the last successful field calibration.

T A B L E 1

Typical K-Factor

Model Size (pulses / gallon)

G2_05 1/2 in. 2500

G2_07 3/4 in. 1100

G2_10 1 in. 560

G2_15 1-1/2 in. 215

G2_20 2 in. 100

G2P05 1/2 in. 2400

G2P10 1 in. 540

G_T-051 1/2 in. 10000

G_T-075 3/4 in. 3750

G_T-100 1 in. 896

G_T-150 1-1/2 in. 350

G_T-200 2 in. 181

G_T-300 3 in. 50

G_P-050 1/2 in. 10000

G_P-051 1/2 in. 10000

G_P-075 3/4 in. 3750

G_P-100 1 in. 896

G_P-150 1-1/2 in. 340

G_P-200 2 in. 181

GM001 1/8 in. 5855

GM002 1/4 in. 3785

GM003 1/4 in. 1514

GM005 1/2 in. 424

GM006 3/4 in. 197

GM007 1 in. 197

GM010 1 in. 136

GM015 1-1/2 in. 55

GM020 2 in. 25

Field Calibration Procedures

(Correction Factor Method)

If the display was purchased with a meter body then the

field calibration method set at the factory is the Correction

Factor method.

This method allows the user to tweak the factory calibration

by a percent that represents application, fluid or plumbing

differences.

1. To calibrate, press and hold the CALIBRATE and DISPLAY

buttons for about 3 seconds until you see FLdCAL. Release

both buttons and you will see CF-00.0. You are now in the

field calibration mode and values from -99.9% to +99.9%

can be entered.

2. The +/– position appears either as an “underscore” character for plus, or as a “hyphen” character for minus. The

DISPLAY button selects the position and the CALIBRATE

button toggles this character.

3. The DISPLAY button can then be pushed to select the

numeric positions. Press the CALIBRATE button to scroll

from 0 to 9. Enter the percentage of change you want the

display to correct. When satisfied with the value, press

both CALIBRATE and DISPLAY buttons simultaneously.

CALEnd will be displayed and unit will go back to normal

operation, less the FAC (factory calibration) icon.

4. All enabled units-of-measure remain visible and selectable – the entered correction will be applied to all enabled

units.

5. To return to factory calibration (FAC), press and hold both

CALIBRATE and DISPLAY buttons for about 3 seconds

until FAcCAL is displayed. Then release buttons. Unit

should return to normal operation and FAC icon is visible.

Setting 4-20 mA Endpoints

The 4-20 mA endpoint settings are independent from the

display calibration. If you reset the response time you MUST

reset the 4-20 mA endpoints.

All units are shipped with the following items preset:

• 4 mA setpoint = 10 Hz

• 20 mA setpoint = 1000 Hz

• Response time = 0.7 seconds

Any new values you set for these items are automatically

saved when the transmitter is powered down, and automatically restored the next time power is applied.

Procedure

Before you start, the fluid pumping system should be ready

to make two simple calibrating runs, first at the lowest anticipated flowrate, and then the second at the highest anticipated flowrate. Position yourself so you can easily operate

the transmitter’s pushbuttons. You should be able to see the

indicator light (the small window beside the “4” button).

10

Page 11

Setting the Low (4 mA) Endpoint:

To set 4 mA at zero flow, go to step 3. Otherwise follow

steps 1, 2 and 3:

1. Start the fluid pumping system. Set it for steady flow at

the lowest anticipated rate (or the rate at which you want

a “minimum” indication).

2. Wait while the fluid flow is uninterrupted for at least 10

seconds.

3. While watching the transmitter’s indicating light, press

and hold both its “SET” and “4” buttons. Release them

when the light blinks.

NOTE: The length of time between “button press” and “light

blink” depends on the transmitter response time. The

maximum is 5.2 seconds. If you can’t see the indicator

light (if you’re outdoors in bright light), you can safely just

count to 10 while holding the pushbuttons.

NOTE: After setting the minimum, the loop current should be

registering at or near 4 mA. Don’t worry if it’s not exact, it

will be correct after setting the high (20 mA) endpoint.

Setting the High (20 mA) Endpoint

1. Start the fluid pumping system. Set it for steady flow at

the highest anticipated rate (or the rate at which you want

a “maximum” indication).

2. Wait while the fluid flow is uninterrupted for at least 10

seconds.

NOTE: If you observe the current loop after completing the

procedure, it should be registering at or very near 20

mA (within the resolution specifications for the present

conditions).

3. While watching the transmitter’s indicating light, press

and hold both its “SET” and “20” buttons. Release them

when the light blinks.

NOTE: During the high and low setpoint procedure, if the new

settings are very different from the previous settings, it is

possible to reverse the 4 mA and 20 mA setpoints so that

the 4 mA frequency is higher than the 20 mA frequency.

The situation corrects itself after you complete both

setpoints. If the new settings are close to the previous

settings, you may safely set either the low and high settings independently.

Lockout Feature

This transmitter includes a user selectable lockout feature.

Select the feature after setting the 4 and 20 mA endpoints

during initial use. The lockout feature prevents tampering with

the 4 and 20 mA settings on the transmitter.

Before activating the lockout feature make sure there is no

signal being received by the transmitter. If signal is being

received, deactivate it by one of the following methods:

• Stop the flow through the line that is being recorded.

• Disconnect the output device on the flowmeter.

Locking / Unlocking the Transmitter

Position yourself so you can easily operate the pushbuttons on

the transmitter. You should be able to see the indicator light.

To lock the transmitter, use the pushbuttons to enter the

following sequence with a brief pause between each button

press: 20 – 20 – 20 – SET. The indicator light will blink twice

to indicate the unit is locked.

To unlock the transmitter, use the pushbuttons to enter the

following sequence with a brief pause between each button

press: 4 – 4 – 4 – SET. The indicator light will blink once to

indicate the unit is unlocked.

Checking the Status of the Lockout Feature

To check the status of the transmitter, use the pushbuttons

to enter the following sequence with a brief pause between

each button press: SET – 4 – 20 – SET. The indicator light

will blink once if unlocked or twice if locked.

Optional 0-20 mA Mode

A few current loop systems use 0-20 mA output. The input

signal frequency of “0” produces an output analog signal of

“0” with direct proportionality and no offset.

NOTE: A true loop current of “0” in a loop powered device

like the GPI transmitter is not obtainable. That’s because

the current loop powers the transmitter, and its operating current is non-zero even at zero frequency input. In

0-20 mode, the GPI Transmitter’s loop current will drop

to as near zero as possible at zero input, in most units

between 1 and 2 mA.

Procedure

1. To enter 0-20 mode, simply press and hold all three pushbuttons simultaneously (4, SET, and 20) at any flowrate.

Continue holding until the indicator light blinks (light will

blink in up to 5 seconds) and release all buttons. This

sets the LOW END calibration point to zero/zero.

2. Set the 20 mA endpoint as described above under 4-20

mA calibration.

3. The special 0-20 mode will remain in effect until a new

4 mA endpoint is established in the usual way.

Auxiliary 0-5 VDC

The 4-20 mA Out with Display is equipped with an auxiliary

voltage output with a range of 0-5 VDC. This signal is capable

of dropping to within a few milliVolts of zero, and thus may

be more suitable for use in the 0-20 mode.

No special equipment is required to use the 0-5V output,

but wiring to customer equipment is different (see Wiring

Diagram 4).

11

Page 12

Changing Response Time

The 4-20 mA with Display comes from the factory with a

default 0.7 seconds response time.

WARNING

If you reset the response time (procedure detailed below) you MUST then reset the 4-20 mA endpoints.

To give good performance with a variety of sensor types,

many frequency-to-analog converters, including the GPI

4-20 mA Out with Display, offer two or more settings for

“response time” (sometimes referred to as “settling time” or

“averaging time”).

• Longer (slower) response times are needed for sensor

types that generate very low frequency outputs (like

GM Series oval gear flowmeters).

• Operating a meter at high flowrates may require a

shorter (faster) response time to achieve the best

transmitter performance.

• Shorter (faster) response times are preferable for sensors that generate higher frequency outputs (GPI turbine

meters, for example).

• Longer (slower) response times are also appropriate in

situations where sensor-output frequency fluctuates or

wobbles substantially.

The GPI 4-20 mA Out with Display offers a choice of five response-time settings, selectable by the unit’s pushbuttons.

MAINTENANCE

Check cable-entry seals periodically. Tighten and/or apply

sealant if needed. This is especially important in environments containing heavy concentrations of dust, oil mist, or

other residue.

Check all wiring connections occasionally for oxidation or

corrosion. Clean and re-seat if such conditions are noted.

If necessary, check and re-seat any connections that may

have been subjected to strain (during rework or construction,

for example).

Procedure

1. Start with the unit unpowered. If the unit is presently

operating, temporarily disable its external power supply.

Be sure to allow at least 30 seconds to elapse with unit

unpowered.

2. Press and hold the “4” button. While holding, watch

the indicator light and power up the 4-20 mA Out with

Display.

3. Shortly after power is applied, the light will blink one or

more times. Count the number of blinks (from 1 to 5 blinks)

and release the button after the blinking has finished.

NOTE: If necessary, repeat steps 1 through 3 to get the

number of blinks corresponding to the response time

you want.

Blinks Response Time

1 blink 0.3 second

2 blinks 0.7 second

3 blinks 1.3 second

4 blinks 2.6 second

5 blinks 5.2 second

In normal operation, the 4-20 mA Out with Display always averages two sequential input readings. The time delay from an

abrupt change in input frequency to a final, stabilized output

reading is always twice that shown in the above table.

12

Page 13

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

A. METER IS NOT 1. Field Calibration not performed properly. Field Calibrate again or select Factory Calibration.

ACCURATE

2. Factory Calibration not suitable Perform a Field Calibration according to Calibration Section or

for liquid being measured. select the proper Factory Calibration selection (i.e., gallon or litre).

3. Improper installation of flowmeter. Check for electrical noise, pulsation or swirl in the flow.

4. Flowrates too high or too low. See section on display calibration for flowrates.

B. READOUT FADED 1. Power not connected. Check power supply.

OR BLANK

2. Wiring incorrect. Verify connections.

3. Computer defective. Contact the factory.

4. Temperature limits exceeded. Check temperature specifications.

C. NORMAL FLOW- 1. Field Calibration not performed correctly. Field Calibrate again or select Factory Calibration.

RATE B UT METER

2. Computer defective. Contact the factory.

DOES NOT COUNT

(Meter comes on

3. Loose wire or mis-wired. Check wiring diagram or cable installation.

when DISPLAY

4. Sensor not attached to turbine. Check continuity of sensor.

button pushed)

5. Faulty sensor. Contact the factory.

D. LOOP OUTPUT 1. 4 mA / 20 mA setpoints bad or not set. Perform new setpoint procedure for both 4 mA and 20 mA points.

WITHIN NORMAL

RANGE, BUT

INCORRECT

E. LOOP OUTPUT 1. Output response-time setting too short, Select a longer response-time setting.

“BOUNCES” especially for slow input signal.

ERRATICALLY

2. Input connections bad. Check all signal-input connections for intermittent open- or

(is unstable)

short-circuits.

F. LOOP-OUTPUT 1. Output response-time setting too long, Select a shorter response-time setting.

STABLE BUT especially for fast input signal.

RESPONSE TIME

TOO SLOW

G. LOOP-OUTPUT OK, 1. 0-5 V output loaded too heavily. Be sure 0-5 V load impedance is at least 1000 ohms (1KΩ).

BUT 0-5 V OUTPUT

2. Wiring incorrect. Verify connections.

DOESN’T WORK

H. LOOP OUTPUT 1. Loop not supplying power. Be sure loop power supply is present and working, and has

“STUCK”AT ZERO correct polarity.

(No reading at all,

2. Loop connections bad. Check all loop connections for open- or short-circuits.

regardless of input

signal.)

3. Transmitter is faulty. Replace transmitter.

I. LOOP OUTPUT 1. 4 mA / 20 mA setpoints bad or Perform new setpoint procedure for both 4 mA and 20 mA

“STUCK” AT LOW not set. points.

VALUE (Between 1

and 4 mA) RE- 2. No input signal. Verify presence of input signal at terminal block.

GARDLESS OF

INPUT SIGNAL 3. Input connections bad. Check all signal input connections for open- or short-circuits.

4. Unit is faulty. Replace unit.

J. LOOP OUTPUT 1. 4 mA / 20 mA setpoints bad or Perform new setpoint procedure for both 4 mA and 20 mA

“STUCK” AT FULL- not set. points.

SCALE (above

20 mA) REGARD- 2. Short-circuit between Loop (–) Check all Loop and LOCAL-COM circuitry for shorts.

LESS OF INPUT and LOCAL-COM circuits.

SIGNAL

3. Incorrect connection of Hall Hall Effect requires dedicated power supply.

Effect device.

13

Page 14

DIMENSION DRAWINGS

14

Page 15

ILLUSTRATED PARTS DRAWING

12

13

11

14

15

20

16

17

18

8

10

9

21

19

7

6

5

4

3

2

Item No.

No. Part No. Description Req’d.

1 120512-01 Switch Keypad Kit ............................................................1

2 120048-01 Gasket .............................................................................. 1

3 12051803 Computer Kit (Hours) ........................................................ 1

12051804 Computer Kit (Minutes) .....................................................1

4 120043-01 PCB Assembly ..................................................................1

5 904005-63 Screw, 4-40 x 3/16 in. ....................................................... 2

6 901002-82 O-Ring ..............................................................................1

7 120509-01 Adapter Kit - Remote Display & Local (GM001, .................

GM002 & GM003) ........................................................1

120509-02 Adapter Kit - Local (GM005 & GM007) ............................. 1

120509-03 Adapter Kit - Local (GM010, GM015 & GM020) ............... 1

12051701 Adapter Kit (GX510) .......................................................... 1

8 904006-94 Screw, Tapping, GM001, GM002 and GM003 ..................2

9 120058-01 Bracket .............................................................................1

10 904005-13 Screw, 6-32 x 1/2 in. ......................................................... 4

* Varies by model.

1

Item No.

No. Part No. Description Req’d.

11 904002-44 Screw, 8-32 x 5/16 in. ....................................................... 2

12 125066-20 Cable, 20 ft. ......................................................................1

125066-3 Cable, 100 ft. .................................................................... 1

13 906005-47 Threaded Plug ..................................................................

14 902005-9 Strain Relief ......................................................................

15 901002-87 O-Ring ..............................................................................

16 904006-95 Screw, Hex Socket M5-0.8 x 12:

For GM005 and GM007 ............................................... 2

For GM010, GM015 and GM020 .................................4

17 120054-01 Main Circuit Assembly ......................................................1

18 904005-28 Sealing Seal, 1/4-20 x 5/8 in. ........................................... 4

19 904005-74 Screw, Fillister HD, #6-32 x 3/8", CR ...............................2

20 906005-48 Seal for Threaded (Item #13) Plug ....................................

21 90400811 Washer, Flat, #6 (Type B), Narrow, SS .............................. 2

*

*

*

*

15

Page 16

SPECIFICATIONS – LOCAL MODEL

Applications:

Use for indoor or outdoor applications where occasional

moisture is common.

Materials:

Acetal, Amorphous Nylon, Silicone Rubber, Polyester

(decals), Viton (gasket & seals), Stainless Steel (fasteners)

Power Source:

2-wire, loop powered*. 8.5 VDC to 35 VDC loop voltage

required for correct operation.

Outputs**:

Analog Primary: 4-20 mA current loop. With loop voltage

maintained within specified limits, will maintain advertised

linearity over 4 mA to 20 mA range, with good linearity in

over-range conditions to about 1.5 mA and 25 mA.

Analog Auxiliary: 0 to 5 VDC. Relationship to primary current output: V(volts) = l (ma) ÷ 5 . Will maintain advertised

linearity over 0.8 V to 4.0 V range, with good linearity in

over-range conditions to about 0.1 V and 4.9 V.

Recommended minimum driven impedance = 10K Ohms.

Digital (Pulse-Out): Open Collector, square wave. Will

switch up to 60 V and up to 200 mA. Closed circuit voltage drop typically 0.1 V; guaranteed less than 0.5 V at any

current up to 200 mA.

Configuration:

2-Totals (1 cumulative and 1 batch), Rate, 2 Cals

(Factory calibration in gallons or litres; 1 field calibration)

Input Signal:

Hall Effect, Reed Switch, NPN, Open Collector or

Sine Wave

Time Base:

Hours or minutes

Unit of Measure:

U.S. gallons or litres

Accuracy / Performance:

Possible conversion error, in addition to any inaccuracy of

coupled flowmeter, as follows:

Max. Conversion Error: (nonlinearity plus span, any input,

loop current output, 0°C to 70°C, loop voltage supply 12

VDC to 24 VDC) 0.5% of span plus possible resolution

uncertainty.

Max. Conversion Resolution Uncertainty: (Loop current

output, when properly calibrated) Larger of 0.1 mA or

[20 mA / (10 x ( f20–f4)]. Where f20 = frequency at 20 mA,

f4 = frequency at 4 mA.

Speed of Response: After step change in input frequency,

loop output guaranteed stable within 3 x accumulating time

(Accumulating time user selectable from 0.3 sec, 0.7 sec,

1.3 sec, 2.6 sec, 5.2 sec).

Frequency Range:

0.25 to 1,000 hertz

Batch Total:

Up to 999,999 (x100)

Cumulative Total:

Up to 999,999 (x100)

Temperature:

Ambient Temperature: +32° F to 140° F (0° C to 60° C)

Cable:

No cable provided

Mechanical Connections:

Display is mounted directly to flow meter body.

Electrical Connections:

GX500 - Two strain relief ports

GX510 - One strain relief port: one threaded plug

G2 Series - Two strain relief ports

GM Local Models - Two strain relief ports

GM 1/2 in. and Larger - One strain relief port: one

threaded plug

Shipping Weight:

1.1 lb. (.5 kg)

* Models utilizing Reed Switch pickup are completely loop powered, and

do not require any additional power supply. Note, however, that models

utilizing Hall Effect signal pickup require an additional independent, iso-

lated DC power supply for powering the Hall Effect device.

** If you want to use the 4-20 mA output and one or both of the other

outputs at the same time, you must provide electrical isolation between

the current loop and all other circuit elements. Failure to do so will result in

incorrect 4-20 mA signal conversion, and possible damage to the unit.

16

Page 17

SPECIFICATIONS – REMOTE MODEL

Applications:

Use for indoor or outdoor applications where occasional

moisture is common.

Materials:

Acetal, Amorphous Nylon, Silicone Rubber, Polyester

(decals), Viton (gasket & seals), Stainless Steel (fasteners),

PVC (cable jacket)

Power Source:

2-wire, loop powered*. 8.5 VDC to 35 VDC loop voltage

required for correct operation.

Outputs**:

Analog Primary: 4-20 mA current loop. (This is also the

power supply input for the module.) With loop voltage

maintained within specified limits, will maintain advertised

linearity over 4 mA to 20 mA range, with good linearity

in over-range conditions to about 1.5 mA and 25 mA.

Absolute maximum current limit under fault conditions

approximately 35 mA.

Analog Auxiliary: 0 to 5 VDC. Relationship to primary current output: V(volts) = l (ma) ÷ 5 . Will maintain advertised

linearity over 0.8 V to 4.0 V range, with good linearity in

over-range conditions to about 0.1 V and 4.9 V.

Recommended minimum driven impedance = 10K Ohms.

Digital (Pulse Out): Open Collector, square wave. Will

switch up to 60 V and up to 200 mA. Closed circuit voltage

drop typically 0.1 V; guaranteed less than 0.5 V at any in

range current.

Configuration:

2-Totals (1 cumulative and 1 batch), Rate, 2 Cals

(Factory calibration in gallons or litres; 1 field calibration),

K-factor to match published K-factor for each size meter.

Batch Total:

Up to 999,999 (x100)

Cumulative Total:

Up to 999,999 (x100)

Ambient Temperature:

+32° F to +140° F (0° C to +60° C)

Cable:

20 feet, 3-conductor (red, black & white), tinned drain wire,

22 AWG, PVC jacket .212 dia., (Reference Belden 9363 or

equivalent cable)

Mechanical Connections:

Wall or pipe mountable with standard U-bolts

Electrical Connections:

GX500 - Two strain relief ports

GX510 - One strain relief port: one threaded plug

G2 Series - Two strain relief ports

GM Local Models - Two strain relief ports

GM 1/2 in. and Larger - One strain relief port: one

threaded plug

Shipping Weight:

1.1 lb. (.5 kg)

* To power some low power pickup/display devices, such as a GPI

“EDM” module, a loop powered GX500 can supply 5 VDC at up to approximately 2.5 mA without degrading conversion accuracy. However, “active” pickup devices or conditioners (i.e., Hall Effect or R-F) usually require

more current. If such a device is used, or if you use the optically isolated

inputs, you must provide an independent, isolated DC power supply to

operate the pickup circuitry.

** If you want to use the 4-20 mA output and one or both of the other

outputs at the same time, you must provide electrical isolation between

the current loop and all other circuit elements. Failure to do so will result in

incorrect 4-20 mA signal conversion, and possible damage to the unit.

Time Base:

Hours or minutes

Unit of Measure:

U.S. gallons or litres

Frequency Limits for Correct Operation:

Display and

Input Type Analog Conversion Digital Output

LLC (sine): approx. 11-1000 Hz approx. 0-1000 Hz

HLLF: 0.25-150 Hz 0-150 Hz

HLHF: 0.25-1200 Hz 0-1200 Hz

Optically Isolated HLLF: same as standard HLLF

Optically Isolated HLHF: same as standard HLHF

Accuracy / Performance:

Max. Conversion Error: (nonlinearity plus span, any input,

loop current output, 0°C to 70°C, loop voltage supply 12

VDC to 24 VDC) 0.5% of span plus possible resolution

uncertainty. Coupled flowmeter may add additional error.

Max. Conversion Resolution Uncertainty: (Loop current

output, when properly calibrated) Larger of 0.1 mA or

[20 mA / (10 x ( f20–f4)]. Where f20 = frequency at 20 mA,

f4 = frequency at 4 mA.

Speed of Response: After step change in input frequency,

loop output guaranteed stable within 3 x accumulating time

(Accumulating time user selectable from 0.3 sec, 0.7 sec,

1.3 sec, 2.6 sec, 5.2 sec).

17

Page 18

SERVICE

The Waste Electrical and Electronic Equipment (WEEE) directive

(2002/96/EC) was approved by the European Parliament

and the Council of the European Union in 2003. This symbol

indicates that this product contains electrical and electronic

equipment that may include batteries, printed circuit boards,

liquid crystal displays or other components that may be

subject to local disposal regulations at your location. Please

understand those regulations and dispose of this product in

a responsible manner.

For warranty consideration, parts, or other service information, please contact your local distributor. If you need further

assistance, contact the GPI Customer Service Department

in Wichita, Kansas, Monday-Friday, 8:00 a.m. to 5:00 p.m.

Central time.

Tel: 316-686-7361

Fax: 316-686-6746

Toll free: 1-888-996-3837

To obtain prompt, efficient service, always be prepared with

the manufacturing date code, found behind the coverplate.

For warranty work, always be prepared with your original sales

slip or other evidence of purchase date.

Please contact GPI before returning any part. It may be

possible to diagnose the trouble and find a solution with a

telephone call. GPI can also inform you of any special requirements you will need to follow for shipping.

WEEE DIRECTIVE

18

Page 19

Page 20

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

1-888-996-3 837

Limited Warranty Policy

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205, hereby provides a limited warranty against defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. This product includes a 1 year warranty. Manufacturer’s sole

obligation under the foregoing warranties will be limited to either, at Manufacturer’s option, replacing or repairing defective Goods (subject to

limitations hereinafter provided) or refunding the purchase price for such Goods theretofore paid by the Buyer, and Buyer’s exclusive remedy for

breach of any such warranties will be enforcement of such obligations of Manufacturer. The warranty shall extend to the purchaser of this product

and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of manufacture or on the date of purchase with an original sales receipt. This warranty shall not apply

if:

A. the product has been altered or modified outside the warrantor’s duly appointed representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in accordance with

the manufacturer’s operating instructions.

To make a claim against this warranty, contact the GPI Customer Service Department at 316-686-7361 or 888-996-3837. Or by mail at:

The company shall, notify the customer to either send the product, transportation prepaid, to the company at its office in Wichita, Kansas, or to

a duly authorized service center. The company shall perform all obligations imposed on it by the terms of this warranty within 60 days of receipt

of the defective product.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for which it was

designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702 (governs the resale availability of the warranty terms).

Great Plains Industries, Inc.

5252 E. 36

Wichita, KS, USA 67220-3205

th

St. North

GPI is a registered trademark of Great Plains Industries, Inc.

© 2010 by GREAT PLAINS INDUSTRIES, INC., Wichita, KS

Printed in U.S.A. 06/10

Rev. H 920765-05

Loading...

Loading...