Page 1

MS244G

0899

0001

Positive Displacement Flowmeters

GM50 series instruction manual

GM50 Pulse • GM50 Standard LCD • G540 Deluxe LCD • From serial No. CXXXX

Page 2

Thank you for purchasing a GPI GM

Series Flow Meter. Please take a few

minutes to read through this manual

before installing and operating your

meter. If you have any problems with

the meter, refer to the maintenance

and trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the M50

Series meters with pulse outputs and

liquid crystal displays. For models

with deluxe liquid crystal display an

additonal instruction manual is

supplied. If you need further

assistance, contact your local GPI

representative or contact GPI by

telephone or fax.

The GPI GM Series Flow Meter has

incorporated the oval rotor principal

into its design. This has proven to be a

reliable and highly accurate method

of measuring flow. Exceptional

repeatability and high accuracy over a

wide range of fluid viscosities and

flow rates are features of the GM

Series flow meter design. The low

pressure drop and high pressure rating

means the GM Series flow meter is

suitable for both gravity and pump (in

line) applications.

The GPI GM Series flow meters are

available in either aluminum or 316

stainless steel. Standard rotors are

made from PPS (Polyphenylene

Sulfide Resins) with optional 316

stainless steel rotors available for both

stainless steel and aluminum models.

The M50 Series is available with

either;

* Standard Pulse

* Standard LC Display and Pulse

* Deluxe LC Display and Pulse

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter (refer to

the GPI fluid compatibility chart), or

consult your local GPI representative

for advice.

This meter will handle particle sizes up

to 0.4mm/0.016”.

To prevent damage from dirt or foreign

matter, GPI recommends a Y or Basket

type 60 mesh strainer be installed as

close as possible to the inlet side of the

meter (if required contact GPI for

further information).

Note: When a strainer is installed it

should be regularly inspected and

cleaned. Failure to keep the strainer

clean will dramatically effect flow

meter performance.

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Note: Failure to do this could damage

the meter.

For pump applications, turn off the

pump at the end of each day.

Maintenance can be carried out to the

liquid crystal displays and pulse units

without removing or isolating the meter

from the line. When maintenance to

any other part of the meter is required,

the meter must be isolated and the line

pressure reduced.

The reed switch pulse unit can cause

inaccurate rate counts when used with

high speed counters. It is advised that

a debounce circuit be used or

alternatively use the hall effect sensor

option.

PTB - Deluxe LC Display

EEX1A IIC T6 (PTBnr EX-93.C4033X)

1

To the owner

Important Information

Page 3

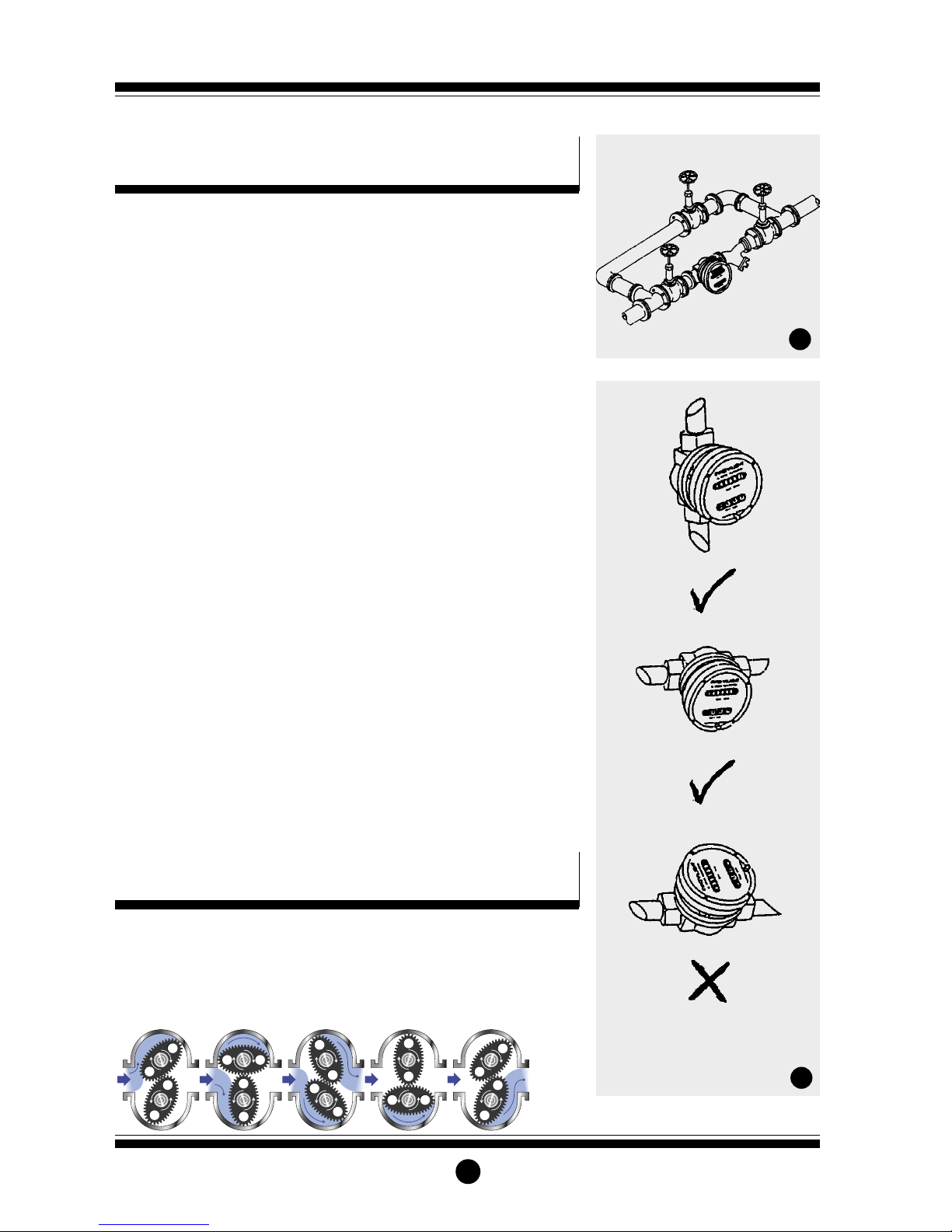

1] GPI recommends that when setting

up pipework for meter installations

a bypass line be included in the

design. This provides the facility for

a meter to be removed for

maintenance without interrupting

production. (See Fig.1)

2] Use thread sealant on all pipe

threads. For flanged versions 2”

ANSI 150lb or DIN16, appropriate

companion flanges and gaskets are

required.

3] For pump applications ensure pipe

work has the appropriate working

pressure rating to match the pressure

output of the pump. The maximum

working pressures are;

2” flanged stainless steel or aluminum

series. See appropriate ANSI/DIN

flange rules.

4] Install a wire mesh strainer (Y or

basket type 40 mesh as close as

possible to the inlet side of the meter.

5] Ensure that the meter is installed so

that the flow of the liquid is in the

direction of the arrows embossed on

the meter body.

6] The meter can be installed in any

orientation as long as the meter

shafts are in a horizontal plane.

(Refer to Fig.2 for correct

installation) The register assembly

may be orientated to suit the

individual installation.

Note: Incorrect installation can cause

premature wear of meter components.

7] Do not over tighten meter connections.

8] It is important that after initial

installation you fill the line slowly,

high speed air purge could cause

damage to the rotors.

9] Test the system for leaks.

10] Check the strainer for swarf or

foreign material, after the first 200

litres check periodically,

particularly if the flow rate

decreases.

2

Installation

When fluid passes through the meter,

rotors turn. The magnets which are

located in the rotors will pass across

the pulser circuit board (containing

either Reed switches or Hall Effect

sensors). A signal is received which is

then sent by the Pulse Circuit Board

(PCB) to the relevant LC display or

receiving instrument.

Operation

1

2

Bypass Line

Flow Outlet

Flow Inlet

Strainer

Do Not Install Meter This Way

Page 4

Disassembly

Ensure that the fluid supply to the

meter is disconnected, and the line

pressure is released before

disassembly, with the exception for

repair or maintenance to the LC

Display or PCB where there is no

necessity to isolate the meter from

flow. Refer to the exploded parts

diagram on pages 7 and 8 for item

numbers.

1a] Units with Pulse Caps; Undo the

conduit connector, remove pulse

cap (item 9) and remove the wires

from the pulse terminal board (item 5).

1b] Standard LC Display; Mark the

display orientation with a marking

pen, unscrew the four large screws

(Item 30) on top of the LC Display.

Carefully separate the LC Display

from the plastic housing and

disconnect the wires from the

Reed Switch Connections for PCB Terminals - refer Fig.3

Hall Effect Sensor Connections - refer Fig.4

3

Electrical Connections

Service Instructions

3

Contact rating 15VA

Maximum Voltage 150VDC

Configuration 1

2 x pulse outputs

Configuration 2

Link 2 & 3 for double

pulse output

LCD Versions

1 x Hall Effect Sensor

1 x Reed Switch

1 - Reed Switch

2 - Reed Switch

3 - HE Common 4 - HE Signal

5 - HE Supply +

Pulse V

ersions Only

2 x Hall Effect Sensor

1 - HE Supply +

2 - HE 1 Signal

3 - HE Common 4 - HE 2 Signal

5 - HE Ground

4

Hall Effect Voltage 4.5 to 24 VDC

Current Draw Minimum 4.6mA

Output NPN Open Collector 25mA

Page 5

This section of the instruction manual

assists you in the operating of the GPI

Standard LC Display. Please take a few

minutes to acquaint yourself with the

information that follows.

Replace Battery

1] Remove the two large screws (Item

30) and the two small screws (Item

31) from the battery cover plate

(Item 29).

2] Remove the battery cover plate

Standard LC Display

4

pulse terminal block. (See Standard

LC Display instructions).

1c] Deluxe LC Display; Mark the

display orientation with a marking

pen, remove the four retaining

screws on the display face (Item

16). Lift off the display unit and

remove the 9 pin connector at the

back of the display unit. (Refer to

separate Deluxe LC Display

instruction manual).

2] Remove the mounting adaptor plate

and gasket (Item 14).

3] Loosen the eight cap head screws

(Item 7) that hold down the meter

cap (Item 4), remove the screws,

washers and lift off the cap.

4] Remove the o’ring (Item 2) from the o’ring

groove in the meter cap (Item 4).

5] Remove rotors (Item 3).

Reassembly

1] Before reassembling check the

condition of the rotors (replace if

necessary).

2] Check that the smooth side of the

rotors (not the plug side) is facing

you when inserting the rotors, the

smooth side of the rotor is the

magnet side. There is no difference

between rotor one or rotor two.

3] Replace the rotors (Item 3) onto the

shafts at 90oto each other (refer Fig.

5) and check their operation by

turning either of the rotors. If the

rotors are not in mesh correctly or

do not move freely, remove one of

the rotors and replace correctly at

90oto the other rotor. Re-check the

operation of the rotors.

4] Replace the o’ring (Item 2) into

groove in the meter cap, if the o’ring

has grown or is damaged in any way

replace it with a new part.

5] Replace the meter cap making sure

that the locating pin in the body

lines up with the hole in the meter

cap. Insert the cap head screws (Item

7) and tighten in the sequence 1, 6,

2, 5, 3, 7, 4, 8.

6] The replacement of cables and

connectors are a reversal of the

disassembly procedure, replace

conduit fitting if required. When

replacing the Standard LC Display or

the Deluxe LC Display, confirm the

orientation marks made on

disassembly are aligned then screw

the register into place.

7] Test the meter by turning the rotors

with a finger or by applying very low

air pressure (no more than a good

breath) to one end of the meter,

before returning the meter to the line.

Pulse Circuit Board (PCB) Notes:

The PCB (Item 5) is fitted with (A) two

reed switches; (B) hall effect sensors; or

(C) one reed switch and one hall effect

sensor. The PCB board is fastened to

the meter cap (Item 4) by two screws

and stand off’s. All care and caution

should be taken when removing or

handling the PCB as both the reed

switch and hall effect sensor are fragile.

Individual reed switches or hall effect

sensors are not available as individual

replacement parts and are only

available with the PCB (Item 5).

5

Rotors must be at 90oto each other.

Rotor #2

Rotor #1

6

Standard LC Display

Page 6

5

(Item 29) and gasket (Item 28).

3] Remove battery, and clean any

corrosion from the battery terminals

(to protect terminals from corrosion

or condensation coat the terminals

with petroleum jelly).

4] Install the new battery.

5] Check gasket (Item 28) for damage

(replace if required). Position gasket

(Item 28) and cover plate (Item 29)

correctly, insert the screws and

tighten.

Display Operation

All meter operations are reflected in the

readout on the face of the meter. The

readout contains three lines of

information; refer to Fig. 7.

Note: The calibration is preset and is

permanently stored in the meter’s

computer.

The meter will turn on automatically

when the liquid flows through the

meter. The meter can also be turned on

manually by pressing and releasing the

display button.

T

urn Off

The meter turns off automatically two

minutes after flow stops. When the

meter is off, the readout is blank.

Batch T

otal

The resettable batch total indicates flow

during a single use. This total can be

reset by holding down the display

button for three seconds until zeros

appear. The batch total can be found by

pressing and releasing the display button

until the bottom line displays “Total 2”.

Cumulative T

otal

The cumulative total is the total of all

the liquid measured since the meter’s

power supply was connected. This total

cannot be manually zeroed, but will

zero when the battery has been

removed, goes dead, or when it

reaches the maximum value of

999,999.

The cumulative total can be found by

pressing and releasing the display

button until the bottom line displays

“Total 1 Locked”.

Flow Rate

The flow rate is the rate the fluid is

flowing through the meter. The flow

rate setting can be found by pressing

and releasing the display button until

the bottom line displays “flow rate”.

Propeller

Any time liquid flows through the

meter, a small propeller displays.

Battery Replacement

Your meter is powered by a 9 volt

lithium battery. (Replacement batteries;

Lithium U9VL, Alkaline 522 or

MN1604). If the meter’s readout should

become dim or blank, the battery

should be replaced.

When the battery either falls or is

disconnected the batch and cumulative

totals return to zero. The factory

calibration is retained in the meter’s

computer permanently and will not be

affected by battery failure.

Auxiliary Facilities

Connection of an external 12 volt DC

power supply facility;

1] Remove the 4 large screws (Item 30)

and remove the register from the

coverplate.

2] Disconnect the internal battery.

3] Solder the external power leads to

the terminals marked ‘Ext 12V’ on

the registers printed circuit board.

4] Re-assemble the register onto the

coverplate, replace the 4 screws

(Item 30) and screw firmly together.

Connection of external pulse output

1] Remove the 4 large screws (Item 30)

and remove the register coverplate.

2] Connect external signal lead. (Refer

Fig. 8)

Pulse O/P and Ext Power are the

connections located on the interface

PCB, to use this output a 1K resistor

will need to be soldered between the +

voltage of the external power input and

the + of the pulse O/P. Pulse signal

represents the output cabling to the

receiving instrument.

7

Top line indicates

“Preset Factory Calibration”

Bottom line indicates

“Totaliser” mode

Middle

line

indicates

“Flow”

Page 7

6

Meter Trouble Shooting

8

1KR (2 watt 1%)

Pulse O/P PCB Connection

Ext Power PCB

Connection 12~24

vdc 100mA

Pulse Signal to Instrument

TROUBLE SHOOTING GUIDE

TROUBLE

Fluid will not flow through meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

LCD Register not working

CAUSE

a] Foreign matter blocking rotors

b] Line strainer blocked

c] Damaged rotors

d] Meter connections over tightened

e] Fluid is too viscous

a] Strainer is partially blocked

b] Fluid is too viscous

a] Fluid flow rate is too high or too low

b] Fluid is too viscous

c] Excess wear caused by incorrect

installation

a] Faulty hall effect sensor

b] Faulty reed switch

c] Magnets failed

a] Battery not connected properly

b] Battery flat

c] Faulty wiring connections

d] Faulty LC display

e] Faulty connection from LC display

to Pulse PCB

REMEDY

a] Dismantle meter, clean rotors

(Strainer must be fitted in line)

b] Clean strainer

c] Replace rotors (Strainer must be

fitted in line)

d] Re-adjust connections

e] See specifications for maximum

viscosity

a] Clean strainer

b] See specifications for maximum

viscosity

a] See “specifications” for minimum

and maximum flow rates

b] Consult GPI

c] Check meter body and rotors.

Replace as required. Refer to

installation instructions

a] Replace PCB Board

b] Replace PCB Board

c] Replace magnets

a] Check battery connections

b] Replace battery

c] Check wiring for loose or faulty

connections

d] Replace LC display

e] Check wiring connections

Note: Internal 9 volt battery must be disconnected when using the display pulse output.

Page 8

7

Meter Parts Listing

1

23 4 56 7 8 910

1 1 MS283F Meter Body 2” ANSI 150lb Flange (Aluminium)

1 1 MS281D Meter Body 2” DIN16 Flange (Aluminium)

1 1 MS281F Meter Body 2” ANSI 150lb Flange (S/Steel)

1 1 MS283D Meter Body 2” DIN16 Flange (S/Steel)

21* BS252 “O” Ring (NBR)

21* BS252E “O” Ring (EPDM)

21* BS252TE “O” Ring (Teflon)

21* BS252V “O” Ring (Viton)

32* MS147S Rotors PPS (Polyphenylene Sulfide Resins)

32* MS147TS High Temperature Rotors (PPS)

32* MS147HS High Viscosity Rotors (PPS)

32* MS147HTS HighViscosity/High Temperature Rotors (PPS)

4 1 MS230 Meter Cap (Aluminium)

4 1 MS231 Meter Cap (Stainless Steel)

51* MS201-R PCB (Standard Reed Switch)

51* MS201-HE PCB (Hall Effect Sensor)

5 1 MS201-R/HE PCB ( 1 Reed Switch & 1 Hall Effect Sensor)

6 4 MS284S PCB Board Screws

76* MS243S Meter Cap Screws (Standard)

76* MS282S Meter Cap Screws (Stainless Steel)

81* MS300 Pulser Cap Gasket

9 1 MS160 Pulser Cap (Aluminium) 20mm Conduit Thread

9 1 MS160N Pulser Cap (Aluminum) 1/2” NPT Thread

9 1 MS170 Pulser Cap (Stainless Steel) 20mm Conduit Thread

9 1 MS170N Pulser Cap (Stainless Steel) 1/2” NPT Thread

10 4 MS115S Pulser Cap Screw (Stainless Steel)

11 1 MS37 Warning Lebel (Not Shown)

12 1 MS14 Explosion Proof Approval Label (Not Shown)

13 1 Customer to Specify Legend Plate (Not Shown) inc. Hammer Screws

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Key:

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

Rec.

Parts

Page 9

8

MS280S Deluxe LCD Display (Complete)

14 1 MS279 Mounting Adaptor Plate

15 4 * MS117S Adaptor Screws

16 1 * MS69 LC Display Unit

17 4 * MS118S LC Display Mounting Screws

18 1 * MS127 Battery Retaining Screw

19 1 * MS126 Battery (Standard) CR2040

20 1 * MS68 Connector and Cable (Not Shown)

21 1 MS87 PTB Approval Label (Not Shown)

22 1 * MS128 Extended Life Battery 2/3 AA (Not Shown)

NOTE: Note Suitable for Intrinsic Use

33 1 * MS307 Gasket

MS275S Standard LC Display (Complete)

23 1 MS238 Mounting Adaptor Plate

24 4 * MS203S Adaptor Screws

25 1 * BS045 “O”Ring

26 1 * MS205 LC Display

27 1 * MS274 9 Volt Battery

28 1 * MS184S (Inc. MS184B) Battery Gasket

29 1 * MS184S (Inc. MS184A) Battery Cover

30 4 * MS206S Register Screws

31 4 * MS182S Battery Cover Plate Screws

32 1 Customer to Specify Battery Cover Label

Display Parts Listing

823242526282930

27

32 31

814

15

18 19

1716

33

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Rec.

Parts

Page 10

9

Meter Specifications

Heating Jackets

Meter Type

Flow Ranges

(Litres per minute/US Gallons per

minute)

Above 5 Centipoise

Below 5 Centipoise

Accuracy of Reading

Maximum Viscosity*

Maximum Operating Pressure

Maximum Operating Temperature

Pulse Type

Pulses Per Litre/US Gallon

Pulse

15 to 350/ 4 to 92

33 to 300/ 9 to 79

+/- 0.5%

1000 Centipoise

As per flange rule

80°C/ 176°F

Dual Reed Switches or

Hall Effect Sensor or

combination HE

Sensor/Reed Switch

6.68/ 13.3 or 25.28/ 50.34

Pulse with Standard

LC Display

15 to 350/ 4 to 92

33 to 300/ 9 to 79

+/- 0.5%

1000 Centipoise

As per flange rule

80°C/ 176°F

Dual Reed Switches or

Hall Effect Sensor or

combination HE

Sensor/Reed Switch

6.68/ 13.3 or 25.28/ 50.34

Pulse with Deluxe

LC Display

15 to 350/ 4 to 92

33 to 300/ 9 to 79

+/- 0.5%

1000 Centipoise

As per flange rule

80°C/ 176°F

Dual Reed Switches or

Hall Effect Sensor or

combination HE

Sensor/Reed Switch

6.68/ 13.3 or 25.28/ 50.34

1

2

3

Complete Assembly: GHJ500-1 - Aluminium BSP

GHJ500-2 - Aluminium NPT

Spare Parts Listing:

GHJ400-1: MS333 SHCS Screws

MS133B Jacket Body - Aluminium/BSP

BS156 “O” Ring

GHJ400-2: MS333 SHCS Screws

MS133N Jacket Body - Aluminium/NPT

BS156 “O” Ring

* Unless High Viscosity or High Temperature Rotors are fitted

Page 11

178mm

102mm

185mm

55

mm

10

Meter Dimensions

178mm

86mm

188mm

18mm

55mm

137mm

178

mm

55mm

GM50 Pulse Meter Dimensions

GM50 Pulse Meter with Standard LC Display

GM50 Pulse Meter with Deluxe LC Display

240mm

152mm

213mm

210mm

240mm

152mm

210mm

240

mm

127

mm

235mm

152mm

Page 12

Warranty

Great Plains Industries, Inc. Limited Warranty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205,

hereby provides a limited one year warranty against defects in material and workmanship on

all products manufactured by Great Plains Industries, Inc. This warranty shall extend to the

purchaser of this product and to any person to whom such product is transferred during the

warranty period.

The warranty period shall begin on the date of the original new equipment purchase.

Warrantor’s obligation hereunder shall be limited to repairing defective workmanship or

replacing or repairing any defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed

representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed

or operated other than in accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company

at its address below no later than 30 days after the expiration of the warranty period. Such

notice shall identify the defect in the product. The company shall, within 14 days of receipt of

such notice, notify the customer to either send the product, transportation prepaid, to the

company at its office in Wichita, Kansas, or to a duly authorized service center. The company

shall perform all obligations imposed on it by the terms of this warranty within 60 days of

receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR

DIRECT, INDIRECT, INCIDENTALAND CONSEQUENTIAL DAMAGES INCURRED IN THE

USE OR LOSS OF USE IF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any

particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from

U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Loading...

Loading...