Page 1

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter. Refer to

Industry fluid compatibility charts or

consult your local representative for

advice.

To prevent damage from dirt or foreign

matter it is recommended that a Y or

basket type 200 mesh strainer be

installed as close as possible to the inlet

side of the meter. Contact your local

representative for advice.

Note:

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Failure to do this could damage the

meter.

To reduce pressure build up turn off the

pump at the end of each day.

Positive displacement flowmeters

GM001 series instruction manual

To the owner

Operation

1

Please take a few minutes to read

through this manual before installing

and operating your meter. Always

retain this manual for future reference.

If you have any problems with the

meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM001

Series meters. For models with display,

an additional manual is supplied. If you

need further assistance, contact your

local representative or distributor for

advice.

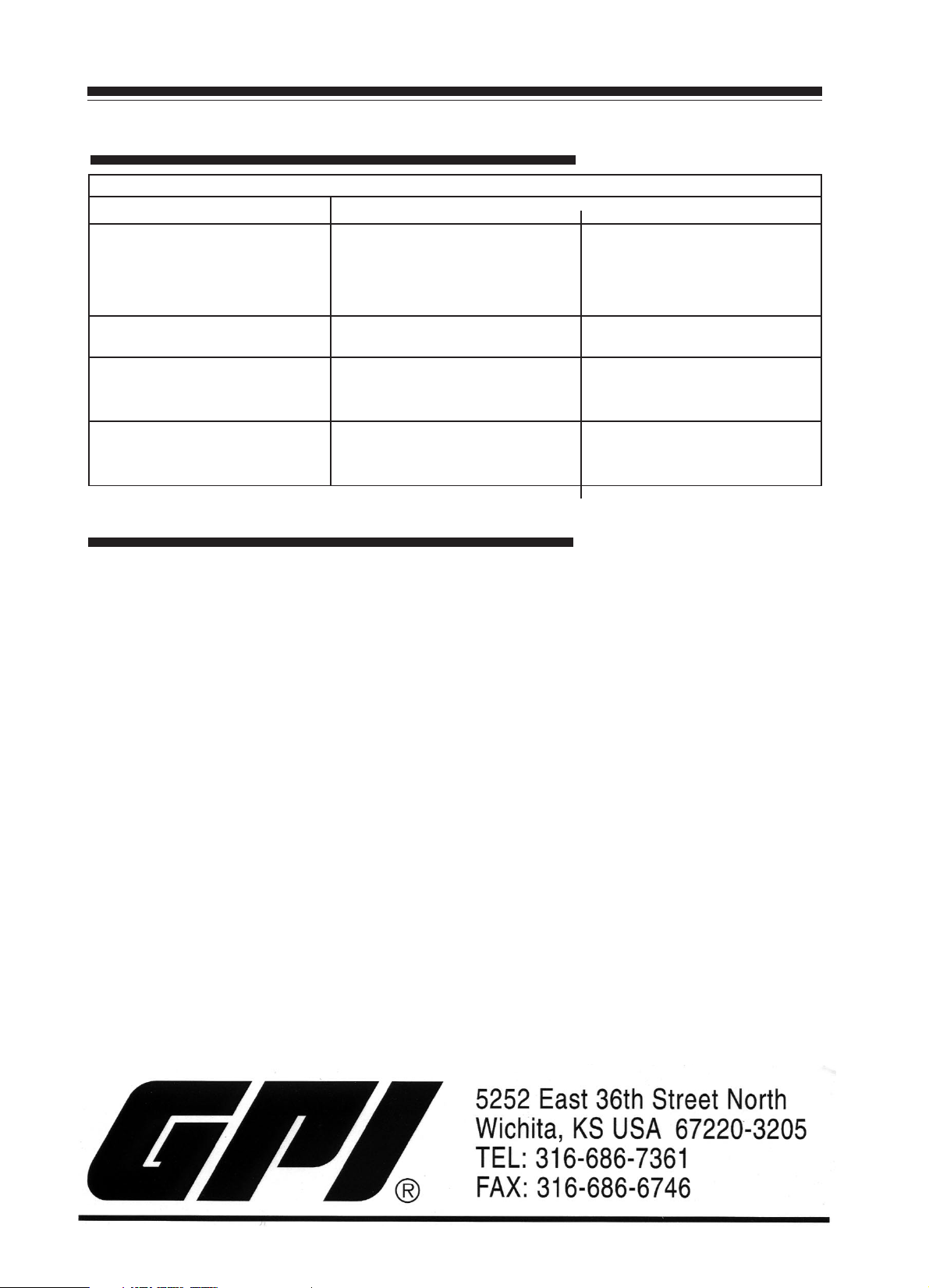

This Flowmeter has incorporated the

oval rotor principal into its design. This

has proven to be a reliable and highly

accurate method of measuring flow.

Exceptional repeatability and high

accuracy over a wide range of fluid

viscosities and flow rates are features of

the oval rotor design. With low pressure

drop and high pressure rating means

oval rotor flow meters are suitable for

both gravity and pump (in-line)

applications.

GM001 Series Flowmeters are available

in Aluminium or 316 Stainless Steel.

Standard rotors are made from 316

Stainless Steel.

MS15G

0603

0002

Page 2

1. Use thread sealant on all pipe

threads.

2. Ensure the meter is installed so that

rotor shafts are always in a

horizontal plane. Flow is bi-

directional.

3. GPI recommends use of flexible

connections.

4. Extreme care must be taken when

installing the meter. Pipe strain or

overtightening meter connections

can cause meter damage.

2

Installation

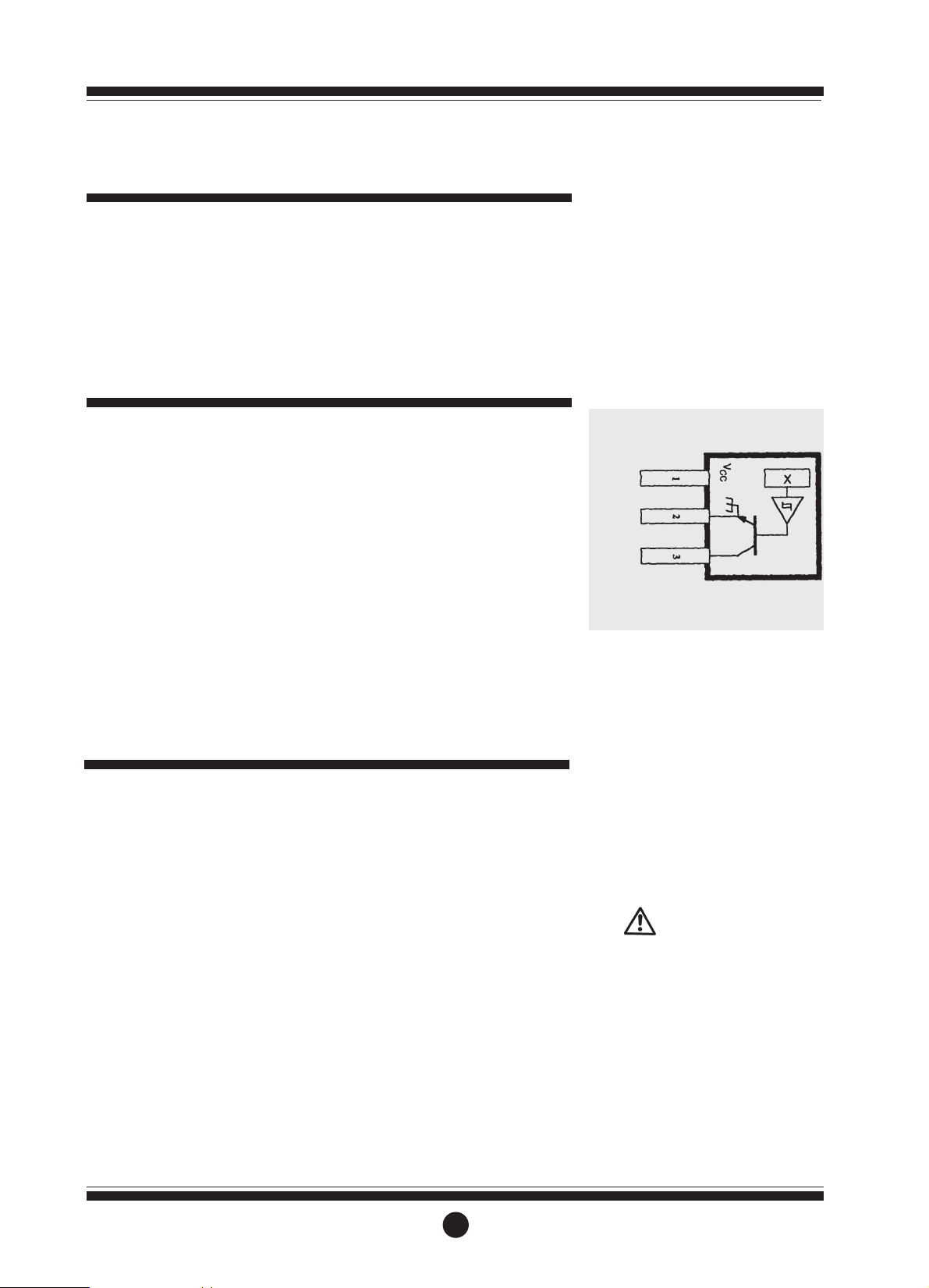

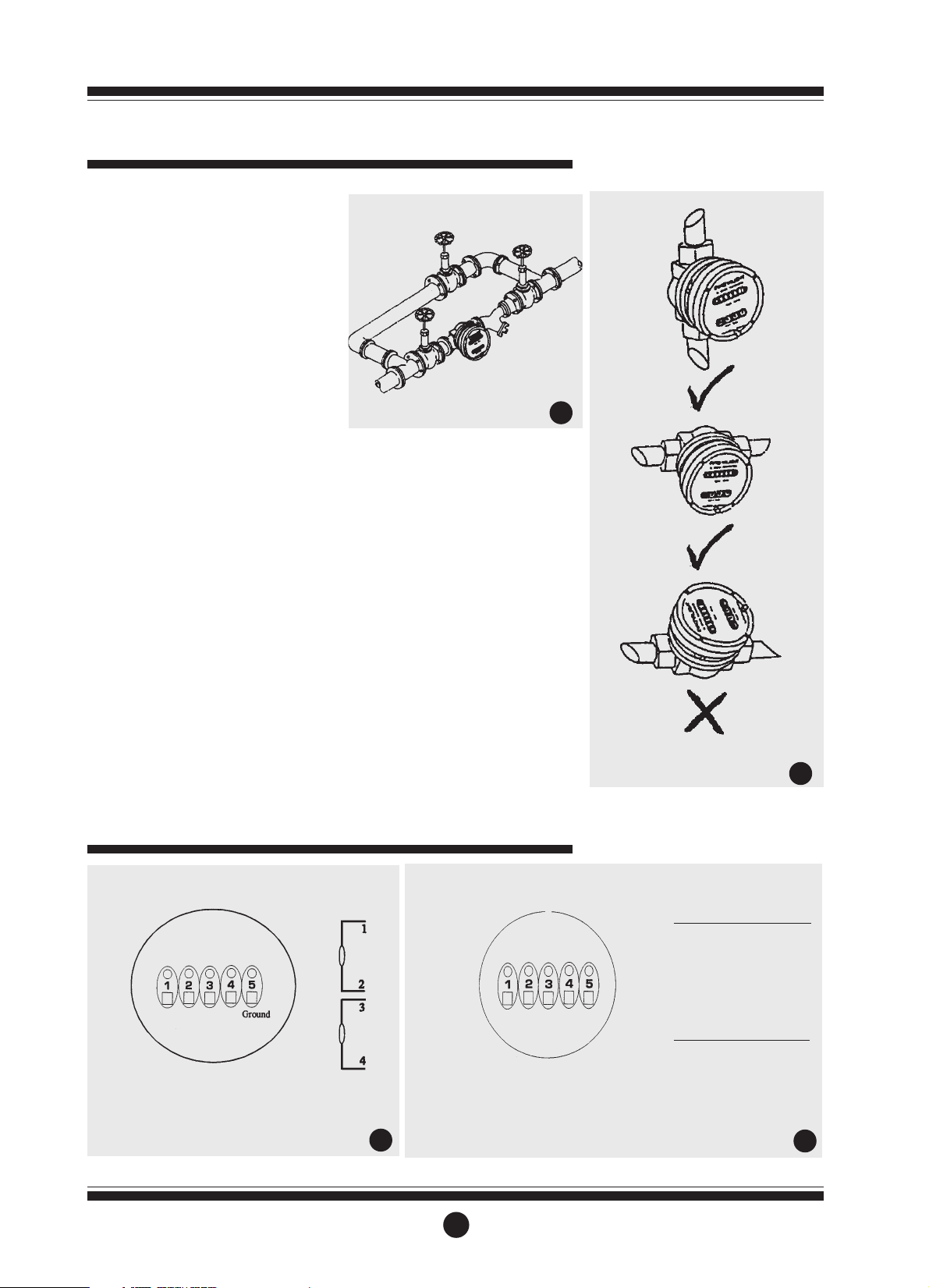

Hall Effect Sensor Specifications;

l 4.5V to 24V (4.6 ~ 9mA) operation

needs only an unregulated supply.

l Open collector 25mA output NPN

compatible with digital logic.

l Reverse battery protection.

l Temperature -40oC / -40oF ~

150oC / 300oF.

Reed Relay Specifications;

l Two wire SPST N/O.

l Switching voltage 150VDC

maximum current 0.25 AMPS.

l Rating 3 watts.

l Temperature -40oC / -40oF ~

150oC / 300oF.

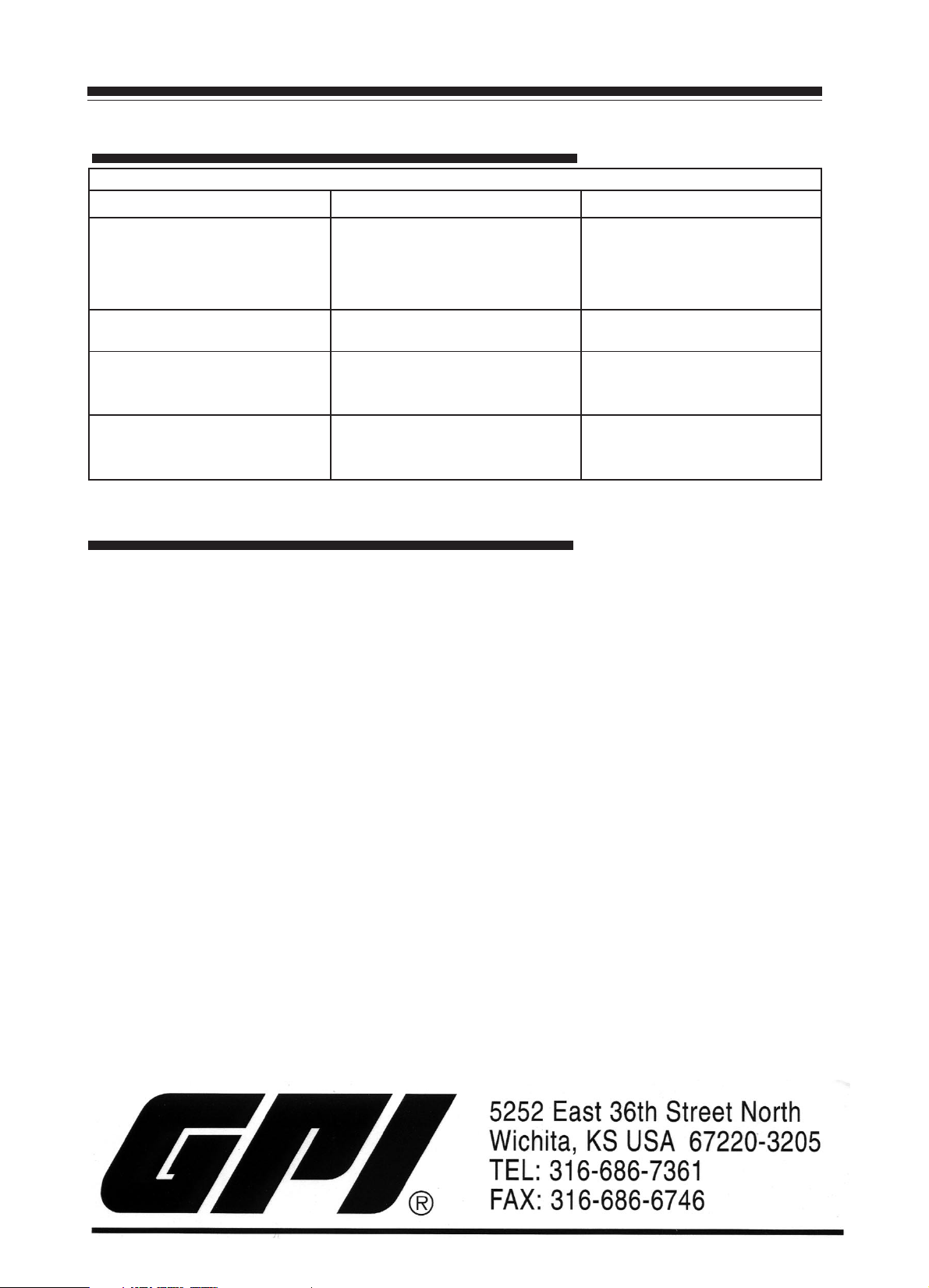

Pulser details

Hall Effect Sensor Wiring Details

Red - Supply

Green - Ground

Blue - Output

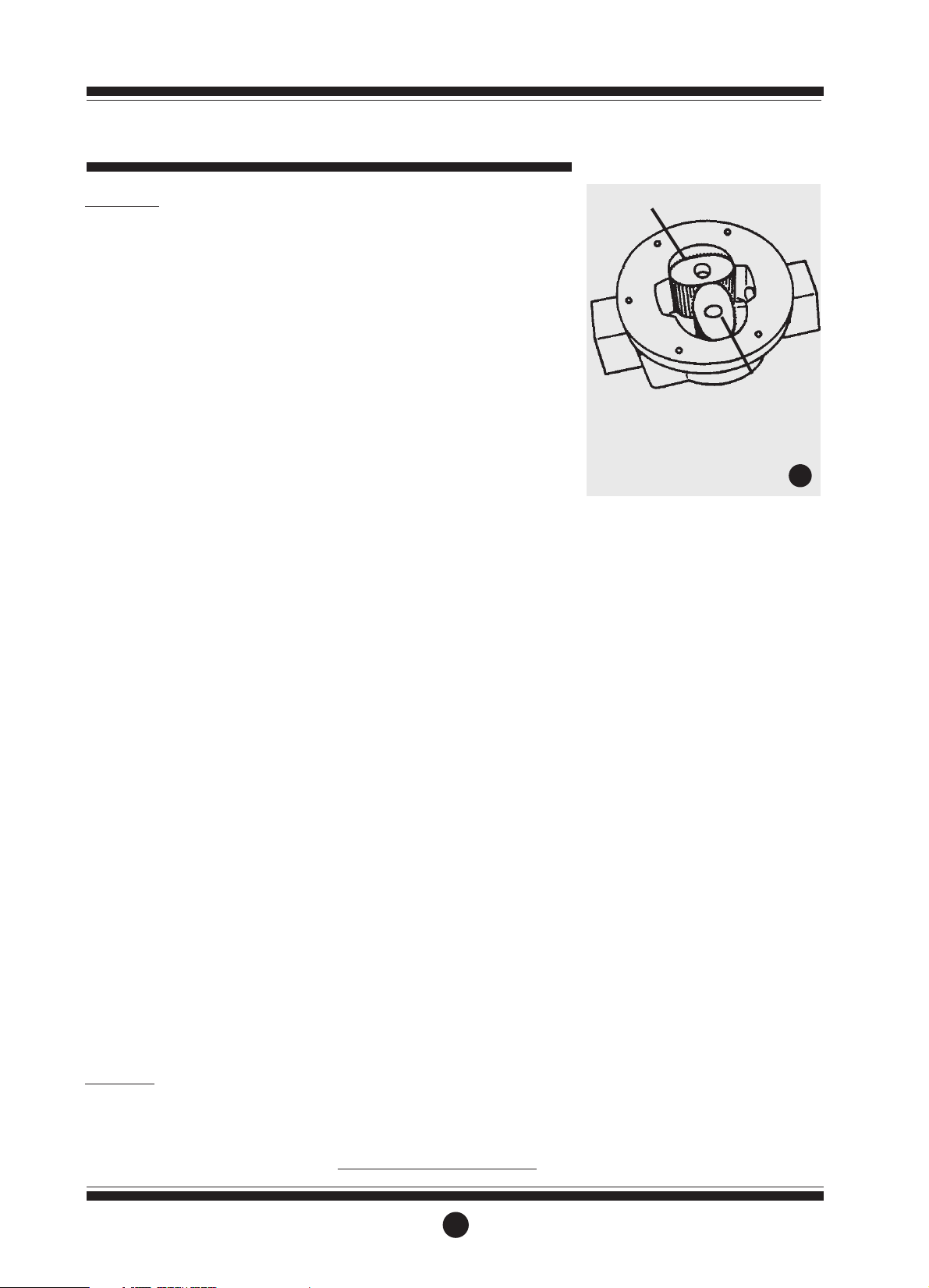

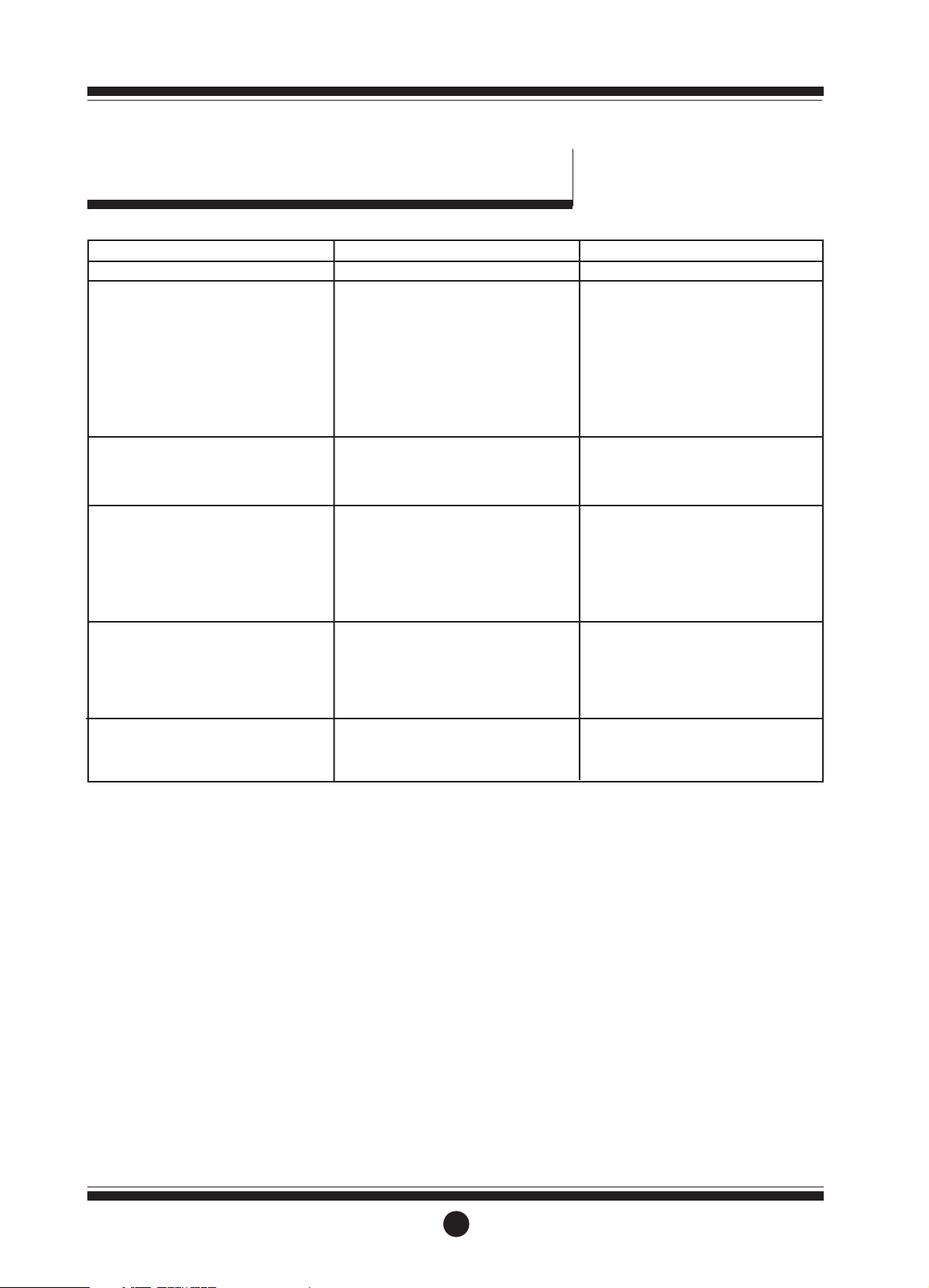

Disassembly:

1. Ensure the fluid supply to the meter

has been disconnected, and the

line pressure has been released

before disassembly.

2. Remove four (4) screws (Item 3) and

remove the meter body cover (Item

2).

3. Remove o-ring (Item 5) and inspect

(replace o-ring if damaged).

4. Remove rotors (Item 4), clean and

inspect (replace rotors if damaged).

Reassembly:

1. Place rotors (Item 4) into the meter

body. The rotors should be at 90

o

to each other.

Note: The rotor with magnets must be

placed in the body on the same side as

the groove on the body (refer to

diagram).

2. Lightly rotate the rotors (Item 4) by

hand (they must rotate freely).

3. Install o-ring (Item 5).

4. Replace the meter cap (Item 2).

Note: The groove on the cover must

line up with the groove on the meter

body (refer to diagram).

5. Replace four screws (Item 3).

CAUTION:

Care must be taken not to overtighten

the screws (Item 3) or damage may

occur.

Maintenance

Page 3

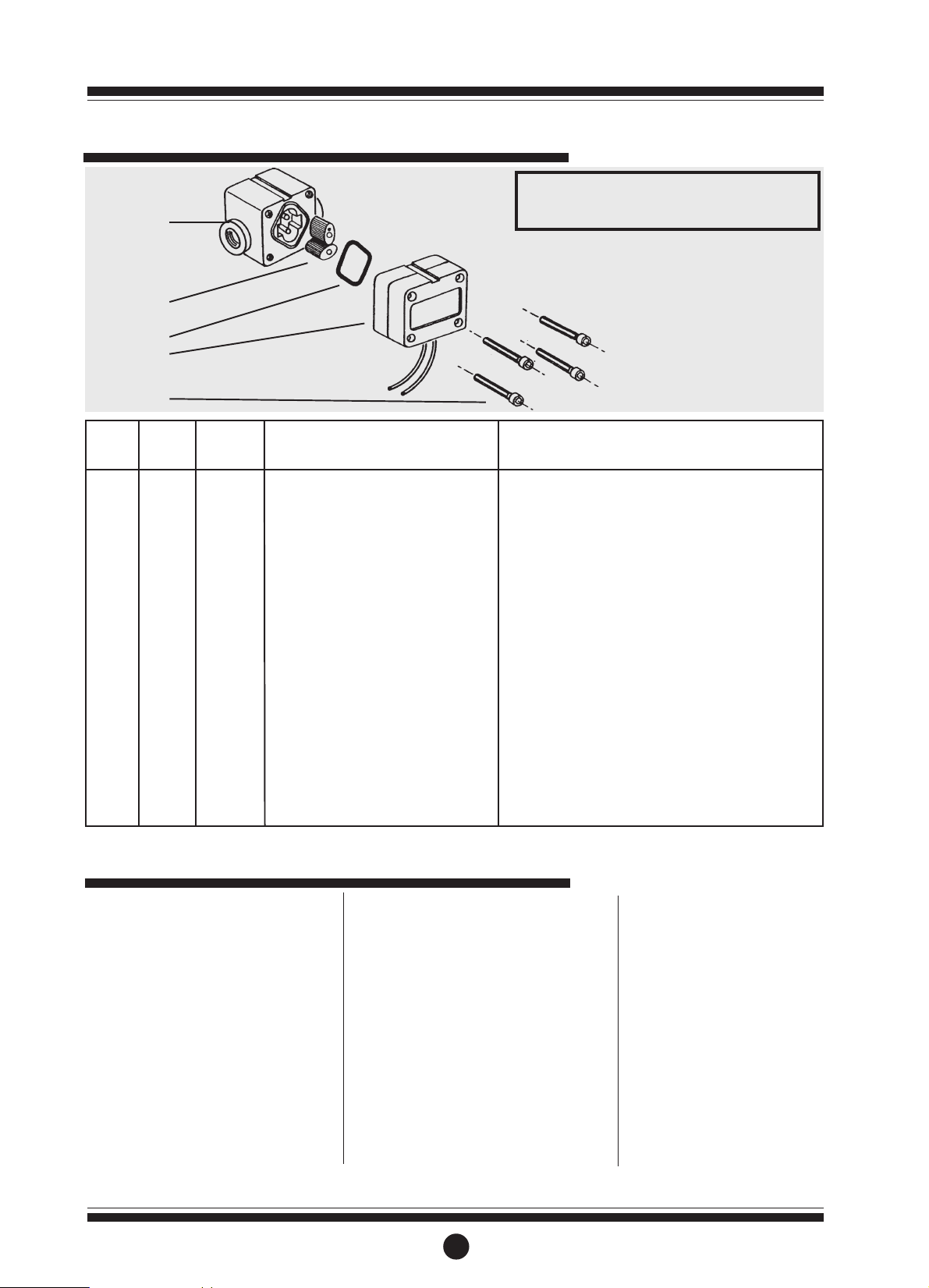

3

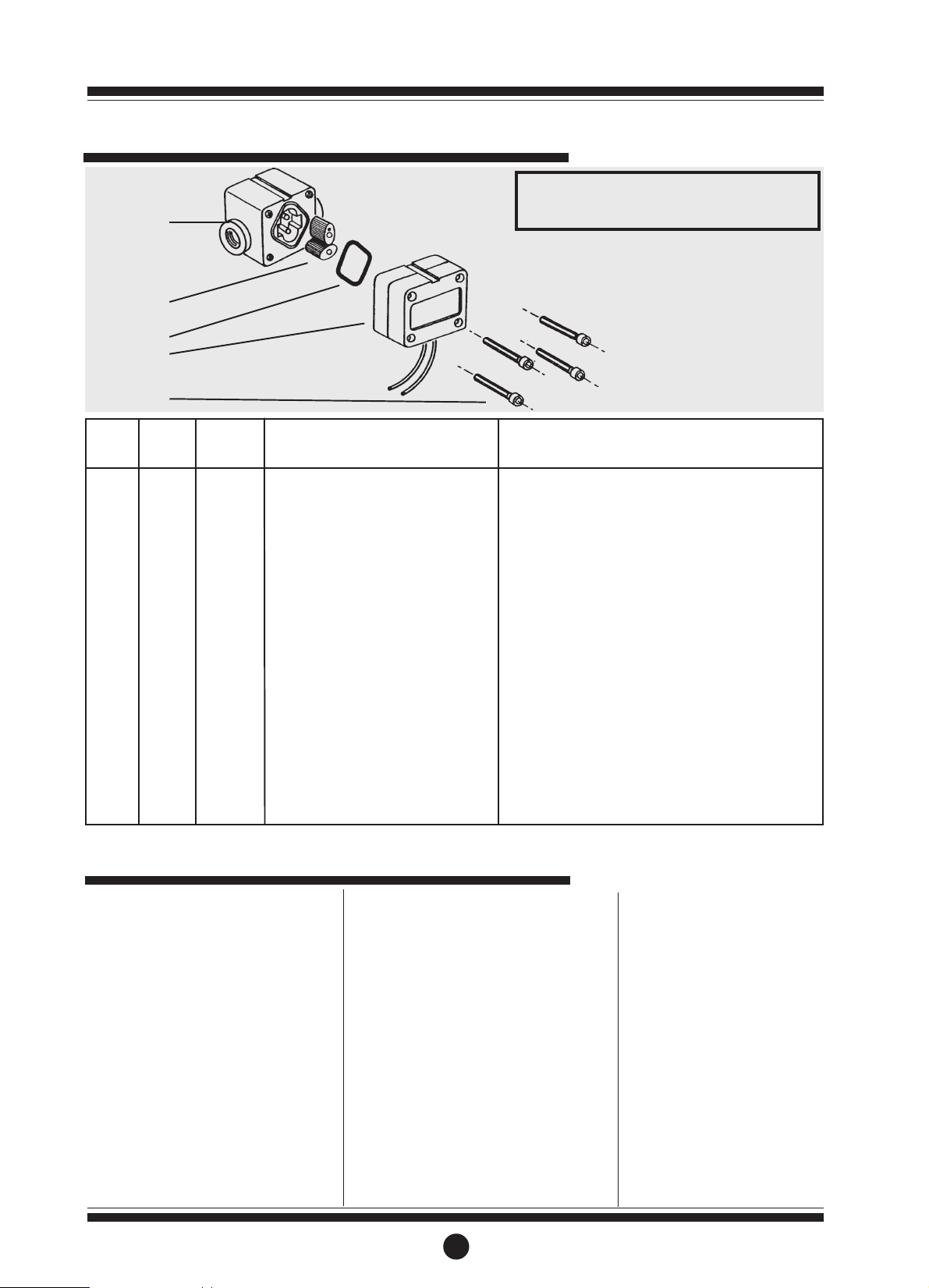

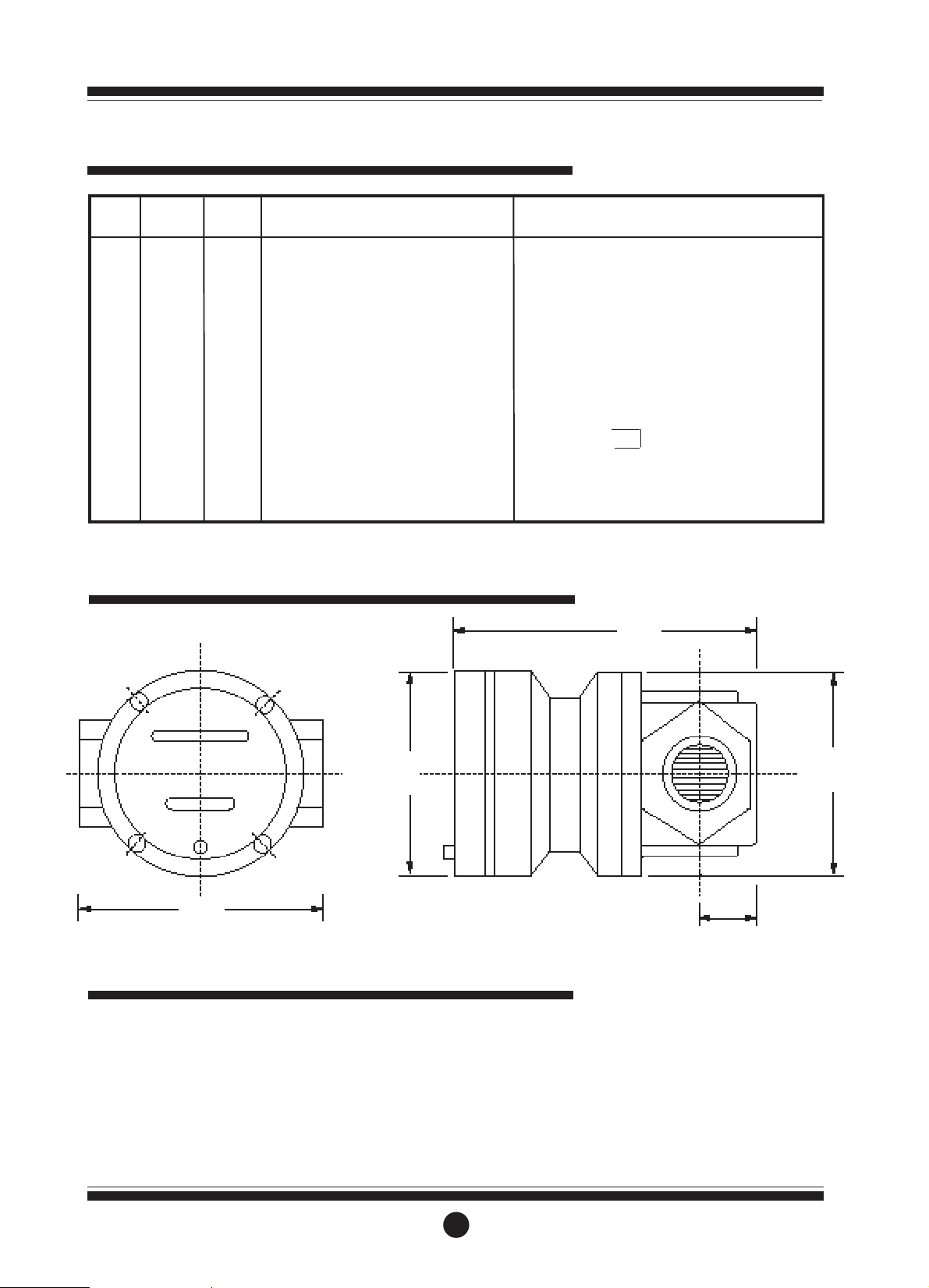

Display parts listing

1

2

3

4

5

Key:

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

1 1 MS600BS Meter Body Assy. (BSP) Stainless Steel

1 1 MS600NS Meter Body Assy. (NPT) Stainless Steel

1 1 MS605BS Meter Body Assy. (BSP) Aluminium

1 1 MS605NS Meter Body Assy. (NPT) Aluminium

21u MS3R-S Meter Cap Hall Effect Sensor Aluminium

21u MS3S-S Meter Cap Hall Effect Sensor Stainless Steel

21u MS3R-SR Meter Cap Reed Switch Aluminium

21u MS3S-SR Meter Cap Reed Switch Stainless Steel

34u MS98s Screws Aluminium

34

uu

MS113s Screws Stainless Steel

42

uu

MS601S Rotor Set Stainless Steel

51u BS127Vs O-ring (Viton)

51u BS127Ps O-ring (Perfluro Elastomer)

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Rec.

Parts

Meter specifications

Meter Type Stainless Steel Models Aluminium Models

Flow Ranges (Litres/hr or US Gall./hr)

Above 5 centipoise 0.5 to 50 / 0.132 to 13.2 0.5 to 50 / 0.132 to 13.2

Below 5 centipoise 2 to 50 / 0.528 to 13.2 2 to 50 / 0.528 to 13.2

Accuracy of Reading +/- 1% +/- 1%

Maximum Viscosity 1000 Centipoise 1000 Centipoise

Max. Operating Pressure 1000kPa/150PSI/10Bar 500kPa/75PSI/5Bar

Maximum Operating Temperature 120oC / 248oF80

o

C / 176oF

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Pulses per Litre/US Gallons 1547/5855.4 1547/5855.4

Meter Dimensions (Width x Height) 50x50mm / 1.97” x 1.97” 50x50mm / 1.97”x1.97”

Meter Dimensions Port Face to Face 67mm / 2.63” 60mm / 2.36”

Weight 602g / 21.23oz 308g / 10.86oz

Wetted Components 316 SS , Sapphire 6061 Alum., 316 SS, Sapphire

Page 4

Warranty

Trouble shooting

TROUBLE

Fluid will not flow through the meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

TROUBLE SHOOTING GUIDE

CAUSE

A] Foreign matter blocking rotors

B] Line strainer blocked

C] Damaged rotors

D] Meter connections over tightened

A] Line stariner partially blocked

B] Fluid is too viscous

A] Fluid flowrate is too low or too high

B] Air in fluid

C] Excess wear caused by incorrect installation

A] Faulty hall effect sensor or reed switch

B] Faulty magnet

C] Rotors installed in wrong position

REMEDY

A] Dismantle meter, clean rotors (Strainer must

be fitted in line.

B] Clean strainer

C] Replace rotors (Strainer must be fitted in

line)

D] Re-adjust connections

A] Clean strainer

B] Maximum viscosity 1000 centipoise

A] See specifications for min. and max.

flowrates

B] Bleed air from system

C] Check meter body and rotors

A] Replace meter cap

B] Replace rotors

C] Refer to correct rotor positioning - assembly

instructions.

Great Plains Industries, Inc. Limited Warranaty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby provides a limited one year

warranty against defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. This warranty

shall extend to the purchaser of this product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall be

limited to repairing defective workmanship or replacing or repairing any defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed

representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in

accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its address below no later than

30 days after the expiration of the warranty period. Such notice shall identify the defect in the product. The company shall, within

14 days of receipt of such notice, notify the customer to either send the product, transportation prepaid, to the company at its office

in Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations imposed on it by the terms of

this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL

AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE IF THE PRODUCT WARRANTED

HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for

which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Page 5

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter. Refer to

Industry fluid compatibility charts or

consult your local representative for

advice.

To prevent damage from dirt or foreign

matter it is recommended that a Y or

basket type 200 mesh strainer be

installed as close as possible to the inlet

side of the meter. Contact your local

representative for advice.

Note:

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Failure to do this could damage the

meter.

To reduce pressure build up turn off the

pump at the end of each day.

Positive displacement flowmeters

GM002 series instruction manual

To the owner

Operation

1

Please take a few minutes to read

through this manual before installing

and operating your meter. Always

retain this manual for future reference.

If you have any problems with the

meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM002

Series meters. For models with display,

an additional manual is supplied. If you

need further assistance, contact your

local representative or distributor for

advice.

This Flowmeter has incorporated the

oval rotor principal into its design. This

has proven to be a reliable and highly

accurate method of measuring flow.

Exceptional repeatability and high

accuracy over a wide range of fluid

viscosities and flow rates are features of

the oval rotor design. With low pressure

drop and high pressure rating means

oval rotor flow meters are suitable for

both gravity and pump (in-line)

applications.

GM002 Series Flowmeters are available

in either PPS (Polyphenylene Sulfide)

Aluminium or 316 Stainless Steel.

Standard rotors are made from 316

Stainless Steel. Optional PPS rotors

with Hastalloy C Shafts available on

PPS models only.

MS16G

0603

0005

Page 6

1. Use thread sealant on all pipe

threads.

2. Ensure the meter is installed so that

rotor shafts are always in a

horizontal plane. Flow is bi-

directional.

3. GPI recommends use of flexible

connections.

4. Extreme care must be taken when

installing the meter. Pipe strain or

overtightening meter connections

can cause meter damage.

2

Installation

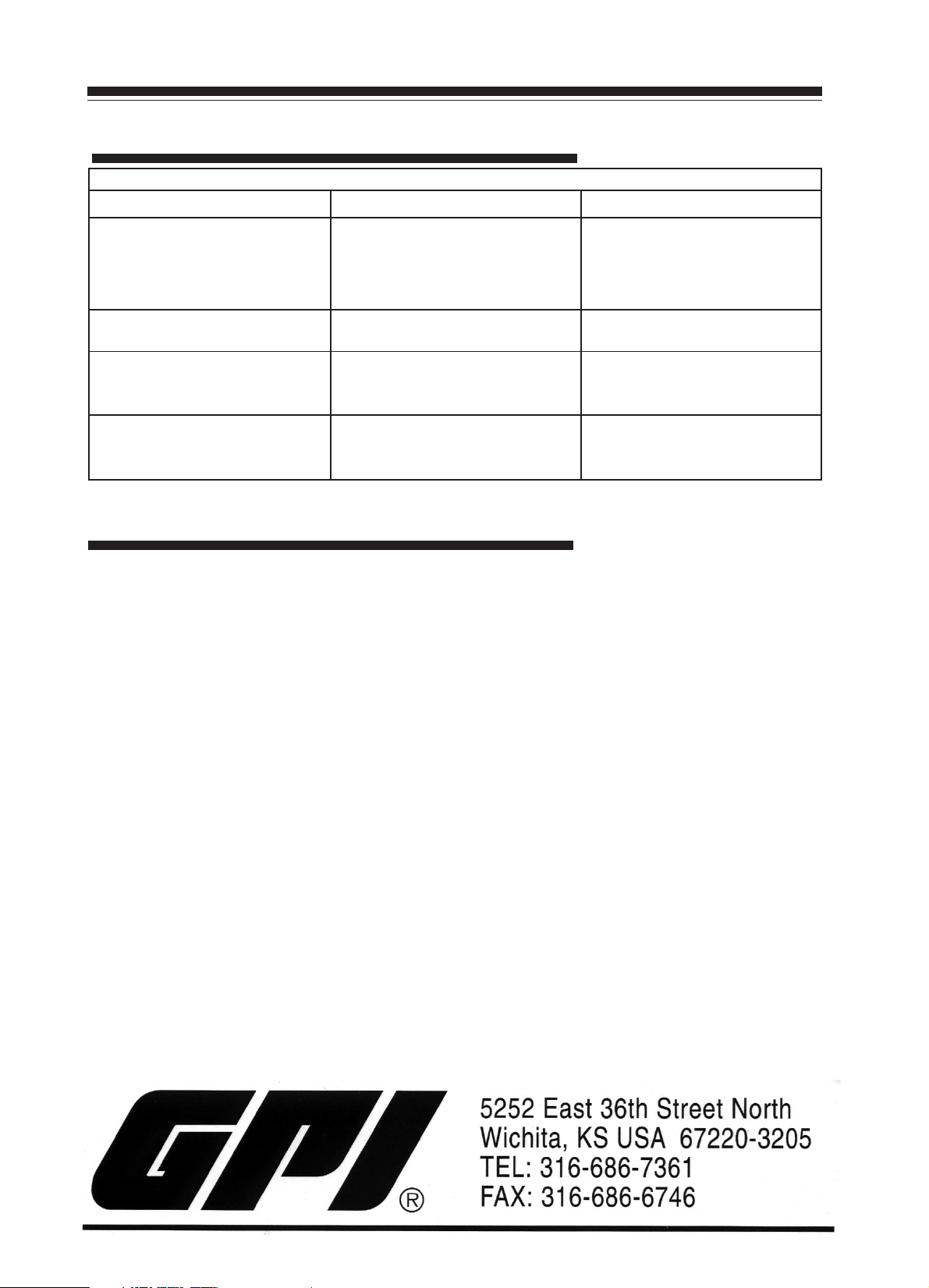

Hall Effect Sensor Specifications;

l 4.5V to 24V (4.6 ~ 9mA) operation

needs only an unregulated supply.

l Open collector 25mA output NPN

compatible with digital logic.

l Reverse battery protection.

l Temperature -40oC / -40oF ~

150oC / 300oF.

Reed Relay Specifications;

l Two wire SPST N/O.

l Switching voltage 150VDC

maximum current 0.25 AMPS.

l Rating 3 watts.

l Temperature -40oC / -40oF ~

150oC / 300oF.

Pulser details

Hall Effect Sensor Wiring Details

Red - Supply

Green - Ground

Blue - Output

Disassembly:

1. Ensure the fluid supply to the meter

has been disconnected, and the

line pressure has been released

before disassembly.

2. Remove four (4) screws (Item 3) and

remove the meter body cover (Item

2).

3. Remove o-ring (Item 5) and inspect

(replace o-ring if damaged).

4. Remove rotors (Item 4), clean and

inspect (replace rotors if damaged).

Reassembly:

1. Place rotors (Item 4) into the meter

body. The rotors should be at 90

o

to each other.

Note: The rotor with magnets must be

placed in the body on the same side as

the groove on the body (refer to

diagram).

2. Lightly rotate the rotors (Item 4) by

hand (they must rotate freely).

3. Install o-ring (Item 5).

4. Replace the meter cap (Item 2).

Note: The groove on the cover must

line up with the groove on the meter

body (refer to diagram).

5. Replace four screws (Item 3).

CAUTION:

Care must be taken not to overtighten

the screws (Item 3) or damage may

occur.

Maintenance

Page 7

3

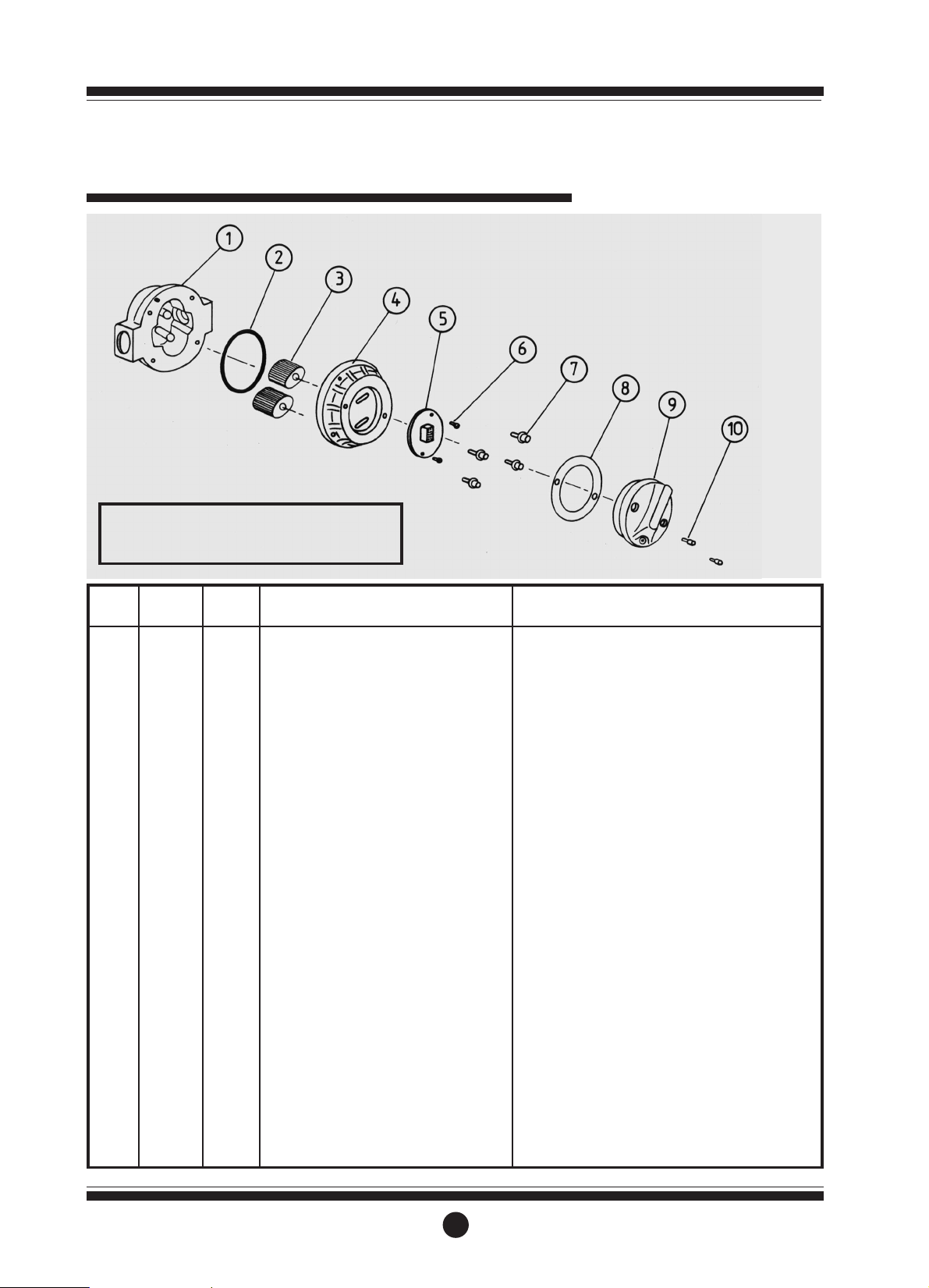

Display parts listing

1

2

3

4

5

1 1 MS1R-1S Meter Body Assy. (BSP)

1 1 MS1R-1C Meter Body Assy. (BSP) Hastalloy C Shafts

1 1 MS1S-1S Meter Body Assy. (BSP) Stainless Steel

1 1 MS1R-2S Meter Body Assy. (NPT)

1 1 MS1R-2C Meter Body Assy. (NPT) Hastalloy C Shafts

1 1 MS1S-2S Meter Body Assy. (NPT) Stainless Steel

1 1 MS1AL-1S Meter Body Assy. (BSP) Aluminium

1 1 MS1AL-2S Meter Body Assy. (NPT) Aluminium

21u MS3R-S Meter Cap Hall Effect Sensor

21u MS3S-S Meter Cap Hall Effect Sensor Stainless Steel

21u MS3R-SR Meter Cap Reed Switch

21u MS3S-SR Meter Cap Reed Switch Stainless Steel

34u MS98s Screws

34

uu

MS113s Screws Stainless Steel

42u MS6s Rotor Set

42

uu

MS6-1s Rotor Set Stainless Steel

51u BS127Vs O-ring (Viton)

51u BS127Ps O-ring (Perfluro Elastomer)

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Rec.

Parts

Key:

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

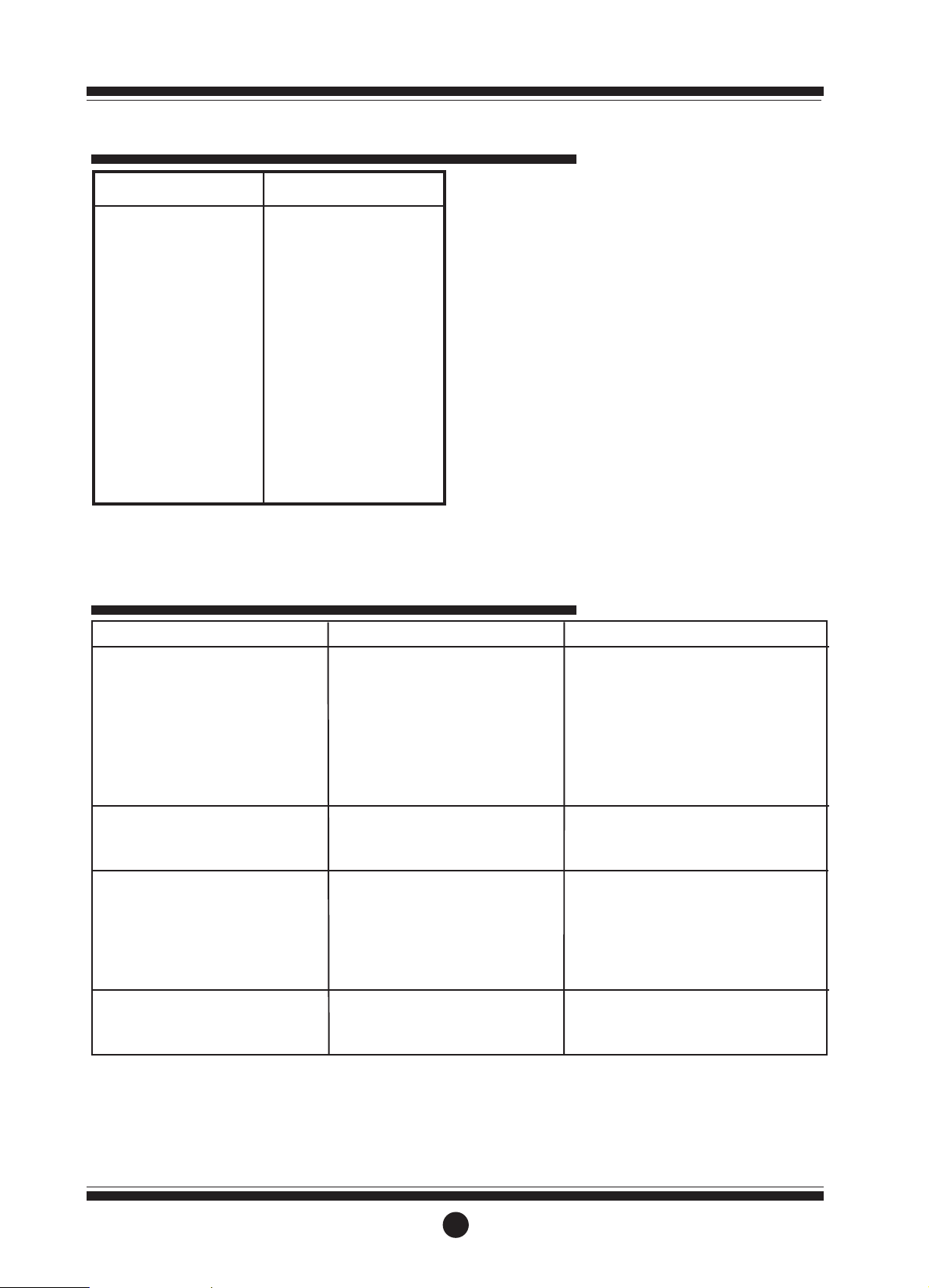

Meter specifications

Meter Type SS & Ryton Models Aluminium Models

Flow Ranges (Litres/hr or US Gall./hr)

Above 5 centipoise 2 to 100 / 0.53 to 26.4 2 to 100 / 0.53 to 26.4

Below 5 centipoise 5 to 100 / 1.32 to 26.4 3 to 100 / 0.8 to 26.4

Accuracy of Reading +/- 1% +/- 1%

Maximum Viscosity 1000 Centipoise 1000 Centipoise

Max. Operating Pressure Ryton Models 500kPa/75PSI/5Bar 500kPa/75PSI/5Bar

SS Models 1000/kPa/150PSI/10Bar 80oC / 176oF

Maximum Operating Temp. Ryton Models 80oC / 176oF

SS Models 120oC / 240oF

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Pulses per Litre/US Gallons 1000/3785 1000/3785

Meter Dimensions (Width x Height) 50x50mm / 1.97” x 1.97” 50x50mm / 1.97”x1.97”

Meter Dimensions Port Face to Face 65mm / 2.58” 60mm / 2.36”

Weight Ryton Models 240g / 8.5oz 310g / 11oz

SS Models 600g / 21.2oz

Wetted Components SS Models 316 SS, Zirconia Bush 6061 Alum., 316 SS, Ryton

Ryton Models Ryton, 316 SS, Zirconia Bush, Hastalloy C Zirconia Bush

Page 8

Warranty

Trouble shooting

TROUBLE

Fluid will not flow through the meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

TROUBLE SHOOTING GUIDE

CAUSE

A] Foreign matter blocking rotors

B] Line strainer blocked

C] Damaged rotors

D] Meter connections over tightened

A] Line stariner partially blocked

B] Fluid is too viscous

A] Fluid flowrate is too low or too high

B] Air in fluid

C] Excess wear caused by incorrect installation

A] Faulty hall effect sensor or reed switch

B] Faulty magnet

C] Rotors installed in wrong position

REMEDY

A] Dismantle meter, clean rotors (Strainer must

be fitted in line.

B] Clean strainer

C] Replace rotors (Strainer must be fitted in

line)

D] Re-adjust connections

A] Clean strainer

B] Maximum viscosity 1000 centipoise

A] See specifications for min. and max.

flowrates

B] Bleed air from system

C] Check meter body and rotors

A] Replace meter cap

B] Replace rotors

C] Refer to correct rotor positioning - assembly

instructions.

Great Plains Industries, Inc. Limited Warranaty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby provides a limited one year

warranty against defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. This warranty

shall extend to the purchaser of this product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall be

limited to repairing defective workmanship or replacing or repairing any defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed

representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in

accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its address below no later than

30 days after the expiration of the warranty period. Such notice shall identify the defect in the product. The company shall, within

14 days of receipt of such notice, notify the customer to either send the product, transportation prepaid, to the company at its office

in Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations imposed on it by the terms of

this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL

AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE IF THE PRODUCT WARRANTED

HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for

which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Page 9

MS17G

0603

0008

Positive displacement flowmeters

GM003 series instruction manual

To the owner

Operation

1

Please take a few minutes to read

through this manual before installing

and operating your meter. Always

retain this manual for future reference.

If you have any problems with the

meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM003

meters. For models with displays, an

additional manual is supplied. If you

need further assistance, contact your

local representative or distributor for

advice.

This Flowmeter has incorporated the

oval rotor principal into its design. This

has proven to be a reliable and highly

accurate method of measuring flow.

Exceptional repeatability and high

accuracy over a wide range of fluid

viscosities and flow rates are features of

the oval rotor design. With low pressure

drop and high pressure rating means

oval rotor flow meters are suitable for

both gravity and pump (in-line)

applications.

The GPI GM003 Series Flowmeters are

available in either PPS (Polyphenylene

Sulfide Resins),

Aluminium or 316 Stainless Steel.

Standard rotors are made from 316

Stainless Steel. Optional PPS rotors

with Hastalloy C Shafts available on

PPS models only.

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter. Refer to

Industry fluid compatibility charts or

consult your local representative for

advice.

To prevent damage from dirt or foreign

matter it is recommended that a Y or

basket type 200 mesh strainer be

installed as close as possible to the inlet

side of the meter. Contact your local

representative for advice.

Note:

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Failure to do this could damage the

meter.

To reduce pressure build up turn off the

pump at the end of each day.

Page 10

1. Use thread sealant on all pipe

threads.

2. Ensure the meter is installed so that

rotor shafts are always in a

horizontal plane. Flow is bi-

directional.

3. GPI recommends use of flexible

connections.

4. Extreme care must be taken when

installing the meter. Pipe strain or

overtightening meter connections

can cause meter damage.

2

Installation

Hall Effect Sensor Specifications;

l 4.5V to 24V (4.6 ~ 9mA)

operation needs only an

unregulated supply.

l Open collector 25mA output

NPN (Current Sink) compatible

with digital logic.

l Reverse battery protection.

l Temperature -40oC / -40oF ~

150oC / 300oF.

Reed Relay Specifications;

l Two wire SPST N/O.

l Switching voltage 150VDC

maximum current 0.25 AMPS.

l Rating 3 watts.

l Temperature -40oC / -40oF ~

150oC / 300oF.

l Duty Cycle 20% on 80% off.

Pulser details

Hall Effect Sensor Wiring Details

Red - Supply

Green - Ground

Blue - Output

Disassembly:

1. Ensure the fluid supply to the meter

has been disconnected, and the

line pressure has been released

before disassembly.

2. Remove four (4) screws (Item 3) and

remove the meter body cover (Item

2).

3. Remove o-ring (Item 5) and inspect

(replace o-ring if damaged).

4. Remove rotors (Item 4), clean and

inspect (replace rotors if damaged).

Reassembly:

1. Place rotors (Item 4) into the meter

body. The rotors should be at 90o

to each other.

Note: The rotor with magnets must be

placed in the body on the same side as

the groove on the body (refer to

diagram).

2. Lightly rotate the rotors (Item 4) by

hand (they must rotate freely).

3. Install o-ring (Item 5).

4. Replace the meter cap (Item 2).

Note: The groove on the cover must

line up with the groove on the meter

body (refer to diagram).

5. Replace four screws (Item 3).

CAUTION:

Care must be taken not to overtighten

the screws (Item 3) or damage may

occur.

Maintenance

1

2

Reed Switch Wiring Details

Page 11

1 1 MS2R-1S Meter Body Assy. (BSP)

1 1 MS2R-1C Meter Body Assy. (BSP) Hastalloy C Shafts

1 1 MS2S-1S Meter Body Assy. (BSP) Stainless Steel

1 1 MS2R-2S Meter Body Assy. (NPT)

1 1 MS2R-2C Meter Body Assy. (NPT) Hastalloy C Shafts

1 1 MS2S-2S Meter Body Assy. (NPT) Stainless Steel

1 1 MS2AL-1S Meter Body Assy. (BSP) Aluminium

1 1 MS2AL-2S Meter Body Assy. (NPT) Aluminium

21u MS3R-S Meter Cap Hall Effect Sensor

21u MS3S-S Meter Cap Hall Effect Sensor Stainless Steel

21u MS3R-SR Meter Cap Reed Switch (Ryton & Alumin. Models)

21u MS3S-SR Meter Cap Reed Switch Stainless Steel

34u MS98s Screws (Ryton & Alumin. Models)

34

uu

MS113s Screws Stainless Steel

4 2 u MS7-1Es Rotor SS Hall (Set)

4 2 u MS7-1HEs Rotor SS High Viscosity Hall (Set)

42

uu

MS7-1Rs Rotor SS Reed (Set)

42

uu

MS7-1HRs Rotor SS Reed High Viscosity (Set)

42u MS7Rs Rotor PPS Reed (Set)

42u MS7Es Rotor PPS Hall (Set)

51u BS127Vs O-ring (Viton)

51u BS127Ps O-ring (Perfluro Elastomer)

3

Display parts listing

1

2

3

4

5

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part DescriptionRec.

Parts

Key:

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

Meter specifications

Meter Type SS & Ryton Models Aluminium Models

Flow Ranges (Litres/hr or US Gall./hr)

Above 5 centipoise 15 to 500 / 4 to 132 15 to 500 / 4 to 132

Below 5 centipoise 25 to 500 / 6 to 132 25 to 500 / 6 to 132

Accuracy of Reading +/- 1% +/- 1%

Maximum Viscosity 1000 Centipoise 1000 Centipoise

Max. Operating Pressure Ryton Models 500kPa/75PSI/5Bar 500kPa/75PSI/5Bar

SS Models 1000/kPa/150PSI/10Bar

Max. Operating Temp. Ryton Models 80oC / 176oF80

o

C / 176oF

SS Models 120oC / 248oF

Pulse Type Hall Effect Sensor/Reed Switch Hall Effect Sensor/Reed Switch

Pulses per Litre/US Gallons 400/1514 400/1514

Meter Dimensions (Width x Height) 50x50mm / 1.97” x 1.97” 50x50mm / 1.97”x1.97”

Meter Dimensions Port Face to Face 65mm / 2.58” 60mm / 2.36”

Weight SS 600g / 21.2oz Ryton 240g / 8.5oz 320g / 12oz

Wetted Components SS Models 316 SS, Zirconia Bush 6061 Alum., 316 SS, Ryton

Ryton Models Ryton, 316 SS, Zirconia Bush, Hastalloy C Zirconia Bush

Page 12

Warranty

Trouble shooting

TROUBLE

Fluid will not flow through the meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

TROUBLE SHOOTING GUIDE

CAUSE

A] Foreign matter blocking rotors

B] Line strainer blocked

C] Damaged rotors

D] Meter connections over tightened

A] Line stariner partially blocked

B] Fluid is too viscous

A] Fluid flowrate is too low or too high

B] Air in fluid

C] Excess wear caused by incorrect installation

A] Faulty hall effect sensor or reed switch

B] Faulty magnet

C] Rotors installed in wrong position

REMEDY

A] Dismantle meter, clean rotors (Strainer must

be fitted in line.

B] Clean strainer

C] Replace rotors (Strainer must be fitted in

line)

D] Re-adjust connections

A] Clean strainer

B] Maximum viscosity 1000 centipoise

A] See specifications for min. and max.

flowrates

B] Bleed air from system

C] Check meter body and rotors

A] Replace meter cap

B] Replace rotors

C] Refer to correct rotor positioning - assembly

instructions.

Great Plains Industries, Inc. Limited Warranaty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby provides a limited one year

warranty against defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. This warranty

shall extend to the purchaser of this product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall be

limited to repairing defective workmanship or replacing or repairing any defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed

representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in

accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its address below no later than

30 days after the expiration of the warranty period. Such notice shall identify the defect in the product. The company shall, within

14 days of receipt of such notice, notify the customer to either send the product, transportation prepaid, to the company at its office

in Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations imposed on it by the terms of

this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL

AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE IF THE PRODUCT WARRANTED

HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for

which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Page 13

MS345G

0603

0005

Positive Displacement Flowmeters

GM005 series instruction manual

GM005 Pulse Meter From serial No. CXXXX

Page 14

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter. Refer to

industry fluid compatibility charts or

consult your local representative for

advice.

To prevent damage from dirt or foreign

matter it is recommended that a Y or

Basket type 60 mesh strainer be

installed as close as possible to the

inlet side of the meter. Contact your

local representative for advice.

Note: When a strainer is installed it

should be regularly inspected and

cleaned. Failure to keep the strainer

clean will dramatically effect flow

meter performance.

Note: To prevent damage caused by air

purge slowly fill the meter with fluid.

To reduce pressure build up turn off the

pump at the end of each day.

Maintenance can be carried out to the

liquid crystal displays and pulse units

without removing or isolating the meter

from the line. When maintenance to

any other part of the meter is required,

the meter must be isolated and the line

pressure reduced.

The reed switch pulse unit can cause

inaccurate rate counts when used with

high speed counters. It is advised that a

debounce circuit be used. Contact your

meter distributor for further

information.

When fluid passes through the meter

the rotors turn, as shown below. The

magnets which are located in the rotors

will pass across the pulser circuit board

(containing either Reed switches or

Hall Effect sensors). A signal is

generated which is then sent by the

Pulse Circuit Board (PCB) to the

relevant LC display or receiving

instrument.

Operating Principle

Please take a few minutes to read

through this manual before installing

and operating your meter. Always

retain this manual for future reference.

If you have any problems with the

meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM005

Series meters with Pulse outputs. For

models with an Liquid Crystal Display

an additional instruction manual is

supplied. If you need further assistance,

contact your local representative or

distributor for advice.

This Flow Meter has incorporated the

oval rotor principal into its design. This

has proven to be a reliable and highly

accurate method of measuring flow.

Exceptional repeatability and high

accuracy over a wide range of fluid

viscosities and flow rates are features of

the oval rotor design. With low

pressure drop and high pressure rating

oval rotor flow meters are suitable for

both gravity and pump (in line)

applications.

Flow meters are available in either

Aluminium or 316 Stainless Steel.

Standard rotors are made from PPS

(Polyphenylene Sulfide Resins) with

optional 316 Stainless Steel rotors

available for both Stainless steel and

Aluminium models.

GM005 Series Meters are available

with either;

* Pulse output

* Standard LC Display and Pulse

1

To the owner

Important Information

Page 15

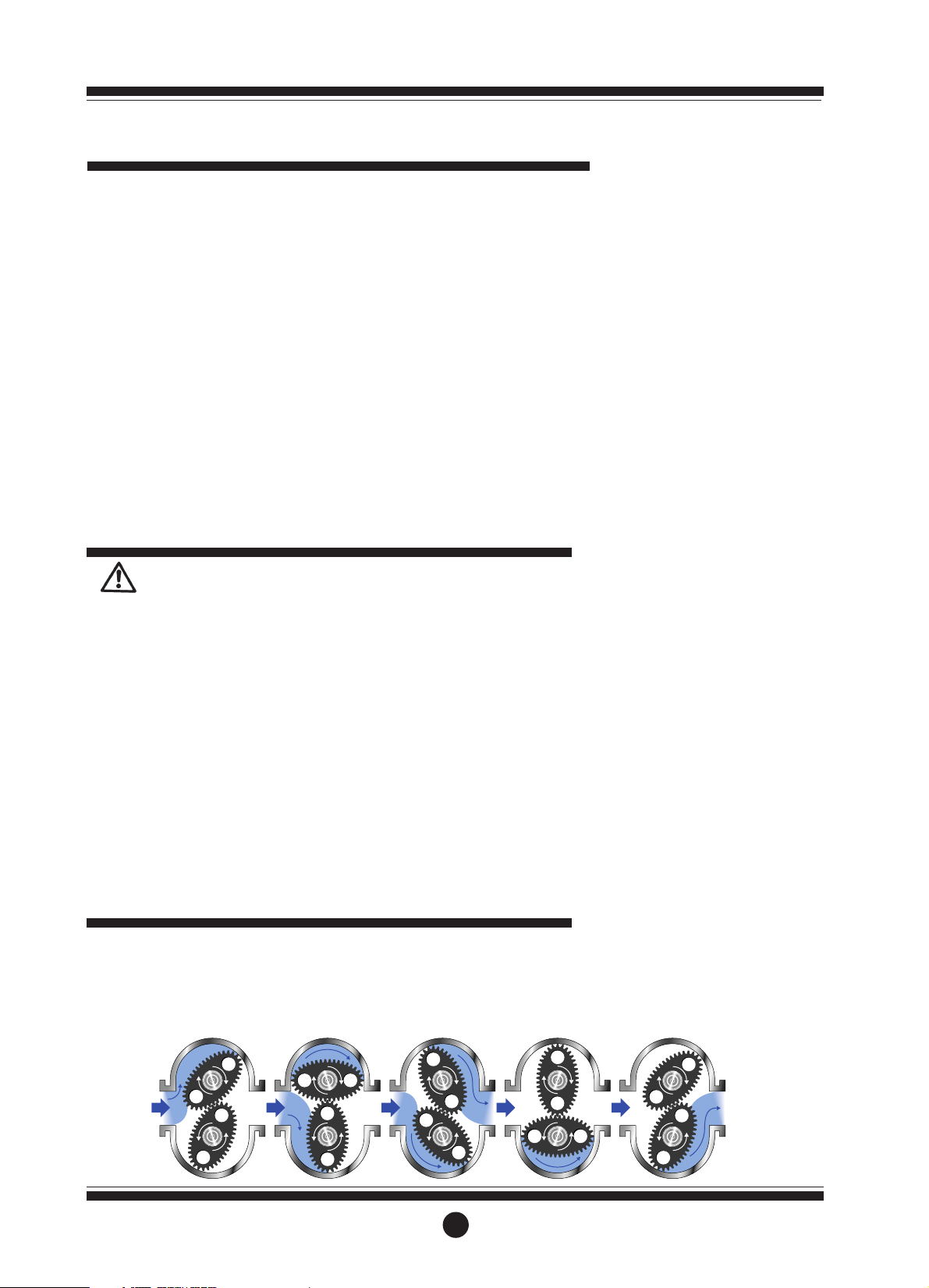

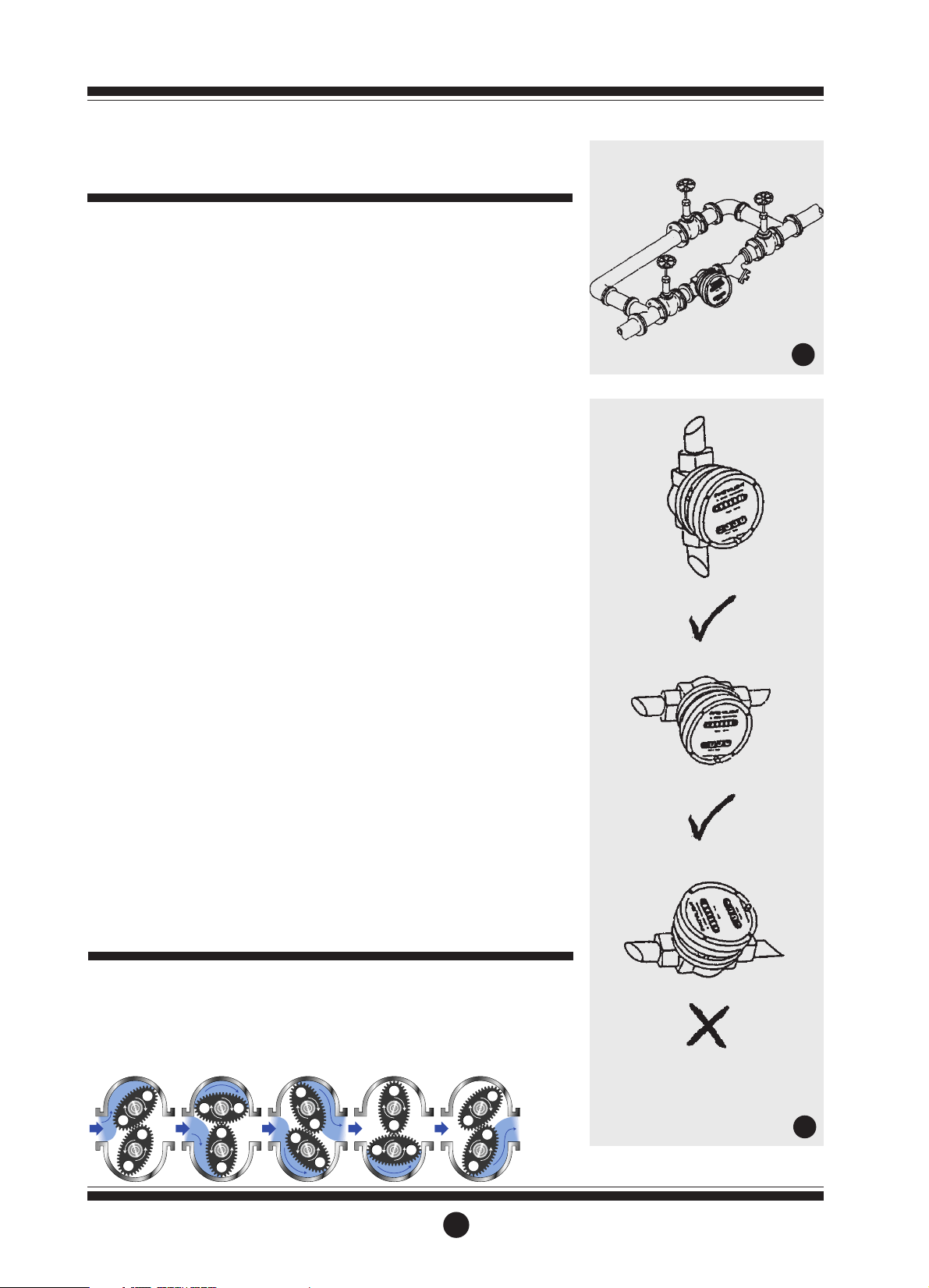

1] it is recommended that when setting

up pipework for meter installations a

bypass line be included in the design.

This provides the facility for a meter

to be removed for maintenace

without interrupting production. (See

Fig.1)

2] Use thread sealant on all pipe

threads.

3] For pump applications ensure pipe

work has the appropriate working

pressure rating to match the pressure

output of the pump. See Meter

Specifications section for further

details.

4] Install a wire mesh strainer (Y or

basket type 60 mesh as close as

possible to the inlet side of the meter.

5] Ensure that the meter is installed so

that the flow of the liquid is in the

direction of the arrows embossed on

the meter body.

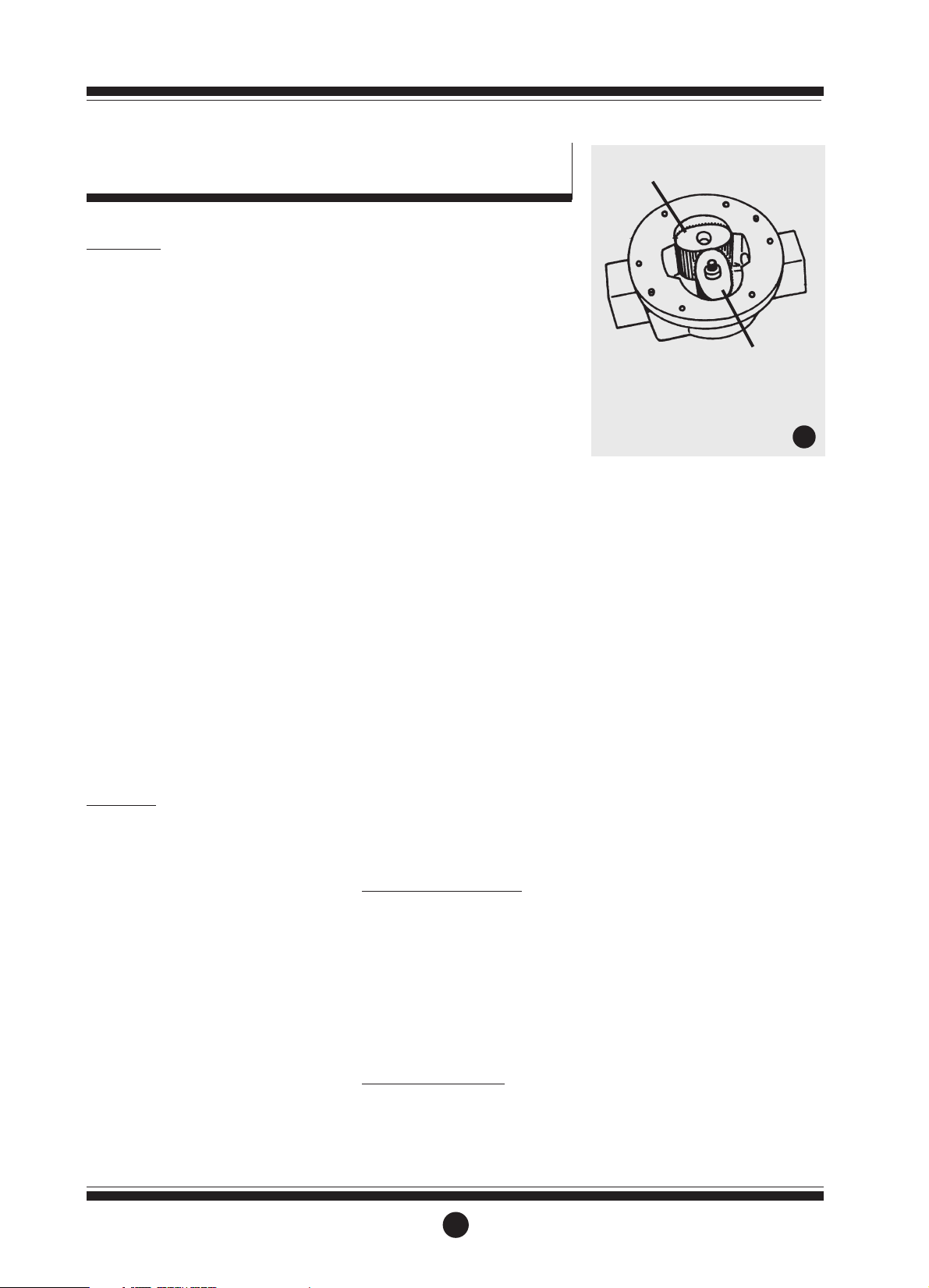

6] The meter can be installed in any

orientation as long as the meter shafts

are in a horizontal plane. (Refer to

Fig.2 for correct installation) The

register assembly may be orientated

to suit the individual installation.

Note: Incorrect installation can cause

premature wear of meter components.

7] Do not over tighten meter

connections.

8] It is important that after initial

installation you fill the line slowly,

high speed air purge could cause

damage to the rotors.

9] Test the system for leaks.

10] Check the strainer for swarf or

foreign material, after the first 200

litres check periodically,

particularly if the flow rate

decreases.

2

Installation

1

2

Bypass Line

Flow Outlet

Flow Inlet

Strainer

Do Not Install Meter This Way

Electrical Connections

Contact rating 15VA

Maximum Voltage 150VDC

Note: Double rate pulse output not available

3

4

Reed/Hall combination

1 - Reed Switch

2 - Reed Switch

3 - HE Common 4 - HE Signal

5 - HE Supply +

Hall/Hall Combination

1 - HE1 Supply +

2 - HE1 Signal

3 - HE Common 4 - HE2 Signal

5 - HE Ground

Hall Effect Voltage 4.5 to 24 VDC

Current Draw Minimum 4.6mA

Output NPN Open Collector 25mA

Reed Switch Connections

Hall Effect or Reed/Hall Sensor Connections

Page 16

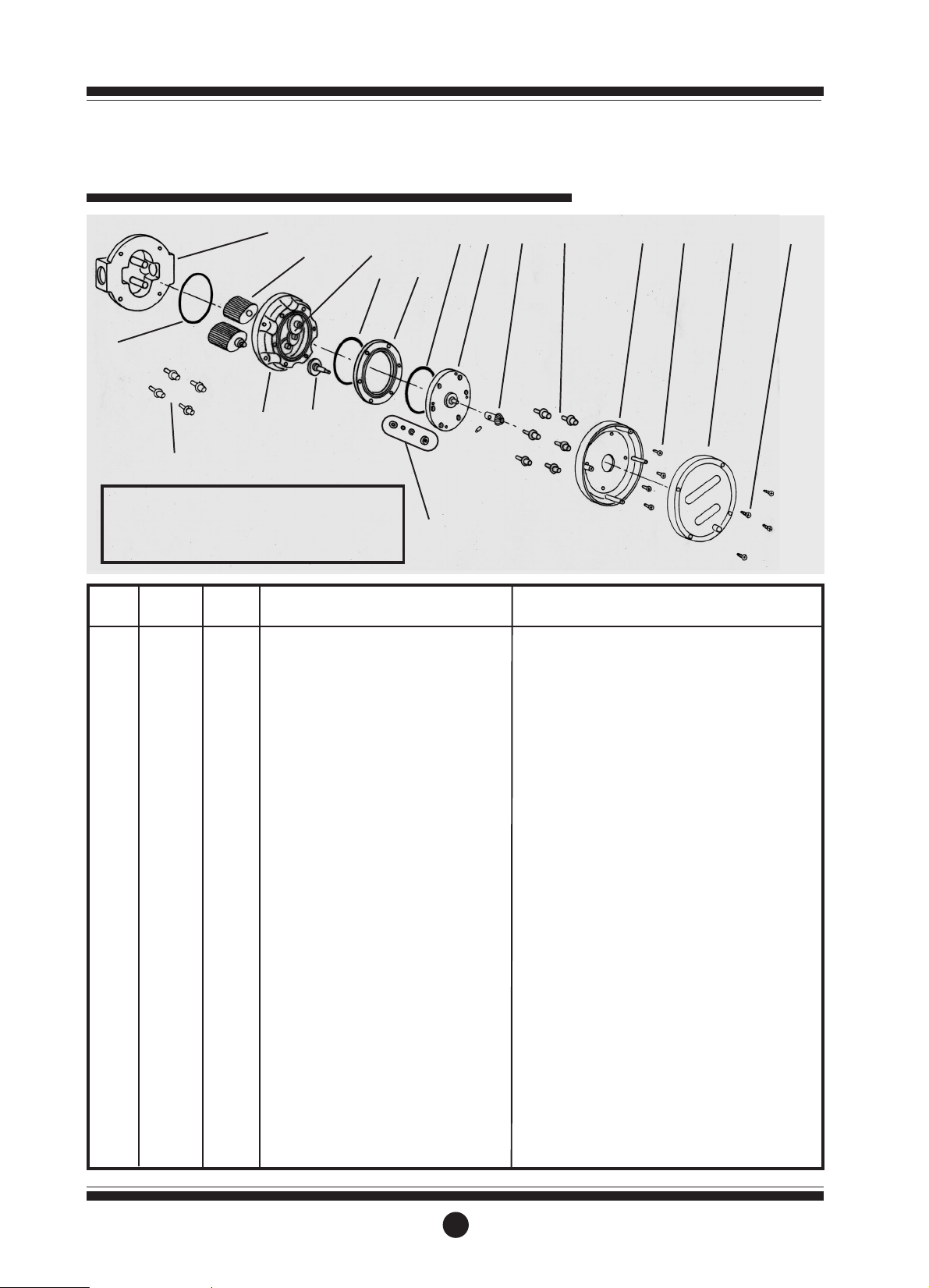

Disassembly

Ensure that the fluid supply to the

meter is disconnected, and the line

pressure is released before

disassembly, with the exception for

repair or maintenance to the LC

Display or PCB where there is no

necessity to isolate the meter from flow.

Refer to the exploded parts diagram on

subsequent pages for item numbers.

1a] Pulse Caps models: Undo the

conduit connector, remove pulse

cap (item 9) and remove the wires

from the pulse terminal board (item 5).

1b] Standard LC Display: Mark the

display orientation with a marking

pen, unscrew the four large screws

(Item 26) on top of the LC Display.

Carefully separate the LC Display

from the plastic housing and

disconnect the wires from the

pulse terminal block. (Refer to

additional Standard LC Display

instruction manual).

2] Remove the mounting adaptor plate

and gasket (Item 14).

3] Loosen the cap head screws (Item 7)

that hold down the meter cap (Item

4), remove the screws, washers and

lift off the cap.

4] Remove the o’ring (Item 2) from the o’ring

groove in the meter cap (Item 4).

5] Remove rotors (Item 3).

Reassembly

1] Before reassembling check the

condition of the rotors (replace if

necessary).

2] Check that the smooth side of the

rotors (not the plug side) is facing

you when inserting the rotors, the

smooth side of the rotor is the

magnet side. There is no difference

between rotor one or rotor two.

3] Replace the rotors (Item 3) onto the

shafts at 90oto each other (refer Fig.

5) and check their operation by

turning either of the rotors. If the

rotors are not in mesh correctly or

do not move freely, remove one of

the rotors and replace correctly at

90oto the other rotor. Re-check the

operation of the rotors.

4] Replace the o’ring (Item 2) into

groove in the meter cap, if the o’ring

has grown or is damaged in any way

replace it with a new part.

5] Replace the meter cap making sure

that the locating pin in the body

lines up with the hole in the meter

cap. Insert the cap head screws

(Item 7) and tighten in a diagonal

sequence 1, 3, 2, 4, etc.

6] The replacement of cables and

connectors are a reversal of the

disassembly procedure, replace

conduit fitting if required. When

replaceing the Standard LC Display,

confirm the orientation marks made

on disassembly are aligned then

screw the register into place.

7] Test the meter by turning the rotors

with a finger or by applying very low

air pressure (no more than a good

breath) to one end of the meter,

before returning the meter to the line.

Pulse Circuit Board (PCB) Notes:

The pulse PCB (Item 5) is fitted with (A)

two reed switches; (B) hall effect

sensors; or (C) one reed switch and one

hall effect sensor. The PCB board is

fastened to the meter cap (Item 4) by

two screws and stand off’s. All care and

caution should be taken when

removing or handling the PCB as both

the reed switch and hall effect sensor

are fragile.

Reed switch or hall effect sensors are

not available as individual replacement

parts and are only available with the

complete PCB (Item 5).

3

Service Instructions

5

Rotors must be at 90oto each other.

Rotor #2

Rotor #1

Page 17

4

Meter Parts Listing

1 1 MS298B Meter Body 1/2” BSP (Aluminium)

1 1 MS298N Meter Body 1/2” NPT (Aluminium)

1 1 MS337B Meter Body 1/2” BSP (Stainless Steel)

1 1 MS337N Meter Body 1/2” NPT (Stainless Steel)

21u BS145S “O” Ring (NBR)

21u BS145TES “O” Ring (Teflon)

21u BS145VS “O” Ring (Viton)

32u MS342S Rotors PPS (Polyphenylene Sulfide Resins)

32

uu

MS342-1S Rotors (Stainless Steel)

32u MS342HS High Viscosity Rotors (PPS)

32u MS342-1HS High Viscosity Rotors (Stainless Steel)

4 1 MS297 Meter Cap (Aluminium)

4 1 MS338 Meter Cap (Stainless Steel)

51u MS344-RS PCB (Standard Reed Switch)

51u MS344-HES PCB (Hall Effect Sensor)

5 1 MS344-R/HES PCB ( 1 Reed Switch & 1 Hall Effect Sensor)

6 2 MS284S PCB Board Screws

74u MS346S Meter Cap Screws (Standard)

74u MS350S Meter Cap Screws (Stainless Steel)

81u MS340S Pulser Cap Gasket

9 1 MS296 Pulser Cap (Aluminium) 20mm Conduit Thread

9 1 MS296N Pulser Cap (Aluminum) 1/2” NPT Thread

9 1 MS339 Pulser Cap (Stainless Steel) 20mm Conduit Thread

9 1 MS339N Pulser Cap (Stainless Steel) 1/2” NPT Thread

10 2 MS347S Pulser Cap Screw (Stainless Steel)

11 1 MS37 Warning Label (Not Shown)

13 1 Customer to Specify Legend Plate (Not Shown) inc. Hammer Screws

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Key:

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

Rec.

Parts

Page 18

Pulse

1 to 30/ 0.26 to 8

3 to 25/ 0.8 to 6.60

+/- 0.5%

1000 Centipoise

5500kPa/ 800 PSI/ 55 BAR

80°C/ 176°F

(S.S. Models 120°C/ 248°F)

Dual Reed Switches or Hall

Effect Sensor or combination

HE Sensor/Reed Switch**

112 / 224

* Unless High Viscosity Rotors are fitted.

5

Meter Specifications

Meter Type

Flow Ranges

Litres/minute - US Gall/min

Above 5 Centipoise

Below 5 Centipoise

Accuracy of Reading

Maximum Viscosity*

Max. Operating Pressure

Max. Operating Temp.

Pulse Type

Pulses Per Litre/US Gallon

Meter Trouble Shooting

TROUBLE

Fluid will not flow through meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

CAUSE

a] Foreign matter blocking rotors

b] Line strainer blocked

c] Damaged rotors

d] Meter connections over tightened

e] Fluid is too viscous

a] Strainer is partially blocked

b] Fluid is too viscous

a] Fluid flow rate is too high or too low

b] Fluid is too viscous

c] Excess wear caused by incorrect

installation

a] Faulty hall effect sensor

b] Faulty reed switch

c] Magnets failed

REMEDY

a] Dismantle meter, clean rotors

(Strainer must be fitted in line)

b] Clean strainer

c] Replace rotors (Strainer must be

fitted in line)

d] Re-adjust connections

e] See specifications for maximum

viscosity

a] Clean strainer

b] See specifications for maximum

viscosity

a] See specifications for minimum and

maximum flow rates

b] Bleed air from system

c] Check meter body and rotors.

Replace as required. Refer to

installation instructions

a] Replace PCB Board

b] Replace PCB Board

c] Replace magnets

Page 19

Warranty

Meter Dimensions

96mm

70mm

100mm

105mm

18mm

20mm

Pulse Meter Dimensions

Great Plains Industries, Inc. Limited Warranty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby provides a limited one year warranty against defects in material and

workmanship on all products manufactured by Great Plains Industries, Inc. This warranty shall extend to the purchaser of this product and to any person to whom such

product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall be limited to repairing defective workmanship or

replacing or repairing any defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in accordance with the manufacturer’s operating

instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its address below no later than 30 days after the expiration of the warranty

period. Such notice shall identify the defect in the product. The company shall, within 14 days of receipt of such notice, notify the customer to either send the product,

transportation prepaid, to the company at its office in Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations imposed on it by the

terms of this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES

INCURRED IN THE USE OR LOSS OF USE IF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Page 20

MS489G

0703

0004

Positive Displacement Flowmeters

GM505 series instruction manual

GM505 Mechanical meter • From serial No. CXXXX

Page 21

Thank you for purchasing a GPI GM

Series Flow Meter. Please take a few

minutes to read thorugh this manual

before installing and operating your

meter. If you have any problems with

the meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM505

Series meters with mechanical

displays. If you need further assistance,

contact your local GPI representative

or contact GPI by telephone or fax for

advice.

The GPI GM Series Flow Meter has

incorporated the oval rotor principal

into its design. This has proven to be a

reliable and highly accurate method of

measuring flow. Exceptional

repeatability and high accuracy over a

wide range of fluid viscosities and flow

rates are features of the GM Series flow

meter design. The low pressure drop

and high pressure rating means the GM

Series flow meter is suitable forboth

gravity and pump (in line) applications.

The GPI GM Series flow meters are

available in either aluminium or 316

stainless steel. Standard rotors are

made from PPS.

The GM505 Series mechanical

displays have a resettable batch

totaliser and non-resettable

accumulative totaliser.

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter (refer to

the GPI fluid compatibility chart), or

consult your local GPI representative

for advice.

To prevent damage from dirt or foreign

matter, GPI recommends a Y or Basket

type 60 mesh strainer be installed as

close as possible to the inlet side of the

meter (if required contact GPI for

further information).

Note: When a strainer is installed it

should be regularly inspected and

cleaned. Failure to keep the strainer

clean will dramatically effect flow

meter performance.

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Note: Failure to do this could damage

the meter.

For pump applications, turn off the

pump at the end of each day.

1

To the owner

Important Information

Page 22

1] GPI recommends that when setting

up pipework for meter installations a

bypass line be included in the

design. This provides the facility for

a meter to be removed for

maintenace without interrupting

production. (See Fig.1)

2] Use thread sealant on all pipe

threads.

3] For pump applications ensure pipe

work has the appropriate working

pressure rating to match the pressure

output of the pump.

4] Install a wire mesh strainer (Y or

basket type 60 mesh as close as

possible to the inlet side of the meter.

5] Ensure that the meter is installed so

that the flow of the liquid is in the

direction of the arrows embossed on

the meter body.

6] The meter can be installed in any

orientation as long as the meter

shafts are in a horizontal plane.

(Refer to Fig.2 for correct

installation) The register assembly

may be orientated to suit the

individual installation.

Note: Incorrect installation can cause

premature wear of meter components.

7] Do not over tighten meter connections.

8] It is important that after initial

installation you fill the line slowly,

high speed air purge could cause

damage to the rotors.

9] Test the system for leaks.

10] Check the strainer for swarf or

foreign material, after the first 200

litres check periodically,

particularly if the flow rate

decreases.

2

Installation

When fluid passes through the meter,

rotors turn. The gear located on top of

one of the rotors drives the mechanical

registers gear train which provides an

accurate readout.

Operation

1

2

Bypass Line

Flow Outlet

Flow Inlet

Strainer

Do Not Install Meter This Way

Page 23

Disassembly

Ensure that the fluid supply to the meter

is disconnected, and the line pressure

is released before disassembly. Refer to

the exploded parts diagram on page 5

for item numbers.

1] Remove the four screws (Item 17)

located on the face of the register.

Then remove the face plate cover

including register assembly.

2] Remove the four register mounting

screws (Item 15). Then remove the

lower half of the register housing.

3] Remove the six cover plate screws

(Item 12) and remove the cover

plate (Item 11).

4] Remove the four meter cap screws (Item

5) and remove the meter cap (Item 4).

5] Remove rotors (Item 3).

Reassembly

1] Clean all components before

reassembly.

2] Before reassembly check the

condition of the rotors (Item 3).

Replace if necessary.

3] Replace the rotor (with the gear) on

the short shaft in the housing then

place the 2nd rotor onto the shaft

so as the rotors are at 90° to each

other. (Refer Fig 3). Check rotor

operation by turning either of the

rotors. If the rotors are not in mesh

correctly or do not move freely

remove one of the rotors and

replace it correctly at 90° to the

other rotor. Recheck the operation

of the rotors.

4] Inspect the gears (Item 6) in the

meter cap (Item 4) for wear.

(Replace if required, refer to spare

parts on page 5 & 6).

5] Replace the o-ring (Item 2) into the

groove in the meter cap, if the o-

ring has been distorted or is

damaged in any way replace it with

a new part.

6] Replace the meter cap, making sure

the meter cap and the gear on the

rotor meshes correctly with the gear

in the meter cap (Item 4). Insert the

allen screws (Item 5) and tighten in

the sequence 1, 4, 2, & 3.

7] Inspect the bevel gear (Item 13), o-

ring (Item 10), and output gear (Item

7) for wear or damage. (Replace

faulty components if necessary).

8] Replacement of output shaft, bush

and seal.

Disassembly of output shaft

a.Remove the bevel gear.

b.Remove the circlip and push out

the output shaft assembly, including

washer.

c.Remove the seal.

d.Carefully press out the output shaft

bush (If required).

Assembly of output shaft

a.Carefully press the new output

shaft bush into place (Use Loctite

Primer 7471, as per instructions,

followed by sealant Loctite 262).

b.Insert a new seal into the groove of

the output shaft bush.

c.Replace the output gear and

washer and replace the circlip to

lock the output gear shaft into place.

d.Replace the bevel gear (Item 13)

and tighten the grub screw onto flat

face of shaft.

9] Place the o-ring (Item 10) into the

groove in the meter cap (Replace the

o-ring seal if required).

10] Place the cover plate onto the meter.

Replace the cover plate screws and

tighten the six cap head screws (Item

12) firmly.

11] Place the lower cover plate of the

register into position. Replace the

four screws (Item 15) and tighten.

12] Position the register correctly on top

of the lower register cover. Replace

the four screws (Item 17) and

tighten.

13] Test the meter by turning the rotors

with a finger or by applying low air

pressure (No more than a good

breath) to one end of the meter,

before returning meter to the line.

3

Service Instructions

5

Rotors must be at 90oto each other.

Rotor #2

Rotor #1

Page 24

4

Meter Trouble Shooting

TROUBLE SHOOTING GUIDE

TROUBLE

Fluid will not flow through meter

Reduced flow through the meter

Meter reading inaccurate

Fluid flows but no reading on meter

Fluid leaks into register

CAUSE

a] Foreign matter blocking rotors

b] Line strainer blocked

c] Damaged rotors

d] Meter connections over tightened

e] Fluid is too viscous

a] Strainer is partially blocked

b] Fluid is too viscous

a] Fluid flow rate is too high or too low

b] Fluid is too viscous

c] Excess wear caused by incorrect

installation

a] Bevel gear is loose on shaft

b] Rotor drive gear is damaged

c] Transmission gears damaged

d] Register gears damaged

a] Seal worn or damaged on the cover

plate

REMEDY

a] Dismantle meter, clean rotors

(Strainer must be fitted in line)

b] Clean strainer

c] Replace rotors (Strainer must be

fitted in line)

d] Re-adjust connections

e] See specifications for maximum

viscosity

a] Clean strainer

b] See specifications for maximum

viscosity

a] See “specifications” for minimum

and maximum flow rates

b] Bleed air from system

c] Check meter body and rotors.

Replace as required. Refer to

installation instructions

a] Tighten grub screws

b] Replace rotor

c] Replace gears

d] Replace register assembly

a] Replace seal (Check seal

compatibility with fluid)

Page 25

5

Meter Parts Listing

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Rec.

Parts

1

2

3

4

5

7

11

13

10

Key:

* Parts for US Gallon Models Only

u Indicates recommended Spare Parts to stock

Bold text indicates Stainless Steel Model Parts

8 / 9

8A / 9A O-ring Only

12

14 15

16

17

6

20

21

1 1 MS298B Meter Body 1/2” BSP (Aluminium)

1 1 MS298N Meter Body 1/2” NPT (Aluminium)

1 1 MS337B Meter Body 1/2” BSP (Stainless Steel)

1 1 MS337N Meter Body 1/2” NPT (Stainless Steel)

21u BS145TES “O” Ring (Teflon)

21u BS145VS “O” Ring (Viton)

32u MS342MS Rotors PPS (Polyphenylene Sulfide Resins)

32u MS342MHS High Viscosity Rotors (PPS)

4 1 MS544S Meter Cap Liters (Aluminium)

4 1 MS547S Meter Cap US Gallons (Aluminium)

4 1 MS545S Meter Cap Liters (Stainless Steel)

4 1 MS546S Meter Cap US Gallons (Stainless Steel)

54u MS346S Meter Cap Screws (Standard)

54u MS350S Meter Cap Screws (Stainless Steel)

61u MS539S Complete Gear Set - Liters

61u MS541S Complete Gear Set - US Gallons

71u MS77S Output Gear & Shaft Assembly

81u MS78S Coverplate Seal/Bush Set Standard

8A 1 u OR42CS Solvent o-ring (Perfluoro Elastomer)

91u MS78C Coverplate Seal/Bush Set Solvent

9A 1 u V7-007S O-ring (Viton)

10 1 u BS145TES O-ring (Teflon)

10 1 u BS145VS O-ring (Viton)

**

Page 26

11 1 MS99S Coverplate (Aluminium) includes bush

11 1 MS99-1S Coverplate (Stainless Steel) includes bush

12 6 u MS312S Coverplate Screws - Litre Model

12 6 u MS313S Coverplate Screws (Stainless Steel) Litre Model

12 6 u MS419S Coverplate Screws - US Gallon Model

12 6 u MS420S Coverplate Screws (Stainless Steel) US Gallon Model

13 1 u MS83S Bevel Gear Set

14 1 MS140S Bottom Register Coverplate

15 4 u MS111S Mounting Screws

16 1 u MS141M4GS Register Assembly with Coverplate - Liters

16 1 u MS141UGS Register Assembly with Coverplate - US Gallons

17 4 u MS129S Register Body Screws

20 1 u BS145TES O-Ring (Teflon)

20 1 u BS145VS O-Ring (Viton)

21 1 u MS423S Spacer Ring (Aluminium) US Gallon Model Only

21 1 u MS423-1S Spacer Ring (Stainless Steel) US Gallon Model Only

6

Meter Parts Listing

Rec.

Parts

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

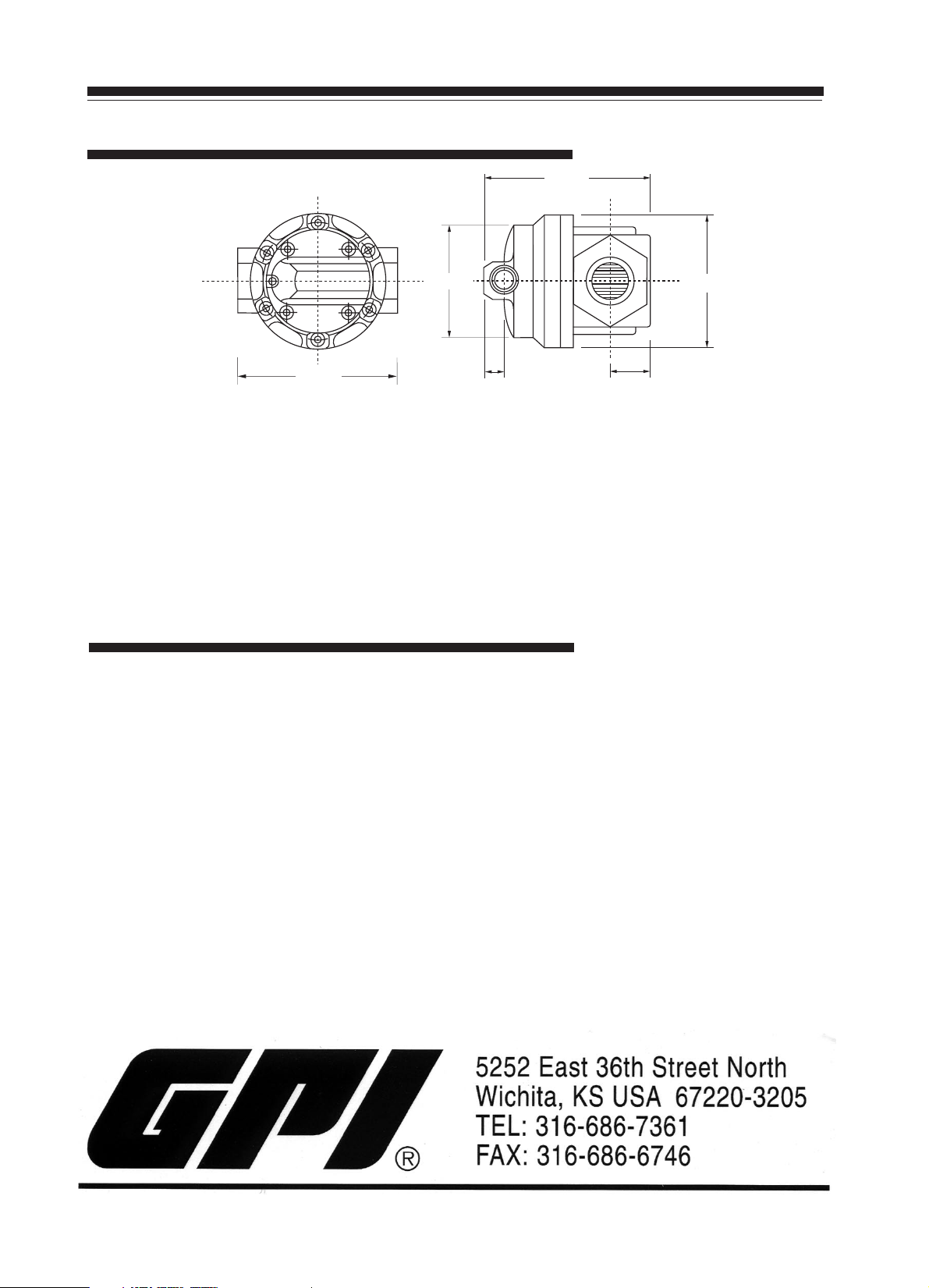

Meter Dimensions

112 mm

125mm

24mm

GM505 Mechanical Meter Dimensions

100mm

115 mm

Meter Specifications

Flow Ranges

(Litres per minute/US Gallons per minute)

Above 5 Centipoise 1 to 30/ 0.26 to 8

Below 5 Centipoise 3 to 25/ 0.8 to 6.6

Accuracy of Reading +/- 1%

Maximum Viscosity 1000 Centipoise

Maximum Operating Pressure 3450 kPa / 500 PSI / 34.5 BAR

Operating Temp. Range -10°C / 14°F to 80°C / 176°F

Page 27

Great Plains Industries, Inc. Limited

Warranty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby

provides a limited one year warranty against defects in material and workmanship on all products

manufactured by Great Plains Industries, Inc. This warranty shall extend to the purchaser of this

product and to any person to whom such product is transferred during the warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s

obligation hereunder shall be limited to repairing defective workmanship or replacing or repairing any

defective part or parts. This warranty shall not apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed

representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or

operated other than in accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its

address below no later than 30 days after the expiration of the warranty period. Such notice shall

identify the defect in the product. The company shall, within 14 days of receipt of such notice, notify

the customer to either send the product, transportation prepaid, to the company at its office in

Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations

imposed on it by the terms of this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR

DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE

OR LOSS OF USE IF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any

particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S.

state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Warranty

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

MS499G

0603

0003

Positive Displacement Flowmeters

GM007 series instruction manual

GM007 Pulse Meter From serial No. CXXXX

Page 37

Thank you for purchasing a GPI GM

Series Flow Meter. Please take a few

minutes to read through this manual

before installing and operating your

meter. If you have any problems with

the meter, refer to the maintenance

and trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM007

Series meters with pulse outputs. For

models with displays an additonal

instruction manual is supplied. [If you

need further assistance, contact your

local GPI representative or contact

GPI by telephone or fax.]

The GPI GM Series Flow Meter has

incorporated the oval rotor principal

into its design. This has proven to be a

reliable and highly accurate method

of measuring flow. Exceptional

repeatability and high accuracy over a

wide range of fluid

viscosities and flow rates are features

of the GM Series flow meter design.

The low pressure drop and high

pressure rating means the GM Series

flow

meter is suitable for both gravity and

pump (in line) applications.

The GPI GM Series flow meters are

available in aluminum, 316 stainless

steel, or PPS. Standard rotors are made

from PPS (Polyphenylene Sulfide

Resins) with optional 316 stainless

steel rotors available for either

stainless steel or aluminium models.

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Before use, confirm the fluid to be used

is compatible with the meter (refer to

the GPI fluid compatibility chart), or

consult your local GPI distributor for

advice.

To prevent damage from dirt or foreign

matter, GPI recommends a Y or Basket

type 60 mesh strainer be installed as

close as possible to the inlet side of the

meter (if required contact GPI for

further information).

Note: When a strainer is installed it

should be regularly inspected and

cleaned. Failure to keep the strainer

clean will dramatically effect flow

meter performance.

To prevent damage to the meter slowly

fill the system with fluid (this will

prevent damage caused by air purge).

Note: Failure to do this could damage

the meter.

For pump applications, turn off the

pump at the end of each day.

Maintenance can be carried out to the

liquid crystal displays and pulse units

without removing or isolating the meter

from the line. When maintenance to

any other part of the meter is required,

the meter must be isolated and the line

pressure reduced.

The reed switch pulse unit can cause

inaccurate rate counts when used with

high speed counters. It is advised that

a debounce circuit be used or

alternatively use the hall effect sensor

option.

1

To the owner

Important Information

Page 38

1] GPI recommends that when setting

up pipework for meter installations

a bypass line be included in the

design. This provides the facility for

a meter to be removed for

maintenance without interrupting

production. (See Fig.1)

2] Use thread sealant on all pipe

threads.

3] For pump applications ensure pipe

work has the appropriate working

pressure rating to match the

pressure output of the pump.

4] Install a wire mesh strainer (Y or

basket type 60 mesh as close as

possible to the inlet side of the

meter.

5] Ensure that the meter is installed so

that the flow of the liquid is in the

direction of the arrows embossed

on the meter body.

6] The meter can be installed in any

orientation as long as the meter

shafts are in a horizontal plane.

(Refer to Fig.2 for correct

installation) The register assembly

may be orientated to suit the

individual installation.

Note: Incorrect installation can cause

premature wear of meter

components.

7] Do not over tighten meter

connections.

8] It is important that after initial

installation you fill the line slowly,

high speed air purge could cause

damage to the rotors.

9] Test the system for leaks.

10] Check the strainer for swarf or

foreign material, after the first 200

litres check periodically,

particularly if the flow rate

decreases.

2

Installation

When fluid passes through the meter,

the rotors turn. The magnets which are

located in the rotors will pass across

the pulser circuit board (containing

either Reed switches or Hall Effect

sensors). A signal is received which is

then sent by the Pulse Circuit Board

(PCB) to the relevant LC display or

receiving instrument.

Operation

1

2

Bypass Line

Flow Outlet

Flow Inlet

Strainer

Do Not Install Meter This Way

Page 39

Disassembly

Ensure that the fluid supply to the

meter is disconnected, and the line

pressure is released before

disassembly, with the exception for

repair or maintenance to the LC

Display or PCB where there is no

necessity to isolate the meter from the

flow. Refer to the exploded parts

diagram on pages 5.

1a] Units with Pulse Caps; Undo the

conduit connector, remove pulse cap

(item 9) and remove the wires from the

pulse terminal board (item 5).

1b] Standard LC Display; Mark the

display orientation with a marking

pen, unscrew the four large

screws on top of the LC Display.

Reed Switch Connections for PCB Terminals - refer Fig.3

Hall Effect Sensor Connections - refer Fig.4

3

Electrical Connections

Service Instructions

3

Contact rating 15VA

Maximum Voltage 150VDC

Configuration 1

2 x pulse outputs

Configuration 2

Link 2 & 3 for double

pulse output

LCD Versions

1 x Hall Effect Sensor

1 x Reed Switch

1 - Reed Switch

2 - Reed Switch

3 - HE Common 4 - HE Signal

5 - HE Supply +

Pulse V

ersions Only

2 x Hall Effect Sensor

1 - HE Supply +

2 - HE 1 Signal

3 - HE Common 4 - HE 2 Signal

5 - HE Ground

4

Hall Effect Voltage 4.5 to 24 VDC

Current Draw Minimum 4.6mA

Output NPN Open Collector 25mA

Page 40

4

Carefully separate the LC Display

from the plastic housing and

disconnect the wires from the

pulse terminal block.

2] Remove the mounting adaptor plate

and gasket (Item 8).

3] Loosen the four cap screws (Item 7)

and nuts that hold down the meter

cap (Item 4), remove the screws

and nuts and lift off the cap.

4] Remove the o’ring (Item 2) from the

o’ring groove in the meter cap (Item 4).

5] Remove rotors (Item 3).

Reassembly

1] Before reassembling check the

condition of the rotors (replace if

necessary).

2] Check that the smooth side of the

rotors (not the plug side) is facing

you when inserting the rotors, the

smooth side of the rotor is the

magnet side. There is no difference

between rotor one or rotor two.

3] Replace the rotors (Item 3) onto the

shafts at 90oto each other (refer

Fig. 5) and check their operation by

turning either of the rotors. If the

rotors are not in mesh correctly or

do not move freely, remove one of

the rotors and replace correctly at

90oto the other rotor. Re-check the

operation of the rotors.

4] Replace the o’ring (Item 2) into

groove in the meter cap, if the

o’ring has grown or is damaged in

any way replace it with a new part.

5] Replace the meter cap. Insert the

cap head screws (Item 7) and fix

nuts and tighten in the sequence 1,

3, 2, 4

6] The replacement of cables and

connectors are a reversal of the

disassembly procedure, replace

conduit fitting if required. When

replaceing the Standard LC Display,

confirm the orientation marks made

on disassembly are aligned then

screw the register into place.

7] Test the meter by turning the rotors

with a finger or by applying very low

air pressure ( a good breath) to one

end of the meter, before returning

the meter to the line.

Pulse Circuit Board (PCB) Notes:

The pulse PCB (Item 5) is fitted with

(A) two reed switches; (B) hall effect

sensors; or (C) one reed switch and

one hall effect sensor. The PCB board

is fastened to the meter cap (Item 4)

by two screws and stand off’s. All care

and caution should be taken when

removing or handling the PCB as both

the reed switch and hall effect sensor

are fragile.

Individual reed switches or hall effect

sensors are not available as

replacement parts and are only

available with the PCB (Item 5).

5

Rotors must be at 90oto each other.

Rotor #2

Rotor #1

Meter Trouble Shooting

TROUBLE

Fluid will not flow through meter

Reduced flow through the meter

Meter reading inaccurate

Meter not giving a pulse signal

CAUSE

a] Foreign matter blocking rotors

b] Line strainer blocked

c] Damaged rotors

d] Meter connections over tightened

e] Fluid is too viscous

a] Strainer is partially blocked

b] Fluid is too viscous

a] Fluid flow rate is too high or too low

b] Fluid is too viscous

c] Excess wear caused by incorrect

installation

a] Faulty hall effect sensor

b] Faulty reed switch

c] Magnets failed

REMEDY

a] Dismantle meter, clean rotors

(Strainer must be fitted in line)

b] Clean strainer

c] Replace rotors (Strainer must be

fitted in line)

d] Re-adjust connections

e] See specifications for rated viscosity

a] Clean strainer

b] See specifications for rated viscosity

a] See “specifications” for flow range

b] Bleed air from system

c] Check meter body and rotors.

Replace as required.

a] Replace PCB Board

b] Replace PCB Board

c] Replace rotors

Page 41

5

Meter Parts Listing

1

23 4 56 7 8 9 10

1 1 MS351B Meter Body 1” BSP (PPS) & St St Shafts

1 1 MS351N Meter Body 1” NPT (PPS) & St St Shafts

1 1 MS352B Meter Body 1” BSP (PPS) & Hastalloy Shafts

1 1 MS352N Meter Body 1” NPT (PPS) & Hastalloy Shafts

21u BS235TE “O” Ring (Teflon) Encapsulated

21u BS235V “O” Ring (Viton)

32u MS370S Rotors PPS (Polyphenylene Sulfide Resins)

3 2 MS370CPS Rotors PPS **

4 1 MS405R Meter Cap (PPS)

51u MS368-R PCB (Standard Reed Switch)

51u MS344-HE PCB (Hall Effect Sensor)

5 1 MS368-R/HE PCB ( 1 Reed Switch & 1 Hall Effect Sensor)

6 2 MS284S PCB Board Screws

74u MS350S Meter Cap Screws (Stainless Steel)

81u MS340 Pulser Cap Gasket

9 1 MS406R Pulser Cap (PPS) 16mm Conduit Thread

9 1 MS406R-N Pulser Cap (PPS) 1/2” NPT Thread

10 2 MS347S Pulser Cap Screw (Stainless Steel)

11 1 MS37 Warning Label (Not Shown)

12 1 Specify plate details Legend Plate (Not Shown) inc. Hammer Screws

33 1 MS111 Earthing Screw

34 4 MS497S Nut - Stainless Steel - Not Shown, recessed in body

**For PPS Meters fitted with Hastalloy shafts only

Item

No.

No.

Off.

Part or Set

(Order from this column only)

Part Description

Key:

u Indicates recommended Spare Parts to stock

Rec.

Parts

33

Meter Specifications

Flow Ranges (Litres/min. - US Gall./min.)

Above 5 Centipoise

Below 5 Centipoise

Accuracy of Reading

Maximum Viscosity

Maximum Operating Pressure

Maximum Operating Temperature

Pulse Type

Pulses Per Litre/US Gallon

3 to 80 / 0.8 to 21

8 to 70 / 2 to 18.5

+/- 0.5%

1000 Centipoise

1000 kPa/ 150 PSI/ 10 BAR

80°C/ 176°F

Dual Reed Switches or Hall Effect Sensor or

combination HE Sensor/Reed Switch

52 or 104/197 or 394

Page 42

Warranty

Great Plains Industries, Inc. Limited Warranty Policy

Great Plains Industries, Inc., 5252 East 36th Street North, Wichita, Kansas USA 67220-3205, hereby provides a limited one

year warranty against defects in material and workmanship on all products manufactured by Great Plains Industries, Inc. This

warranty shall extend to the purchaser of this product and to any person to whom such product is transferred during the

warranty period.

The warranty period shall begin on the date of the original new equipment purchase. Warrantor’s obligation hereunder shall

be limited to repairing defective workmanship or replacing or repairing any defective part or parts. This warranty shall not

apply if:

a.)The product has been altered or modified outside the warrantor’s duly appointed representative;

b.)The product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in

accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, notice of claim must be given in writing to the company at its address below no later

than 30 days after the expiration of the warranty period. Such notice shall identify the defect in the product. The company

shall, within 14 days of receipt of such notice, notify the customer to either send the product, transportation prepaid, to the

company at its office in Wichita, Kansas, or to a duly authorized service center. The company shall perform all obligations

imposed on it by the terms of this warranty within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC. EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT,

INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE IF THE PRODUCT

WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for any particular purpose other than for

which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from U.S. state to U.S. state.

NOTE: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT - Part 702

(governs the resale availability of the warranty terms).

Meter Dimensions

70mm

108mm

120mm

18mm

30

mm

Pulse Meter Dimensions

100mm

Page 43

MS51G

0603

0003

Positive Displacement Flowmeters

GM010 series instruction manual

GM010 Pulse Meter From serial No. CXXXX

Page 44

Thank you for purchasing a GPI GM

Series Flow Meter. Please take a few

minutes to read thorugh this manual

before installing and operating your

meter. If you have any problems with

the meter, refer to the maintenance and

trouble shooting sections of this

manual.

This manual contains connection and

operating instructions for the GM010

Series meters with pulse outputs. For

models with display, an additonal

instruction manual is supplied. If you

need further assistance, contact your

local GPI representative or contact GPI

by telephone or fax for advice.

The GPI GM Series Flow Meter has

incorporated the oval rotor principal

into its design. This has proven to be a

reliable and highly accurate method of

measuring flow. Exceptional

repeatability and high accuracy over a

wide range of fluid viscosities and flow

rates are features of the GM Series flow

meter design. The low pressure drop

and high pressure rating means the GM

Series flow meter is suitable forboth

gravity and pump (in line) applications.

The GPI GM Series flow meters are

available in either aluminium or 316

stainless steel. Standard rotors are

made from PPS (Polyphenylene Sulfide