Page 1

Automatic Level

GL-332

INSTRUCTIONS FOR USE

Page 2

- 1 -

Contents

1. Technical Data............................................................................................02

2. Structure Focusing.....................................................................................03

3. Method of Operation..................................................................................06

3.1 Setting and Levelling................................................................................06

3.2 Aiming and Fousing..................................................................................06

3.3 Staff Reading............................................................................................07

4. Check and Adjusting..................................................................................08

4.1 Correct the parallelism for both circle bubble and Vertical axis...............08

4.2 Check and Adjusting for leveling of sight line of telescope......................09

5. Service and Maintance...............................................................................10

Page 3

- 2 -

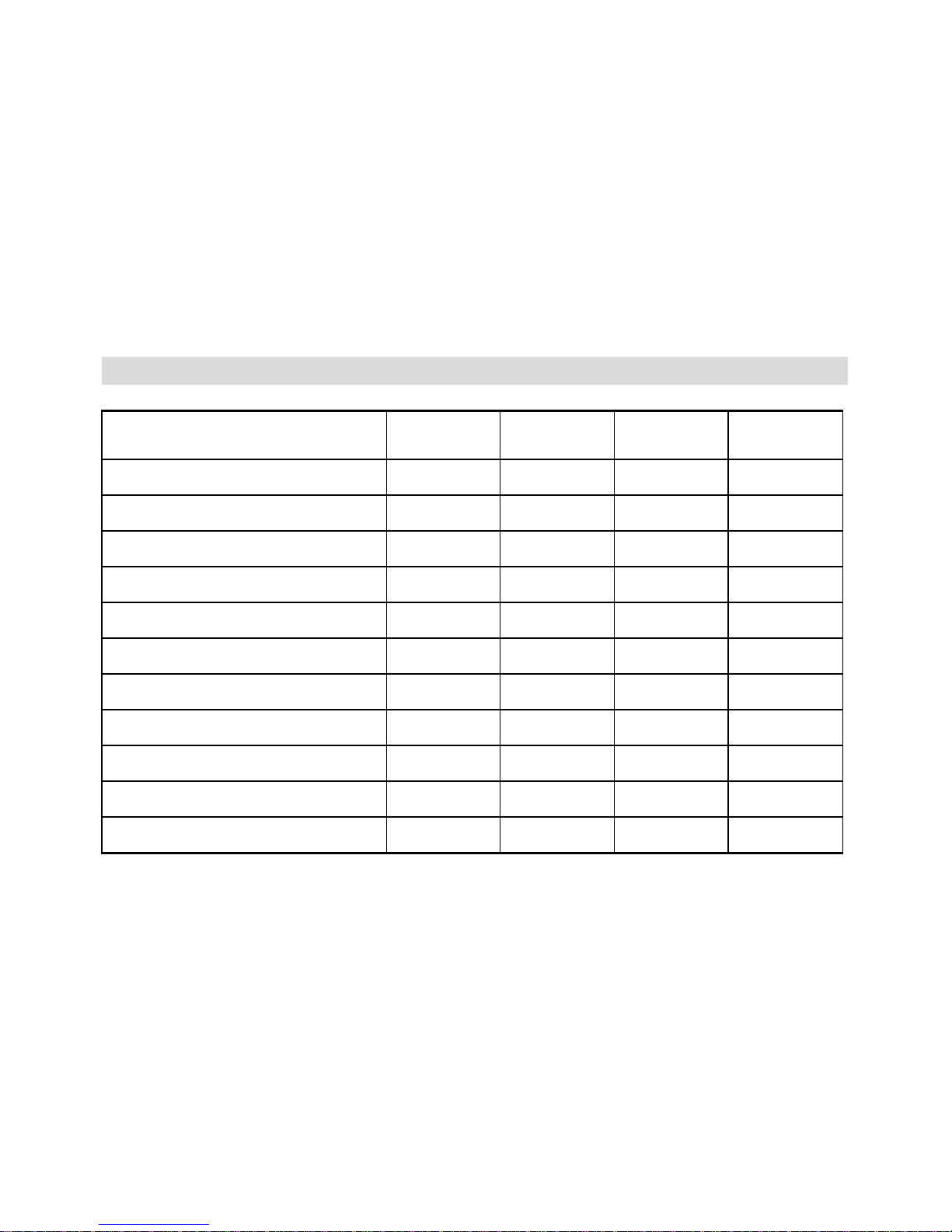

1. Technical Data

Standard deviation of 1KM

double-run levelling

≤2.5mm

≤2.0mm

≤1.5mm

≤1.5mm

Telescope

Erect Erect Erect Erect

Magnification

20X 24X 28X 32X

Clear objective aperture

38mm 38mm 38mm 38mm

Field angle

1゚20' 1゚20' 1゚20' 1゚20'

Shortest focusing distance

0.6m 0.6m 0.6m 0.6m

Multiplication factor

100 100 100 100

Additive constant

0 0 0 0

Compensator working range

±15' ±15' ±15' ±15'

Compensator setting accurancy

±0.8" ±0.6" ±0.5" ±0.3"

Sensitivity of circular bubble

8' / 2mm

8' / 2mm

8' / 2mm

8' / 2mm

Graduation interval

1゚ 1゚ 1゚ 1゚

Page 4

- 3 -

2. Structure Features

a. The telescope has system of erect internal focusing which can be used to obtain

reversed image by way of prism. It is of sealed type to prevent from dust, water

and steam.

b. All the optical parts are coated with transmissive and reflective films to reduce loss

in luminous energy.

c. Hair cross-spring suspension prism is used for the compensator, and the labyrinth

damper will stop the compensator within short time to raise efficiency.

d. The instrument matched with warning set so it can check the working situation of

compensator and the property of leveling.

e. Friction brake and the structure of whole circle micro-drive is used for instrument

horizontal micro-motion, which has the advantages of reliable in structure and easy

in operation.

f. Instrument (Fig.1) and (Fig.2)

Page 5

- 4 -

Fig 1

Focusing knob

Telescope

Objective

Endless horizontal

Foot screw

Page 6

- 5 -

Fig 2

Endless horizontal

Foot screw

Bubble observer

Eyepiece cover

Eyepiece

Adjusting screw

Graduation

Circular bubble

Page 7

- 6 -

3. Method of Operation

3.1 Setting and Levelling

a. To adjust tripod, and let the flat part of tripod in a leveling position, with its height

basically in the same line of the telescope and the operator's eyes.

b. To set the instrument on tripod, and to connect the instrument to the tripod with the

central screw.

c. With the help of leveling screw. Center the circular bubble exactly at the position.

3.2 Aiming and Focusing

a. To rotate eyepiece cover, observe through the eyepiece of the telescope, and let the

sight distance line in graduated scale clear.

b. To aim the staff by rough finder, to rotate the focusing hand wheel until sight of

staff clear (forward to far away, and backward to nearer), then to rotate the hand

wheel of endless horizontal micro-motion and let the sight of staff on center.

Page 8

- 7 -

3.3 Staff reading

a. When the instrument aiming at the staff, the

reading of the center line is the altitude. (Fig.3)

is 1.614m

b. To have the readings respectively for the upper

line and the lower, the distance from station

point to the staff will be(upper line

reading-lower line reading)×100. (Fig.3) is

(1.675–1.550)×100 = 12.5m

c. When the vertical hair in sight distance lines

aiming at object A, the indicating angle in dial

will be ∠AOB = α–β

Fig 3

Fig 4

0

A B a b

Page 9

- 8 -

4. Checking and adjusting

Before leaving the factory, each centerline is properly adjusted, the centerline is

properly adjusted, the centerlines may deviate from proper position after

transportation or long time operation. So to check and adjust the main centerlines is

necessary before measuring and surveying is field work.

4.1 Correct the parallelism for both circle bubble and vertical axis to set the

instrument on tripod, and to rotate leveling screws until bubble is centered. If to rotate

the instrument on 180゚, the bubble remains centered, bubble position is correct,

otherwise if must be corrected in following way.

a. To rotate foot screw, enabling bubble to move centered, and it's movement will

behalf deviation from the total value.

b. To adjust the bubble adjusting screw, enabling bubble to move centered, and repeat

until the bubble does not move along with rotating of the instrument.

Page 10

- 9 -

4.2 Check and adjusting for leveling of sight

line of telescope (Check and adjusting angle)

select a check line about 45–60m on a even

ground, divide it on 3 parts with the same

length (Fig.5), staff on points B&C. Suppose the mean reading by the instrument at

point A is a1, b1; and the mean reading by the instrument at point D is a2, b2, if

Δ=(a2,-b2)–(a1-b1)≤±3mm the angle is within tolerance, otherwise the instrument

must by readjusted in the following way:

a. First to calculate Δ= (a2,–b2)–(a1–b1) suppose a3 = a2–Δ

b. The instrument remained at point D, aiming at staff B, to remove the eyepiece

cover you will see a reticle adjusting screw (Fig.6), remove the adjusting screw on

gradudted scale carefully with adjusting needle until the graduated scale center

A

B C D

a

4

’

a4

a

1

’

a1

a 2

a

2

’

a 3

a

3

’

Fig 5

Page 11

- 10 -

coincide with a3, then to close the eyepiece cover and to check and adjust in the

same way again.

5. Service and maintenance

a. The instrument must be avoided directly from

sunshine at working time to keep accuracy.

b. After finish survey each part of instrument must

be clean and mount into instrument box.

c. Whist off dust from optical eiement by soft hair

brush, soft paper specially used for cleaning glasses and soft leather. Do not touch lens by hand.

d. If there is any trouble in working or the instrument has been br–(Fig.6) oken, you

may return it to our factory or send it to qualified department to repair it. It is

forbidden to dismantle the instrument randomly.

e. The instrument must be stored in the room with acid climate, clean and good

ventilation.

Adjusting screw

Adjusting screw

Page 12

Giant Precision Instrument Co., Ltd.

International sales dep.

No.69, Anhe Rd., Zhonghe Dist., New Taipei City, Taiwan (R.O.C.) Zip:23576

Tel: 886-2-2231-7282 Fax: 886-2-2231-7281

Loading...

Loading...