Page 1

Page 2

TABLE OF CONTENTS

SPECIFICATIONS ......................................................................................1

MOUNTING ................................................................................................3

WIRING .....................................................................................................4

THEORY OF OPERATION .........................................................................6

MILIVOLT INPUT OPTION JUMPER SELECTIONS ..................................7

FRONT PANEL OPERATIONS ...................................................................8

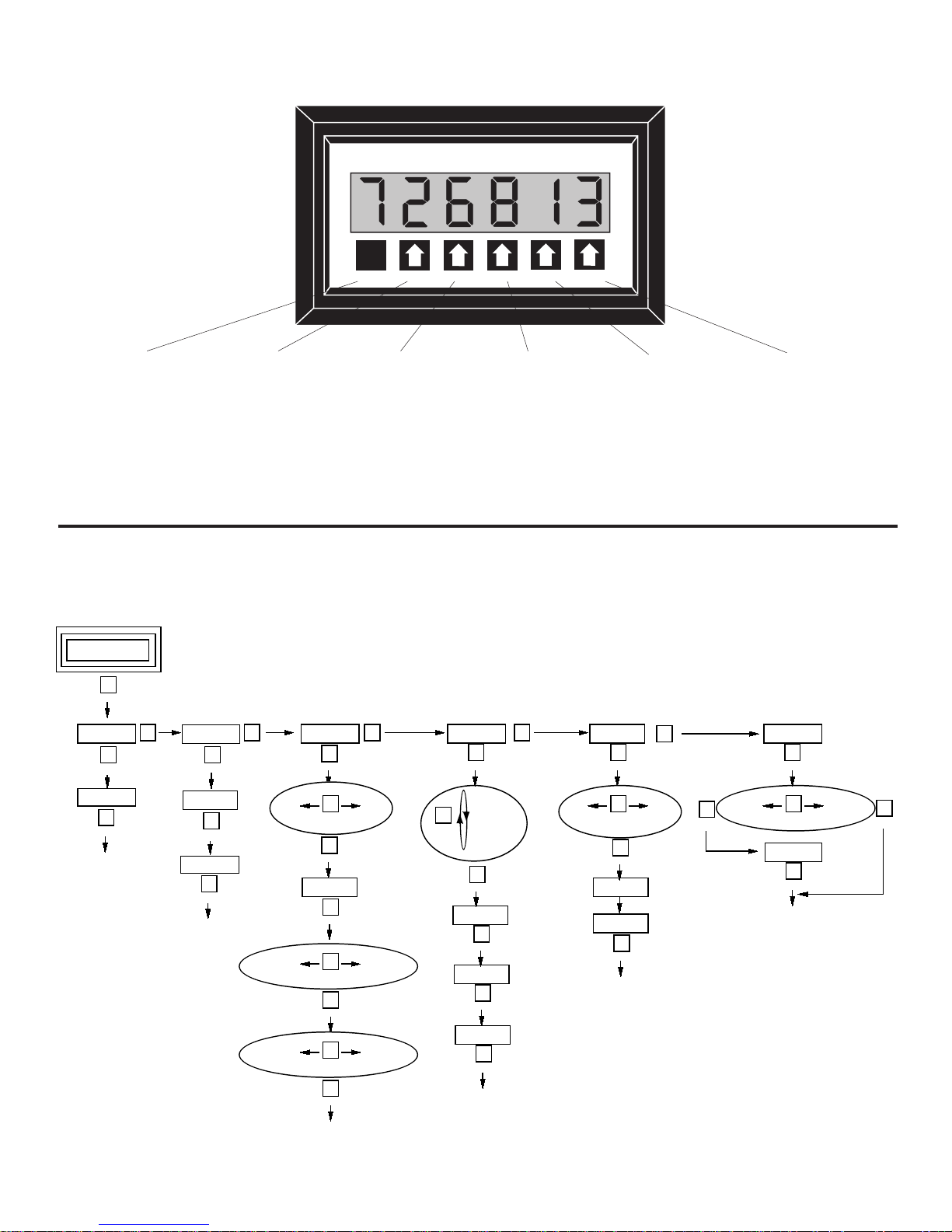

PROGRAMMING FLOW CHART ...............................................................8

DEFINITIONS OF MENU PROMPTS .........................................................9

CALCULATING SCALE FACTORS ............................................................11

PROGRAMMING ........................................................................................ 12

TROUBLESHOOTING GUIDE ................................................................... 17

WARRANTY

DECODING PART NUMBER

Page 3

3.622

(92)

1.772

(45)

4.437

(112.7)

2.625

(66.68)

0.587

(14.91)

4.245

(107.8)

BEZEL

GASKET

CUSTOMER PANEL

Panel Thickness 0.062" (1.5)

to 0.187" (4.7) max.

3.925

(99.7)

Dimensions:

Flowmeter Solenoid Valve

STOP

RST

ENTER

LOCK

PRE A

PROG

VIEW

START

A

B

C

D

E

SPECIFICATIONS

(continued)

Panel

Cutout

Application

2

Page 4

3.622

(92)

1.772

(45)

4.437

(112.7)

2.625

(66.68)

0.587

(14.91)

4.245

(107.8)

BEZEL

GASKET

CUSTOMER PANEL

Panel Thickness 0.062" (1.5)

to 0.187" (4.7) max.

3.925

(99.7)

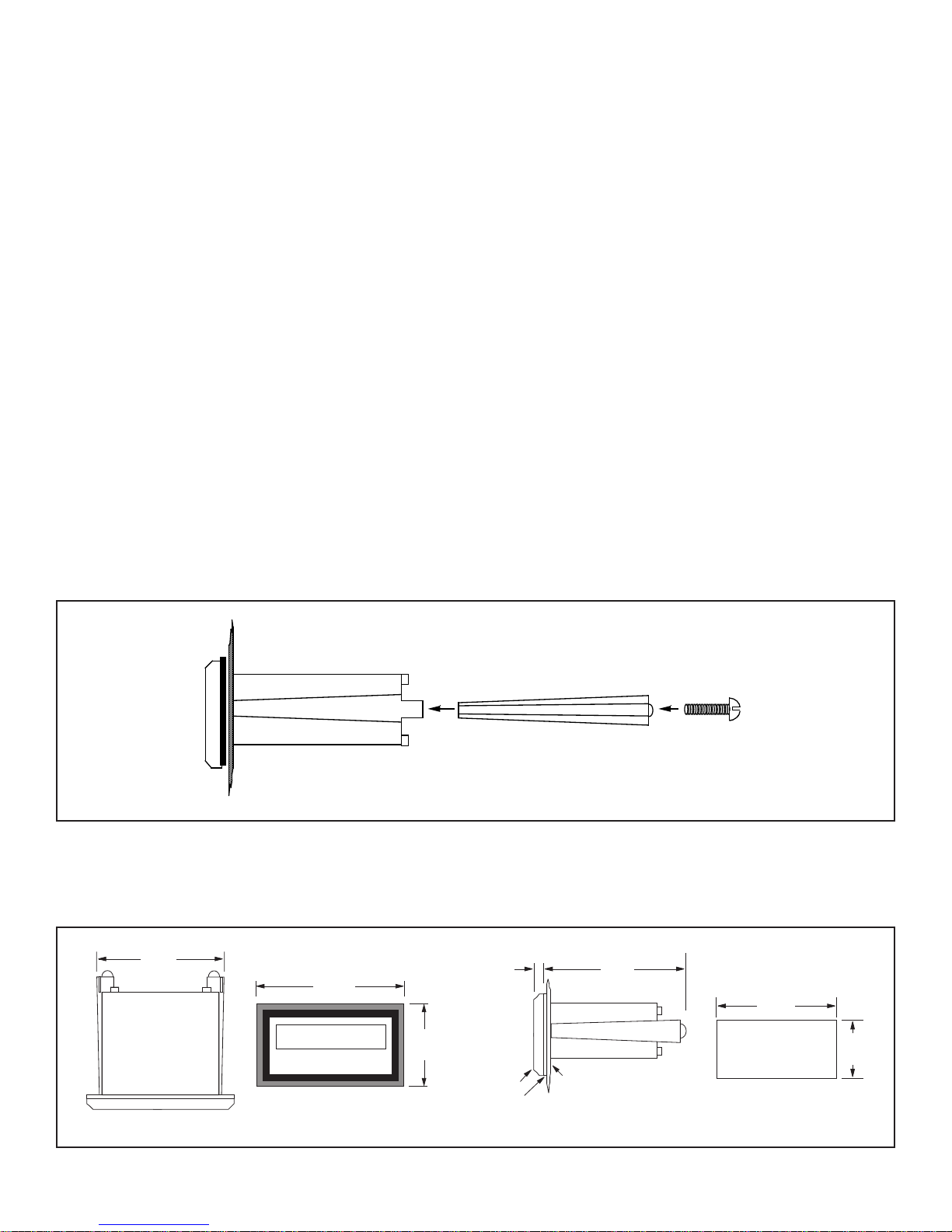

MOUNTING

FIG. A

The unit is designed to be mounted with a gasket providing a water tight seal. Two mounting brackets are provided to secure

the unit to the panel. A panel less than .1" may distort if the clamps are screwed too tightly.

Slide the body of the unit through the rubber gasket. Insert the unit into the panel. As shown in "FIG. A", slide the brackets

up the groove to press against the back of the panel. Insert screws into rear of brackets and tighten them evenly and alternately. Do not over tighten! A normal level of torque is required. Maximum torque should be 3" pounds.

This product is designed to be panel mounted and is NEMA 4 rated if proper mounting procedures are followed and the

required and supplied hardware is correctly used.

If the panel in which the unit is mounted is less than .125 of an inch thick, the possibility exists that there will be some flexing. Should this flexing occur, the resulting deformation of the panel could cause a loss of the water tight seal. In case this

should occur, the use of silicone or other sealant would be recommended.

This product is designed to the NEMA 4 standard. However, the fact that we are unable to control either the location in which

the device is installed or the actual installation itself requires that the company's liability shall extend only to the repair or

replacement of a defective product.

We are prepared to offer additional assistance in those special situations where normal mounting methods do not seem

to satisfy the customers needs. This assistance may be obtained by calling the factory and asking for Industrial Customer

Service.

FIG. A

DIMENSIONS

3

Panel

Cutout

Page 5

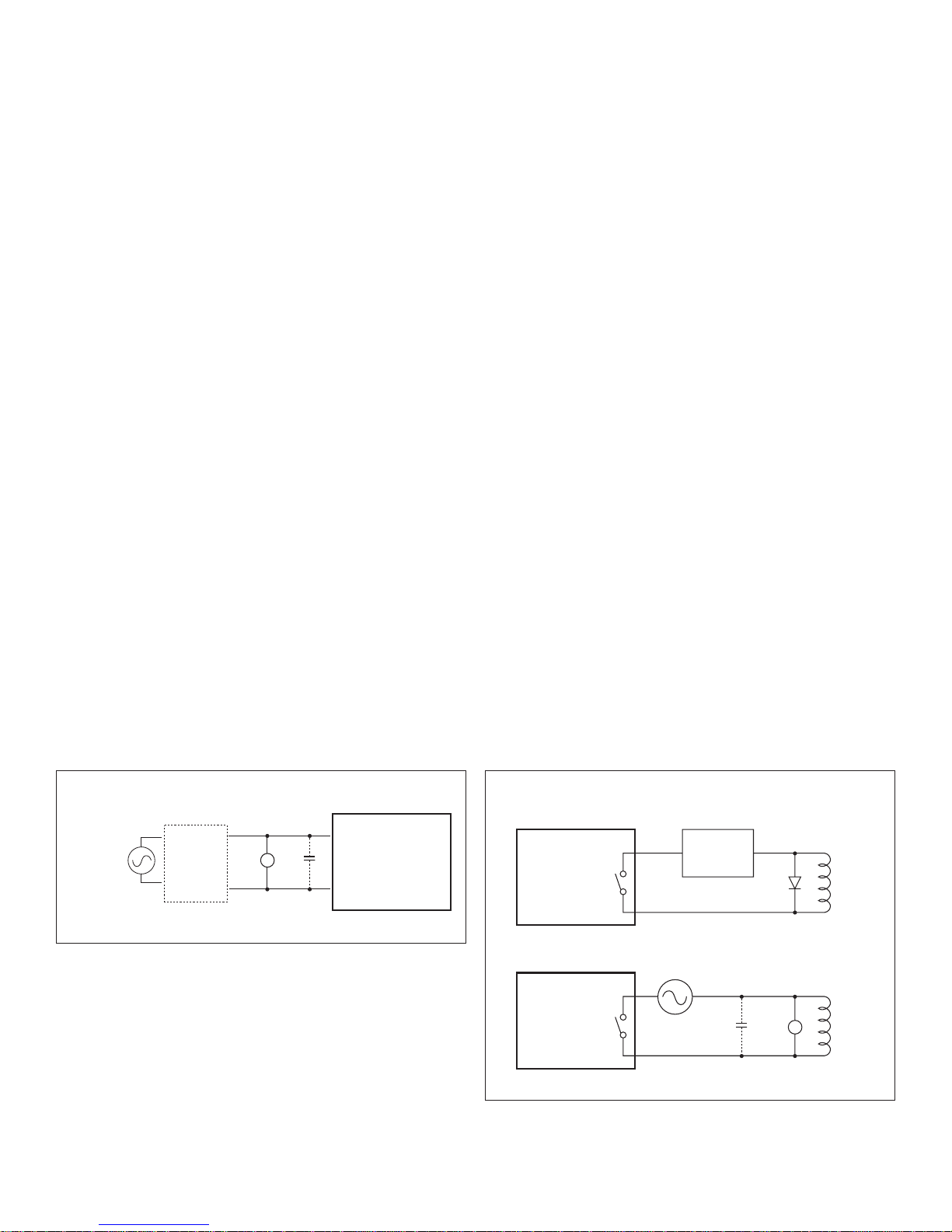

WIRING

Supply Line Suppression

ELECTRONIC

INSTRUMENT

MOV

CAP

AC

SUPPLY

OPT.

RFI

LINE

FILTER

SUPPRESSION

AT AC INPUT

Relay Contact Suppression

DC

SUPPLY

ELECTRONIC

INSTRUMENT

RELAY

CONTACT

+

-

DIODE

LOAD

DC Load

ELECTRONIC

INSTRUMENT

RELAY

CONTACT

MOV

LOAD

CAP

AC

SUPPLY

AC Load

The rear terminal contains 12 screw terminals for connecting #14 to #28 gauge wire.

The unit is controlled by a microprocessor and, therefore, an electrically "noisy" environment could cause operating problems.

The input power line should not be common to power lines for motors, pumps, contactors, etc.

The unit is designed to be immune from line or RF voltage interference. In some environments voltage spikes of over 100

volts, even 1000 volts, can occur. When common to a power line driving motors voltage fluctuations can be extreme and

rapid. Lines driving DC or AC solenoids, relays, or actuators can also cause problems.

Four sources of noise can occur:

1) AC power line noise - If the unit cannot be connected to a clean power source, an inductive load suppressing device

(MOV as GE # V130LA1 or Resistor Capacitor as Paktron # .2 uf/220 ohm @ 400V) can be installed. Although

locating the suppressor across the AC supply at the unit should help, best results are obtained by connecting the

suppressor across the leads of the "load" at the device causing the spike.

2) Input line noise -The noise is carried on the input and D.C. ground lines. Make sure the input wires are never run into

the unit in a bundle with power input lines. Also, keep these input lines isolated from inductive lines from devices

drawing heavy loads. If there is a possibility of electrical noise, we recommend using shielded cable, with the shield

being hooked to the D.C. ground terminal on the instrument, and to "earth" at one point in the circuit, preferably at the

D.C. ground terminal of the unit.

3) Output lines - The unit has two relay outputs. When these outputs are used to run external relays or solenoids, spikes

can be generated upon activation. This noise can spread through the instrument causing operating problems. If the

source is a D.C. operated device, a general purpose diode (IN4004) placed across the solenoid prevents electrical

noise spikes. Connect the cathode (banded side) to the more positive side of the coil. If the source is an A.C.

operated device, use a MOV or Resistor Capacitor across the coil.

4) 12 VDC output supply - Noise can be generated on the 12 VDC output supply if it is used to drive inductive loads or if

the current draw exceeds 50 mA. Insure that all inductive loads have a diode (such as IN4004) across the coil and

that the current does not exceed 50 mA.

4

Page 6

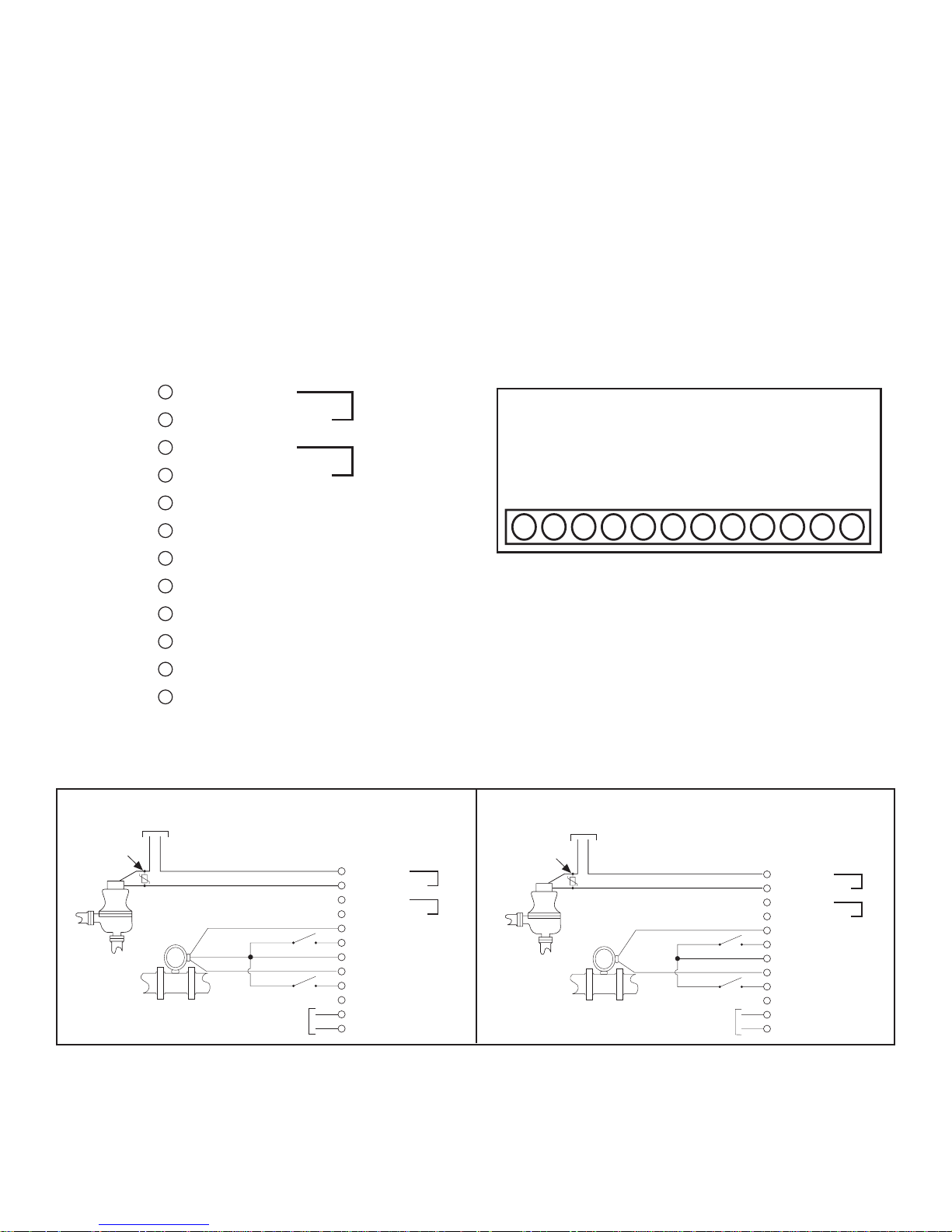

WIRING

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- COUNT

6- START

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

9- STOP/RESET

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

RELAYS

A

B

REAR VIEW

1 2 3 4 5 6 7 8 9 10 11 12

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- COUNT

6- START

7- +12VDC OUT/+DC IN

8- -DC (GROUND)

9- STOP/RESET

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

RELAYS

A

B

High level voltage pulse

+

–

Turbine Flowmeter

(preamplifier fitted)

AC

Power

115 VA C

SOLENOID

VA L VE

MOV

recommended

115 VA C

AC

Power

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- COUNT

6- START

7- +12VDC OUT/+DC IN

8- -DC (GROUND)

9- STOP/RESET

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

RELAYS

A

B

Low level mV pulse

–

Turbine Flowmeter

(without preamplifier)

115 VA C

SOLENOID

VA LV E

MOV

recommended

115 VA C

(continued)

AC / DC Power Connections

NOTE: Connect power only after other connections are finished. Do not touch the live AC power terminals! The unit has been designed with an isolated AC input. Thus, polarity is not a concern for the AC input. Connect AC power to pins 11 and 12. The chassis is

plastic, therefore earth ground is not used. For D.C. operation, connect + 12V to pin 7 and - D.C. to pin 8.

Sensor Connections

These diagrams show how to hook typical input sensors to the unit. The unit supplies an unregulated 12 Volt (50mA) output to power

these sensors (Pin 7).

A valid pulse is one which makes a transition from the off-state (0 to 1V) to the on-state (4 to 30V): a positive going edge. The input

impedance is 10K Ohms to ground. The unit can be programmed from the front panel for slow switch closure inputs up to 40Hz (select

"Lo CPS"), or solid state switches (select "hi CPS") up to 9.99KHz. No rear terminal jumpers are required. Use PNP (sourcing) type

pulsers.

Wiring Terminations:

Typical Flowmeter Connections

Magnetic Pickup (30 mV) Pulse Input High Impedance (4-30VDC) Pulse Input with Analog Output

5

Page 7

THEORY OF OPERATION

Batching

After the batcher has been programmed, it will operate

as follows:

The unit will reset to "0" (count up mode) or load Preset

A (count down mode) when RESET/STOP is activated.

(front button or rear input)

When Start (front button or rear input) is activated, Relay

A (and Relay B if Prewarn is selected) will energize and

the right decimal will light. The unit will count in engineering units corresponding to the input scaling.

If Prewarn is selected for Relay B, Relay B will drop out

when the count is at the selected number (Preset B)

before final Preset A. When Preset A (or "0") is reached,

Relay A drops out and the right decimal turns off. (The

right decimal turns on whenever Relay A is energized).

At the end of the batch the display is immediately loaded

with "P" and Preset A number. At this point you can:

Press START to reset and start another batch

Press PRE A to change Preset A

Press VIEW to view count (over-run)

Press RESET/STOP to reset to "0" (Preset A)

Relay B Operation

Relay B can be programmed as a prewarn relay or grand

total/batch counter alarm.

When Relay B is set for Prewarn, Relay B will energized

when the batcher is started. Relay B will drop out when

the count is at the selected number (Preset B) before

final Preset A. This is often used for slow down (2 stage

batching).

When Relay B is set for total (Batch or Grand Total),

Relay B will energize for the selected time duration when

the Batch/Grand Total reaches Preset B. If the Relay is

set to latch, it can be reset by resetting the Batch/Grand

Total. (as described above).

Relay B as Scaled Pulse Output

To use output B as a scaled output proceed as follows:

1) Select gr tot under count section of menu.

2) Select tot under relay section of menu.

3) Enter the desired duration for the B Relay.

4) Set Pre B at desired scaling (pre b is a divider).

Maximum output frequency is 15 pulses/second.

If RESET/STOP is activated while the unit is started,

Relay A (and Relay B if Prewarn) will drop out and the

last count will remain on the display. Press START to

continue the batch or RESET/STOP to abort the batch.

All starts are inhibited if RESET/STOP is held active.

Grand Total or Batch Counter

The second counter (displayed with inverted decimals)

can be programmed as a Grand Total or Batch counter.

The Grand counter counts the grand total, the Batch

counter counts the total number of complete batches.

These counters can only be reset from the front panel

while viewing them. To reset, press the VIEW key until

the displays shows a number with all decimals lit. Press

RESET/STOP to reset.

Presets

Preset A can be viewed and changed by pressing the

"PRE A" button. The present Preset A will appear.

Press buttons "A" through "E" to load in desired Preset

A. Press the ENTER button once to enter.

Preset B can be viewed and changed by entering the

program menu. Press the PRGM button. PRE B will appear. Press ENTER. The present Preset B will appear.

Press buttons "A" through "E" to load in desired Preset

B. Press the ENTER button once to enter.

VIEW Button

The VIEW button allows you to alternately view:

1. Count of "A" (Batch)

2. Rate of "A" (Batching speed)

3.* A) Grand Total if "gr tot" is selected

B) Number of Batches if "BA tot" is se-

lected

* All decimal points are inverted when Grand/Batch Total

is being displayed.

6

Page 8

MILLIVOLT INPUT OPTION JUMPER SELECTIONS

J4

J5

J6

J3

J1

J2

CR1

R3

C8R7R5

R4

U1

CR2

REV

20229

CR6

CR3

U3

P1

R10R6C6

C7

CR4

CR5

C4

R2

R1

C3

C5

U2

U4

6U

U5

R8

R9

C1

C2

C9

B

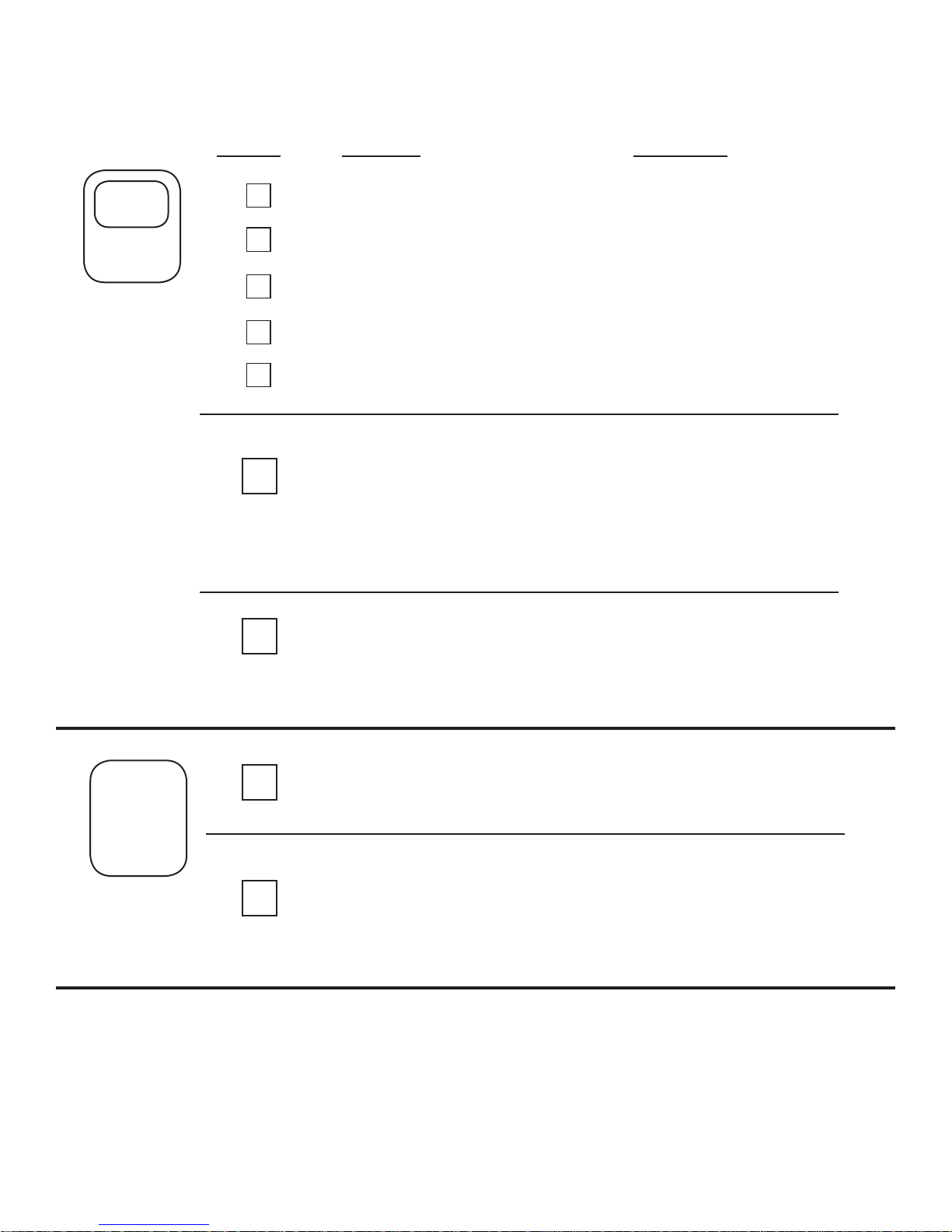

Millivolt Input Option Jumper Selections

If the unit has the millivolt input bd.# 20229, the count input

can be separately solder jumper programmed to accept

either a low millivolt or 4-30 V input. Each unit shipped is

programmed according to part number. If solder jumpers

are made, the part number should be modified to reflect the

changes made

C=CLOSE, O=OPEN

4-30V INPUT Millivolt INPUT

J1-O, J2-C, J3-O J1-C, J2-O, J3-C

7

Page 9

FRONT PANEL OPERATIONS

FACToR

RUN MODE

DP FAc

#####

ENTER

ENTER

ENTER

PRGM

CouNT

ENTER

RST�0SET

PR

PRGM

ENTER

DP LoC

ENTER

gr tot

ba tot

PRGM

ENTER

RUN MODE

ENTER

RATE

ENTER

ENTER

RUN MODE

NoR ##

ENTER

FiguR#

ENTER

DLY #

ENTER

LoC

ENTER

LC�

PRg

LC�

ALL

PRGM

ENTER

CoDE

#####

RUN MODE

ENTER

RELAY

ENTER

##.##

ENTER

ENTER

ENTER

RUN MODE

PRGM

PRGM

PRGM

PRGM

pre b

RUN MODE

#####

ENTER

ENTER

PRGM

hi cps

lo cps

PRGM

SECS�

NNiNS�

hours

PRGM

tot

preuu

PRGM

Start Here

A

STOP

RST

B

C

D

E

ENTER

LOCK

PRE A

PROG

VIEW

START

Press to STOP /

RESET in operating

mode; Press to "ENTER" in programming mode.

Press to "enter"

LOCK code for

panel lock.

Press to view or

change Preset A

Press to cycle

through PROGRAM choices;

Press to step

through set up

choices in program mode.

PROGRAMMING FLOWCHART

Press to alternately view Rate,

A Total or B Total

Press to Start

8

Page 10

DEFINITIONS OF MENU PROMPTS

The following is a list of abbreviations as they appear on the display and front panel of the unit.

ABBREVIATION DESCRIPTION

PRE B PRESET B - This is the setpoint for Relay B. Preset B can be used as a Prewarn or Grand/Batch Total

alarm.

FACTOR SCALING FACTOR - This portion of the menu is used to set the 5 digit dividing scale factor for the count

input.

DP F A DECIMAL POINT FOR FACTOR A - Enter location of decimal point for scaling Factor A by pressing the

button under the digit where the decimal is desired.

COUNT PORTION OF MENU FOR SETTING COUNTER VARIABLES

RST 0 RESET TO 0 - Counter will reset to 0. The Batcher will count up from 0.

SET PR SET TO PRESET - Counter will reset to preset A. The Batcher will count down from preset A.

DP LOC DECIMAL POINT LOCATION - Enter desired location of decimal by pushing the button under the digit

where the decimal is desired. Changing the decimal will change the decimal location in the counter's

presets and rate display.

gr tot GRAND TOTAL- This sets the second counter to count the Grand Total.

ba tot BATCH TOTAL- This sets the second counter to count the number of Batches.

HI CPS HIGH COUNTS PER SECOND - This sets the unit for high count speeds (0-9.99 kHz)

LO CPS LOW COUNTS PER SECOND – This sets the unit for contact debounce filtering (0-40 Hz)

RATE PORTION OF MENU FOR SETTING RATE VARIABLES

sec SECONDS - The rate display will read in rate per second.

mins MINUTES- The rate display will read in rate per minute.

hours HOURS - The rate display will read in rate per hour.

NOR## NORMALIZING FACTOR - Normalizes (averages) the data being received. Higher settings provide more

normalizing (averaging) for a more stable display. Derived from the equation:

(Old Data x "NOR" + New Data)

("NOR" + 1)

FIGUR ## SIGNIFICANT FIGURE - This sets the amount (1-5) of meaningful figures the unit will display. (RATE DIS

PLAYONLY).FOREXAMPLE:If"2"issetasthegure,arateof273.45willbedisplayedas270.

9

Page 11

DEFINITIONS OF MENU PROMPTS

(continued)

ABBREVIATION DESCRIPTION

DLY## DELAY FACTOR - The amount of time (02 to 24 sec.) the unit will "look" for valid data, before the display

defaults to zero. (RATE DISPLAY ONLY)

LOC LOCK - This portion of the menu allows you to set lock functions (Lock functions apply only to front panel)

1) lock the program (Preset A is still accessible)

2) lock all (locks program & presets; Start & Stop/Reset are accessible).

LC PRG LOCK PROGRAM - This will lock the program. Preset A can be changed, start, stop & reset will function

when the unit is in the lock mode (lock ON).

LC ALL LOCK ALL - This will lock the program and the presets when the unit is in the locked mode. Preset A can

be viewed, but not changed. Start and Stop/Reset buttons will still operate.

CODE LOCK CODE - This message (code) will flash on display for approximately 3 seconds. It will be followed

by a 5 digit number (xxxxx). The number you enter here will be the code to lock and unlock the unit.

RELAY RELAY - This portion of the menu allows you to set your relay operation variables.

preuu PREWARN - When this is selected Relay B energizes when started and drops out at "Preset B" amount

before batch is complete.

TOT RELAY B FOR TOTALIZER - When this is selected relay B will activate when the selected Grand or Batch

total has reached Preset B.

b##.## RELAY B DURATION - This message will appear when "TOT" is selected. It is the duration which the

relay will remain energized (00.01 to 99.99 sec). If 00.00 is selected, the relay will latch until reset. When

the duration is not at 00.00, the Grand/Batch totalizer will autorecycle.

10

Page 12

CALCULATING SCALE FACTORS

The unit has a programmable scale factor to scale the input pulses. It is a 5 digit , floating decimal divider factor. The factor

to enter is the number of pulses per the desired unit of measurement. The factor ranges from 0.0001 to 99999.

Scale factor calculations are simple. Here are some examples:

DECIMAL LOCATION:

When a decimal is desired for display, special care must be taken when programming the Factor (factor) and Decimal

Location (Dp loc). The factor must be entered in pulses per units desired for display. (i.e. pulse per 1 unit, pulses per 0.1

units, pulses per 0.01 units, etc.) The Decimal Location (Dp loc) controls the decimal placement for the display. For each

decimal place you move for Dp loc, you must also move the decimal for the factor (dp f a).

Example: The flow sensor outputs 678.4 pulses per gallon.

To display whole gallons (1 gal) enter 678.4 for the factor

To display tenths of gallons (0.1 gal) enter 67.84 for the factor

To display hundredths of gallons (0.01) gal) enter 6.784 for the factor

SCALING FACTOR EXAMPLES:

Flow Batching: You want to fill a 55.0 gallon drum. The flow sensor gives 387 pulses per gallon.

Solution - Dial in a scale factor of 38.7 (38.7 to display 0.1 gal; 387 for whole gal.)

Under count, set dploc to dplo.c to read tenths of gallons.

Set PRE A at 55.0; Wire Relay A to solenoid valve.

Converting Scale Factors

When different units of measure are given than what is desired, simply convert the given Scale Factors to reflect the desired units using the following calculations.

Pulses Per Unit (given) = Scale Factor

Units Conversion Factor

Use the Units Conversion Chart below when converting the given Scale Factor. Be sure to use the Scale Factor for whole

units and divide it by the proper Conversion Factor.

UNITS CONVERSION CHART

To convert: divide factor by To convert: divide factor by

ft to m 0.3048 kg to lb 2.2046

ft2 to m2 0.0929 l to ft3 0.0353

ft3 to m3 0.02832 l to gal 0.2642

ft3 to gal 7.4805 m to ft 3.2808

gal to l 3.7854 m2 to ft2 10.7639

gal to m3 0.00379 m3 to ft3 35.3147

gal to ft3 0.1337 m3 to gal 264.172

gal to lb (H2O) 8.3378 lb to kg 0.45359

11

Page 13

PROGRAMMING

STEP

1

SETTING

PRESET B

STEP

2

SETTING

SCALING

FACTOR

PRESS

PRGM

ENTER

PRGM

PRGM

ENTER

DISPLAY

pre b

#####

pre b

Factor

dp fac

REMARKS

This section of the menu is used to set

Preset B value.

This is Preset B. To change, press the

arrow key under the digit(s) to change.

Press ENTER to enter the displayed

value.

This section of the menu is used to

set up the scaling factor for the count

input.

This sets the decimal for factor A. Press

the arrow key under the digit where

the decimal is desired. To clear the

decimal, press the arrow key furthest

to the right (PRGM) .

ENTER

#####

This is the scaling factor for the count

input. To change, press the arrow key

under the digit(s) to change. Press

ENTER to enter the displayed value.

12

Page 14

PROGRAMMING

(continued)

STEP

3

SETTING

THE

COUNTER

PRGM

PRGM

PRGM

ENTER

ENTER

ENTER

pre B

factor

count

rst 0

or

set pr

dp loc

gr tot

or

ba tot

This section of the menu sets up the

counter information.

Press the PRGM key to choose RST 0

(reset to 0, count up) or SET PR (set to

preset, count down), press the ENTER

key to enter the displayed choice.

This sets the decimal location for the A

& B counters. Press the arrow key under

the desired digit location. To clear the

decimal, press the arrow key furthest

to the right. Press the ENTER key to

enter the displayed location.

This section sets the second counter

operation. Press the program key to

choose GR TOT (Grand Total) or BA

TOT (Batch Total). Press the ENTER

key to enter the displayed choice.

ENTER

hi cps

or

lo cps

Press the PRGM key to choose

HIGH CPS (0-9.99KHz) or LOW CPS

(0-40Hz). Press the ENTER key to

enter the displayed choice.

13

Page 15

STEP

4

SETTING

THE RATE

PRGM

PRGM

PROGRAMMING

(continued)

REMARKSPRESS DISPLAY

pre b

factor

PRGM

PRGM

ENTER

ENTER

ENTER

ENTER

count

rate

secs

mins

or

hours

nor ##

figur #

dly #.#

This section of the menu is used to set up

the rate information.

Press the PRGM key to choose secs (rate

per second), mins (rate per minute)or

hours (rate per hour). Press ENTER to

enter displayed choice.

This sets the normalizing (averaging) factor. Press the arrow keys under the desired

digits to change. Press ENTER to enter

displayed value.

This sets the number of significant figures

to be displayed. Press the arrow key under

the digit to change. Press ENTER to enter

displayed value.

This sets the delay time (2 to 24 sec.) that

the unit will "look" for valid input data before

the display falls to 0. Press the arrow key

under the digits to change. Press ENTER

to enter displayed value.

14

Page 16

PROGRAMMING

(continued)

STEP

5

SETTING

LOCK

PRESS

PRGM

PRGM

PRGM

PRGM

PRGM

ENTER

DISPLAY REMARKS

pre b

factor

count

rate

loc

This section of the menu is used to set up the

lockout type and code number.

LC PG = Locks program but presets and reset

LC PG

or

LC ALL

are accessible. (see description)

LC ALL= Locks all keypad buttons except

START, STOP/RESET & VIEW.

Press the PRGM button to toggle between

choices; Press ENTER to enter displayed

choice.

SETTING

THE

LOCK

STATUS

ENTER

LOCK

ENTER

CoDE

Flashes

followed by:

#####

CoDE

Flashes

followed by:

0

LoC

or

uN LoC

After CODE flashes the display will show the

existing lock code. To change the code press

the key under each digit to be changed. Press

ENTER to enter displayed value.

(see below to turn lock ON or OFF)

Key in the lock code (see programming step

4) by pressing the keys under the digits to be

changed. Press the ENTER key to enter the

displayed code.

After the code is entered the unit will display

LOC (unit is locked) or UN LOC (unit is unlocked). This message will be displayed for

approximately 3 seconds before the unit returns to the run mode.

15

Page 17

PROGRAMMING

(continued)

STEP

6

SETTING

THE

RELAYS

PRGM

PRGM

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

DISPLAYPRESS

pre b

factor

count

rate

loc

relay

tot

or

preuu

b##.##

REMARKS

This section sets up the relay information.

Press the PRGM key to choose tot (Relay B

assigned to total) or PREW (Relay B assigned

to prewarn). Press enter when the desired

choice is displayed.

This will only appear if tot selected. This is

the duration (.01 to 99.99 sec) that relay B

will remain energized. If 00.00 is selected, the

relay will latch until reset.

SETTING

THE

PRESETS

PRE A

PRGM

PRE A

Followed by

last PRE A

entered

PRE B

PRE A = Preset A (Batch Amount); The set

point at which output A will drop out after

started. If the displayed value is not the desired preset, press the keyunder the digit(s)

to be changed.

PRE B = Preset B ;

a) Tot selected The set point at which

output B will energize.

b) preuu selected The number of counts

before batch ends that

output B will drop out.

If the displayed value is not the desired

preset, press the key under the digit(s) to be

changed.

16

Page 18

TROUBLESHOOTING GUIDE

PROBLEM SOLUTIONSPOSSIBLE CAUSES

Power is applied to unit but the display

does not light.

Unit works, but occasionally the display

freezes or skips counts.

Input signal is connected but the unit

does not count or display rate.

Rate is displaying: r FFFFF.

1. AC or DC power wiring is incorrect.

1. Line noise is affecting the processor

due to a current spike or surge.

1. Input wiring is incorrect.

2. Scale factors are incorrect.

3. Transmitting device is defective.

4. Wrong debounce filtering selected.

5. Batcher is defective.

1. The unit is trying to display a

number which it can't (too small or

too large).

2. Line noise affected unit on power

up.

1. Recheck power wiring

1. Use a different power supply or

install a surge suppressor.

1. Recheck input wiring.

2. Recheck scale factors and factor

calculations.

3. Replace transmitting device.

4. Recheck debounce filtering selection

"hi cps" or "lo cps".

5. To confirm set scale factor at one,

connect a wire to pin #7 and

touch it to pin # 5 (input A). Each

time pin #5 is touched counter A

should count once. If not, call

factory for RMA.

1. Check scaling factor, if it is correct,

lower the number of significant

figures.

2. Reprogram the unit and be sure to

enter a decimal (enter one and re

move it if a decimal is not desired).

Relays are not activating properly.

Grand / Batch Counter resets before

reaching 999999.

Various menu items are not being displayed.

1. START not activated.

2. Wrong relay duration.

3. Relay set for wrong activation

i.e. tot instead of preuu.

1. Relay duration is set at a value

other than 00.00. This causes the

counter to auto-reset at the preset.

1. The menu flow chart and the setup

steps show the setup for units with

all of the available options. Options

not ordered will be suppressed in

the programming menu.

1. Relay A (and B if Prewarn) will only

energize when start is activated.

2. Recheck programmed relay duration.

3. Recheck programmed relay

activation mode.

1. If Relay B output is not being used,

set the relay duration to 00.00.

1. Disregard any menu items

which appear on the flowchart and

setup steps, but do not appear on

the unit's display.

17

Page 19

Loading...

Loading...