Page 1

G8 Portable Fuel Transfer Pump

Owner’s Manual

GENERAL INFORMATION

This pump is designed

for use only with gasoline

(up to 15% alcohol blends

such as E15), diesel fuel

(up to 20% biodiesel

blends such as B20) and

kerosene. Do not use

this pump for dispensing

any uids other than

those for which it was

designed. To do so may damage

pump components and will void the

warranty.

This pump is designed to operate

on a typical 12-volt DC automotive

electrical system. The pump is

designed to operate with 12-volts DC

at the motor leads and the ratings

are determined at this voltage.

Performance may vary due to length

of power cord, battery condition or

output from vehicle charging system

that will affect system voltage.

The rated duty cycle of this pump

is 15 minutes ON and 30 minutes

OFF. Allow the pump to cool for 30

minutes.

Do not leave the system running

without uids. “Dry running” can

damage the pump. If the system fails

to deliver fuel after 15 to 20 seconds,

turn the system off and refer to the

Troubleshooting Section.

NOTE: This pump is not intended for

use with an automatic nozzle.

WARNING: This product shall not be

used for pumping fuel or other liquids

into aircraft.

NOTE: An automatic bypass valve

prevents pressure build up when the

pump is on with the nozzle closed. To

avoid motor damage, do not run the

pump more than 5 minutes with the

nozzle closed.

Do not pump the tank completely

dry, as contaminants from the bottom

of the tank may enter the pump.

IMPORTANT! DO NOT RETURN

THIS PRODUCT TO THE STORE.

Please contact Great Plains

Industries, Inc. before returning

any product. If you are missing

parts, or experience problems

with your installation, contact our

Customer Support Department.

We will be happy to assist you. Call

800-835-0113 or 316-686-7361 or

email: gpisales@gplains.com.

922130-01 Rev-04/2017

Page 2

SAFETY INFORMATION

Observe all safety precautions

concerning safe handling of

petroleum fuels.

If using solvent to clean pump

components or tank, observe

the solvent manufacturer’s

recommendations for safe use and

disposal.

For your safety, please take a

moment to review the warnings

throughout this manual.

To prevent physical injury, observe

precautions against re or explosion

when dispensing fuel. Do not operate

the system in the presence of any

source of ignition including running

or hot engines, lighted cigarettes, or

gas or electric heaters.

Observe precautions against

electrical shock when operating

the system. Serious or fatal shock

can result from operating electrical

equipment in damp or wet locations.

Inspect external pump wiring

regularly to make sure it is in good

condition. To avoid electrical shock,

use extra care when connecting the

pump to power.

Avoid prolonged skin contact with

petroleum fuels. Use protective

goggles, gloves, and aprons in

case of splashing or spills. Change

saturated clothing and wash skin

promptly with soap and water.

Observe precautions against

electrical shock when servicing the

pump. Always disconnect power

before repairing or servicing.

Never apply electrical power to the

system when any of the coverplates

are removed.

2

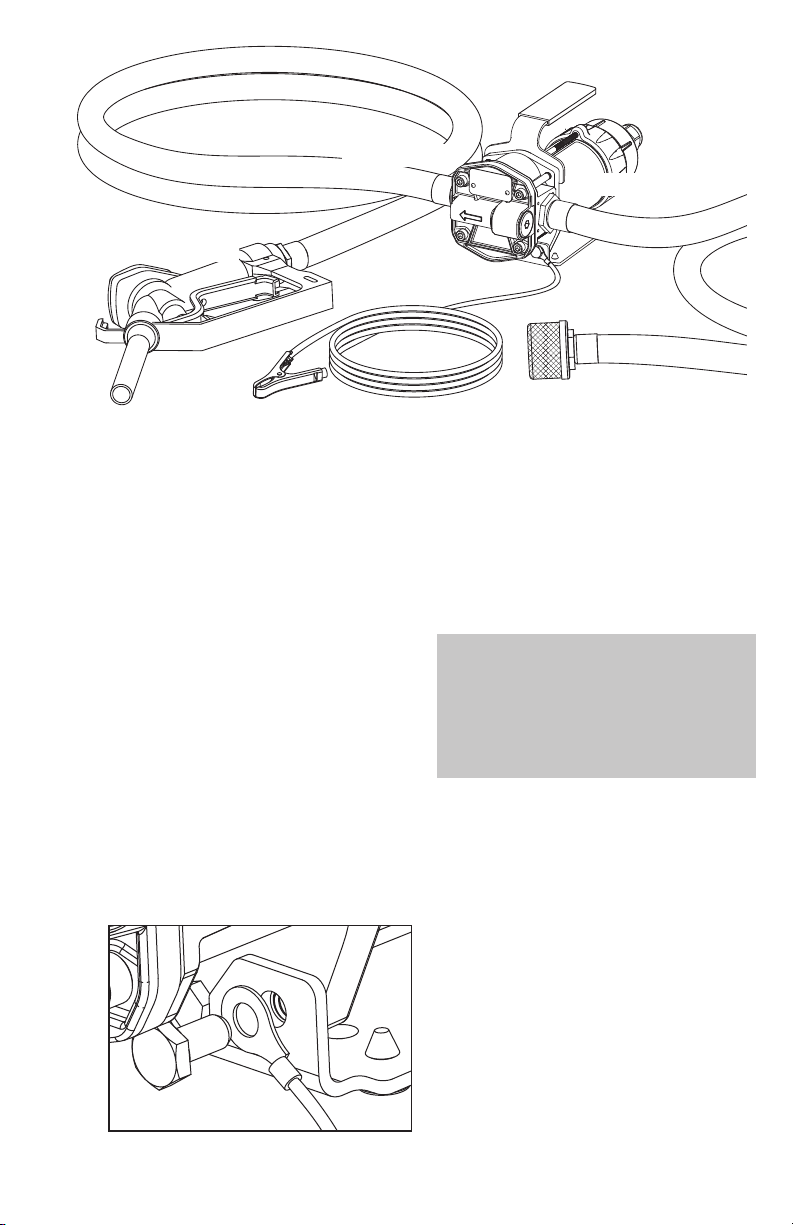

INSTALLATION & OPERATION

Pump Installation

Make sure all threaded fuel

connections are wrapped with three

to four turns of the supplied thread

tape.

Make sure supply tank or container

is vented. A vent cap rated at 3 psi or

less is recommended.

NOTE: These components have

not been evaluated as part of the

UL Listed Equipment and are not

intended for use in a Hazardous

(Classied) Location.

Install Inlet Hose and Strainer

Wrap the threads of one end of the

inlet hose 3 or 4 times with thread

tape (supplied). Install hose end into

inlet side of pump (see Figure 1) and

tighten. Wrap threads on other end

of hose 3 or 4 times with thread tape

(supplied). Install metal strainer and

tighten. To avoid damage to pump

from dirt and debris, do not operate

pump without strainer.

Install Outlet Hose and Nozzle

Wrap the threads of one end of the

outlet hose 3 or 4 times with thread

tape (supplied). Install hose into

outlet side of pump (see Figure 1)

and tighten. Wrap threads on other

end of hose 3 or 4 times with thread

tape (supplied). Install manual nozzle

and tighten. To minimize static

electricity build up and possible

explosion, use only static wire

conductive hose when pumping

Page 3

MANUAL NOZZLE

OUTLET SIDE

INLET SIDE

Figure 1

GROUND WIRE

ammable uids. Keep the ll

nozzle in constant contact with the

container being lled during the lling

process. Sparks or static discharge

will cause explosions.

Install Ground Wire

An external ground wire is provided

for use where required. GPI strongly

recommends grounding your pump

prior to use. To attach the ground

wire, remove one of the 1/4-20 x

1/2” hex head screws and install the

ground wire ring terminal (see Figure

2). Reinstall hex head screw and

tighten securely. Attach the alligator

clamp end of the ground wire to the

earth or chassis ground of the vehicle

your are lling.

STRAINER

Connect to Power Source

NOTE: This pump is designed to

operate on a typical 12-volt DC

automotive electrical system.

DO NOT attempt to connect to a 24volt or 115-volt electrical system.

WARNING: Carefully route the power

cord to the battery, protecting the

power cord from hot surfaces, sharp

edges or anything that could damage

the power cord, resulting in a short

circuit.

A 20-amp inline fuse is supplied on

the power cord’s red wire to protect

the motor and power cord. Connect

the red wire with red clamp to the

positive (ungrounded) side of the

power source. Connect black wire

with black clamp to the negative

(grounded) side of the power source.

Figure 2

NOTE: Power cord components,

such as the switch and fuse, have

not been evaluated as part of the

U. L. Listed equipment.

3

Page 4

SWITCH

Figure 3

FUSE & HOLDER

NOTE: This pump is pre-wired for

installation in CLASS I, DIVISION 2

locations such as portable fuel tanks,

trailers, etc. Connection to a battery

will depend upon the application.

WARNING: This pump is not

intended for use in CLASS I,

DIVISION I locations.

Dispense Fuel

First, insert the nozzle into the

receiving tank, and then turn on the

pump with the inline switch (see

Figure 3). Squeeze the nozzle handle

to start fuel ow. When done, release

the nozzle handle and turn the pump

off at the switch. Always insert nozzle

into tank before turning pump on.

This pump is designed to be selfpriming. If fuel is not delivered within

15 to 20 seconds, turn the pump

off and refer to the Troubleshooting

Section of this manual.

After running the pump for a

maximum of 15 minutes, allow it to

cool for 30 minutes.

When nished refueling, make sure

the pump is turned off at the switch

and disconnect the power cord from

the 12-volt power source.

MAINTENANCE

This pump is designed for minimum

maintenance. Motor bearings are

sealed and require no lubrication.

Inspect the pump and components

regularly for fuel leaks and make sure

the hose and power cord are in good

condition. Keep the pump exterior

clean to help identify leaks.

Do not use this pump for water,

chemicals or herbicides. Dispensing

any uid other than that listed in this

manual will damage the pump. Use

of the pump with unauthorized uids

will void the warranty.

An automatic bypass valve prevents

pressure build up when the pump is

on with the nozzle closed. To avoid

pump damage, do not run the pump

more than 5 minutes with the nozzle

closed.

4

A kit containing O-rings, motor

shaft seal and gears is available for

this pump. To order replacement

kit, contact GPI and ask for part

number #147500-01 Gears and Seals

Overhaul Kit.

Page 5

Inspect and Service Bypass

Poppet

To clean and service the Bypass

Poppet (see Figure 4):

• Remove the bypass plug with

O-ring, Spring, and poppet with

O-ring.

• Wipe parts and poppet cavity

with a clean cloth.

• When inspecting O-rings, look

for breaks, wear, and signs of

deterioration, such as swelling.

• Replace O-rings as necessary.

• Before seating, coat O-rings with

light grease.

• Make sure O-rings are well seated

and reinstall bypass poppet

assembly.

• Before installing the plug, unwrap

thread 3 or 4 times with thread

tape. Torque plug to 90 - 100

in•lbs.

Figure 4

PLUG

PLUG

O-RINGS

POPPET O-RING

POPPET

SPRING

Inspect and Service Gears

To clean and service gears

(See Figure 5):

• Remove the (4) 1/4-20 socket

head screws, (2) hex nuts, handle

and gear coverplate.

• Remove coverplate O-ring and

inspect for wear or damage.

Replace as needed.

• Before seating, coat O-rings with

light grease.

• Remove the gears and inspect for

wear or damage. Replace gears

as needed, making sure they turn

freely.

• Reinstall, coverplate, handle nuts

and hex screws (longer screws

are on top. Torque hex screws to

75 -85 in•lbs.

Inspect and Replace Motorshaft

Seal

To inspect and replace shaft seal

(See Figure 5):

• Remove the (4) 1/4-20 socket

head screws, (2) hex nuts, handle

and gear coverplate.

• Remove the pump housing. The

motorshaft seal is located on the

backside of the pump housing.

• Carefully remove shaft seal,

(noting orientation) and inspect

for wear or damage. Replace as

needed, making sure seal is well

seated in recess.

• Reinstall all parts. Torque hex

screws to 75 -85 in•lbs.

COVERPLATE

O-RINGS

Figure 5

MOTORSHAFT SEAL

GEARS

5

Page 6

TROUBLESHOOTING

MOTOR DOES NOT RUN

PROBABLE CAUSE SOLUTION

Inpect for defective wiring or

Electrical connection is faulty

Fuse is blown

Motor is burned out Inspect and replace as necessary

MOTOR RUNS BUT DOES NOT PUMP FLUID

PROBABLE CAUSE SOLUTION

Fuel level is low Fill tank

System air leak

LOW FLOWRATE

PROBABLE CAUSE SOLUTION

improper electrical connections.

Repair as needed

Inspect fuse in fuse holder. If blown,

replace

Tighten all pump ttings and

connections. Inspect hoses for leaks

or damage. Replace as needed

Strainer is clogged Clean strainer

Tighten all pump ttings and

System air leak

Fuel tank is empty Fill tank

Poor connections or low voltage

For further assistance, visit gpi.net/solutions-center or call 1-800-835-0113.

6

connections. Inspect hoses for leaks

or damage. Replace as needed

Make sure electrical connections are

secure. Also, check battery voltage

Page 7

SPECIFICATIONS

APPLICATIONS

The G8 Fuel Transfer Pump is

designed to safely transfer low

viscosity petroleum fuels such as

gasoline (up to 15% alcohol blends

such as E15), diesel fuel (up to 20%

biodiesel blends such as B20) and

kerosene.

PUMP HOUSING

Corrosion-resistant aluminum

PERFORMANCE

Pump Rate:

Duty Cycle:

Up to 8 GPM

(30 LPM)

15 min. ON,

30 min. OFF

Suction Lift: Up to 5.5 ft. (1.7 m)

OPERATING TEMPERATURE

-20°F to +125°F (-29°C to +52°C)

OPERATING PRESSURE

10 PSI / 0.69 bar

ELECTRICAL

Input: 12-volt DC

Current Draw: 15 amp

1100 RPM,

Motor:

1/10 HP,

Listed to UL and

Canadian Standards

MECHANICAL CONNECTIONS

Inlet: 3/4” NPT

Outlet: 3/4” NPT

SHIPPING WEIGHT

15.4 lbs / (6.9 kg)

PARTS & SERVICE

In order to preserve the UL Listing for

the motor, do not attempt to service

the motor. For products serviced

outside the factory, the UL nameplate

must be defaced to indicate that

the equipment may no longer meet

the requirements for UL Listing. This

does not apply to products serviced

outside the factory under the UL

program for Rebuilt Motors for Use in

Hazardous Locations.

For warranty consideration, parts,

or other service information, please

contact your local distributor. If you

need further assistance, contact the

GPI Customer Service Department

in Wichita, Kansas, during normal

business hours.

A toll free number is provided for

your convenience.

1-800-835-0113

To obtain prompt, efcient service,

always be prepared with the

following information:

• The model number of your pump.

• The serial number or

manufacturing date code of your

pump.

• Part descriptions and numbers.

For warranty work, always be

prepared with your original sales slip

or other evidence of purchase date.

Please contact GPI before returning

any parts. It may be possible to

diagnose the trouble and identify

needed parts in a telephone call.

GPI can also inform you of any

special requirements you will need

to follow for shipping fuel dispensing

equipment.

CAUTION: Do not return the

pump or parts without prior

approval from the GPI Customer

Service Department. Due to strict

government regulations, GPI cannot

accept parts unless they have been

drained and cleaned.

7

Page 8

LIMITED WARRANTY

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205, hereby

provides a limited warranty against defects in material and workmanship on all products

manufactured by Great Plains Industries, Inc. This product includes a 2 year warranty from

date of purchase as evidenced by the original sales receipt. A 30 month warranty from

product date of manufacture will apply in cases where the original sales receipt is not available. Reference product labeling for the warranty expiration date based on 30 months from

date of manufacture. Manufacturer’s sole obligation under the foregoing warranties will be

limited to either, at Manufacturer’s option, replacing or repairing defective Goods (subject to

limitations hereinafter provided) or refunding the purchase price for such Goods theretofore

paid by the Buyer, and Buyer’s exclusive remedy for breach of any such warranties will be

enforcement of such obligations of Manufacturer. The warranty shall extend to the purchaser

of this product and to any person to whom such product is transferred during the warranty

A. the product has been altered or modied outside

the warrantor’s duly appointed representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been installed or operated other than in accordance with the manufacturer’s operating instructions.

period. This warranty shall not apply if:

To make a claim against this warranty, contact the GPI Customer Service Department at

316-686-7361 or 800-835-0113. Or by mail at:

Great Plains Industries, Inc.

5252 E. 36

th

St. North

Wichita, KS, USA 67220-3205

The company will step you through a product troubleshooting process to

determine appropriate corrective actions.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY FOR

DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE

USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or tness for any

particular purpose other than for which it was designed.

This warranty gives you specic rights and you may also have

other rights which vary from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702

(governs the resale availability of the warranty terms).

© 2017 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc. / 800-835-0113 / GPI.net

922130-01 Rev- 04/2017

Loading...

Loading...