Page 1

Industrial Grade

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

1- 888 -99 6-3 837

09 COMPUTER

ELECTRONICS

Owner’s Manual

09/11

Rev. F 920709-05

Page 2

To the owner…

Congratulations on receiving your

GPI Industrial Grade Computer

Electronics. We are pleased to provide you with a product designed

to give you maximum reliability and

efciency.

Our business is the design, manufacture, and marketing of liquid handling, agricultural, and recreational

products. We succeed because we

provide customers with innovative,

reliable, safe, timely, and competitively-priced products. We pride

ourselves in conducting our business

with integrity and professionalism.

We are proud to provide you with a

quality product and the support you

need to obtain years of safe, dependable service.

President

Great Plains Industries, Inc.

TABLE OF CONTENTS

General Information

Installation

Operation

Calibration

.................................... 3

...................................... 4

.................................... 5

User Conguration........................ 6

Maintenance

Troubleshooting

Specications

Parts

........................................... 10

Service........................................ 10

WEEE Directive

...................... 2

................................. 7

............................ 8

............................... 9

.......................... 10

GENERAL INFORMATION

This manual will assist you in operating and maintaining the Computer Electronics of the GPI Industrial Grade Meters. (See Figure 1)

Calibration details are given in this

manual. Information on turbine housings and accessory modules are

contained in other manuals. Please

reference those as necessary.

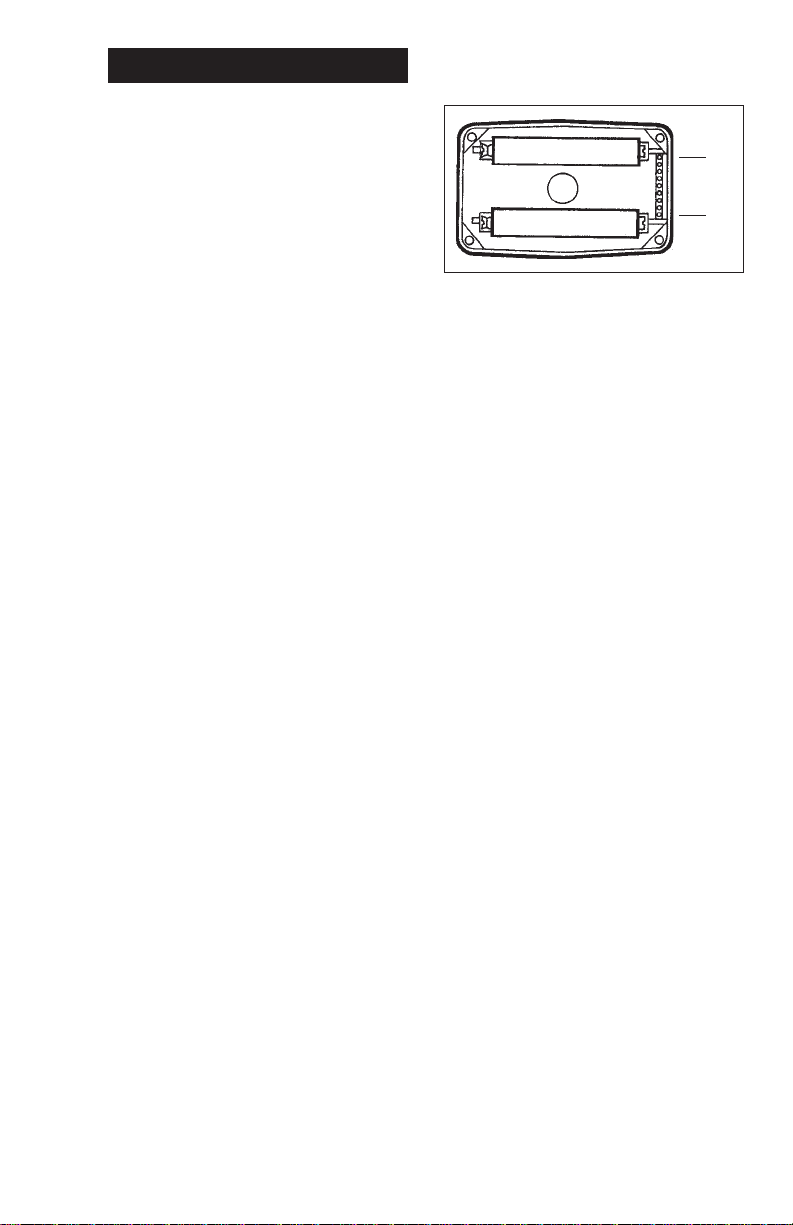

Figure 1

Turbine Housing

Computer Electronics

(Sold Separately)

2

Before Getting Started

Take the time to fully acquaint yourself with all information about the

components of your GPI Electronic

Digital Meter. If you need assistance,

contact the distributor from whom

you purchased your computer.

This symbol is used throughout the manual to call your

attention to safety messages.

WARNING

CAUTION

Warnings alert

you to the potential for personal

injury.

Caut i o n s call

your attention to

practices or procedure s w h i c h

may damage your

equipment.

Page 3

Notes give information that can

improve efciency of operations.

It is your responsibility to make sure

that all operators have access to adequate instructions about safe operating and maintenance procedures.

Read Me!

For your safety, review the major

warnings and cautions below before

operating your equipment.

WARNING

The apparatus enclosure may

contain aluminum and is considered to constitute a potential risk

of ignition by impact or friction.

Care must be taken into account

during installation and use to

prevent impact or friction.

WARNING

Part of the enclosure is constructed from plastic. To prevent

the risk of electrostatic sparking

the plastic surface should only

be cleaned with a damp cloth.

1. This equipment is approved to

handle only uids that are compatible with all wetted materials.

2. Wh en me asur ing fl amma ble

liquids, observe precautions

against re or explosion.

3. When handling hazardous liquids, always follow the liquid

manufacturer’s safety precautions.

4. Wh en working in haz ardous

environments, always exercise

appropriate safety precautions.

5. For best results, always verify

accuracy before use.

Product Description

These computer electronics are

designed specically for use on GPI

Industrial Grade Turbine Housings.

They are also designed to work with

several accessory output modules.

The CMOS, microprocessor-based

electronics have extremely low power requirements and data retention

capabilities in both RAM and ROM.

Information is clearly displayed on

a large 6-digit LCD readout with

two-point oating decimal for totals

from .01 to 999,999. All operations

are easily accessed with the two

buttons on the front panel.

Liquid flows through the turbine

housing causing an internal rotor to

spin. As the rotor spins, an electrical

signal is generated in the pickup coil.

This pulse data is translated from

the turbine into calibrated ow units

shown on the computer’s readout.

Upon receipt, examine your equipment for visible damage. The compu ter is a prec isio n meas urin g

instrument and should be handled as

such. If any items appear damaged

or missing, contact your distributor.

Make sure your computer model

meets your specic needs. Refer to

the Specications Section to conrm

required features. The model number

of your computer is displayed on the

lower front side of the computer and

also underneath a battery.

INSTALLATION

If you ordered your computer electronics with a turbine housing, it is

installed at the factory.

If you ordered your computer separately from your turbine, simply mount

the computer on the turbine with the

four screws at the corners of the

faceplate. Make sure the seal is fully

seated before tightening the screws.

3

Page 4

If you ordered the computer with

turbine and an accessory module,

please review and thoroughly understand all installation instructions

before proceeding.

All GPI turbines are designed to

measure ow in only one direction.

The direction is indicated by the arrow cast-molded in the turbine outlet.

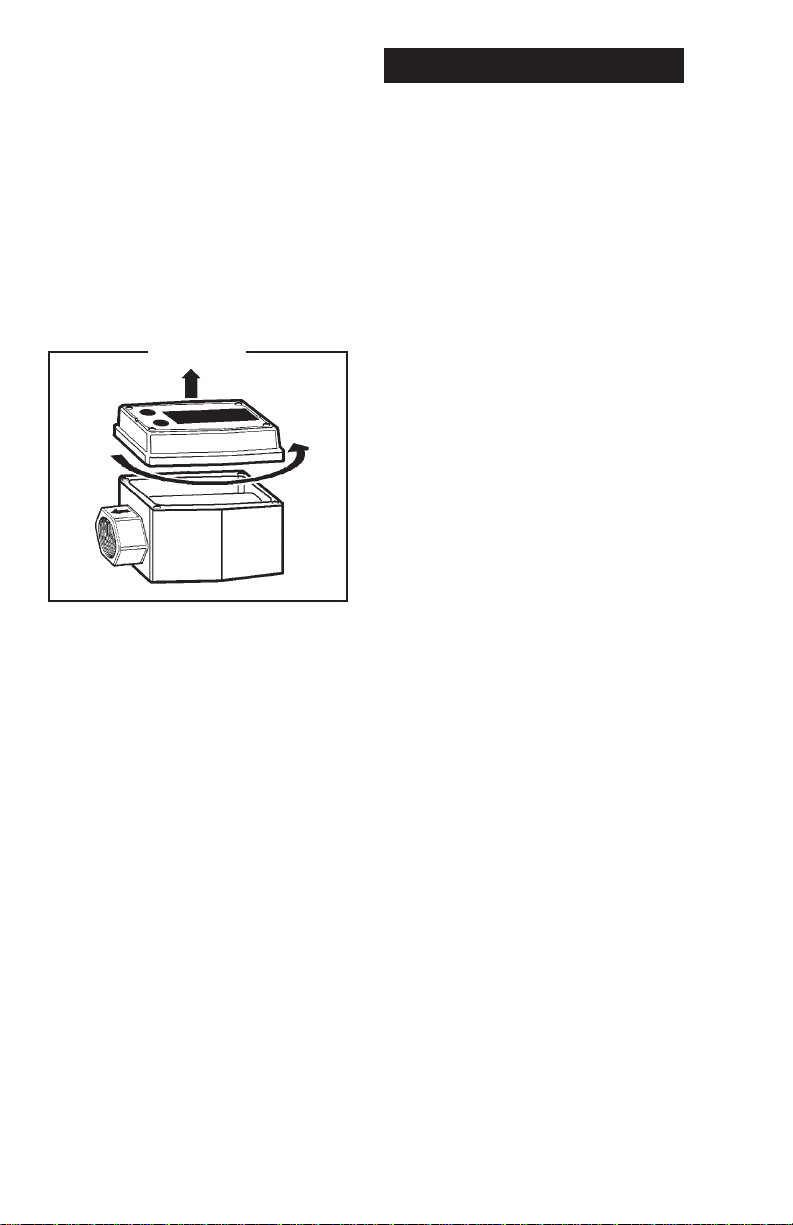

If the computer display is upside

down, remove the four screws, turn

the display 180 degrees and reinstall

the screws. See Diagram 1.

Diagram 1

Avoid electronically “noisy” environments. Install at least 6 inches

(15.2 cm) away from motors, relays,

or transformers.

Our computer electronics are Factory

Mutual Approved, C-UL Classied

and carry a Class 1, Division 1 Approval for hazardous environments.

In addition, GPI meters have NEMA

Type 4 enclosures.

To ensure accurate measurement,

remove all air from the system before use.

It is strongly recommended that accuracy be veried prior to use. To do

this, remove all air from the system,

measure an exact known volume

into an accurate container, and verify

the volume against the readout or

recording equipment. If necessary,

use a correction factor to gure nal

volume. For best results, accuracy

should be veried periodically as part

of a routine maintenance schedule.

4

OPERATION

Computer Display

All operations are reected in the

LCD readout. The large center digits

indicate amounts, where smaller

words or “icons” located above and

below indicate specic information

regarding totals, ow, calibration and

units of measure.

Activate the Meter

Computer is on continuously and always ready to perform. The computer

is powered by eld replaceable batteries. When display becomes dim,

faded or the low battery message

appears (see below), the batteries

need to be replaced. Reference the

Maintenance Section for details.

Batch and Cumulative

Totals

The computer maintains two totals.

The Cumulative Total provides continuous measurement and cannot

be manually reset. The Batch Total

can be reset to measure ow during

a single use. The Cumulative Total is

labeled with TOTAL 1, Batch Total is

labeled TOTAL 2 BATCH.

When the Cumulative Total reaches

a display reading of 999,999 the

computer will highlight an X10 icon.

This indicates to the operator that a

zero must be added to the 6 digits

shown. When the next rollover occurs,

the computer will highlight an X100

icon. This indicates to the operator

that two zeroes must be added to

the 6 digits shown.

Press the DISPLAY button briey to

switch between the TOTAL 1, TOTAL

2 BATCH and FLOWRATE. Press

DISPLAY briey to display the TOTAL

2 BATCH. Hold the DISPLAY button

for 3 seconds to reset the Batch Total

to zero.

Page 5

When uid is owing through the

meter, a small propeller icon is highlighted.

NOTE: Totalization counts total units

without differentiating between

gallons, litres or eld calibrated

units.

Flowrate Feature

(some models)

To use this feature, press and release DISPLAY until FLOWRATE

icon appears. The factory set time

base will be highlighted to the right of

FLOWRATE (M = minutes, H = hours,

D = days). When FLOWRATE is invoked, the display will be indicating

rate of ow.

Switching between different units will

not corrupt the Total’s contents. For

example, in GL mode, the computer

totalizes 10.00 gallons, if the user

switches to LT mode, the display will

read 37.85 litres (the same volume,

different unit).

The “eld” calibration may be set by

the user, and can be changed or modied at any time using the calibration

procedure described in the Calibration Section. Totals or owrate derived

from the eld calibration are invoked

when the FAC icon is no longer visible

on the top line of the display.

CALIBRATION

Factory and Field

Calibration

All calibration information is visible to

the user as icons on the top line of

the display, above the numeric digits.

All units are congured with a “factory” calibration. Both gallons and

litres are available (“GL” or “LT” will

be displayed). While holding the

CALIBRATE button, briey press

DISPLAY to toggle between gallons

and litres. This factory calibration

(indicated with FAC) is permanently

programmed into the computer and

is not user adjustable.

NOTE: Your computer may have oth-

er units of measure programmed

into it. If so, holding the CALIBRATE button and momentarily

pressing the DISPLAY button

will toggle through all factory set

units. Other possible units are:

IGL (imperial gallon), QT (quart),

CF (cubic feet), CM (cubic meter),

BL (42 gal. barrel), CC (cubic

centimeter) or OZ (ounce).

Verify Accuracy Before

Beginning Field Calibration

For the most accurate results,

dispense at a owrate which best

simulates your actual operating conditions. Avoid “dribbling” more uid or

repeatedly starting and stopping the

ow. This can result in less accurate

calibrations.

Make sure you meet the meter’s

minimum owrate requirements:

1/2 in. meter 1 GPM (3.8 LPM)

3/4 in. meter 2 GPM (7.6 LPM)

1 in. meter 5 GPM (18.9 LPM)

1-1/2 in. meter 10 GPM (37.9 LPM)

2 in. meter 20 GPM (75.7 LPM)

The use of a uniformly dependable,

accurate calibration container is

recommended for the most accurate

results. For best results, the meter

should be installed and purged of air

before eld calibration.

Due to high owrate on the 2 inch

meter, it is strongly recommended

that Field Calibration be completed

with a combination of volume and

weight determined with ne resolution scales.

5

Page 6

Field Calibration Necessity

Field Calibration and Factory Calibration are dened in the Operation

Section. Factory calibration settings

are programmed into each computer

during manufacturing, using stoddard

test solvent at 70° F (21° C) for low ow

and 1-inch meters and water at 70° F

(21° C) for 2-inch meters. Settings are

correct for light liquids such as water,

gasoline or diesel. Readings using

the Factory Calibration (FAC) may

not be accurate in some situations,

for example, “heavy” liquids such as

motor oil, under extreme temperature

conditions, non-standard plumbing

congurations or with uids other

than mentioned above.

For improved accuracy under such

conditions, the computer allows for

“eld” calibration, that is, user entry

of custom calibration parameters. A

“single point” calibration may yield

acceptable accuracy when used in

a non-standard application.

Field Calibration

Procedures

(Correction Factor Method)

1. To calibrate, press and hold the

CALIBRATE and DISPLAY buttons for about 3 seconds until

you see FLdCAL. Release both

buttons and you will see CF - 00.0.

You are now in the eld calibration

mode and values from -99.9% to

+99.9% can be entered.

+

2. The

3. The DISPLAY button can then

/– position appears either

as an “underscore” character for

plus, or as a “hyphen” character

for minus. The DISPLAY button selects the position and the

CALIBRATE button toggles this

character.

be pushed to select the numeric

positions. Press the CALIBRATE

button to scroll from 0 to 9. Enter

the percentage of change you

want the display to correct. When

satised with the value, press

both CALIBRATE and DISPLAY

buttons simultaneously. CALEnd

will be displayed and unit will go

back to normal operation, less the

FAC (factory calibration) icon.

4. All enabled units-of-measure remain visible and selectable – the

entered correction will be applied

to all enabled units.

5. To return to factory calibration

(FAC), press and hold both CALIBRATE and DISPLAY buttons for

about 3 seconds until FAcCAL is

displayed. Then release buttons.

Unit should return to normal operation and FAC icon is visible.

USER CONFIGURATION

The “09” series GPI display has

been programmed with many new

features, most of which can be enabled by the end user by way of a

conguration process. By disabling

“unnecessary” features, day-to-day

owmeter operation can be greatly

simplied, making the unit easier to

use. There are several features that

GPI disables by default when shipping standard meters. (For example,

K-Factor Entry Field Calibration, described below.) For more advanced

users, it may be desirable to enable

ALL possible features. User congurable features include:

• Totalizers/Modes Enabled (Cumu-

lative Total, Batch 2 Total, Flowrate

Mode)

• Flowrate Timebase (Units per

Minutes, Hours and Days)

• Factory Calibration Curve Units

Enabled (Gallons, Imperial Gallons, Litres, Quarts, Ounces, Cubic

Feet, Cubic Centimeters, Cubic

Meters or Barrels (42 gal.)

• Dispense/Display or K-Factor En-

try Calibration

6

Page 7

Changing Conguration

Settings

Access to the configuration process is restricted for security until a

“password” is entered. Contact your

distributor or GPI to get the password

and instructions to unlock and reset

conguration settings. This information is also available on the GPI Web

site. Congurations are entered and

stored as six-digit “codes” where

each digit represents a setting for

one of the conguration options. New

conguration settings are stored in

the computer’s long-term memory

and will not be lost either in OFF

mode or during battery change.

K-Factor Entry Field

Calibration

Presently all GPI computers are

programmed with three different

eld calibration methods, only one

of which is active, the “correction/

factor” calibration procedure described above. It is possible to activate “K-Factor entry” or “dispense/

display” eld calibration by changing

conguration settings. Contact your

distributor or GPI to get the correct

password, conguration code, and

instructions for this calibration method. This information is also available

on the GPI Web site.

MAINTENANCE

When batteries are disconnected or

fail, the Batch and Cumulative Totals

will maintain the value they had.

Factory and Field Calibration Curves

are retained in the meter’s computer

when power is lost.

It is strongly recommended that

battery check and terminal cleaning

be a part of a routine maintenance

schedule. Battery terminals should

be cleaned annually. Batteries can be

replaced without removing the meter

from the piping system.

Replace Batteries

1. Remove the corner screws from

the meter face and lift the computer electronics from the turbine.

2. Remove the batteries.

3. Check the battery terminals and

remove any corrosion.

4. Install the new batteries and

make sure the positive posts

are positioned correctly. When

the batteries are installed correctly, the computer powers on

automatically and the readout

displays information.

5. Make sure the seal is fully seated

before placing the computer electronics on the turbine. Tighten the

four screws.

6. Do not clean exterior of computer

assembly with Isopropyl Alcohol.

The computer electronics is powered

by lithium batteries. Removing the

batteries before storing the meter

will extend battery life. If the meter’s

readout should become dim, blank

or the low battery message appears

(see below), the batteries should be

replaced. Replacement batteries can

be ordered from your distributor or

the factory. See details in the Parts

Section.

7

Page 8

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

A. METER IS 1. Field Calibration not per- Field calibrate again or select Factory

NOT

formed properly Calibration.

ACCURATE

2. Factory Calibration not Perform a Field Calibration according

suitable for liquid being to Calibration Section.

measured

3. Meter operated below Increase owrate.

minimum owrate

4. Meter partially clogged Remove meter. Clean carefully. Make

with dried liquid sure rotor spins freely.

5. Turbine bearings partially Remove meter. Clean carefully. Make

clogged with dried liquid sure rotor spins freely.

6. Sealant material Remove meter. Make sure rotor spins

wrapped around rotor freely.

7. Installed too close to Install correctly.

ttings

8. Installed too close to Install correctly.

motors or electrically

“noisy” environment

B. READOUT 1. Batteries weak, dead, or Remove computer, check and replace

FADED OR

not connected batteries if necessary.

BLANK

2. Computer defective Contact the factory.

C. NORMAL 1. Field Calibration not Field Calibrate again or select Factory

FLOWRATE

performed correctly Calibration.

BUT METER

DOES NOT

freely.

COUNT

3. Sealant material Remove meter. Make sure rotor spins

wrapped around rotor freely.

4. Computer defective Contact the factory.

D. REDUCED 1. Meter clogged with dried Remove meter. Clean carefully. Make

FLOWRATE

liquids sure rotor spins freely.

AND METER

2. Below minimum owrate Increase ow.

DOES NOT

COUNT

E. CANNOT GET 1. Wrong button sequence Proceed with calibration according to

METER INTO

the Calibration Section.

FIELD CALI-

2. Computer circuit board Replace computer. Contact the factory.

BRATION

defective

3. Button defective Replace computer. Contact the factory.

2. Rotor stuck or damaged Remove meter. Make sure rotor spins

8

Page 9

SPECIFICATIONS

Standard Features Include:

• 2 Totalizing Registers

• 1 Factory Calibration Curve

• 1 Field Calibration Curve

• Rate of Flow Feature

• Flowrate Time Base in Minutes

Input Pulse Rate:

Minimum Pulse In: DC

Minimum Coil Input: 10 Hz

Maximum Raw: 1,000 Hz

K-Factor:

Minimum: .01 pulses/unit

Maximum: > 999,999 pulses/

unit

Field Calibration Correction:

Minimum: -99.9%

Maximum: +99.9%

Readout Totals:

Min. Display: 0.01

Max. Display: 999,999 (x100)

Temperatures:

Operational: +0° to +140° F

(-18° to +60° C)

Storage: -40° to +158° F

(-40° to +70° C)

If wider operating temperature

ranges are desired, reference

information on GPI Remote Kits.

Power:

Internal Power

Supply: 2 Lithium

Batteries at

3 volts each

Battery Life: 5 years

Optional

External Power

Module: 7-30-volts DC

Computer Electronics

Terminal Connections

J 1

J 10

J-1 Reset

Programming interfaces. Not

accessible to user.

J-2 Pulse Signal Output

This supplies a high-level am-

plied open collector signal.

Output will withstand a maximum open-circuit voltage of

60-volts DC and a maximum

closed-circuit of 100 mA.

J-4 Pulse Signal Input

Requires a sine or square

wave with open-circuit voltage of 3-30 volts P-P, a maximum rise/fall rate of 0.01 V/µ

second and a maximum frequency of 750 Hz.

J-5 Power Input

Whe n us ed with Gro u nd

(J1-6), this has reverse polarity protection, but no on-board

voltage regulation. Supplied

voltage may be 5-volts to

10-volts DC.

J-6 Ground

J-7, 8, Programming interfaces. Not

accessible to user.

9, 10

NOTE: Safety approvals are void

if any external connections

are made to computer electronics.

9

Page 10

PARTS

The factory, when provided with

model number and serial number,

can replace your entire Computer

Electronics Assembly.

Order replacement kits, parts, and

accessories with the part numbers

given here.

Part No. Description

113520-1 Battery Replacement Kit

901002-52 Seal

116000-1 Large (5 gal.) Calibration

Container

SERVICE

For warranty consideration, parts,

or other service information, please

contact your local distributor. If you

need further assistance, call the

GPI Customer Service Department

in Wichita, Kansas, during normal

business hours.

1-888-996-3837

To obtain prompt, efcient service,

always be prepared with the following information:

1. The model number of your com-

puter electronics.

2. The serial number or manufactur-

ing date code of your computer

electronics.

3. Specic information about part

numbers and descriptions.

For warranty work always be prepared with your original sales slip

or other evidence of purchase date.

Returning Parts

Please contact the factory before returning any parts. It may be possible

to diagnose the trouble and identify

needed parts in a telephone call. GPI

can also inform you of any special

handling requirements you will need

to follow covering the transportation

and handling of equipment which has

been used to transfer hazardous or

ammable liquids.

CAUTION

Do not return computer electronics or meters without specic

authority from the GPI Customer

Service Department. Due to strict

regulations governing transportation, handling, and disposal of

hazardous or ammable liquids,

GPI will not accept computer

electronics or meters for rework

unless they are completely free

of liquid residue.

CAUTION

Meters not ushed before shipment can be refused and returned to the sender.

WEEE DIRECTIVE

The Waste Electrical and

Electronic Equipment (WEEE)

directive (2002/96/EC) was

approved by the European

Parliament and the Council of

the European Union in 2003.

This symbol indicates that this

product contains electrical and

electronic equipment that may

include batteries, printed circuit boards, liquid crystal

displays or other components that may be subject

to local disposal regulations at your location. Please

understand those regulations and dispose of this

product in a responsible manner.

10

Page 11

Declaration of Conformity

Manufacturer’s Name: Great Plains Industries, Inc.

Manufacturer’s Address: 5252 East 36th Street North

Wichita, KS USA 67220-3205

Declares, that the product:

Product Name: Electronic Digital Meter

Model Numbers: 03*****

A1***********

A2***********

G2*********

Model numbers include all combinations

of an alpha-numeric series as illustrated above.

Conform to the following Standards:

EMC: EN 50081-1 (Reference EN 55022)

EN 50082-1

Energy - Limited Apparatus: EN 50021

I.P. Code: BS EN 60529

Supplementary Information:

“The products comply with the requirements of the EMC

Directive 89/336/EEC and the ATEX Directive 94/9/EC

(ANNEX VIII).”

I, the undersigned, hereby declare that the equipment specied above

conforms to the above Directive(s) and Standard(s).

Signature:

Full Name: Mr. Grant Nutter

Position: President

Great Plains Industries, Inc.

Place: Wichita, KS USA

May 2003

11

Page 12

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

1- 888 -99 6-3 837

Limited Warranty Policy

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205,

hereby provides a limited warranty against defects in material and workmanship on all

products manufactured by Great Plains Industries, Inc. This product includes a 1 year

warranty. Manufacturer’s sole obligation under the foregoing warranties will be limited

to either, at Manufacturer ’s option, replacing or repairing defective Goods (subject

to limitations hereinafter provided) or refunding the purchase price for such Goods

theretofore paid by the Buyer, and Buyer’s exclusive remedy for breach of any such

warranties will be enforcement of such obligations of Manufacturer. The warranty shall

extend to the purchaser of this product and to any person to whom such product is

transferred during the warranty period.

The warranty period shall begin on the date of manufacture or on the date of purchase

with an original sales receipt. This warranty shall not apply if:

A. the product has been altered or modied outside the warrantor’s duly appointed

representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has

been installed or operated other than in accordance with the manufacturer’s

operating instructions.

To make a claim against this warranty, contact the GPI Customer Service Department

at 316-686-7361 or 888-996-3837. Or by mail at:

The company shall, notify the customer to either send the product, transportation prepaid,

to the company at its ofce in Wichita, Kansas, or to a duly authorized service center.

The company shall perform all obligations imposed on it by the terms of this warranty

within 60 days of receipt of the defective product.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES

INCURRED IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED

HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or tness

for any particular purpose other than for which it was designed.

This warranty gives you specic rights and you may also have other rights which vary

from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part

702 (governs the resale availability of the warranty terms).

Great Plains Industries, Inc.

5252 E. 36

th

St. North

Wichita, KS, USA 67220-3205

Factory Mutual Approved

Intrinsically Safe for Class I, II, III, Division 1, All Groups.

GPI is a registered trademark of Great Plains Industries, Inc.

© 2011 by GREAT PLAINS INDUSTRIES, INC., Wichita, KS.

Printed in U.S.A.

09/11

Rev. F 920709-05

Loading...

Loading...