Page 1

5252 East 36th Street North

Wichita, KS USA 67220-3205

TEL: 316-686-7361

FAX: 316-686-6746

FM-300H and

FM-300HR

Electronic Disc Meter Owner’s Manual

06/10

Rev. C 920679-06

Page 2

To the owner…

Congratulations on receiving your GPI

Electronic Disc Meter. We are pleased to

provide you with a meter designed to give

you maximum reliability and efficiency.

Our business is the design manufacture,

and marketing of liquid handling, agricultural, and recreational products. We

succeed because we provide customers

with innovative, reliable, safe, timely, and

competitively-priced products. We pride

ourselves in conducting our business with

integrity and professionalism.

We are proud to provide you with a quality product and the support you need to

obtain years of safe, dependable service.

President

Great Plains Industries, Inc.

TABLE OF CONTENTS

General Information ............................ 2

Before Installation ............................... 3

Installation .......................................... 3

Before Each Use ................................. 3

Operation ............................................ 4

Calibration .......................................... 5

Maintenance ....................................... 6

Troubleshooting .............................9-10

Illustrated Parts List .......................... 11

Specifications ................................... 12

Service .............................................. 12

2

GENERAL INFORMATION

This manual assists you in operating and

maintaining your meter. Please take a few

moments to acquaint yourself with the

information here.

If you need assistance, contact the dealer

from whom you pur chased your meter.

If You Measure in Litres

This manual commonly refers to “gallons.” If your meter is factory calibrated in

litres, consider all references to “gallons”

apply equally to “litres.”

This symbol is used throughout

the manual to call your attention

to safety messages.

WARNING

CAUTION

Notes give you information that can

improve efficiency of opera tions.

It is your responsibility to:

• make sure all operators have access to

adequate instructions about safe operating and maintenance procedures.

• know and follow all safety precautions as specified by your chemical

manufacturer for handling of the fluid

being metered.

Warnings alert you

to the potential for

personal injury.

Cautions call your

attention to practices or procedures

which may cause

damage to your

equipment.

Read Me!

For your safety, review the major warnings and cautions below before operating

your meter.

1. This meter is approved to handle

water, pesticides, fertilizers, and

most industrial fluids. Do not use for

gasoline, diesel or other fluids. Do not

use this meter with flammable liquids.

Page 3

2. When handling hazardous chemicals,

always follow the chemical manufacturer’s safety precautions. Wear

protective clothing such as goggles,

gloves, and respirators, as instructed.

3. To avoid damage, DO NOT blow

compressed air through the meter.

Your electronic disc meter is designed

for measuring a wide range of chemicals.

The meter translates flow data from the

nutator disc into calibrated units shown

on the meter’s readout. A field replaceable battery provides power.

BEFORE INSTALLATION

Upon receipt, examine your meter for

visible damage. Remove protective plugs

and caps for a thorough inspection. If any

items are damaged or missing, contact

your distributor.

CAUTION

To avoid damage, DO NOT blow

compressed air through the meter.

3. Replace the gasket and battery

cover and tighten securely. Torque

the screws to 9 to 10 in. lbs.

INSTALLATION

NOTE: To avoid damage to the inlet

and outlet, install this meter ONLY

on plastic hose end or pipe fittings.

1. To protect against leakage, seal all

threads with two or three turns of

®

Teflon

tape or a pipe thread sealant compatible with the liquid being

measured. Make sure the Teflon

tape or sealant does not interfere

with flow.

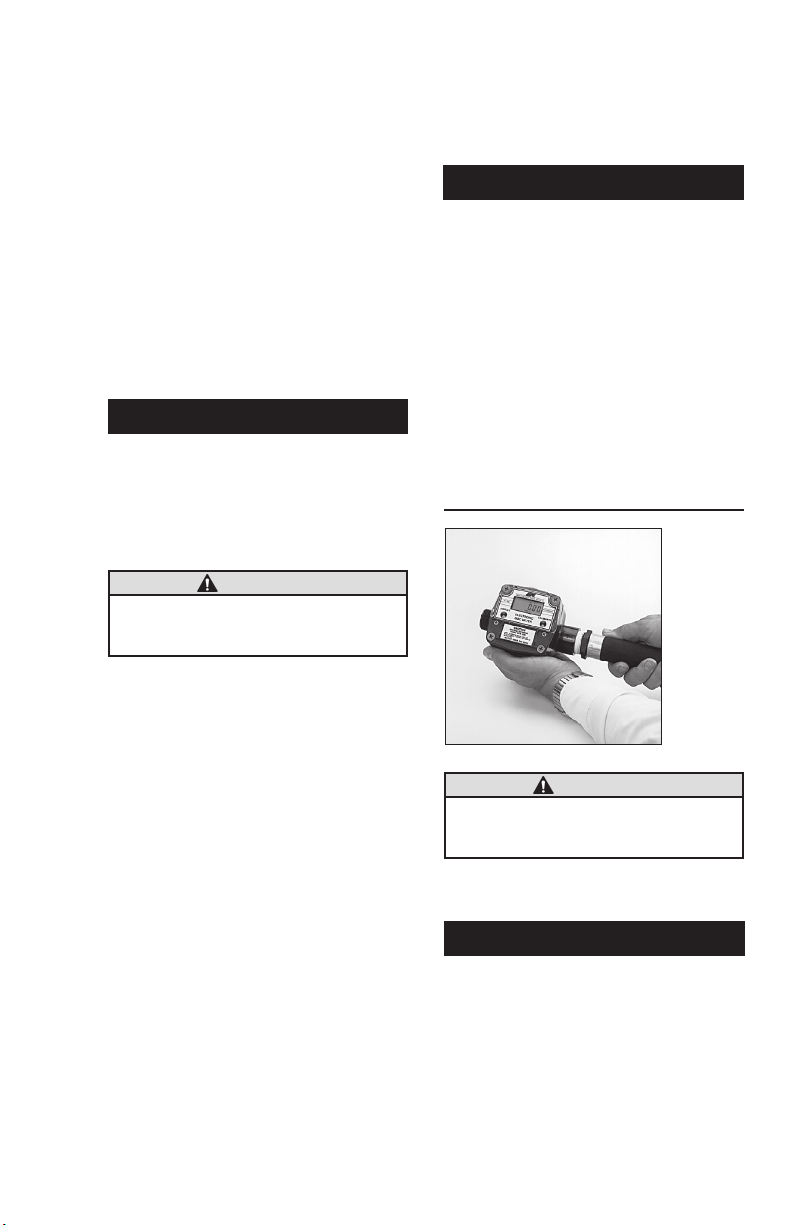

2. Hand-tighten the meter onto the fittings until snug. (Figure 1)

®

Figure 1

If the meter is located in a rigid piping

system where the fluid is trapped (for

example, by gravity, valves or nozzles)

thermal expansion of the fluid can create

pressure spikes that can damage a meter.

Install a thermal relief valve or otherwise

allow for thermal expansion of the fluid.

Connect Battery

To save power, this meter is shipped with

the battery disconnected. Before using,

connect the battery using the instructions below:

1. Remove the two large and two small

screws from the battery coverplate

located on the lower portion of the

meter face.

2. Remove the battery and plug into

battery connections. When connected properly, numbers appear in

the meter readout.

CAUTION

To avoid damage to the housing,

DO NOT use a wrench.

BEFORE EACH USE

If the meter has been used before, make

sure it is flushed and cleaned as outlined

in the Maintenance Section.

Press and release the DISPLAY button to

ensure the meter is operating. Numbers

will display from the last use.

3

Page 4

If the display becomes dim, faded or the

low battery message appears (see below),

battery needs to be replaced. Reference

the Maintenance Section for details. Also

check battery terminals for corrosion. To

prevent corrosion from condensation,

coat the terminals with petroleum jelly.

Verify Meter Accuracy

Before using, verify calibration and check

the meter’s accuracy.

1. If desired, hold down DISPLAY for

three seconds to zero the meter’s

Batch Total. When zeros appear,

release the button.

2. Meter an exact known volume into

an accurate container. For best results, meter with one continuous full

stream.

3. Check the readout. If the amount

metered is accurate, field calibration is not needed. If not, refer to

the Calibration Section for further

instructions.

NOTE: Best performance can be ob-

tained by using the factory calibration.

OPERATION

WARNING

This meter is approved to handle

water, pesticides, fertilizers and

most industrial fluids. Do not use

for gasoline, diesel or other fuels.

Do not use this meter with flammable liquids.

Computer Display

All operations are reflected in the LCD

readout. The large center digits indicate

amounts, where smaller words or “icons”

located above and below indicate

specific information regarding totals, flow,

calibration and units of measure.

Activate the Meter

Computer is on continuously and always

ready to perform. The computer is

powered by a field replaceable battery.

When display becomes dim, faded or the

low battery message appears, the battery

needs to be replaced. Reference the

Maintenance Section for details.

Batch and Cumulative Totals

The computer maintains two totals. The

Cumulative Total provides continuous

measurement and cannot be manually

reset. The Batch Total can be reset to

measure flow during a single use. The

Cumulative Total is labeled TOTAL 1,

Batch Total is labeled TOTAL 2 BATCH.

When the Cumulative Total reaches a

display reading of 999,999 the computer

will highlight an X10 icon. This indicates to

the operator that a zero must be added to

the 6 digits shown. When the next rollover

occurs, the computer will highlight an

X100 icon. This indicates to the operator

that two zeros must be added to the 6

digits shown.

Press the DISPLAY button briefly to switch

between the TOTAL 1, TOTAL 2 BATCH

and FLOWRATE (if applicable). Press

DISPLAY briefly to display the TOTAL 2

BATCH. Hold the DISPLAY button for 3

seconds to reset the Batch Total to zero.

When fluid is flowing through the meter, a

small propeller icon is highlighted.

4

Page 5

Flowrate Feature

Some models have of Rate of Flow

mode. To use this feature, press and

release DISPLAY until FLOWRATE icon

appears. The factory set time base will

be highlighted to the right of FLOWRATE

(M = minutes). When FLOWRATE is

invoked, the display will be indicating

rate of flow.

CALIBRATION

Factory and Field Calibration

All calibration information is visible to the

user as icons on the top line of the display,

above the numeric digits.

All units are configured with a “factory”

calibration. Some models are calibrated

with gallons (GL) and others calibrated

with litres (LT). This factory calibration

(indicated with FAC) is permanently

programmed into the computer and is

not user adjustable.

The “field” calibration may be set by the

user, and can be changed or modified at

any time using the calibration procedure

described in the Calibration Section.

Totals or flowrate derived from the field

calibration are invoked when the FAC

icon is no longer visible on the top line

of the display.

Field Calibration

Factory calibration settings are customprogrammed into each flowmeter during

production, and are correct for light fluids

such as water or heavier liquids like pesticides or light oil. However, readings using

the standard factory calibration curves

may not be accurate in some situations –

variations in chemical formulation, viscosity, temperature, and flowrates all effect

meter accuracy. To ensure accuracy, it is

important to check accuracy frequently

and field calibrate when necessary.

Field Calibration Procedures

(Dispense/Display Method)

1. To field calibrate, press and hold the

CALIBRATE and DISPLAY buttons

for about 3 seconds until you see

FLdCAL. Release both buttons and

you will see dd000.0. You are now in

the field calibration mode.

2. Dispense a known amount of fluid

at a flowrate representative of the

application. Any amount between .1

and 999.9 units can be used. Display

will count up while fluid is flowing

through the meter.

3. The DISPLAY button can then be

pushed to select the digit location

and the CALIBRATE button can be

pushed to scroll the desired value at

the blinking position. Edit the amount

shown with the value that was dispensed above. Values from 000.1 to

999.9 can be entered.

4. When satisfied with the value, press

both CALIBRATE and DISPLAY buttons simultaneously. CALEnd will

be displayed and unit will go back

to normal operation, less the FAC

(factory calibration) icon.

5. The meter will now be operating with

a custom calibration number unique

to the above dispense procedure. No

unit of measure (gallon, litre, etc.) icon

will be highlighted.

NOTE: If the field calibration mode is

entered and NO fluid is dispensed,

then upon leaving, the computer will

use data from the last successful field

calibration.

5

Page 6

Calibration Container

The desired calibration container should

be uniformly dependable and constructed

with a graduated neck. The container’s

volume indicator should be clearly and

precisely marked. It is helpful if the

container’s material allows a window

through which the level of liquid can be

viewed. GPI offers a properly designed

calibration container for volumes of 5

gallons or 5 litres.

DO NOT use several smaller containers or

a larger container with a 5-gallon marking.

For the most accurate results, dispense

at flowrates that best simulate your actual

operating conditions. Avoid “dribbling”

more fluid or repeatedly starting and stopping the flow. These actions will result in

less accurate calibrations.

During calibration, make sure you meet

the meter’s minimum flowrate requirements of 2 GPM (7 LPM).

Before calibrating, purge the system of

air using instructions in the Before Each

Use section.

1. Ensure all chemical is drained from

the meter. This could include draining

the hose, meter and nozzle.

2. Wearing protective clothing, loosen

the meter from fittings by hand.

CAUTION

To avoid damage to the housing, do

not use a wrench.

If the meter is not immediately installed

again, cap the hose end to prevent spills

and drying. The nozzle could be used for

this purpose. Flush the meter if it will not

be in use for more than two weeks.

Flushing

When removed or not in use for more than

two weeks, flush the meter to remove

chemical residue.

CAUTION

Do not submerge the meter.

If needed, clean the meter using Cleaning

instructions.

MAINTENANCE

This meter is virtually maintenance free.

It is important, however, that the nutator

disc moves freely.

To prevent drying of chemical on internal

assemblies, meters should be kept free

of chemical when not in use for extended

periods of time. Flush and clean after each

use to promote trouble-free operation.

Removal

WARNING

During meter removal, chemical may

spill. Follow the chemical manufacturer’s safety precautions for

cleanup of minor spills.

6

Cleaning

During use, the meter should be kept free

of liquid to ensure drying does not occur

inside the meter. If drying should occur,

the nutator will stick or drag, affecting accuracy. If this occurs, cleaning is required.

Cleaning the Nutator

1. Loosen the screws on the back of

the meter about 1/4 inch (0.6 cm).

(Figure 2)

Figure 2

Page 7

2. Tap the screws with a hammer to

loosen the coverplate from the housing. (Figure 3) Remove the screws

and washers.

5. Gently remove the metal clips holding

the nutator in place. (Figure 6) Take

care not to damage the O-ring on the

nutator inlet.

Figure 3

3. Gently pry the coverplate from the

housing. Take care not to damage

the coverplate, housing, or O-ring.

(Figure 4)

Figure 4

Figure 6

6. Remove the nutator.

7. Using water or a solvent-based fluid

and a brush, carefully remove residue

from the nutator disc, nutator halves,

signal generator, and inside of housing. Allow all parts to dry.

CAUTION

Do not submerge the meter.

8. When the nutator turns freely, assemble and install following the

instructions below.

4. Remove the signal generator from

the pin on the nutator disc.

(Figure 5)

Figure 5

Assemble Nutator

1. Assemble the nutator disc and nutator halves. Install the O-ring on the

nutator inlet.

2. Install the nutator in the meter housing. Make sure the nutator O-ring fits

properly against the meter inlet.

3. Secure the nutator with the metal

clips. Beginning opposite the inlet,

install a clip in each slot in the housing. Push each clip down firmly until

seated.

4. Place the signal generator on the nutator pin. Make sure it rotates freely

on the pin.

7

Page 8

5. Coat the O-ring lightly with bearing

grease and seat securely on the

coverplate.

6. With the display facing up, turn the

coverplate to the desired orientation.

Align holes on coverplate and housing.

7. Secure the coverplate by evenly

tightening screws to 25 to 35 in. lbs.

Figure 7

Storage

After thoroughly cleaning the meter, disconnect the battery and store the meter

in a clean, dry location.

Battery Replacement

Your meter is equipped with a fieldreplaceable 9-volt alkaline battery.

If the meter’s readout should become dim,

blank, faded, or the low battery message

appears, replace the battery.

Batch and Cumulative Totals, as well as,

Factory and Field Calibrations are not lost

when the battery is replaced or power

is lost. They are saved in the meter’s

computer and are available after a new

battery is installed. You do not need to

repeat Field Calibration.

Check the battery and terminals at least

every year to ensure proper operation. It

is strongly recommended that terminals

be cleaned annually.

NOTE: The battery can be replaced

without removing the meter from the

hose or pipe.

2. Remove the battery coverplate and

gasket. (Figure 8)

Figure 8

3. Remove the battery and, if necessary, clean corrosion from the battery

terminals. (Figure 9) To prevent corrosion from condensation, coat the

terminals with petroleum jelly.

Figure 9

To replace battery or clean terminals:

1. Remove the two large and two small

screws from the battery coverplate

located on the lower portion of the

meter face. (Figure 7)

8

Page 9

4. Install the new battery.

When the battery is installed cor-

rectly, the computer powers on

automatically. Check the readout to

make sure normal meter functions

have resumed before assembling

End of Season

To ensure proper operation, the meter

should be cleaned prior to extended

periods of inactivity and at the end of

the season before storage. Disconnect

the battery before storage.

again. If necessary, seat the battery

again.

5. Make sure the coverplate gasket is in

good condition and properly seated.

Replace, if needed.

6. Replace the battery cover. Torque the

screws to 9 to 10 in. lbs.

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

A. METER IS NOT 1. Field Calibration not Field calibrate again or select Factory

ACCURATE performed properly Calibration.

2. Factory Calibration not Perform a Field Calibration according

suitable for liquid being to Calibration Section.

measured

3. Meter operated below Increase flowrate. See Specifications

minimum flowrate Section.

4. Meter partially clogged Remove meter. Disassemble and care-

with dried liquid fully clean dried chemical from the

nutator. Make sure the nutating disc

moves freely. Assemble again.

®

5. Teflon

material in flow path path and seal fittings. Install again.

6. Nutator misaligned Disassemble meter and install nutator

again. Ensure O-ring and retainer clips

are in place.

B. READOUT 1. Batteries weak, dead Replace battery. Install again, making

FADED OR or not connected sure the gasket seats evenly around

BLANK the coverplate.

2. Battery terminal Clean corrosion from the terminals.

corroded

3. Computer defective Contact the factory.

tape or other Remove meter. Clear material from flow

9

Page 10

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

C. NORMAL FLOW-

1. Field Calibration not Field calibrate again or select Factory

RATE BUT

performed correctly Calibration.

METER DOES

2. Nutator misaligned Disassemble meter and install nutator

NOT COUNT

again. Ensure O-ring and retainer clips

(Meter comes on

are in place.

when DISPLAY

3. Signal generator disc Replace signal generator disc. Contact

button pushed.)

missing or damaged the factory.

4. Computer defective Contact the factory.

D. REDUCED FLOW- 1. Meter clogged with Remove meter. Disassemble and clean

RATE & METER dried liquids dried chemical from the nutator. Make

DOES NOT sure the nutating disc moves freely.

COUNT

DISPLAY button

pushed.)

(Meter Assemble again.

comes on when

E. CANNOT GET 1. Button push sequence Make sure CALIBRATE is held down

METER INTO incorrect while DISPLAY is pushed. Hold both

FIELD CALIBRA- buttons for 3 seconds. Readout will then

TION show dd-000.0. Release both buttons.

Proceed with calibration according to

Calibration Section.

2. Computer circuit Contact the factory.

board defective

F. METER 1. Meter installed without Remove meter. Wrap male connections

CONNECTIONS thread sealant with 3 to 4 wraps of thread tape or com LEAK patible sealing compound. Install again.

2. Connecting threads Remove meter and inspect threads. Re damaged place damaged connections. If threads

are damaged, contact the factory.

3. Screws on back of Tighten screws. Torque to 25 to 35 in.

meter loose lbs.

4. Coverplate O-ring Install O-ring on coverplate again.

missing, damaged, or

improperly installed

5. Meter housing Inspect housing for cracks. If cracks

cracked present, contact the factory.

10

Page 11

ILLUSTRATED PARTS LIST

Item No.

No. Part No. Description Req’d.

1 120505-1 Housing Kit .......................... 1

1-A 904004-19 Screw, 1/4-20 x 1-3/4 in. ..... 4

1-B 904005-29 Washer, 1/4 in. ..................... 4

2 120503-1 Nutator Kit ........................... 1

2-A 111045-4 Nutator Seal ........................1

3 120013-1 Clip ...................................... 4

4 120504-1 Signal Generator Kit ............ 1

5* 120502-11 Coverplate Assy Kit, gallon .1

120502-18 Coverplate Assy Kit, litre ..... 1

* The Battery Cover and Gasket Kit, Item 7, is included in the Coverplate Assembly Kit, Item 5.

Item No.

No. Part No. Description Req’d.

5-A 901001-78 O-ring .................................. 1

6 902004-20 9 Volt Transistor Battery ......1

7* 120501-3 Battery Cover and

Gasket Kit ............................ 1

7-A 904005-28 Self-Sealing Screw,

1/4-20 x 5/8 in. ....................2

7-B 904005-27 Sems Screw,

6-32 x 3/8 in. ....................... 2

7-C 120028-1 Gasket .................................1

11

Page 12

SPECIFICATIONS

SERVICE

Applications

Flow Range: 2-20 GPM (7-75 LPM)

Operating Environment: Outdoor, oper-

ating temperature range of 0° F

to +130° F (-18° C to +54° C).

Electronic Nutating Disc designed

for mounting on hoses or pumps of

fluid transfer systems.

Power: 9 Volt alkaline battery

Maximum Working Pressure: 50 PSIG

(3.4 bar)

Maximum Display Value:

999,999 (x100)

Accuracy

Factory Calibration: ± 2%

Field Calibration: ± 0.5%

Materials

Housing: PBT Polyester

Seals: Viton

Wetted Parts: PBT Polyester, 303/304

Stainless Steel, Ferrite

Mechanical

Inlet: 1 inch NPT female

Outlet: 1 inch NPT male

Dimensions

Height: 4 inches (10.3 cm)

Depth: 3.1 inches (8.1 cm)

Width: 6 inches (15.2 cm)

Shipping Weight

3 lbs. (1.4 kg)

Storage Temperature

-40° F to +158° F (-40° C to +70° C)

For warranty consideration, parts, or

other servicing information, please contact your local distributor. If you need

further assistance, call the GPI Customer

Service Department in Wichita, Kansas,

during normal business hours.

1-800-835-0113

To obtain prompt, efficient service, always be prepared with the following

information:

1. The model number of your meter.

2. The serial number or manufacturing

date code of your meter.

3. Specific information about part numbers and descriptions.

For warranty work always be prepared

with your original sales slip or other evidence of purchase date.

Returning Parts

Please contact the factory before returning any parts. It may be possible to

diagnose the trouble and identify needed

parts in a telephone call or letter. GPI can

also inform you of any special handling

requirements you will need to follow

covering the transportation and handling

of equipment which has been used to

transfer hazardous liquids.

CAUTION

Do not return meters without specific authority from the GPI Customer Service Department. Due to

strict regulations governing transportation, handling, and disposal of

hazardous liquids, GPI will not accept meters for rework unless they

are completely free of chemical.

12

Page 13

Page 14

Page 15

Page 16

5252 Ea st 3 6th Stre et N orth

Wichita , KS USA 672 20-3 205

TEL: 31 6-68 6-73 61

FAX: 316- 686- 674 6

Limited Warranty Policy

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205, hereby

provides a limited warranty against defects in material and workmanship on all products

manufactured by Great Plains Industries, Inc. This product includes a 2 year warranty

from date of purchase as evidenced by the original sales receipt. A 30 month warranty

from product date of manufacture will apply in cases where the original sales receipt is not

available. Reference product labeling for the warranty expiration date based on 30 months

from date of manufacture. Manufacturer’s sole obligation under the foregoing warranties

will be limited to either, at Manufacturer’s option, replacing or repairing defective Goods

(subject to limitations hereinafter provided) or refunding the purchase price for such Goods

theretofore paid by the Buyer, and Buyer’s exclusive remedy for breach of any such warranties will be enforcement of such obligations of Manufacturer. The warranty shall extend

to the purchaser of this product and to any person to whom such product is transferred

during the warranty period.

This warranty shall not apply if:

A. the product has been altered or modified outside the warrantor’s duly appointed

representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been

installed or operated other than in accordance with the manufacturer’s operating

instructions.

To make a claim against this warranty, contact the GPI Customer Service Department at

316-686-7361 or 800-835-0113. Or by mail at:

GPI will step you through a product troubleshooting process to determine appropriate

corrective actions.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY FOR

DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE

USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for

any particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have other rights which vary from

U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702

(governs the resale availability of the warranty terms).

Great Plains Industries, Inc.

5252 E. 36

th

St. North

Wichita, KS, USA 67220-3205

GPI is a registered trademark of Great Plains Industries, Inc.

© 2010 by GREAT PLAINS INDUSTRIES, INC., Wichita, KS.

Printed in U.S.A.

06/10 Rev. C 920679-06

Loading...

Loading...