Page 1

RT14 Flow Rate Totaliser

Instrucon Manual

Version 21.16

Page 2

•

General Information

This manual provides the necessary information for installation and operation of

your flow instrument; for detailed information on any flowmeters or accessories

supplied with your instrument please consult the relevant flowmeter product

manual. This instrument should only be installed and maintained by persons

familiar with local regulations, particularly those for workplace Health and Safety.

For best results, please make yourself familiar with the contents of all relevant

product manuals prior to installation and commissioning. If further assistance is

required please consult the distributor from whom you purchased your device.

DISPOSAL WITHIN THE EUROPEAN UNION - WEEE

The WEEE Directive requires that this product be recycled

when disposed of within the European Union

• The crossed out wheelie bin symbol shown in this manual

signifies that this product should not be disposed of in general

waste or landfill.

• Please contact the local dealer or national distributor from

whom this product was purchased for information on recycling

electronic equipment within your region.

2

Page 3

Table of Contents

1. Introduction ................................................................................................... 4

1.1 Product Overview.............................................................................................4

1.2 Specifications ...................................................................................................5

2. Operation ....................................................................................................... 6

2.1 LCD Display ......................................................................................................6

2.2 Keypad Function ..............................................................................................7

2.3 Operating Functions ........................................................................................8

3. Mechanical Installation ................................................................................ 13

3.1 General Requirements ...................................................................................13

3.2 Conduit Entries ...............................................................................................13

3.3 Integral Meter Mounting ...............................................................................13

3.4 Wall and Pipe Mounting ..............................................................................14

3.5 Panel Mounting ...........................................................................................14

4. Electrical Installation .................................................................................... 15

4.1 Terminal Identification ..................................................................................15

4.2 Input Connections ..........................................................................................16

4.3 Output Connections .......................................................................................18

4.4 Connections for Combined Outputs ...............................................................23

5. Programming Parameters ............................................................................ 24

5.1 PIN Program Protection .................................................................................24

5.2 Engineering Units ...........................................................................................24

5.3 Time-base for Rate.........................................................................................24

5.4 Decimal Places ...............................................................................................25

5.5 K-Factor Entry ................................................................................................25

5.6 Input Type Configuration ...............................................................................25

5.7 Non-Linearity Correction ................................................................................25

5.8 Digital Output ................................................................................................26

5.9 Analogue Output ...........................................................................................27

5.10 Advanced Menu .........................................................................................28

6. Programming Flowchart ............................................................................... 30

7. Program Detail Record ................................................................................. 33

8. Spare Parts ................................................................................................... 34

9. Manufacturer’s Declaration ......................................................................... 36

3

Page 4

1. Introduction

1.1 Product Overview

The RT14 Rate Totaliser is designed for computing, displaying and transmitting totals and

flowrates from a flowmeter with a pulse or frequency output. The instrument will display Flow

Rate, Total and Accumulated Total in engineering units as programmed by the user. Simple

flow chart programming with scrolling English prompts guides you through the programming

routine greatly reducing the need to refer to the instruction manual. All user program data is

retained if the battery is removed.

Environments

The instrument is weatherproof to IP66/67 (Nema 4X) standards; a UV resistant glass

reinforced nylon housing with stainless steel screws & a mix of Nitrile O-ring seals and

Polyurethane gaskets allow the instrument to maintain its environmental protection across a

wide operating temperature range. The instrument suits harsh indoor and outdoor

environments & conforms to the European Directive for Electro Magnetic Compatibility.

Features

Displays of Total, Accumulated Total, and Flowrate, 10 point Linearisation, PIN Protection,

4~20mA analogue output, selectable digital output for pulse output or High / Low flow alarms.

Installation

Specifically engineered to be directly mounted on a variety of flowmeters, wall or surface

mounted, pipe or panel mounted. Various mounting kits are available. The instrument can be

self-powered or may be powered by an external DC supply or by a 2-wire analogue loop.

4

Page 5

1.2 Specifications

High impact glass reinforced Nylon (PA6) with a Polycarbonate lens, Nitrile O-Ring

Operating Temperature Range is -30oC ~ +80oC (-22oF ~ +176oF)

LCD

Display:

8 digit alpha-numeric LCD display with 12mm characters

Display backlight available with external DC power

Total units are selectable for litres, millilitres, gallons, cubic metres, quarts,

of /second, /minute, /hour, or /day

Universal pulse/frequency input compatible with Reed Switch, NPN or PNP sensors,

Minimum signal amplitude for Coil signals is 90mV pk-pk

Sensor

5V/20mA regulated sensor supply is available with external DC power applied.

AA 3.6V Lithium Thionyl Chloride Battery

See section 2.3.11 for more details on battery life

Regulated 12V ~ 30V DC

Lower current supply is required with lower supply voltages

12 ~ 30V DC 2-wire loop power

@ 30VDC – 900Ω Max @24VDC – 630Ω Max @12VDC – 90Ω Max

12 Bit 4-20mA analogue signal with an accuracy of ±0.05% F.S. at 25oC

22mA over-range when full-scale flowrate is exceeded

One selectable digital output programmable for Scaled Pulse, Unscaled Pulse, High

Signal accessible via passive NPN output or isolated output

Passive NPN digital output, 30VDC 300mA maximum

See section 2.3.11

Isolated digital output which is NPN/PNP selectable via wiring.

*requires external DC power to operate*

Physical

Units

Signal

Input:

Power

Battery

Power

External

DC Power

Loop

Power

seals and Polyurethane gaskets, providing an IP rating of IP66/67

kilograms, pounds, or NONE.

Rate units are independently selectable for all of the above, with time-base options

Variable Reluctance Coils (Turbine Flowmeters), and Weigand Sensors (voltage

pulse signals). 1.2Khz maximum input frequency for NPN/PNP, 2kHz maximum for

Coil inputs, 120Hz maximum for Reed Switch inputs.

A separate low power sensor supply is available when loop powered

Expected battery life under ideal conditions is 5 years

Maximum current draw on external power is 100mA @ 30V

Load Limits:

Analogue

Output

Digital

Output

Passive

NPN Out

Isolated

Digital Out

±0.25% F.S. at extreme ambient temperatures (-30oC or +80oC)

Software setting of Zero and Span, software trim of zero and full scale

Alarm, Low Alarm, or High/Low Alarm.

100Hz Maximum output frequency for scaled pulse or alarms.

Can be operated on battery power with a reduced battery lifetime

50V AC/DC 300mA maximum

5

Page 6

2. Operation

Upon entering the programming mode

2.1 LCD Display

the LCD will conduct a display test

where all LCD segments are displayed

for 3 seconds

Rate display is indicated by the RATE

flag in the bottom row of the display.

8 digits are available for Rate display,

user selectable for up to 3 decimal

places.

Rate units and time-base are displayed

at the top of the display. Rate units

may differ from Total units (e.g. Litres

and mL/min)

Total display and Accumulated Total

displays are also indicated clearly with

identifiers shown in the bottom row of

the display.

The presence of an input signal is indicated by movement of the flow indicator (propeller) in

the bottom left of the display. At low input frequencies the flow indicator will move upon

receipt of each individual input pulse, and at higher input frequencies it will rotate at a fixed

speed.

The LCD display will update with a frequency of 1Hz when the instrument is operating on

battery power; this will increase for a period of 30 seconds following a button press to 8Hz for

totals and 4Hz for flowrate. When powered by external DC or Loop power the LCD will update

at a constant 8Hz/4Hz.

6

Page 7

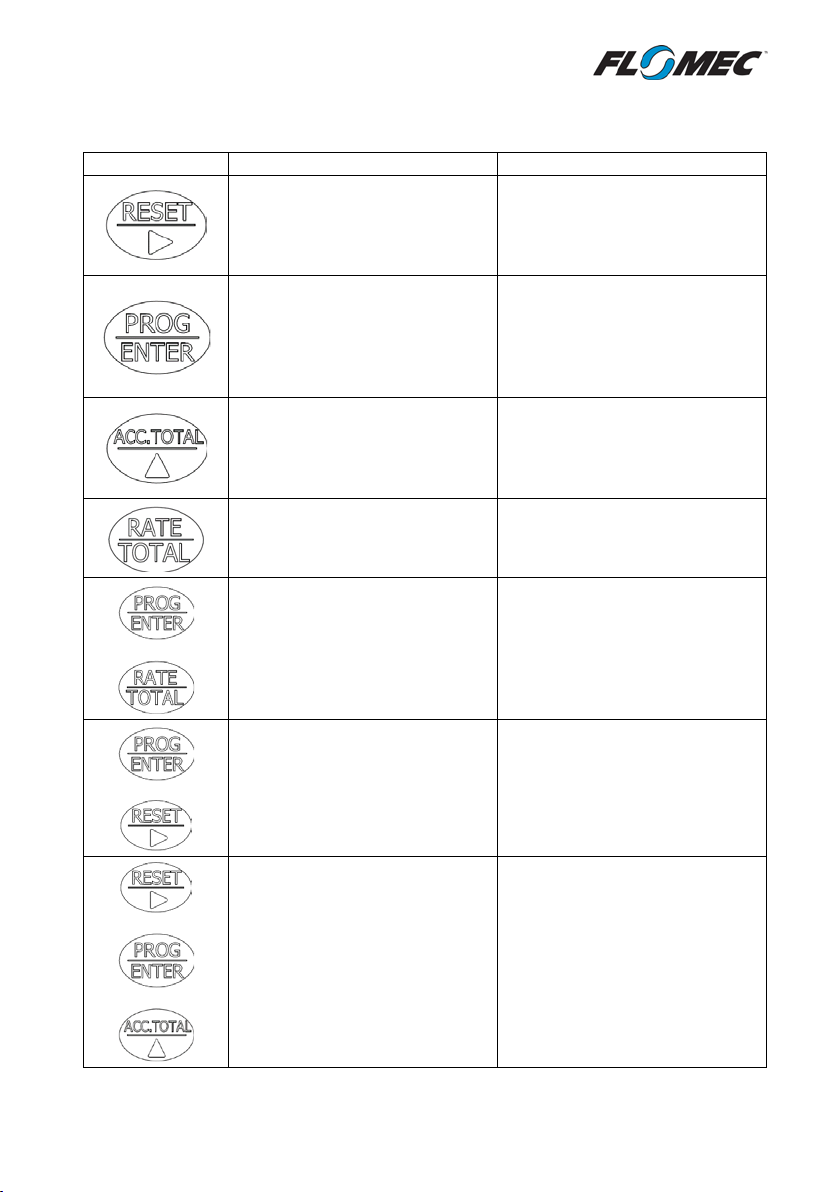

2.2 Keypad Function

KEY

FUNCTION IN OPERATING MODE

FUNCTION IN PROGRAM MODE

Press and hold for 3 seconds to

display to reset it

Each press progresses to the next

operating mode.

Press and hold to display the

accumulated total display.

reset the Total display to zero.

Total must be displayed on LCD

Press and hold to display the

software version (tag number is

displayed if enabled)

accumulated total. Holding this

key for 10 seconds will latch the

Toggles between the Rate and

Total displays

Press and hold both buttons

+

+

simultaneously for a duration of

5 seconds to enter the

programming mode

Press and hold PROG/ENTER and

then press RESET to toggle

between displaying software

version, serial number, and tag

number (if tag no. is enabled )

Selects the digit to be

incremented/edited, moves the

curser to the right.

program step.

Holding for 3 seconds will save all

program settings and exit to

Increments the selected digit

Moves one step backwards in the

program

No Function

No Function

+

+

Press and hold for 7 seconds to

perform a hard restart of the

software. To be used in the case

of ‘frozen’ software which may

be caused by user faults such as

short circuiting of the instrument.

*CAUTION*

Press and hold for 7 seconds in

Programming Mode to wipe all

settings from the device and

reset to factory default settings.

Record all important settings

before resetting the instrument.

7

Page 8

2.3 Operating Functions

2.3.1 Resettable Total

The display toggles between Rate and Total displays when the RATE/TOTAL key is pressed.

Pressing the RESET key and holding for a period of 3 seconds while the Total is displayed on

the LCD will cause the Total to reset to zero.

2.3.2 Accumulated Total

The Accumulated Total is displayed momentarily whenever the ACC.TOTAL key is pressed,

holding the key will hold the Accumulated Total display. If permanent display of the

Accumulated Total is required, this can be achieved by pressing and holding the ACC.TOTAL

key for a period of 10 seconds. Once this is done the Accumulated Total display will latch every

time the ACC.TOTAL key is pressed; to revert the Accumulated Total display to a momentary

display hold the ACC.TOTAL key again for 10 seconds.

The Accumulated Total display can only be reset by entering into the Programming Mode

and progressing to the Accumulated Total Reset function in the Advanced Menu. Protection of

the Accumulated Total reset can be achieved by PIN protecting the Programming Mode.

2.3.3 Rate Display

The Flow Rate Display is toggled by pressing the RATE/TOTAL key; Rate display remains

active until the RATE/TOTAL key is pressed again. The update frequency of the Rate display is

influenced by two parameters; the update frequency of the display (1Hz on battery power, 4Hz

on external DC or loop power), and the Rate Calculation Pulses parameter. If the update

frequency of the Rate Display is too slow consider reducing the number of pulses for the rate

calculation (see section 5.10). Conversely if it is required to stabilise an erratic Rate Display,

increasing the Rate Calculation Pulses parameter will achieve this.

Other parameters which influence the Rate Display are the Rate Damping, and Low

Frequency Cut-Off settings. Rate Damping will smooth out rapid changes in the flow rate in

order to maintain a steady display, however in systems where fast changes in the flowrate

must be displayed the Rate Damping parameter should be minimised.

The minimum input frequency requirement for a Rate Display is 0.2Hz with the factory

settings; this can be reduced to 0.1Hz by adjusting the Low Frequency Cut-off parameter. Note

that Totalisation is not effected by the Low Frequency Cut-off parameter.

8

Page 9

2.3.4 Display Backlight

The display backlight will be automatically enabled upon connection of an external DC

voltage supply in the range of 12-30V; the backlight is not available when operating on battery

or loop power. If it is required to reduce power consumption while operating on external DC

power the backlight can be overridden in the Advanced Menu (see section 5.10).

2.3.5 Analogue Output

The loop powered 4-20mA Analogue Output is a passive non-isolated output capable of

retransmitting the flowrate to remote instrumentation or control systems such as a PLC or

DCS. The Analogue Output can be spanned anywhere within the operating range of the

associated flowmeter; both the 4mA and 20mA points are software programmable in the units

selected for the Rate display. The instrument will over-range to 22mA which allows the user to

identify when the system is exceeding its maximum normal flowrate (i.e. identifying a fault

condition).

The Analogue Output accuracy is ±0.05% of Full Scale (0.01mA) at a regular ambient

temperature of 25

o

C. Due to the effects of temperature changes on the internal components,

the accuracy will become progressively worse as the ambient temperature moves further

away from 25

o

C; up to a worst case of ±0.25% of Full Scale (0.05mA) at the extremes of the

instrument’s operating range (-30oC or +80oC)

If required, the Analogue Output can be software adjusted to achieve the best accuracy

under the specific operating temperature of your installation. The 4mA and 20mA points are

both adjustable in 0.001mA increments by accessing the Analogue Output Adjustment section

of the Advanced Menu (see section 5.10 of this manual).

2.3.6 Unscaled Pulse Output

The Unscaled Pulse Output function is used to retransmit the input signal from the

associated flowmeter; it will maintain the same frequency and duty cycle as the input signal.

When setting up a system with two separate Total displays on two separate instruments the

Unscaled Pulse Output is the best method of transmitting the Total value to the secondary

totalising instrument.

The Unscaled Pulse signal can be transmitted as an NPN signal from the passive digital

output, or as an NPN or PNP signal from the isolated digital output. The passive digital output

can be used on battery power, however transmitting the signal via the isolated output will

require an external DC power supply.

9

Page 10

2.3.7 Scaled Pulse Output

The Scaled Pulse Output is used to transmit the totalised volume at a user selectable

resolution; this is programmed as a volume quantity per output pulse (e.g. 10Litres/Pulse or

100mL/Pulse). The frequency of the Scaled Pulse Output signal automatically adjusts according

to the input frequency and the scale factor, up to a maximum limit of 100Hz.

The Scaled Pulse signal can be transmitted in the same way as the Unscaled Pulse signal

above, either through the passive or isolated output.

The pulse width of the Scaled Pulse output is fixed at 300ms for output frequencies below

1.67Hz, however once above 1.67Hz the instrument adjusts the pulse width according to the

frequency to give a 50:50 duty cycle up to the maximum output frequency of 100Hz. Systems

should be designed to stay below the 100Hz limit, however if 100Hz is exceeded the

instrument will output at 100Hz and store any excess pulses in memory. Pulses stored in

memory will continue to output after the flow has stopped until the stored pulse count

reaches zero.

2.3.8 Alarm Output

Flow Rate Alarms may be programmed for High, Low, or High/Low; the digital output will

trigger when the registered flowrate passes the configured set-point(s). For a Low Alarm the

output will trigger once the flowrate drops below the set-point, a High Alarm will trigger with a

flowrate over the set-point, and a High/Low alarm will trigger if the flowrate is either over the

upper set-point or below the lower-set point.

Each set-point is configured with its own dead-band percentage which allows the user to set

a buffer zone (hysteresis) to avoid alarm “chattering” (switching quickly on-off-on-off) with a

flowrate hovering around the set-point. The dead-band setting is entered as a percentage of

the set-point value; e.g. a 5% dead-band with a 100L/min High Flow Alarm will trigger ON at

100L/min but will not turn OFF until the flow drops to below 95L/min.

Alarm Outputs can operate as an NPN signal via the passive digital output, or as a PNP or

NPN signal via the opto-isolated output. For relay switching be sure to follow the requirements

in the relevant wiring diagram in section 4.3.

2.3.9 Passive NPN Transistor Output

The passive NPN transistor output is the default method of transmitting the pulse or alarm

outputs, as it is the easiest and lowest cost solution where an NPN signal below 30VDC is

suitable. The passive NPN output shares a common ground inside the instrument, so may not

be suitable for installations requiring an analogue output in combination with a digital output,

as it may cause analogue signal issues due to the formation of a ground loop.

10

Page 11

The passive NPN output will function on battery power, however this will reduce the battery

life of the instrument by approximately 50%. For applications requiring an alarm output which

is not triggered often the effect on battery life is expected to be negligible.

Internal protection is provided for voltage spikes caused by switching inductive loads (relays,

solenoids, etc.) by fitment of an internal flyback (suppressor) diode to the passive NPN output.

No additional circuit components are required when triggering a DC relay or DC solenoid with

this output.

2.3.10 Isolated Digital Output

The Isolated digital output is provided by means of an Opto-Coupler, which provides a signal

with no electrical connections to the other internal circuitry of the instrument. The isolated

output should be used preferentially whenever a user requires both an analogue output and a

digital output (alarm or pulse signal) to a common receiving instrument; this will avoid the

creation of ground loops which interrupt the analogue signal. The isolated digital output is also

chosen whenever a PNP signal is required; the configuration of PNP vs. NPN is accomplished

via wiring which can be seen in the electrical installation section of this manual (section 4.3).

The isolated digital output is rated to 50V AC or DC, and 300mA; so should be used instead of

the passive NPN output for switching any loads greater than 30VDC or for switching any low

voltage AC loads <50VAC. The isolated digital output is not internally protected from voltage

spikes generated by inductive loads such as relays or solenoids, so a diode (1N004

recommended) should be fitted across any inductive DC loads as shown in section 4.3.5. For AC

relays or solenoids voltage spike protection should be provided by fitment of a metal oxide

varistor fitted in place of the diode (EPCOS SIOV-S05K50 or SIOV-S07K50 recommended).

Where the recommended diode or varistor is not available, a similar component of equivalent

specification may be used.

2.3.11 Battery Power

The instrument is powered by a Lithium Thionyl Chloride (Li/SOCl2) AA size battery which is

non-rechargeable. When operating under average conditions the instrument is expected to

have approximately 5 years of battery life; average conditions are considered to be a reed

switch input from a Flomec flowmeter with no outputs used. High input frequencies (~1kHz

and higher) from a turbine flowmeter will reduce battery life by around 20%, and operation of

a battery powered scaled pulse output will reduce battery life by approximately 50%. When

the NPN transistor is used for an alarm with infrequent operation the reduction of battery life

may be negligible.

11

Page 12

A low battery is indicated by the battery symbol on the lower line of the LCD display;

illumination of this indicator shows that the battery should be replaced as soon as possible.

Generally the remaining battery life after low battery indication is several days however this is

not guaranteed. Replacement batteries are available from the instrument manufacturer or

they may be purchased independently by the user; for user replacement it is recommended

that a Tekcell SB-AA11 battery be used. Use of a battery which is not a 3.6V Lithium Thionyl

Chloride type will void the instrument warranty.

2.3.12 External DC Power

External DC power may be connected to the instrument in the range of 12-30V DC; this will

activate the LCD backlight, the sensor supply, and the isolated output. When external DC

power is provided the instrument will no longer draw any power from the battery – the

battery will then only be used as a backup power source. With the battery in backup mode the

life is expected to be approximately 8-10years.

2.3.13 Sensor Supply

The instrument is equipped with a regulated sensor supply (5V/20mA maximum) terminal

which is suitable for powering hall-effect sensors in Flomec flowmeters. The sensor supply is

only available when the instrument is connected to an external 12-30V DC supply, it is not

available under loop power. 20mA of sensor current is available when the external DC supply is

24V or higher; Flomec flowmeters will only require 12V DC supply to the instrument.

12

Page 13

3. Mechanical Installation

3.1 General Requirements

Installation of this product should only be carried out by suitably qualified/trained personnel

with an understanding of local regulations regarding electrical installations, and if relevant

Hazardous Area electrical installations.

It is recommended that the instrument is installed in a location where it is shielded from

extreme varying weather conditions, and from chances of physical impact. Never install the

instrument in an area which will expose it to temperatures outside its specified operating

temperature range.

3.2 Conduit Entries

Each instrument is equipped with three conduit entries which are factory sealed to maintain

the IP rating of the enclosure. To gain access to a conduit entry the integral moulded plug must

be broken out of the electrical entry. Inserting a suitably sized screw driver or Allen-key into

the centre of the conduit entry plug and bend the plug back and forth until it breaks away

from the enclosure.

Always use IP rated cable glands when fitting cable to the instrument. If any electrical

entries are opened using the method above and are later not used, these must be sealed using

a threaded conduit plug with an appropriate IP rating (IP66 or IP67 is recommended)

3.3 Integral Meter Mounting

This instrument may be purchased as a meter mount display which will mount on the top of

any Flomec flow meter. For any instruments purchased as field mount, these may be

converted to a meter mount instrument by purchasing a new rear enclosure.

Likewise for mounting of instruments on flowmeters with a process temperature of over

o

80

C there is a ‘Cooling Fin Kit’ available from the manufacturer which will allow this; these

may be retro-fitted in the field with minimal effort.

13

Page 14

3.4 Wall and Pipe Mounting

Panel mount

Cut a 106.5mm (4.2 ”)

Mounting of the instrument in a panel

42.6 mm

( 1.67

18 mm

( 0.7

96 mm ( 3.8 ” )

Mounting of the instrument on

a pipe or flat surface (such as a

wall) can be accomplished using

the ‘Wall Mount Kit’, or ‘Pipe

Mount Kit’ available from the

manufacturer.

3.5 Panel Mounting

requires a 106.5mm – 107.8mm (4.20” -

4.25”) round hole to be cut in the panel.

Up to a 109mm (4.30”) is suitable if the

IP65 rating is not required.

The rear enclosure of the instrument can

be mounted behind the panel (as per

diagram to the right) to protect the back of

the electronics module if required,

however this is not compulsory.

When panel mounted the IP rating of the

instrument is reduced to IP65 on the front

side of the panel only – with the rear

enclosure mounted behind the panel the

back side of the instrument will have an

IP20 rating.

” )

” )

diameter hole in panel

14

Page 15

4. Electrical Installation

All wiring connections should be made with good quality shielded instrument cable; wiring

between terminals which are inside the instrument enclosure, or between a flowmeter and an

integrally mounted instrument may use non-shielded wire. Cable shields or drain wires should

be connected to the instrument ground (GND) at the instrument end only – isolate the

shield/drain wire at the flowmeter end of the cable.

The terminal connections on the instrument will allow for usage of wiring up to 2.5mm

section (14AWG) – if two wiring connections into the same terminal are required the

maximum cross section of each wire is 0.75mm2. Wire insulation should be stripped to a length

of 6.5mm and conductors should be fitted to the terminals so that there is minimal exposed

conductor. Terminals can be tightened with a No.1 Phillips head screwdriver, or a 3mm or 1/8”

flat blade screw driver.

4.1 Terminal Identification

The terminal connections are divided into 4 separate sections by their function; all input

terminals are on the left and all output terminals on the right - see below for more detail.

There is a separate ground (GND) terminal in each section of terminals; as this instrument has

a common ground, all GND terminals are internally connected.

2

cross

15

Page 16

4.2 Input Connections

The input type must be set in the software before the below wiring connections will function

4.2.1 Reed Switch Input

4.2.2 NPN Sensor Input (Hall Effect)

16

Page 17

4.2.3 PNP Sensor Input

4.2.4 Voltage Pulse Input (Wiegand Sensor / DP Meters)

17

Page 18

4.2.5 VR Coil Input (Turbine Meters)

4.3 Output Connections

4.3.1 Passive NPN Digital Output with Unpowered Sensor

Notes: Shown here with Reed Switch input, Coil and Voltage Pulse inputs also suitable for this

configuration. *External 12-30V DC power supply to instrument is optional.

18

Page 19

4.3.2 Passive NPN Digital Output with Powered Sensor

4.3.3 PNP Digital Output – configuration suitable for all input types

19

Page 20

4.3.4 Digital Output to a Relay – Recommended connection for all 12-30V DC Relays

Note: Wiring connection from voltage supply to +24V terminal on instrument is not

compulsory, however it will prolong battery life.

4.3.5 Digital Output to a Relay – For up to 50V DC and 50V AC Relays

Note: This output type is not internally protected from voltage spikes from inductive loads, a

diode must be fitted as shown for DC loads, or a Metal Oxide Varistor fitted for AC circuits.

20

Page 21

4.3.6 Analogue Output with an Unpowered Sensor – Negative Reference

Notes: Shown here with Reed Switch input, Coil and Voltage Pulse inputs also suitable for this

configuration.

4.3.7 Analogue Output with an Unpowered Sensor – Positive Reference

Notes: Shown here with Reed Switch input, Coil and Voltage Pulse inputs also suitable for this

configuration.

21

Page 22

4.3.8 Analogue Output with a Powered Sensor – Negative Reference

4.3.9 Analogue Output with a Powered Sensor – Positive Reference

Note: Some instrumentation systems may have a common ground between the analogue input

and the DC supply, for those systems this wiring configuration will not be possible and

configuration 4.3.8 must be used.

22

Page 23

4.4 Connections for Combined Outputs

4.4.1 Combined Analogue Output and NPN Digital Output to Common Receiver

4.4.2 Combined Analogue Output and PNP Digital Output to Common Receiver

23

Page 24

5. Programming Parameters

Total Unit

Rate Unit

Density

Conversion Factor

Kilograms

Litres

1200kg/m3 1.200

Litres

Kilograms

1200kg/m3

0.833

US Barrels (none)

Gallons

N/A

42.000

5.1 PIN Program Protection

Any user defined PIN other than 0000 will engage the program protection mode; after the

PIN protection mode is enabled failure to input the correct PIN number will deny the user the

ability to change any of the program parameters, but will allow read only access to the user so

that they may view existing program settings.

Only one PIN may be set at any one time, but this can be changed at any time by entering the

programming mode, entering the existing PIN, and then changing the PIN to a new number. A

second backup PIN exists in the software which can be used should the user programmed PIN

be lost – contact the manufacturer should you require the backup PIN.

5.2 Engineering Units

The engineering units for the instrument may be selected from any of the following; Litres,

millilitres, cubic Metres, kilograms, Gallons, Quarts, Pounds, or none. The unit ‘none’ is used

where the user requires a unit other than those available and the number of pulses / unit are

known for the required unit – for example US Barrels can be used by selecting the units as

‘none’.

The Total and Rate units are programmed separately, and may be selected as separate units,

for example millilitres for total, and L/hr for the flowrate. When the selected Total unit and the

selected Rate unit are both units of volume, or are both units of mass (e.g. Litres and Gallons,

kilograms and pounds) the instrument will calculate the difference without further user input.

However when the units are a mixture of volume and mass, the user must enter their own rate

conversion factor.

5.2.1 Rate Units Conversion

The Rate Conversion Factor is calculated as the quantity of Rate units per Total unit – see the

following chart for some examples:

5.3 Time-base for Rate

The time-base for the Rate display may be selected from any of the following; units/second,

units/minute, units/hour, units/day. The Rate time-base setting with determine the units used

in programming the analogue output set points.

24

Page 25

5.4 Decimal Places

Software

Setting

Maximum

Frequency

OM Meters

DP Meters

OM Meters – Hall Effect

EGM Meters – Hall Effect

Other manufacturer’s

Flow Meters

Variable Reluctance Coil

Turbine Flowmeters

Coil

2kHz

Wiegand Sensor

DP Meters - Voltage Pulse

Coil

2kHz

Decimal places are separately adjustable for Total, Accumulated Total, and Rate from zero to

three decimal places. The decimal places setting for Rate will set the available decimal places

in the analogue output set point. The decimal place settings for Total and Accumulated Total

do not influence configuration of the pulse output.

5.5 K-Factor Entry

The K-factor entry screen allows entry of up to 7 whole numbers and 4 decimals, however

only the first 7 significant digits are used by the software in calculating totals. When entering

the K-factor screen not all available digits are shown; moving the curser to the right will show

the remaining available digits. Note that when different engineering units are configured for

Total and Rate, the K-factor should be entered in the engineering units which are selected for

Total.

5.6 Input Type Configuration

The input type can be selected from the following; Reed switch, NPN, PNP, or Coil. The

following table should be referenced when selecting the correct software setting for your

flowmeter. Instruments delivered integrally mounted to a flowmeter will have this

parameter factory set and do not require user adjustment.

Sensor Type Used in:

Reed Switch

NPN Sensor

PNP Sensor

5.7 Non-Linearity Correction

Non-linearity correction (NLC) allows the instrument to correct for known inaccuracies in a

flow-meter, thereby improving the overall measurement accuracy, and in many cases

increasing the effective flow range of the measurement system. Non-linearity correction can

be used on battery power however battery life will be reduced according to usage.

DP Meters – Hall Effect

25

REED 120Hz

NPN 1.2kHz

PNP 1.2kHz

Page 26

Non-linearity correction functions as an intermediate process between the receiving of input

pulses and the calculation of totals; therefore all subsequent processes such as Rate

calculation, analogue output calculations, and pulses/alarm outputs are also corrected

according to the settings programmed for the non-linearity correction.

The non-linearity correction function is programmed using up to 10 frequency points, and a

K-factor for each frequency point. Not all 10 points must be used, however a minimum of 2

points is required. Below the minimum frequency point the instrument will use the K-factor

entered for the lowest point, similarly above the maximum frequency point the instrument will

use the K-factor entered for the highest point. Linear interpolation is used between frequency

points.

If any frequency in the programming menu is entered as zero Hz then all remaining

frequency points will be disabled; i.e. if data is entered for points ‘0F’ to ‘4F’ and point ‘5F’ is

entered as 0Hz, points ‘6F’ to ‘9F’ will not be used. Once the non-linearity correction function

is enabled the general K-factor entered at Level 5 of the program is disabled; if the nonlinearity correction is later disabled the instrument will revert to the general K-Factor.

Data for entry of Non-Linearity Correction is available for Flomec meters when purchased

with a multi-point factory calibration. Alternatively NLC data can be obtained with a field

calibration of the meter.

5.8 Digital Output

The digital output function is configurable for either a pulse output according to totalised

flow, or an alarm output according to flowrate. The pulse output can be configured for an

unscaled pulse or a scaled pulse, and the alarm can be configured for notification of high

flowrates, low flowrates, or a combination of both.

5.8.1 Un-Scaled Pulse

The unscaled pulse output, also commonly referred to as a ‘repeater pulse’ is enabled by

selecting ‘UNSCALED’ in the digital output configuration menu.

5.8.2 Scaled Pulse

The scaled pulse output is enabled by selecting ‘SCALED’ in the digital output configuration

menu. Configuration of this output is accomplished by entering the number of units per output

pulse; e.g. 10 Litres/pulse, 0.1kgs/pulse, etc. The engineering units configured for the Total

display are used to specify the settings for this output. The range of available settings for this

output are from 0000.01 units/pulse up to a maximum of 9999.99 units/pulse.

As there is a frequency limitation on the scaled pulse output of 100Hz it is preferred to

configure the scaled pulse output to keep the output frequency below this limit. If it is

necessary for the scaled pulse output to operate at greater than 100Hz the instrument will

26

Page 27

output the signal at the maximum of 100Hz, and all excess pulses will be stored in memory

until such a time that flow has stopped and the instrument can output the stored pulses – it is

not recommended that systems be designed to operate in this way under normal conditions.

The output frequency can be calculated as follows:

=

If the system design does not allow significant periods of zero-flow where the instrument can

reduce the stored pulse count to zero it is advisable to increase the number of units/pulse in

order to keep the output below 100Hz.

5.8.3 Flow Alarm

The Alarm output is enabled by selecting ‘ALARM’ from the digital output configuration

menu. The alarm output may be configured as a ‘High Alarm’ which will trigger in the event

the flow rate exceeds the alarm set-point, a ‘Low Alarm’ which will trigger in the event the

flow rate drops below the set-point, or a ‘High/Low Alarm’ which is a combination of the two.

Configuration of the Alarm involves selecting the type of alarm, entering the alarm set-point

(specified in Rate units, e.g. L/min), and entering the alarm dead-band. The Alarm dead-band is

an adjustable buffer zone around the set point which provides hysteresis to the system, and

allows the user to overcome alarm chattering when the flowrate is fluctuating around the setpoint. The dead-band setting is entered as a percentage of the set-point value; e.g. a 5% deadband around a 100L/min High Flow Alarm will trigger ON at 100L/min but will not turn OFF

until the flow drops to below 95L/min.

( ) 60( )

( )

5.9 Analogue Output

The 4-20mA analogue output can be configured anywhere within the operating range of the

connected flowmeter; a 22mA over-range is provided for identification of flows exceeding the

maximum flowrate of the connected flow meter.

The output is configured in flowrate units for the zero point (4mA) and the full scale point

(20mA). The decimal places allowed for the set points are equal to the decimal place

configuration of the Rate display. The 4mA and 20mA points may be entered upside-down, i.e.

a 20mA point lower than the 4mA point. For information on testing or adjustment of the 4-

20mA signal see section 5.10.5 below.

27

Page 28

5.10 Advanced Menu

5.10.1 Resetting Accumulated Total

Resetting the accumulated total can only be done at this level of the Advanced Menu; by PIN

protecting the instrument it is possible to remove the ability of an operator to reset the

accumulated total. Once the accumulated total is reset it is not possible to recover the value

which was in the accumulated total – it is advisable to record the accumulated total value

before resetting.

5.10.2 Rate Damping

Flow Rate Damping is used to smooth out fluctuating flow input signals in order to provide a

stable Rate Display and Analogue Output. Most input signals are reasonably stable and need

only the default Rate Damping setting, however for systems with large flow fluctuations the

Rate Damping setting may need to be increased.

If the user requires quick visual indication of changes to a system’s flowrate (either on the

Rate Display, or in the Analogue Output) this can be accomplished by reducing the Rate

Damping setting. To remove all damping from the flow rate calculation Rate Damping can be

set to zero.

5.10.3 Low Frequency Cut-Off

The low frequency cut-off parameter is used to adjust the minimum frequency required for

the rate display and analogue output functions. This setting is useful to avoid spikes in the rate

display and analogue output from “apparent flow” which could be caused by movement of

liquid in the pipes of a mobile installation (on a truck etc.), pulsations from a dead-headed

pump, etc.

The default value for the low frequency cut-off is 0.2Hz, and the parameter is adjustable

from 0.1Hz up to 9.9Hz. It is not possible to enable a rate display or analogue output for input

frequencies below 0.1Hz.

5.10.4 Rate Calculation Pulses

The purpose of the ‘Rate Calculation Pulses’ parameter is to determine the number of input

pulses which are used in calculation of the flow rate; the more pulses which are used the more

accurately the Rate Display will represent the average flow-rate of the system. The parameter

is adjustable from 1 to 255 pulses per calculation. For systems using pumps with a nonuniform rate of delivery (piston pumps or similar) it is important to have a high value for this

parameter as it will produce a stable rate display and analogue output which is representative

of the average flow through the pipe.

For systems with a steady and uniform flow through the pipe, lower values can be used for

this parameter in order to achieve a more responsive rate display and analogue output.

28

Page 29

However it should be kept in mind that for any battery powered applications, using a value

lower than the default will decrease battery life.

5.10.5 Analogue Output Adjustment

The analogue output may be adjusted/trimmed at this level of the program; this should not

be necessary in most applications as the analogue output is factory calibrated, however it may

be useful when operating at extreme ambient temperatures.

There are two parameters which the user can set; the 4mA adjustment and the 20mA

adjustment. With the 4mA adjustment showing on the instrument display the unit will output

4mA to the receiving instrument, likewise with the 20mA adjustment showing on the display

the unit will output 20mA. By noting the difference in the receiving instrument’s reading in mA

the user can correct any errors.

The display allows entry of the adjustment in 0.001mA steps, and adjustments may be made

in the positive or negative direction. The default adjustment direction is positive, however

this can be changed by holding the ‘UP arrow’ key for 3 seconds.

5.10.6 Backlight Override

The backlight is automatically enabled whenever external DC power is connected to the

instrument; this feature may be over-ridden in this level of the program. The backlight

override may be set to ‘ON’ (normal function), ‘OFF’ (always off), or ‘INT’ (intermittent, the

backlight will be on for 30 seconds following a button press). Note that ‘INT’ operation still

requires external DC power.

5.10.7 Tag Number Entry

The user may enter an identifying tag number into the instrument, according to the P&ID of

the installation where it is used. The default tag number is FIT-000 allowing quick entry of a

simple ISA-5.1 standard Tag Number, however this can be expanded up to 12 digits of

alphanumerical characters and hyphens (e.g. FIT-123-45AB). The leading 3 digits (FIT;

describing the device as a Flow Indictor/Transmitter) may also be changed to any

alphanumeric character to suit the user’s requirements.

Once a tag number is entered it is viewed during the operating mode by pressing and holding

the PROG/ENTER key; when the tag number contains more than 8 digits it will scroll across the

LCD.

29

Page 30

6. Programming Flowchart

30

Page 31

31

Page 32

32

Page 33

7. Program Detail Record

User PIN

Total

Rate

Rate Conversion Factor

Yes No

RCF =

Time Base for Rate

/Sec /Min

/Hr /Day

Total

0

0.0 0.00 0.000

Accum. Total

0

0.0 0.00 0.000

Rate 0 0.0 0.00 0.000

K-Factor (pulses / unit)

K =

Input Type

Reed

Coil NPN PNP

Non Linearity Correction

Yes No

Point 0F

Hz

K =

Point 1F

Hz

K =

Point 2F

Hz

K =

Point 3F

Hz

K =

Point 4F

Hz

K =

Point 5F

Hz

K =

Point 6F

Hz

K =

Point 7F

Hz

K =

Point 8F

Hz

K =

Point 9F

Hz

K =

Digital Output

Yes No

Digital Output Type

Unscaled

Scaled

Alarm

Units per Output Pulse

N/A

Alarm Set-Point

High:

Low:

Alarm Dead-Band

DB%:

Analogue Output

Yes No

Zero Set-Point (4mA)

4mA@

Full Scale Set-Point (20mA)

20mA@

Rate Damping

Low Frequency Cut-off

Rate Calculation Pulses

Backlight Setting

Tag Number

Engineering Units

Decimal

Points

33

Page 34

8. Spare Parts

Description:

Includes:

Part No:

Bezel Cover

1 x Bezel Cover

1306014

Complete replacement front housing with clear

lens and keys. Facia not included

Rear housing for meter mounted instrument

fasteners and seals for meter mounting

Rear housing for meter mounted instrument

fasteners and seals for meter mounting

Field Mount Rear

Housing Kit (M20)

Rear housing for field mounted instrument (M20

electrical entries)

Field Mount Rear

Housing Kit (NPT)

Rear housing for field mounted instrument (NPT

electrical entries)

All internal and external fasteners, including

meter mount screws.

Housing Seal

BS046 Buna-N (Nitrile) O-Ring

BS046B

Facia Sticker

(Decal)

Safe Area Battery

3.6V AA Lithium Battery

1312035

Tekcell SB-AA11

Tadiran TL5903/S

Spare parts for your instrument are available from the local dealer or national distributor

from whom you purchased the instrument; see spare parts list below to determine which

parts numbers you require.

Front Housing Kit

Meter Mount Rear

Housing Kit (M20)

Meter Mount Rear

Housing Kit (NPT)

Fastener Kit

Alternative Replacement Battery for Safe Area Units Only

Note: Use of a battery which is not a 3.6V Lithium Thionyl Chloride type will void the

instrument warranty.

(M20 electrical entries). Includes the required

(NPT electrical entries). Includes the required

Self-adhesive facia (decal) with Flomec logo 1315147

1502058

1502001

1502002

1502003

1502004

1508128

34

Page 35

Notes:

35

Page 36

9. Manufacturer’s Declaraon

We, Trimec Industries Pty Ltd, of Sydney Australia, trading as Great Plains

Industries Australia or ‘FLOMEC’

Declare under our sole responsibility that the RT14 Rate Totaliser is in conformance with

the following European direcves:

2014/30/EU EMC Direcve

Conformity is declared under the following standards

EN61000-6-2:2005

Electromagnec compability (EMC).Generic standards. Immunity for industrial

environments

EN61000-6-3:2007

Electromagnec compability (EMC). Generic standards. Emission standard for

residenal, commercial and light-industrial environments

EN61326-1:2013

Electrical equipment for measurement, control and laboratory use. EMC

requirements. General requirements

2011/65/EU RoHS Direcve

Conformity is declared under the following standards

EN50581:2012

Technical documentaon for the assessment of electrical and electronic products

with respect to the

Mahew Wyres, Sydney, Australia

Engineering Manager 21/05/2016

Trimec Industries Pty. Ltd.

RT14 Instrucon Manual IM-RT14-2116

restricon of hazardous substances

Loading...

Loading...