Page 1

Product Owner’s Manual

EN

QS200

Insertion Ultrasonic

Flowmeter

U.S. Design Patent No. D845,804 - Ultrasonic Insert

U.S. Design Patent No. D845,805 - Tee Housing for Ultrasonic Insert

STANDARD METERS:

QS200-10, QS200-15, QS200-20, QS200-30, QS200-40

NSF CERTIFIED METERS:

QS200-10PW, QS200-15PW, QS200-20PW, QS200-30PW, QS200-40PW

STANDARD RETROFIT INSERT:

QS200

920901-01 Rev C04/29/2019

Page 2

Please save these instructions for future reference. Read carefully before attempting

to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply

with instructions could result in personal injury and/or property damage.

Please refer to back cover for information regarding this product’s warranty and

other important information.

DO NOT RETURN THIS PRODUCT TO THE STORE!

Please contact Great Plains Industries, Inc.® before returning any product. If you are

missing parts, or experience problems with your installation, contact our Customer

Support Department. We will be happy to assist you.

Call: 888-996-3837 or 316-686-7361

Email: meters@gplains.com

SAVE FOR YOUR RECORDS

Model #: ___________________

Serial #: ___________________

Purch. Date: _______________

Page 3

BEFORE YOU BEGIN

tools.eps

Heavy_Hazard.eps

tools.eps

box.eps

Heavy_Hazard.eps

Hot_surface.eps

tools.eps

box.eps

magnify_2.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

Usage Requirements

• This meter is for use with water only.

• This meter is not legal for trade applications.

• This meter has a permanent factory setting for measuring water only.

Power Source Requirements

• This meter requires DC power from a customer-provided controller in

order to provide flow information back to the controller.

Tools and Materials Needed

• Wire strippers, wire cutters, screwdriver, tape measure

• PVC pipe fittings (as needed), PVC pipe primer, PVC pipe cement

• Direct burial wire splices, valve box

• #18 AWG wire cable (Direct Burial) (Controller manufacturer may

recommend thicker guage wire for longer distances)

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

UNPACKING

Contents: QS200-10, -15, -20, -30, -40 or

QS200-10PW, -15PW, -20PW, -30PW, -40PW Meters

Note: The “PW” suffix denotes an NSF certified meter

(1) QS200 Ultrasonic insert assembly (2) K-factor Decals

(1) PVC Pipe Tee (for 1 in., 1-1/2 in., 2 in., 3

in., or 4 in. diameter pipe)

(1) Quick Release Pin

Contents: QS200 Retrofit Insert (Not available as NSF certified)

(1) QS200 Ultrasonic insert assembly (1) Quick Release Pin

(1) Set of two O-rings (round profile) (1) Owners Manual

(2) K-factor Decals

Inspect

• After unpacking the unit, inspect carefully for any damage that may

• See General Safety Instructions, and all Cautions, Warnings, and

(1) Owners Manual

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with carrier.

Dangers as shown.

OPERATION TROUBLESHOOTING

MAINTENANCE /

REPAIR

3

Page 4

GENERAL SAFETY INSTRUCTIONS

IMPORTANT: It is your responsibility to:

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

• Ensure that all equipment operators have access to adequate

instructions concerning safe operating and maintenance procedures.

gasoline, jet fuel, kerosene, etc.), aromatic hydrocarbons or other

incompatible chemicals

NOTE: Be sure O-rings and seals are kept in good repair.

considered prior to putting into service.

pressure. See specifications for your model.

product.

result in inaccurate readings.

This product is not approved for use with

petroleum products (diesel fuel, unleaded

This product is not approved for use in hazardous

locations.

When applying power, adhere to specifications

listed in appropriate electronics manual.

Disconnect external power before attaching or

detaching input or output wires.

Compatibility of this product’s material and the

process fluid and/or environment should be

Product should never be operated outside its

published specifications for temperature or

Make sure flow and pressure have been eliminated

from process pipe prior to installing or removing

Installation near high electromagnetic fields and

high current fields is not recommended and may

Do not allow water to freeze in meter. Ice

expansion may burst the plastic housing.

Do not allow this meter to be used with steam.

TROUBLESHOOTING OPERATION

MAINTENANCE /

REPAIR

4

Page 5

SPECIFICATIONS

QS200-10 QS200-15 QS200-20 QS200-30 QS200-40

QS200-10PW QS200-15PW QS200-20PW QS200-30PW QS200-40PW

Tee Housing

Material

Insert

Housing

PPS (Polyphenylene sulde) / ULTEM® (Polyetherimide)

Material

Type Ultrasonic Flowmeter

Powered by

Unit of

Measure

Flow Rate

0.22-33 GPM

0.83-124.92 L/min

0.1-15 ft/sec

0.55-82 GPM

2.08-310.41 L/min

0.1-15 ft/sec

Accuracy +/- 2% of Reading

Uncertainty

0.04 GPM

0.018 ft/sec

Max.

Working

Pressure

Operating

Temperature

Storage

Temperature

Field

Calibration

Inlet / Outlet

Connections

Weight

INSERTS - ALL METER SIZES

1 in. Female

Socket

0.95 lbs.

(0.43kg)

OFF State Current 200µA (typical)

OFF State V-High

Transducer Excitation

ON State Current

ON State V-Low ON State Current * 50Ω

Output Frequency 0 to 100 Hz

Output Pulse Width 4mSec (Approx.)

SCH 80 PVC (Polyvinyl chloride)

DC power provided by customer controller

7.5V (dc) min to 36V (dc) max

OFF State Current: 200μA (typical)

Controller Dependant

0.92-138 GPM

3.48-522.39 L/min

0.1-15 ft/sec

0.10 GPM

0.018 ft/sec

0.17 GPM

0.018 ft/sec

150 PSI @ 70°F (10.3 bar @ 60°C)

+32°F to +140°F (0°C to +60°C)

+32°F to +140°F (0°C to +60°C)

No

1 1/2 in.

Female

Socket

1.12 lbs.

(0.51kg)

2 in. Female

Socket

1.39 lbs.

(0.63kg)

Supply Voltage - (OFF State

Current * Supply impedance)

(Supply Voltage / (Supply

impedance + 50Ω))

2.06-309 GPM

7.80-1169.70 L/min

0.1-15 ft/sec

0.37 GPM

0.018 ft/sec

3 in. Female

Socket

2.52 lbs.

(1.14kg)

3.58-537 GPM

13.55-2032.78 L/min

0.1-15 ft/sec

0.65 GPM

0.018 ft/sec

4 in. Female

Socket

3.21 lbs.

(1.46kg)

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

MAINTENANCE /

REPAIR

5

Page 6

SPECIFICATIONS (CONTINUED)

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

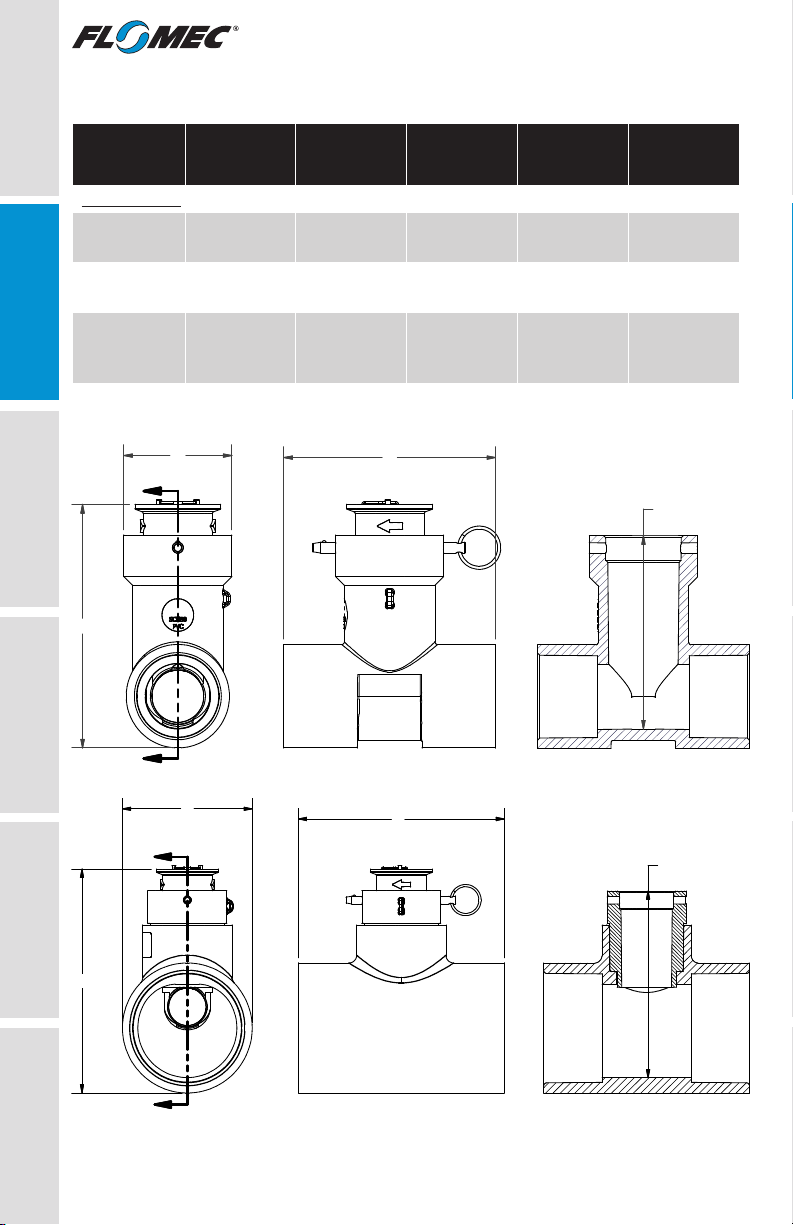

Dimensions

A. Length

B. Height

C. Width

(at widest

point)

D. Depth

SECT

B

QS200-10,

QS200-10PW

4.25 in.

(108mm)

5.38 in.

(137mm)

2.50 in.

(64mm)

4.47 in.

(114mm)

C

1 INCH

QS200-15,

QS200-15PW

1-1/2 INCH

4.90 in.

(124mm)

5.63 in.

(143mm)

2.50 in.

(64mm)

4.47 in.

(114mm)

A

QS200-20,

QS200-20PW

2 INCH

5.56 in.

(141mm)

6.12 in.

(156mm)

2.88 in.

(73mm)

4.94 in.

(125mm)

QS200-30,

QS200-30PW

3 INCH

6.63 in.

(168mm)

7.20 in.

(183mm)

4.18 in.

(106mm)

4.91 in.

(124mm)

QS200-40,

QS200-40PW

4 INCH

7.38 in.

(187mm)

8.41 in.

(213mm)

5.23 in.

(133mm)

6.17 in.

(156mm)

D

TROUBLESHOOTING OPERATION

MAINTENANCE /

REPAIR

SECT

C

SECT

B

SECT

Figure 1

6

For 1 in., 1-1/2 in., & 2 in. Meters

A

For 3 in. & 4 in. Meters

SECT VIEW

(TEE ONLY)

D

SECT VIEW

(TEE ONLY)

Page 7

SPECIFICATIONS (CONTINUED)

K-Factor Information

NOTE: The meter size is molded on the vertical arm of the Tee

FLOMEC ultrasonic meters use K-factor plus offset numbers for greater

accuracy during calibration. These values are derived by calibrating the

meters using NIST traceable instrumentation. Using both sets of values to

calibrate the meters provides greater accuracy than using only a K-factor

value. The K-factor and offset values for each meter are listed below.

IMPORTANT: The K-factors provided are for reference. Accuracy can

be affected by plumbing configuration, fluid condition, adjoining pipe

schedule, type of meter tee (if using QS200 insert in non-FLOMEC tee),

and entrapped air. Customers should always validate accuracy and adjust

K-factor as needed.

GETTING STARTED

SPECIFICATIONS

SAFETY /

Meter

Model

Size

FLOMEC TEE

K-Factor

(frequency)

Offset

NON-FLOMEC TEE

K-Factor

(frequency)

QS200-10 1 in. 0.5386 0 N/A

QS200-15 1-1/2 in. 0.7926 0 0.7947

QS200-20 2 in. 1.3765 0 1.3583

QS200-30 3 in. 3.8444 0 4.2505

QS200-40 4 in. 7.1676 0 7.2229

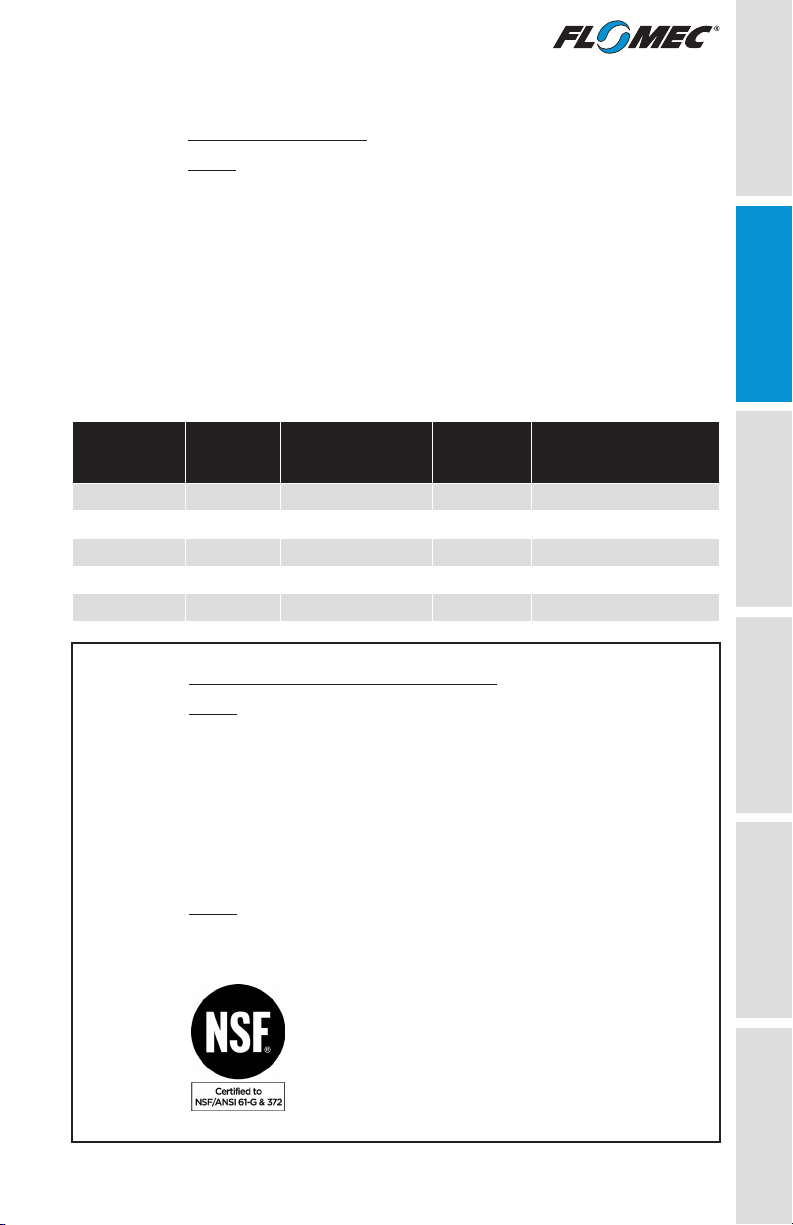

NSF CERTIFICATION INFORMATION

NOTE: QS200 meter are available as a standard meter, or as an

NSF certified meter. Only QS200 meters ordered as a complete unit

(ultrasonic insert installed in FLOMEC tee) qualify to be NSF certified.

Standard meter: The identification plate on the top of the ultrasonic

insert is marked “QS200”.

NSF certified meter: The identification plate on the top of the

ultrasonic insert is marked “QS200PW”, and the tee body is marked

with an NSF certification decal for additional identification.

NOTE: NSF certified meters use the same part number structure as

non-NSF models, except for the addition of the “PW” suffix on the end.

The “PW” suffix indicates an NSF certified meter. e.g., QS200-15PW.

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

NSF certification is valid only

when product is marked per

above information.

MAINTENANCE /

REPAIR

7

Page 8

INSTALLATION

GETTING STARTEDOPERATION

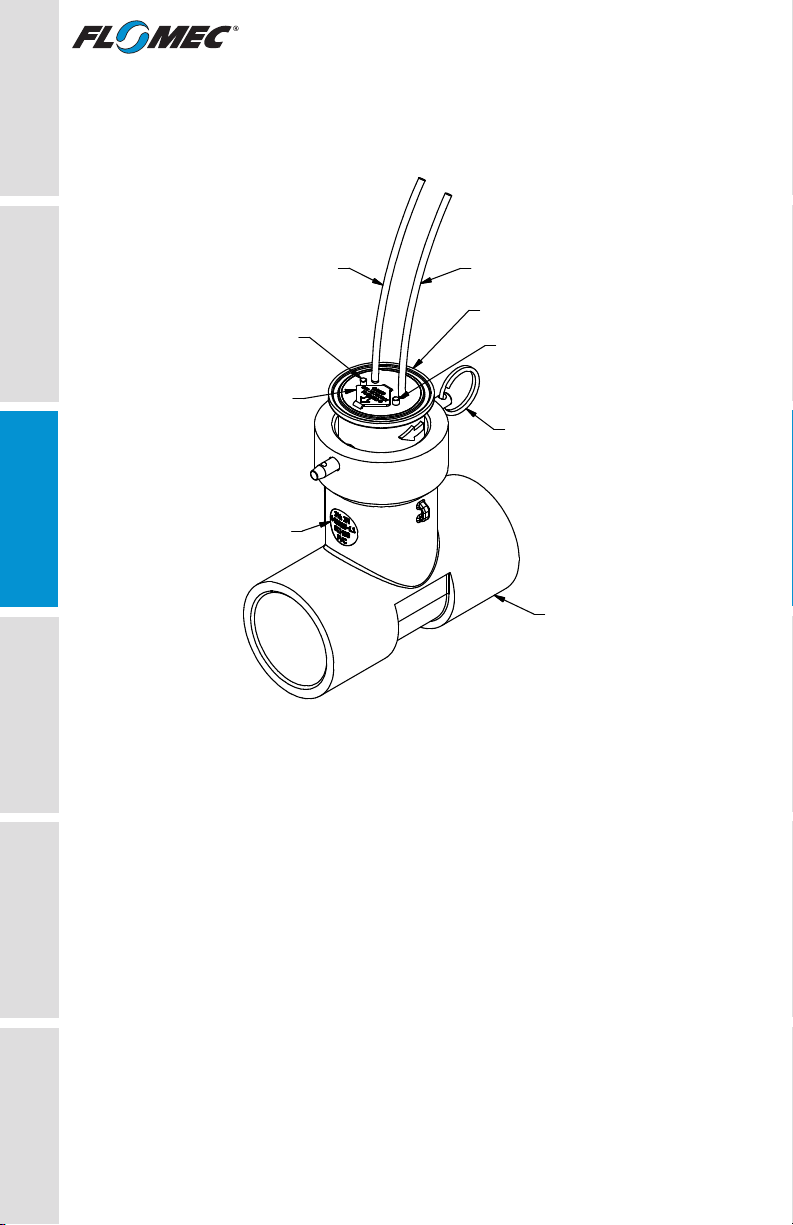

Below is a typical QS200 meter with labeled components. Familiarize

yourself with the meter before installation.

SAFETY /

ASSEMBLY /

SPECIFICATIONS

INSTALLATION

BLACK WIRE

GREEN LED

I.D. PLATE WITH

SERIAL NUMBER

AND FLOW ARROW

SIZE INFO

Figure 2

RED WIRE

INSERT ASSY.

AMBER LED

QUICK RELEASE

PIN

TEE

TYPICAL QS200 METER

TROUBLESHOOTING

REPAIR

8

MAINTENANCE /

Page 9

INSTALLATION (CONTINUED)

Provide a straight pipe run of at least 10Xs the pipe’s diameter upstream of

the meter, and at least 5Xs the pipe’s diameter downstream of the meter.

The arrow embossed on the insert body denotes the flow direction.

FLOW DIRECTION

ARROW

INSERT

TOP VIEW

INSTALL AT

ANGLE, IF

POSSIBLE

GETTING STARTED OPERATION TROUBLESHOOTING

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Figure 3

DOWNSTREAM

5Xs

UPSTREAM

10Xs

FLOW DIRECTION

Install Meter Onto Pipe

NOTE: There is no need to remove the insert to install the meter. The meter

must be installed with the arrow on the insert pointing in the flow direction.

If the meter is accidentally installed backwards, simply remove the insert,

rotate 180 degrees so the arrow points in the flow direction, and reinstall the

insert.

The Tee is bidirectional, the insert is not. The insert operates correctly as

long as the insert arrow is pointed in the direction of flow. The insert can be

rotated 180 degrees, so its arrow can always be pointed in the direction of

flow regardless of Tee installation.

If space allows, install Tee / insert at an angle rather than pointing up

(see Figure 3).

NOTE: For 1 inch pipe installations, this angle is especially important and

should be set at 45 degrees for most accurate meter operation.

MAINTENANCE /

REPAIR

9

Page 10

INSTALLATION (CONTINUED)

1. Remove all burrs from the pipe ends I.D. and O.D. edges and the Tee

sockets I.D. edges (see Figure 4).

GETTING STARTED

SAFETY /

SPECIFICATIONS

2. Clean and apply primer to the pipe ends and Tee sockets

(see Figure 5).

3. Apply PVC cement to pipe ends and Tee sockets and quickly

assemble the parts while the cement is fluid. Follow the cement

manufacturer’s instructions (see Figure 6).

4. Hold the cemented parts together for at least 30 seconds.

REMOVE BURRS

Figure 4 Figure 5

ASSEMBLY /

INSTALLATION

Figure 6

For Below Ground Installation

1. Install a valve box around the insert. Valve box extensions may be

needed depending on depth (see Figure 7).

NOTE: A minimum of 10 in. thick layer of gravel should be installed

immediately below the meter and valve box.

TROUBLESHOOTING OPERATION

APPLY PRIMER

APPLY CEMENT

REPAIR

10

MAINTENANCE /

Figure 7

Page 11

INSTALLATION (CONTINUED)

Wiring Connections

NOTE: Wiring diagram is shown in next section.

1. When using 18 AWG cable, cut off the unused wires so that they are

even with the sheath of the cable.

NOTE: For 18 AWG connections, remember the color of the twisted pair of

wires you use so that you can make an identical connection with the same

wires later.

2. 3M DBR/Y-6 Splice Kit Instructions:

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Figure 8a

Figure 8c

Figure 8b

OPERATION TROUBLESHOOTING

Figure 8d & 8e

MAINTENANCE /

REPAIR

11

Page 12

INSTALLATION (CONTINUED)

TO FLOW " + "

a. Strip insulation ¾ in. (19 mm).

b. With wire ends even, insert wires into the connector and tighten until

GETTING STARTEDOPERATION

SAFETY /

ASSEMBLY /

SPECIFICATIONS

INSTALLATION

secure.

c. Insert the connector all the way into the tube until the connector rests

on the bottom of the tube.

NOTE: If having difficulty getting the twist-on connector down into the tube

when using small gauge wires, use a thin, non-conductive object to push

the connector to the bottom of the tube. Upon removal of the object, ensure

that no voids or water paths remain in the grease.

d. Fold the wires into the channels.

e. Close the cap.

Wiring Diagram

This diagram shows connection to a RAINBIRD® Flow Smart Module.

Connections to other flow controllers may vary.

ON FLOW SMART

MODULE

18 AWG CABLE

to CONTROLLER

FLOW INSERT

TROUBLESHOOTING

Figure 9

REPAIR

12

1212

MAINTENANCE /

RED

BLACK

DBR/Y-6

SPLICE KIT

TO FLOW " - "

ON FLOW SMART

MODULE

Page 13

NOTES

GETTING STARTED

GETTING STARTED OPERATION TROUBLESHOOTING

SPECIFICATIONS

SPECIFICATIONS

SAFETY /

SAFETY /

INSTALLATION

INSTALLATION

ASSEMBLY /

ASSEMBLY /

OPERATION TROUBLESHOOTING

MAINTENANCE /

REPAIR

13

13

1313

Page 14

OPERATION

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

OPERATION

Each QS200 meter is shipped with two K-factor decals (placed loose inside

the owner’s manual packet). One is to affix on or near the installed meter for

on-site use if desired. The other decal is to affix to a convenient spot on or

near the controller for immediate reference if desired.

LEDs Functionality

There are two LEDs on the QS200 product. The GREEN LED is used

to indicate basic power and functionality of the meter. The AMBER LED

is used to indicate that there is a flow of water through the QS200 meter

insert. The LEDs will behave in the following manner to indicate different

modes of operation:

MODE LED BEHAVIOR

Power Disconnected

or Meter Failure:

No Flow Low

Power Mode:

No Flow or Reverse

Flow Active Mode:

Low Flow

Active Mode:

**High Flow

Active Mode:

**NOTE: To save power it is normal for the LEDs to be dim when flashing at

higher flow rates. At very high flow rates, the AMBER LED will appear to be

constantly ON but dim.

Both GREEN and AMBER LEDs are OFF.

GREEN LED flashes ON/OFF at a rate

of approximately 2 blinks per second.

GREEN LED flashes ON/OFF at a rate

of approximately 8 blinks per second.

GREEN LED flashes ON/OFF at a rate of

approximately 8 blinks per second and the

AMBER LED flashes ON/OFF at a rate that is

proportional to the rate of water flow thru the

meter.

GREEN LED flashes ON/OFF at a rate of

approximately 8 blinks per second and the

AMBER LED will appear to be constantly ON, but

will be dim.

TROUBLESHOOTING

REPAIR

14

1414

MAINTENANCE /

Page 15

TROUBLESHOOTING

1. The LEDs are the primary indicators of meter performance. Refer to

the Operations Section for LED indicating functionality.

2. Entrained air is air bubbles suspended in the water flow. Entrained

air creates errors in accuracy of ultrasonic technology meters.

Recommend a maximum of 10% entrained air in the water flow.

3. The faces of the transducers need to be clean and free of oily

substances for accurate operation. Do not touch transducers with

fingers, oily rags, etc.

DO NOT use wire brushes or abrasives to clean the faces of the

transducers (see Figure 10).

4. Ensure the flow direction arrow is pointing in the direction of flow for

correct LED functionality.

5. Ensure the quick release pin is installed in the tee to maintain pressure

and alignment of the insert in the tee.

GETTING STARTED TROUBLESHOOTING

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Figure 10

TRANSDUCER

FACES

15

1515

OPERATION

MAINTENANCE /

REPAIR

Page 16

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

REPAIR

QS200 Insert Replacement and

QS200 Retrofit Insert Installation Instructions

NOTE: These instructions are intended to assist in replacing the insert in an

existing FLOMEC® QS200 ultrasonic Meter.

These instructions also apply when a FLOMEC QS200 insert is used as

a replacement insert in other brands of Tee type meters, that have an

obsolete or unreliable insert.

The FLOMEC QS200 is a direct replacement for a paddle wheel type insert

in most meters that have a Tee type housing.

Keep the new insert free of dirt and debris during

installation.

Check Meter Size

If your flow controller requires a meter K-factor, use the K-factor for your

size meter (see SPECIFICATIONS section). If the meter size is unknown, it

is easily determined using one of the following methods (for FLOMEC and

other brands):

1. Dipstick Method (For 2 in., 3 in. and 4 in. meters only):The interior

depth of the meter body indicates its size. To check, remove the old

insert from the meter body and insert the end of a stiff tape measure

down into the insert bore until it touches the bottom of the meter body

bore. Read the depth shown on the tape measure at the top of the

Tee housing (see Figure 11) and compare with dimension “D” in the

specifications section (see Figure 1).

2. Line Pipe Size Method: Normally, the line pipe size is the same as the

meter size. Figure 12 shows line pipe sizes.

NOTE: FLOMEC Tees are marked with hallmark of size, part number,

SCH80 and pressure.

TROUBLESHOOTING OPERATION

MAINTENANCE /

REPAIR

Figure 11

16

Page 17

REPAIR (CONTINUED)

1.315

Ø

[1 5/16]

1" PIPE

3.500

Ø

[3 1/2]

1.900

Ø

[1 29/32]

1 1/2" PIPE

Ø

[4 1/2]

4.500

2.375

Ø

[2 3/8]

2" PIPE

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Figure 12

OPERATION TROUBLESHOOTING

3" PIPE

4" PIPE

MAINTENANCE /

REPAIR

17

Page 18

REPAIR (CONTINUED)

Remove Old Insert From Tee

1. Clean all dirt and debris away from the immediate area of the old insert

GETTING STARTED

2. Remove the old insert. Grasp the insert flange with your hand and pull

NOTE: The FLOMEC Multi-Tool (p/n 146055-501) can be used to make

SAFETY /

ASSEMBLY /

SPECIFICATIONS

INSTALLATION

removal of old insert easier (see Figure 17).

NOTE: When replacing another manufacturer’s insert with the QS200

Retrofit Insert, the old insert could have a sediment or mineral buildup and

need to be leveraged out of the tee.

and the top of the meter, then pull out the quick release pin from the

meter (see Figure 13).

straight up and out of the Tee, making sure no dirt or other particles fall

into the insert bore of the meter (see Figure 14).

TROUBLESHOOTING OPERATION

MAINTENANCE /

Figure 13 Figure 14

REPAIR

18

Page 19

REPAIR (CONTINUED)

Install New or Replacement Insert Into Tee

1. The Tee insert bore must be clean before installing the insert and the

(2) black O-rings on the insert should be fully lubricated.

2. Orient the insert over the insert bore so that the arrow on the insert is

pointing in the direction of flow.

3. Insert the insert straight down into the Tee.

4. Push down on the insert flange and twist slightly to install, and to

align the retaining pin holes in the insert with the holes in the Tee (see

Figure 15).

NOTE: The FLOMEC Multi-Tool (p/n 146055-501) can be used to make

installing new insert easier (see Figure 18).

NOTE: The O-rings on the outside of the QS200 Retrofit Insert are square

profile O-rings. When installing in another brand of Tee, if the insert fits

too tight into the Tee, replace the square profile O-rings with the round

profile O-rings included with the QS200 Retrofit Insert. Their installation

could make installation easier in tight fitting Tees. The O-rings must be fully

lubricated before insert installation.

5. Next, replace the quick release pin (see Figure 16).

6. Using the splicing and wiring information (see WIRING

CONNECTIONS and WIRING DIAGRAM in the INSTALLATION

section), connect the wiring from the new insert to the wiring cable of

the controller.

7. Energize the insert and verify that it is operating properly (see

Troubleshooting section if required).

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

Figure 15 Figure 16

MAINTENANCE /

REPAIR

19

Page 20

REPAIR (CONTINUED)

Using the FLOMEC Multi-Tool

The multi-tool was designed exclusively for tee type meters that use an

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

insertion type insert. It facilitates easier removal of the insert, whether from

a QS200 meter or other brands of tee type insertion meters.

It is especially useful when attempting to remove an old, inoperative,

or inaccurate insert from another brand of tee type insertion meter for

replacement with a QS200 insert.

The multi-tool is versatile, compact and fits easily into the valve box for

close quarters use.

The pointed end is designed for use as:

1. A versatile pry bar and driving wedge. On other brands of tee type

2. An alignment tool to align the pin holes of the new insert with the pin

3. A cleaning tool for clearing debris from the valve box lid groove or

The U-formed end is designed for use as:

4. A handle for leverage when using the pointed end.

5. A levering tool by slipping the U-formed end around the insert between

The multi-tool (P/N 146055-501) is a separate item available to the

customer, and is listed in the repair parts list near the back of the manual.

insertion meters, when the insert lip may be too close to the top of the

tee to use the U-formed end of the multi-tool, use the pointed end (as

pry bar or driving wedge) between the insert lip and top of the tee to

break the insert loose and gain room between the insert lip and tee to

use the U-formed end to lever the insert up and out.

holes in the tee.

other crevices.

the insert lip and the top of the tee. This positions the tool for use as a

lever for levering inserts up and out of the tee for replacement. It can

be levered up or down, and can be rotated to any quadrant around the

insert in order to give the best position for leverage.

TROUBLESHOOTING OPERATION

MAINTENANCE /

REPAIR

20

Page 21

REPAIR (CONTINUED)

Remove Old Insert From Tee with FLOMEC Multi-Tool

GETTING STARTED

SPECIFICATIONS

SAFETY /

PRY UP - To break a stuck insert loose

LEVERAGE - To Lift insert up and out

Figure 17

Install New QS200 Insert FLOMEC Multi-Tool

DRIVING WEDGE - To lift insert more

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

PIN HOLE ALIGNMENT For easy pin install

Figure 18

CLEAN LID GROOVE Remove dirt, roots, debris

MAINTENANCE /

REPAIR

21

Page 22

REPAIR PARTS ILLUSTRATION FOR QS200

Do not return this product without prior approval

GETTING STARTED

to strict government regulations, GPI cannot accept par ts unless

they have been drained and cleaned.

from the GPI Customer Service Depar tment. Due

SAFETY /

ASSEMBLY /

SPECIFICATIONS

3

1

INSTALLATION

2

TROUBLESHOOTING OPERATION

MAINTENANCE /

REPAIR

22

Page 23

REPAIR PARTS LIST FOR QS200

Ref.

No.

1 O-Ring Seal Kit 146500-01

2 Hardware Kit 146500-2

3 Ultrasonic Insert QS200

3 Ultrasonic Insert, Potable Water QS200PW

- Housing, 1 inch tee, PVC, Spare 146010-511

- Housing, 1-1/2 inch tee, PVC, Spare 146015-511

- Housing, 2 inch tee, PVC, Spare 146020-511

- Housing Assembly, 3 inch tee, PVC, Spare 146030-512

- Housing Assembly, 4 inch tee, PVC, Spare 146040-512

- Multi-Tool, Spare 146055-501

Description

Includes (2) square profile O-rings &

(2) round profile O-rings

Includes (1) quick release pin

Includes (1) insert assembly w/square profile

O-rings, (2) round profile O-rings,

(1) quick release pin, (2) K-factor decals &

(1 owner’s manual)

Includes (1) insert assembly w/square profile

O-rings, (2) round profile O-rings,

(1) quick release pin, (2) K-factor decals &

(1 owner’s manual)

Part Number

GETTING STARTED

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

OPERATION TROUBLESHOOTING

PARTS & SERVICE

For warranty consideration, parts, or other service information, please

contact your local distributor. If you need further assistance, contact

the GPI Customer Service Department in Wichita, Kansas, during

normal business hours.

A toll free number is provided for your convenience.

1-888-996-3837

To obtain prompt, efficient service, always be prepared with the following

information:

• The model number of your meter.

• The serial number or manufacturing date code of your meter.

• Part descriptions and numbers.

For warranty work, always be prepared with your original sales slip or other

evidence of purchase date.

IMPORTANT: Please contact GPI before returning any parts. It may be

possible to diagnose the trouble and identify needed parts in a telephone

call.

MAINTENANCE /

REPAIR

23

Page 24

FLOMEC® TWO-YEAR LIMITED WARRANTY

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205,

hereby provides a limited warranty against defects in material and workmanship on all

products manufactured by Great Plains Industries, Inc. This product includes a 2 year

warranty. Manufacturer’s sole obligation under the foregoing warranties will be limited

to either, at Manufacturer’s option, replacing or repairing defective Goods (subject

to limitations hereinafter provided) or refunding the purchase price for such Goods

theretofore paid by the Buyer, and Buyer’s exclusive remedy for breach of any such

warranties will be enforcement of such obligations of Manufacturer. The warranty shall

extend to the purchaser of this product and to any person to whom such product is

transferred during the warranty period.

The warranty period shall begin on the date of manufacture or on the date of

purchase with an original sales receipt. This warranty shall not apply if:

A. the product has been altered or modified outside the warrantor’s duly appointed

representative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been

installed or operated other than in accordance with the manufacturer’s operating

instructions.

To make a claim against this warranty, contact the GPI Customer Service Department at

316-686-7361 or 888-996-3837.

Or by mail at:

Great Plains Industries, Inc.

5252 E. 36th St. North

Wichita, KS, USA 67220-3205

The company will step you through a product troubleshooting process to determine

appropriate corrective actions.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY

FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED

IN THE USE OR LOSS OF USE OF THE PRODUCT WARRANTED HEREUNDER.

The company herewith expressly disclaims any warranty of merchantability or fitness for

any particular purpose other than for which it was designed.

This warranty gives you specific rights and you may also have

other rights which vary from U.S. state to U.S. state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT –

Part 702 (governs the resale availability of the warranty terms).

IP68

© 2019 Great Plains Industries, Inc., All Rights Reserved.

Great Plains Industries, Inc. / 888-996-3837 / FLOMEC.net

920901-01 Rev C04/29/2019

Loading...

Loading...