PCD Pump User Guide

Precision Dispensing Systems

Version 6.0

February 20, 2019

Part No. 22293078M

for use with:

PCD3........... PN 22293093, 22293093-1004

PCD3L ........ PN 22293093-1002

PCD3H ........ PN 22293093-1003, 22293121

PCD4........... PN 22293081, 22293098, 22293098-0002

PCD4L......... PN 22293122

PCD4H ........ PN 22293103, 22293227-0002, 22293227-0003

PCD4HB...... PN 22293205, 22293240

PCD6........... PN 22293160-001

PCD6HB...... PN 22293161-003

PCD7H ........ PN 22293306-0003

prepared by GPD Global® Documentation Department

611 Hollingsworth Street

Grand Junction, CO, USA 81505

tel: +1.970.245-0408 • fax +1.970.245-9674

request@gpd-global.com • www.gpd-global.com

Copyright © 2019 GPD Global® • All Rights Reserved

GPD Global

©

Contents

Safety Notices ............................................................................................................... iii

Warranty ......................................................................................................................... iv

Scope of Supply ............................................................................................................. 1

Introduction .................................................................................................................... 1

Functional Description ................................................................................................ 1

Applications ................................................................................................................ 1

Features ..................................................................................................................... 1

Options ....................................................................................................................... 1

Pump Identification ........................................................................................................ 2

Installation ...................................................................................................................... 3

Mounting Hardware .................................................................................................... 3

Integration on Robotic Systems ................................................................................. 4

Integration on Table Top Systems ............................................................................. 6

Operations ...................................................................................................................... 8

1- Read Safety Notices .............................................................................................. 8

2- Initial Start Up ........................................................................................................ 8

3- Prime Pump with Medium .................................................................................... 11

4- Install Pump ......................................................................................................... 11

Maintenance ................................................................................................................. 12

Flush Pump .............................................................................................................. 12

Clean PCD3, PCD3L, PCD3H ................................................................................. 13

Clean PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H ....................... 17

Troubleshooting ........................................................................................................... 22

Parts Lists ..................................................................................................................... 23

Specifications ............................................................................................................... 23

Additional Dimensions .............................................................................................. 28

Threads & Materials ................................................................................................. 31

References .................................................................................................................... 32

Disposal ................................................................................................................... 32

Connection Options .................................................................................................. 32

Assembly Drawings .................................................................................................. 34

2/20/19 ii

PCD Pump User Guide Safety Notices

Safety Notices

Despite adhering to all applicable safety guidelines, some hazards remain which should be

taken note of for operation of the system:

CAUTION: Very high pressures can be produced, depending on the viscosity and speed of

rotation, and this could result in unintended spurting of medium. Check the flow quantity in

relation to the dispensing needle used.

CAUTION: For initial start up and after being refilled, air bubbles in the medium could cause

an uncontrollable spurting from the outlet nozzle. Only start production operation once the dispense pump has been completely bled.

CAUTION: Wear suitable protective clothing if chemical, corrosive, or dangerous

products are to be used. Note and comply with the safety stipulations and the

information from the manufacturer. Ensure sufficient bleeding or extraction of air.

Take special safety precautions if working with dangerous media; for example, provide eye flushing facilities if working with corrosive chemicals.

CAUTION: Preparation before starting up - visual check. Make a daily visual check of the

dispense pump before starting work and before each shift change. If there is any doubt that the

unit is not perfectly ready for operation, it must be shut down at once and inspected by a suitably qualified person before it used again.

General Safety

Informal safety measures

• Always keep the operation and maintenance instructions with the dispense pump.

• This is to be supplemented by the generally and locally applicable rules and regulations to

prevent accidents and for protection of the environment.

Operating environment, prevention of damage

In order to prevent damage and to ensure chambers required for precise dispensing are filled,

make sure that:

• the dispense pump is never operated without medium (the stator will be destroyed),

• the discharge side is not closed off during operation.

Appropriate use, warranty

The dispenser pump is intended to be used for the conveying and precise dispensing of media

in non-explosion-proof environments.

Check the chemical resistance of the parts in contact with the product before starting up the

unit for the first time. Refer to Specifications

Any of the following that are done without the explicit and written approval of the manufacturer:

• conversions or additions,

• the use of non-original spare parts,

• repairs carried out by companies or persons that have not been authorized by the manufacturer

(pg 23).

can lead to the warranty being rendered null and void. The manufacturer shall have no liability whatsoever for damage resulting from failure to follow the Operations

Maintenance

(pg 12) instructions.

2/20/19 GPD Global

(pg 8) and

®

iii

PCD Pump User Guide Warranty

Qualifications of the operating and maintenance personnel

The owner bears the responsibility for ensuring that operating and maintenance personnel

have the required qualifications. The operation and maintenance instructions must be read

and understood. Comply with the relevant applicable technical and safety regulations.

Organizational measures

The owner is to provide any personal protective equipment that is required. All the safety

devices are to be checked regularly. Wear protective glasses and a protective suit for

operation and cleaning to protect against any chemicals that may be sprayed out.

Warranty

General Warranty. Subject to the remedy limitation and procedures set forth in the Section

“Warranty Procedures and Remedy Limitations,” GPD Global warrants that the system will

conform to the written description and specifications furnished to Buyer in GPD Global’s

proposal and specified in the Buyer’s purchase order, and that it will be free from defects in

materials and workmanship for a period of one (1) year. GPD Global will repair, or, at its

option, replace any part which proves defective in the sole judgment of GPD Global within one

(1) year of date of shipment/invoice. Separate manufacturers’ warranties may apply to components or subassemblies purchased from others and incorporated into the system. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES,EXPRESS

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

Limitations. GPD Global reserves the right to refuse warranty replacement, where, in the sole

opinion of GPD Global the defect is due to the use of incompatible materials or other damages

from the result of improper use or neglect.

This warranty does not apply if the GPD Global product has been damaged by accident,

abuse, or has been modified without the written permission of GPD Global.

Items considered replaceable or rendered unusable under normal wear and tear are not

covered under the terms of this warranty. Such items include fuses, lights, filters, belts, etc.

Warranty Procedures and Remedy Limitations. The sole and exclusive remedy of the

buyer in the event that the system or any components of the system do not conform to the

express warranties stated in the Section “Warranties” shall be the replacement of the

component or part. If on-site labor of GPD Global personnel is required to replace the nonwarranted defective component, GPD Global reserves the right to invoice the Buyer for

component cost, personnel compensation, travel expenses and all subsistence costs. GPD

Global’s liability for a software error will be limited to the cost of correcting the software error

and the replacement of any system components damaged as a result of the software error. In

no event and under no circumstances shall GPD Global be liable for any incidental or consequential damages; its liability is limited to the cost of the defective part or parts, regardless of

the legal theory of any such claim. As to any part claimed to be defective within one (1) year of

date of shipment/invoice, Buyer will order a replacement part which will be invoiced in ordinary

fashion. If the replaced part is returned to GPD Global by Buyer and found by GPD Global in

its sole judgment to be defective, GPD Global will issue to Buyer a credit in the amount of the

price of the replacement part. GPD Global’s acceptance of any parts so shipped to it shall not

be deemed an admission that such parts are defective.

Specifications, descriptions, and all information contained in this manual are subject to change and/or correction

without notice.

Although reasonable care has been exercised in the preparation of this manual to make it complete and accurate, this

manual does not purport to cover all conceivable problems or applications pertaining to this machine.

2/20/19 GPD Global

®

iv

PCD Pump User Guide Scope of Supply

Scope of Supply

Includes PCD Pump, Stator, Syringe Support, Mounting Hardware, Pump Maintenance Tools,

and Documentation:

• PCD Pump User Guide - PN 22293078M

• PCD Pump Parts List - PN 22200613

• KITS: Spare Parts/Setup/Cleaning, PN 22290036

Introduction

The Progressive Cavity Displacement (PCD) Pumps are dispensing devices for precision work

with products requiring very high repeat accuracy with a wide range (low-to-high) viscosity.

These dispense pumps are true volumetric dispensing systems that can be dismantled in a

short period of time when maintenance is required.

Functional Description

PCD Pumps use a rotating displacement consisting of a rotor and a stator.

A number of voids are produced as a result of the various geometries of the conveying

elements. Conveying that is either proportional to the angle of rotation or else is RPMdependent (produced by the rotation of the rotor in the stator).

Since the direction of flow is reversible, the medium can be sucked back to allow a clean break

of the thread. Self-sealing depends on the viscosity.

Applications

PCD Pumps are classified by the minimum volume and the maximum flow rate. Compatible

fluids for all models generally have a viscosity of less than 60,000 cps and include fluid types

such as water, grease, gel, silicones, glues, LED encapsulants, underfills, fats, oils, colors,

sealing compounds, adhesives, etc.

Features

• PCD3 - The PCD3 model is designed for low volume applications with a minimum volume

of 1

• PCD4 - The PCD4 model is designed for applications with a minimum volume of 4

a maximum rate of 6 ml/minute.

• PCD6 & PCD7- PCD6 and PCD7 models offer a higher flow rate than PCD3 and PCD4.

PCD6 has a minimum volume of 15

has a minimum volume of 60

• H and L - Both H and L models benefit from lower priming volumes and air-free reservoir

change. H models use a high precision motor and may be used with the GPD stand-alone

controllers.

• PCD3H and PCD4H - These models offer higher resolution in dispense volumes. PCD3H

and PCD4H models include a low volume feed way for lower priming volumes and also

offer a higher resolution of dispense volume. Available only on MAX Series and DS Series

systems.

µL and a maximum flow rate of 1.3 ml/minute.

µL and

µL and a maximum flow rate of 18 ml/minute. PCD7

µL and a maximum flow rate of 60ml/minute.

Options

A material level detect option is available for all PCD pump models when used on these GPD

Global platforms: MAX Series or DS Series.

2/20/19 GPD Global

®

1

PCD Pump User Guide Pump Identification

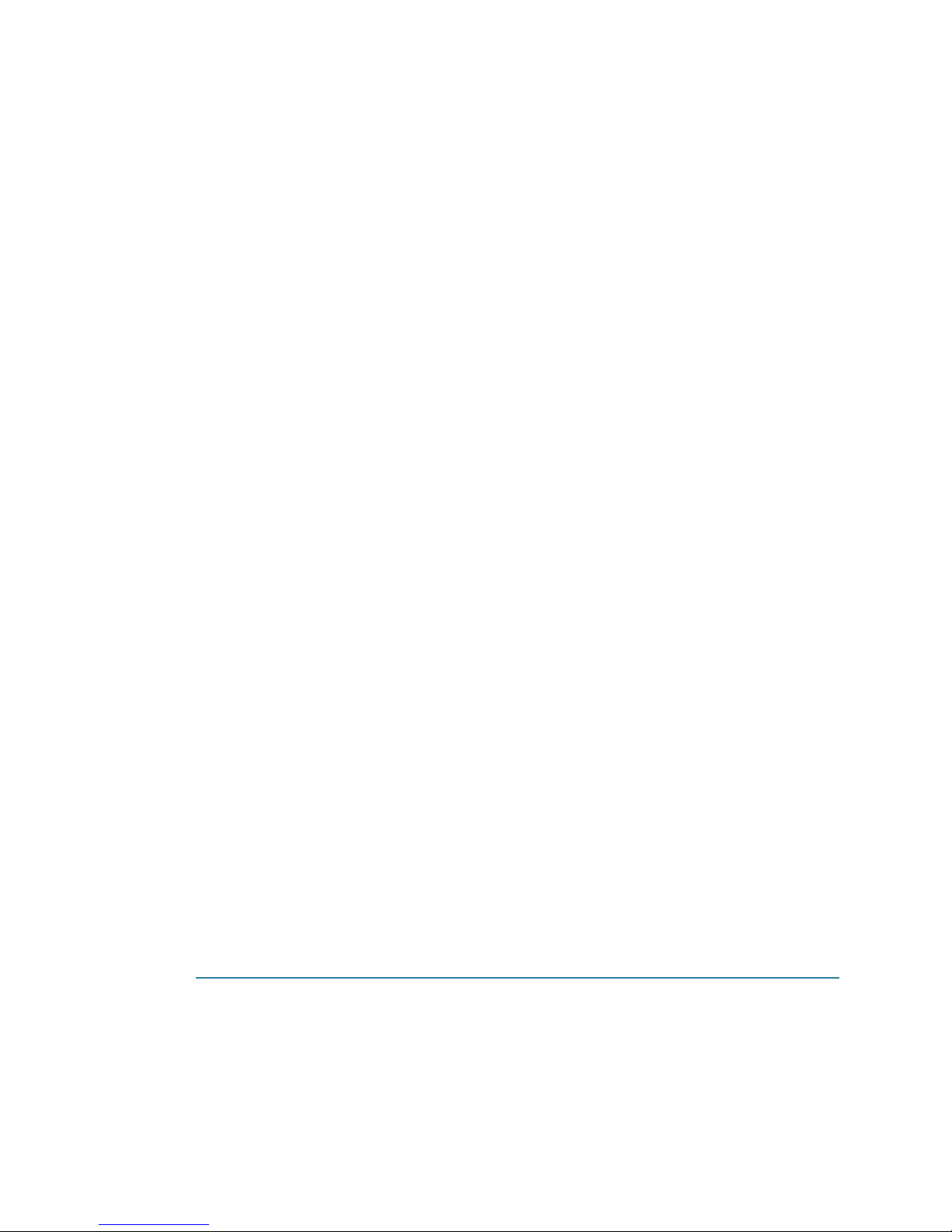

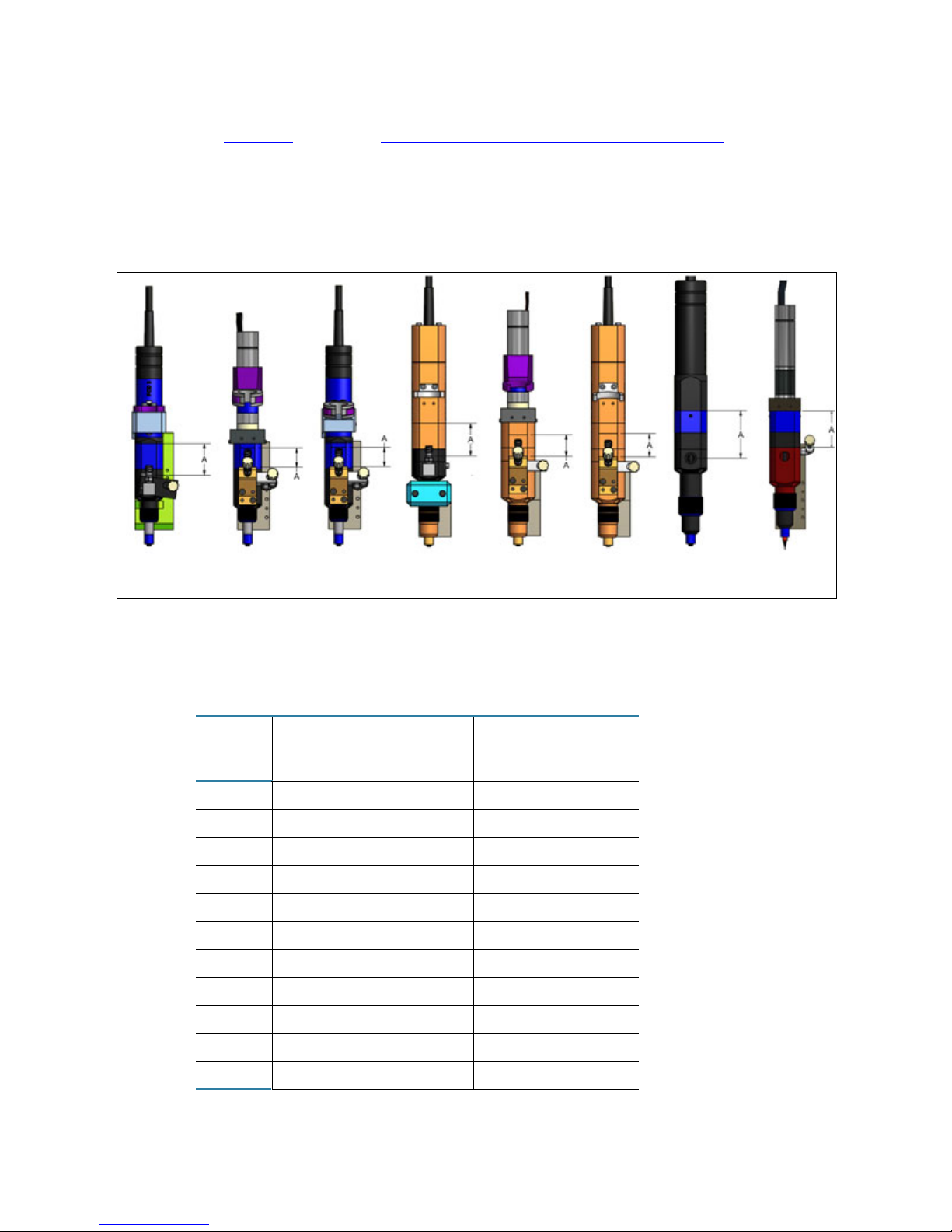

PCD3H

PCD4

PCD4L

PCD4H

PCD3

PCD3L

PCD6

PCD4HB

PCD6HB

22293093-1003

22293093-1002

22293093 &

22293103

22293122

22293081

22293240

22293161-001

22293161-003

22293093-1004

(previously 22293120)

(previously 22293228)

PCD7H

22293306-0003

Pump Identification

Figure 1: Models by Name and Part Number

Each pump model can be identified by the type of motor and feed way it uses.

Table 1: Distinguishing Features

Feed Way Motor

High Volume Low

Vol ume

Model Part Number

PCD3 22293093-1004 X X

PCD3L 22293093-1002 X X

PCD3H 22293093-1003 X X

22293121 X X

PCD4 22293081 X X

22293098-0002 X

PCD4L 22293122 X X

PCD4H 22293103 X X

PCD4HB 22293240 X X

PCD6 22293161-001 X X

PCD6HB 22293161-003 X X

PCD7H 22293306-0003 X X

Cylindrical,

Shiny

Square Cylindrical,

Black

Dual Flat

Further individual model detail is available here: Assembly Drawings

2/20/19 GPD Global

®

(pg 34)

2

PCD Pump User Guide Installation

Installation

• Mounting Hardware (pg 3)

• Integration on Robotic Systems

• Integration on Table Top Systems

Mounting Hardware

Any PCD model can be integrated with GPD hardware or non-GPD hardware using either a

GPD Clamp Positioning Mount or a GPD Taper-Lock™.

(pg 4)

(pg 6)

• Taper-Lock™ Mount

• Clamp Positioning Mount

(pg 3)

(pg 3)

Taper-Lock™ Mount

The Taper-Lock™ is a quick, secure, and convenient (no tools required) way to mount any

GPD pump to a system. All PCD pumps use the same Taper-Lock™ hardware.

To mount a PCD pump on non-GPD hardware with a Taper-Lock™ mount:

1. Prepare you hardware to accept the Taper-Lock™hardware. For hole pattern and dimension details, refer to Taper-Lock Mounting Detail - 22110291

(pg 60).

2. Fasten the Taper-Lock™to your hardware.

3. Mount the pump in the Taper-Lock™.

a. Press down and hold the latching lever at the top of the mount.

b. Align and engage the pump with the top dowel pin of the mount.

c. Apply downward pressure to the pump while releasing the latching lever.

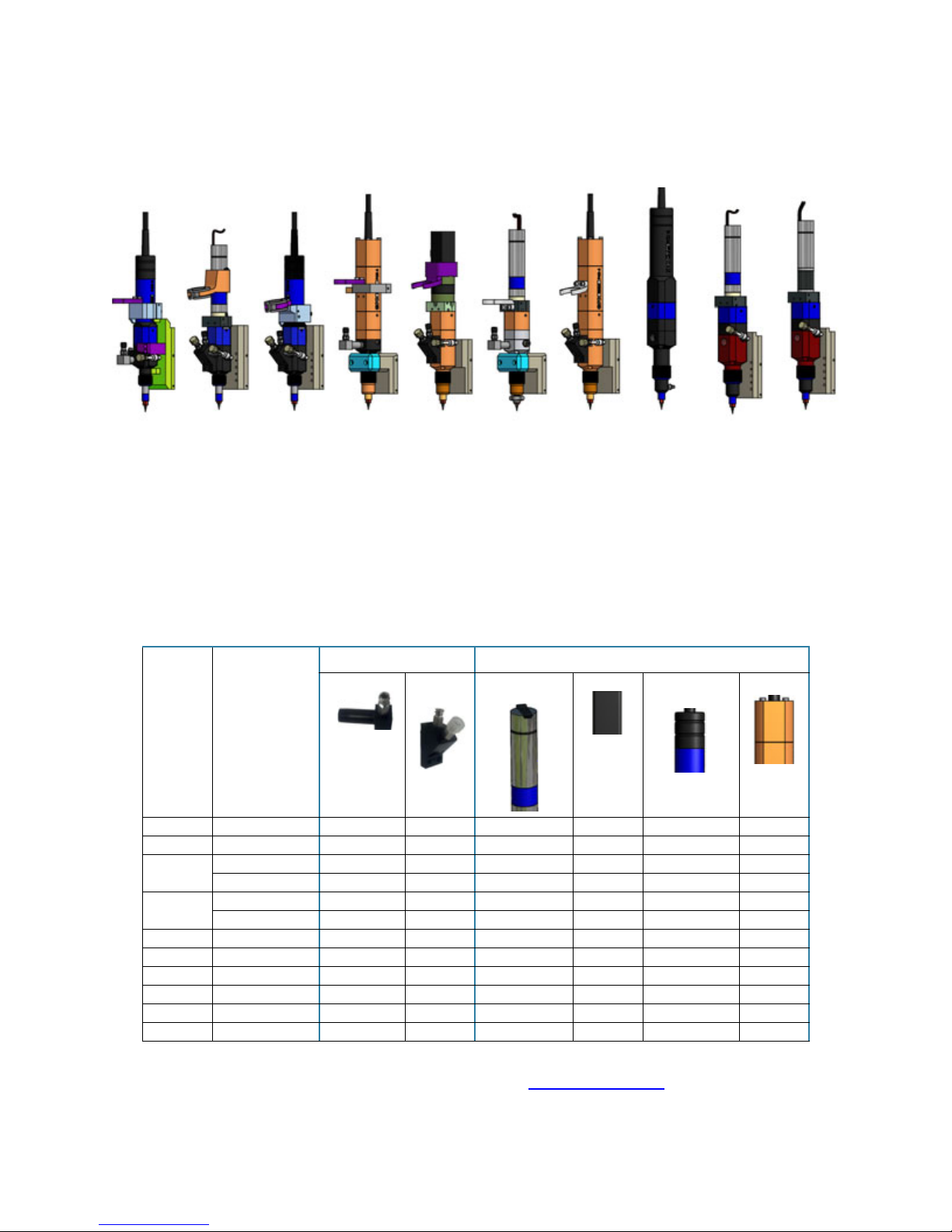

Clamp Positioning Mount

To mount a PCD pump on non-GPD hardware with a Clamp Positioning Mounts:

1. Select a clamp mount sized to fit your PCD pump.

PCD3, PCD3L, PCD3H

2/20/19 GPD Global

Figure 2: Clamp Positioning Mounts by Model*

PCD4, PCD4L, PCD4H,

PCD4HB PCD6, PCD6HB

* All mounts use the same screw: PN SACAM040070010

®

3

PCD Pump User Guide Installation

PCD3 PCD3H PCD3L PCD4H PCD4L

PCD4

PCD6

PCD4HB

PCD6HB

PCD7

PCD7H

2. Prepare your hardware to accept the clamp mount. Refer to Clamp Mount Dimensions -

22212002 (pg 59) and Clamp Mount Hole Patterns & Groove - 22212002 (pg 58).

3. Fasten the clamp mount to your hardware.

4. Position the PCD pump body so the clamp mount is located within the indicated mounting

range (A), and then tighten the clamp mount screw.

Figure 3: Position Clamp Mount on PCD Body within “A” Range

Integration on Robotic Systems

1

Table 2: Controller Required for Integration by Pump

GPD Integrated

Pump

PCD3

PCD3L

PCD3H

PCD4

PCD4L

PCD4H

PCD4HB

PCD6

PCD6HB

PCD7

PCD7H

Electronic Control System

for MAX Series & DS Series

x

x

x

x

x

Machine Integrated

Controller

x

x

x

x

x

x

2/20/19 GPD Global

®

4

PCD Pump User Guide Installation

Machine Integrated Controller

This GPD Global controller allows integrators to use PCD pumps in their

designs. Requirements:

• 24V signal to enable forward motion

• 24V signal to enable reverse motion

• Variable 0-10V signal to control the speed in forward or reverse

Install on GPD Global MAX Series or DS Series Robotic System

PCD3H, PCD4H, PCD4HB, PCD6HB, PCD7H

To mount one of these PCD pump models on a standard GPD Global MAX Series or DS

Series dispensing system:

1. Mount material on the pump.

2. Mount the pump in the Taper-Lock™ mount:

a. Press down and hold the latching lever at the top of the mount.

b. Align and engage the pump with the top dowel pin of the mount.

c. Apply downward pressure to the pump while releasing the latching lever.

3. Connect the two (2) pump cables into the base of the dispensing system Z-axis motor

cover.

PCD3, PCD3L, PCD4, PCD4L, PCD6, PCD7H

NOTE: To operate pump models PCD3, PCD3L, PCD4, and PCD4L, the GPD Global MAX

Series or DS Series dispensing system must be configured with a tabletop controller and cable

for pump control. To mount one of these PCD pump models on an upgraded dispensing

system (configured with a tabletop controller and cable):

1. Mount material on the pump.

2. Press the dispenser MOTION STOP button to remove power from the PCD controller.

3. Mount the pump in the Taper-Lock™ mount:

a. Press down and hold the latching lever at the top of the mount.

b. Align and engage the pump with the top dowel pin of the mount.

c. Apply downward pressure to the pump while releasing the latching lever.

4. Connect the pump cable to the dispenser receptacle panel.

5. Release the MOTION STOP button to return power to the PCD controller.

Install on Non-GPD Equipment

For easy-installation options available for mounting any model of PCD pump on non-GPD

hardware, refer to Mounting Hardware

(pg 3).

2/20/19 GPD Global

®

5

PCD Pump User Guide Installation

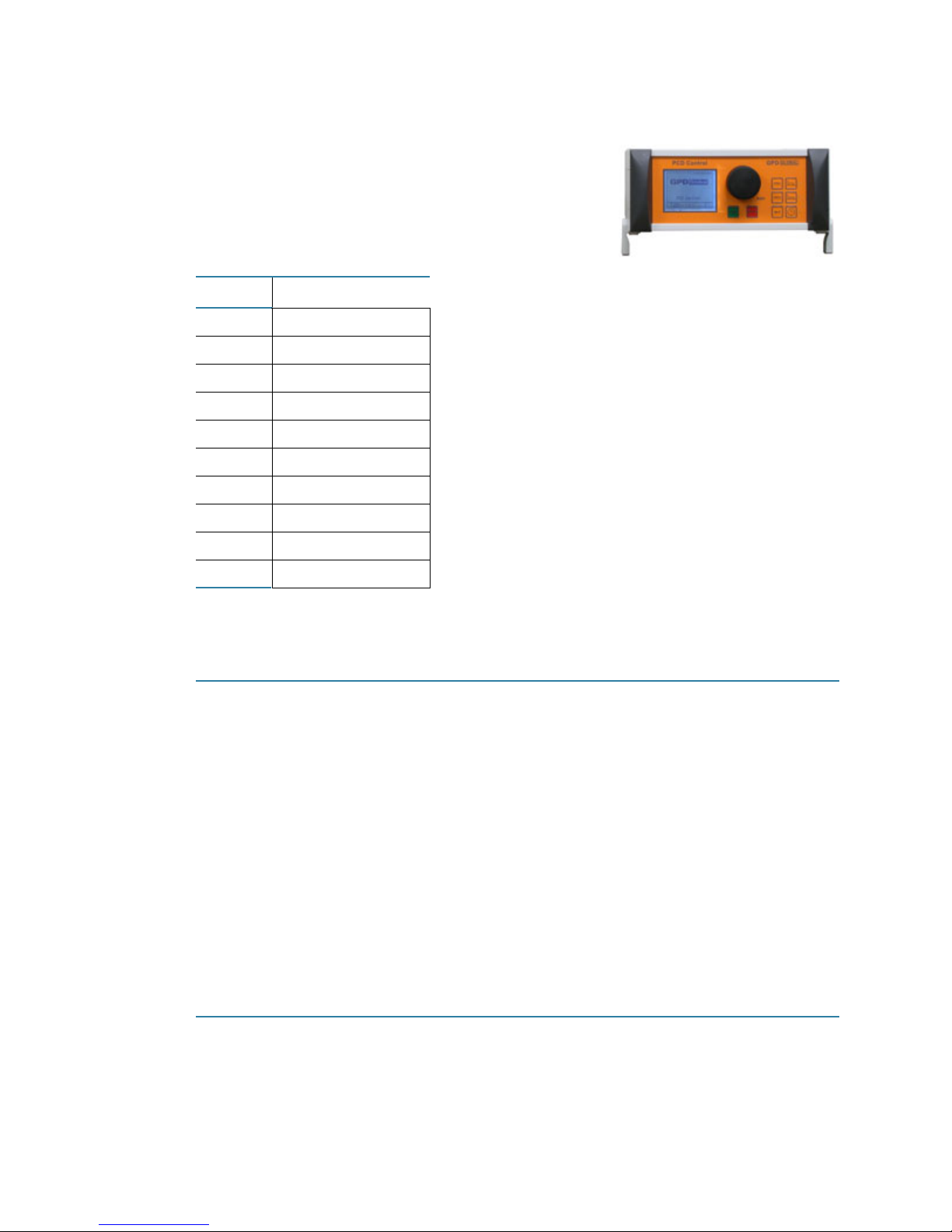

Integration on Table Top Systems

All relevant settings for your production results can be

easily saved via a graphic user interface if you operate

your dispense pump with a GPD Global PCD Tabletop

Controller especially matched to the pump.

Table 3: Pumps with Table Top

Capability

Pump Controller

PCD3

PCD3L

PCD3H

PCD4

PCD4L

PCD4H

PCD4HB

PCD6

PCD6HB

PCD7H

x

x

–

x

x

–

–

x

–

x

Install on GPD Global Island Series Robotic System

PCD3, PCD3L, PCD4, PCD4L, PCD6, PCD7H

To mount a PCD pump on a GPD Global Island Series dispensing system:

1. Turn off the PCD Tabletop Controller or, if system is configured with one, turn off the pump

power switch.

2. Mount the pump in the Taper-Lock™mount:

a. Press down and hold the latching lever at the top of the mount.

b. Align and engage the pump with the top dowel pin of the mount.

c. Apply downward pressure to the pump while releasing the latching lever.

3. Connect the pump cable to the power port on the Z axis.

4. Turn on the PCD Tabletop Controller or, if your system is configured with one, turn on the

pump power switch.

Install Pump in PCD Table Stand

PCD3, PCD3L, PCD4, PCD4L, PCD6, PCD7H

To mount a PCD pump in a PCD Table Stand:

1. Place a PCD Table Stand on a level surface.

2/20/19 GPD Global

®

6

PCD Pump User Guide Installation

(A) Extension arm

(B) Clamp handle

(C) Bracket screw

(D) Cable

(E) Bracket

2. Prepare the PCD Table Stand to hold a pump:

a. With one hand, support the extension arm (Item A) while loosening the clamp handle

(Item B) with the other hand.

b. As needed, slide and rotate the extension arm vertically and laterally to establish

desired position and orientation.

c. To lock the extension arm in place, tighten the clamp handle.

d. Using a 4 mm Allen key, loosen the bracket screw (Item C).

3. Mount a pump in the PCD Table Stand:

a. Disconnect the pump cable from the pump controller.

b. Feed the pump cable (Item D) through the bracket

(Item E).

c. Then position the pump in the bracket so the central

barrel (black section) of the pump is positioned in the

bracket as shown above.

d. Tighten the bracket screw (Item C).

2/20/19 GPD Global

®

7

PCD Pump User Guide Operations

Operations

Prior to operations, identify which model of PCD pump you will be using. Each PCD pump

model can be identified by the type of motor and feed way it uses; see details under Pump

Identification (pg 2).

1- Read Safety Notices

IMPORTANT: Prior to start up, read Safety Notices (pg iii) as this information must be read

and understood prior to using the pump!

2- Initial Start Up

CAUTION: Do not switch on the dispense pump before medium has been fed into it. There is a

danger of damage to the pump if it is run dry. Even a brief period of dry run time can lead to the

destruction of the stator.

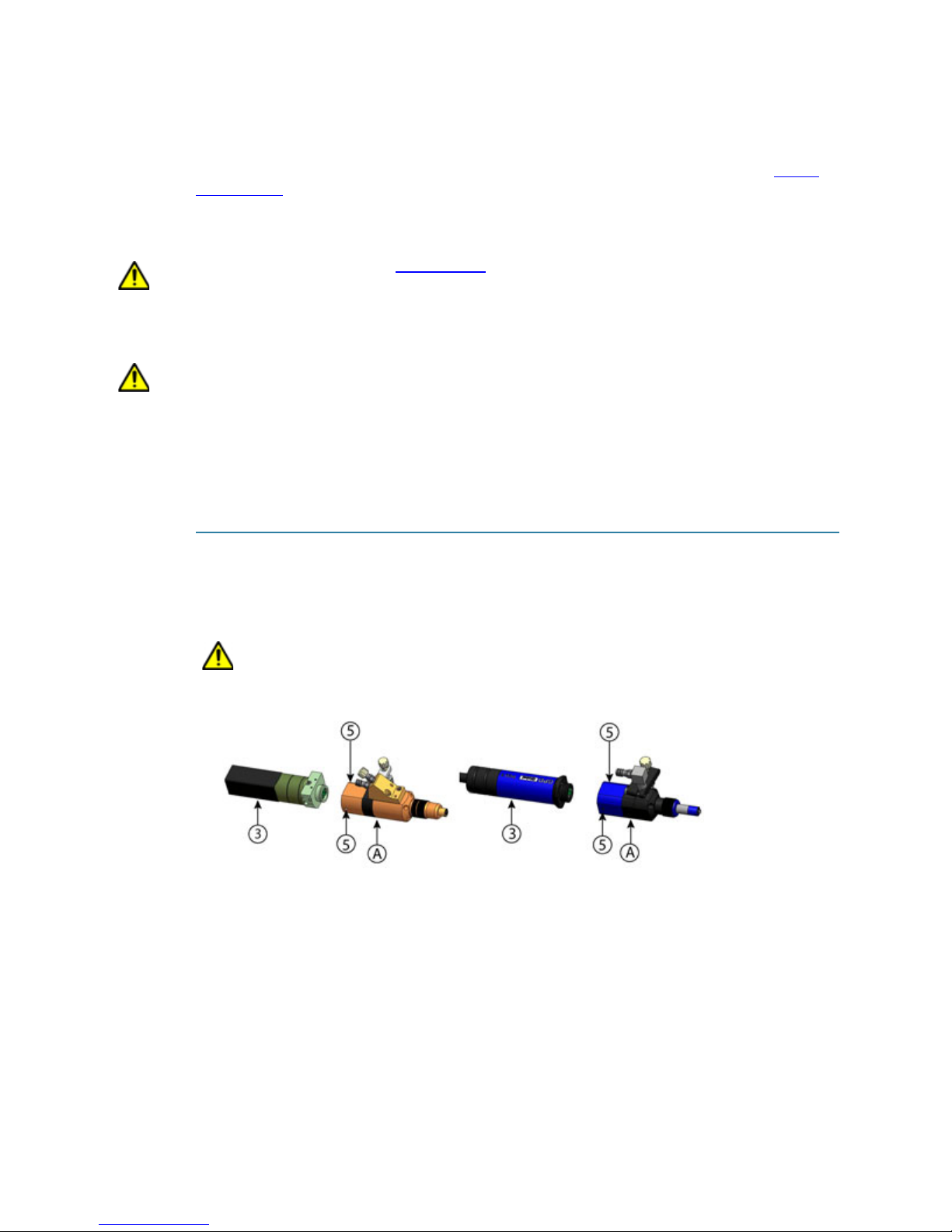

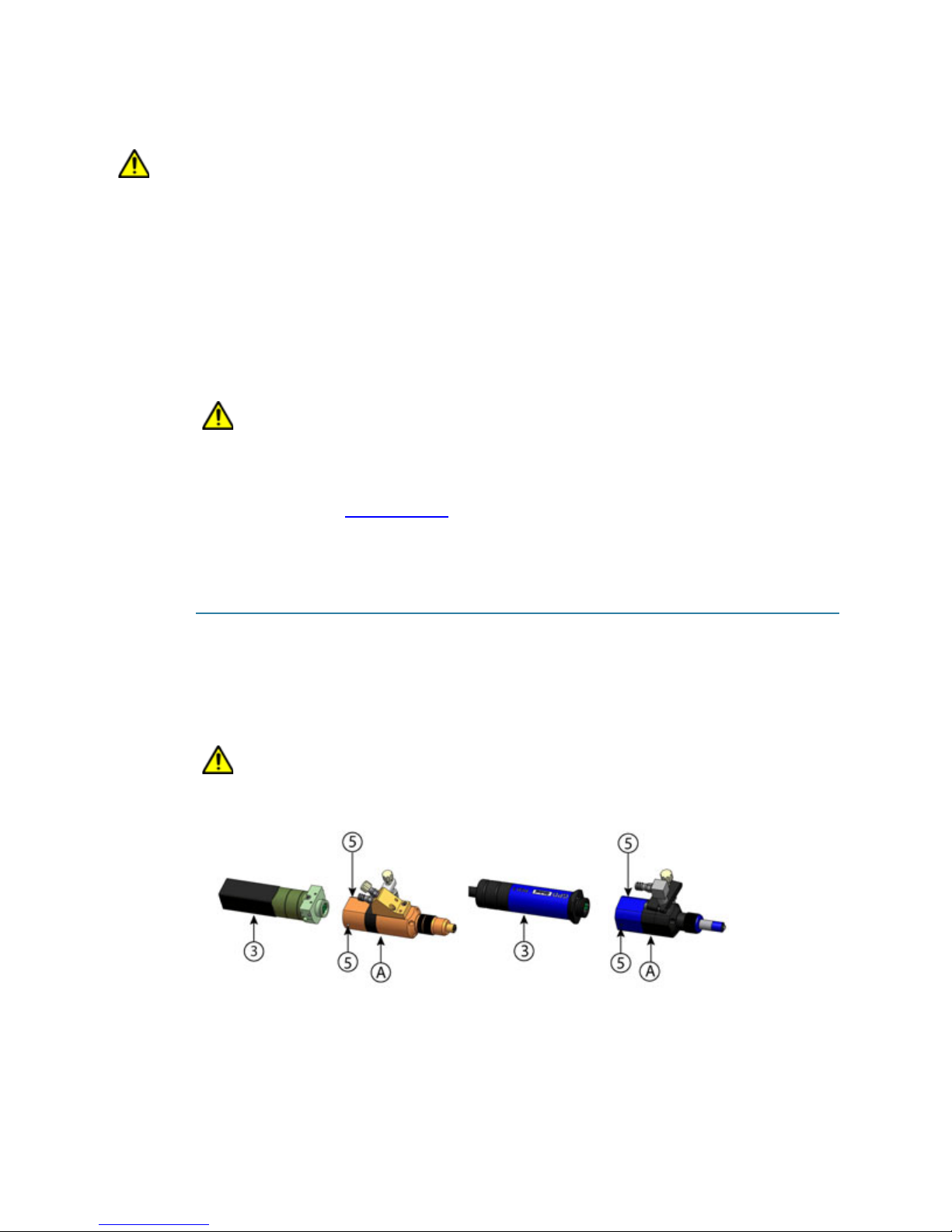

A- Disconnect Dispense Unit from Drive Unit

PCD3, PCD3L, PCD3H, PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB,

PCD7H

To disconnect the dispense and drive units from each other:

1. Loosen the two (2) set screws (Item 5).

2. Gently pull the drive unit (Item 3) away from the dispense unit (Item A).

CAUTION: Proceed carefully to avoid damage to the fit.

2/20/19 GPD Global

®

8

PCD Pump User Guide Operations

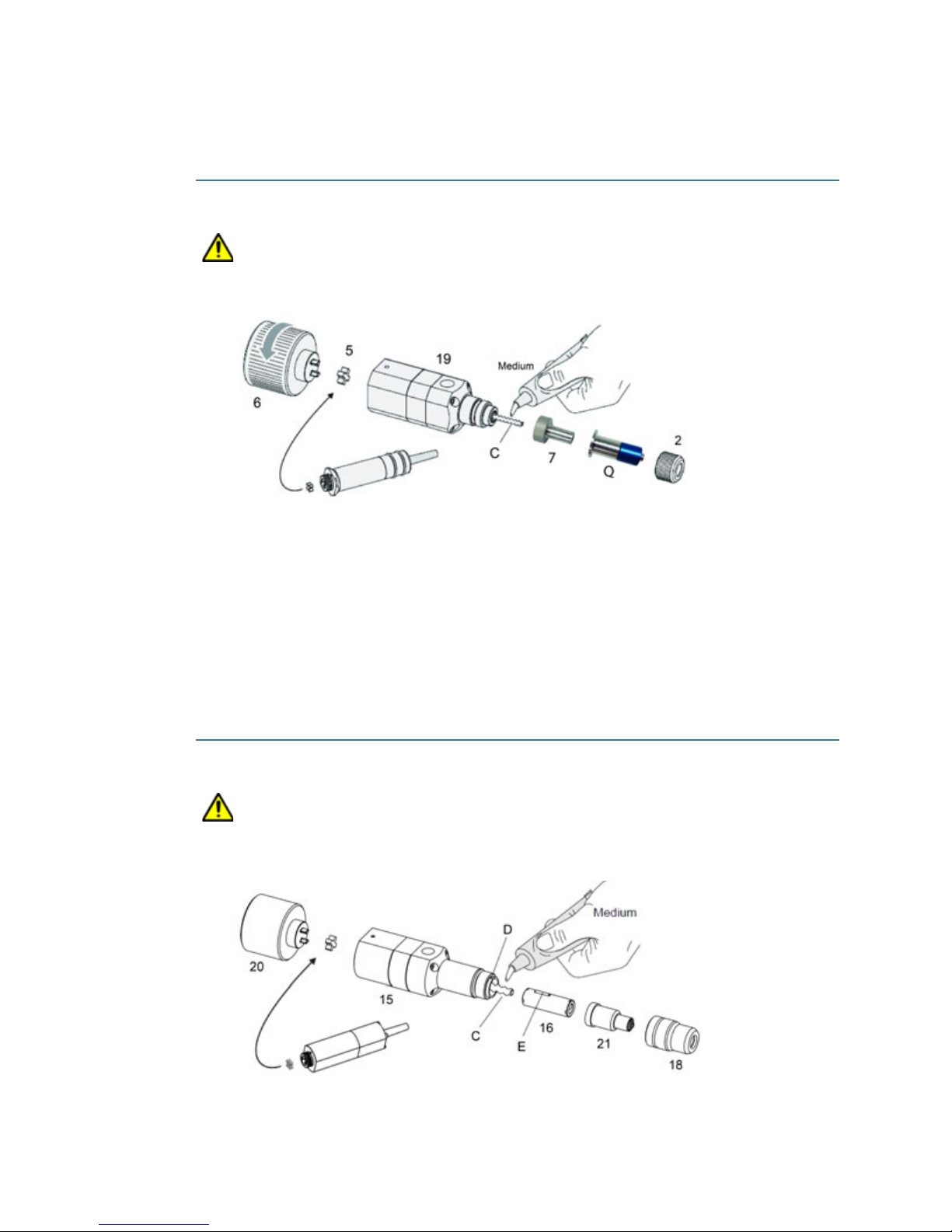

B- Insert Stator

PCD3, PCD3L, PCD3H

To attach the stator for the first time:

CAUTION: DO NOT assemble the pump dry. There is a danger of damage to the pump if it is

run dry. Even a brief period of dry run time can lead to the destruction of the stator.

1. Unscrew the union ring (Item 2) from the dispenser housing (19).

2. Remove the stator cover (Item Q) and set aside.

3. Wet the rotor (Item C) with the medium to be used or a suitable lubricant.

4. Screw the stator (Item 7) onto the rotor (Item C) until it reaches the limit on the body (Item

19). There will be approximately 1 mm between the end of the stator and the threads of

the dispenser housing.

5. Place the stator cover (Item Q) over the stator (Item 7) and install the union ring (Item 2),

firmly clamping the two pieces together.

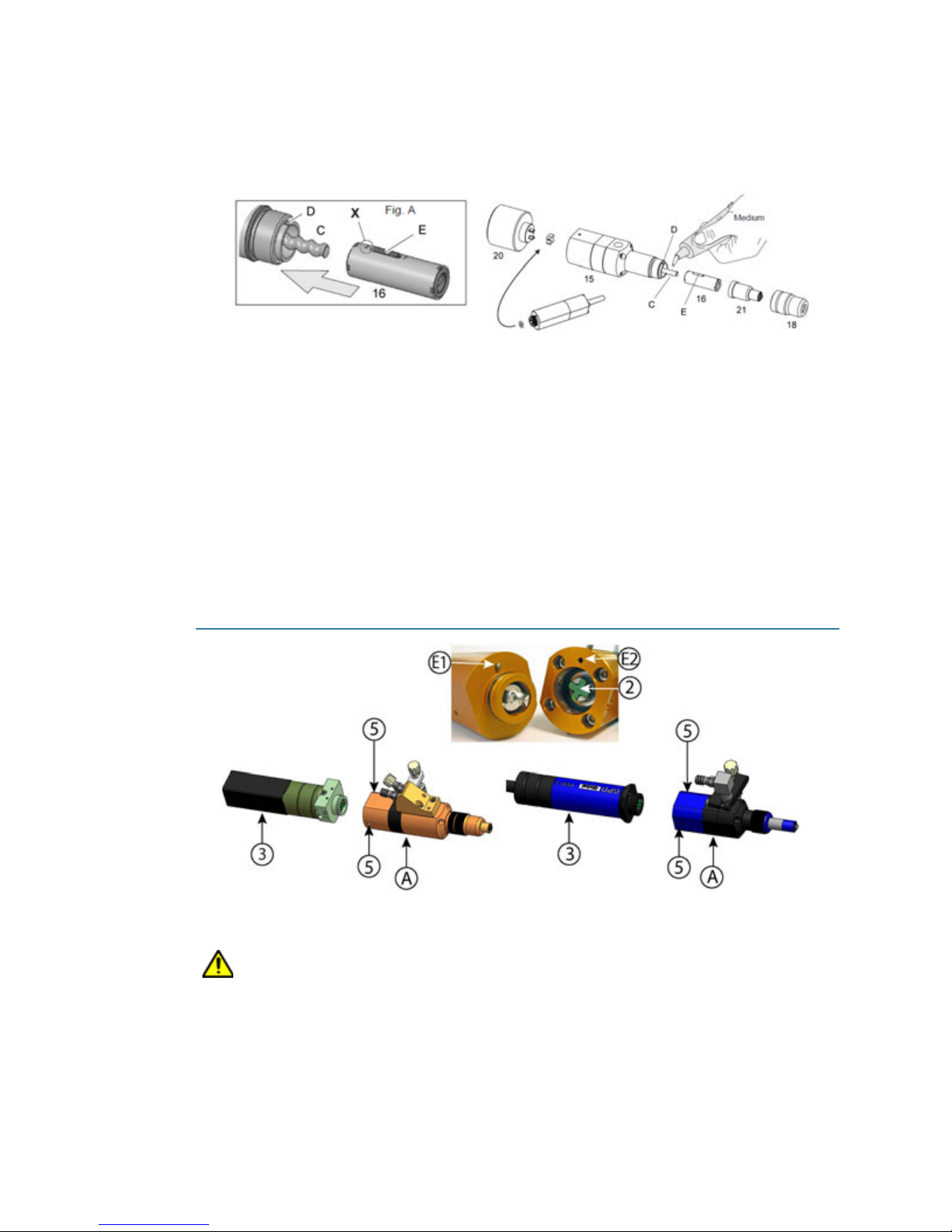

PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H

To insert the stator for the first time:

CAUTION: DO NOT assemble the pump dry. There is a danger of damage to the pump if it is

run dry. Even a brief period of dry run time can lead to the destruction of the stator.

1. Unscrew the union ring (Item 18), and then slide both the union ring and threaded sleeve

(Item 21) away from dispenser housing (Item 15).

2/20/19 GPD Global

®

9

PCD Pump User Guide Operations

2. Couple the assembly aid (Item 20) to the dispense pump housing (Item 15). The starshaped coupling (Item 5) must be attached to the dispenser pump housing (Item 15).

3. Wet the rotor (Fig A, Item C) with the medium or a suitable lubricant.

4. Orient the ‘X’ end (see Fig. A) of the stator (Item 16) toward the rotor (Item C) and then

turn the stator on the rotor until the dowel pin begins to engage with the key way (Fig. A,

Item D).

5. Lightly press the stator in the direction of the dispenser housing (Item 15) and turn the

assembly aid in the direction of the arrow until the stator has been guided into the dispense pump housing. The dowel pin will barely be visible in the key way (Item D).

6. Uncouple the assembly aid, install the end piece and the union ring, and attach the

required needle/nozzle.

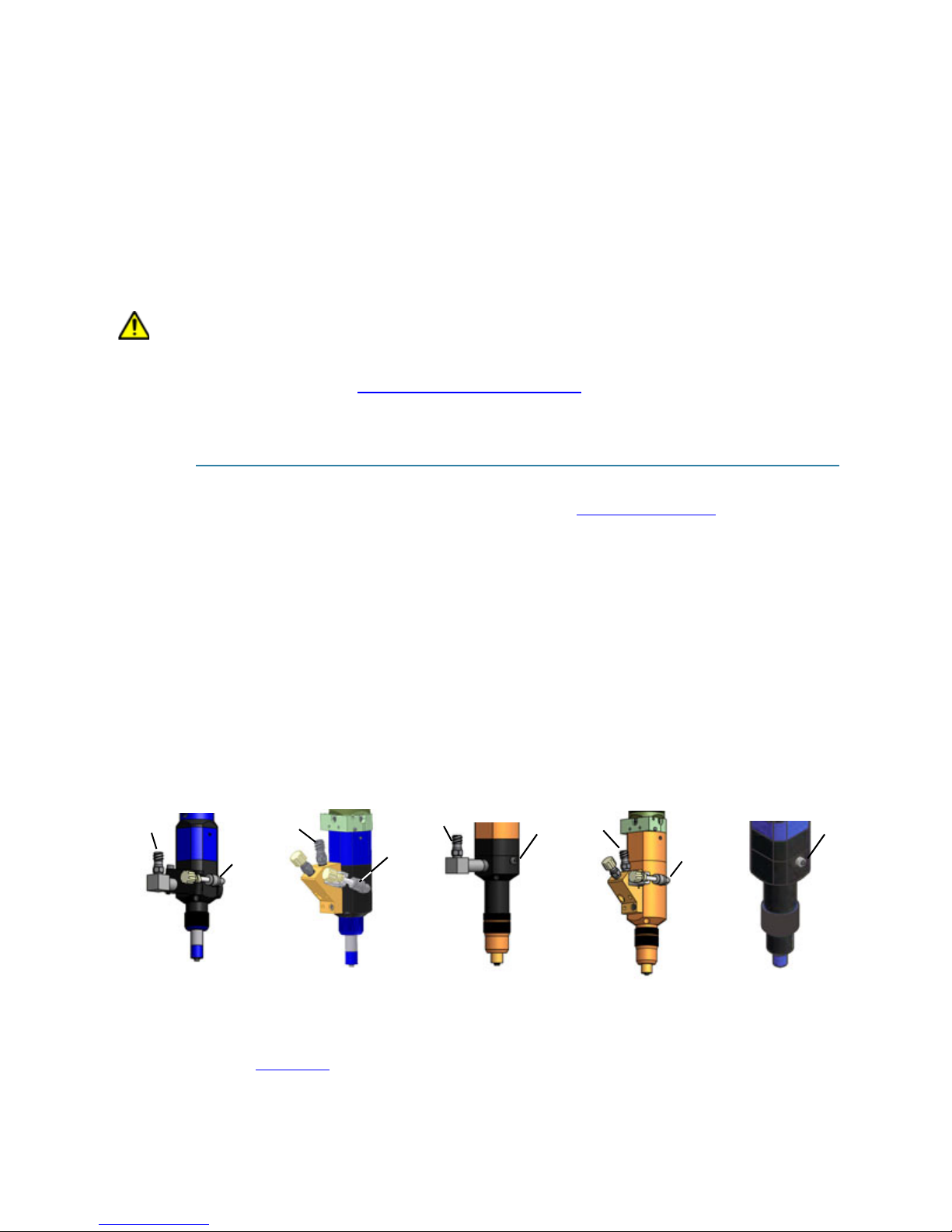

C- Connect Dispense Unit to Drive Unit

PCD3, PCD3L, PCD3H, PCD4, PCD4L, PCD4H PCD4HB, PCD6, PCD6HB,

PCD7H,

To connect the dispense and drive units together:

CAUTION: Proceed carefully to avoid damage to the fit.

1. Loosen the two (2) set screws (Item 5) so they do not protrude into the coupling area.

2. Verify the star coupling (Item 2) is seated properly in the dispense unit (Item A).

NOTE: Inspect the star-shaped coupling (Item 2) and adjacent O-ring for wear. Replace

these items as needed

2/20/19 GPD Global

®

10

PCD Pump User Guide Operations

PCD4, PCD4HB PCD4L, PCD4HPCD3

32

32

32

31

31

F

PCD3L, PCD3H PCD6, PCD6HB

32

F

31

PCD7, PCD7H

3. Couple the drive unit (Item 3) with the dispense unit (Item A) until there is a gap <1 mm

between the anti-rotation lock (Item E1) and the dispense unit (Item A).

4. Rotate the drive unit (Item 3) until the anti-rotation lock (E1) aligns with the anti-rotation

lock feature (Item E2) of the dispense unit (Item A).

5. Press the drive unit (Item 3) and the dispense unit (Item A) together completely.

6. Lightly turn the set screws (Item 5) to secure units together.

3- Prime Pump with Medium

CAUTION: Follow the safety stipulations and instructions of the manufacturer of the medium to

be used to fill the unit. If applicable, use protective equipment.

NOTE: Priming a pump can be performed online or offline. When working offline, GPD Global

recommends using the Install Pump in PCD Table Stand

PCD3, PCD3L, PCD3H, PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB,

PCD7H

1. Connect a material reservoir (cartridge, supply line, tank) of material to the pump adapter/

feed reservoir (Item 32). For thread details, refer to Threads & Materials

(pg 6) method.

(pg 31).

2. Connect air (0.14-0.2 bar [2-3 psi]) to the material reservoir.

3. For applicable models, verify the purge tube support (Item 31) is secured in the tube support and then remove the cap. For all other models, remove the bleed port plug (Item F).

4. Orient the dispense pump so the needle/nozzle end points downward.

5. Increase air pressure on the material reservoir until material feeds into the purge tube (or

out of the bleed port. Using a cup or wipe to catch expelled material, allow a small amount

of material to bleed from the purge tube to ensure all air is displaced.

6. For applicable models, screw the cap onto the purge tube. For all other models, screw the

bleed port plug (Item F) into the bleed port.

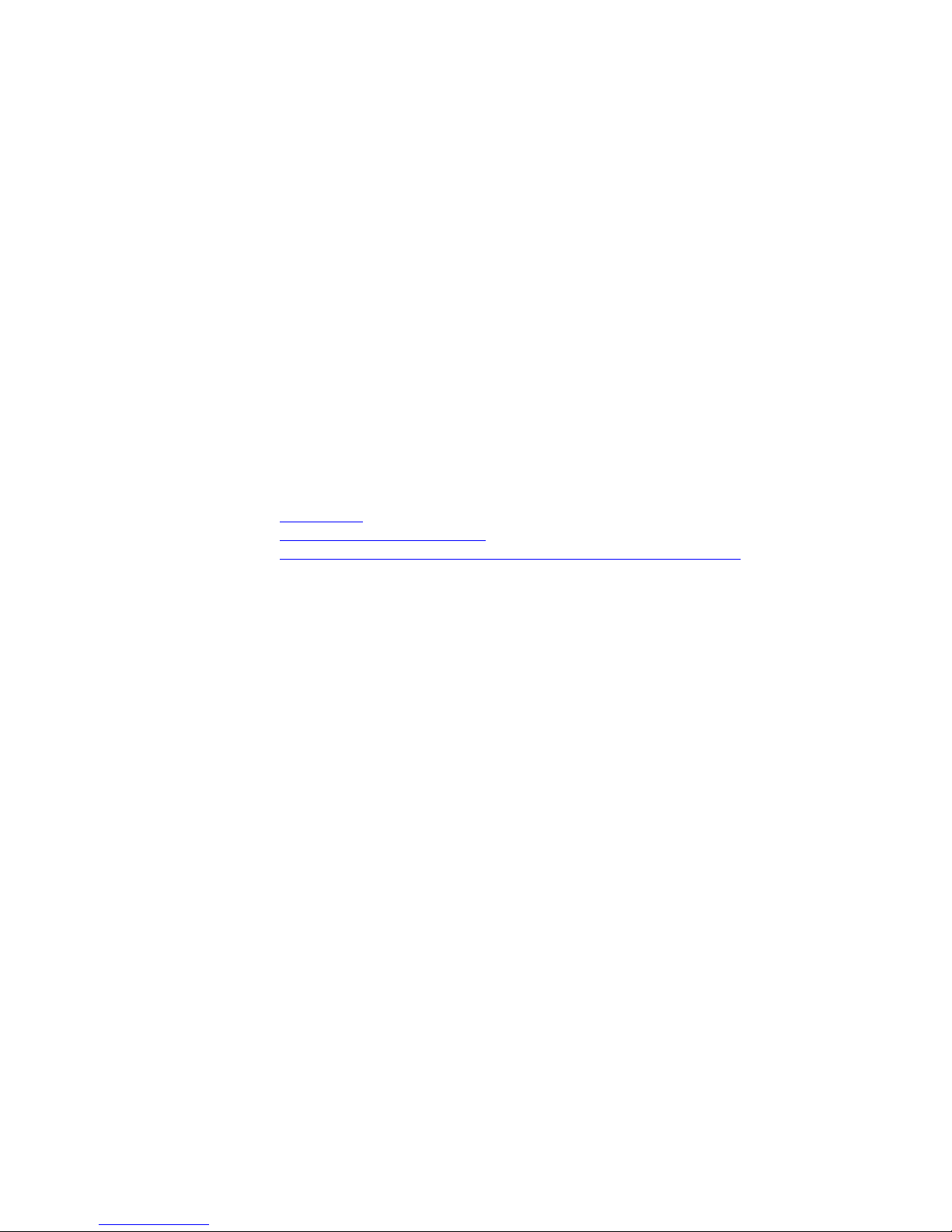

Figure 4: Adapter/feed reservoir (32), purge tube support (31), & bleed port plug (F) by pump model

4- Install Pump

2/20/19 GPD Global

Refer to Installation (pg 3).

®

11

PCD Pump User Guide Maintenance

Maintenance

Cleaning Time

Cleaning a pump requires 15 minutes or more. The amount of time required relates

directly to type of material and solvent used.

Cleaning Kit

PCD Pump Series Cleaning Kit (PN 22110467)

Kit contents are illustrated in this document: KITS: Spare Parts/Setup/Cleaning (PN

22290036).

Cleaning Frequency Guidelines

Initially, a once a month inspection and cleaning is recommended, then based on your

experience using with the pump and fluid, extend or shorten the cleaning interval as

needed.

Cleaning frequency is determined according to the type of fluid being dispensed. For

pumps in continuous use, clean in intervals no greater than 3 x fluid pot life. For

pumps dispensing fluids stable at room temperature and that have no significant pot

life issues, the pump may be run continually without issue.

Cleaning Procedures

• Flush Pump

• Clean PCD3, PCD3L, PCD3H

• Clean PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H

(pg 12)

(pg 13)

(pg 17)

Flush Pump

The flush procedure is used primarily when underfill material needs to be purged from the

pump. The dispense tip and needle can be removed or left in place:

• The dispense tip may be left in place or removed during the flush procedure.

• If a disposable needle is present, remove and discard it.

• A needle intended for reuse can remain in place on the pump as the flush procedure will

clean the needle.

To flush fluid from the pump:

1. Remove the fluid reservoir from the pump.

2. If present, remove disposable needle.

3. Install an empty syringe on the pump.

4. Fill the syringe with a suitable solvent.

5. Set the pump to purge into a purge cup or suitable container.

6. Continue to purge until all dispense fluid has been purged and only solvent is exiting the

pump.

2/20/19 GPD Global

®

12

PCD Pump User Guide Maintenance

Clean PCD3, PCD3L, PCD3H

IMPORTANT: Wear suitable protective clothing if chemical, corrosive, or dangerous products

are to be used. Note and comply with the safety stipulations and the information from the manufacturer. Ensure sufficient bleeding or extraction of air. Take special safety precautions if working

with dangerous media; for example, provide eye flushing facilities if working with corrosive

chemicals.

1 - Cleaning Kit

Obtain the recommended Cleaning Kit (pg 12).

2- Flush Pump

Prior to disconnecting the pump from its power source, flush the pump with a syringe of appropriate solvent, stopping the flush before pump runs dry.

CAUTION: Never run the pump dry. There is a danger of damage to the pump if it is run dry.

Even a brief period of dry run time can lead to the destruction of the stator.

3- Remove Power

Disconnect the drive unit power supply and uncouple it from the dispensing unit in the reverse

order as described in 4- Install Pump

(pg 11).

4- Remove Drive Unit from Dispense Unit

PCD3, PCD3L, PCD3H

1. Remove material syringe (not shown) and set it aside.

2. Remove the needle/nozzle (not shown) and either clean or dispose of it.

3. Partially loosen set screws (Item 5).

4. To separate drive unit (Item 3) from dispense unit (Item A), pull units apart.

CAUTION: Proceed carefully to avoid damage to the fit.

2/20/19 GPD Global

®

13

PCD Pump User Guide Maintenance

5- Remove & Clean Stator

PCD3, PCD3L, PCD3H

To access the stator (Item 7):

1. Unscrew and remove union ring (Item 2).

2. Remove the stator assembly (Item 3) by unscrewing it (do NOT pull) from the dispenser

housing (Item 19).

3. Remove the stator cover (Item Q) from the stator (Item 7) and, as needed, clean stator

cover.

4. Carefully and thoroughly clean stator (Item 7) using swabs and brushes supplied in the

cleaning kit. Remove all debris; anything less than a thorough cleaning can affect pump

performance.

RECOMMENDATION: To clean the stator thoroughly, use an ultrasonic cleaner with an

appropriate solvent.

6- Remove & Clean Feed Way

PCD3L, PCD3H

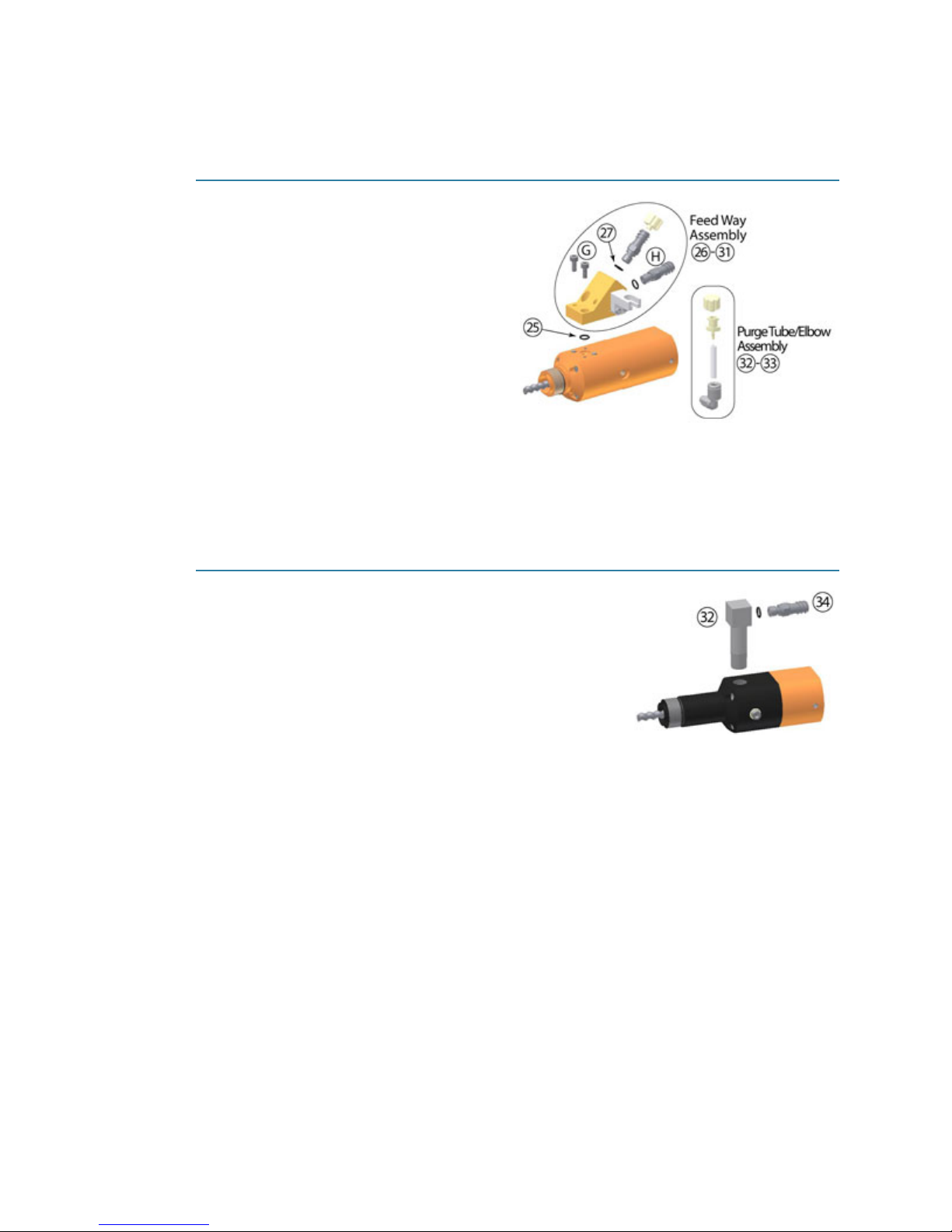

1. To separate the feed way assembly (Items 26-31) and O-ring (Item 25) from the pump

body, remove screws (Item G).

2. Clean feed way assembly (Items 26-31):

a. Remove luer feed ways (Item H) and associated O-rings. Replace O-rings if brittle or

worn.

b. Clean and flush feed way body and luer feed ways (H) using cleaning kit supplies.

c. Inspect and clean O-ring (Item 25). Replace O-rings if brittle or worn.

2/20/19 GPD Global

®

14

PCD Pump User Guide Maintenance

3. Unscrew and remove the purge tube/elbow assembly (Items 32-33) by pressing inward

slightly while compressing the ring on elbow.

4. Replace the purge tube and clean the elbow. The elbow will need to be replaced after being

cleaned several times; use good judgement regarding cleanliness of elbow.

PCD3

1. Separate the purge tube (Item 31) from the purge tube support (Item 36).

2. Unscrew the feed way (Items 32) from the pump

body.

3. Separate the luer feed way (Item 34) and associated O-ring from the feed way (Item 32).

4. Clean and flush feed way and luer feed way using

cleaning kit supplies.

5. Inspect and clean O-ring. Replace O-ring if brittle

or worn.

6. Remove and clean the purge tube assembly:

a. Remove the purge tube (Item 31) from the

elbow (Item 37) by pulling down on the orange

ring and then pulling the purge tube out of the elbow.

b. Using a crescent wrench, unscrew the elbow (Item 37) from the pump body.

c. Replace the purge tube and clean the elbow. The elbow will need to be replaced after

being cleaned several times; use good judgement regarding cleanliness of elbow.

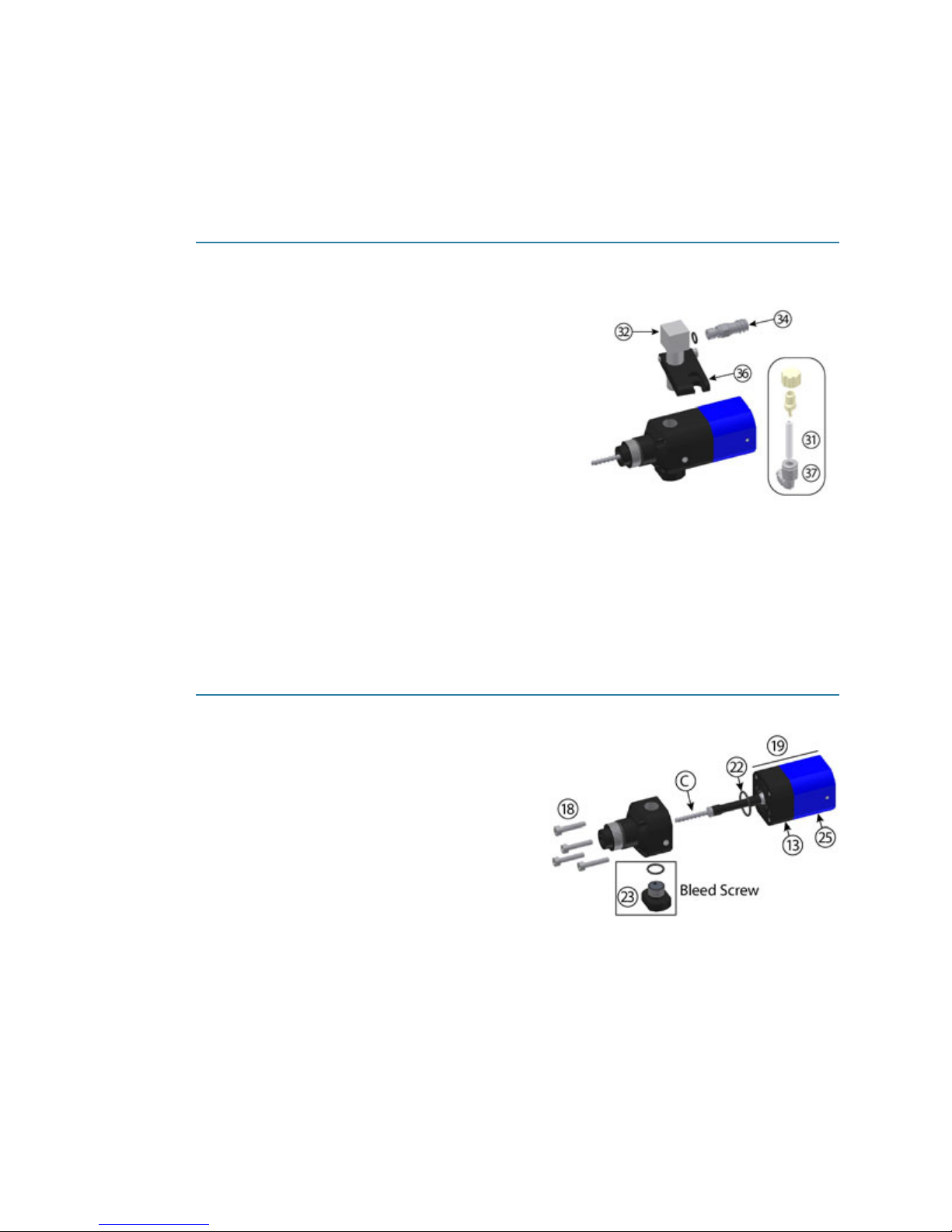

7- Clean Dispenser Housing & Rotor

PCD3, PCD3L, PCD3H

1. If a bleed screw (Item 23) is present, remove

it from dispenser (Item 19) and verify the

rubber disk that fits into the bleed screw has

been removed from dispenser housing; otherwise, skip this step.

2. Remove screws (Item 18) and then separate

dispenser housing (Item 19) from “bearing

housing with rotor” assembly (Items 13 and

25).

3. Inspect and clean O-ring (Item 22). Replace

if it is brittle or worn.

4. Using a cloth and brush, clean thoroughly:

– dispenser housing (Item 19)

– rotor (see Item C)

– (if present) bleed screw (Item 23) and rubber disk

CAUTION: DO NOT rinse “bearing housing with rotor” (Items 13 and 25) or submerge it in

an ultrasonic cleaner as either action could damage bearings.

2/20/19 GPD Global

®

15

PCD Pump User Guide Maintenance

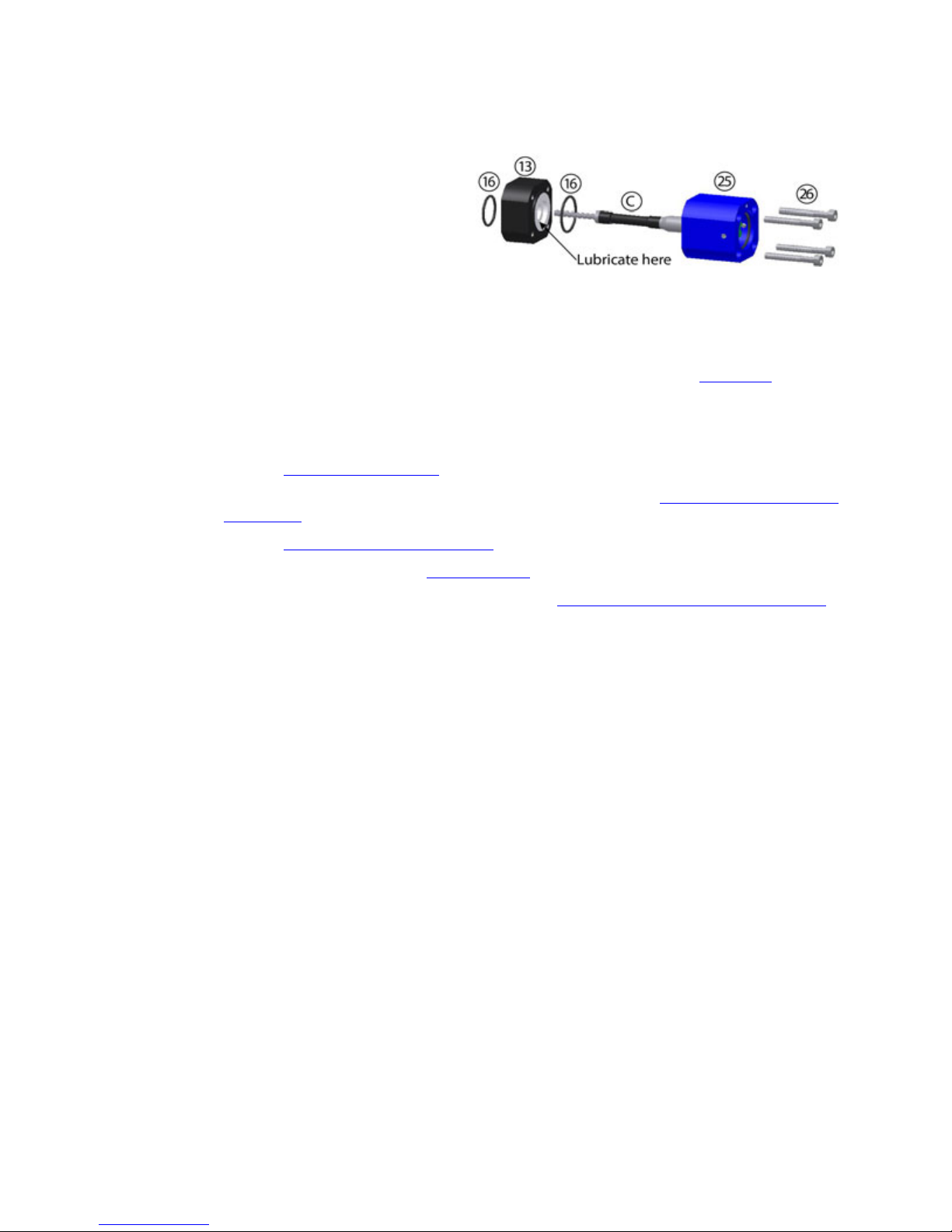

8- Clean Seal Housing

IMPORTANT: Perform this step only

as needed; in rare cases, the seal

housing (Item 25) may need to be

cleaned.

1. Remove screws (Item 26).

2. Unsnap and pull seal housing

(Item 13) over rotor (Item C) and away from bearing housing (Item 25).

3. Thoroughly clean seal housing (Item 13).

4. Inspect and clean the two O-rings (Item 16). Replace if brittle or worn.

5. Liberally lubricate the seal housing (Item 13) using lubricant listed on Parts Lists

9- Reassemble Pump

To reassemble the pump:

1. Perform 8- Clean Seal Housing

2. Do not exceed a tightening torque of 0.35 Nm while performing 7- Clean Dispenser Hous-

ing & Rotor (pg 15) in reverse order.

3. Perform 6- Remove & Clean Feed Way

4. Install the stator according to B- Insert Stator

5. Connect the dispensing unit to the drive unit per C- Connect Dispense Unit to Drive Unit

(pg 10).

(pg 23).

(pg 16) in reverse order.

(pg 14) in reverse order.

(pg 9)

2/20/19 GPD Global

®

16

PCD Pump User Guide Maintenance

Clean PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H

IMPORTANT: Wear suitable protective clothing if chemical, corrosive, or dangerous products

are to be used. Note and comply with the safety stipulations and the information from the

manufacturer. Ensure sufficient bleeding or extraction of air. Take special safety precautions if

working with dangerous media; for example, provide eye flushing facilities if working with

corrosive chemicals.

1 - Cleaning Kit

Obtain the recommended Cleaning Kit (pg 12).

2- Flush Pump

Prior to disconnecting the pump from its power source, flush the pump with a syringe of appropriate solvent, stopping the flush before pump runs dry.

CAUTION: Never run the pump dry. There is a danger of damage to the pump if it is run dry.

Even a brief period of dry run time can lead to the destruction of the stator.

3- Remove Power

Disconnect the drive unit power supply and uncouple it from the dispensing unit in the reverse

order as described in 4- Install Pump

(pg 11).

4- Remove Drive Unit from Dispense Unit

PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB

1. Remove material syringe (not shown) and set it aside.

2. Remove the needle/nozzle (not shown) and either clean or dispose of it.

3. Partially loosen set screws (Item 5).

4. To separate drive unit (Item 3) from dispense unit (Item A), pull units apart.

CAUTION: Proceed carefully to avoid damage to the fit.

2/20/19 GPD Global

®

17

PCD Pump User Guide Maintenance

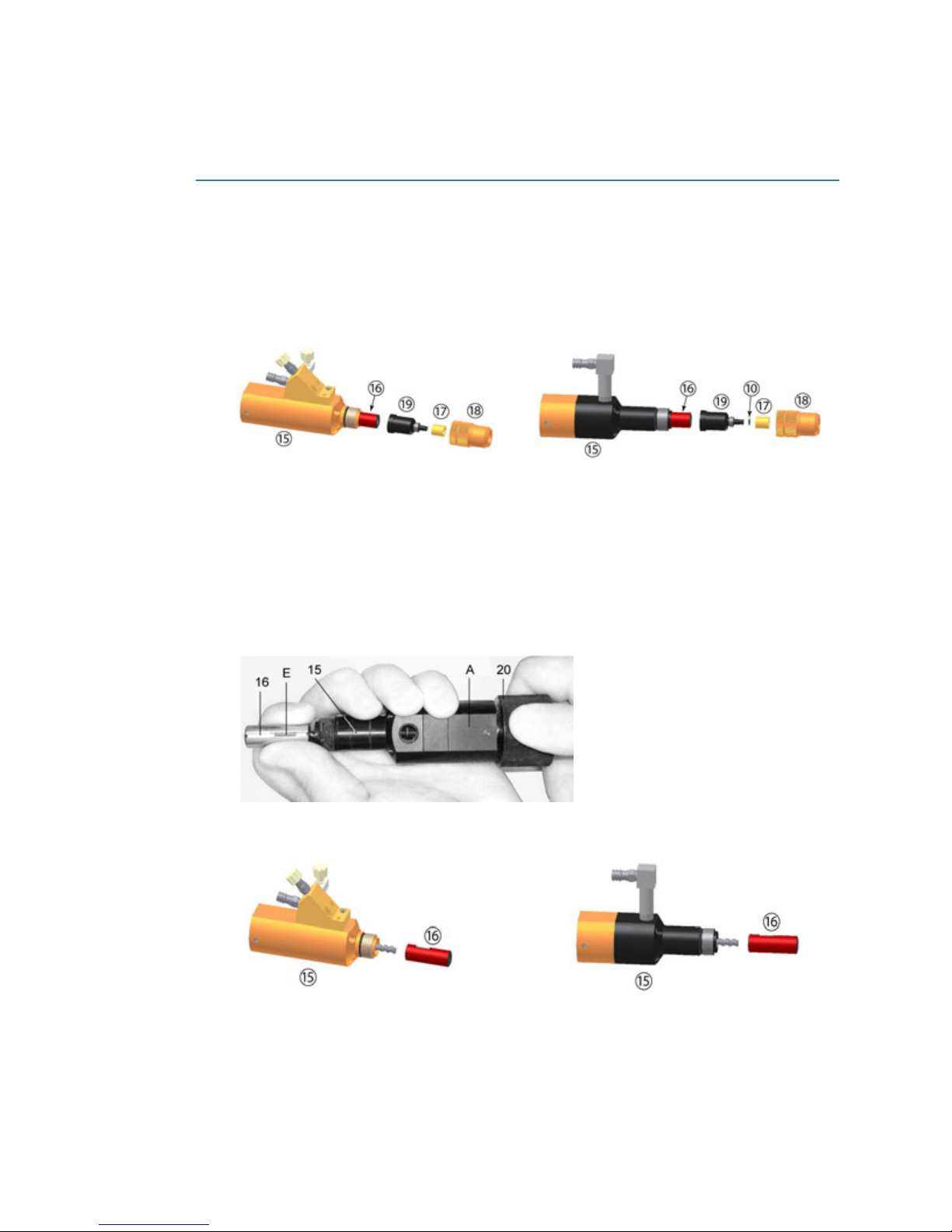

5- Remove & Clean Stator

PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H

1. To access the stator (Item 16):

a. Unscrew and remove union ring (Item18) and end piece assembly (Items 17 and 19)

from dispenser housing (Item 15).

b. Unscrew threaded sleeve (Item 17) from end section (Item 19) and, as needed, clean

threaded sleeve.

c. If an O-ring (Item 10) is present, inspect and clean the O-ring. Replace if it is brittle or

worn.

2. To unscrew the stator (Item 16) from the dispenser housing (Item 15) without separating

the pin (Item E) mounted on the stator:

a. Hold dispenser housing (Item 15) in the palm of one hand with the stator (Item 16)

loosely secured between thumb and forefinger of the same hand.

b. With the other hand, couple and turn the assembly aid (Item 20) counterclockwise in

the base of the dispense unit (Item A) until the stator completely separates from the

dispenser housing (Item 15).

c. Uncouple the assembly aid (Item 20) from the dispenser unit (Item A).

3. Carefully pull the stator (Item 16) away from dispenser housing (Item 15).

4. Carefully and thoroughly clean the stator (Item 16) using swabs supplied in the cleaning

kit. Remove all debris; anything less than a thorough cleaning can affect pump performance.

RECOMMENDATION: To clean the stator thoroughly, use an ultrasonic cleaner with an

appropriate solvent.

2/20/19 GPD Global

®

18

PCD Pump User Guide Maintenance

6- Remove & Clean Feed Way

PCD4L, PCD4H, PCD4HB

1. To separate the feed way assembly

(Items 26-31) and O-ring (Item 25) from

the pump body, remove screws (Item G).

2. Clean feed way assembly:

a. Remove luer feed ways (Item H) and

O-rings (Item 27). Replace O-rings if

brittle or worn.

b. Clean and flush feed way body and

luer feed ways (Item H) using cleaning kit supplies.

c. Inspect and clean O-ring (Item 25).

Replace O-rings if brittle or worn.

3. Unscrew and remove the purge tube/elbow assembly (Items 32-33) by pressing inward

slightly while compressing the ring on elbow.

4. Replace the purge tube and clean the elbow. The elbow will need to be replaced after being

cleaned several times; use good judgement regarding cleanliness of elbow.

PCD4, PCD6, PCD6HB, PCD7H

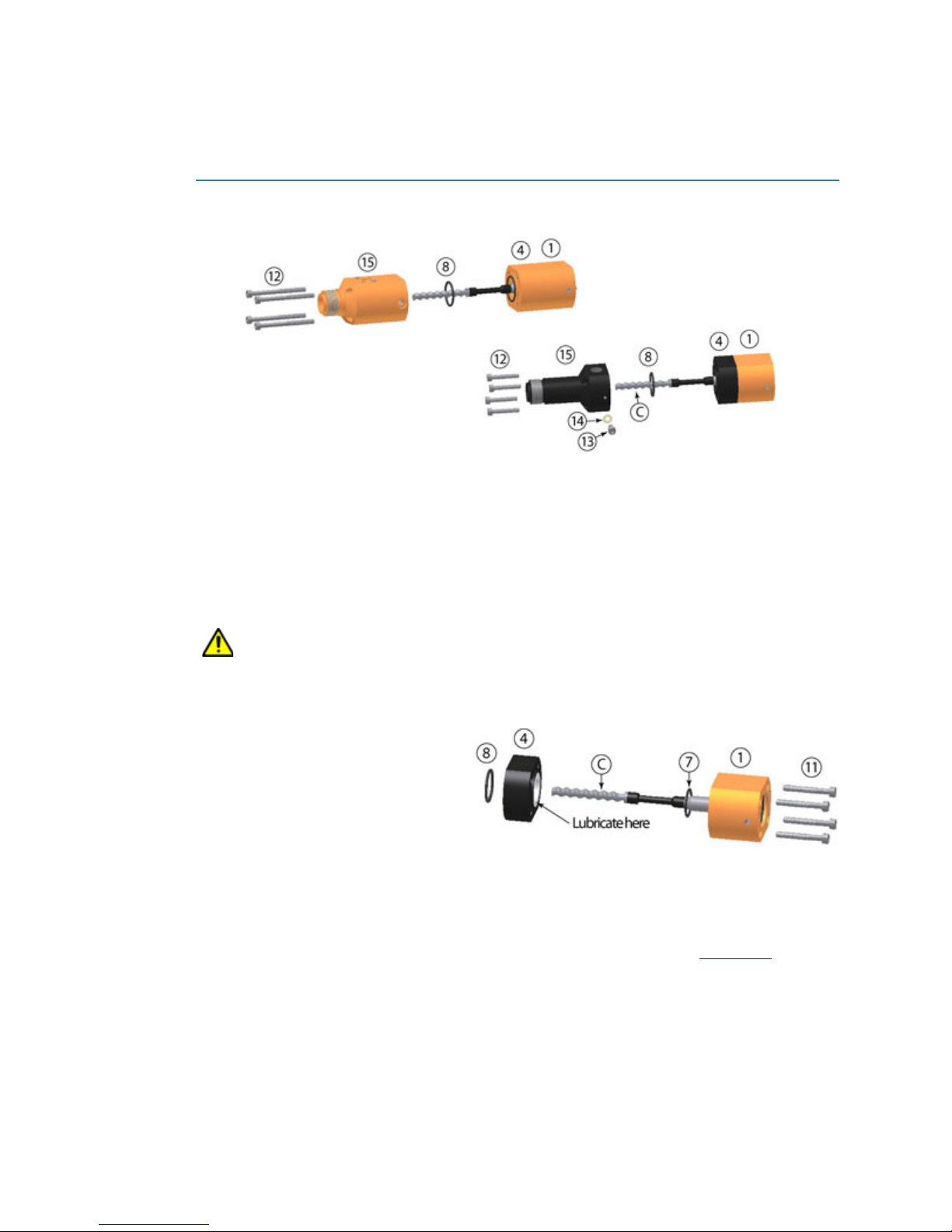

1. If present, unscrew the feed way (Items 32) from the

pump body.

2. Separate the luer feed way (Item 34) and O-ring from the

feed way (Item 32).

3. Clean and flush feed way and luer feed way using cleaning kit supplies.

4. Inspect and clean O-ring. Replace O-ring if brittle or

worn.

2/20/19 GPD Global

®

19

PCD Pump User Guide Maintenance

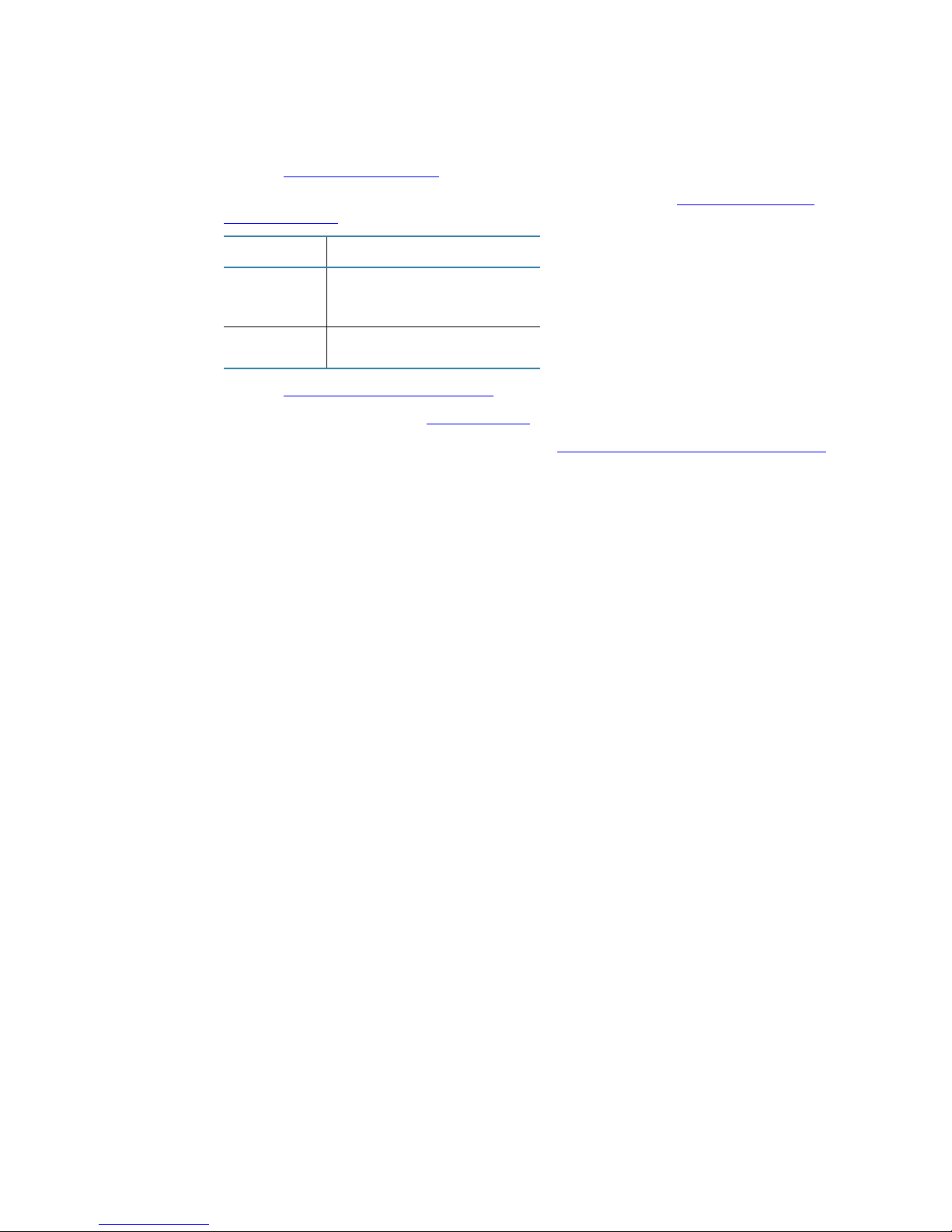

7- Clean Dispenser Housing & Rotor

PCD4, PCD4L, PCD4H, PCD4HB, PCD6, PCD6HB, PCD7H

1. If a bleed screw (Item 13) and washer (Item 14) are present, remove them from the dispenser housing (Item 15); otherwise, skip this step.

2. Remove screws (Item 12) and then separate dispenser housing (Item 15) from “bearing housing with rotor” assembly (Items 1 and 4).

3. Inspect and clean O-ring (Item 8). Replace if it is brittle or worn.

4. Using a cloth and brush, clean thoroughly:

– dispenser housing (Item 15)

– rotor (Item C)

– (if present) bleed screw (Item 13) and washer (Item 14)

CAUTION: DO NOT rinse “bearing housing with rotor” (Items 1 and 4) or submerge it in an

ultrasonic cleaner as either action could damage bearings.

8- Clean Seal Housing

IMPORTANT: Perform this step only

as needed; in rare cases, the seal

housing (Item 4) may need to be

cleaned.

1. Remove screws (Item 11).

2. Unsnap and pull seal housing

(Item 4) over rotor (Item C) and away from bearing housing (Item 1).

3. Thoroughly clean seal housing (Item 4).

4. Inspect and clean the O-rings (Items 7 & 8). Replace if brittle or worn.

5. Liberally lubricate the seal housing (Item 13) using lubricant listed on Parts Lists

(pg 23).

2/20/19 GPD Global

®

20

PCD Pump User Guide Maintenance

9- Reassemble Pump

To reassemble the pump:

1. Perform 8- Clean Seal Housing

(pg 20) in reverse order.

2. Do not exceed tightening torque specified below while performing 7- Clean Dispenser

Housing & Rotor (pg 20) in reverse order.

Pump Model Maximum Tightening Torque

PCD4

PCD4L

PCD4H

PCD6

PCD7

3. Perform 6- Remove & Clean Feed Way

4. Install the stator according to B- Insert Stator

0.35 Nm

0.5 Nm

(pg 14) in reverse order.

(pg 9)

5. Connect the dispensing unit to the drive unit per C- Connect Dispense Unit to Drive Unit

(pg 10).

2/20/19 GPD Global

®

21

PCD Pump User Guide Troubleshooting

Troubleshooting

Table 4: Troubleshooting

Error Possible Cause Correction

No or too little medium

conveyed

Dripping / “running on” of

the medium

Dispense results include

bubbles or skips. Example: Figure 5

Needle blocked. Clean/replace the needle.

Medium hardened. Dispenser clean.

Needle too small or too long. Use a different needle cross-section. Reduce the

speed / flow rate.

Stator swollen. Replace the stator.

Inadequate supply of medium. Supply the medium, check the hose, check the

primary pressure and increase it if necessary.

Motor not connected. Connect the motor.

Sucking back not set correctly. Set the sucking back.

Air bubbles in the medium. Bleed the medium.

Medium compressible. Degas the medium.

The Union ring may have been tightened too much. The union ring holds

the stator in place during dispensing.

If the union ring is too tight, it can collapse the stator on the rotor and

cause voids in dispensed material.

Figure 5: Dispense results include bubbles or skips.

1 - Loosen the union ring 1/8 turn to 1/4 turn.

2 - Rerun dispense process and inspect results.

3 - Repeat above steps until desired results are

attained. Example: Figure 6

2/20/19 GPD Global

Figure 6: Desired results - no bubbles or skips.

®

22

PCD Pump User Guide Parts Lists

Parts Lists

For consumable, spare, and general part information, refer to this document:

PCD Pump Parts List (PN 22200613).

Specifications

• PCD3 Specifications (pg 24)

• PCD4 Specifications

• PCD6 Specifications

• PCD7 Specifications

• Additional Dimensions

• Threads & Materials

(pg 25)

(pg 26)

(pg 27)

(pg 28)

(pg 31)

2/20/19 GPD Global

®

23

GPD Global

©

Specifications

2/20/19 PCD Pump User Guide 24

Tabl e 5 : PCD3 Specifications

Specification

PCD3

22293093-1004

PCD3L

22293093-1002

PCD3H

22293093-1003, 22293121

Dimensions (height, SQ, diameter)

Also see

Additional Dimensions (pg 28)

207.56, SQ 29x29, ø 34.80 mm

(8.176”, SQ 1.142”x1.142”, ø 1.3”)

208.28, SQ 29x29, ø 34.80 mm

(8.176”, SQ 1.142”x1.142”,

ø

1.3”)

220.73, SQ 29x29, ø 34.80 mm

(8.176”, SQ 1.142”x1.142”, ø 1.3”)

Weight approx. 380 g (0.8 lb) approx. 556 g (1.2 lb) approx. 451 g (1.0 lb)

Dispensing volume

≈ 0.012 ml/rotation

Theoretical flow rate per minute ** 0.12 to 1.48 ml/min

Minimum dispensing amount ml 0.001 ml 0.0005 ml

Priming volume

≈ 3 cc ≈1.5 cc

Dispensing precision * ±1%

Repeat accuracy >99%

Minimum operating pressure 0 bar (0 psi), with self-leveling liquid

Maximum operating pressure 0-6 bar (0-87 psi), with non-self-leveling liquid

Maximum dispensing pressure *** 16-20 bar (232-290 psi)

Self-sealing * approx. 2 bar (29 psi)

Maximum viscosity‡ 60,000 cps

Parts touched by medium HD-POM, Stainless steel, Anodized Aluminum

Sealings High-molecular PE, VisChem

Sealings static O-ring Viton

Motor 18 - 24 VDC 24 VDC

Motor rotating speed, per minute 0-120 rpm

Operating ambient conditions

° C

+10 to +40 non-condensing, air pressure 1 bar (14.5 psi)

Medium temperature

° C

+10 to +40

Storage conditions/temp.

° C

dry and dust free, -10 to +40

Cable dimensions O.D.: 9.423 mm (0.371”). Length: 250 mm (10”), extension cable available

Cable flexibility

High flex cable; flex cycles 5 million minimum. Bending radius -min: 5 x d, opt: 10 x d

Cable features

Max voltage 600V. Copper 22AWG. 6 cores of TPE-E. Black jacket of FHF, PUR. Connector at each end.

* Reference medium approx. 1.000 mPas at 20 ° C. Maximum dispensing pressure and self-sealing

decrease with decreasing viscosity and increase with increasing viscosity.

** Volume flow dependent on viscosity and primary pressure.

*** Maximum dispensing pressure and self-sealing decrease with decreasing viscosity and increase with increasing viscosity.

‡Higher viscosity may be possible based on nozzle size and flow rate.

GPD Global

©

Specifications

2/20/19 PCD Pump User Guide 25

Table 6: PCD4 Specifications

Specification

PCD4

22293081

22293098-0002

PCD4L

22293122

PCD4H

22293103

PCD4HB

22293240

Dimensions (height, SQ, dia.)

Also see Additional Dimensions

(pg 28)

230.28, SQ 29, ø 35 mm

(9.457”, SQ 1.142”, ø 1.378”)

230.35, SQ 29, ø 35 mm

(9.457”, SQ 1.142”, ø 1.378”)

240.2, SQ 29, ø 35 mm

(9.457”, SQ 1.142”, ø 1.378”)

252.1, SQ 29, ø 35 mm

(9.927”, SQ 1.142”, ø 1.378”)

Weight approx. 420 g (0.9 lb) 671 g (1.48 lb) approx. 689 g (1.52 lb)

Dispensing volume ≈0.05 ml/rotation

Theoretical flow rate per minute *** 0.5-6.0 ml/min 0.2-6.0 ml/min

Minimum dispensing amount ml * 0.004 ml 0.001 ml

Priming volume ≈ 3 cc ≈ 1.5 cc

Precision ml ±, absolute * ±1%

Repeat accuracy >99%

Minimum operating pressure 0 bar (0 psi), with self-leveling liquid

Maximum operating pressure 0-6 bar (0-87 psi)

Maximum dispensing pressure 16-20 bar (232-290psi)

Self-sealing ** approx. 2 bar (29 psi)

Maximum viscosity‡ 60,000 cps

Parts touched by medium HD-POM, Stainless Steel, Anodized Aluminum

Sealings High-molecular PE, VisChem

Sealings static O-ring Viton

Motor 18-24 VDC incremental encoder Servo

Motor rotating speed, per minute 0-120 rpm

Operating ambient conditions

° C

+10 to +40 non-condensing, air pressure 1 bar (14.5 psi)

Medium temperature

° C

+10 to +40

Storage conditions/temp.

° C

dry and dust free, -10 to +40

Cable dimensions O.D.: 9.423 mm (0.371”). Length: 250 mm (10”), extension cable available

Cable flexibility High flex cable; flex cycles 5 million minimum. Bending radius -min: 5 x d, opt: 10 x d

Cable features

Max voltage 600V. Copper 22AWG. 6 cores of TPE-E. Black jacket of FHF, PUR. Connector at each end.

* Reference medium approx. 1.000 mPas at 20 ° C.

** Maximum dispensing pressure and self-sealing decrease with decreasing viscosity.

*** Depending on viscosity and primary pressure of medium. All pressure details are maximum values for low-to-medium viscosity media (20,000 mPas).

‡Higher viscosity may be possible based on nozzle size and flow rate.

PCD Pump User Guide Specifications

Table 7: PCD6 Specifications

Specification

Also see Additional Dimensions

* Reference medium approx. 1.000 mPas at 20 ° C.

** Maximum dispensing pressure and self-sealing decrease with decreasing viscosity.

*** Depending on viscosity and primary pressure of medium. All pressure details are maximum values for low-to-medium viscosity media (20,000

mPas).

‡Higher viscosity may be possible based on nozzle size and flow rate.

Dimensions (height, SQ, dia.)

Dispensing volume

Theoretical flow rate per minute *** 1.4-16.0*** ml/min

Minimum dispensing amount ml * 0.015 ml

Precision ml ±, absolute * ±1%

Minimum operating pressure 0 bar (0 psi), with self-leveling liquid

Maximum operating pressure 0-6 bar (0-87 psi)

Maximum dispensing pressure 16-20 bar (232-290psi)

Maximum viscosity‡ 60,000 cps

Parts touched by medium HD-POM, Stainless Steel, Anodized Aluminum

Motor rotating speed, per minute 0-120 rpm

Operating ambient conditions

Medium temperature

Storage conditions/temp.

Cable dimensions O.D.: 9.423 mm (0.371”). Length: 250 mm (10”), extension cable available

(pg 28)

Weight 753 g (1.66 lb) approximately 753 g (1.66 lb)

Priming volume ≈ 4 cc

Repeat accuracy >99%

Self-sealing ** approx. 2 bar (29 psi)

Sealings High-molecular PE, VisChem

Sealings static Viton O-ring (medium), NBR (dust)

Motor 18-24 VDC incremental encoder

(10.78”, SQ 1.338”, ø 1.57”)

° C

° C

° C

Cable flexibility High flex cable; flex cycles 5 million minimum. Bending radius -min: 5 x d, opt: 10 x d

Cable features

Max voltage 600V. Copper 22AWG. 6 cores of TPE-E. Black jacket of FHF, PUR. Connector at each

PCD6

22293161-001

274, SQ 34, ø 40 mm

≈ 0.14 ml/rotation

+10 to +40 non-condensing, air pressure 1 bar (14.5 psi)

+10 to +40

dry and dust free, -10 to +40

end.

PCD6HB

22293161-003

255, SQ 34, ø 40 mm

(10.04”, SQ 1.338”, ø 1.57”)

2/20/19 GPD Global

®

26

PCD Pump User Guide Specifications

Table 8: PCD7 Specifications

Specification

Also see Additional Dimensions

* Reference medium approx. 1.000 mPas at 20 ° C.

** Maximum dispensing pressure and self-sealing decrease with decreasing viscosity.

*** Depending on viscosity and primary pressure of medium. All pressure details are maximum values for low-to-medium viscosity media (20,000

mPas).

‡Higher viscosity may be possible based on nozzle size and flow rate.

Dimensions (height, SQ, dia.)

Dispensing volume

Theoretical flow rate per minute *** 5.3-60.0*** ml/min

Minimum dispensing amount ml * 0.06 ml

Precision ml ±, absolute * ±1%

Minimum operating pressure 0 bar (0 psi), with self-leveling liquid

Maximum operating pressure 0-6 bar (0-87 psi)

Maximum dispensing pressure 16-20 bar (232-290psi)

Maximum viscosity‡ 60,000 cps

Parts touched by medium HD-POM, Stainless Steel, Anodized Aluminum

Motor rotating speed, per minute 0-120 rpm

Operating ambient conditions

Medium temperature

Storage conditions/temp.

Cable dimensions O.D.: 9.423 mm (0.371”). Length: 250 mm (10”), extension cable available

(pg 28)

Weight 753 g (1.66 lb)

Priming volume ≈ 4 cc

Repeat accuracy >99%

Self-sealing ** approx. 2 bar (29 psi)

Sealings High-molecular PE, VisChem

Sealings static Viton O-ring (medium), NBR (dust)

Motor 18-24 VDC incremental encoder

° C

+10 to +40 non-condensing, air pressure 1 bar (14.5 psi)

° C

° C

Cable flexibility High flex cable; flex cycles 5 million minimum. Bending radius -min: 5 x d, opt: 10 x d

Cable features

Max voltage 600V. Copper 22AWG. 6 cores of TPE-E. Black jacket of FHF, PUR. Connector at each

PCD7H

22293306-003

274, SQ 34, ø 40 mm

(10.78”, SQ 1.338”, ø 1.57”)

≈ 0.53 ml/rotation

+10 to +40

dry and dust free, -10 to +40

end.

2/20/19 GPD Global

®

27

PCD Pump User Guide Specifications

Additional Dimensions

PCD3 (PN 22293093-1004)

PCD3L (PN 22293093-1002)

PCD3H (PN 22293093-1003)

PCD3H legacy (PN 22293121)

2/20/19 GPD Global

®

28

PCD Pump User Guide Specifications

PCD4 (PN 22293081)

PCD4L (PN 22293122)

PCD4H (PN 22293103)

PCD4HB (PN 22293240)

2/20/19 GPD Global

®

29

PCD Pump User Guide Specifications

PCD6 (PN 22293161-001)

PCD6HB (PN 22293161-003)

PCD7H (PN 22293306-003)

2/20/19 GPD Global

®

30

PCD Pump User Guide Specifications

Threads & Materials

Table 9: Threads & Materials Specifications

Threads/Materials

Used

Medium input

Bleed hole

Threads

Nozzle Connection

PCD3

22293093-1004

1/8” cylindri-

cal Whit-

worth pipe

thread

Luer DIN

EN 20594-1

Luer Lock

DIN EN

1707 with

O-ring, pat-

PCD3H

22293093-1003

22293121

PCD3L

22293093-1002

Standard luer lock or 1/4-32

M5 x 0.8

Standard conical (6% taper)

luer lock

22293081

22293098-0002

1/8” cylin-

drical Whit-

worth pipe

M3 x 5.5

DIN 13

Luer Lock

DIN EN

1707 with

O-ring, pat-

ented

Dispenser housing,

end nozzles

Dispenser parts, motor

housing

Screws, washers, etc.

Stator elastomer, flexible shaft covering

Shaft sealing rings Z80

Materials

O-rings Viton

Drive shaft, rotor A4 Stainless steel*

HD-POM Anodized aluminum PM black Anodized aluminum POM black

Anodized aluminum

Stainless

steel A2

VisChem,

Chemrez

Stainless steel

Kalrez,

Chemrez

Stainless

steel A2

VisChem,

Chemrez

Stainless

1.4305

* Plating options available.

PCD4

thread

ented

steel

PCD4H

22293103

Standard luer lock or

1/4-32

PCD4L

22293122

PCD6

22293161-001

1/4” cylindrical Whitworth

pipe thread DIN/ISO 228

M5 x 0.8 M4 x 8 DIN 13

Standard conical (6%

taper) luer lock

Luer Lock DIN EN 1707

with O-ring, patented

Stainless steel Stainless steel A2

Kalrez,

Chemrez

VisChem,

Chemrez

Stainless steel* Stainless steel 1.4305

PCD7H

22293306-003

2/20/19 GPD Global

®

31

PCD Pump User Guide References

References

• Disposal (pg 32)

• Connection Options

• Assembly Drawings

Disposal

The final disposal of the dispense pump is to be done in an environmentally-appropriate

manner. All the materials and packaging must be handled in accordance with the recycling

stipulations.

Do not dispose of electrical parts in the household garbage. They are to be taken to the appropriate collecting points. 2002/96/EU (WEEE) EU DIRECTIVE concerning used electrical and

electronic equipment.

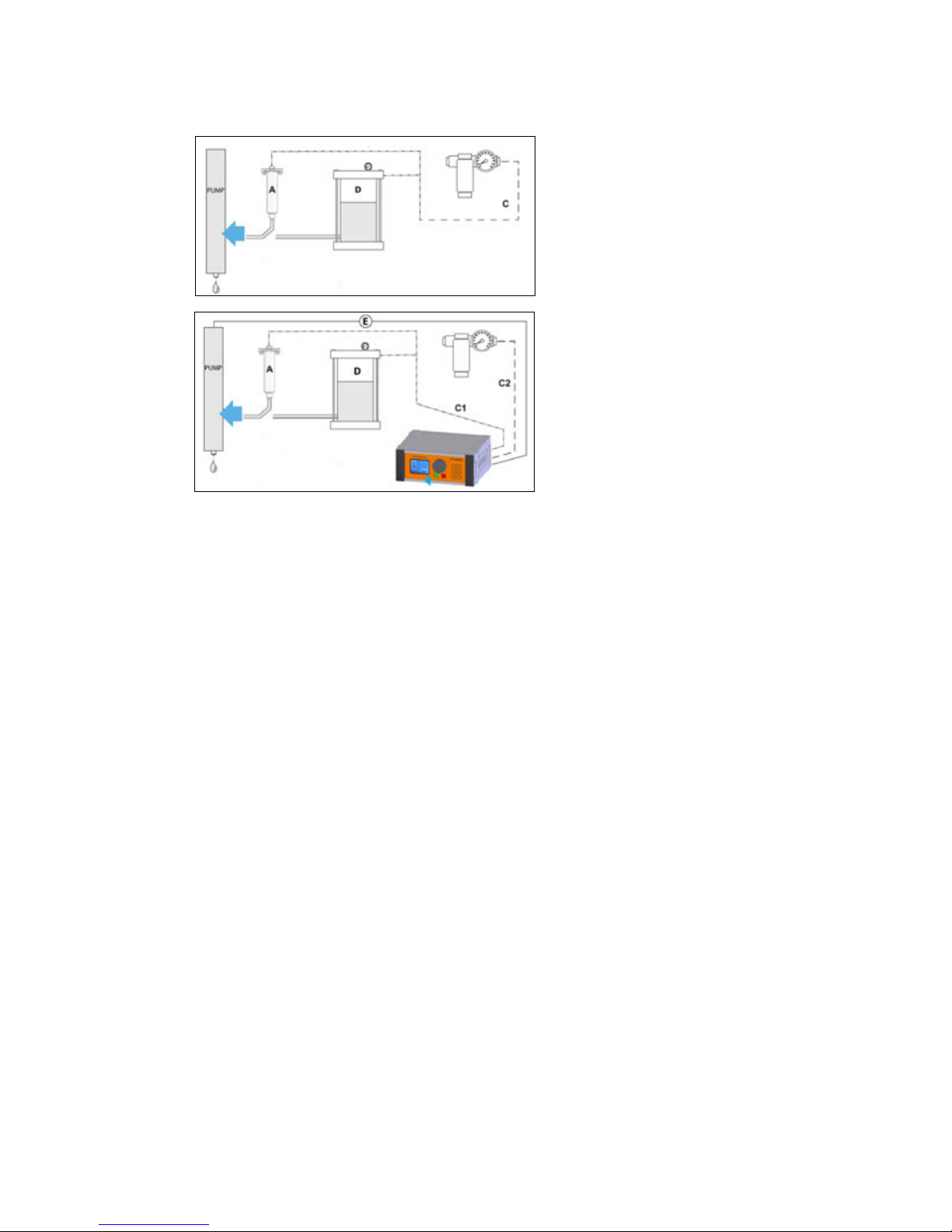

Connection Options

Gravity Fed, Low Viscosity Medium

(pg 32)

(pg 34)

A = supply of medium from a cartridge (A).

B = supply of medium from a bottle (B).

D = Power supply drive unit

Select a size of hose such that the liquid flows out of the dispense pump by gravity without air bubbles.

Self-suction is possible.

2/20/19 GPD Global

®

32

PCD Pump User Guide References

Pressurized, Medium/High Viscosity Medium

A - supply of medium from a cartridge

C - compressed air, 0-7 bar regulated

C1 - compressed air, 0-6 bar regulated.

C2 - Compressed air, 7 bar, dry, clean, oil-free

D - supply of medium from a pressure tank.

E - Power supply drive unit

Compressed air supplies either the cartridge (A) or pressure tank (D).

1 - Cartridge (Item A) supplied with compressed air (C or C1), connected to the dispense pump.

2 - Medium supply from the pressure tank (Item D).

2/20/19 GPD Global

®

33

PCD Pump User Guide References

Assembly Drawings

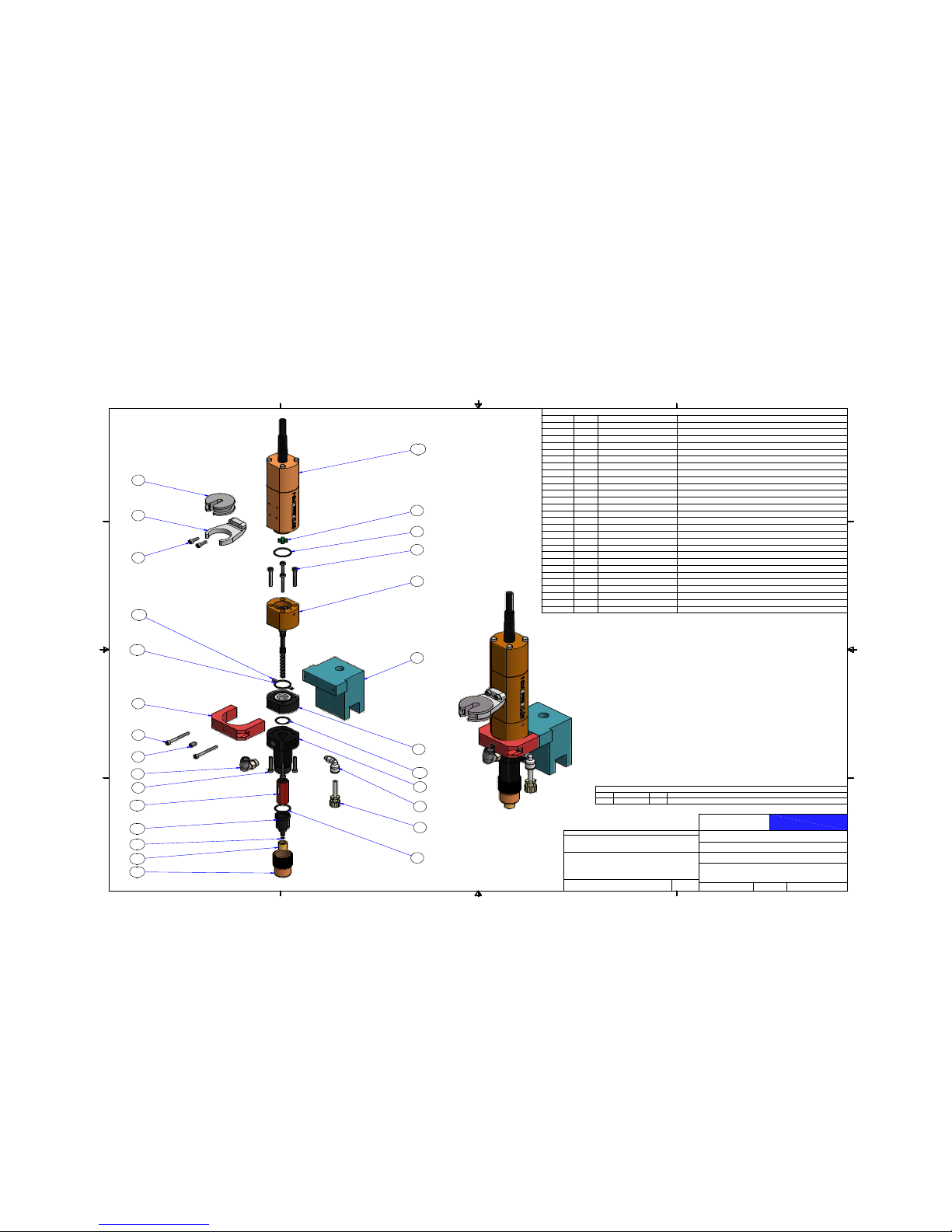

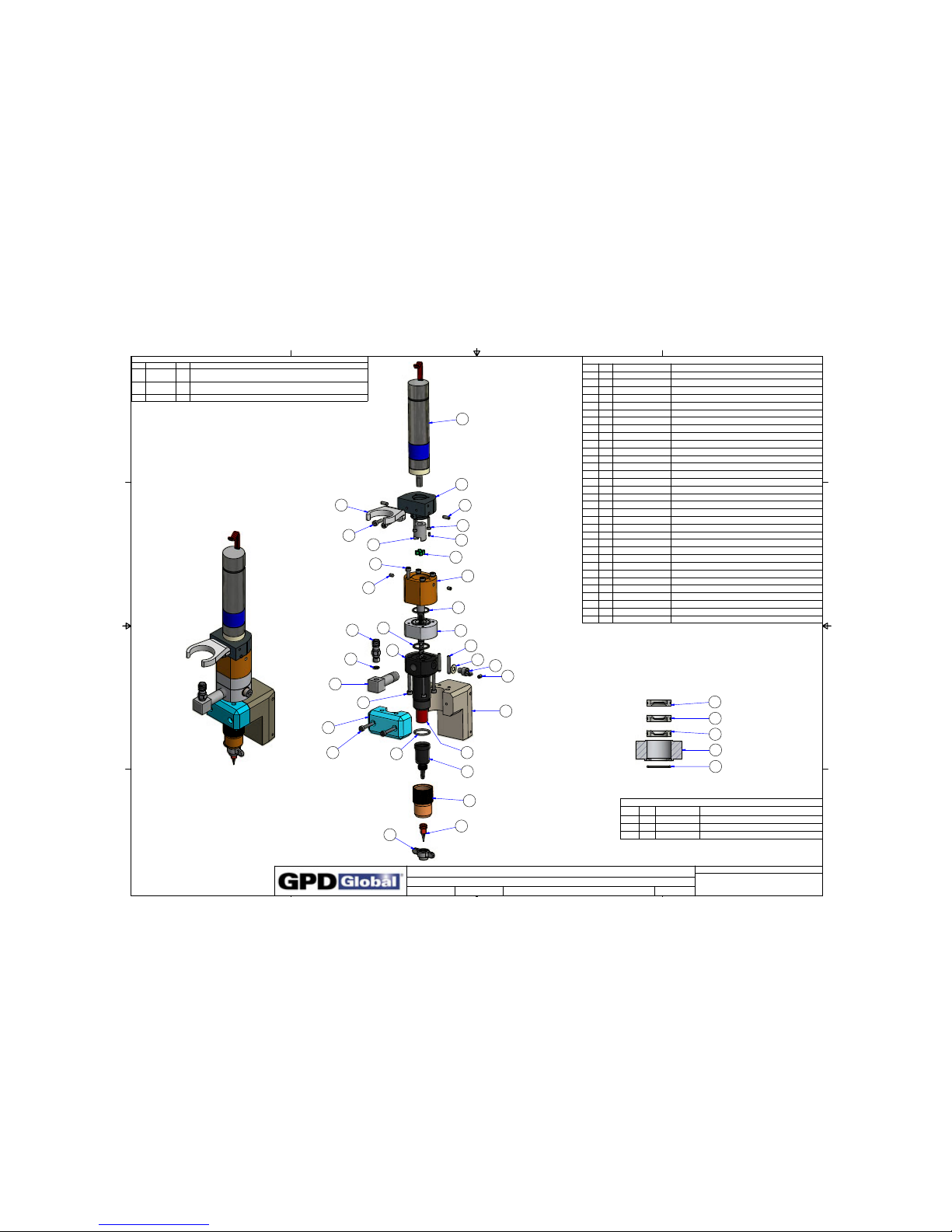

PCD3 Models

• PCD3 - 10/4807 (pg 35)

• PCD3 - 22293093-1004

– 22293091 replaced by 22293093-1004

• PCD3 - 22293093

• PCD3L - 22293093-1002

– 22293120 replaced by 22293093-1002

• PCD3H - 22293093-1003

– 22293228 replaced by 22293093-1003

• PCD3H legacy - 22293121

• PCD3 Stator End Piece - 22293179

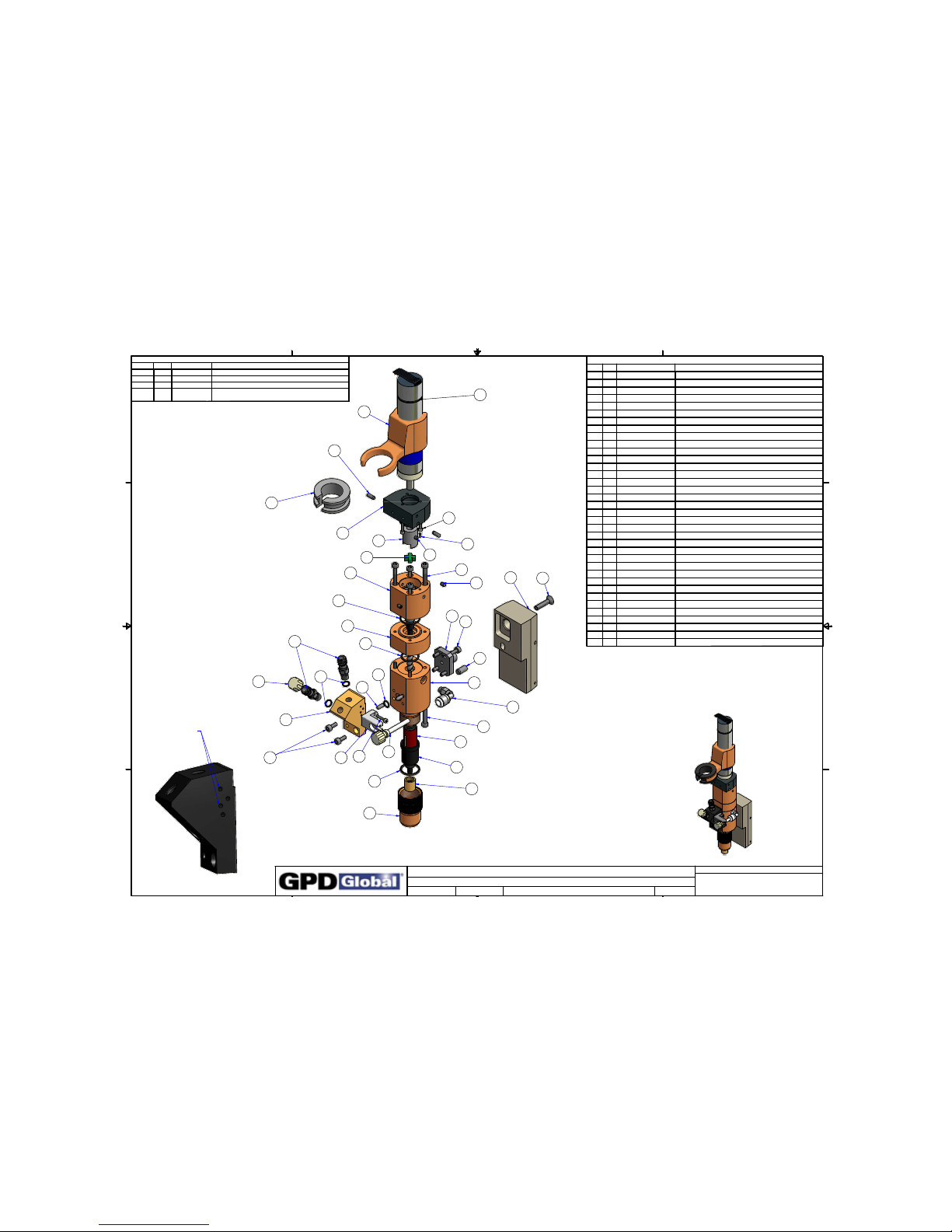

PCD4 Models

• PCD4 - 2650-0048 (pg 42)

• PCD4 - 22293098

• PCD4 - 22293081

• PCD4 - 22293098-0002

• PCD4L - 22293122

• PCD4H - 22293103

• PCD4H - 22293227-0002

• PCD4H - 22293227-0003

• PCD4HB - 22293240

• PCD4HB legacy - 22293205

(pg 36)

(pg 37)

(pg 38)

(pg 39)

(pg 40)

(pg 41)

(pg 43)

(pg 44)

(pg 45)

(pg 46)

(pg 47)

(pg 48)

(pg 49)

(pg 50)

(pg 51)

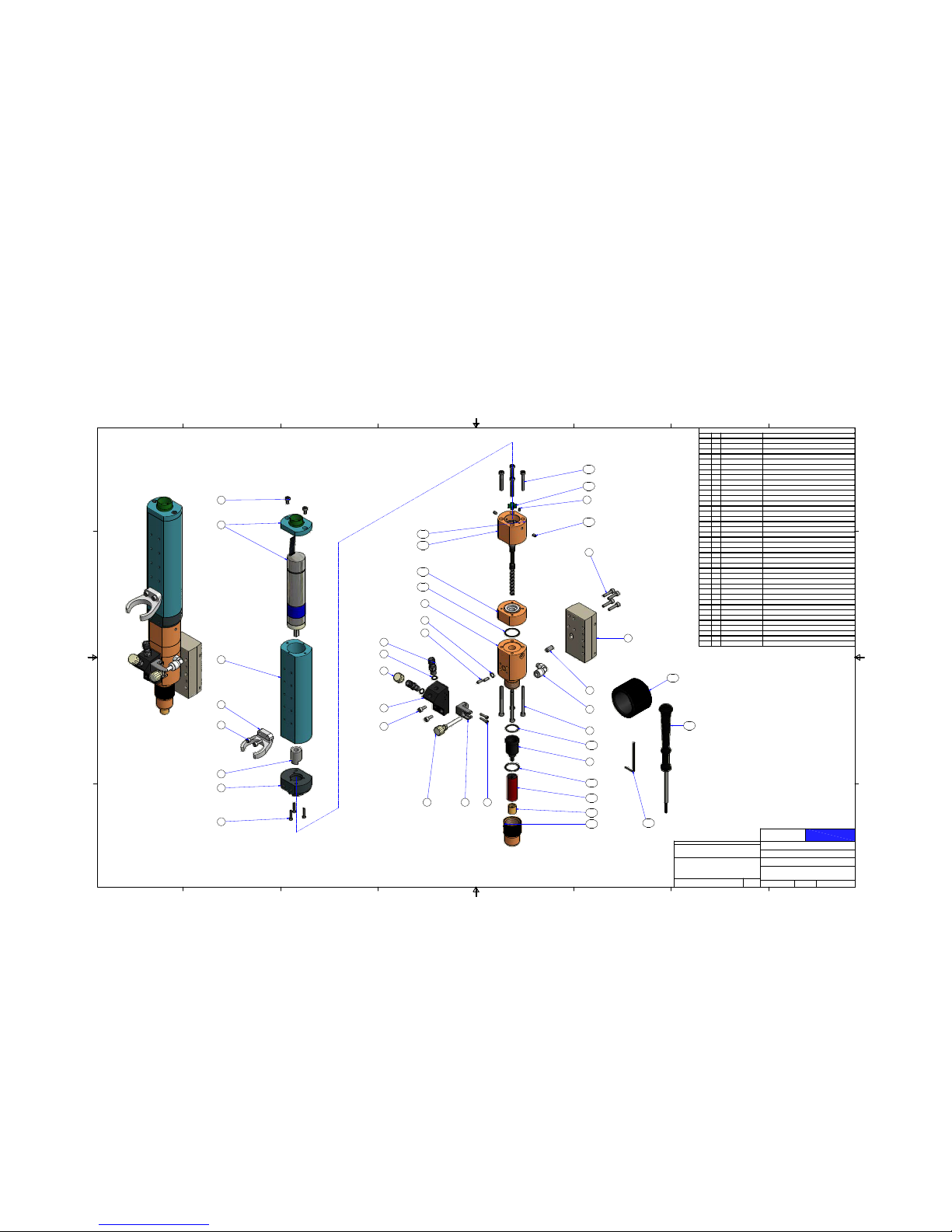

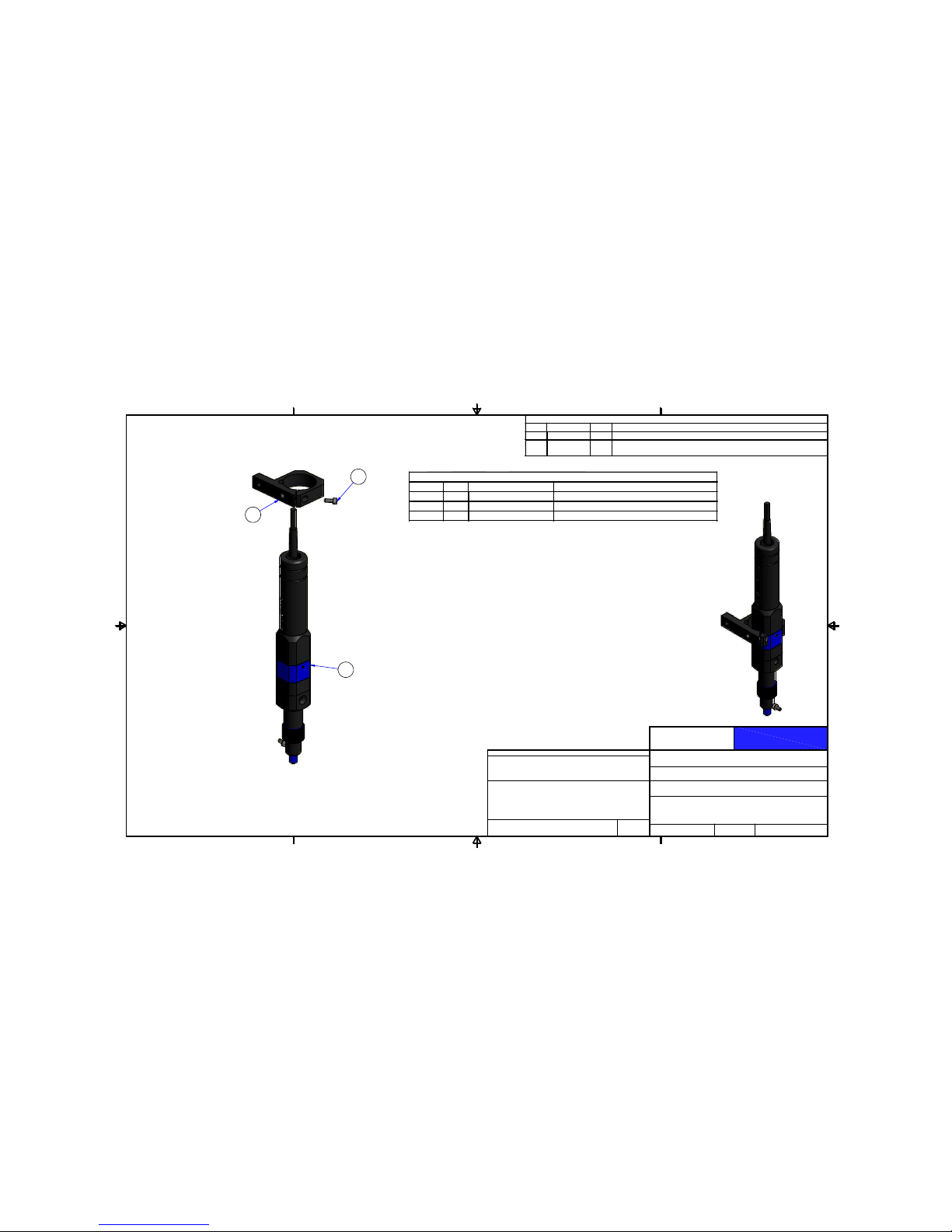

PCD6 Models

• PCD6 - 22293160 (pg 52)

• PCD6 - 22293161-001

• PCD6HB - 22293161-003

(pg 53)

(pg 54)

PCD7 Models

• PCD7H - 22293306-003 (pg 55)

Related Items

Level Detect

• Level Detect, DS Series - 22110521

• Level Detect, MAX Series - 22293101

Mounting Detail

• Clamp Mount Hole Patterns & Groove - 22212002

• Clamp Mount Dimensions - 22212002

• Taper-Lock Mounting Detail - 22110291

(pg 56)

(pg 57)

(pg 59)

(pg 60)

(pg 58)

2/20/19 GPD Global

®

34

GPD Global

©

PCD3 - 10/4807

2/20/19 PCD Pump User Guide 35

PCD3 - 10/4807

Parts List

DESCRIPTIONPART NUMBERQTYITEM

ORING,VITON,SPECIAL_.25 X .18 X

.035

10/042711

ELBOW,5/32 HOSE10/1804

12

ADAPTER, THD, LUER, FEMALE,

SST,1/4-32

10/317113

COUPLING STAR SHAPED10/4673

14

ASSEMBLY AID HAND DRIVER10/4674

1

5

SET SCREW M3 X 510/467826

O-RING FKM 16MM DIA X 1.2510/4679

17

O-RING FKM 13MM DIA X 1.2510/4683

18

SEAL SET W/HOUSING

10/468619

ALLEN SCREW M3 X 2510/4687

4

10

O-RING NBR 17MM DIA X 1.2510/4691

113

DISPENSING UNIT PCD3 CPL10/4822

114

UNION RING PCD310/4823115

DRIVE UNIT CPL_PCD 310/4826116

O-RING FKM 14MM DIA X 1.510/4829

117

BLEED SCREW PCD310/4830

118

O-RING FKM 8MM DIA X 1.2510/4831119

ALLEN SCREW M3 X 1610/4834

420

PURGE TUBE ASSY PCD VALVES

22110495122

FEED RESERVOIR_PCD

22203375123

DISPENSER HOUSING

PCD3_MODIFIED

22203403124

TUBE SUPPORT_PCD3 PURGE

22203411125

BEARING HOUSING W/ROTOR SET

CPL

22203466126

CAP SCREW, SST, 3MM X 0.5

20MM LG

SACSM030050020

128

STATOR END

PIECE_PCD3_MOD_FEMALE

22203583129

STATOR END

PIECE_PCD3_MOD_MALE

22203584130

THREADED SLEEVE_LUER-LOCK10/4690131

WASHER_TEFLON_.197ID X .280OD

X .015 THICK

2825-0035132

END PIECE_PCD3_STATOR

MOD_ASSY

22293179133

1

1

2

2

3

3

4

4

A A

B B

DWG SIZE

DWG NO

SHEET

OF

DRAWN BY

DESCRIPTION

ASSEMBLY

FINISH

MATERIAL

TOLERANCES UNLESS OTHERWISE SPECIFIED

FRACTIONS B1/32

HEAT TREATMENT

X.XX B0.015

X.XXX

B

0.005

ANGULAR

B

0.5

`

RUNOUT B0.003 T.I.R.

METRIC

0.0 MM

B

0.4 MM

0.00 MM

B

0.1 MM

GPD

Global

VALVE PCD3 W 1 METER CABLE

10_4807

1

1

B

ARM

11/2/2010

0 MM B1.0 MM

REVISION HISTORY

REV DATE BY DESCRIPTION

A6/24/16IHD

REPLACED PART 27, 22293179 WITH CORECTED 22293179 ASSEMBLY, PART 33

22

8

2

23

1

3

28

25

24

19

18

20

17

15

9

7

5

6

10

26

4

13

LAST REVISED 11/10/17

29

32

30

31

16

14

33

GPD Global

©

PCD3 - 22293093-1004

2/20/19 PCD Pump User Guide 36

PCD3 - 22293093-1004

PARTS LIST

DESCRIPTION

PART NUMBER

QTY

ITEM

ELBOW_MALE_M5X4MM TUBE

10/2017

11

ADAPTER, THD, LUER, FEMALE, SST,1/4-3210/3171

1

2

ORING,VITON_5mmID X 1mmW

10/4912

1

3

PURGE TUBE ASSY PCD VALVES2211049514

FEED RESERVOIR_PCD22203375

15

SYRINGE SUPPORT_PCD 450_SNAP STYLE22203379

1

6

MOTOR CLAMP_SYRINGE SUPPORT_PCD 45022203380

17

MALE ADAPTER_PCD322203402

1

8

MOTOR CLAMP_PCD32220340419

TUBE SUPPORT_PCD3 PURGE22203411

1

10

PUMP_PCD3_BASE22293093-0004

111

DISPENSER HOUSING PCD3_MODIFIED22203403111.1

PUMP PCD322293093

1

11.2

COUPLING STAR SHAPED

10/4673

111.2.1

ASSEMBLY AID HAND DRIVER

10/4674

1

11.2.2

SET SCREW M3 X 5

10/4678

211.2.3

SEAL SET W/HOUSING10/4686

111.2.4

ALLEN SCREW M3 X 25

10/4687

4

11.2.5

O-RING NBR 17MM DIA X 1.25

10/4691

111.2.6

WRENCH_HEX-KEY_2.5MM W/HANDLE10/4772

1

11.2.7

UNION RING PCD3

10/4823

1

11.2.8

ALLEN SCREW M3 X 16

10/4834

411.2.9

O-RING_FKM_.547ID X .051W2575-0004

1

11.2.10

O-RING_FKM_.632 ID X .047 SECTION2575-0005

1

11.2.11

O-RING FKM 14MM DIA X 1.52575- 0007111.2.12

BEARING HOUSING W/ROTOR SET CPL

22203466

1

11.2.13

END PIECE_PCD3_STATOR MOD_ASSY22293179111.2.14

THREADED SLEEVE LUER-LOCK10/4690

1

11.2.14.3

WASHER_TEFLON_.197ID X .280OD X .015 THI2825-0035

1

11.2.14.4

STATOR END PIECE_PCD3_MOD_FEMALE22203583111.2.14.1

STATOR END PIECE_PCD3_MOD_MALE22203584

1

11.2.14.2

ASSY_DRIVE UNIT_PCD3_HOUSING22293221111.2.15

WRENCH_HEX-KEY_1.5MM_L SHAPE

M2003

1

11.2.16

DOWEL PIN 1/8 X 1.0 LONG

DA12100

1

12

SCR.A.CP.SST.MET.M3X.5_12MM LGSACSM030050012213

SCR.A.CP.SST.MET.M3X.5_20MM LGSACSM0300500202

14

SCR.A.CP.SST.MET.M3X.5_30MM LGSACSM0300500302

15

1

1

2

2

3

3

4

4

A A

B B

C C

D D

DWG SIZE

DWG NO

SHEET

OF

DRAWN BY

DESCRIPTION

ASSEMBLY

FINISH

MATERIAL

TOLERANCES UNLESS OTHERWISE SPECIFIED

FRACTIONS B1/32

HEAT TREATMENT

X.XX B0.015

X.XXX

B

0.005

ANGULAR

B

0.5

`

RUNOUT B0.003 T.I.R.

METRIC

0.0 MM

B

0.4 MM

0.00 MM

B

0.1 MM

GPD

Global

PUMP_PCD

22293093-1004

1 1

C

MW

9/27/2017

PCD3

ASSEMBLY

0 MMB1.0 MM

REVISION HISTORY

REV DATE BY DESCRIPTION

-- -

ORIGINAL ISSUE

A

6/1/2018

HTB ROTATED THE PUMP VIEW NOZZLE DOWN

13

6

7

14

8

12

11.2.15

11.2.6

9

15

11.2.5

11.2.1

11.2.13

11.2.11

11.2.4

11.2.10

11.1

1

11.2.12

11.2.9

11.2.14.1

11.2.14.2

11.2.14.4

11.2.14.3

11.2.8

2

3

5

4

14

10

11.2.7

11.2.2

11.2.16

11.2.3

2X

4X

4X

2X

2X

GPD Global

©

PCD3 - 22293093

2/20/19 PCD Pump User Guide 37

PCD3 - 22293093

Parts List

DESCRIPTIONPART NUMBERQTYITEM

COUPLING STAR SHAPED10/467311

ASSEMBLY AID HAND DRIVER10/4674

12

SET SCREW M3 X 510/4678

23

SEAL SET W/HOUSING10/468614

ALLEN SCREW M3 X 2510/4687

45

O-RING NBR 17MM DIA X 1.2510/4691

16

WRENCH_HEX-KEY_2.5MM W/HANDLE10/4772

1

7

UNION RING PCD310/482318

DRIVE UNIT CPL PCD310/4826

19

DISPENSER HOUSING PCD310/4828

110

ALLEN SCREW M3 X 16

10/4834411

BEARING HOUSING W/ROTOR SET CPL22203466112

END PIECE_PCD3_STATOR MOD_ASSY

22293179113

ASSY_DRIVE UNIT_PCD3_HOUSING

22293221114

O-RING_FKM_.547ID X .051W2575-0004115

O-RING_FKM_.632 ID X .047 SECTION2575-0005116

O-RING FKM 14MM DIA X 1.5

2575-0007117

WRENCH_HEX-KEY_1.5MM_L SHAPE

M2003118

1

1

2

2

3

3

4

4

A A

B B

DWG SIZE

DWG NO

SHEET

OF

DRAWN BY

DESCRIPTION

ASSEMBLY

FINISH

MATERIAL

TOLERANCES UNLESS OTHERWISE SPECIFIED

FRACTIONS B1/32

HEAT TREATMENT

X.XX B0.015

X.XXX

B

0.005

ANGULAR

B

0.5

`

RUNOUT B0.003 T.I.R.

METRIC

0.0 MM

B

0.4 MM

0.00 MM

B

0.1 MM

GPD

Global

VALVE_PCD3_10" WIRE LENGTH_VER1

22293093

1

1

B

MW

4/13/2011

PUMP_PCD3

10/4807

NA

0 MM B1.0 MM

REVISION HISTORY

REV DATE BY DESCRIPTION

A 8/19/13 BLH 22293179 REPLACED 10/4824 STATOR ASSY

B2/7/14IAH

REMOVED 22203403, ADDED BALLOON FOR 22203401, ADDED PART 22203466

C 7/25/2017 MW ADD STOCK PARTS AND TOOLS TO BOM

NOTES:

1. DISASSEMBLE PUMP 10/4807 RETAINING BOX AND TOOLS.

2. DISCARD O-RINGS INCLUDED WITH PUMP AND USE SPECIFIED O-RINGS ON REASSEMBLY.

3. REPLACE MOTOR HOUSING WITH PN 22203401.

4. MODIFY BEARING HOUSING W/ROTOR SET CPL AS PER DRAWING 22203466.

5. MODIFY AND REPLACE STATOR END PIECE AS PER DRAWING 22293179.

6. REASSEMBLE PUMP AND RETURN TO BOX WITH TOOLS.

7

2

18

6

1

5

12

16

4

15101117138

4X 4X

3 2X

14

GPD Global

©

PCD3L - 22293093-1002

2/20/19 PCD Pump User Guide 38

PCD3L - 22293093-1002

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

ELBOW_MALE_M5X4MM TUBE10/2017

11

ADAPTER, THD, LUER, FEMALE, SST,1/4-3210/3171

22

LUER CAP FITTING MALE LOCKING10/4836

13

ORING,VITON_5mmID X 1mmW10/4912

94

PURGE TUBE ASSY PCD VALVES

2211049515

BUSHING,10CC

2214104316

ADAPTER MOUNT_PCD3 VER2

2220343017

CLIP_PURGE VENT_PCD4H

2220345318

SYRINGE TUBE/VENT BLOCK, PCD4H

2220345419

MALE ADAPTER_PCD4H_SHORT CONFIG

22203457110

MOTOR CLAMP_SYRINGE SUPPORT_PCD 450

22203465111

SYRINGE SUPPORT_PCD3L_SNAP STYLE

22203619112

PUMP_PCD3L BASE

22293093-0002113

DISPENSER HOUSING_PCD3_MODIFIED

22203474113.1

SCR.A.CP.SST.MET.M3X.5_25MM LGSACSM030050025

413.2

VALVE_PCD3L

22293093113.3

COUPLING STAR SHAPED10/4673

113.3.1

SET SCREW M3 X 510/4678

213.3.2

O-RING NBR 17MM DIA X 1.2510/4691

113.3.3

ALLEN SCREW M3 X 2510/4687

413.3.4

UNION RING PCD310/4823

113.3.5

SEAL SET W/HOUSING10/4686

113.3.6

END PIECE_PCD3_STATOR MOD_ASSY

22293179113.3.7

STATOR END PIECE_PCD3_MOD_FEMALE

22203583113.3.7.1

STATOR END PIECE_PCD3_MOD_MALE

22203584113.3.7.2

THREADED SLEEVE LUER-LOCK10/4690

113.3.7.3

WASHER_TEFLON_.197ID X .280OD X .015 THI

2825-0035113.3.7.4

BEARING HOUSING W/ROTOR SET CPL

22203466113.3.8

O-RING_FKM_.632 ID X .047 SECTION

2575-0005113.3.9

O-RING_FKM_.547ID X .051W

2575-0004113.3.10

O-RING FKM 14MM DIA X 1.5

2575-0007113.3.11

ASSEMBLY AID HAND DRIVER10/4674

113.3.12

WRENCH_HEX-KEY_1.5MM_L SHAPEM2003113.3.13

WRENCH_HEX-KEY_2.5MM W/HANDLE10/4772113.3.14

ASSY_DRIVE UNIT_PCD3_HOUSING22293221113.3.15

DOWEL PIN 3mm X 8mmDAM03008314

DOWEL PIN 5mm X 10mmDAM05010115

SCR.A.CP.SST.MET.M2X.4_10MM LGSACSM020040010216

SCR.A.CP.SST.MET.M3X.5_6MM LGSACSM030050006617

SCR.A.CP.SST.MET.M3X.5_12MM LGSACSM030050012219

SCR.A.CP.SST.MET.M3X.5_16MM LGSACSM030050016120

SCREW,FLATHEAD,4MM X 18LG ALLOYSAFANM040070018121

1

1

2

2

3

3

4

4

A A

B B

C C

D D

DWG NO

SHEET

OF

DRAWN BY

DESCRIPTION

ASSEMBLY

MATERIAL

GPD

Global

PUMP_PCD3L

22293093-1002

1 1

MW

9/22/2017

PUMP PCD

ASSEMBLY

REVISION HISTORY

REV DATE BY DESCRIPTION

A 12/7/2017 MW SCREW WAS 4X SACSM030050008 IS 4X SACSM030050006

13.3.12

13.3.13

13.3.14

21

10

177

19

12

6

13.3.15

13.3.3

13.3.4

13.3.1

13.3.8

13.3.2

13.3.9

13.3.6

13.3.10

15

13.2

13.3.11

13.3.7.1

13.3.7.2

13.3.7.4

13.3.7.3

13.3.5

13.1

14

1618

5

17

2

3

2

4

11

20

14

2X

3X

2X

4X

4X

4X

9

GPD Global

©

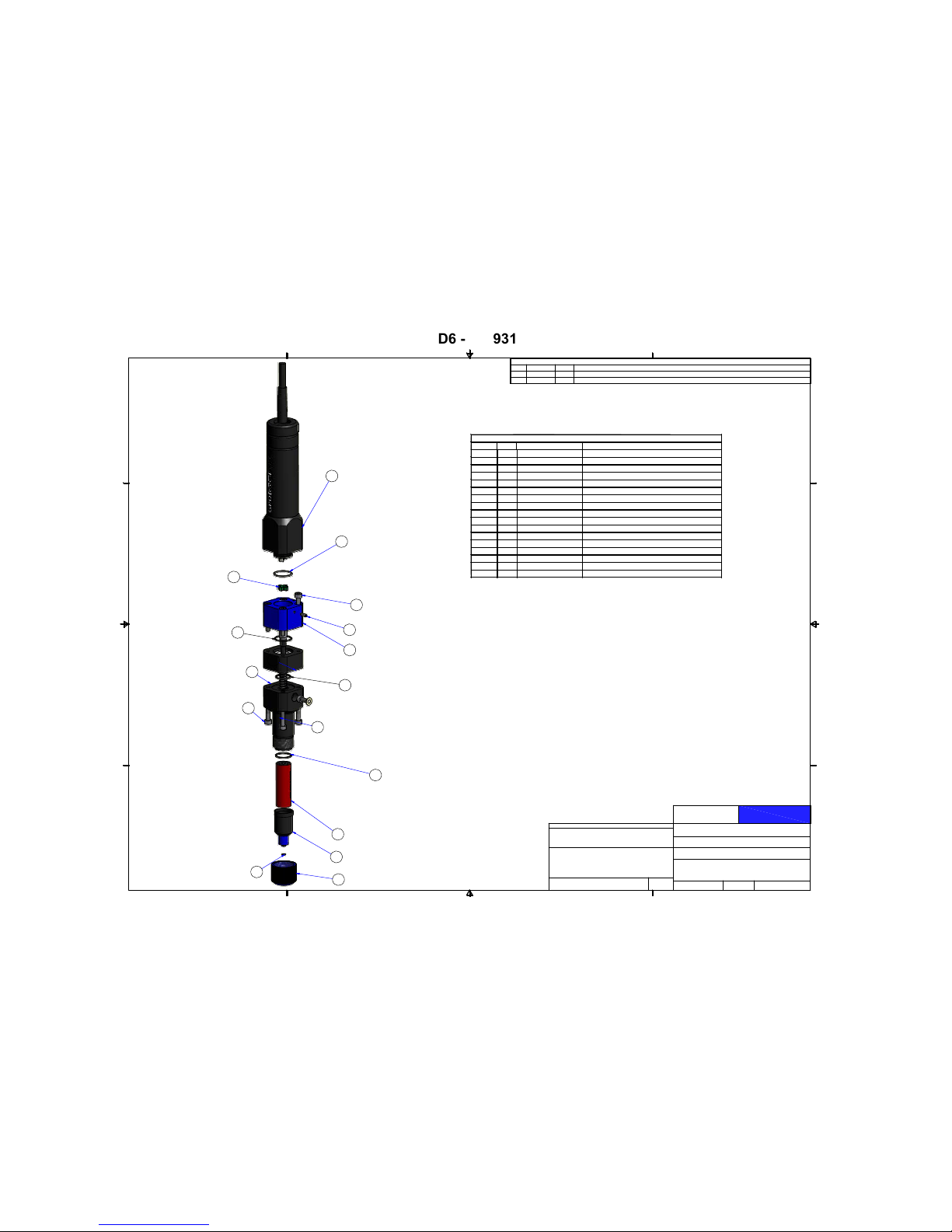

PCD3H - 22293093-1003

2/20/19 PCD Pump User Guide 39

PCD3H - 22293093-1003

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

ELBOW_MALE_M5X4MM TUBE

10/2017

11

ADAPTER, THD, LUER, FEMALE, SST,1/4-3210/317122

LUER CAP FITTING MALE LOCKING

10/4836

1

3

ORING,VITON_5mmID X 1mmW

10/4912

34

PURGE TUBE ASSY PCD VALVES22110495

15

BUSHING,10CC22141043

1

6

ADAPTER MOUNT_PCD3 VER222203430

17

SUPPORT TAB_LUER FITTING_PCD4H22203453

1

8

SYRINGE TUBE/VENT BLOCK, PCD4H

2220345419

MALE ADAPTER_PCD4H_SHORT CONFIG22203457

1

10

SYRINGE SUPPORT_PCD_SNAPSTYLE_RND22203606

111

PUMP_PCD3H BASE22293093-0003112

PUMP PCD3H22293093

1

12.1

COUPLING STAR SHAPED

10/4673

112.1.1

ASSEMBLY AID HAND DRIVER

10/4674

1

12.1.12

SET SCREW M3 X 5

10/4678

212.1.2

SEAL SET W/HOUSING10/4686

112.1.6

ALLEN SCREW M3 X 25

10/4687

4

12.1.4

WRENCH_HEX-KEY_2.5MM W/HANDLE10/4772

112.1.14

UNION RING PCD310/4823

1

12.1.5

BEARING HOUSING W/ROTOR SET CPL

22203466

1

12.1.8

END PIECE_PCD3_STATOR MOD_ASSY22293179112.1.7

O-RING_FKM_.547ID X .051W2575-0004

1

12.1.10

O-RING_FKM_.632 ID X .047 SECTION2575-0005

1

12.1.9

O-RING FKM 14MM DIA X 1.52575-0007112.1.11

WRENCH_HEX-KEY_1.5MM_L SHAPEM2003

1

12.1.13

DISPENSER HOUSING_PCD3_MODIFIED22203474112.2

SCR.A.CP.SST.MET.M3X.5_25MM LGSACSM030050025

4

12.3

SCR.A.CP.SST.MET.M2X.4_14MM LGSACSM020040014312.4

BODY ADAPTER_MICRO MOTOR ADAPTER22203605112.5

DOWEL PIN 2mm X 6mmDAM02006

1

12.6

DOWEL PIN 3mm X 8mmDAM03008212.7

COUPLER,6MM22203421

1

12.8

DEVICE_MOTOR_SERVO_20 PIN CONNECTOR22293288

1

12.9

SET.A.CU.SST.MET_ 3MMX0.5 X 3MM LG SSTTACSM030050003112.10

DOWEL PIN 3mm X 8mmDAM03008213

SCR.A.CP.SST.MET.M2X.4_10MM LGSACSM0200400102

14

SCR.A.CP.SST.MET.M3X.5_8MM LGSACSM030050008

615

SCREW,FLATHEAD,4MM X 18LG ALLOYSAFANM040070018

1

16

1

1

2

2

3

3

4

4

A A

B B

C C

D D

DRAWING NUMBER

SHEET OF

DRAWN BY:

DESCRIPTION:

ASSEMBLY:

PUMP_PCD3H

22293093-1003

1 1

ARM

8/14/2017

DATE:

MOUNT BLEED TUBE

ON THESE HOLES

REVISION HISTORY

REV BY DATE DESCRIPTION

A MW 11/14/2017 UPDATE CHANGES TO 22293093-0003

12.9

12.5

12.7

12.4

16

7 15

12.1.6

12.1.10

12.2

12.1.11

12.3

12.1.7

12.1.5

10

14

18

5

15

4

3

2

13

12.1.9

12.1.8

12.1.2

12.1.1

12.1.4

6

11

12.6

3X

4X

3X

2X

2X

3X

4X

2X

9

12.8

12.10

12.1.14

12.1.13

12.1.12

GPD Global

©

PCD3H legacy - 22293121

2/20/19 PCD Pump User Guide 40

PCD3H legacy - 22293121

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

ELBOW_MALE_M5X4MM TUBE10/2017

11

ADAPTER, THD, LUER, FEMALE, SST,1/4-3210/3171

22

LUER CAP FITTING MALE LOCKING10/4836

13

ORING,VITON_5mmID X 1mmW10/4912

34

PURGE TUBE ASSY PCD VALVES

2211049515

MOTOR/GEARBOX ASSEMBLY

2214103316

BUSHING,10CC

2214104317

COUPLER,6MM

2220342118

ADAPTER MOUNT_PCD3 VER2

2220343019

SYRINGE SUPPORT_PCD4H_SNAP STYLE

22203448110

BODY ADAPTER_PCD4H MOTOR INTERFACE

22203449111

SUPPORT TAB_LUER FITTING_PCD4H

22203453112

SYRINGE TUBE/VENT BLOCK, PCD4H

22203454113

MALE ADAPTER_PCD4H_SHORT CONFIG

22203457114

DISPENSER HOUSING_PCD3_MODIFIED

22203474115

PUMP PCD3 LEGACY

22293093116

COUPLING STAR SHAPED10/4673

116.1

SET SCREW M3 X 510/4678

216.2

O-RING NBR 17MM DIA X 1.2510/4691

116.3

ALLEN SCREW M3 X 2510/4687

416.4

UNION RING PCD310/4823

116.5

SEAL SET W/HOUSING10/4686

116.6

END PIECE_PCD3_STATOR MOD_ASSY

22293179116.7

STATOR END PIECE_PCD3_MOD_FEMALE

22203583116.7.1

STATOR END PIECE_PCD3_MOD_MALE

22203584116.7.2

THREADED SLEEVE LUER-LOCK10/4690

116.7.3

WASHER_TEFLON_.197ID X .280OD X .015 THI

2825-0035116.7.4

BEARING HOUSING W/ROTOR SET CPL

22203466116.8

O-RING_FKM_.632 ID X .047 SECTION

2575-0005116.9

O-RING_FKM_.547ID X .051W

2575-0004116.10

O-RING FKM 14MM DIA X 1.5

2575-0007116.11

ASSEMBLY AID HAND DRIVER10/4674

116.12

WRENCH_HEX-KEY_1.5MM_L SHAPEM2003116.13

WRENCH_HEX-KEY_2.5MM W/HANDLE10/4772116.14