Operating Guide

In addition to installation, set up, and operating

specifications details.

Bills of Material

Includes an illustrated bill of material with associated

part numbers for each CF-9 subassembly.

Die Catalog

Catalog of dies precisely manufactured by GPD Global®

variety of component shapes.

Set Up Form

Fill out this Set Up form and then use it as a guide for

consistent results for each component part number.

Documentation Package

for CF-9 Taped Radial Component Lead Former

PN 901-1-01

CONTENTS of CF-9 Documentation Package

procedures, this guide includes electrical schematics and

maintenance, troubleshooting, spare parts, and

to accurately form Radial components into a wide

611 Hollingsworth Street

Grand Junction, CO, USA 81505

tel: +1.970.245-0408

fax: +1.970.245-9674

request@gpd-global.com

www.gpd-global.com

CF-9

Radial Lead Forming Machine

User's Guide

Version 2.1

June 4, 2014

Prepared by

GPD Global

®

Documentation Department

©

Copyright

2014 GPD Global

All Rights Reserved

GPD Global

611 Hollingsworth Street

Grand Junction, CO 81505

(970) 245-0408

CF-9 User's Guide CF-9 Radial Lead Forming Machine

Part No. 901-1-07 Serial No.

®

®

CF-9 User's Guide

Warranty

GPD Global (GPD) warrants that this product will be free from defects in material and

workmanship for a period of one (1) year from the date of original purchase. GPD will repair, or

at its option, replace this GPD product during the war ranty period at no charge, provided it is

returned (shipping-postage paid) to the GPD, Colorado service facility.

The one year warranty does not cover nor mal wear and tear to the cutting and forming tooling,

since life usually depends on use.

This warranty does not apply if the GPD product has been damaged by accident, abuse, misuse,

or misapplication, has been modified without the wri tten permission of GPD, or if any GPD serial

number has been removed or defaced.

GPD IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING FROM THE BREACH OF ANY EXPRESS OR IMPLIED WARRANTY INCLUDING

ANY COSTS OR DAMAGE TO PROPERTY, AND, TO THE EXTENT PERMITTED BY LAW,

DAMAGES FOR PERSONAL INJURY. THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES. ANY IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN

DURATION TO ONE (1) YEAR FROM THE DATE OF RECEIPT OF THIS PRODUCT. GPD'S

LIABILITY ON ANY CLAIM OF ANY KIND INCLUDING NEGLIGENCE, FOR LOSS OR

DAMAGE ARISING OUT OF, CONNECTED WITH OR RESULTING FROM THE BREACH OF

ANY EXPRESS OR IMPLIED WARRANTY OR THE DELIVERY, REPAIR, OR USE OF ANY

GPD PRODUCT SHALL IN NO CASE EXCEED THE PRICE ALLOCABLE TO THE GPD

PRODUCT WHICH GIVES RISE TO THE CLAIM.

Specifications, descripti ons, and all information contained in this manual are subject to change

and/or correction without notice.

Although reasonable care has been exerci sed in the preparation of this manual to make it

complete and accurate, this manual does not purport to cover all conceivable problems or

applications pertaining t o this machine.

09/30/92 GPD Global i

CF-9 User's Guide

Safety Instructions

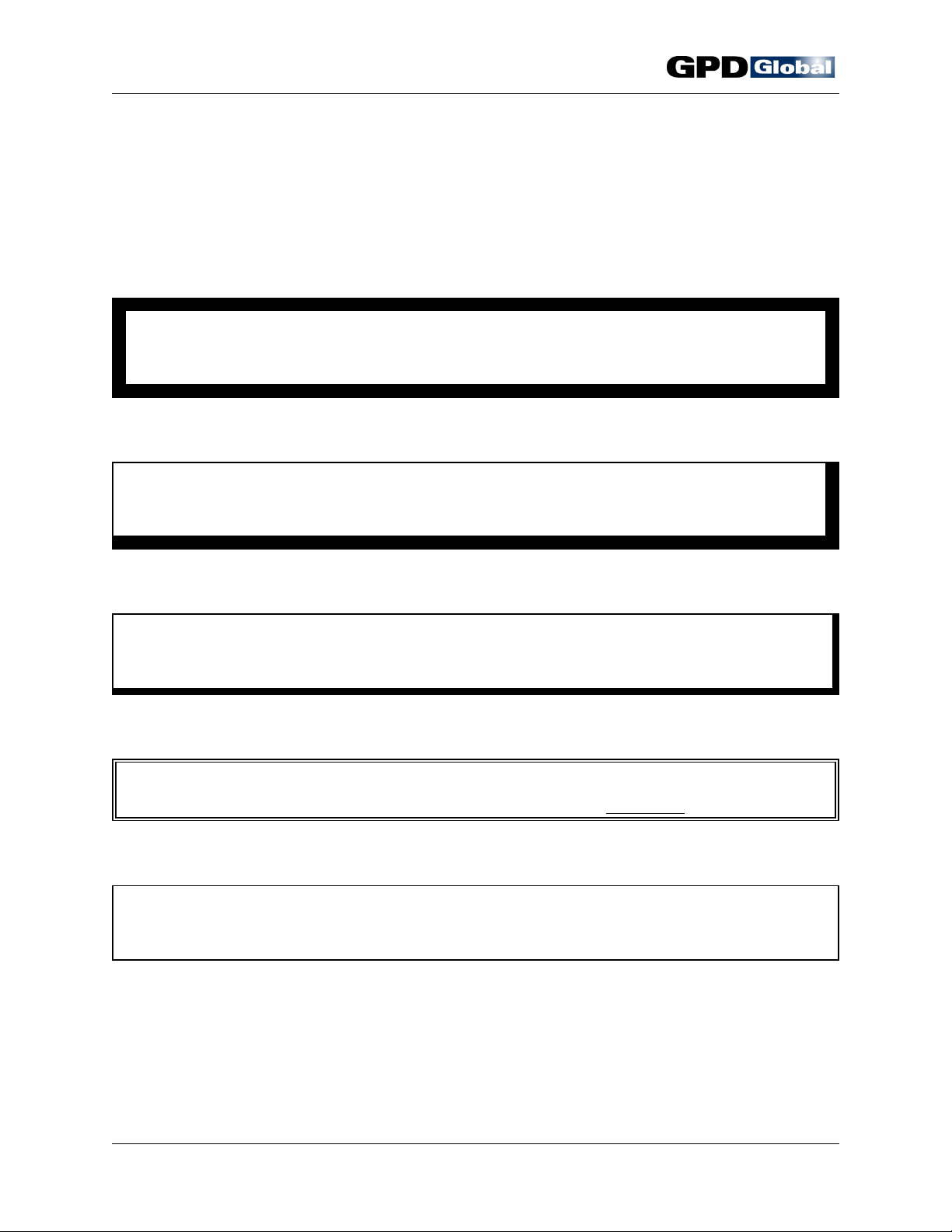

Symbol samples and definit ions for the DANGER, WARNING, CAUTION, IMPORTANT and

NOTE safety notices used in this document are as follows:

** D A N G E R **

Danger notices are used in this document t o emphasize life threateni ng or potentially

harmful situations.

W A R N I N G

Warning notices are used in this document to emphasize chance of injury, harm to l ife or

limb due largely to something beyond one's control.

C A U T I O N

Caution notices are used in this document to alert one to avoid danger or harm and where

equipment might be damaged if care is not taken.

I M P O R T A N T

Important notices are used i n this document to call attention to imperative infor m ation.

NOTE

Note is used in this document to call attention to information that is especially significant in

understanding and operating the equipment.

ii GPD Global 09/30/92

CF-9 User's Guide

Table of Contents

Introduction ................................................................ 1

Function ................................................................... 3

Theory of Operation .......................................................... 4

Machine Part Identification ..................................................... 5

Principal Parts ........................................................ 5

Adjustment Parts ...................................................... 6

Control Panel ......................................................... 7

Die Block Assembly.................................................... 8

Die Markings ......................................................... 9

Installation ................................................................. 11

Operating Instructions ........................................................ 13

Setup ............................................................... 13

Die Installation .................................................. 14

Station Adjustment............................................... 16

Component Alignment ............................................ 17

Load Components ..................................................... 18

Power On............................................................ 18

Process Components ................................................... 19

Power Off............................................................ 19

Preventive Maintenance ...................................................... 21

Troubleshooting ............................................................. 23

Slide Travel .......................................................... 24

Slide Clearance ....................................................... 25

Specifications............................................................... 29

Suggested Spare Parts ....................................................... 31

Appendices ................................................................ 33

Appendix A - Die Informati on ............................................. 35

Appendix B - Common CF-9 Lead Forms ................................... 37

Appendix C - CF-9 Accessories ........................................... 39

Appendix D - Electrical Schematic & Assembly Drawing ....................... 43

Index ...................................................................... 45

Reference CF-9 Component Forming Di e Catalog

09/30/92 GPD Global iii

CF-9 User's Guide

Table of Figures

Figure 1 Principal Parts .................................................. 5

Figure 2 Adjustment Parts ................................................ 6

Figure 3 Control Panel .................................................... 7

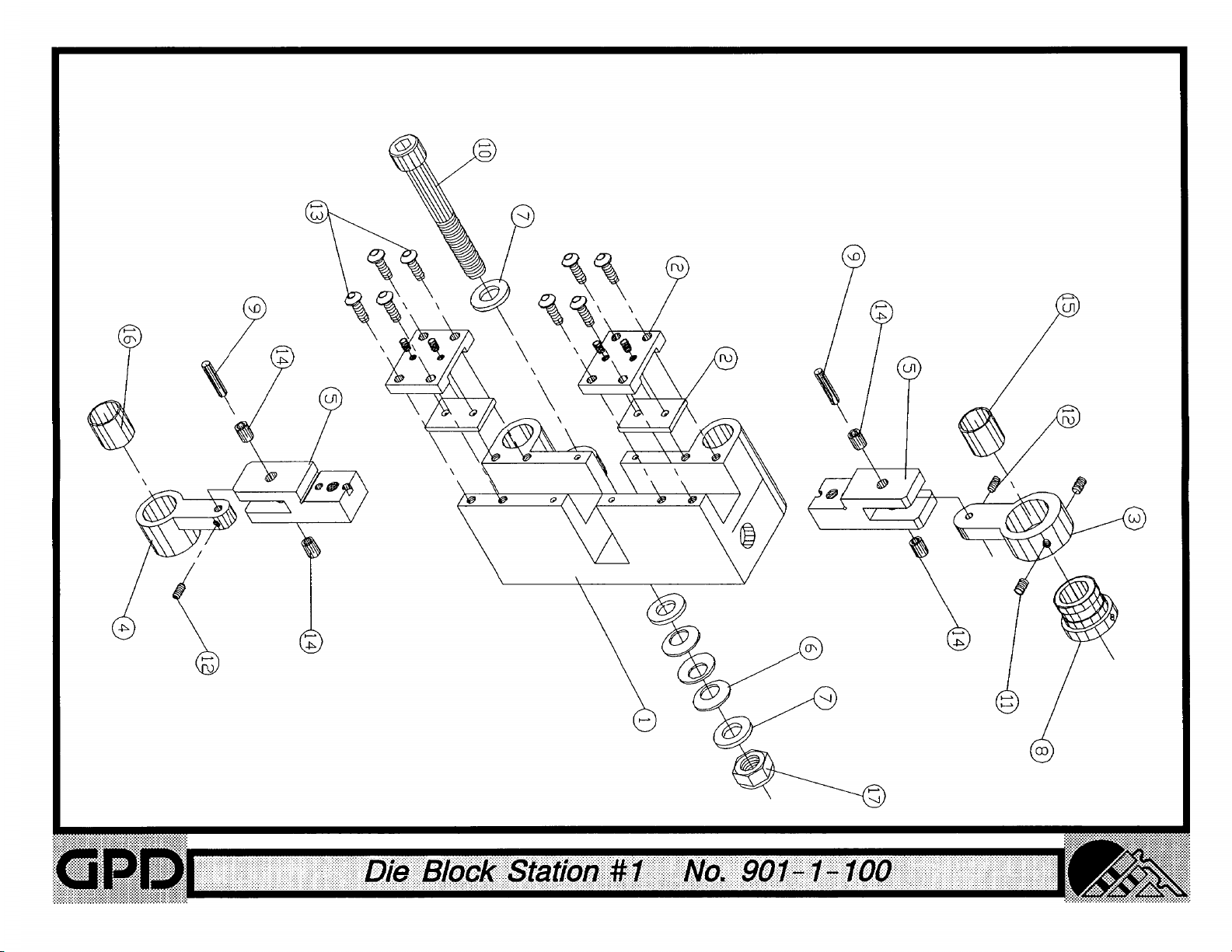

Figure 4 Die Block Assembly, Station 1...................................... 8

Figure 5 Die Forming Style Series ......................................... 9

Figure 6 Die & Station Markings ........................................... 9

Figure 7 CF-9 Installation................................................. 11

Figure 8 Die Mounting Surface & Die Block Sli de .............................. 14

Figure 9 Die Alignment & Knife Clearance ................................... 14

Figure 10 Ejector Brackets................................................. 15

Figure 11 Adjust Large Ejector Bracket ....................................... 15

Figure 12 Adjust Small Ejector Bracket ....................................... 15

Figure 13 Station Position Adjustment........................................ 16

Figure 14 Die Block Assembly Adjusting Bolts ................................. 16

Figure 15 Component Position Relative to Tape Hole ........................... 17

Figure 16 Align & Load Components ......................................... 18

Figure 17 Die Block Assembly Lubrication .................................... 21

Figure 18 Die Block Assembly Maintenance ................................... 21

Figure 19 Die Block Assembly Slide Travel.................................... 24

Figure 20 Die Block Assembly Slide Clearance................................. 25

Figure 21 Die Block Assembly Lubrication .................................... 26

Figure 22 GPD's CF-9 Taping Specification Requirements ....................... 30

Figure 23 Forming Style Series ............................................. 35

Figure 24 Examples of Die Numbers......................................... 35

Figure 25 Examples of Die Number Location .................................. 35

Figure 26 Electronic Component Counter Installation ............................ 40

Table of Charts

Chart 1 Preventive Mai ntenance Schedule .................................. 21

Chart 2 Troubleshooting Guide ........................................... 23

iv GPD Global 09/30/92

CF-9 User's Guide

Introduction

This document is intended for use by those who install, operat e and maintain GPD's CF-9 Radial

Lead Forming Machine (GPD Part# CF9. BASE.120 or CF9.BASE.230).

CF-9 Radial Lead Forming Machine

GPD's self-contained CF-9 Radial Lead For ming Machine has become the industry standard for

versatility, accuracy , repeatability, and ease of setup and change over. The CF-9 forms and cuts

to length a wide variety of two- and three-leaded taped radial components such as TO-92's,

capacitors, transisto rs, and LED's. It processes both st andard and special forms precisely and

repeatedly.

Two die stations with st andard micrometer scale indicators adjust independently. Performing

adjustments with the micrometer scales enables quick setup of proper forming and/or cutting

settings.

As the first component moves through the system, i t is presented to two die stations. The first

die station is generally used to form components, and the second to cut components from the

tape. Depending on the components being processed and the desired component lead form,

the second station may be used to both cut and form, just cut, or be excluded in order to l eave

components on tape.

The indexing system, the heart of the CF-9, drives the studded transfer belt. The studs, or pins,

on the belt pick up the tape holes and index exactly

The CF-9 is ruggedly constructed of heavy duty parts and sealed ball bearing shaft assemblies

for low maintenance. All of the machine's parts are precisely made and treated to pr event

corrosion, enhance appearance, or facilitate proper function.

The tape roller guide includes studded pr otrusions to hold the component tape sol idly in place —

the tape cannot run off the driv e belt mechanism. Waste tape feeds down a tape exit chute and

out to the side of the machine for easy disposal.

The CF-9's capabilities expand with its Loose/Bulk Component Feeder and Automatic Taped

Component Re-reeler accessories by combining the functions of several machines into one.

Additional accessories such as the Elect ronic Component Counter, Component Detect ion

System, Lazy Susan, Work Station, and Footswit ch are also available to help increase your

production and profit.

1/2" (12.70 mm) every time.

09/30/92 GPD Global 1

CF-9 User's Guide

CF-9 Lead Forming Dies

The CF-9 offers unique versatility through the use of a large selection of dies. The CF-9

operates on a system of di es and die blocks. Each die combination is designed t o form a

specific lead configuration. Numerous standard and special CF-9 Lead Forming Die sets are

available to provi de a variety of component forms and lead configurations. Many different die

sets for various transi stor hole patterns are also available.

A minimal amount of preparation time is required to reset the machine for processing different

component sizes. Dies are easi ly replaced within minutes.

GPD's CF-9 dies are precisely manufactured using a unique die const ruction process. Most

dies are built with a sectional, laminated construction method for exceptional wearing ability.

Before lamination, all dies are buffed and polished to exacting smoothness, particularly in the

actual forming and cutting ar eas.

2 GPD Global 09/30/92

CF-9 User's Guide

Function

CF-9 Radial Lead Forming Machine

The CF-9 performs the following functions:

• Forms and cuts up to 25,000 radial components per hour with a variable speed motor.

• Produces a variety of lead forms.

• Accommodates components with a wi de range of lead diameters.

• Handles a diversity of hole-to-hole spacings.

• Controls accuracy and repeatability through the use of a solid gear train, cam, and cam

follower indexing system.

Most cutting and formi ng needs are covered with the standard dies we offer. Sever al of the

most common component forms the CF-9 produces are illustrated in the Common CF-9 Lead

Forms appendix.

CF-9 Lead Forming Dies

CF-9 Lead Forming Die sets are available to perform the following functions:

• Produce both common and special configurations. GPD is pleased to design custom dies

for you. If you have unusual requirements, your GPD representative w ill be happy to assist

you with any custom die orders.

• Form two-leaded components with up to .400" (10.16 mm) center-to-center dimensions.

• Form three-leaded TO-92 transist ors.

• Offer unique versatility through the use of a large selection of different dies to form a wide

variety of component shapes.

NOTE

All CF-9 dies will also work on the GPD CF-10 Loose/Bulk Component Lead Former.

09/30/92 GPD Global 3

CF-9 User's Guide

Theory of Operation

The CF-9 performs the following steps during a cycle:

1. Feeds taped radial components from the reel holder through a pair of tape r oller guides

into the feeding mechanism and the formi ng and cutting die stations.

2. Forms the component in the first die station.

3. Indexes the formed component to the second die station while simul taneously indexi ng the

next component into the first die station.

4. Cuts the formed component from the tape i n the second die station, drops the component

in the component bin, and disposes of the tape down a waste tape exit chute while

simultaneously forming the component at the first die station.

5. Initiates next cycle.

NOTE

Depending on the components being processed and the desired component lead form, die

Station 2 may be used t o both cut and form, just cut, or be excluded in order to leave

components on tape.

4 GPD Global 09/30/92

3

CF-9 User's Guide

Machine Part Identification

The CF-9's principal machine and die elements are identified and illustrated in this section.

Information for elements not defined elsewhere is also included here.

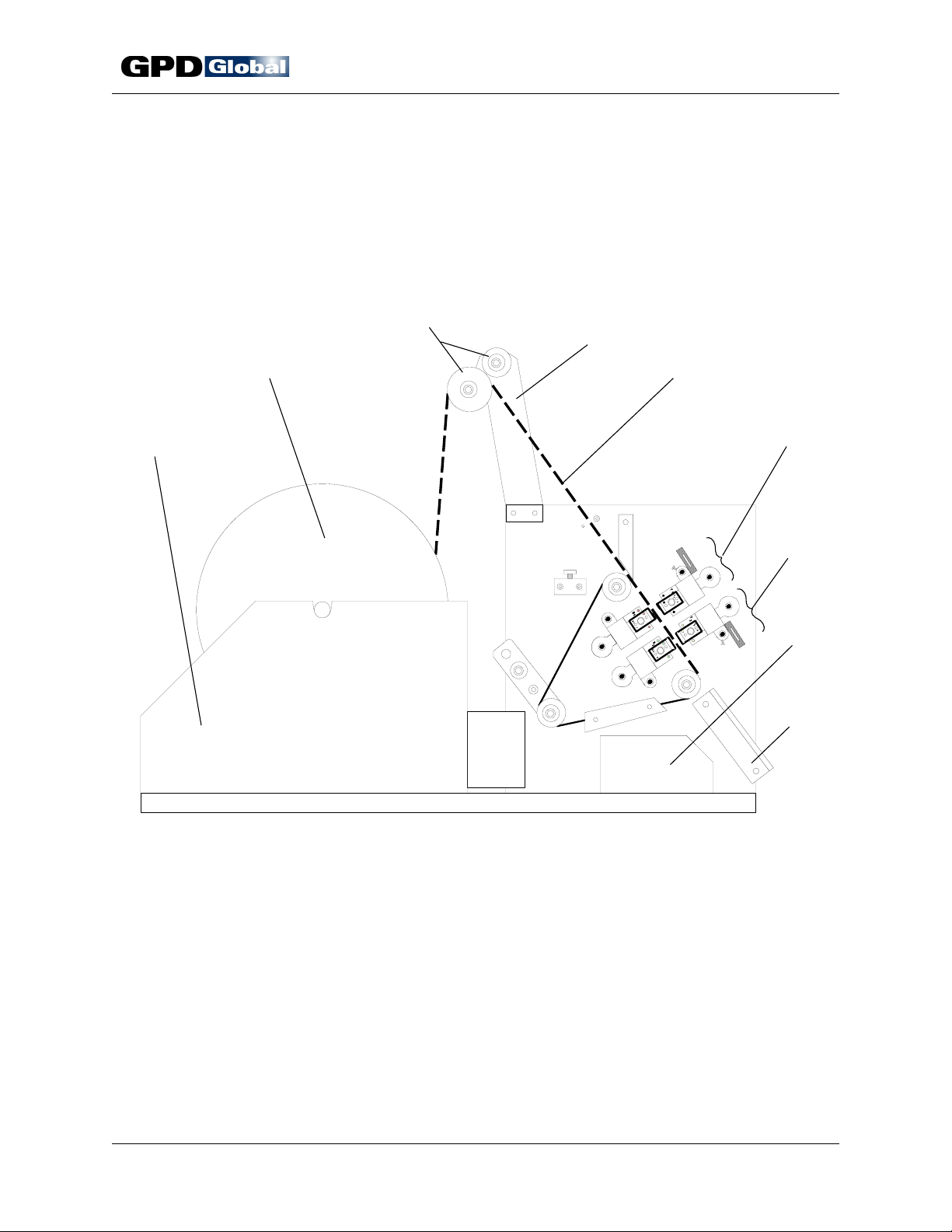

Principal Parts

4

1

2

5

6

7

8

9

Figure 1 Principal Parts

Item 1 Reel Holder Item 6 Die Block Assembly, St ation 1

Item 2 Component Reel / Ammo Pack Item 7 Die Block Assembly, St ation 2

Item 3 Tape Roller Guide Item 8 Component Bin

Item 4 Tape Guide Arm Item 9 Tape Exit Chute

Item 5 Taped Components

Die Stations

Station 1 is adjustable and normal ly used as a forming station. Station 2, also adjustable,

is normally used as a cutting station. More complicated forms may require Station 2 to

complete the forming function pr ior to cutting the component fr om the tape, or special

flattening blocks can be inserted if additional dimple alignment is required.

09/30/92 GPD Global 5

3

CF-9 User's Guide

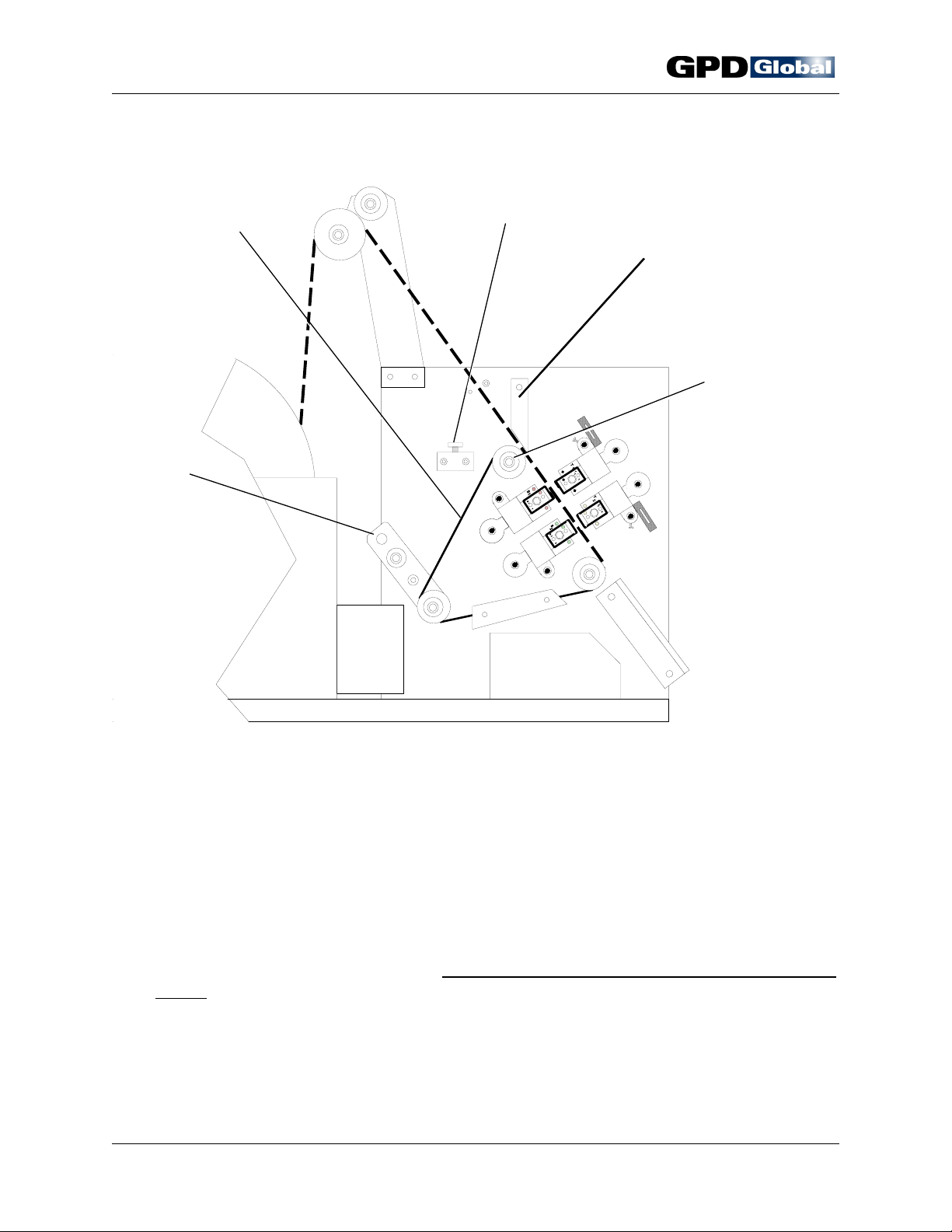

Adjustment Parts

2

1

4

5

Figure 2 Adjustment Parts

Item 1 Belt Tension Release Bar Item 4 Component Tape Pressure Plate

Item 2 Transfer Belt Lever

Item 3 Safety Shield Lock Item 5 Drive Pulley

Hand Crank

Not shown. The hand crank port is locat ed in the lower left corner of machine's back

panel. By inserting the supplied Allen Key in this port, the operator can slowly operate the

CF-9 manually, moving all mechanisms during setup, adjustment, testing, or

troubleshooting to assure proper die and component positioning. The hand crank can be

used to move mechanisms in reverse onl y during setup and only when no components are

loaded.

Safety Shield

Not shown. The safety shi eld must be in place during machine operations. Machine

operations cease whenever the shield is opened.

(adjusts Transfer Belt timing)

6 GPD Global 09/30/92

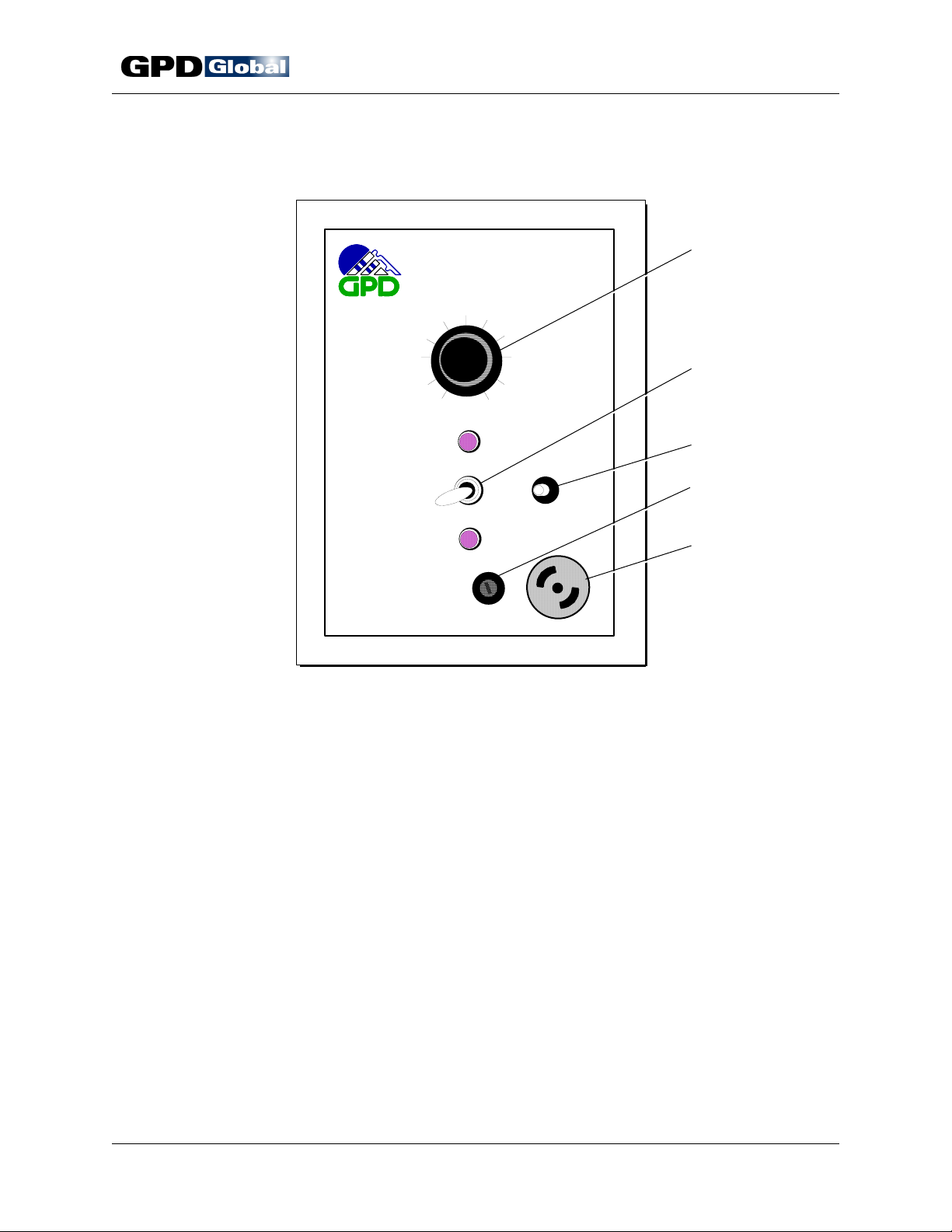

Control Panel

CF-9 User's Guide

1

5

4

3

6

7

10

RUN

STOP

AUX.

8

9

RESET

CF9

Component

Former

2

1

0

Figure 3 Control Panel

Item 1 Speed Control Item 4 Fuse

Item 2 Power Switch

(RUN, STOP, AUX)

Item 5 Accessory Outlet

Item 3 Reset Button

2

3

4

5

Speed Control

The speed control regulates both the variable speed motor and power supply and enables

the machine to operate in a range fr om 0 to 25,000 cycles per hour . The operator has full

freedom to select whatev er speed is appropriate to the work being performed.

Reset Button

As a safety feature, power is not automatically restored by closing the safety shield. To

restore power, it is necessary to cl ose the shield and then push the reset butt on. Normal

operation can then be resumed.

09/30/92 GPD Global 7

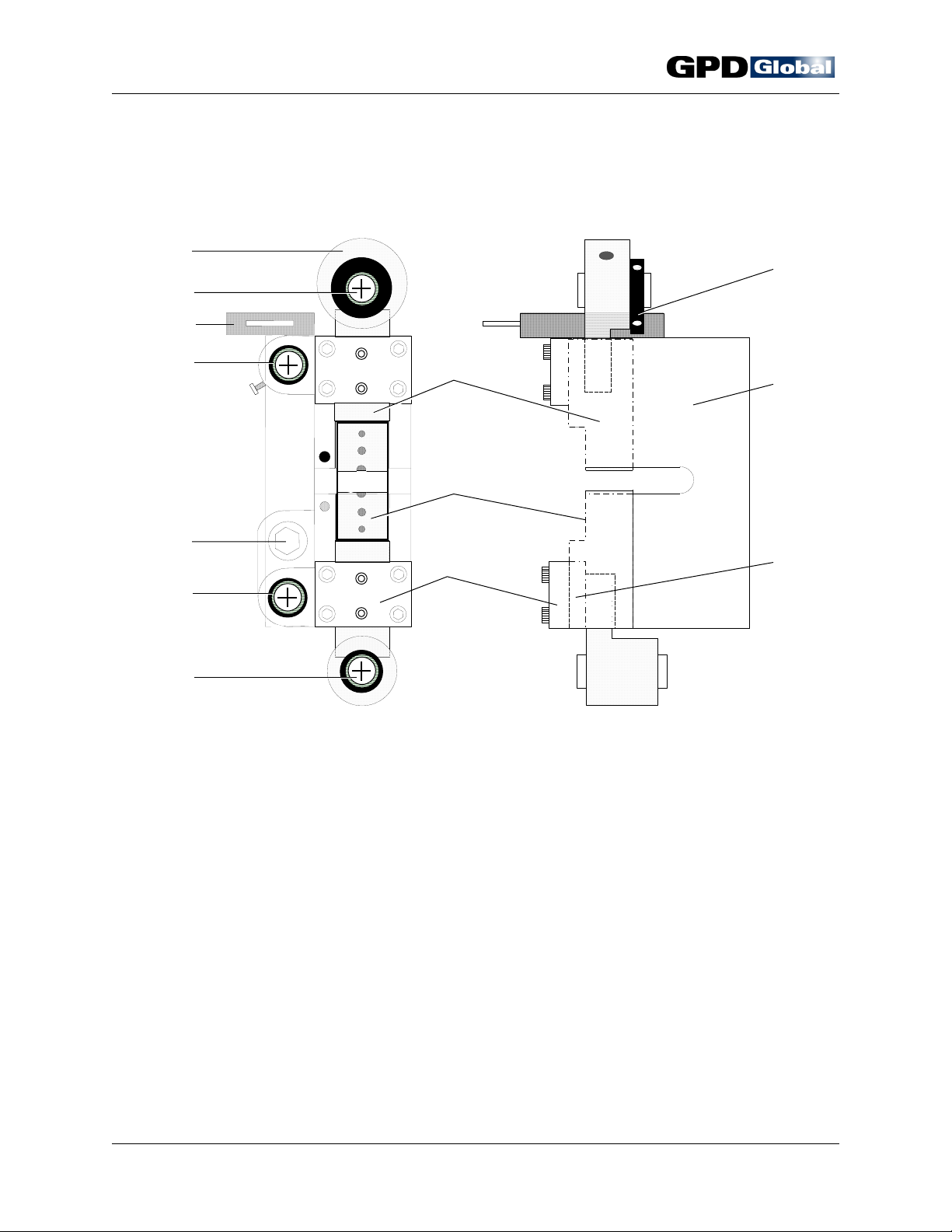

CF-9 User's Guide

Die Block Assembly

1

2

3

4

5

4

2

9

6

T

1

10

7

B

1

8

11

Figure 4 Die Block Assembly, Station 1

Item 1 Eccentric Crank Item 7 Die Mounting Area

Item 2 Crank Shaft Item 8 Cover Plate

Item 3 Micrometer Scale Indicator Item 9 Crank Adjuster

Item 4 Die Station Guide Shaft Item 10 Die Block

Item 5 Die Block Adjusting Bolt Item 11 Wear Plate

Item 6 Die Block Slide

Micrometer Scale Indicator

The micrometer scale indicator mount ed on each die station makes the lead cut length

adjustment operation quick, easy, and highly accurate to .0005" (0.0127 mm).

8 GPD Global 09/30/92

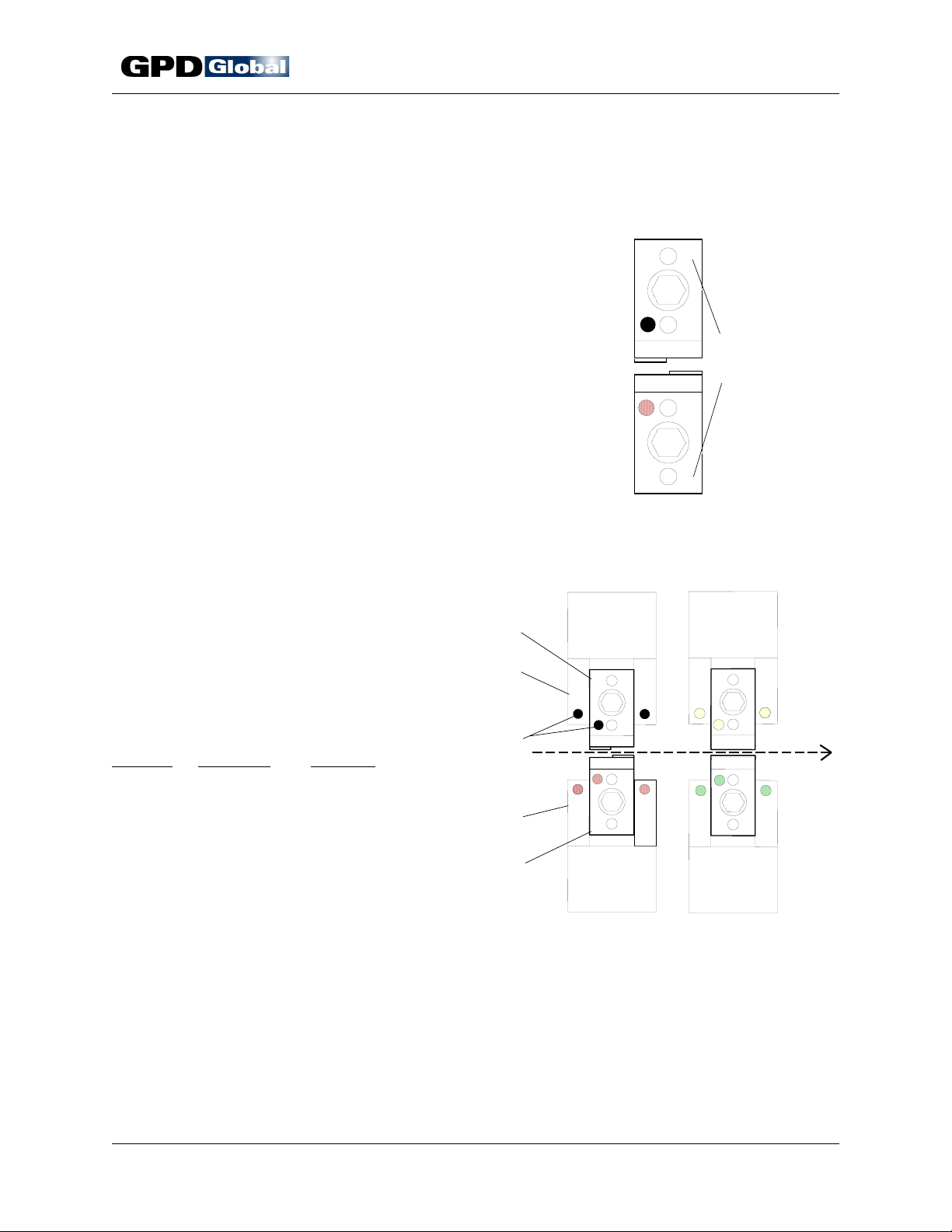

Die Markings

Dies and knives are paired and stamp mar ked with the following

symbols so each can be readily identified and installed in the

correct station posit ion:

• Forming Style Series Number

• Installation Marking

• Installation Color Dot

Forming Style Series

The forming style ser ies is stamped on its right hand side of

each die and knife (Figure 5). Refer t o the Die Information

appendix for specifics.

Installation Marking

Installation Color Dot

Characters are stamped on the left hand side of

each die half (Figure 6, Item 1) to indicate proper

die position in the formi ng and cutting stations.

Corresponding markings are stamped on each

station's stationary plate (Item 2). A color dot

(Item 3) associated with installation location is

also stamped on each die half and stationary

plate.

Marking

Color Dot Location

T1 Black Top die, Station 1

B1 Red Bottom die, Station 1

T2 Yellow Top die, Station 2

B2 Gr een Bottom die, Station 2

1

2

T

1

3

B

2

1

1

CF-9 User's Guide

T

2

1

Forming

Style Series

B 1

2

Figure 5

T

1

B 1 2 B 2 5

Die Forming Style Series

2

T

2

T

2

B

2

5

Tape

Figure 6 Die & Station Markings

09/30/92 GPD Global 9

CF-9 User's Guide

This page left blank (almost).

10 GPD Global 09/30/92

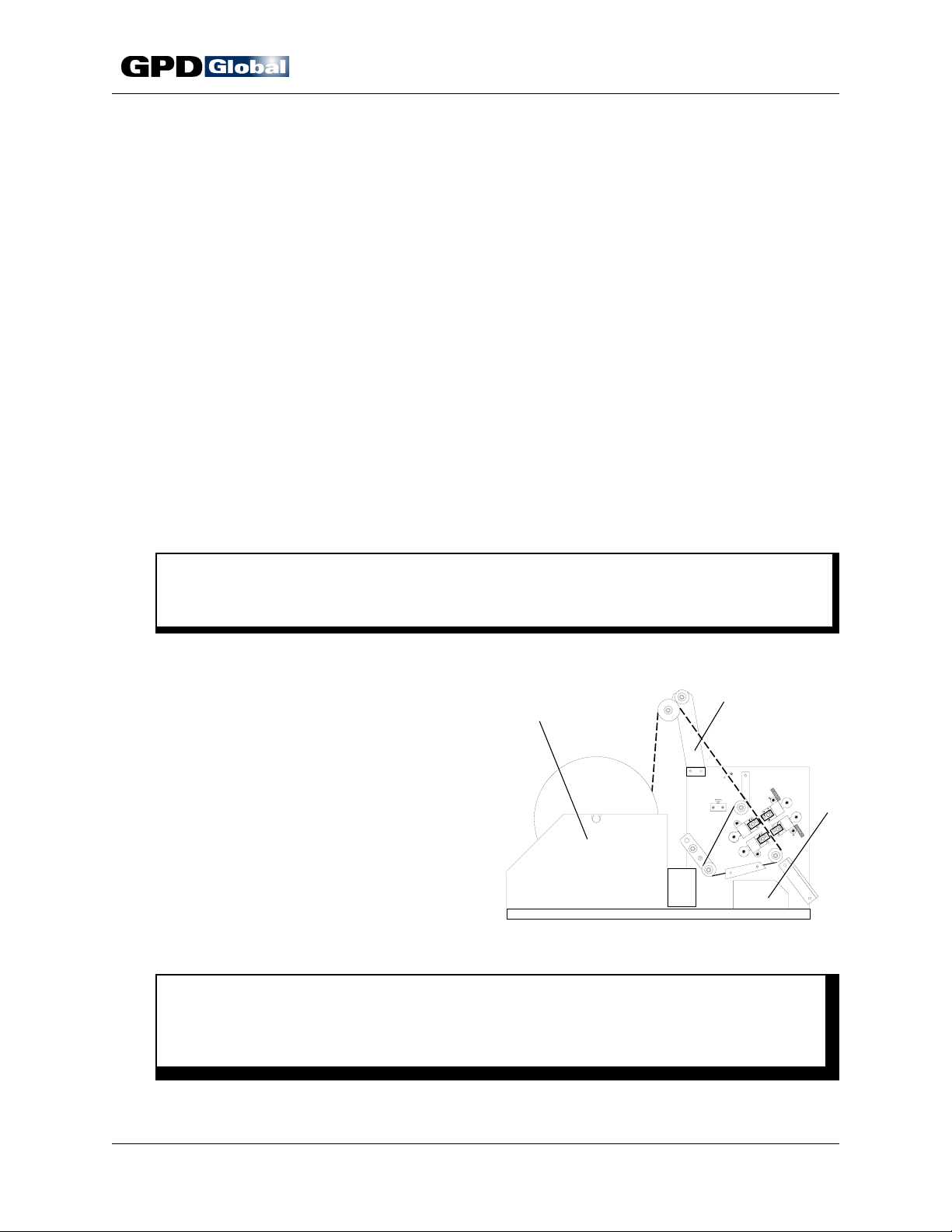

3

CF-9 User's Guide

Installation

1. Carefully unpack and check your CF-9 for possible shi pping damage. If any obvi ous

damage is observed, contact GPD's ser vice department prior t o operating the machine.

2. Standard equipment included with the CF-9:

1 Standard Die Set 1 Reel / Ammo Pack Holder

1 Standard Knife Set 1 Operating Manual

1 Anti-static Shield and Bin Package 1 Set of Wrenches

1 LCD Micrometer Adjustment Package

3. Position the CF-9 on a level, stable working surface. I f usi ng the optional Lazy Susan or

Work Station, install CF-9 on these at this time.

4. Assemble reel holder and tape guide arm. Refer to Figure 7, Items 1 & 2 for pr oper

placement on the machine. The screws (1/ 4-20x1/2") for securing t he reel holder and tape

guide arm are located in the appropriate holes in the CF-9's main frame.

C A U T I O N

Never pull, push or lift machine by reel holder or tape guide arm - this could bend

them out of alignment and seriously affect machine performance.

5. Assemble safety shiel d with hinges and 10-32x3/8" screws attached to shield.

2

6. Position component bin (Item 3).

7. Install any accessory equipment to be used

during processing. Refer to CF-9

Accessories appendix.

8. Set speed control to zero (0) position.

9. Hook up electrical power per your local

electrical code and machine specifications.

Refer to Specifications.

1

Figure 7 CF-9 Installation

W A R N I N G

Make sure the power suppli ed is of proper voltage and is fused at t he proper

amperage. This information is recor ded in Specifications and on the serial number

plate located on the power cord side of the machine.

09/30/92 GPD Global 11

CF-9 User's Guide

This page left blank (almost).

12 GPD Global 09/30/92

CF-9 User's Guide

Operating Instructions

I M P O R T A N T

Read this manual before turning the power on. Failure to follow the instructions i n this

manual could result in damage to the machine and/or dies. Uneven forming of t he

component leads and/or machine failure could result.

Requirements

• The component reel tape must be sturdy enough to maintain adequate component pitch to

prevent improper component feeding. If tape integrity is acceptable, the component body

will be supported and stress will not be placed on leads during lead forming.

• Taped component leads must be straight to prevent misfeeding and unacceptable lead

forms. GPD's Component Detection System identifies bent components and stops

machine operations to prevent die breakage. Refer to the CF-9 Accessories appendix.

Suggestions

• Use quality component s on quality tape.

• Planning prior to lead for m ing operations is suggested as this enables users to quickly

produce the maximum number of components for a gi ven system configuration.

W A R N I N G

For operator and machine safety, keep fingers, clothing, and foreign objects away from the

machine's moving mechanisms whil e in operation. Failure to do so may result in bodily

injury or damage to the machine.

Setup

1. Turn power switch to OFF.

2. Plug machine into appropriate power supply. Refer to Specifications.

3. Select appropriate dies and knives. Refer to CF-9 Component Forming Die Catalog.

4. Install proper dies and knives according to the follow ing die installation instructions.

5. Use hand crank to check for proper die setup.

09/30/92 GPD Global 13

1

CF-9 User's Guide

Die Installation

To properly position dies in Stations 1 and 2 and insure efficient machine use, follow

the die installation steps below. Be sure to test all adjustments with the manual hand

crank to verify that component body will not be damaged by forming dies or knives

and that the component is centered between the die station tooli ng.

1. Select dies. Refer to CF-9 Component Forming Die Catalog.

2. Clean dies and die slide locating sur faces per Preventive Maintenance "Daily"

instructions.

3. Install dies:

a. Refer to Die Markings (page 9) for proper locations.

b. Carefully place each die on proper die mounting surface (Figur e 8, Item

1) and bolt in place with a 5/8" (15.75 mm) screw. Then manuall y turn

machine's hand crank (page 6) until die block slides (Item 2) are in their

fully closed position.

T

1

B

1

1

2

2

3

Figure 8 Die Mounting Surface & Die Block

Slide

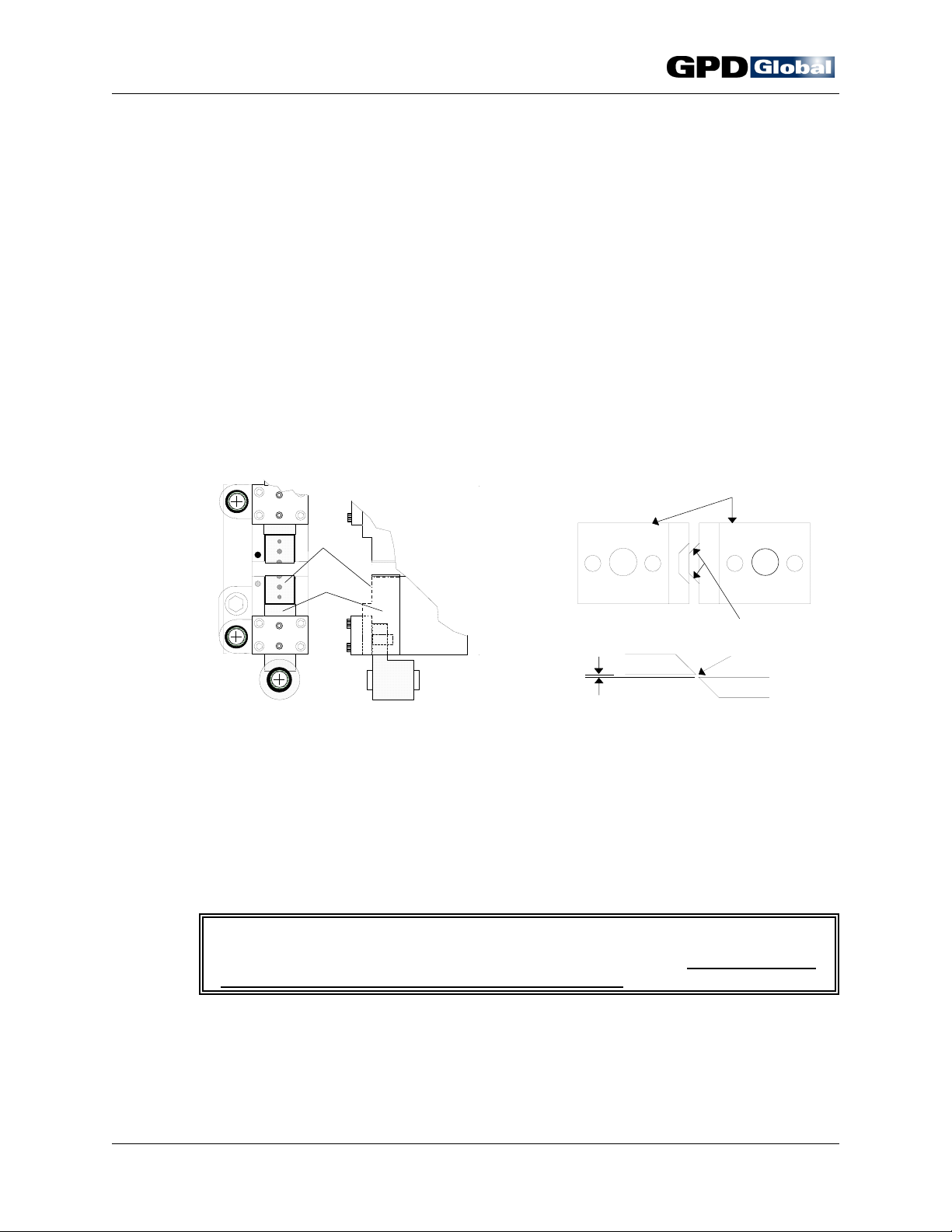

Figure 9 Die Alignment & Knife Clearance

c. Visually inspect alignment of die forming area to insure equal spacing on

both sides (Figure 9, Item 2).

d. Properly align die edges (Item 1) in relation to each other, centering each

die and knife in its station.

e. Adjust air gap clearance between dies (Item 3) to an even distance.

4. Check die alignment with hand cr ank prior to powering on machine.

I M P O R T A N T

The hand crank can be used to move mechanisms in reverse only during setup

and only when no components are loaded in machine.

5. Adjust die stations as necessary to obtain desired form and cut by aligni ng

components with dies and adjusti ng each station's height per the fol lowing

Station Adjustment and Component Alignment instructions.

14 GPD Global 09/30/92

CF-9 User's Guide

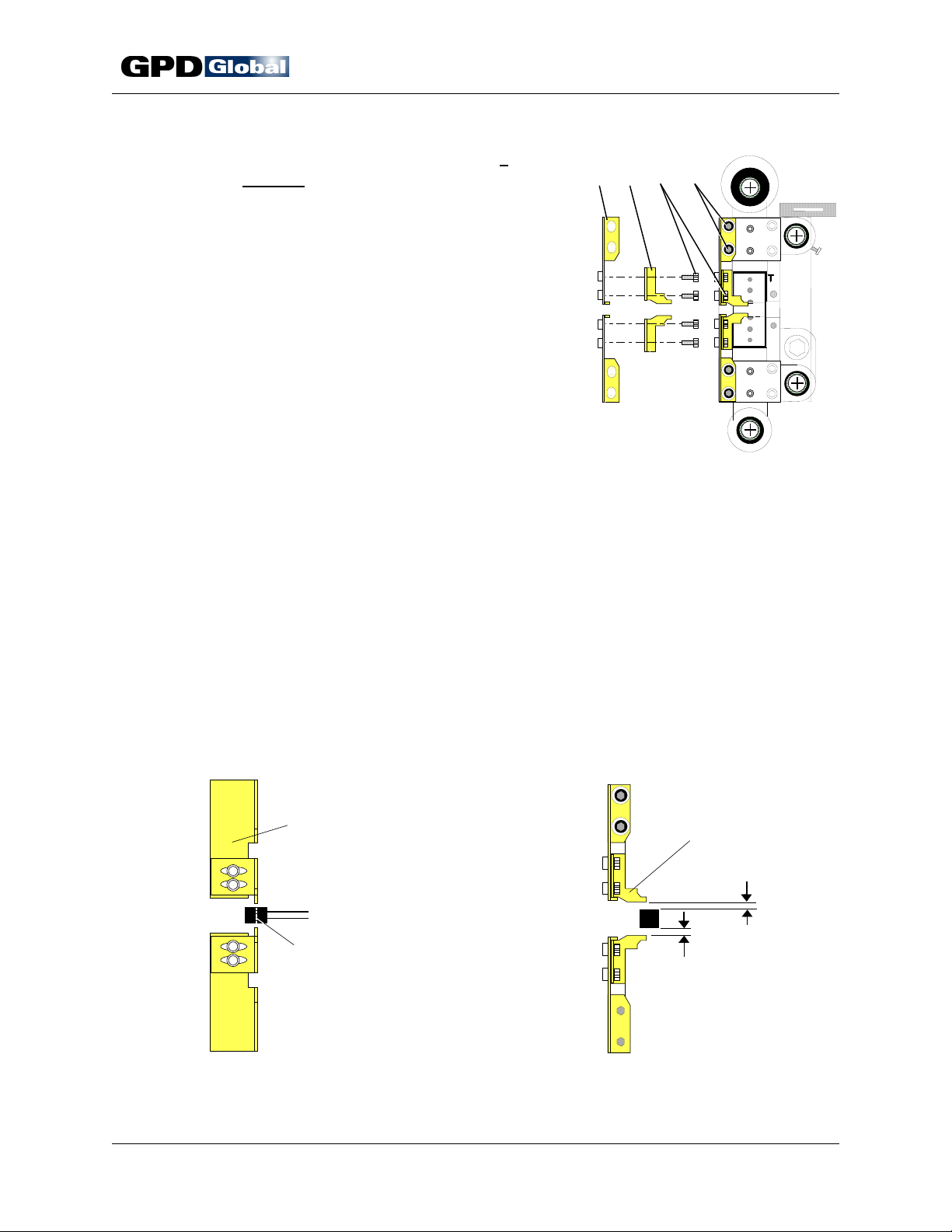

6. Install and adjust ejector brackets if

required. Required usage is indi cated for

123 4

each die, when appropriate, in the CF-9

Component Forming Die Cat al og. Certain

complicated lead forms require ejector

bracket installation to insure that

component does not remain in die. If

ejector bracket installation and adjustment

is not required, skip to Station Adjustment

on page 16.

Suggestion: Remove the small ejector

brackets when not required to simplify die

installation.

Two sets of ejector brackets are factory

Figure 10 Ejector Brackets

mounted on die Station 2 (Figure 10).

Each large ejector bracket (Item 1)

mounts to the Station 2 die block assembly with two screws (Item 4). Each

small ejector bracket (Item 2) mounts to the large ejector bracket with two

screws (Item 3).

2

B

2

Adjust for Component Body Thickness: Adjust for Component Body Height:

a. Loosen screws (Figure 10, Item 4). a. Loosen screws (Figure 10, Item 3).

b. Adjust each large ejector bracket b. Align center line of component body

(Item 1) to obtain an air gap of between small ejector brackets as

approximately 1/32" (0.794 mm) as illustrated in Figure 12.

illustrated in Figure 11. c. Tighten screws.

c. Tighten screws.

Large Ejector

Bracket

Small Ejector

Bracket

1/32"

1/32"

Component

Body Center

Line

Figure 11 Adjust Large Ejector Bracket

Figure 12 Adjust Small Ejector Bracket

09/30/92 GPD Global 15

2

CF-9 User's Guide

Station Adjustment

The CF-9's die stations are independentl y

adjustable to control for ming and cutting

locations. The action performed on component

leads by each die stat ion can be relocated from

a zero (0) position. GPD suggests setting the

zero (0) refer ence point at the machine's upright

plate (Figure 13, Item 1). This position also

corresponds with the lead wire point of

attachment to the tape. Refer to Taping

Specifications on page 30.

Backlash is eliminated during station adjustment

by three (3) beveled washers located on each

station adjusting bolt.

The standard micrometer scale (Item 2) attached to each station, indicates the

distance from the component's point of attachment on the tape to the point of station

action on the component lead. These scales are accurat e to .0005" (0.0127 mm).

1

Figure 13 Station Position Adjustment

Cut Lead Length

Station Position Station Action Location

Longest Fully ret racted Zero (0) position - the point at which

component attaches to tape.

Shortest Fully ext ended The point as near as possible to the

component body. Each extension

movement of station positi on creates a

correspondingly shorter lead length.

To adjust station position:

1. Position die block against

machine upright plate.

2. Turn on micrometer scale and

reset to zero (0).

3. Adjust die station using

supplied 1/4" T-handle wrench

Station 1

Adjusting Bolt

T

12

B

1

T

B

2

Station 2

Adjusting Bolt

in station die block adjusting

bolt (Figure 14).

a. To extend station, turn

wrench counterclockwise.

Figure 14

b. To retract station, turn wrench clockwise

Die Block Assembly Adjusting Bolts

.

16 GPD Global 09/30/92

CF-9 User's Guide

4. Record your micr ometer setting. Then machine can be setup quickly the next

time you process t he same component type.

5. Repeat Station Adjustment procedure for remaining die station.

Component Alignment

The CF-9 indexes exactly 1/2" (12.70 mm) every time,

however, component position relative to the t ape hole

may vary from your last run due to variances between

vendors or lots because:

• Distance from tape hole to component lead wire

may vary (Figure 15, Item 1) .

• Tape hole may be located betw een or under

component (Items 2 & 3).

A variance requires readjusting component alignment

with die stations — a simple matter of repositioning a

pulley (Figure 16, Item 4).

1

2

C A U T I O N

Testing component position relati ve to dies

MUST be done prior to automatic machine

operations.

To align components with die stations:

1. Manually index machine with hand crank just until components are centered

between dies and just before die touches component wires. Turn hand crank

slowly while visually inspecting for the relative position between components

and tape holes.

Figure 15 Component

Position Relative to Tape Hole

C A U T I O N

Dies should just start coming together - they should NOT be closed or

touching component.

C A U T I O N

DO NOT rotate mechanisms in reverse to check timing.

2. Loosen bolt in drive pulley (Figure 16, I tem 4) with supplied 3/16" wrench.

3. Manually turn pulley in either direction to cent rally position a component

between each die station.

4. Lock pulley in its new position by re-tightening the bol t.

5. Repeat step 1 to recheck tape alignment.

3

09/30/92 GPD Global 17

4

CF-9 User's Guide

Load Components

1. Press down on component tape pressure plate lever

(Figure 16, Item 3) to lift plate and open component

tape pathway.

2. Place tape's first hole ov er a pin on the transfer belt

(Item 1).

3. Release component tape pressure plate lever.

4. Using hand crank, manually index first component to

center of die Station 1.

5. Test all adjustments wit h the manual hand crank to

verify that component body will not be damaged by

forming dies or knives and that the component is

centered between the die station tooling.

1

Figure 16

Components

C A U T I O N

If machine is not properly adjusted, damage to components and dies may result.

6. If further adjustments ar e necessary, repeat Setup procedure on page 13.

2

Align & Load

3

Power On

1. Close and lock safety shi eld in place with safety shield lock (Figure 16, Item 2).

W A R N I N G

For operator's safety, do not operate machine w ithout safety shi e ld in place and

do not defeat the safety switch.

2. Set speed control to ze ro (0). If using optional accessories, such as the footswitch or

electronic component counter, set power switch to AUX position. The auxiliary mode

indicator will light if the CF-9 is plugged in.

3. Press reset button.

NOTE

As a safety feature, power is not automatically restored when safety shield i s

closed. Normal operations r esume when reset button is pushed.

4. Turn power switch to ON.

18 GPD Global 09/30/92

CF-9 User's Guide

Process Components

1. Position component reel or ammo pack of taped components in reel holder.

2. Load components. Refer to Load Components on page 18.

3. Close safety shiel d and press reset button.

4. Run machine very slowly to verify proper adjustment. Make furt her adjustments if

necessary to achieve desired results.

C A U T I O N

Testing component position relati ve to dies MUST be done prior to aut omatic

machine operations.

5. Increase machine speed rate to desir ed setting and process components.

6. To process a different component form or type, repeat Setup procedure on page 13.

Power Off

1. Set speed control to zero (0).

2. Turn power switch to OFF.

3. Remove all dies and clean wit h a rust inhibitor and lubricate mechanical moving

parts per Preventive Mai ntenance.

09/30/92 GPD Global 19

CF-9 User's Guide

This page left blank (almost).

20 GPD Global 09/30/92

1

CF-9 User's Guide

Preventive Maintenance

The preventive maintenance steps i n this section are intended prim arily for t he machine

operator, however , only qualified service or maintenance personnel should perform the steps

requiring access to the machine' s cabinet interior. The CF-9 is constructed so that pulleys,

belts, and bearings should not need to be replaced for many years, provided t he machine is

used according to instructions.

3

1

T

2

1

B

1

T

2

B

2

4

T

1

B

1

1

3

Figure 17 Die Block Assembly Lubrication Figure 18 Die Block Assembly Maintenance

Preventive Maintenance Schedule

Interval Location Action

Daily Dies/Knives Remove all dies/knives, inspect for wear, and clean

(8 hours of with rust inhibitor.

operation)

Die Block Assembly Inspect and lubricate eccentric shafts and bushings

Inspect for foreign matter or dust build-up. Brush

clean.

(Figure 17, Item 1) and die block guide shafts (Item 2)

with a light machine oil (3-in-1).

2

Place a drop of light machine oil (3-in-1) on slide

surfaces (Figure 17, Item 3) and in lubrication hole

(Item 4).

Apply oil to each of the four crank pins (Figure 18, Item

2).

Drive Belt Inspect belt pins and cogs for wear.

Schedule continues on followi ng page.

09/30/92 GPD Global 21

CF-9 User's Guide

Preventive Maintenance Schedule

(continued)

Interval Location Action

Monthly Die Block Assembly Clean die block adjusting bolt (Figure 18, Item 1) with

Inside Cabinet Inspect component drive belt for proper tension.

Yearly Safety Shield Apply a drop of light machine oil on each safety shield

solvent and apply a small amount of oil to its thread

near machine upright plate.

Spray molly grease on gears. Wipe off excess oil.

Lightly grease cam lobes and cam follower rollers.

Wipe off excess grease.

Check motor brushes and motor drive belt. Replace if

they appear worn or frayed.

CAUTION: DO NOT

drive belt without first loosening the motor mount

screws.

hinge. Wipe off excess oil.

attempt to remove or replace a

22 GPD Global 09/30/92

CF-9 User's Guide

Troubleshooting

The CF-9's hand crank is a useful troubleshooti ng feature enabling you t o manually move all

mechanisms. Simply insert the supplied Allen key in the hand crank port and turn. The hand

crank can be used to move mechanisms in reverse only during setup and only when no

components are loaded in machine.

Adjustment instructi ons for slide travel and sli de clearance follow the guide below.

Troubleshooting Guide

Problem Possible Cause Action

Dies, knives, and/or bushings Incorrect setup. Verify that proper tooling is being used. Refer

damaged or wearing to die catalog for correct die/knife and

prematurely. application combination.

Verify dies/knives are properly matc hed.

Verify that tooling is properly adjusted per

Setup.

Die/knife striking component. Inspect and set per Die Installation.

Ejector brackets not installed. Install ejector brackets per Die Installation

Foreign matter, dust build up. Inspect and clean per Preventive Maintenance.

Incorrect slide gap. Check gap with gauge block per Slide Travel.

Incorrect die alignment. Inspect and set per Die Installation.

Incorrect slide clearance. Inspect and set per Slide Clearance.

Incorrect size screw securing die. Secure die with correct size screw.

Machine performance Foreign matter, dust build up. Inspect and clean per Preventive Maintenance.

generally poor.

Component tape slipping off Belt studs missing or loose. Replace belt.

belt.

Inadequate lubrication. Oil per Preventive Maintenance.

Worn parts or dies. Inspect and replace as necessary.

Incorrect die alignment. Inspect and set per Die Installation.

Transfer belt timing. Set timing with drive pulley (page 6, I tem 5).

Incorrect size screw securing die. Secure die with correct size screw.

Transfer belt tension slack. Reset belt tension.

Misaligned reel holder. Realign or replace reel holder.

Missing pins on tape guide arm. Replace pins or tape guide arm.

Incorrect size screw securing die. Secure die with correct size screw.

instructions.

Guide continues on following page.

09/30/92 GPD Global 23

CF-9 User's Guide

Troubleshooting Guide

(continued)

Problem Possible Cause Action

Machine cutting improperly. Slide clearance too large. Reset slide t r avel per Slide Clearance.

Incorrect slide gap. Set gap per Slide Travel.

Worn eccentric shaft bushing. Replace bushing.

Worn dies. Replace or repair dies.

Incorrect size screw securing die. Secure die with correct size screw.

No machine movement. Broken drive belt. Replace drive belt.

Blown fuse. Replace fuse.

NOTE: As a preventive measure, turn speed

control to zero (0) before turning machine on.

Power not restored after closing safety Press reset button.

shield.

Machine not plugged in. Plug machine in per Specifications.

Machine not turned on. Turn machine on per Operating Instructions.

Speed control set to zero (0). Set speed control to appropriate operating

Drive pulley set screws loose. Tighten set screws.

Incorrect size screw securing die. Secure die with correct size screw.

speed.

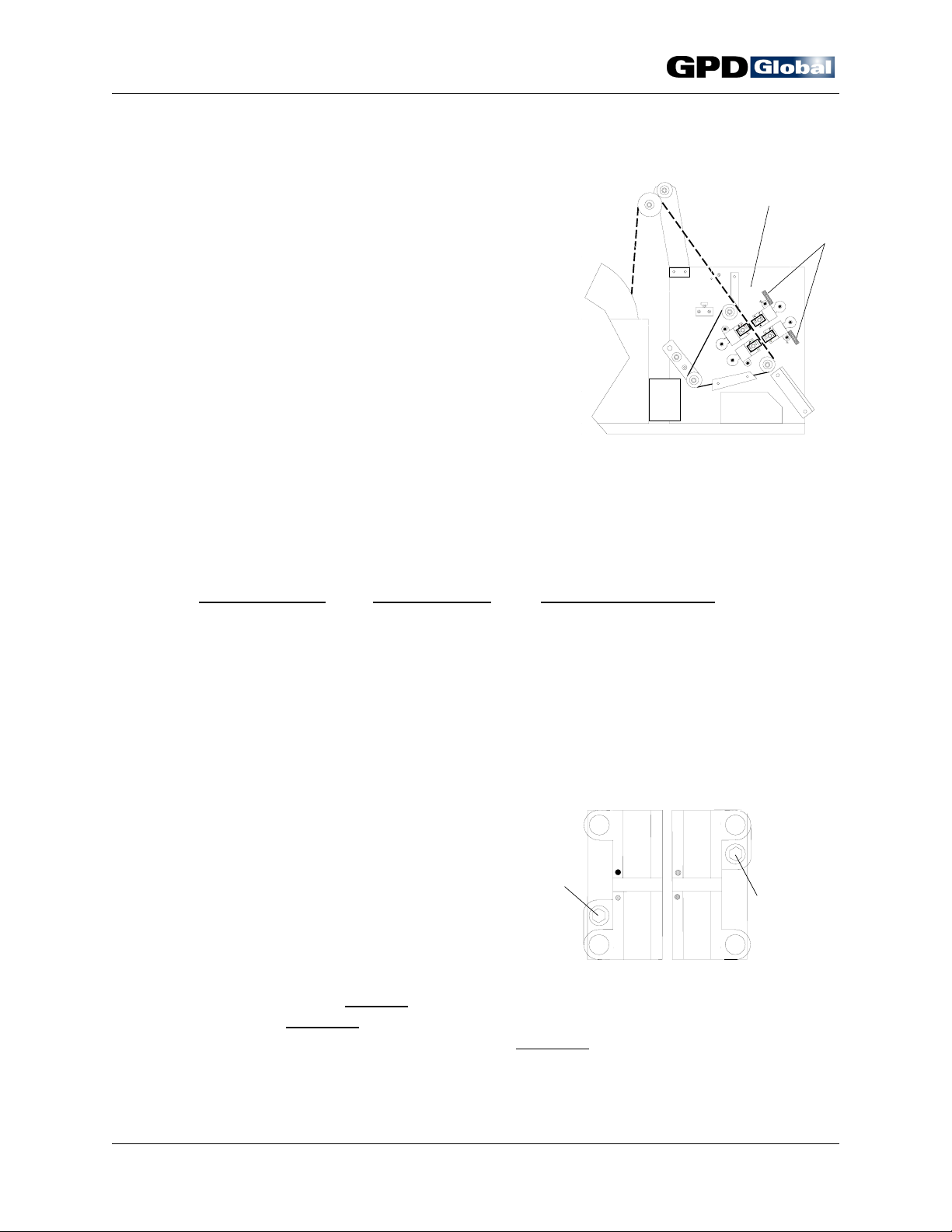

Slide Travel

To adjust slide travel:

1. Unplug machine.

2. Insert provided 1.934" gauge block (Figure

19, Item 1) while manuall y turning

machine's hand crank until die block slides

(Item 5) are fully closed.

3. Check for gauge block movement. If

movement does not

Clearance. If movement does

occur, proceed to Slide

occur, adjust

the crank adjuster (Item 3):

a. Loosen crank set screws (Item 2).

b. Use wrench in crank adjustor holes

(Item 4) to rotate crank adjuster until

gauge block no longer moves.

c. Tighten eccentric crank screws.

d. Replace bushings if movement cannot be elimi nated through adjustment.

1

Figure 19

T

1

1.934"

B

1

Die Block Assembly Slide Travel

2

3

4

5

24 GPD Global 09/30/92

6

7

CF-9 User's Guide

Slide Clearance

To adjust slide clearance:

1

1. Remove die block assembly. Station 1 die

block assembly is illustrated in Figure 20.

2

a. Remove from the CF-9:

• Tape exit chute

• Component transfer belt

3

• Transfer belt guide and

component tape pressure plate

(located on either side of

4

transfer belt)

b. Raise die block approximately 1"

(25.40 mm) from machine upright

Figure 20 Die Block Assembly Slide Clearance

plate using machine's die block

adjusting bolt (Figure 20, Item 3).

c. Remove mounting screws from micrometer scale's lower mounting block.

d. Turn die block adjusting bolt until die block no longer moves and then slide die block

straight off machine.

T

1

B

1

5

9

8

2. Clean parts.

a. Remove and discard set screws in cover plate (Figure 20, I tem 6).

b. Remove slide (Item 9) from die block.

c. Use a degreaser (brake cleaner) to remove all oil fr om slide, die block, and wear

plate (Items 9, 8, and 7).

C A U T I O N

Do not expose micrometer scales t o degreaser (brake cleaner) as it clouds the

clear face plate.

d. Measure all surfaces for wear and inspect for scratches and gouges. Replace parts

if raised material is visible on working plane.

e. Lightly st one all surfaces.

f. Blow dry all parts.

3. Reassemble die block.

a. Install slides in die block.

NOTE

Position slide with the eccentric bushing in the eccentric crank (Item 1) in die

block's top half (T1 or T2).

b. Slip wear plate face up between cover plate and slide.

c. Align wear plate counter sunk holes with cover plate set screws.

d. Install new set screws and lightly tighten.

e. With slides in closed position, locate a dial indicator on die mounting surfaces (Item

09/30/92 GPD Global 25

CF-9 User's Guide

8) and compare heights. For mated dies to function together properl y, replace dies

and/or slide blocks if heights ar e not within .0005" (0.0127 mm) of each other.

4. Set clearance.

a. Loosen cover plate's inner set screw (Figure 20, Item 4) approximately a quarter turn.

b. Slowly loosen outer set screw (Item 5) just until slide moves freely.

c. Tighten inner set screw unt il a slight drag is felt.

d. Install die screw in slide to prevent sli de from slipping out of die block.

e. Position slide flush wi th back side of die block.

f. Locate a dial indicator on the slide's die mounting surface and set the clearance to

.0007 - .001" (.0178 - .0254 mm) by pulling up on die screw. After clearance is set,

verify that slide moves freely.

NOTE

If slide does not move freely, loosen outer set screw slightly. Recheck clearance.

g. Secure screws by applying modest amount of penet rating thread locker (Loct ite

#290).

h. Repeat step 4. for remaining slides.

5. Lubricate parts.

a. Generously apply 5 weight oil (3-in-1)

1

to all sides of slide and crank pin

(Figure 21, Item 3), working in

thoroughly.

C A U T I O N

D

O NOT USE A PENETRATING OIL

(WD-40)

BLOCK SEIZURE

AS THIS WILL CAUSE DIE

.

2

T

1

B

1

1

b. Sparingly apply oil to eccentr ic crank

shafts (Item 1) and die block guide

shafts (Item 2).

6. Reinstall die block assembly.

a. Slide die block assembly straight onto machine until die block adjusting bolt reaches

hole.

b. Thread die block adjusting bolt into hole.

c. Replace mounting screws for digital scale's lower mounting block.

Figure 21 Die Block Assembly Lubrication

3

26 GPD Global 09/30/92

CF-9 User's Guide

d. Position die block assembly approximately 1" (25.40 mm) from machine upright plate

using die block adjusting bolt.

e. Lay machine on its back cov e r with die blocks up and cabinet's back air vent clear.

Run machine in this position for appr oximately one (1) hour to allow oil to distribute

evenly. Dur ing this time period, slowly increase machine speed and check cover

plate and die block for heat.

C A U T I O N

I

F EXCESSIVE HEAT IS DETECTED OR A SQUEAK IS HEARD, STOP THE MACHINE. REPEAT

COMPLETE SLIDE CLEARANCE PROCEDURE

f. Reassemble the following:

• Digital scale lower mounting block screws

• Belt guide and pressure plate

• Component transfer belt (Adj ust so belt is taut.)

• Tape exit chute

• Die screws

g. Reset slide travel adjustment - refer to Slide Travel on page 24.

.

09/30/92 GPD Global 27

CF-9 User's Guide

This page left blank (almost).

28 GPD Global 09/30/92

L

L

2

Specifications

Power Requirements

120 Volt Model 230 Volt Model

120 Volts

Neutral

Safety (Eart h) Ground

5 Amps

60 Hz Safety (Eart h) Ground

1

230 Volts

2.5 Amps

50/60 Hz

CF-9 User's Guide

Dimensions

Height........

Length .......

Width ........

Standard CF-9

12.00 inches

(304.80 mm)

13.25 inches

(336.55 mm)

13.50 inches

(342.90 mm)

CF-9 with

Reel Holder

18.62 inches 29.50 inches

(472.95 mm) (749.30 mm)

13.25 inches 26.00 inches

(336.55 mm) (660.40 mm)

28.00 inches 39.00 inches

(711.20 mm) (990.60 mm)

CF-9

Work Station

Weight

Standard CF-9 .............................................58 lbs. (26.31 kg)

Capacities

Production Rate

The CF-9 is capable of forming and cutting up to 25,000 components per hour.

Micrometer Scale

Display increments to .0005" (0.0127 mm)

±.002" Repeatability

09/30/92 GPD Global 29

CF-9 User's Guide

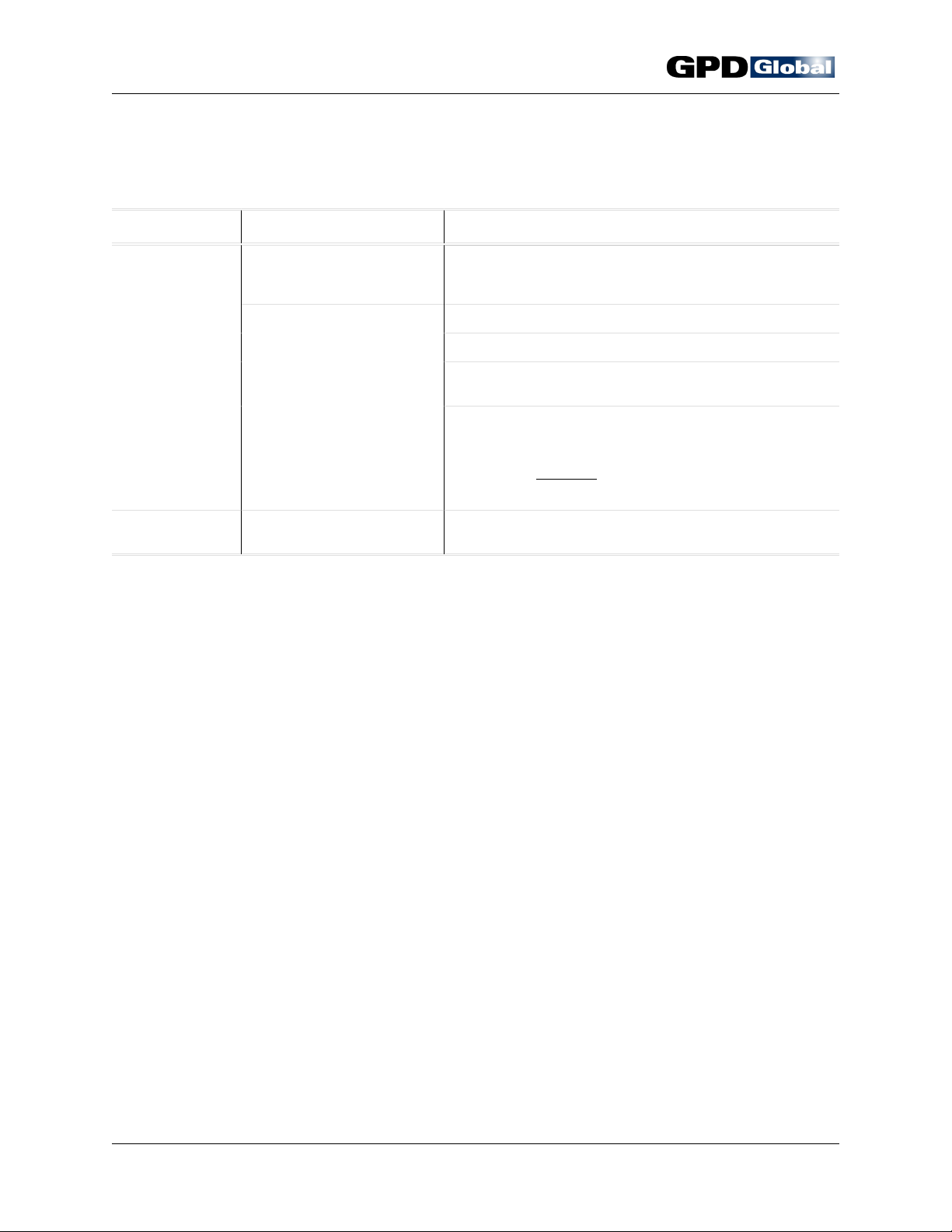

Taping Specifications

The CF-9 will process components if taped to the E.I.A. standards listed below for taping of

radial components AND

cases, standard tooling may work with l ess than this minimum operating clear ance.

Custom tooling or custom taping may be required in cer tain instances.

there is a minimum of .300" (7. 62 mm) operating clearance. In some

Y

X

C

A

Figure 22 GPD's CF-9 Taping Specifications

B

GPD CF-9

Taping Specification Li mits

Symbol Definition Inch MM

X Height to seating plane (formed leads) .300 ± .010 7.62 ± 0.25

Y Operating Clearance - All dies except style 8A .300 minimum 7.62 minimum

Seating plane (straight leads)

8A style die .350 minimum 8.89 minimum

E.I.A.

Taping Specification Li mits

Symbol Definition Inch MM

A Component centering .250 ± .012 6.35 ± 0.30

B Sprocket hole pitch .500 ± .012 12.70 ± 0.30

C Carrier tape width .710 + .039 18.00 + 1.00

to to

—.020 —0.50

30 GPD Global 09/30/92

CF-9 User's Guide

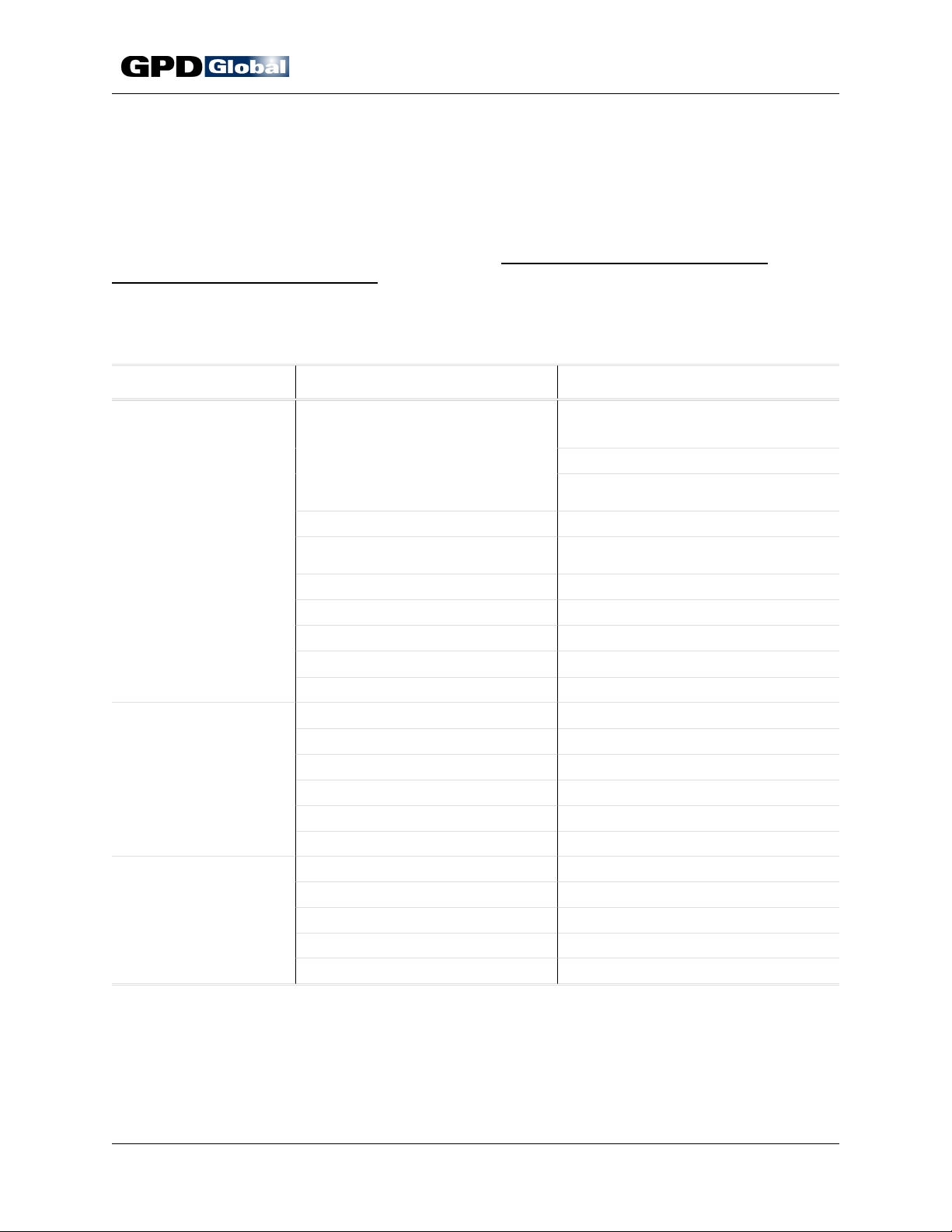

Suggested Spare Part Kits

The following suggested spare parts kits for the GPD CF-9 list the items included in each kit and

the GPD part number for each item.

GPD Part

Number Part Description Qty.

925-1-2 120V 60Hz Spare Parts Kit 1

(consists of the followi ng items)

BELTS

901-3-101 Transfer Belt 1

D0001 Motor Belt 1

INDEX WHEEL ASSEMBLY

806-1-3 Roller 16

G1007 Retaining Ring 16

FUSE

4300-0026 Fuse MDL 5A, Slow Blow 1

925-1-3 230V 50/60Hz Spare Parts Kit 1

(consists of the followi ng items)

BELTS

901-3-101 Transfer Belt 1

D0001 Motor Belt 1

INDEX WHEEL ASSEMBLY

806-1-3 Roller 16

G1007 Retaining Ring 16

FUSE

4300-0025 Fuse MDL 2.5A, Slow Blow 1

09/30/92 GPD Global 31

CF-9 User's Guide

Suggested Spare Parts

The following suggested spare parts listing is for those customers in locations where next day

delivery service from the USA in not avai lable.

GPD Part

Number Part Description Qty.

120V 60 Hz Spare Parts

G1003 Circlip 10

L0503 Bushing 2

L0601 Bushing 2

2200-0008 Speed Control, 120V, 60 Hz 1

821-4-12 Circlip Plier 1

901-1-102 Die Station #2 1

925-1-2 Spare Parts Kit, 120V 1

230V 50/60 Hz Spare Parts

G1003 Circlip 10

L0503 Bushing 2

L0601 Bushing 2

2200-0014 Speed Control, 230V, 50/60 Hz 1

821-4-12 Circlip Plier 1

901-1-102 Die Station #2 1

925-1-3 Spare Parts Kit, 230V 1

32 GPD Global 09/30/92

CF-9 User's Guide

Appendices

Table of Contents

Appendix A - Die Informati on ................................................... 35

Forming Style Series .................................................... 35

Die Number............................................................ 35

Appendix B - Common CF-9 Lead Forms ......................................... 37

Appendix C - CF-9 Accessories ................................................. 39

Lead Forming Dies ...................................................... 39

Component Detection System ............................................. 39

Electronic Component Counter ............................................ 39

Footswitch ............................................................. 40

Lazy Susan (Rotating Machine Platform)..................................... 40

Loose/Bulk Component Feeder ............................................ 41

Taped Component Re-Reeler ............................................. 41

Work Station ........................................................... 41

Appendix D - Electrical Schematic & Assembly Drawing ............................. 43

09/30/92 GPD Global 33

CF-9 User's Guide

This page left blank (almost).

34 GPD Global 09/30/92

9

D

F

905-4AF905-3JA

905-3H

CF-9 User's Guide

Appendix A - Die Information

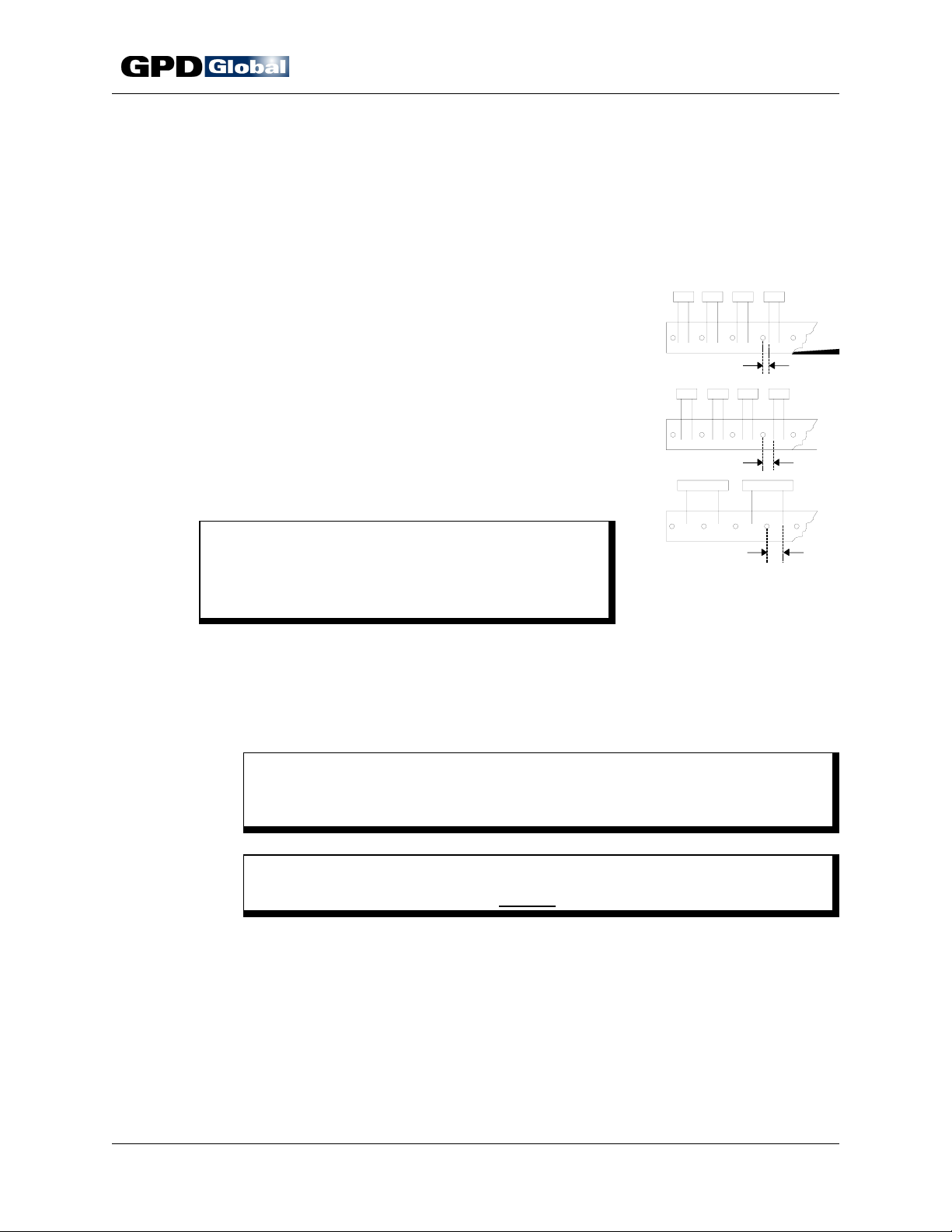

Forming Style Series

The forming style series is stamped on the right hand side of each die and knife (Figure 23):

T

2

1

Forming

Style Series

B 1

2

Figure 23

Forming Style Series

Die Number

Forming Style Series

Number

Description

1 Die, 3 Lead Radial (typically TO-92), In-Line

2 Die, 2 Lead Radial, Stand-Off, Opposing Dimple

2C Die, 2 Lead Radial, Lock-In Stand-Off, Opposing Dimple

3 Die, 2 Lead Radial, Lock-In Stand-Off

4A Die, 2 Lead Radial, Spreading

4B Die, 2 Lead Radial, Reducing

5Knife

7 * Die, 2 Lead Radial, 90° Bend

8A Die, 2 Lead Radial, Spreading, Lock- In Stand-Off

8B Die, 2 Lead Radial, Reducing, Lock-I n Stand-Off

10 Die, 2 Lead Radial, Stand-Off Lock-In

11 Die, 2 Lead Radial, Flush Mount Lock-In

* NOTE: GPD has an adjustable

90° bend 7-styl e die

available. Call GPD for details. (970) 245-0408

ie Type

05-3JA

Forming style

series

905-4A

T

3 4A

1

JA

T

1

F

T

3H

1

Wire to hole

specification

Forming

dimension

Figure 24 Examples of Die Numbers Figure 25 Examples of Die Number Location

B 1

JA

For further die specificati on details, refer to the CF-9 Component Forming Die Catal og.

B 1 3 4A

F

B 1 3H

09/30/92 GPD Global 35

CF-9 User's Guide

This page left blank (almost).

36 GPD Global 09/30/92

CF-9 User's Guide

Appendix B - Common CF-9 Lead Forms

Some examples of the most common component forms produced by the CF-9 are shown below.

Die Form Die Form

Form

Number Description Form Number Description

905-1 Middl e Lead Offset 905-4A Spread Form

with Lock-In Form

905-1A Middle Lead Offset 905-4B Reducing Form

Form

905-1CA In-Line Lock- In 905-7 90° Angle Bend

Stand-Off Form

905-1H4 Middle Lead Offset 905-8A Spread Form with

905-1H5 with 3 Lead Lock-In Lock-In Stand-Off

905-1L4 Form

905-2 Stand-Off with 905-8B Reducing Form

Opposing Dimple with Lock-I n StandForm Off

905-2C Lock-In Stand-Off 905-10 Low Profile Stand-

with Opposing Off Lock-In Form

Dimple Form

905-3 Lock-In Stand-Off 905-11 Flush Mount Lock-

Form In Form

09/30/92 GPD Global 37

CF-9 User's Guide

This page left blank (almost).

38 GPD Global 09/30/92

CF-9 User's Guide

Appendix C - CF-9 Accessories

The following optional accessories for GPD's CF-9 are specifically designed to help you increase

production and profit.

Lead Forming Dies

The CF-9 operates on a system of dies and die blocks. Each combination is designed to form a

specific lead configuration. Numerous standard and special CF-9 Lead Forming Die sets are

available to provi de a variety of component forms and lead configurations such as lock-ins,

standoffs, standoff lock-ins, spreading, reducing, and ninety-degree bends. Many different die

sets for various transi stor hole patterns are also av ailable. Dies are avail able to form two leaded

components with center-to-center dimensions up to .400" (10.16 mm) as well as 3-leaded TO-92

transistors. All CF-9 dies will also work on the GPD CF-10 Loose/Bulk Component Lead

Former.

Each die is clearly identified and color coded. This color codi ng, in combination with t he roll

pins, insures against installation mistakes. Changing dies i s a matter of one screw. Remove

the die you wish to change and replace it wit h a new die.

Standard dies are secured in place w ith 10-32x5/8" screw s - these accompany the CF-9

machine. When a special die requires a longer screw, it is supplied with the die.

Most cutting and formi ng needs are covered with the st andard dies we offer. However, if you

have unusual requirements, GPD will be pleased to design custom dies for you. Your GPD

representative will be happy to assist you with any custom die orders.

Component Detection System

The CF-9's Component Detection System option helps prevent die breakage by identifying bent

components on tape and stopping CF-9 operations prior to a misaligned component entering the

first die station.

Electronic Component Counter

The electronic counter is an automati c component counter that unerringly detects even the

smallest component on the CF-9. I nstallation is simple and fast so t hat one counter can easily

be moved from one CF-9 to another as counti ng requirements change.

The counter has two operation modes, pr e-determining and totalizing. You can preset the total

number of components you wish to run, and the counter's predetermining mode automatically

shuts off the machine when the preset count is reached. The counter's totalizing mode gives

you a cumulativ e count of all the components the machine has processed.

09/30/92 GPD Global 39

CF-9 User's Guide

Counter Installation:

1. Remove cap screw (Figure 26, Item 2).

2. Slide counter bracket onto dowel pin (Item 1).

Replace and tighten cap screw to secure counter

mounting.

3. Place counter on top of CF-9 cabinet.

4. Plug counter bracket wiring harness into counter's

back panel.

5. Plug counter power cord w ith twist lock plug i nto

accessory outlet on CF-9's control panel.

6. Plug counter's regular pow er cord into a power

source per Specifications.

Figure 26 Electronic Component Counter

Footswitch

The optional footswitch is a real operator convenience. After easily installing the footswitch, the

operator need only position the CF-9 power sw itch to the AUX position and depr ess the

footswitch to operate the machine.

Installation

1

2

Footswitch Installation:

1. Turn power switch to off.

2. Set speed control to zero (0).

3. Insert footswitch plug into accessory outlet on CF-9's control panel and turn clockwise

lock in place.

4. Set power switch to AUX position. The auxiliary mode indicator lights.

5. Set speed control to desired operating speed.

To remove footswitch, tu rn plug counterclockwise

.

to

Lazy Susan (Rotating Machine Platform)

This rotating, circular platform allows the operator to easily rotate the entire machine t o gain

better access for setup, die changes, and normal maintenance. The Lazy Susan has been

specifically const ructed to operate smoothly under the CF-9's wei ght. Covered in ridged, ant istatic material, this turntable holds the machine securely in any position with its unique graphite,

anti-drift system.

40 GPD Global 09/30/92

CF-9 User's Guide

Loose/Bulk Component Feeder

Process both taped and loose radial components on one machine by using the Loose/Bulk

Component Feeder. This accessory provides the perfect soluti on when you need to form a

relatively small number of components and they are not available or are too expensive on tape.

Load up to ten (10) components in a magazine, place magazine in st aging fixture, and then

lightly press each component down to the top of staging fixture. Remove the magazine and your

components are perfectly aligned, ready to feed directly into the CF-9 in exactly the same

manner as you would feed a strip of taped components. There are four magazine sizes based

on center-to-center requirements with a 1" (25.40 mm) minimum lead length requirement.

Taped Component Re-Reeler

Now you can form and r e-reel radial components for automatic insertion in one operation. With

this accessory, the CF-9 feeds taped components into the first die station, forms t hem, skips the

normal trim operation and sends components straight to the Re-Reel er. Special flattening

blocks can be inserted in the trimming station if additional dimple alignment is required. The rereeler automatically reloads the taped component s back on a reel after the forming process i s

complete.

The optional CF-9 Taped Component Re-Reeler has been specially modified with a slip clutch

assembly on the dri ve motor shaft to allow the operator to adjust dri ve shaft tension. Increasing

shaft tension causes taped components to wind tighter. Decreasing the tension results in more

loosely wound components.

Work Station

The CF-9, dies, and various operational tools can all be mounted on this speci ally construct ed

work station whi ch provides vibration fr ee operations and optimum storage space. The CF-9

Work Station's heavy duty construction includes a 3/8" (9.53 mm) thick aluminum top, a 1"

(25.40 mm) tubular steel frame, and inlaid steel panels.

09/30/92 GPD Global 41

CF-9 User's Guide

This page left blank (almost).

42 GPD Global 09/30/92

CF-9 User's Guide

Appendix D - Electrical Schematic & Assembly Drawing

Drawing Title Drawing Number

CF-9 Electrical Schematic .......................................... 0098001A

CF-9 Electrical Assembly Drawing.................................... 0098002A

09/30/92 GPD Global 43

CF-9 User's Guide

This page left blank (almost).

44 GPD Global 09/30/92

A

Accessories 18, 39

Component Detection System 13, 39

Electronic Component Counter 18, 39

Footswitch 18, 40

Lazy Susan 11, 40

Lead Forming Dies 39

Loose/Bulk Component Feeder 41

Taped Component Re-Reeler 41

Work Station 11, 41

Accessory

Equipment 11

Outlet 7, 40

Adjustment 8

Component Alignment 17

Component Body Height 15

Component Body Thickness 15

Hand Crank 6, 13, 14, 17, 18

Slide Clearance 25

Slide Travel 24

Station 16

Tape Hole to Lead 17

Ammo Pack 5, 19

AUX 18, 40

B

B1 9

B2 9

Belt Tension Release Bar 6

C

Capacities 29

Micrometer 29

Production Rate 29

Component

3 Lead Radial 35, 37

Alignment 17

Ammo Pack 5, 19

Bent 13

Bin 5, 11

Body Height 15

Body Thickness 15

Counter 39

CF-9 User's Guide

Index

Feeder 41

Leads 13

Load 18

Loose 41

Pathway 18

Pitch 13

Process 19

Re-Reeler 41

Reel 5, 19

Reel Tape 13

Tape Pressure Plate Lever 6

Taped 5

TO-92 Transistors 3

Transfer Belt 6

Component Detection System 13, 39

Control Panel 7

Accessory Outlet 7

Fuse 7

Power Switch 7, 13, 18, 19

Reset Button 7, 18, 19

Speed Control 7, 11, 18, 19

Cover Plate 25

Crank

Adjuster 24

Pin 26

Shaft 8

Cycles per hour 7

D

Die

Breakage 13

Custom 30

Die Mounting Surface 14

Functions 3

Information 35

Installation 9, 14

Markings 9

Number 35

Sets 2

Stations 1, 5, 8

Die Block 8

Die Block Assembly 5, 25

Adjusting Bolt 8, 16, 25

Cover Plate 8

Crank Adjuster 8

Crank Shaft 8

09/30/92 GPD Global 45

CF-9 User's Guide

Die Block 8

Die Mounting Area 8

Eccentric Crank 8

Guide Shaft 8, 26

Micrometer Scale Indicator 8, 16

Slide 8, 14

Wear Plate 8

Die Markings

Forming Style Series 9, 35

Installation Color Dot 9

Installation Marking 9

Dimensions 29

Drive Pulley 6, 17

E

E.I.A. Standards 30

Eccentric

Crank 8, 25

Crank Shafts 26

Ejector Brackets 15

Electrical Schematic 43

Electronic Component Counter 18, 39

F

Flattening Blocks 5, 41

Footswitch 18, 40

Forming Style Series 9, 35

Forms

Complicated Lead 15

Lead 3, 37

Function

CF-9 3

Dies 3

Station 1 5

Station 2 4, 5

Fuse 7

I

Indexing System 1

Installation 11

Color Dot 9

Die 14

Die Markings 9

Die Position 9

Ejector Brackets 15

Electronic Component Counter 40

Footswitch 40

Marking 9

K

Knives 9

L

Lazy Susan 11, 40

Lead 13, 17

3 Lead Radial 35, 37

Center-to-Center Dimensions 3

Complicated Lead 15

Cut Length 8, 16

Diameters 3

Forming Dies 39

Forms 3, 37

Point of Attachment 16

Load Components 18, 19

Loose/Bulk Component Feeder 41

M

Machine Upright Plate 16, 25

Maintenance 21

Micrometer Scale 1, 8, 16, 25, 29

G

Gauge Block 24

Guide Shaft 8

Operating

Clearance 30

Instructions 13

H

Hand Crank 6, 13, 14, 17, 18, 23

46 GPD Global 09/30/92

O

CF-9 User's Guide

P

Part Identification 5

Power

Off 19

On 18

Requirements 29

Power Switch 7, 13, 18, 19

AUX 18, 40

Pressure Plate Lever 6, 18

Preventive Maintenance 21

Process Components 19

Production Rate 29

R

Reel Holder 5, 11, 19

Reset Button 7, 18, 19

S

Safety

Shield 6, 11, 18, 19

Shield Lock 6, 18

Screw Sizes 11, 14, 39

Serial Number 11

Setup 13

Slide Clearance 25

Slide Travel 24

Gauge Block 24

Spare Parts 31

Specifications 29

Taping 30

Speed Control 7, 11, 18, 19

Station

Action 16

Adjustment 16

Guide Shaft 8

Position 16

Station 1 5, 14

Station 2 4, 5, 14, 15

Work 41

Hole-to-Hole Spacings 3

Operating Clearance 30

Pressure Plate Lever 6

Roller Guide 1, 5

Taped Component Re-Reeler 41

Taped Components 5

Custom 30

Taping Specifications 30

Tension Release Bar 6

Theory of Operation 4

Transfer Belt 6, 18

Troubleshooting 23

Guide 23

Hand Crank 23

W

Wear Plate 25

Weight 29

Work Station 11, 41

Z

Zero (0) Reference Point 16

T

T1 9, 25

T2 9, 25

Tape 13

Exit Chute 1, 5

Guide Arm 5, 11

Hole to Lead Distance 17

09/30/92 GPD Global 47

CF-9

Radial Lead Forming Machine

Bills of Material

&

Exploded Views

Version 2.2

June 3, 2014

Prepared by

GPD Documentation Department

Copyright (C) 1992, 1996, 2002, 2007, 2014 GPD Global

GPD Global

611 Hollingsworth Street

Grand Junction, CO 81505

(970) 245-0408 FAX (970) 245-9674

CF-9 Bills of Material & Exploded Views

Part No. 901-1-02

®

All Rights Reserved

®

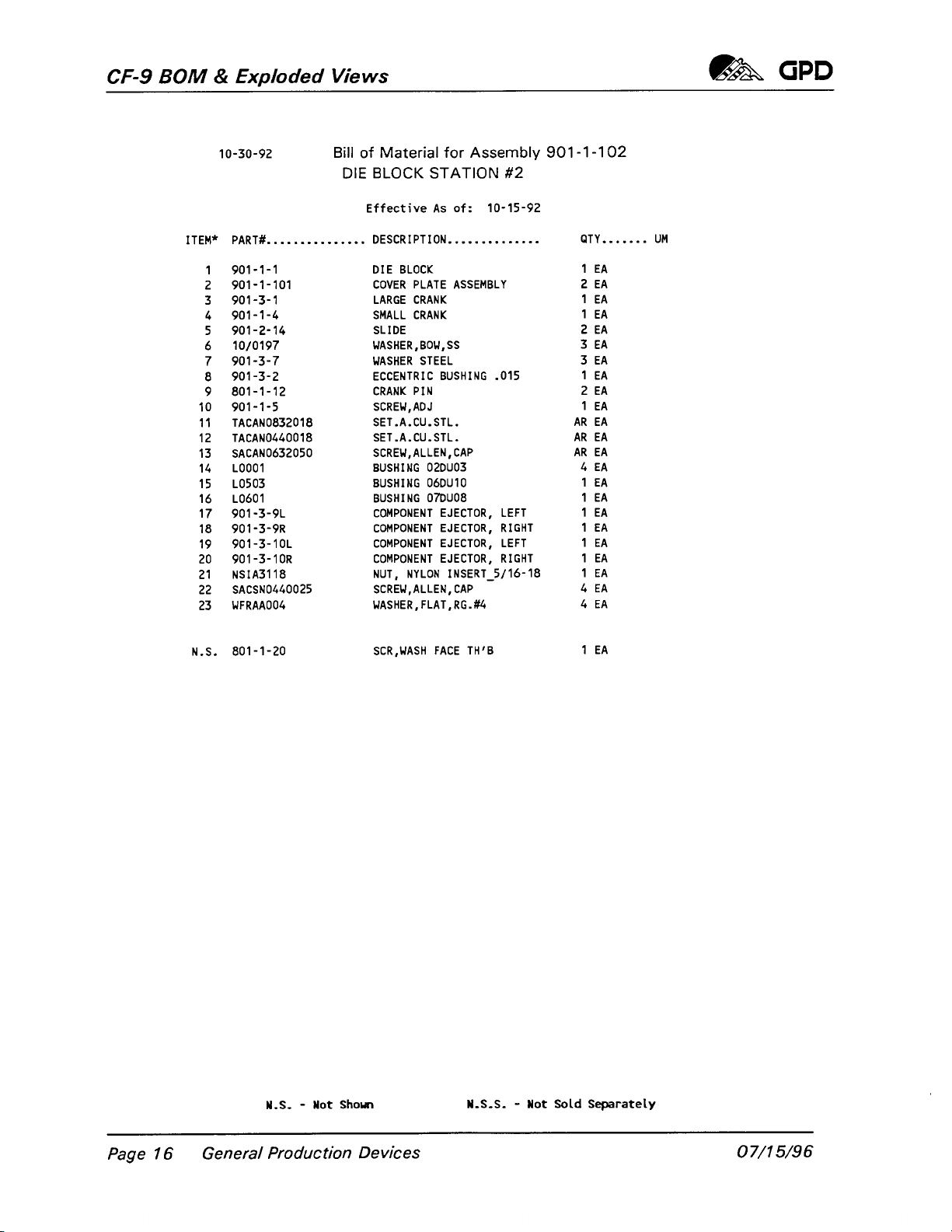

CF-9 BOM & Exploded Views

11-03-11

SPARE PARTS KIT, 120V

Effective As of: 11-03-11

ITEM* PART#............... DESCRIPTION.............. QTY....... UM

1 SACAN1032062 DIE SCREW 6 EA

2 901-3-10 TRANSFER BELT 1 EA

3 4300-0026 FUSE,SLOW BLOW 3 EA

Bill of Material for Assembly 925-1-2

N.S. - Not Shown N.S.S. - Not Sold Separately

Page 36 General Production Devices 06/03/14

Loading...

Loading...