GP MF Series, MF45, MF50, MF55 Repair Manual

MF

8

Repair Manual

General Pump

is a member of

the Interpump Group

MF45 - MF50 - MF55

Ref 310068 Rev.A

06-17

GENERAL PUMP

INDEX

1. INTRODUCTION ..................................................Page 3

2. REPAIR INSTRUCTIONS ...........................................Page 3

2.1 Repairing Mechanical Parts .......................................Page 3

2.1.1 Disassembling of Mechanical Parts ..........................Page 4

2.1.2 Assembly of Mechanical Parts ..............................Page 15

2.1.3 Increase and Reduction Classes ............................ Page 27

2.2 Repairing Hydraulic Parts ........................................Page 27

2.2.1 Disassembling manifold MF45, MF50, MF55: valve inserts ........Page 27

2.2.2 Disassembling manifold MF45, MF50, MF55: sleeves containg seals Page 30

2.2.3 Fitting the manifold .......................................Page 32

2.2.4 Fitting the manifold: sleeves containing seals ..................Page 33

2.2.5 Assembling the valve units manifold ......................... Page 36

2.2.6 Disassembling the piston unit ............................... Page 43

2.2.7 Assembling the piston unit .................................Page 44

3. SCREW CALIBRATION ............................................Page 47

4. REPAIR TOOLS ..................................................Page 47

A member of the Interpump Group

MF SERIES

5. REPLACING THE CON-ROD SMALL END BUSH ....................... Page 48

6. MAINTENANCE LOG ..............................................Page 49

Ref 310068 Rev.A

06-17

Page 2

GENERAL PUMP

A member of the Interpump Group

MF SERIES

1. INTRODUCTION

This manual describes the instructions for Repairing MF Series pumps, and must be carefully read and

understood before performing any repair intervention on the pump. Proper pump operation and longevity

depend on the correct use and maintenance. General Pump declines any responsibility for

damage caused by the misuse or the non-observance of the instructions described in this manual.

2. REPAIR INSTRUCTIONS

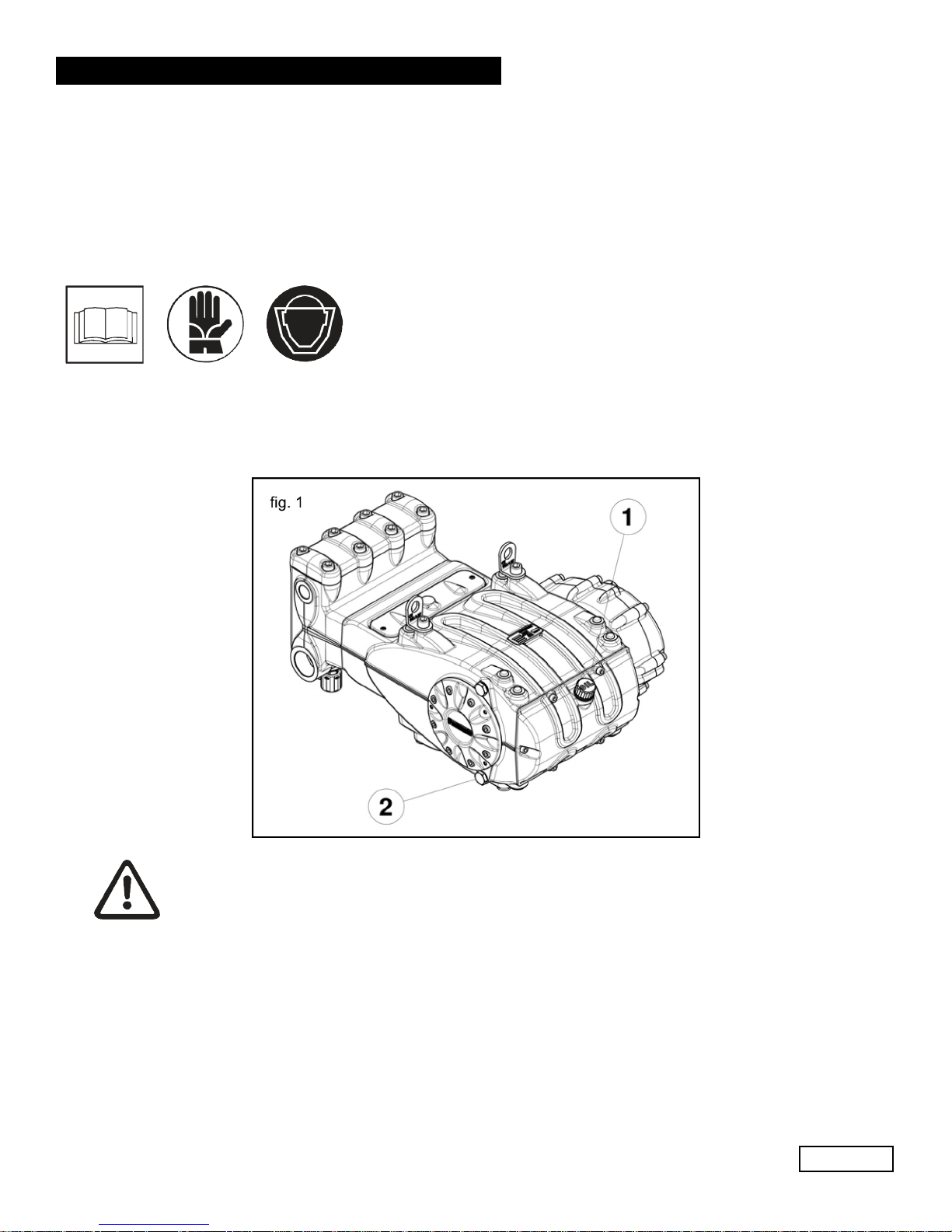

2.1 Repairing Mechanical Parts

Mechanical parts repair must be performed after removal of oil from the casing. To drain

the oil, remove the oil dipstick, (1, fig. 1) and then the draining plug (2, fig. 1).

The oil must be placed in a suitable container and disposed of in special centers.

It absolutely must not be discarded into the environment.

Ref 310068 Rev.A

06-17

Page 3

GENERAL PUMP

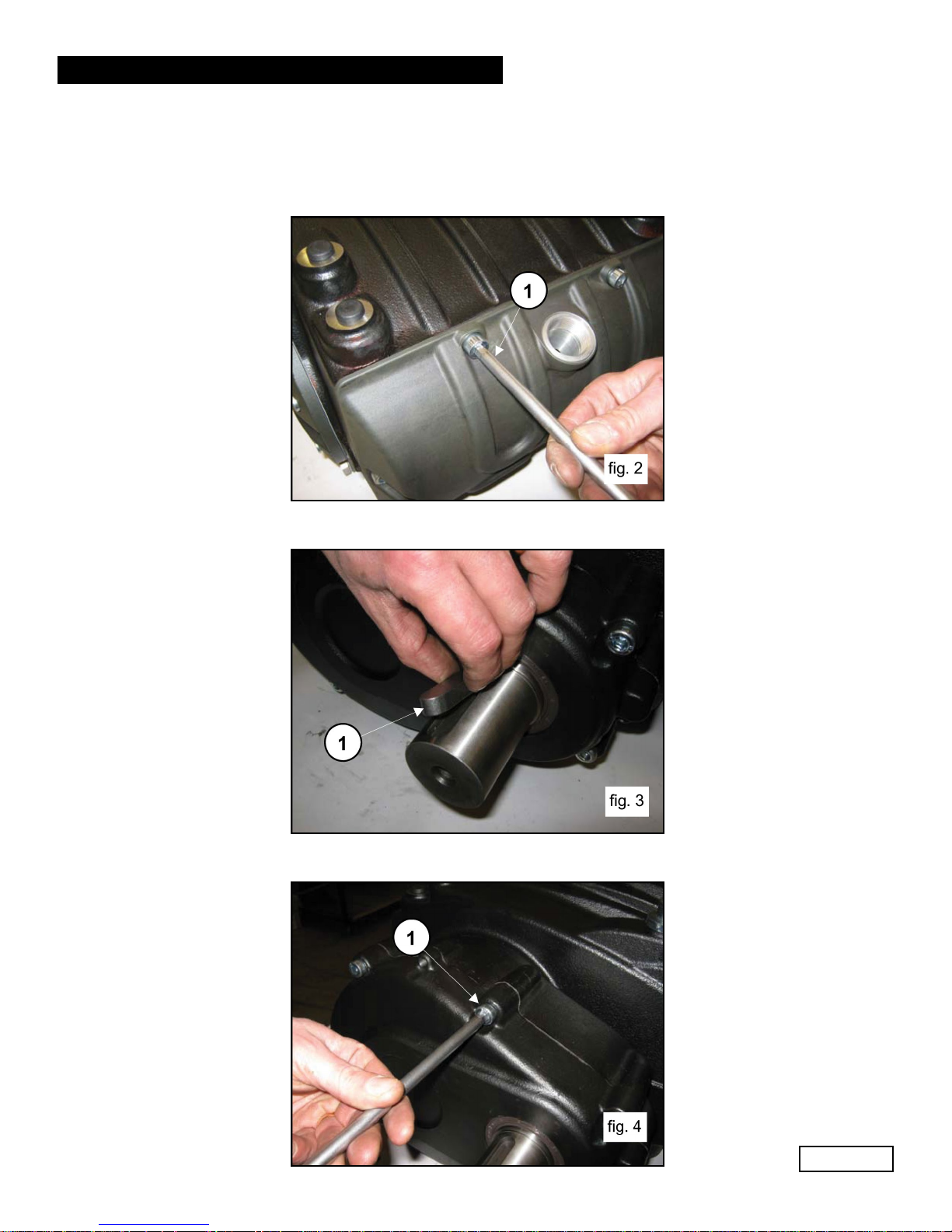

2.1.1 Disassembly of Mechanical Parts

The correct sequence is the following:

Completely drain the oil from the pump, then disassemble the casing cover (and relative o-ring), unscrewing

the 6 M10 screws (1, fig. 2).

A member of the Interpump Group

MF SERIES

Remove the tab from the PTO shaft (2, fig. 3).

Unscrew the reduction gear cover fixing screws (1, fig. 4).

Ref 310068 Rev.A

06-17

Page 4

GENERAL PUMP

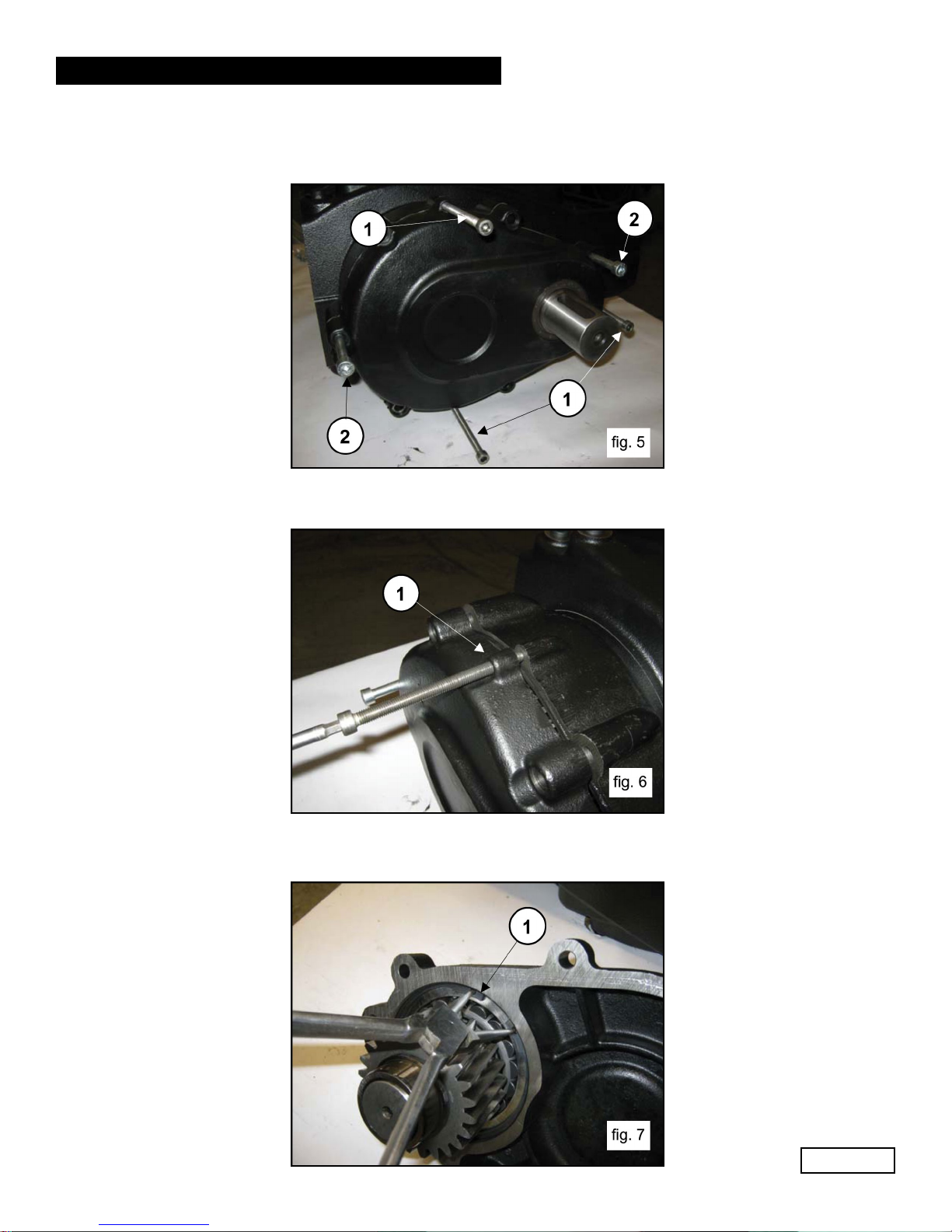

Position the 3 grub screws or M8 threaded screws (1, fig. 5) with the function of extractors in the holes and

two sufficiently long M10 screws with the function of supporting the cover (2, fig. 5).

Slowly screw in the 3 M8 screws (1, fig. 6) with the function of extractors to fully remove the cover unit

and pinion.

A member of the Interpump Group

MF SERIES

Complete disassembly of the reduction gear cover from the pinion is possible following these steps:

Remove the retaining ring Ø120 (1, fig. 7)

Ref 310068 Rev.A

07-17

Page 5

GENERAL PUMP

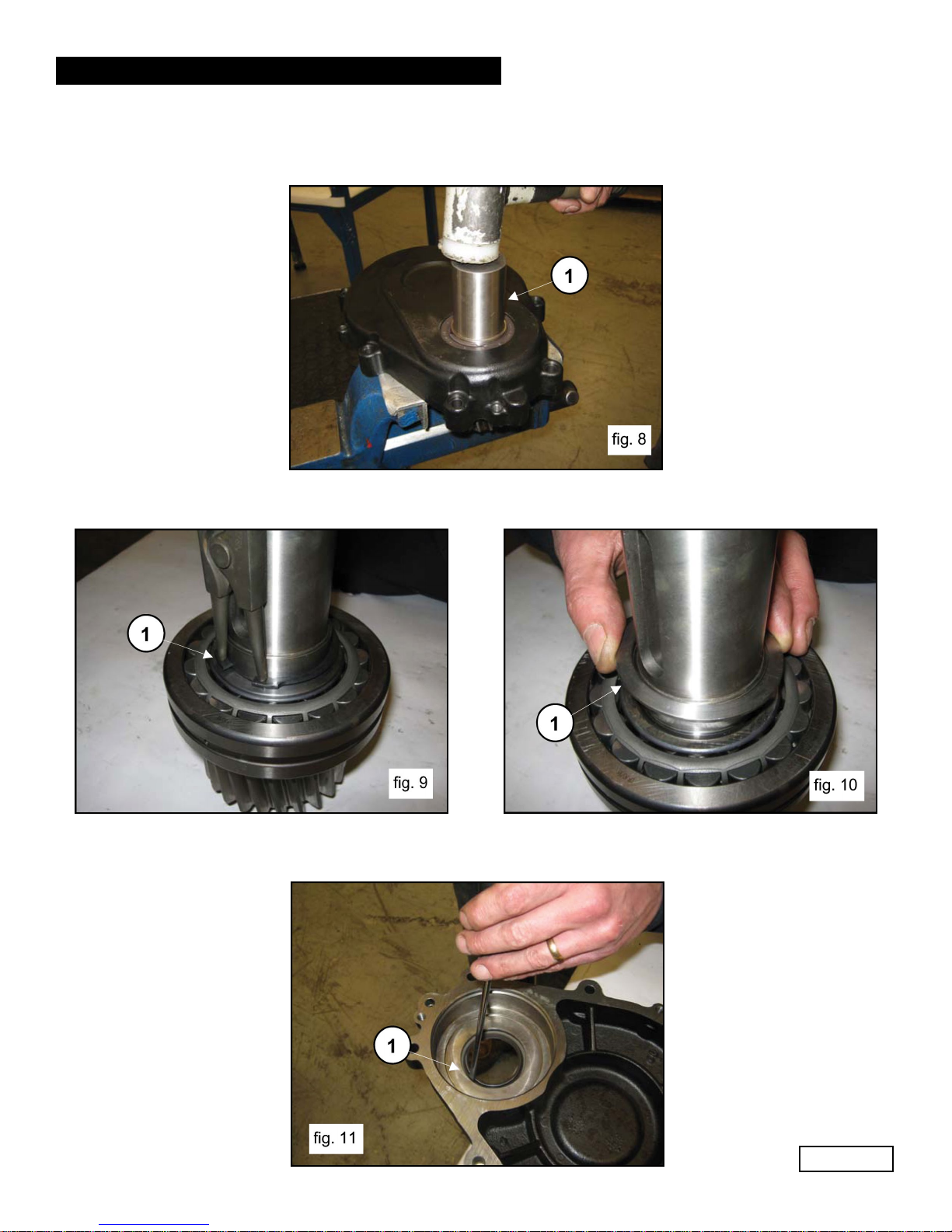

Separate the pinion from the cover, working with an extractor hammer on the pinion itself (1, fig. 8).

Remove the retaining ring Ø55 (1, fig. 9) and the bearing support ring (1, fig. 10) from the pinion.

A member of the Interpump Group

MF SERIES

Extract the seal ring from the reduction gear cover, working from the inner side of the cover (1, fig. 11).

Ref 310068 Rev.A

06-17

Page 6

GENERAL PUMP

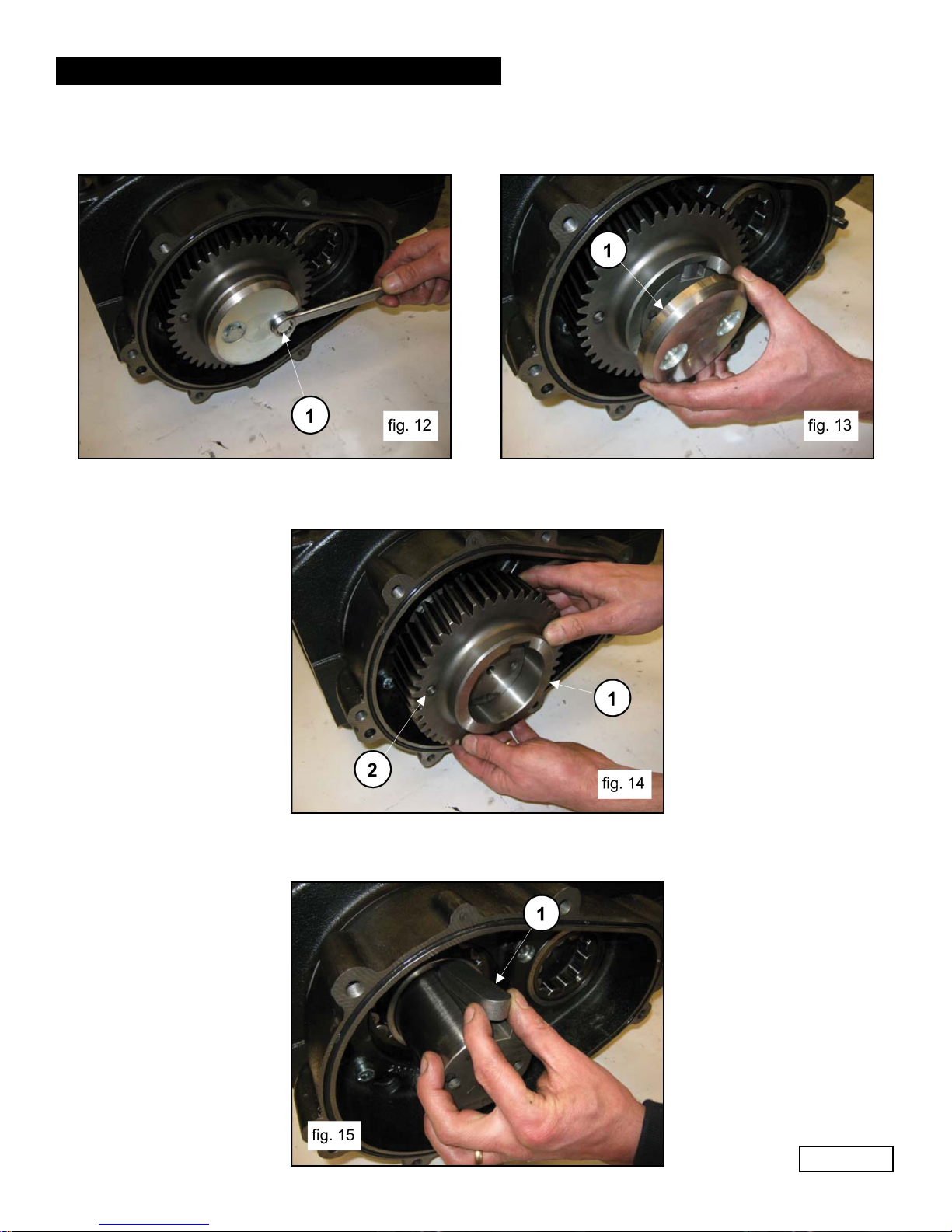

Unscrew the screws holding in the ring gear (1, fig. 12) and remove it (1, fig. 13).

Remove the ring gear (1, fig. 14). Where necessary, it is possible to utilize an extractor hammer to be

applied on the 2 M8 holes (2, fig. 14).

A member of the Interpump Group

MF SERIES

Remove the key from the shaft (1, fig. 15).

Ref 310068 Rev.A

06-17

Page 7

GENERAL PUMP

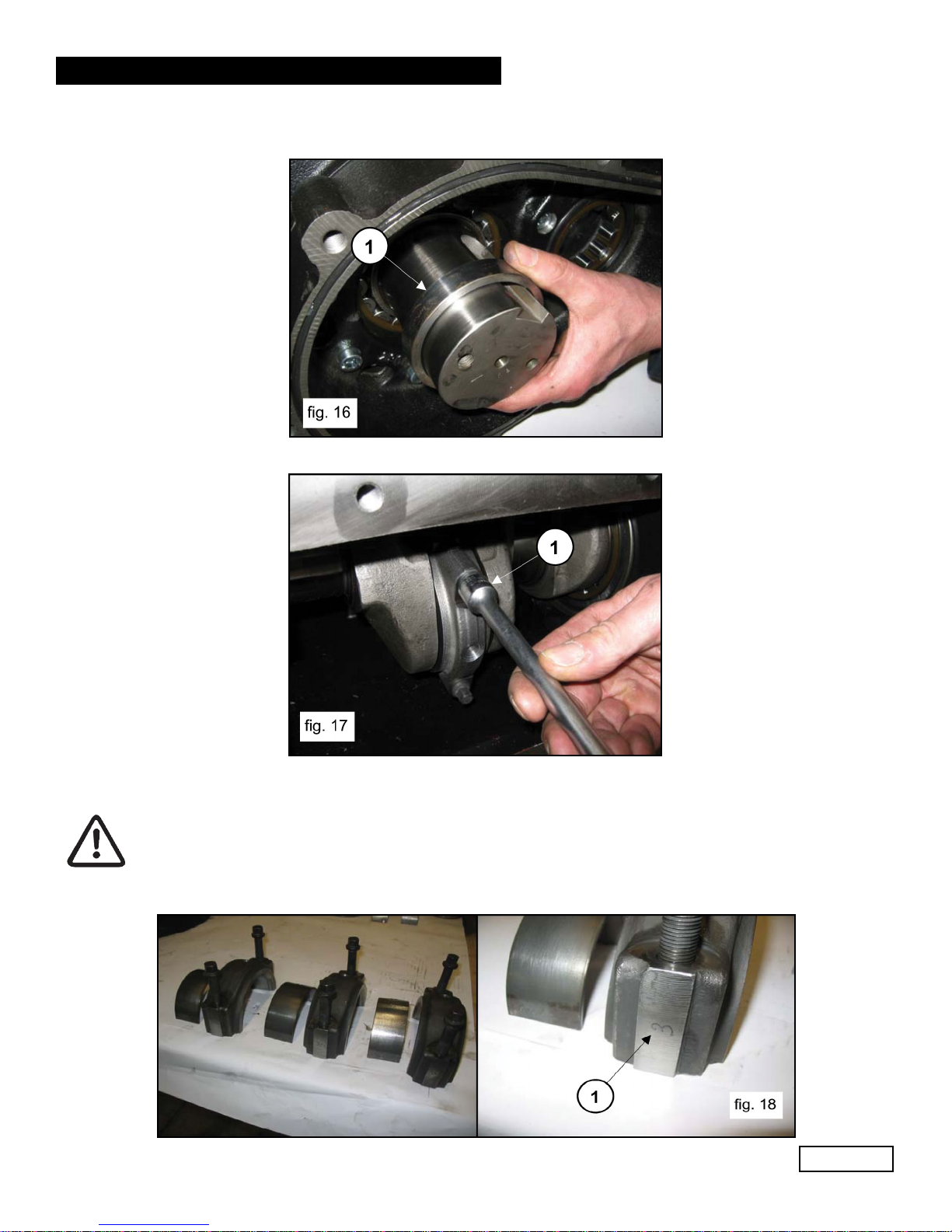

Remove the ring gear support ring (1, fig. 16).

Unscrew the connecting rod screws (1, fig. 17).

A member of the Interpump Group

MF SERIES

Remove the connecting rod caps with the lower semi-bearings, taking special care of the disassembly

sequence during disassembly.

The con-rod caps and their relative half supports must be reassembled in exactly the same

order and coupling with which they were disassembled.

To avoid possible errors, caps and half-supports have been numbered on one side (1, fig. 18).

Ref 310068 Rev.A

06-17

Page 8

GENERAL PUMP

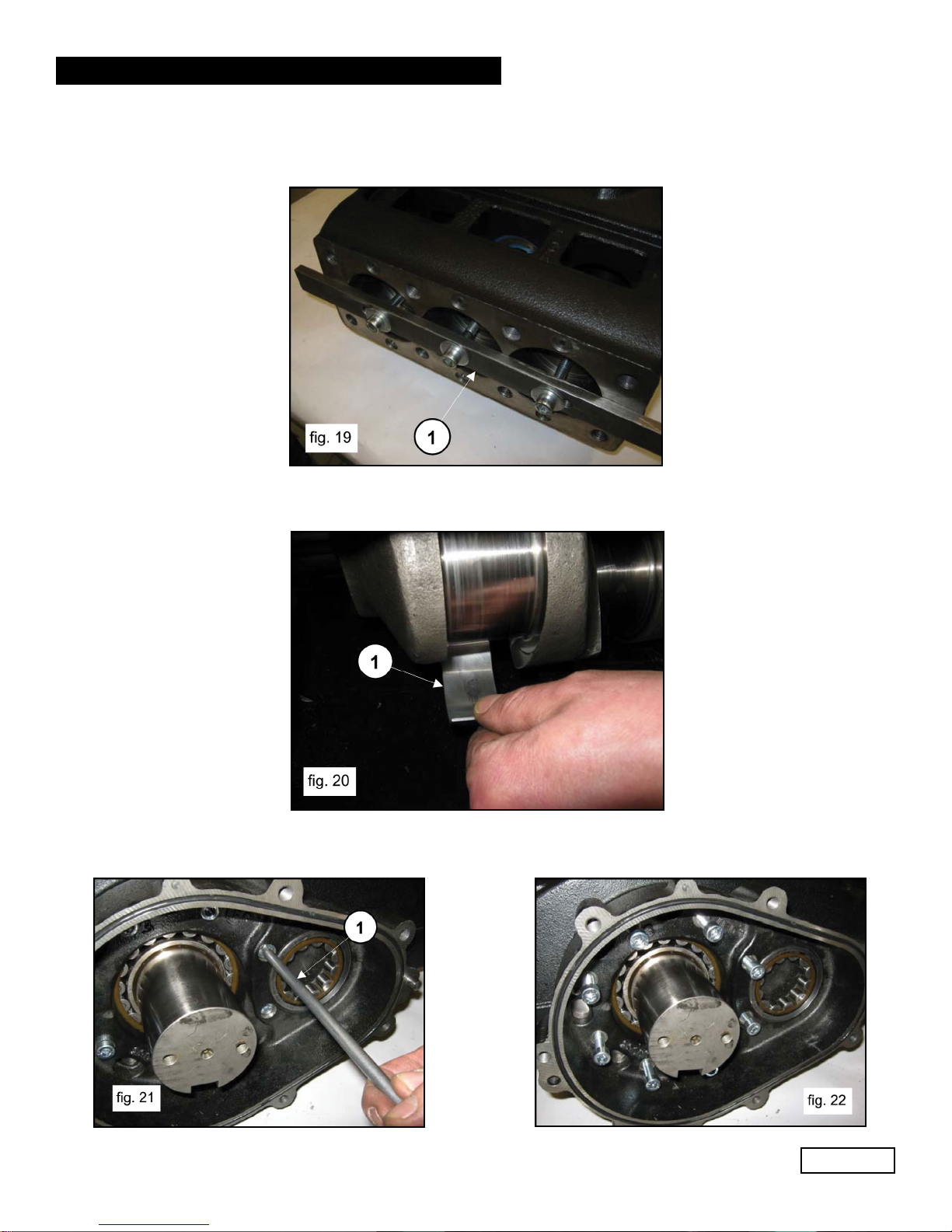

Advance the half supports completely in the direction of the pump head to allow the crankshaft to come

out. To facilitate this operation, use special tool (p/n F27566200) (1, fig. 19).

Remove the three upper half-bearings of the half supports (1, fig. 20).

A member of the Interpump Group

MF SERIES

Unscrew the reduction gear box fixing screws (1, fig. 21 and fig. 22).

Ref 310068 Rev.A

06-17

Page 9

GENERAL PUMP

Position the 3 grub screws or M8 threaded screws (1, fig. 23) with the function of extractors in the holes and

two sufficiently long M10 screws with the function of supporting the reduction gear box (2, fig. 23).

Slowly screw in the 3 M8 screws (1, fig. 24) to prevent the box from tilting too far and getting locking in the

housing. Remove the box while supporting the shaft to prevent damage (1, fig. 25)

A member of the Interpump Group

MF SERIES

Unscrew the bearing cover fixing screws from the opposite side (1, fig. 26 and fig. 27).

Ref 310068 Rev.A

06-17

Page 10

GENERAL PUMP

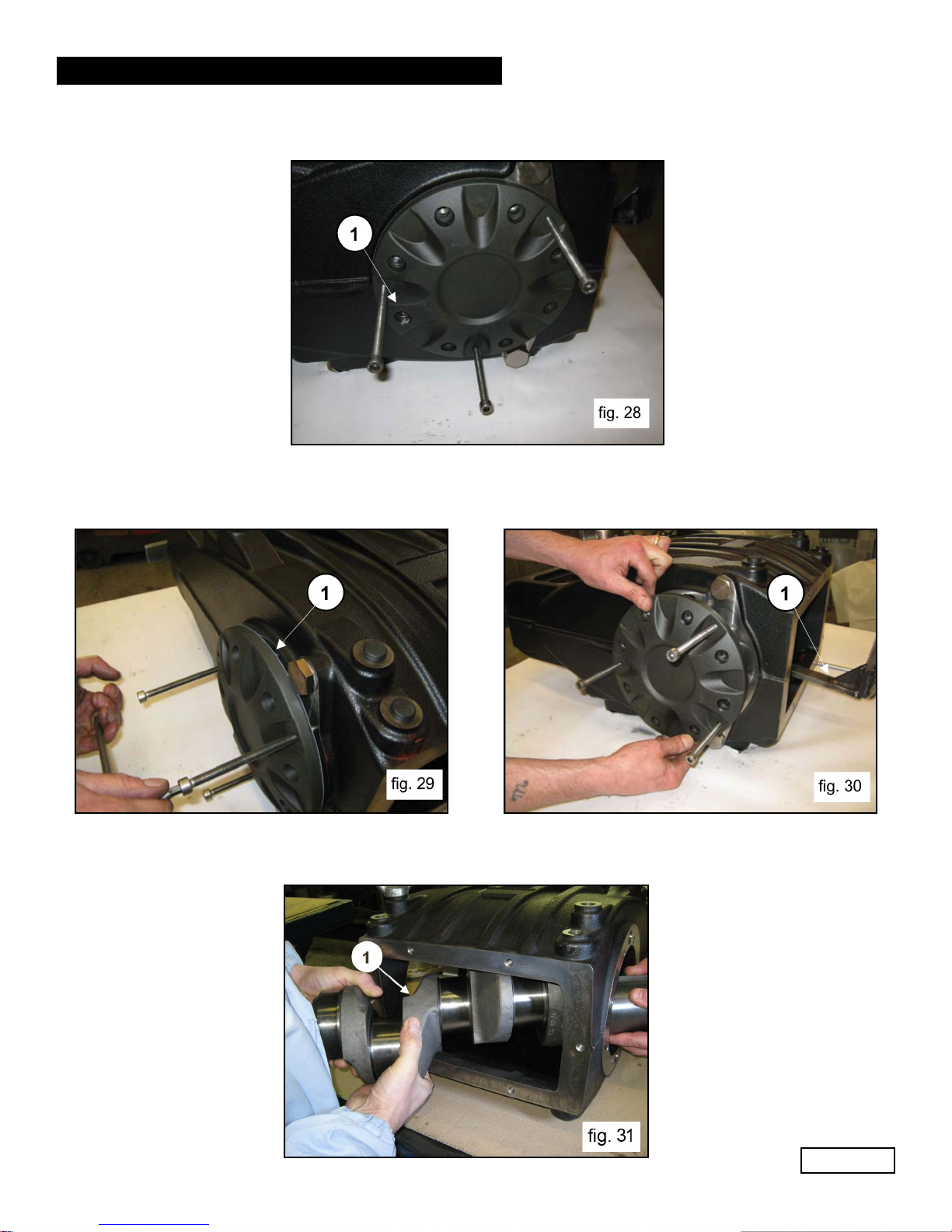

Position the 3 grub screws or M8 threaded screws (1, fig. 28) with the function of extractors in the holes.

Slowly screw in the 3 M8 screws (1, fig. 29) to prevent the cover from tilting too far and getting locked in the

housing. Remove the bearing cover while supporting the shaft to prevent damage (1, fig. 30).

A member of the Interpump Group

MF SERIES

Remove the crankshaft from the rear opening (1, fig. 31)

Ref 310068 Rev.A

06-17

Page 11

GENERAL PUMP

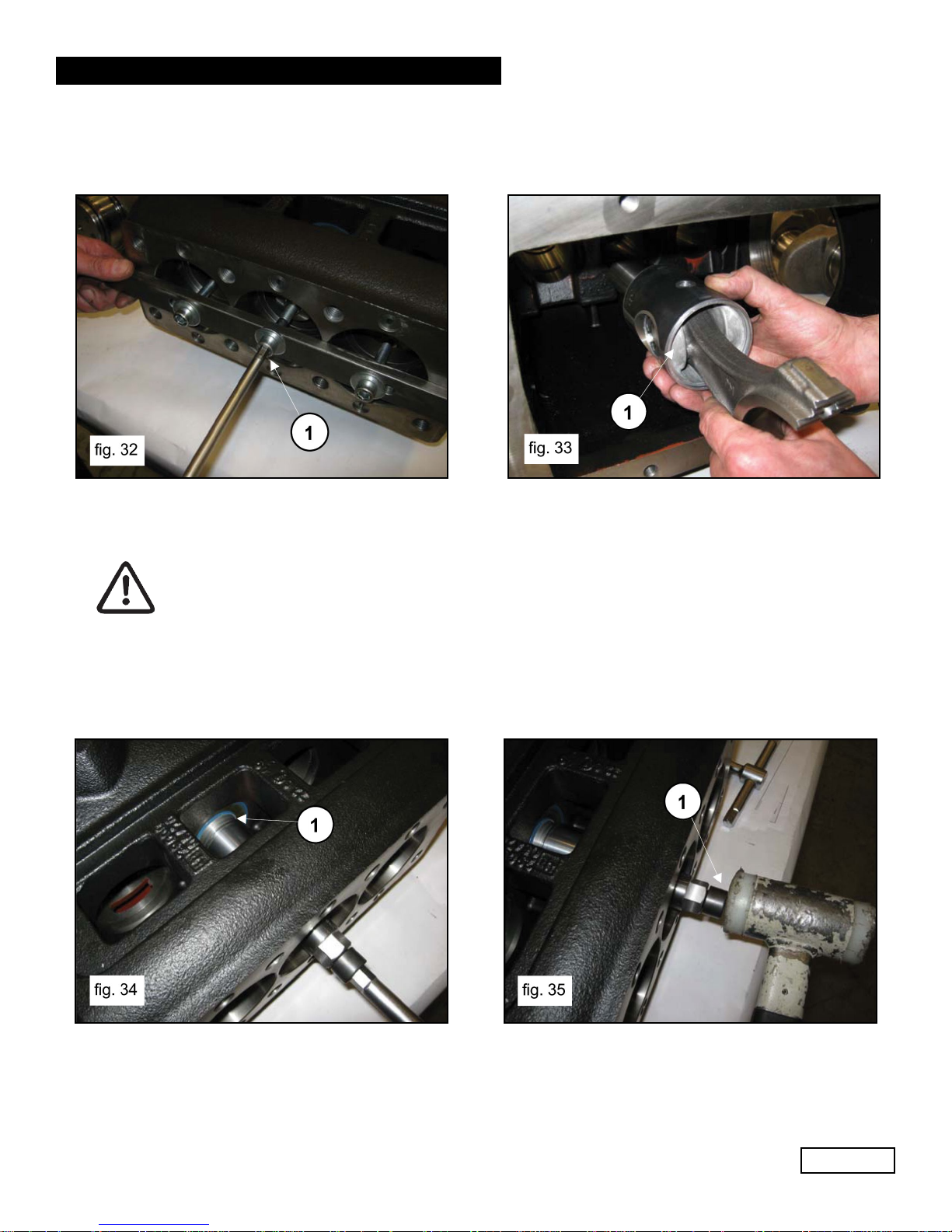

In the event that it is necessary to replace one or more con-rods or plunger guides, operate as follows:

Unscrew the screws with tool #F27566200 to unlock the con-rods (1, fig. 32) and then extract the con-rod

plunger guide units from the back casing opening (1, fig. 33).

It is now possible to disassemble the plunger guide seal rings, taking care to not damage the plunger guide

sliding rod.

Whenever it becomes necessary to replace the plunger guide seal rings without

dismantling the entire mechanical part, it is possible to extract the seal rings with the

use of tool #F27918500 operating as follows:

A member of the Interpump Group

MF SERIES

Insert the tool between the rod and the seal ring (1, fig. 34) and, with the extractor hammer, complete

insertion of the tapered section inside the seal ring (1, fig. 35).

Ref 310068 Rev.A

06-17

Page 12

GENERAL PUMP

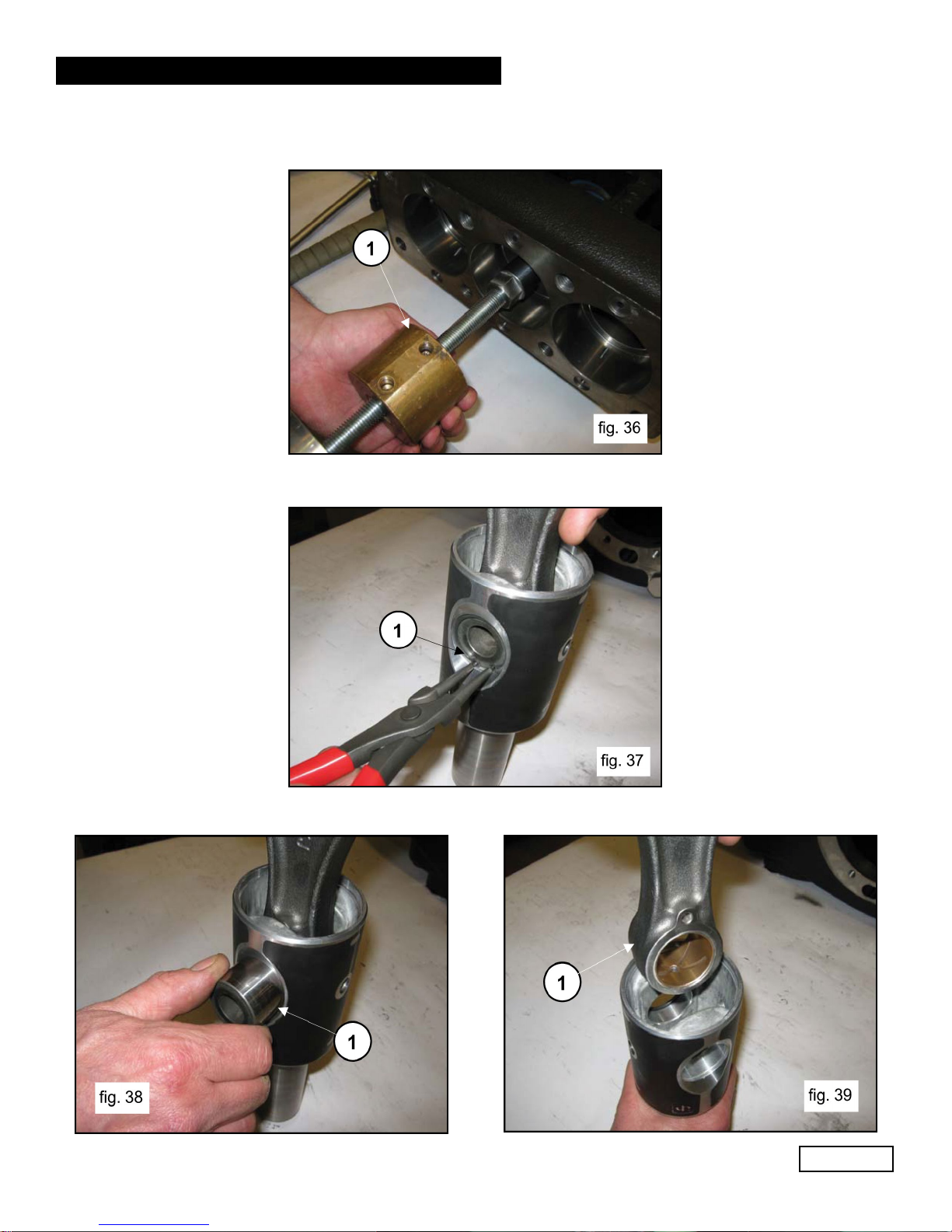

Extract the seal ring using the tool extractor hammer (1, fig. 36).

Remove the two spindle locking retaining rings Ø120 (1, fig. 37).

A member of the Interpump Group

MF SERIES

Remove the spindle (1, fig. 38 and extract the con-rod (1, fig. 39).

Ref 310068 Rev.A

06-17

Page 13

GENERAL PUMP

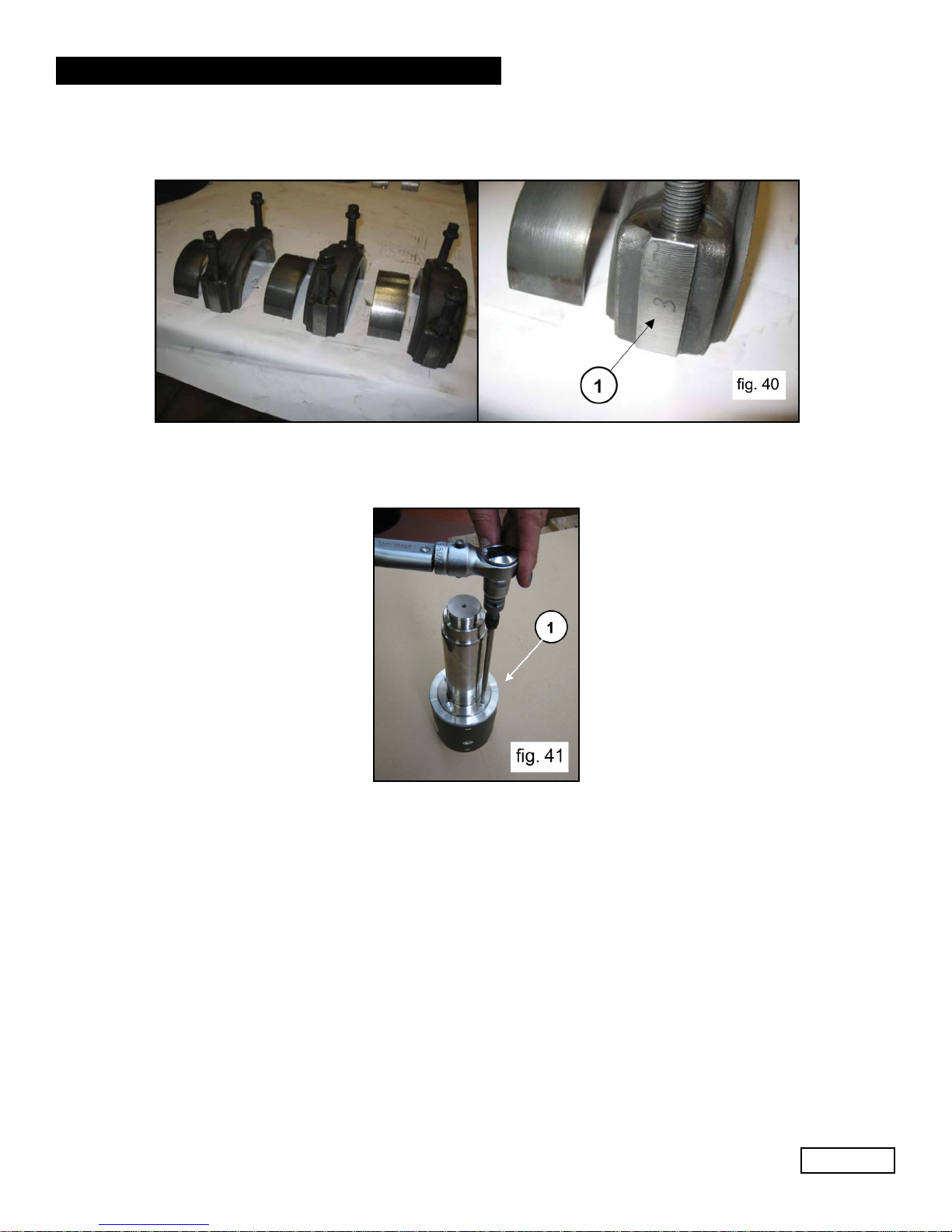

Couple the half supports to the previously disassembled caps, referring to the numbering (1, fig. 40).

To separate the rod from the piston guide, unscrew the round head M6 screws (1, fig. 41)

A member of the Interpump Group

MF SERIES

Ref 310068 Rev.A

06-17

Page 14

GENERAL PUMP

2.1.2 Assembly of Mechanical Parts

Proceed with assembly following the reverse order indicated in point 2.1.1. The proper sequence is as

follows:

Assemble the rod to the plunger guide. Insert the piston guide rod into its seat on the piston guide (1, fig. 42)

and join the rod to the piston guide by means of M6 x 20 screws (1, fig. 43).

A member of the Interpump Group

MF SERIES

Lock the piston guide in a vice (1, fig. 44) and proceed with calibration with a torque wrench (1, fig. 45) as

indicated in paragraph 3 “Screw Tightening Calibration”.

Insert the con-rod in the piston guide (1, fig. 39) and then insert the piston pin (1, fig. 38). Apply the two

spindle locking retaining rings (1, fig. 37).

Assembly has been carried out properly if the con-rod small end, piston guide and

spindle rotate freely.

Separate the caps from the con-rods. Proper coupling can be verified by the numbering on the side

(1, fig. 40).

After having checked casing cleaning, proceed with assembly of half support-piston guide unit inside

casing rods (1, fig. 33).

Insertion of the conrod-plunger guide unit in the casing must be made with the

half bearings set in the direction in which numbers are visible from above.

Ref 310068 Rev.A

06-17

Page 15

Loading...

Loading...