GP MF series, MF50, MF55, MF45 Owner's Manual

MF

8

Owner’s Manual

• Installation

• Use

• Maintenance

General Pump

is a member of

the Interpump Group

MF45 - MF50 - MF55

Ref 310069 Rev. B

07-18

GENERAL PUMP

A member of the Interpump Group

MF SERIES

INDEX

1. INTRODUCTION ............................................................... Page 3

2. DESCRIPTION OF SYMBOLS ....................................................Page 3

3. SAFETY ...................................................................... Page 4

3.1 General safety instructions ....................................................Page 4

3.2 High pressure unit safety requirements ........................................... Page 4

3.3 Safety during operation ....................................................... Page 4

3.4 General procedures for using nozzles ............................................ Page 4

3.5 Safety during unit maintenance .................................................Page 5

4. PUMP IDENTIFICATION ......................................................... Page 5

5. TECHNICAL FEATURES ........................................................Page 6

6. DIMENSIONS AND WEIGHT ..................................................... Page 6

7. OPERATING INSTRUCTIONS ....................................................Page 7

7.1 Water temperature ........................................................... Page 7

7.2 Maximum flow and pressure rates ............................................... Page 7

7.3 Minimum RPM ..............................................................Page 7

7.4 Recommended lubricant types and Manufacturers .................................. Page 7-8

8. PORTS AND CONNECTIONS ....................................................Page 9

9. PUMP INSTALLATION ..........................................................Page 9

9.1 Installation .................................................................Page 9

9.2 Direction of rotation .......................................................... Page 10

9.3 Version change and reducer positioning ..........................................Page 10-11

9.4 Hydraulic connections ........................................................Page 12

9.5 Pump power supply ..........................................................Page 12

9.6 Suction line ................................................................Page 12

9.7 Filtration ...................................................................Page 13

9.8 Outlet line .................................................................. Page 14

9.9 Internal diameter of hose ...................................................... Page 14

9.10 V-belt transmission .........................................................Page 15

10. START UP AND OPERATION ....................................................Page 15

10.1 Preliminary inspections ......................................................Page 15

10.2 Starting up ................................................................ Page 16

11. PREVENTATIVE MAINTENANCE ................................................. Page 16

12. PUMP STORAGE ..............................................................Page 17

12.1 Filling the pump with anti-corrosion emulsion or anti-freeze .......................... Page 17

12.2 Hoses .................................................................... Page 17

13. PRECAUTIONS AGAINST FREEZING ..............................................Page 17

14. WARRANTY TERMS ............................................................Page 17

15 TROUBLESHOOTING ...........................................................Page 18

16. EXPLODED VIEWS AND PARTS .................................................. Page 19-20

17. REPAIR TOOLS ................................................................Page 21

18. MAINTENANCE LOG ........................................................... Page 22

Ref 310069 Rev. B

07-18

Page 2

GENERAL PUMP

A member of the Interpump Group

MF SERIES

1. INTRODUCTION

This manual describes the use and maintenance instructions of the MF pump, and should be carefully read and

understood before using the pump.

Correct use and adequate maintenance will guarantee the pumps trouble-free operation for a long time. General Pump

declines any responsibility for damage caused by misuse or the non-observance of the instructions indicated in this

manual.

Upon receiving the pump, check that it is complete and in perfect condition. Should anything be found out of order, please

contact us before installing and starting the pump.

2. SYMBOL DESCRIPTIONS

Warning

Potential Danger

Read carefully and understand

the manual before operating

the pump

Danger

High Voltage

Danger

Wear protective mask

Danger

Wear goggles

Symbol for protection against

explosion.

This defines special safety requirements

for the us of the pumps in areas indentified

in accordance with the ATEX Directive.

When pumps are ordered in the ATEX

configuration because they are going

to work in areas with a potentially explosive atmosphere, you must STRICTLY

comply with the notes given under the

headings marked with this symbol and

the instructions in the supplementary

instructions manual “ATEX EXPLOSION

PROTECTION”.

(Versions available in compliance with

ATEX:MF)

Danger

Wear protective gloves

Danger

Wear protective boots

Ref 310069 Rev. B

07-18

Page 3

GENERAL PUMP

A member of the Interpump Group

MF SERIES

3. SAFETY

3.1 General Safety Indications

Improper use of pumps and high pressure systems, and the non-compliance with installation and maintenance

instructions may cause severe injury to people and/or damage to property. Anyone assembling or usinge high pressure

systems must possess the necessary competence to do so, should be aware of the characteristics of the components

assembled/used, and must take all precautions necessary to ensure maximum safety in any operating condition. In the

interest of safety, both for the Installer and the Operator, no reasonably applicable should be omitted.

3.2 High pressure unit safety requirements

1. The pressure line must always be equipped with a safety valve.

2. High pressure system components, in particular for those units working outside, must be adequately

protected against rain, frost and heat.

3. The electrical control system must be adequately protected from water spray, and must comply with the

specific regulations in force.

4. High pressure hoses must be properly sized for maximum operating pressure of the system and always and only

used within the operating pressure range specified by the hose manufacturer. The same rules should be observed

for all other auxiliary systems affected by high pressure.

5. The ends of high pressure hoses must be sheathed and secured to a solid structure to prevent dangerous

whiplash in case of bursting or broken connections.

6. Appropriate safety guards must be provided for the pump transmission systems (couplings, pulleys and belts,

auxiliary drives).

3.3 Safety During Operation

The working area of a high pressure system must be clearly marked. Access must be prohibited to un-authorized

personnel and, wherever possible, the area should restricted or fenced. The personnel authorized to access this area

should first be trained, and informed about the risks that may arise from failures or malfunctions of the high pressure unit.

Before starting the unit, the operator must check:

1. That the high pressure system is properly powered (see paragraph 9.5).

2. That pump intake filters are perfectly clean; we advise the use of a device that indicates the filters clogging level.

3. Electrical parts are adequately protected and in perfect condition.

4. The high pressure hoses do not show apparent signs of abrasion, and that fittings are in perfect shape.

Any fault or reasonable doubt that may arise before or during operation should be promptly reported and verified by

competent personnel. In these cases, pressure should immediately be released and the high pressure system stopped.

3.4 General Procedures For Using Nozzles

1. The Operator must always place his/her safety and security first, as well as that of others that may be directly

affected by his/her actions, or any other assessments or interests. The operator’s work must be dictated by common

sense and responsibility.

2. The Operator must always wear a helmet with a protective visor, waterproof clothing, and appropriate boots capable

of guaranteeing grip on wet pavement.

Ref 310069 Rev. B

07-18

Page 4

GENERAL PUMP

Note: appropriate clothing will effectively protect against water spray, but it may not offer adequate protection against the

direct impact of water jets or sprays from a close distance. Some circumstances may require further protection.

3. It is generally best to organize personnel into teams of at least two people capable of giving mutual and immediate

assistance in case of necessity and of taking turns during long and demanding operation.

4. Access to the work area that is within the water jets’ range must be absolutely prohibited to and free from objects

that, inadvertently under a pressure jet, can be damaged and or create dangerous situations.

5. The water jet must only and always be directed in the direction of the work area, including during testing or

preliminary tests or checks..

6. The Operator must always pay attention to the trajectory of the debris removed by the water jet. If

necessary, suitable guards must be provided by the Operator to protect anything that may be accidentally exposed.

7. The Operator should not be distracted for any reason during operation. Workers needing to access the operating

area must wait for the Operator to stop work, and then immediately make their presence known.

8. For safety reasons, it is important that each member of the team is fully aware of the intentions and actions of

other team members in order to avoid dangerous misunderstandings.

9. The high pressure system must not be started up and run under pressure without all team members in position

and without the Operator having already directed his/her lance toward the work area.

3.5 Safety During System Maintenance

1. The pressure system maintenance must be carried out in the time intervals set by the manufacturer who is

responsible for the whole group according to law.

2. Maintenance should always be carried out by trained and authorized personnel.

3. Assembly and disassembly of the pump and its various components must be performed exclusively

by authorized personnel, using appropriate equipment in order to avoid damage to components and connections.

4. Always use original spare parts to ensure total reliability and safety.

A member of the Interpump Group

MF SERIES

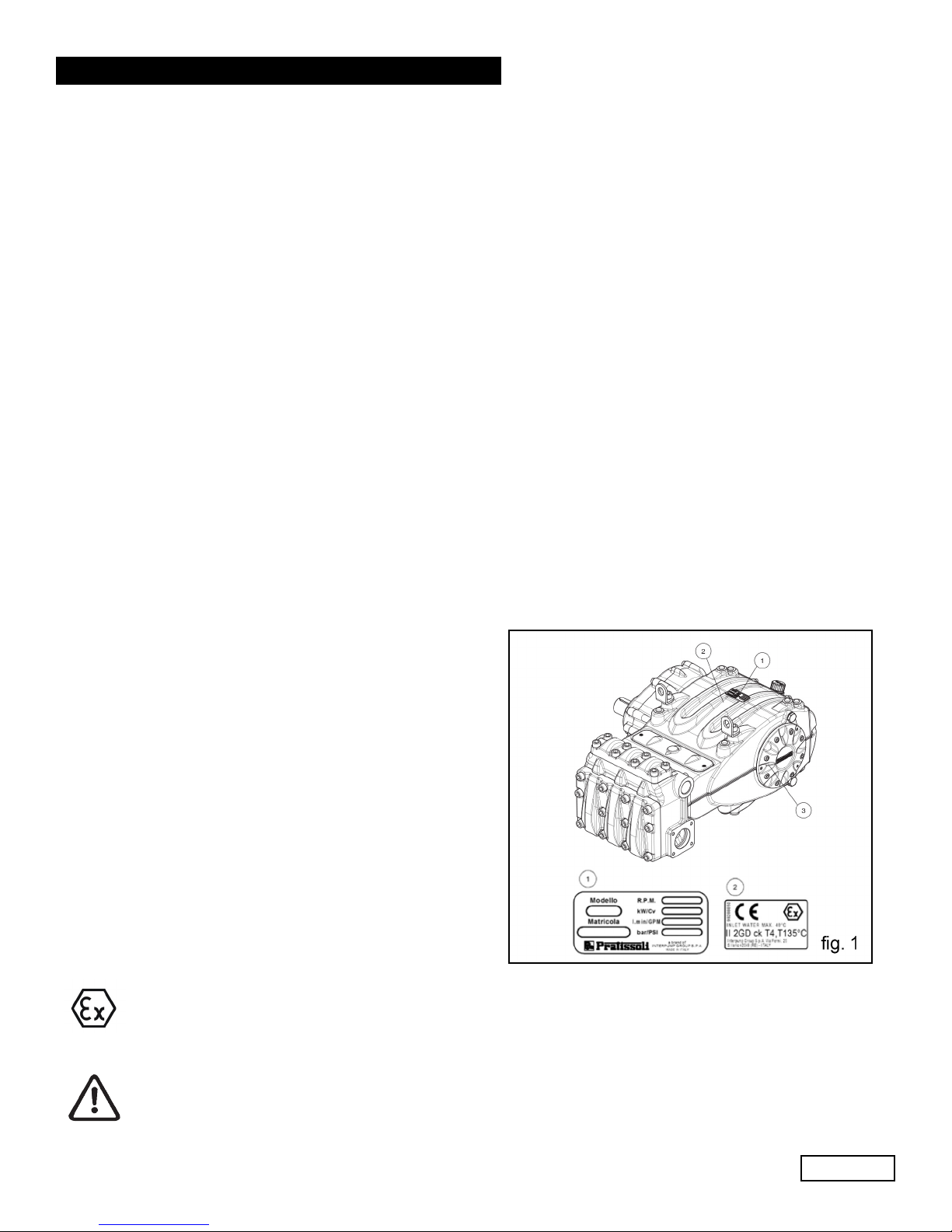

4. PUMP IDENTIFICATION

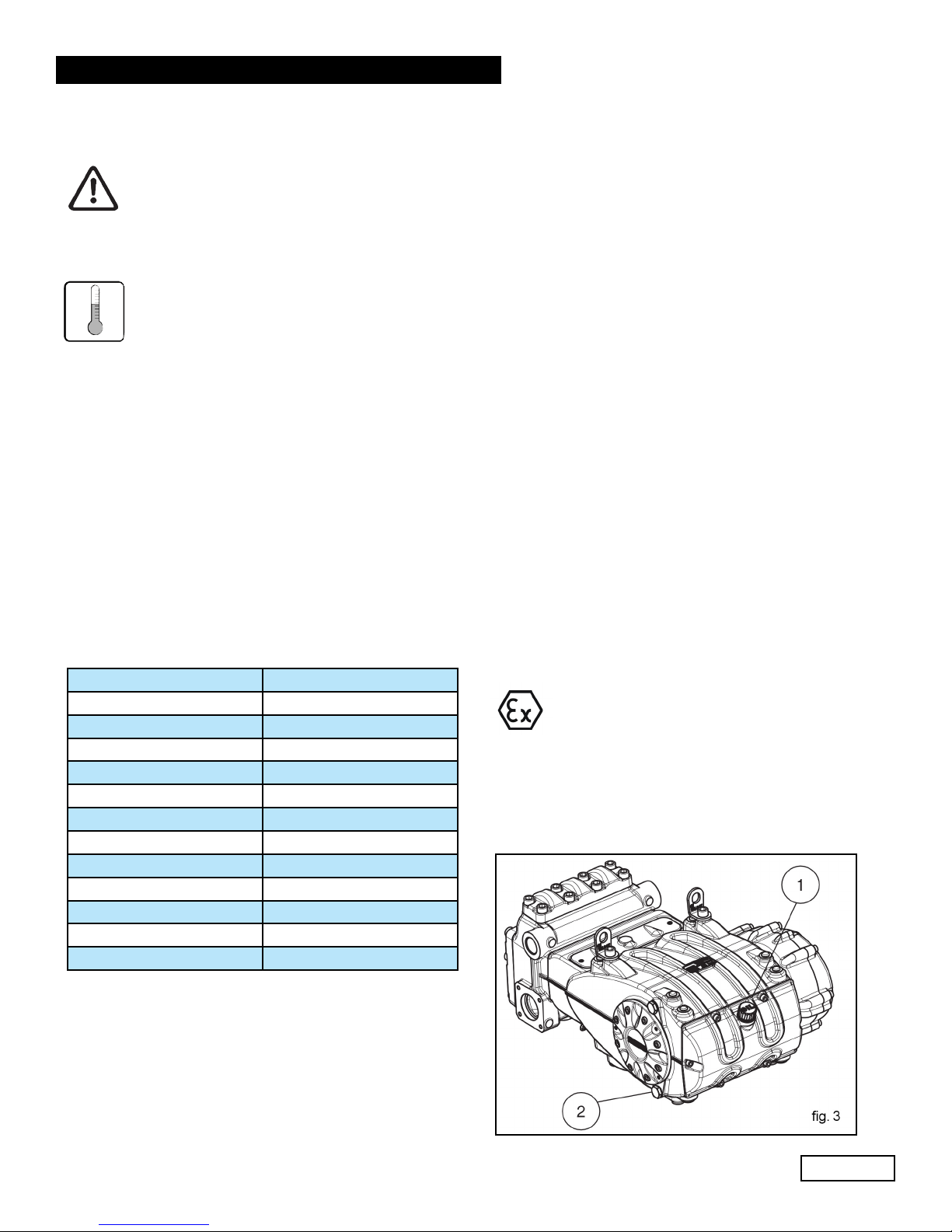

Each pump has a specific label (1, fig. 1) which contains:

Pump model and version

Serial Number

Maximum RPM

Power Hp-kW

Presure - P.S.I.

Flow Rate - GPM

For pumps ordered with the ATEX configuration.

(2, fig. 1) With specific ATEX marking for explosion

protection.

(3, fig. 1) For locating the grounding screw.

Pump model, version and serial number must always

be specified when ordering spare parts.

Ref 310069 Rev. B

07-18

Page 5

GENERAL PUMP

A member of the Interpump Group

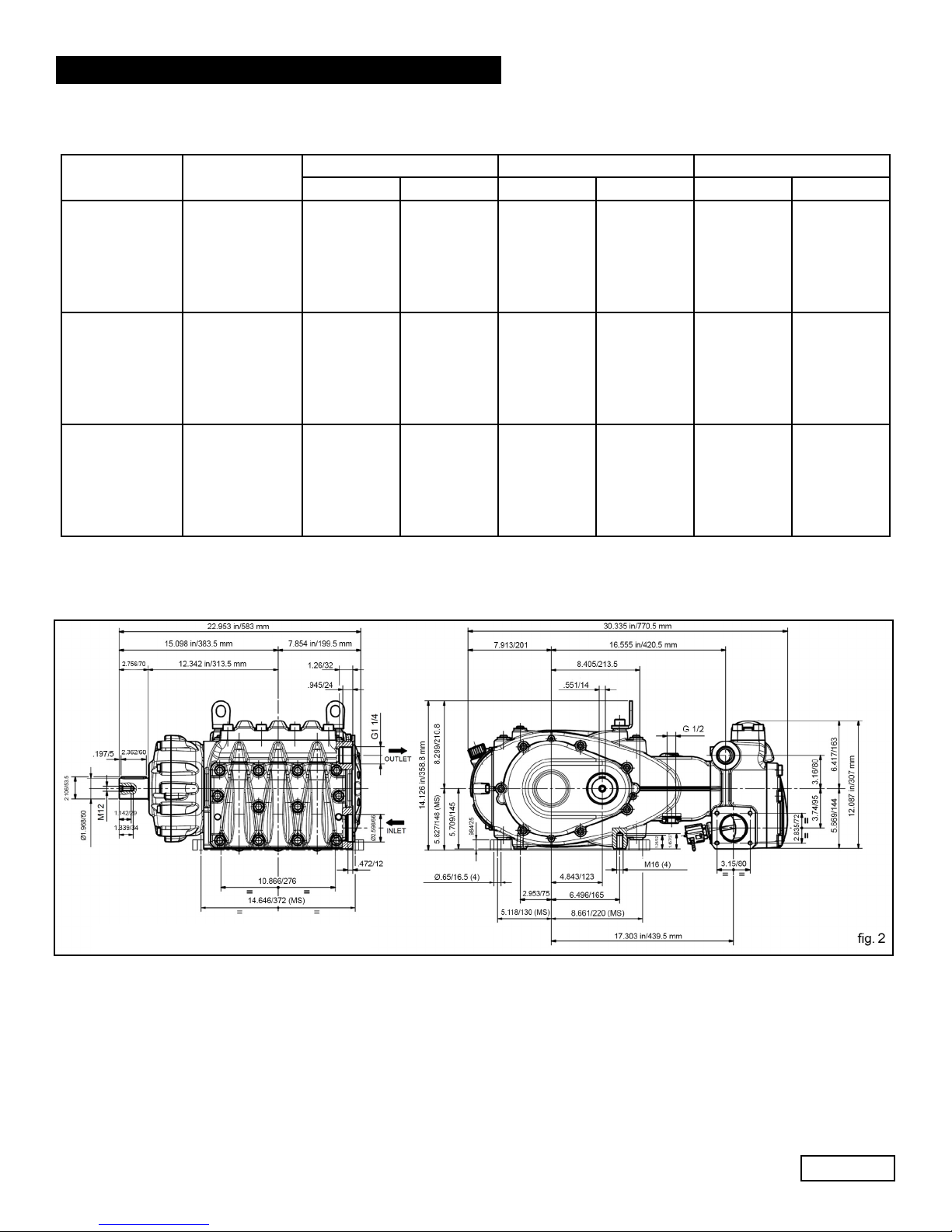

5. TECHNICAL FEATURES

MF SERIES

MODEL RPM

800

1500

MF 45

MF 50

MF 55

1800

2200

2600

800

1500

1800

2200

2600

800

1500

1800

2200

2600

6. DIMENSIONS AND WEIGHT

FLOW RATE PRESSURE POWER

l/min GPM PSI Bar Hp kW

267

267

269

270

270

330

330

332

333

333

399

399

401

403

403

70.6

70.6

71

71.3

71.3

87.2

87.2

87.6

88

88

105.4

105.4

106

106.5

106.5

2900 200

2465 170

2032 140

139

139

140

140

140

146

146

147

147

147

147

145

145

146

147

147

102.2

102.2

102.9

102.9

102.9

107.3

107.3

108.1

108.1

108.1

106.6

106.6

107.3

108.1

108.1

Weight: 551 Lbs./250 Kg.

Ref 310069 Rev. B

07-18

Page 6

GENERAL PUMP

A member of the Interpump Group

7.INFORMATION ABOUT PUMP USE

The MF pump, when not ordered with the ATEX configuration, is designed to operate in environments with

atmosphers that are not potentially explosive, and with filtered water (see par. 9.7)

Other fluids may be used only upon the approval of The Customer Service Department.

MF SERIES

7.1 WaterTemperature

The max water temperature is 104

of up to 1400F (600C) for short periods of time. In this case we advise consulting the Customer Service

Department.

7.2 Max Pressure and Flow Rate

The performance values indicated in the catalog refer to the maximum performance of the pump. Regardless of the power

used, pressure and maximum RPM values indicated on the plate may not be exceeded unless expressly authorized by the

Customer Service Department.

7.3 Minimum Operating Speed

The minimum speed of the crankshaft for these types of pumps is 300 RPM. Any RPM value different from what is

indicated in the performance table (see chapter 5) must be expressly authorized by the Customer Service Department.

7.4

Recommended Lubricant Oil Types & Manufacturers

The pump is delivered with lubricant oil compliant with room temperatures ranging between 32

300C ). Some recommended lubricant types are indicated in the table below; these lubricants are treated with additives

in order to increase corrosion protection and resistance to fatigue. As an alternative, Automotive SAE 85W-90 gearing

lubricants may also be used.

BRAND TYPE

GENERAL PUMP SERIES 220

ARAL Aral Degol BG 220

BP ENERGOL HLP 220

CASTROL Hyspin VG 220, Magna 220

ELF

ESSO NUTO 220

FINA Cirkan 220

FUCHS RENOLIN 220

MOBIL DTE OIL BB

SHELL TELLUS C 220

TEXACO RANDO HD 220

TOTAL CORTIS 220

POLYTELIS 220

0

F (40

0

C).However, it is possible to use the pump at temperatures

0

and 89.60 F (00 and

Set up the pump so that the oil temperature

does not exceed in any case 212°F (100°C)

during pump operation.

Use a temperature probe to be inserted into

the oil drain plug (2, fig. 3). See the “ATEX

EXPLOSION PROTECTION” manual.

ATTENTION: Use only oil with flash point

higher than 392°F (200°C).

Check the oil level by using the oil level dipstick (1, fig.

3). Refill if necessary to top off level. Correct oil level

inspection is done with the pump at room temperature;

oil is changed with the pump at working temperature, by

removing the rear plug (2, fig. 3).

Checking and changing oil is to be carried out as indicated

in Chapter 11. The amount required is 287 oz. (8.5 liters)

for pumps with reduction units and 253 oz (7.5 liters) for

pumps with no reduction units.

Ref 310069 Rev. B

07-18

Page 7

Loading...

Loading...