75 STONE CORE

INSTALLATION MANUAL

(EUROPE)

VERSION 1.6

DATED 18/07/2019

CAUTIONS AND WARNINGS

OVERVIEW

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING: IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE,

INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLATION OR

SERVICING THE EQUIPMENT

IMPORTANT: CONSULT YOUR LOCAL GAS

SUPPLIER FOR A STATEMENT OUTLINING A

PROCEDURE TO BE FOLLOWED IN THE EVENT

YOU SMELL GAS. POST THE STATEMENT IN A

PROMINENT LOCATION.

AREA MUST BE FREE AND CLEAR FROM COMBUSTIBLES AT ALL

TIMES

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATION AIR, INCLUDING VENTILATION OF CYLINDER

ENCLOSURES, IF APPLICABLE

THE CUSTOMER’S BASE MUST NOT BE MADE OUT OF A

COMBUSTIBLE MATERIAL

INSTALLATION MUST CONFORM WITH LOCAL CODES.

THE APPLIANCE MUST BE DISCONNECTED FROM THE GAS

SUPPLY PIPPING SYSTEM DURING ANY PRESSURE TESTING

EXCESS OF 1/2 PSI (3.5KPA).

THE APPLIANCE MUST BE ELECTRICALLY GROUNDED IN

ACCORDANCE WITH LOCAL CODES.

THE STORAGE, HANDLING AND TRANSPORTATION OF ALL

SIZES OF GAS CYLINDERS, MUST BE IN ACCORDANCE WITH

LOCAL CODES. APPLIANCE PRESSURE REGULATOR SHALL BE

INSTALLED TO THE OUTDOORS IN ACCORDANCE WITH LOCAL

CODES.

Symbol

Description

!

An appropriate safety instruction

should be followed or a Warning/

caution to a potential hazard exists

SAVE THESE INSTRUCTIONS

3

CONTENTS

CAUTIONS AND WARNINGS 5

OVEN OVERVIEW 6

FOR YOUR SAFETY 6

PRE-INSTALL 11

EXTRACTION 12

INTRODUCTION 12

OPTION 1 - FLUE 12

OPTION 2 - CANOPY 12

OPTION 2 - CANOPY 13

EXCESSIVE VENTILATION FROM OVER HEAD CANOPIES 13

VENTING 14

INTRODUCTION TO VENTING 14

FACADE CLEARANCE 14

ACCEPTABLE VENTING 15

GENERAL DOS 15

GENERAL DON’TS 15

UNACCEPTABLE VENTING 16

FACTORS AFFECTING FLUE SYSTEM PERFORMANCE 17

EFFECTS FROM ENVIRONMENT 17

FAN AIDED EXTRACTION 17

GAS CLOSURE VENTILATION 18

OVEN SUPPORT STAND ENCLOSURE 18

CLEARANCES 19

CEILING CLEARANCE 19

WALL CLEARANCE 19

BUILD MANUAL 21

PARTS LIST 21

ARCH AND FLOOR 27

DOME AND FLUE 39

INSULATION 49

WOOD FIRED 55

FIRST FIRING 56

INTRODUCTION 56

WOOD FIRING STEPS 56

MAINTENANCE 57

MEASURE OVEN’S TEMPERATURE 57

FINISHED COOKING 57

ASH DISPOSAL 57

CLEANING THE OVEN 57

FLUE SYSTEM MAINTENANCE 57

FUEL OVERLOADING 57

REFUELLING ON TO A LOW FIRE BED 57

COOKING WITH WOOD TIPS 57

WARRANTY 59

Unit 18 & 19, The Runway,

Christchurch, Dorset.

4

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

CAUTIONS AND

WARNINGS

This section details the correct operation

and install of a Gozney Oven.

CAUTIONS AND WARNINGS

OVEN OVERVIEW

FOR YOUR SAFETY

Ensure the oven is installed in accordance with the installation instructions and local

!

building regulations.

Installation and servicing of this product could expose you to glasswool/ceramic

!

fibres as well as calcium silicate dust. Always wear respiratory and eye protection

when installing or servicing this appliance.

It is of utmost importance that the correct air circulation and clearances are

!

complied with at all times. Failure to adhere to the required clearances is a major

cause of oven related fires.

Do not pack clearance spaces with insulation or any other materials that could

!

hamper air circulation.

Never store or use petrol or other such flammable vapours or liquids in the proximity

of this or any other appliance. Always keep the vicinity under and around this

!

appliance free and clear of any combustible materials.

Never use liquid fuels such as petrol, lighter fluid or similar to start, maintain or

!

‘boost’ a fire in the oven.

Ensure the oven is extracted correctly, failure to provide a correct flue/ extraction

!

system for the oven may result in oven damage, fire or even death. Ensure the

correct flue/ extraction system is maintained and cleaned at all times. If uncertain,

do not use the oven.

Oven surfaces are hot whilst in operation. Keep children, pets, members of the

!

public, clothing and furniture away at all times. Direct contact with the oven may

result in skin burns.

Beware of high oven temperatures, ensure you use protective long gloves when

!

handling oven tools. Ensure you use appropriate high heat cookware and oven tools

at all times. Do not place unprotected hands or arms inside the oven whilst the oven

is lit. Wait until the oven is completely cool before removing ashes. Please note,

ashes and embers may retain heat for long periods of time.

Beware of flying sparks from the mouth of the oven, ensure that no combustible

!

materials are within range of the oven at any time. Please refer to this manual’s

section on

Never use ice, water or any other liquids to lower the temperature or extinguish a fire

!

in the oven. This can result in thermal shock and will void manufacturer’s warranty.

Oven Clearances

for more information.

Ensure a fire extinguisher is located at a safe distance from the oven at all times. The

!

correct type of extinguisher for your oven must be used. Please seek advice from a

registered professional for more information.

Always use the Oven Door in accordance with the User Manual. The Door must never

!

be in the Closed position whilst a fire is lit in the oven. Cutting off the oxygen can

cause the fire to erupt suddenly when the door is removed.

w

Unit 18 & 19, The Runway,

Christchurch, Dorset.

6

BH23 4FL.

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

In the event of a power failure, no attempt should be made to operate the oven and the

!

manufacturer Gozney, should be contacted.

For gas models: USE ONLY THE CORRECT GAS FUEL FOR YOUR OVEN BURNER, DO NOT

!

USE ANY PRODUCTS NOT SPECIFIED FOR THIS OVEN. This product must be installed by a

licensed plumber or gas fitter.

Failure to correctly install this oven can result in a fire. Ensure the oven is installed within

!

the manufacturers guidelines. The following operation instructions must be followed to

reduce the risk of a fire.

Do not pack required air spaces with insulation or other materials.

!

Do not store anything directly beneath the oven.

!

It is recommended to install a CO2 alarm and a CO alarm within the same room as the

!

appliance.

It is recommended to use appropriate pizza oven tools to operate the oven safely and

!

efficiently.

Contact Gozney Ltd in the event that your oven requires maintenance or servicing.

7

CAUTIONS AND WARNINGS

DEFRA

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole

or part of the district of the authority to be a smoke control area.

It is an offence to emit smoke from a chimney of a building, from

a furnace or from any fixed boiler if located in a designated smoke

control area. It is also an offence to acquire an “unauthorised

fuel” for use within a smoke control area unless it is used in

an “exempt” appliance (“exempted” from the controls which

generally apply in the smoke control area).

In England appliances are exempted by publication on a list

by the Secretary of State in accordance with changes made to

sections 20 and 21 of the Clean Air Act 1993 by section 15 of

the Deregulation Act 2015. Similarly in Scotland appliances are

exempted by publication on a list by Scottish Ministers under

section 50 of the Regulatory Reform (Scotland) Act 2014.

In Wales and Northern Ireland these are authorised by

regulations made by Welsh Ministers and by the Department of

the Environment respectively.

Further information on the requirements

of the Clean Air Act can be found here at:

https://www.gov.uk/smoke-control-area-rules

Your local authority is responsible for implementing the Clean

Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of Clean Air

Act requirements.

The Gozney 750 oven is an exempt appliance suitable for burning

wood logs and gozney manufactured wood logs in accordance

with the manufacturer instructions.

Unit 18 & 19, The Runway,

Christchurch, Dorset.

8

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

PRE-INSTALL

This section details how to correctly

install a Gozney oven.

PRE-INSTALL

EXTRACTION

INTRODUCTION

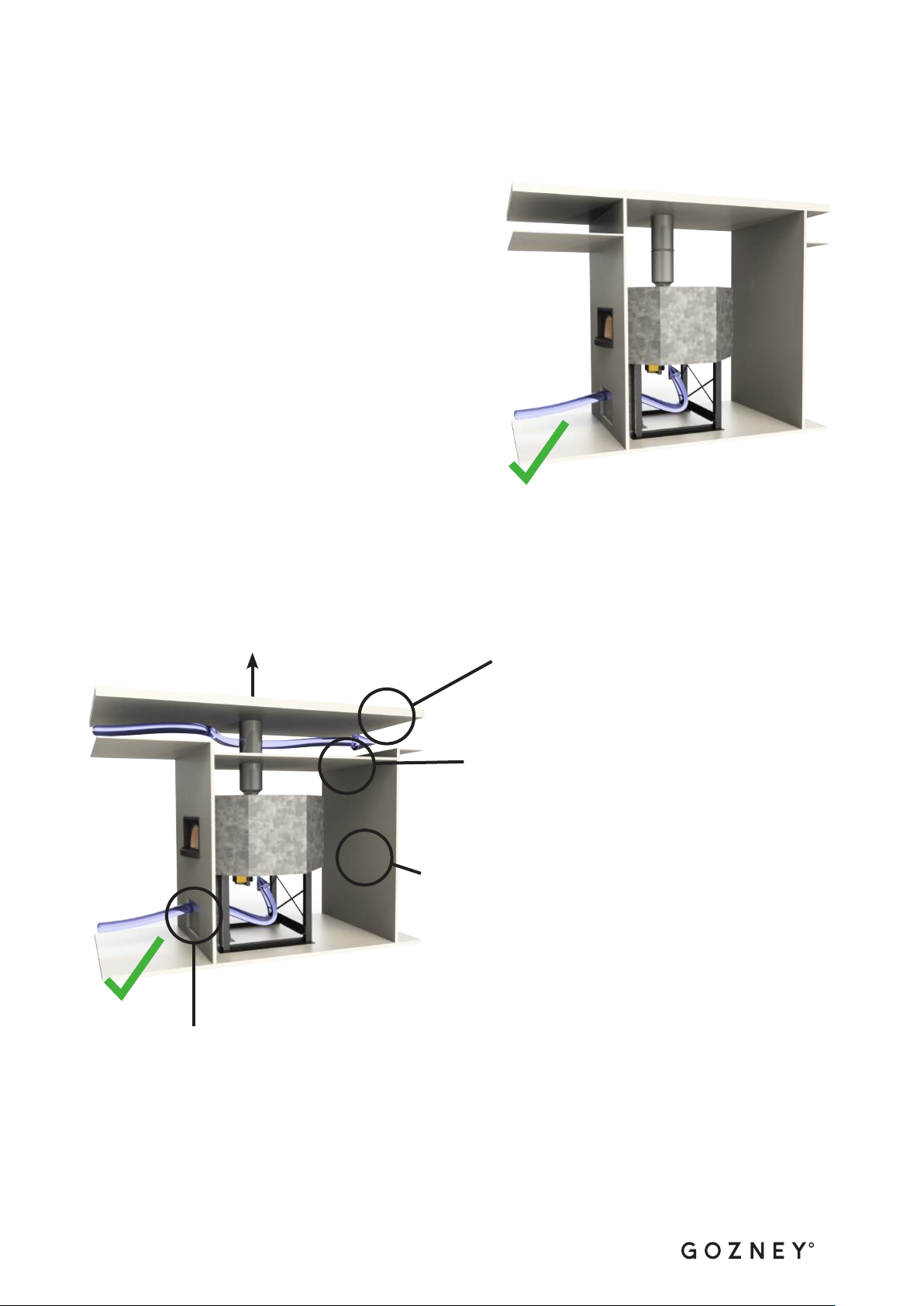

A gas only oven can be extracted with two different methods.

It can have a direct twin walled flue system or an industrial

extraction canopy.

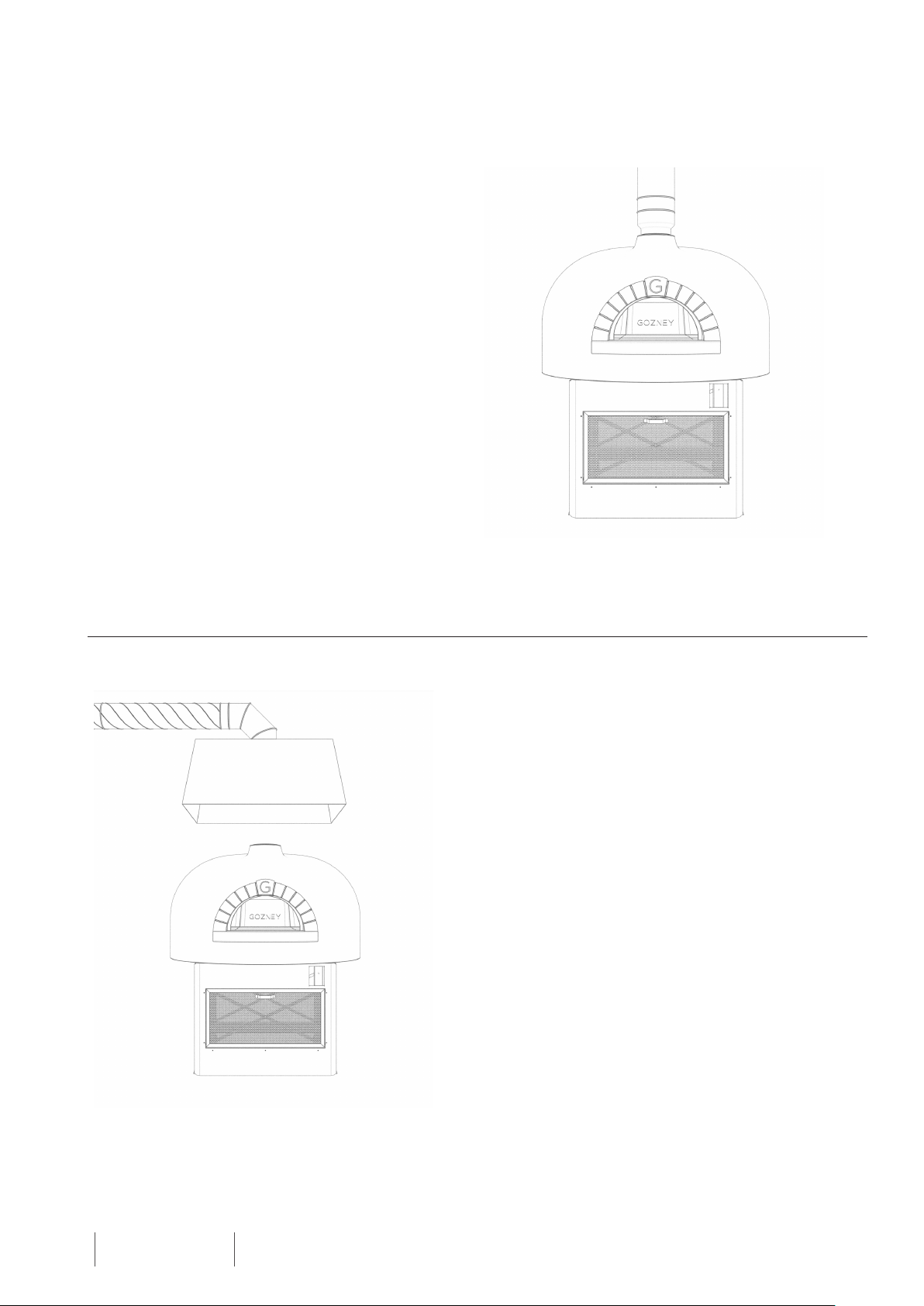

OPTION 1 - FLUE

For a direct flue the oven will require direct connection

to a 150mm (5.9 inch) internal diameter, twin walled flue

system that is appropriate for solid fuel burning. Refer to

the manufacturer’s guidelines regarding installation and

clearances.

Extraction option 1 - Flue

OPTION 2 - CANOPY

When operating a Gozney Oven exclusively on gas, it may be

possible to utilise an existing or new kitchen extract system

via the use of an extraction canopy.

ALWAYS CHECK WITH YOUR EXTRACTION PROVIDER PRIOR

TO USING YOUR OVEN.

When using a canopy for extraction of gas emissions, always

ensure that the canopy is working to a sufficient level prior

to gas burner ignition. In addition, canopy extraction should

remain on for at least 5 minutes after the gas burner flame

has been fully extinguished.

If adding any kind of facade to the oven, always ensure that

proper access is maintained, including sufficient room for

maintenance to the extraction canopy filters.

12

Extraction option 2 - Canopy

Unit 18 & 19, The Runway,

Christchurch, Dorset.

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

WARNING: EMISSIONS FROM THE OVEN WILL BE HOT

AND DISTANCES FROM ANY COMBUSTIBLES (INCLUDING

COMBUSTIBLE EXTRACTION COMPONENTS) MUST BE

ADHERED TO.

!

!

!

!

WARNING: OVEN SHOULD

NEVER BE DIRECTLY

CONNECTED TO A CANOPY

EXTRACTION SYSTEM. ALWAYS

ADHERE TO CLEARANCES FROM

COMBUSTIBLES

WARNING: VENTING OPTION 2

IS FOR A GAS BURNING OVEN

ONLY. NEVER BURN WOOD OR

ANY OTHER SOLID FUELS WHEN

EXTRACTING WITH A CANOPY.

WARNING: ALWAYS ENSURE

THAT A CARBON MONOXIDE

MONITOR IS FITTED WITHIN A

SAFE DISTANCE OF THE OVEN.

WARNING: ENSURE THAT

REGULAR INSPECTION OF

THE EXTRACTION FILTER

IS MAINTAINED. BUILD UP

OF CREOSOTE CAN CAUSE

BLOCKAGES AND RISK OF FIRE

OPTION 2 - CANOPY

It is highly recommended that a sign is placed within close

proximity to warn users never to burn wood in the oven when

extracting with a canopy. Burning wood without the use of a

specialist twin walled flue system can cause breakdown, creosote

build up, melting of the system, and ultimately result in property

damage, injury and in some cases, death.

Dimensions of the canopy must be sufficient for the entirety of

the equipment it is serving, including the oven.

Unless restricted by walls, the dimensions of the canopy must

always exceed the area of the oven mouth and flue terminal

by a minimum of 250mm on each free side, and by 250mm at

the front and rear. These dimensions refer to the inside of the

condensation or stiffening panel / air intake channel of the

canopy.

Gozney Ovens suggest that an extraction canopy is positioned at

a distance of 350mm from the top of the oven dome. Emissions

will be hot when leaving the oven and positioning the extraction

hood at the correct distance from the where emissions exit

is of vital importance. Positioning the canopy closer than

recommended can cause heat damage to the canopy and a

potential risk of fire, whilst positioning the extraction too far away

from the oven is likely to compromise on the canopy’s ability to

extract emissions effectively.

EXCESSIVE VENTILATION FROM OVER

HEAD CANOPIES

In the event that the overhead canopy is extracting too vigorously

it can effect the gas burner’s performance and on occasion,

remove air too quickly from the oven and cause excessive heat

loss. Always check with your extraction provider if you suspect

the canopy is over or under performing.

13

PRE-INSTALL

VENTING

INTRODUCTION TO VENTING

When installing a Gozney commercial gas fired oven there

are some basic guidelines to follow to ensure that the

gas burner is vented well and can operate correctly. Not

adhering to guidelines can be detrimental to the burner’s

performance and can even cause damage to the burner,

wiring and controller components.

The air drawn into the air intake vents should be of the same

atmospheric pressure as that of the oven mouth.

• In order to function properly, the gas burner requires

a sufficient flow of air from the air intake vent on

the burner.

• Drafts and external interruptions to air flow can effect

the efficiency of the gas burner flame or cause it

to fail.

!

!

DAMAGE CAUSED BY NOT

ADHERING TO VENTING

INSTRUCTIONS WILL NOT BE

COVERED BY WARRANTY.

SERVICING & REPAIRS

REQUIRED BY NOT ADHERING

TO VENTING GUIDELINES WILL

NOT BE COVERED BY WARRANTY

• Blocking the air intake will also interrupt the flow of

air and decrease the efficiency and performance of

the burner.

• Always use the correct type of flue

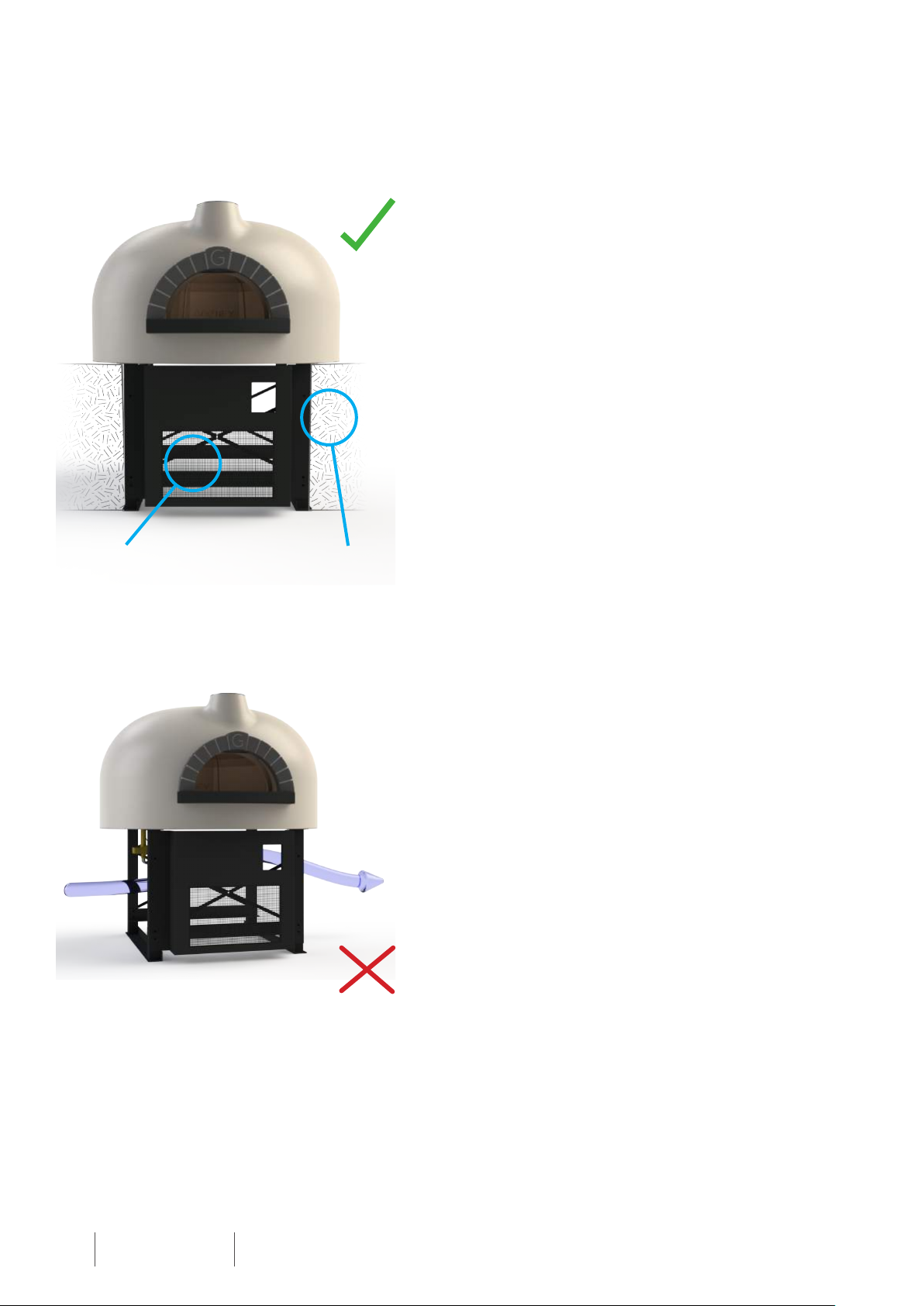

Gozney Classic oven enclosure with adequate venting

FACADE CLEARANCE

When installing a facade to the oven, a minimum of 500

mm x 500 mm or equivalent area air intake is required for

the oven stand enclosure and must be maintained at all

times. This air intake must not be covered or obstructed

with objects and must not be smaller than the dimensions

listed as to provide access and maintenance to the ovens.

Always ensure that the air intake does not become blocked

with insulation or any other materials. Any blockage is likely

to cause interruptions to the air flow and will effect the

performance of the gas burner.

14

IMPORTANT NOTE: IF

ENCLOSING THE OVEN IN A

!

FACADE, YOU MUST LEAVE AN

ACCESS PANEL TO ALLOW FOR

SERVICE OF THE GAS BURNER

SYSTEM AND EXTRACTION

WHERE APPLICABLE.

Unit 18 & 19, The Runway,

Christchurch, Dorset.

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

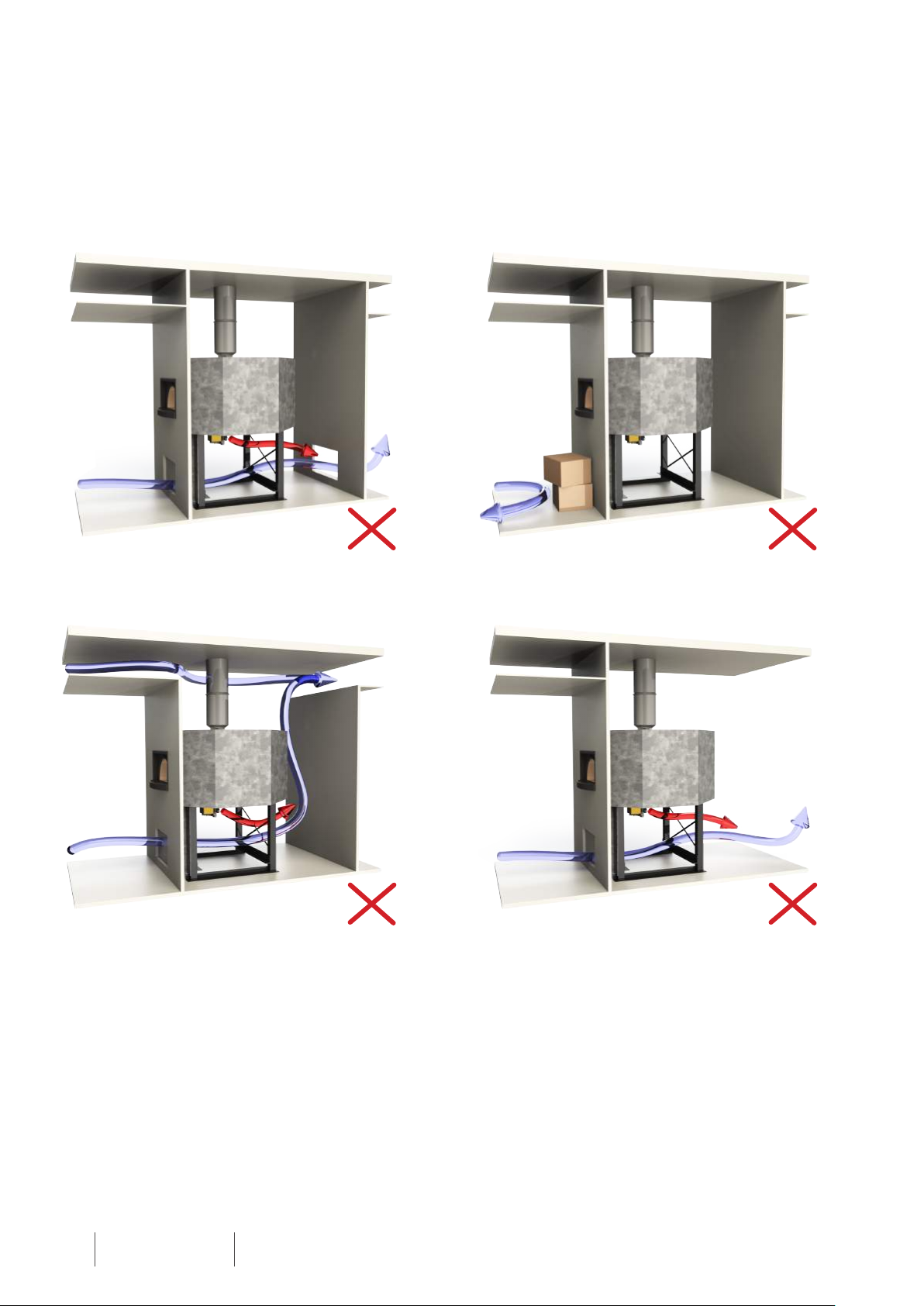

ACCEPTABLE VENTING

It is important that the gas burner has sufficient ventilation

to operate correctly.

GENERAL DOS

• Maintain a clear air flow to the gas burner from the

same area as the oven mouth.

• The gas burner must be accessible at all times.

• Air vent must be no smaller than 500mm x

500mm to allow adequate air flow.

GENERAL DON’TS

• Don’t block the air vent

• Don’t add additional ventilation to the oven enclosure

Type 1 fully sealed enclosure with air vent.

Exhaust Flue Ceiling

Air intake grill and service access panel located

below oven mouth in the enclosure wall.

False ceiling

Additional Ceiling maybe required

if the stud walls finish at the height

of the false ceiling.

Enclosure

walls

Type 2 fully sealed enclosure with air vent

15

PRE-INSTALL

VENTING

UNACCEPTABLE VENTING

Additional Venting or Poorly Sealed enclosure Blocked Air Vent

Enclosure Open to False Ceiling Void No Rear/ceiling/side around Enclosure

16

Unit 18 & 19, The Runway,

Christchurch, Dorset.

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

Flue Extraction

FACTORS AFFECTING FLUE SYSTEM

PERFORMANCE

DOWNDRAFT CONDITIONS

Downdraft is caused when air is forced back down the flue system

and into the oven cavity and room where the oven is situated.

This can be caused by environmental conditions acting on an

incorrectly positioned flue terminal. Downdraft is usually only

apparent in flue systems that do not include fan aided extraction.

EFFECTS FROM ENVIRONMENT

!

Incorrect exhaust draft direction

Correct exhaust draft direction

ALWAYS ENSURE THAT

THE FLUE IS PERFORMING

CORRECTLY PRIOR TO USING

THE OVEN. IF THE FLUE IS NOT

PERFORMING CORRECTLY IT

CAN PUSH EMISSIONS BACK

DOWN INTO THE OVEN CAVITY

AND INTO THE ROOM WHERE

THE OVEN IS SITUATED.

When wind blows across a building, it can cause a difference

in pressure between the entrance and exit of the flue. This will

depend upon the:

• wind speed

• direction of the wind

• position of flue outlet in relation to the building

• location of neighbouring buildings and structures

• geographical features (e.g. hills and valleys).

These can cause or prevent a natural draft to occur in the flue.

Because of this it may cause any one of the following to occur:

• increased flow up the flue

• reduced flow up the flue

• intermittant downdraft.

Because of its nature, wind pressure on occasions can be greater

than the flue draught from open flues. To minimise this effect it is

important that you position the flue terminal where the effect of

the wind is minimised.

FAN AIDED EXTRACTION

If at any moment you believe that the fan is working incorrectly

and pushing emissions back down the flue system, you should

extinguish the oven and extraction immediately and seek further

assistance.

!

INCORRECT EXTRACTION POSES

A SERIOUS RISK OF CARBON

MONOXIDE POISONING.

17

PRE-INSTALL

VENTING

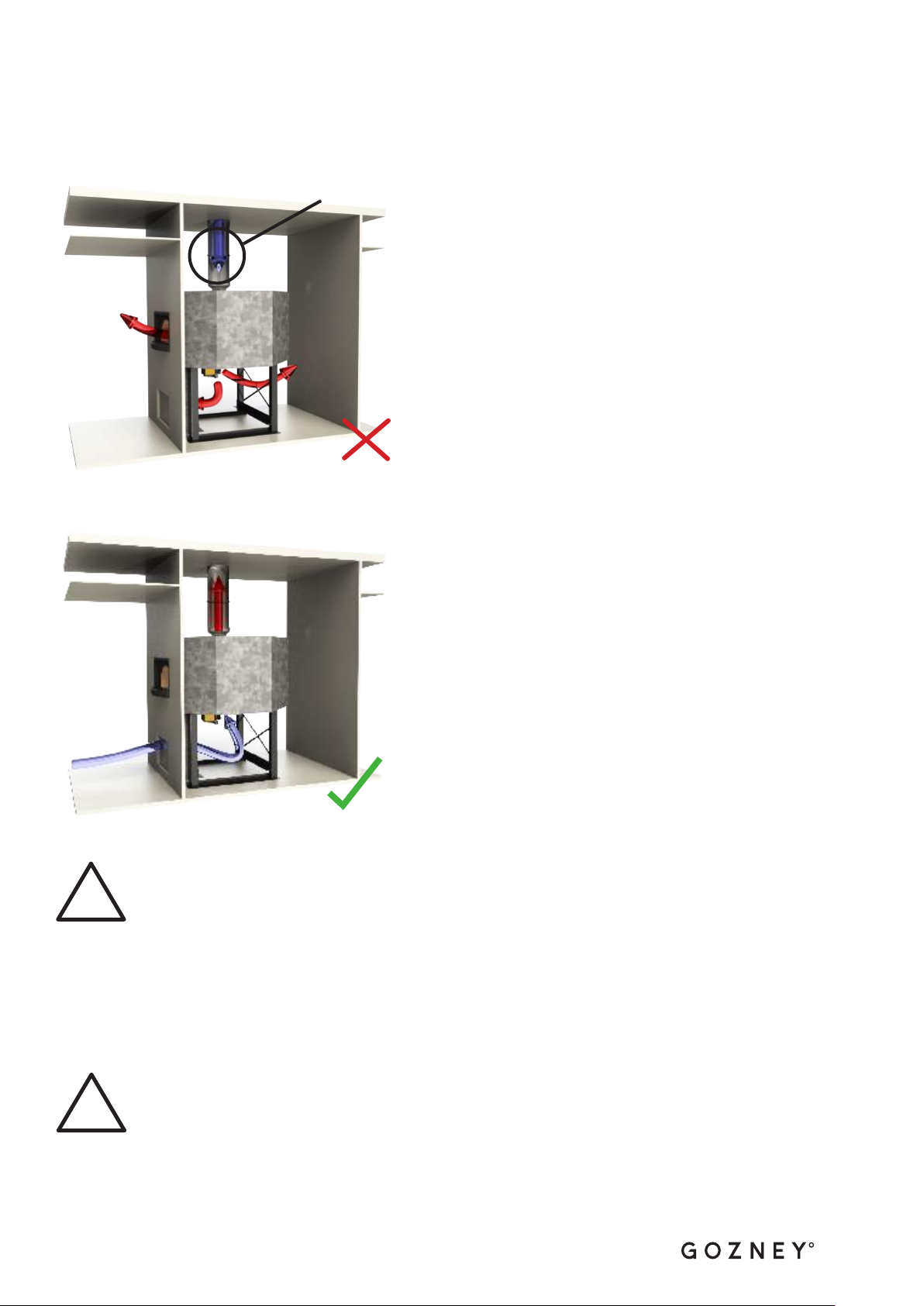

GAS CLOSURE VENTILATION

It is important that the gas burner has sufficient ventilation to

operate correctly.

Gas ovens require clearance air spaces to ensure the gas

burner has adequate air intake. It is necessary to create an air

intake opening, measuring at least 500 mm x 500 mm, located

underneath the oven door/opening, as shown in the diagrams

above. Doing so will ensure that the air required for the gas

burner will be taken from the same atmospheric environment in

which the oven chamber opens. This is required for optimum

gas burner operation.

WARNING: Ensure the air intake opening remains clear from

obstruction at all times. When installing the oven outdoors, the

area around and beneath the oven must be kept clear of grass,

leaves and other combustible materials at ALL times.

Allow vent

Cladding to customers

design

Correct gas enclosure

OVEN SUPPORT STAND ENCLOSURE

In order for the gas burner to operate correctly, the external walls

of the oven support stand must be enclosed on all sides to shield

the gas burner from drafts or other atmospheric interruptions.

Support stand enclosure must be made entirely from noncombustible materials.

18

Incorrect gas enclosure

Unit 18 & 19, The Runway,

Christchurch, Dorset.

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

PRE-INSTALL

CLEARANCES

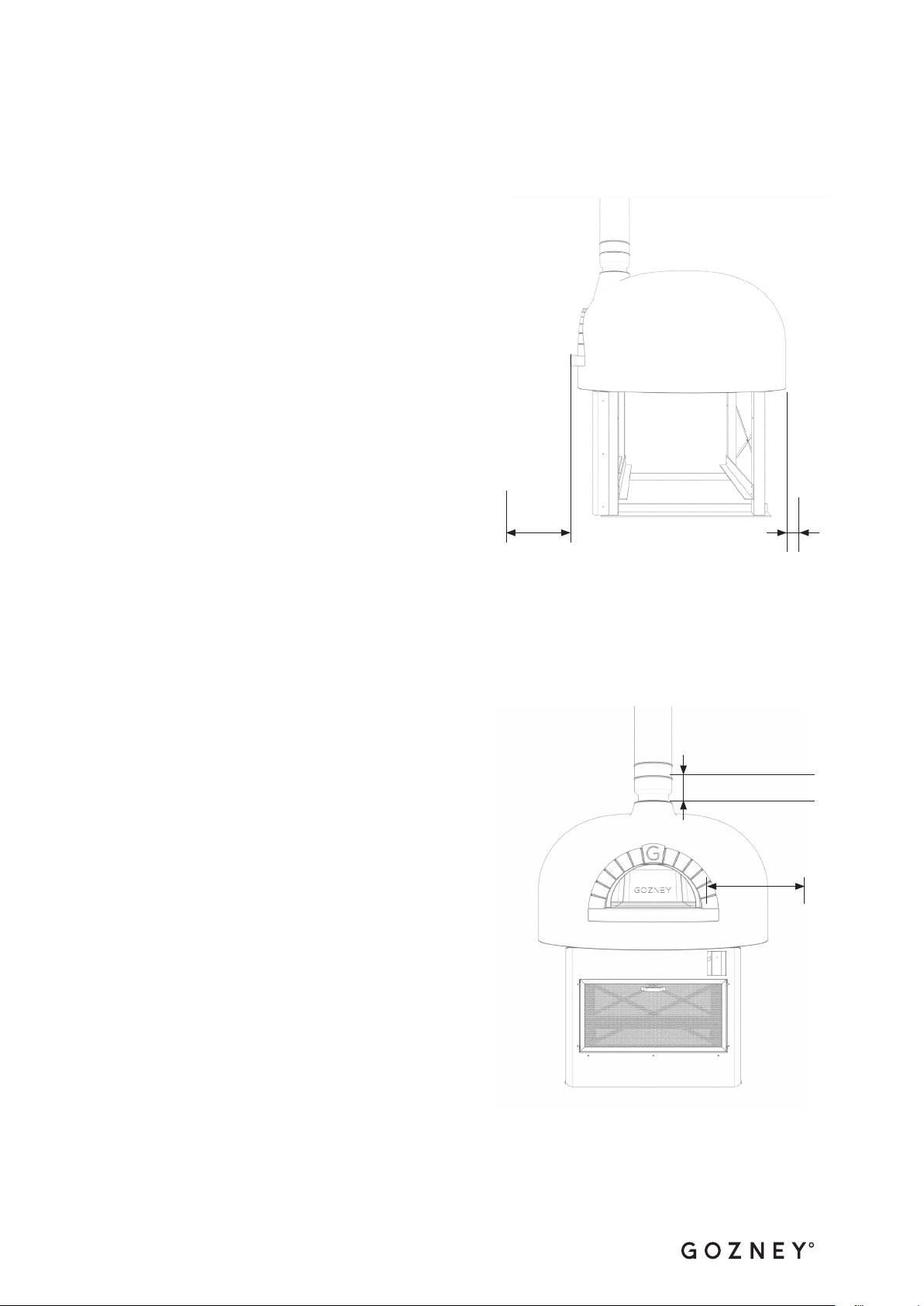

CEILING CLEARANCE

A minimum clearance of 350mm from any combustible

material is required from the top of the oven. These

clearances apply over and above the oven core and

insulation materials, from the outer most extremity of the

oven’s final finished surface.

WALL CLEARANCE

A minimum of 50mm clearance is required from all

sides of the outermost extremity of the oven walls.

If a façade or material is in contact with the oven, it

must be comprised of completely non-combustible

materials. When non-combustible materials are attached

to the oven, the above clearances must be measured

from the outside of those non-combustible materials.

Any materials 750mm to each side of the oven doorway

and above must be constructed of non-combustible

materials.

1000mm 50mm

Side profile of Classic oven.

Red area: minimum clearance

The oven stand should only be installed on a noncombustible floor surface. The non-combustible floor

surface should extend a minimum of 1000mm out in front

of the oven and extend by a minimum of 750mm from either

side of the oven entrance.

When using a gas burning oven the space below the stand

must NEVER be used for storage. This space is required

for air intake of the gas burner. Not maintaining air

access to the burner is a serious risk and could void the

oven warranty.

350mm

750mm

Front profile of traditional oven.

Red area: minimum clearance

19

0.0

Parts List

Liste der Einzelteile

Lista de partes

Elenco delle parti

Liste des pieces

G0518

1x

G0522

1x

G0527

1x

G0521

1x

G0979

1x

Scale: 1:1

G0523

2x

G0980

1x

ZW002ZS001 ZN002 ZS002

6x5x5x6x

Unit 18 & 19, The Runway,

Christchurch, Dorset.

22

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

G0502

1x

G0508

1x

G0509

1x

G0512

1x

G0511

1x

G0510

1x

G0933

1x

G0932

1x

G0818

1x

G0107

12x

23

G0503

1x

G0504

1x

G0505

1x

G0506

1x

G0507

1x

Unit 18 & 19, The Runway,

Christchurch, Dorset.

24

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

25

1.0

Arch and Floor

Bogen und Boden

Arco y piso

Arco e pavimento

Voûte et plancher

4.1

6x

ZS001

6x

4.2

Unit 18 & 19, The Runway,

Christchurch, Dorset.

28

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

4.3

5x 5x

ZN002ZW002

29

4.4

2x

5x

4.5

1x 3x

Unit 18 & 19, The Runway,

Christchurch, Dorset.

30

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

4.6

31

4.7

4.8

1x 2x

Unit 18 & 19, The Runway,

Christchurch, Dorset.

32

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

1.7

ZM006

4.9

1.10

33

4.10

3x

6x

1.10

1.13

50 mm

2”

15 mm

5/8”

4.11

8x

50 mm

2”

Unit 18 & 19, The Runway,

Christchurch, Dorset.

34

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

15 mm

5/8”

4.12

1x

50 mm

2”

4.13

15 mm

5/8”

35

4.14

ZS002

6x

6x

Unit 18 & 19, The Runway,

Christchurch, Dorset.

36

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

37

2.0

Dome and Flue

Kuppel und Kamin

Cúpula y chimenea

Cupola e canna fumaria

Dôme et conduit

2.1

2.2

3x

2.2

2.10

Unit 18 & 19, The Runway,

Christchurch, Dorset.

40

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

2.3

3x

41

2.4

2.5

Unit 18 & 19, The Runway,

Christchurch, Dorset.

42

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

2.6

2.7

43

2.8

Unit 18 & 19, The Runway,

Christchurch, Dorset.

44

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

2.9

45

2.10

Unit 18 & 19, The Runway,

Christchurch, Dorset.

46

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

47

3.0

Insulation

Isolierung

Aislamiento

Isolamento

Isolation

3.1

3.2

Unit 18 & 19, The Runway,

Christchurch, Dorset.

50

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

3.3

Layer 1

Schicht 1

Capa 1

Strato 1

Couche 1

3.4

Layer 2

Schicht 2

Capa 2

Strato 2

Couche 2

3.1

3.3

51

3.5

Layer 3

Schicht 3

Capa 3

Strato 3

Couche 3

3.1

3.3

3.6

Unit 18 & 19, The Runway,

Christchurch, Dorset.

52

BH23 4FL.

w

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

3.7

53

WOOD FIRED

This section details safety and how to

get the most from your oven when firing

on wood.

WOOD FIRED

FIRST FIRING

INTRODUCTION

Before firing the oven for the first time, make sure the render is

completely dry to help minimise excess cracking.

When firing the oven for the first time, it is important to bring

the oven up to temperature slowly. This will help prevent

thermal shock to the refractory parts. It is normal for small

cracks to form on the inside of the dome and on the render on

the outside of the oven during this process. These cracks are

not damaging to the integrity of the oven and do not pose any

cause for concern.

WOOD FIRING STEPS

1. Place a stack of kindling in the centre of the oven

floor. Use ‘chunky kindling’ around 3-4 inches (75100mm) thick and 12 inches (300mm) long.

WARNING: DO NOT OVER FIRE

!

THE OVEN. IF FLAMES EXIT THE

MOUTH OF THE OVEN AND UP

THE FLUE YOU HAVE OVER FIRED

THE OVEN, IF YOU DO SO IT MAY

AFFECT YOUR OVEN WARRANTY.

DO NOT THROW WOOD AGAINST

!

THE BACK OR SIDE WALLS OF

THE OVEN, THIS MAY VOID THE

WARRANTY.

2. Use a natural, taste free, odour free firelighter to light

the stack of dry kindling.

3. Keep gradually add more kindling to the fire. Then

using the turning peel carefully move the fire

around the internal perimeter of the oven to saturate

the sides and back of it.

4. Continue to add wood over the course of a few hours

to fully saturate the oven. A good indicator for

when the oven is fully saturated is when clear

patches that do not have any soot start to form on

internal top of the dome. Then move the fire to the

side of the oven to begin cooking.

5. Once the oven has been cured, future firings can be made

quicker and do not need to be moved around the oven. If

the oven has been left dormant for an extended period of

time it is advised to fire the oven slowly again.

Flame type and

temperature

Recipe examples Wood size and type Using the door

NEVER USE FLAMMABLE LIQUIDS

!

INCLUDING, BUT NOT LIMITED

TO, BARBECUE LIGHTING FLUID,

PETROL OR LIGHTER FLUIDS TO

START OR BOOST A FIRE IN THIS

OVEN. KEEP ALL SUCH LIQUIDS

WELL AWAY FROM THE OVEN

WHILE IT IS IN USE. NEVER USE

UNAPPROVED FUEL IN YOUR

OVEN.

WARNING: BEFORE LIGHTING

!

THE OVEN, ENSURE YOU HAVE

ADHERED TO THE EXTRACTION

SPECIFIED IN THIS MANUAL. IF

YOU ARE UNSURE, DO NOT USE

THE OVEN.

Large rolling flames.

Temperatures of 400C+

Small flames. Temperatures

of 250C-350C

Embers, when the fire has

died down.

Unit 18 & 19, The Runway,

Christchurch, Dorset.

56

BH23 4FL.

Fast cook times such as

Neapolitan pizza.

Finishing meats, charring

vegetables or small items

in a cast iron dishes such as

lasagne.

Slow roasting meats or

vegetables. Baking breads.

w

e

t

www.gozney.com

enquiries@gozney.com

+44 (0)1425 204 999

Lots of small piece of kiln

dried hard wood kindling.

Large pieces of kiln dried

hard wood.

Fire has been left to die

down after the oven has

been saturated.

DO NOT USE THE DOOR.

Ok to use door when ajar do not

close or leave unattended.

Ok to use door in closed or ajar

positions.

WOOD FIRED

MAINTENANCE

MEASURE OVEN’S TEMPERATURE

Using a high heat infrared thermometer gun take a

measurement from the oven floor. The thermometer on the

oven will show the air temperature so may vary to the floor

readings.

FINISHED COOKING

Allow the fire to die down until there are no naked flames

and only embers remain. The door can then be placed in

the closed position to retain heat.

Never use water or other liquids to extinguish the fire within

the oven. This may cause extreme thermal shock to the

refractory and damage the oven.

ASH DISPOSAL

Even after 24 hours ashes can still be hot. When removing

ash from your oven, a non-combustible tool must be used

at all times.

1. Ash should be placed in a metal container, with tight

fitting lid and removed using a non-combustible ash

shovel.

WARNING: DO NOT POUR OR SPRAY

!

LIQUIDS ONTO THE OVEN FLOOR OR

INTO THE OVEN INTERIOR AS THIS

CAN DAMAGE THE OVEN AND COULD

VOID WARRANTY

CAUTION: DISPOSE OF ASHES IN

!

A SAFE MANNER, BEWARE OF HOT

EMBERS EVEN AFTER THE OVEN HAS

COOLED.

REFUELLING ON TO A LOW FIRE BED

If there is insufficient burning material in the firebed to light a

new fuel charge, excessive smoke emission can occur. Refuelling

must be carried out onto a sufficient quantity of glowing embers

and ash that the new fuel charge will ignite in a reasonable

period. If there are too few embers in the fire bed, add suitable

kindling to prevent excessive smoke.

2. The closed container of ashes should be placed in a safe

place until thoroughly cooled.

CLEANING THE OVEN

It is required that the coldest part of the oven floor should

reach temperatures of 343ᵒC (650ᵒF) to be hot enough

for the oven to start “self-cleaning”. To do this raise the

temperature of the oven on to above 360ᵒC (680ᵒF) for a

period of time.

FLUE SYSTEM MAINTENANCE

It is essential that regular cleaning of the flue and extraction

system is undertaken. How you determine a regular cleaning

routine will depend on the fuel burnt and the frequency

of oven use. Failure to maintain a clean extraction or flue

system is a likely source of fire. Ensure a regular cleaning

routine is established and adhered to.

FUEL OVERLOADING

The maximum amount of fuel specified in this manual

should not be exceeded, overloading can cause excess

smoke.

COOKING WITH WOOD TIPS

For the best results and ease of cooking, be sure to use kiln dried

wood with a moisture content of 20% or less, that are less than 4

inches (95mm) thick and 10 inches (300mm) long.

Standard logs (including kiln dried) should not be stored in

a commercial kitchen. Only solid fuels that have been HACCP

certified (Hazard Analysis and Critical Control Point) are permitted

to be stored in commercial kitchen locations. Please contact

Gozney Ovens for more information on HACCP certified fuels.

57

WARRANTY

This section explains the warranty

associated to the oven.

WARRANTY

If you have purchased from us, we offer a warranty on the Products, the details of which are set out below. The warranty terms will

depend on whether you are a consumer or a business customer.

WARRANTY FOR CONSUMERS

1. If you are a consumer purchasing a Product for personal use we warrant to you that for a period of 12 months (in the case of

Roccbox ovens) or 36 months (in the case of other Products) from the date of purchase that your oven will be of satisfactory

quality and reasonably fit for all the purposes for which goods of this kind are commonly supplied; and that, the Products

will match their description or sample.

WARRANTY FOR BUSINESS CUSTOMERS

1.1 If you are purchasing a product for business use we warrant that, for a period of 12 months (in the case of

Roccbox ovens) or 36 months (in case of other Products) from delivery, that your oven will: be free from material

defects in design (unless the design was supplied by you), material and workmanship; and

1.1.2 comply with any agreed specification for the Products.

IMPORTANT INFORMATION RELATING TO WARRANTY CLAIMS

1.2 If you give us notice in writing during the warranty period within a reasonable time of discovery that your oven does not

comply with the warranty set out above; and we are given a reasonable opportunity of examining the Products and we

determine that your oven does not comply with the warranty set out above then we shall, at our option, replace, repair or

refund the price of the defective oven on a pro rata basis based on the market value of the oven at the time any refund is

payable and taking into consideration wear and tear and normal market depreciation in respect of the oven.

1.3 You must provide all information (including photographs where requested) and all assistance reasonably requested by us

in order for us to properly assess your oven.

1.4 We reserve the right to require that faulty ovens be returned to us. In such circumstances we shall refund the cost of carriage

by normal means of returned ovens and the replaced oven will be delivered free of charge by us to you at the original

delivery address. If, following inspection of the returned oven, we determine, acting reasonably, that there has been no

breach of the warranty above we will, if you so request, return the same oven to you at your cost. We shall have no liability

to you (whether the oven is found to breach the applicable warranty or not) for the cost of removing ovens returned to us,

or for re-installing them after they have been returned to you.

1.5 We shall not be liable for the oven’s failure to comply with the warranty above in any of the following events:

1.5.1 you make any further use of the oven after giving notice that it is defective except as permitted in writing by us;

1.5.2 the defect derives from a textual manifest error contained in the order (including typographical errors);

1.5.3 the failure, in our reasonably held belief, is attributable to, caused by or has been substantially aggravated by:

1.5.3.1 any improper use, misuse or unauthorised alteration, storage or installation of the oven by you, your

employees, agents or hired staff;

1.5.3.2 any use of the oven by you, your employees, agents or hired staff in a manner inconsistent with any

specification and our directions; and/or

1.5.3.2.1 damage from external and/or environmental factors (e.g. lightning, electrical surges, floods or incorrect

air flow);.

1.5.4 the defect arises as a result of you not following our instructions in relation to the type of fuel to be used with the

oven, that is, only kiln dried untreated hard wood with a moisture content of 20% or less or our briquettes;

w

Unit 18 & 19, The Runway,

Christchurch, Dorset.

60

BH23 4FL.

www.gozney.com

e

enquiries@gozney.com

t

+44 (0)1425 204 999

1.5.5 the defect arises from the use of salt;

1.5.6 the defect arises from caustic cleaning materials;

1.5.7 the defect arises as a result of fair wear and tear; or

1.5.8 the Products differ from any corresponding specification as a result of changes made to ensure they comply with

applicable statutory or regulatory requirements.

1.5.9 you have modified the oven in any way.

1.6 You shall be liable to cover any reasonable costs incurred by us for the replacement of any oven in the following

circumstances:

1.6.1 the failure of the oven is a result of a defective part or parts not covered by the warranty above;

1.6.2 no fault is found;

1.6.3 the failure of the oven is due to damage caused at your premises;

1.6.4 the failure of the oven is a result of incorrect installation

1.6.5 the failure of the oven is a result of the oven being used in conjunction with other goods not supplied by us;

1.6.6 the failure of the oven is caused by external or environmental factors; or

1.6.7 the failure of the oven is a result of theft, loss or removal of equipment by you or a third party, and such costs may

vary depending upon the location of the oven and any other reasonable costs incurred by us.

1.6.8 the failure of the oven is caused by modifications made by you.

1.7 The warranties in above shall not extend to:

1.7.1 the included tools, safety equipment, pizza peels and finishes such as render;

1.7.2 maintenance items which shall include without limitation airflow adjusters, air and gas mix adjusters, pilot flame

adjusters, door mechanisms, timers, thermometers, lightbulbs, fuses, screws or fasteners; or to

1.7.3 products or components manufactured by third parties, in respect of which we will endeavour to assign for your

benefit such rights (including warranty rights) as we have against the manufacturer.

1.8 Oven cracking is a normal expectation of your wood fired oven and Micro- Mesh Technology ensures the structural integrity

of your oven over time. Hairline cracking is not covered by the warranties above Oven cracks need to exceed 3mm (or over

a £1 coin thickness) to qualify as unusual, smaller hairline cracks are normal. Send us a photo if you need confirmation.

1.9 The warranty above shall apply to any replacement Products supplied by us save that the warranty period for replacement

goods shall be the time remaining on the original Product’s warranty period specified above.

IMPORTANT NOTE

This warranty, and our liability to you, is governed by our standard terms and conditions of sale. Please refer to our standard terms

and conditions at www.gozney.com/terms-conditions In the event of any inconsistency, our standard terms and conditions will

prevail.

61

Loading...

Loading...