Page 1

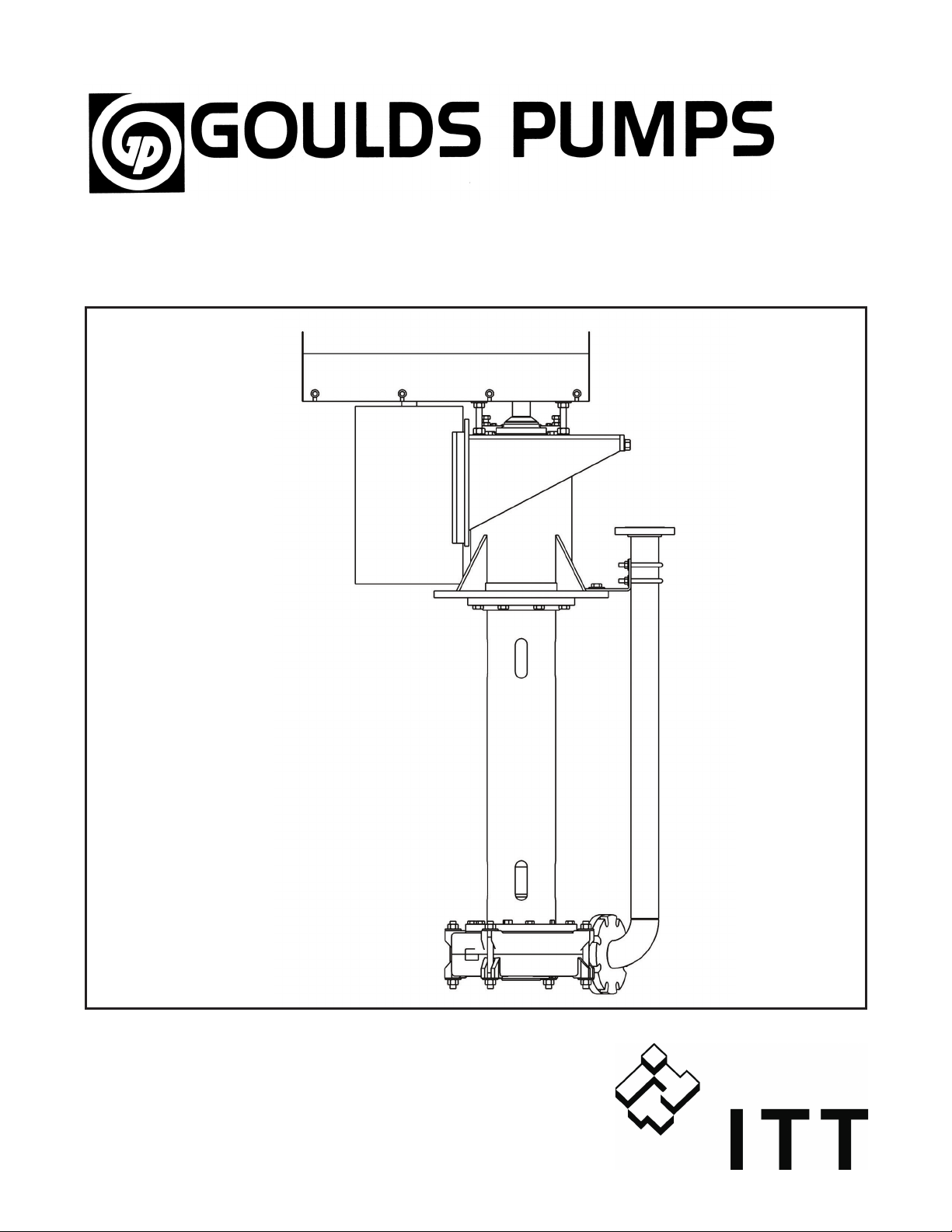

Installation, Operation and Maintenance Instructions

Model VRS

Page 2

2 VRS IOM - 5/08

Page 3

FORWORD

This manual provides instructions on the Installation, Operation, and Maintenance of the Goulds Model VRS Rubber Lined

Vertical Cantilever Pump. This manual covers the standard product plus common options that are available. For special

options, supplemental instructions are supplied. You must read and understand this manual before installing the VRS.

The design, materials, and workmanship incorporated in the construction of Goulds pumps makes them capable of giving

long, trouble-free service. The life and satisfactory service of any mechanical unit, however, is enhanced and extended by

correct application, proper installation, periodic inspection, condition monitoring, and careful maintenance. This instruction

manual was prepared to assist operators in understanding the construction and the correct methods of installing, operating,

and maintaining these pumps.

Goulds will not accept responsibility for damage or delays caused by failure to observe the instructions for

Installation, Operation, and Maintenance contained in this manual.

Warranty is valid only when genuine Goulds parts are used.

Use of the equipment on a service other than stated in the order may nullify the warranty, unless written approval is obtained

in advance from Goulds Pumps, Inc.

To assure proper installation, supervision from an authorized manufacturer’s representative is recommended.

Additional manuals can be obtained by contacting your local Goulds representative.

THIS MANUAL EXPLAINS

Proper Installation

n

Start-up Procedures

n

Operating Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Trouble Shooting

n

Ordering Spares or Repair Parts

n

VRS IOM - 5/08 3

Page 4

4 VRS IOM - 5/08

Page 5

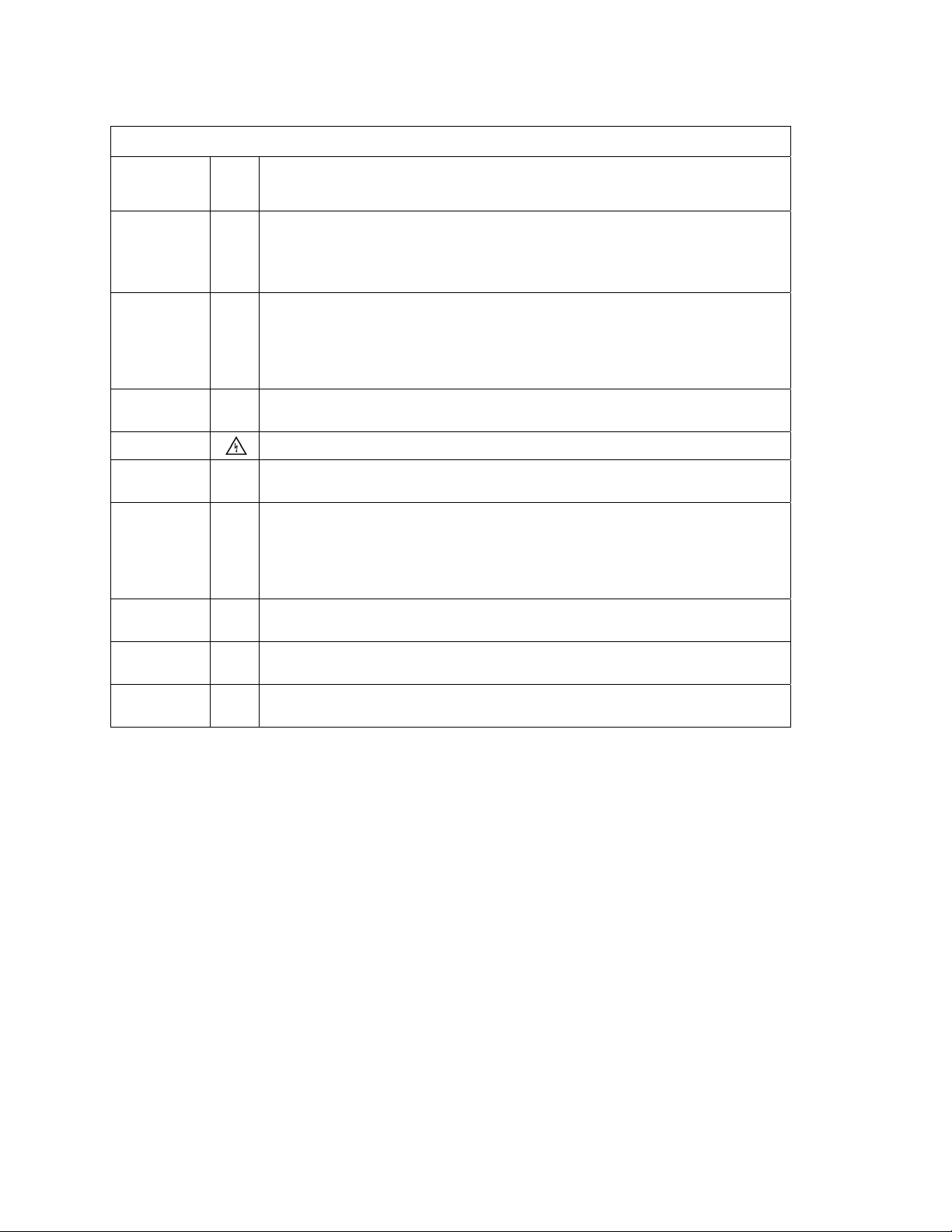

TABLE OF CONTENTS

PAGE SECTION

7 SAFETY

9 GENERAL INFORMATION

11 INSTALLATION

17 OPERATION

19 PREVENTIVE MAINTENANCE

23 DISSASEMBLY AND REASSEMBLY

1

2

3

4

5

6

27 SPARE AND REPAIR PARTS

7

VRS IOM - 5/08 5

Page 6

6 VRS IOM - 5/08

Page 7

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and star t-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 8

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazard o us. An y press ure vessel can explode,

rupture, or discharge its contents if sufficiently ove r press u r i zed causi n g deat h, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 9

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example:

Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoi ded, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 10

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

General Precautions

NEVER use heat to disassemble pump due to risk of explosion from tapped liquid.

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to

trapped liquid.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump without safety devices installed.

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without

prime.

ALWAYS lock out power to the driver befo re per fo rming pump maintenance.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT

Goulds Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with shar p ed ges, especially

impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift

and support equipment can result in serious physical injury and/or equipment

damage. Lift equipment only at specifically identified lifting points or as

instructed in the current IOM. Current manuals are available at

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

Pumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)

must be rated, selected, and used for the entire load being lifted.

Alignment:

WARNING

Shaft alignment procedures must be followed to prevent catastrophic failure of

drive components or unintended contact of rotating parts. Follow coupling

manufacturer’s coupling installation and operation procedures.

S-4

Page 11

WARNING

CAUTION

General Precautions

Before beginning any alignment procedure, make sure driver power is locked out.

Failure to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flan ged con necti on s of t he pump.

This may impose dangerous strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the operation of the pump

resulting in physical injury and damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the

motor is properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat

generation, and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting

the clearance or not following any of the proper procedures can result in sparks,

unexpected heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set

screws loosened prior to setting impeller clearance. Failure to do so could result

in sparks, heat generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified

and must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury

will occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess

heat generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly

certified. Prior to start up, ensure all points of potential leakage of process fluid to

the work environment are closed.

Never operate the pump without liquid supplied to mechanical seal. Running a

mechanical seal dry, even for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the

coupling spacer is removed.

WARNING

WARNING

S-5

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or

discharge valve closed. These conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to pump failure and physical injury.

Page 12

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

General Precautions

Ensure pump is isolated from system and pressure is relieved before

disassembling pump, removing plu gs, ope ni n g vent or drain valves, or

disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to

avoid physical injury and/or equipment damage. Steel toed shoes must be worn at

all times.

The pump may handle hazardous and/or toxic fluids. Observe proper

decontamination procedures. Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical injury. Pumpage must be

handled and disposed of in conformance with applicable environmental

regulations.

Operator must be aware of pumpage and safety precautions to prevent physical

injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent

physical injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,

or 3107, there may be a risk of static electric discharge from plastic parts that are

not properly grounded. If pumped fluid is non-conductive, pump should be

drained and flushed with a conductive fluid under conditions that will not allow

for a spark to be released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion

due to trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause

physical injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can

cause physical injury.

S-6

Page 13

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds represe ntative before proceeding.

Current IOMs are available at

Pumps Sales representative.

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 14

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 15

GENERAL INFORMATION

GENERAL ..........................................9

PUMP DESCRIPTION ...................................9

NAMEPLATE INFORMATION .............................10

RECEIVING THE PUMP .................................10

Storage Requirements ................................10

Handling .......................................10

GENERAL

2

Keep this instruction manual handy for reference. Further

information can be obtained by contacting Goulds Pumps,

Ashland Operations, 500 East Centre St., Ashland, PA

17921 or your local representative.

Goulds Pumps will not be liable for any damages or delay

caused by failure to comply with the provisions of this

instruction manual. This pump is not to be operated at

PUMP DESCRIPTION

The Model VRS pump is a rubber lined vertical cantilever

centrifugal pump. The wet end of the pump contains the

same casing halves, liners, and impeller as a similar size

Model SRL pump.

The impeller is threaded onto the shaft. It is axially

adjustable by means of jacking bolts in the thrust housing

to renew and maintain proper leakage path clearances.

speeds, working pressures, discharge pressures, or

temperatures, nor used on liquids other than stated in the

original order acknowledgment without written permission

of Goulds Pumps.

The heavy duty bearing frame is made of cast iron and

contains a deep groove ball bearing on the inboard side and

an angular contact ball bearing on the outboard side. All

bearings are grease lubricated through fittings on the

bearing frame. The direction of rotation is clockwise when

viewed from the power end to the wet end.

VRS IOM - 5/08

9

Page 16

NAMEPLATE INFORMATION

Every pump has a nameplate that provides information about the pump. The nameplate is located on the bearing frame and

provides information about the pump’s hydraulic characteristics.

Figure 1

Goulds Pumps Nameplate

RECEIVING THE PUMP

Inspect the pump as soon as it arrives. Carefully check that

everything is in good order. Make notes of damaged or

missing items on the receipt and freight bill. File any claims

with the transportation company as soon as possible.

STORAGE REQUIREMENTS

Short Term: (Less than 6 months) Goulds normal

packaging procedure is designed to protect the pump

during shipping in covered trucks and during covered

storage. Upon receipt, store in covered and dry location.

10 VRS IOM - 5/08

Long Term: (More than 6 months) Requires special

precautions. Preservative treatment is applied to bearings

and machined surfaces. Rotate shaft several times every 30

days. Contact driver, coupling and mechanical seal

manufacturers for long term storage procedures.

HANDLING

Use care when moving pump. Lifting equipment must be

able to adequately support the entire assembly.

Page 17

INSTALLATION

SITE/FOUNDATION....................................11

SUMP ............................................11

LEVEL THE PUMP ....................................12

ALIGNMENT PROCEDURE ...............................12

Alignment Checks ..................................12

V-Belt Drive Pumps .................................12

Direct Connect Pumps ................................13

Alignment Criteria ................................13

SetUp.......................................13

Measurement Techniques ............................13

Angular Alignment ................................13

Method 1 - Dial Indicator Method ......................14

Method 2 - Feeler Gauge Method ......................14

Parallel Alignment ................................14

Method 1 - Dial Indicator Method ......................14

Method 2 - Straight Edge Method ......................14

Factors That May Disturb Alignment ......................14

PIPING............................................15

General ........................................15

Final Piping Check ..................................15

3

SITE/FOUNDATION

A pump should be located near the supply of liquid in a

clean dry area free from flooding. The area should provide

adequate space for operation, maintenance, and inspection,

considering complete disassembly and handling of

equipment.

The pump support must be sufficiently substantial and level

to give rigid support to the pump and absorb vibration.

SUMP

The sump must be screened to prevent any foreign objects

from falling into the sump and damaging the pump. The

openings in the screening should be smaller than the

openings in the pump impeller. Guidelines for sump design

can be found in the Hydraulic Institute Standards for sump

design.

The location and size of the mounting holes are shown on

the outline assembly drawing supplied with the pump

order. The bolts which secure the pump to the foundation

should be 1/8” less in diameter than the hole size.

VRS IOM - 5/08

11

Page 18

LEVEL THE PUMP

Leveling the pump is best performed without the drive and

motor installed. Loosen the (4) bearing frame hold down

bolts. Level the bearing housing to within 0.010 in.

(0.25 mm). Place shims between bearing housing and

support so that a gap of no more than 0.002 in (0.05 mm)

exists at any of the (4) anchor bolts when the bolts are

ALIGNMENT PROCEDURE

! WARNING

s

Before beginning any alignment procedur, make sure

driver power is locked out.

Check the alignment twice:

Initial Alignment is done prior to operation when the

•

pump and driver are at ambient temperature.

Final Alignment is done just after operation when the

•

pump and driver are at operating temperature.

NOTE: Proper alignment is the responsibility of the

installer and user of the unit.

Accurate alignment of the equipment must be attained.

Trouble free operation can be accomplished by following

these procedures.

ALIGNMENT CHECKS

Initial Alignment (Cold Alignment)

loose. Tighten the anchor bolts. If a floorplate is used, shim

each anchor bolt location so that a gap of no more than

0.002 in (0.05mm) exists at any of the anchor bolt locations

when the bolts are loose.

Final Alignment (Hot Alignment)

After First Run - To obtain correct alignment when both

pump and driver are at operating temperature. Thereafter,

alignment should be checked periodically in accordance

with plant operating procedures.

V-BELT DRIVE PUMPS

! WARNING

s

Before beginning any alignment procedure, make sure

driver power is locked out.

1. Place a straight edge across the top of the motor and

pump sheaves to measure the angular and parallel

misalignment (see Figure 2). Measure the gap between

the straight edge and the sheaves with feeler gauges. If

the gap exceeds 0.010 in (0.25 mm), adjust the sheaves

along the shafts to correct parallel misalignment and

shim the motor to correct angular misalignment.

2. A dial indicator can be used to check runout on the

periphery and face of each sheave.

Before Connecting Piping - To be sure alignment can be

•

obtained.

After Connecting Piping - To ensure pipe strains have

•

not altered alignment. If changes have occurred, alter

piping to remove pipe strains on pump flanges.

Angular Misalignment Parallel Misalignment Perfect Alignment

Figure 2

V-Belt Drive Alignment

12 VRS IOM - 5/08

Page 19

DIRECT CONNECT PUMPS

ALIGNMENT CRITERIA

Disconnect coupling halves before proceeding with the

alignment. Check for parallel and angular alignment with

either the Dial Indicator Method or the Straight Edge

Method outlined below.

The faces and outside diameters of the coupling halves

must be square and concentric with the bores. Good

alignment is achieved when the dial indicator readings for

both parallel and angular misalignment are 0.003 in

(0.076 mm) total indicator reading (TIR) or less when the

pump and driver are at operating temperature (see Final

Alignment). Figure 3 provides a representation of what to

look for.

Figure 4

Dial Indicator Setup

3

Angular

Misalignment

Direct Connect Alignment

SET UP

! WARNING

s

Before beginning any alignment procedure, make sure

driver power is locked out.

1. Mount two dial indicators on one of the coupling

halves (X) so that they contact the other coupling half

(Y) as shown in Figure 4.

2. Check setting of indicators by rotating coupling half X

to ensure indicators stay in contact with coupling half

Y but do not bottom out. Adjust indicators

accordingly.

Parallel

Misalignment

Figure 3

Perfect

Alignment

Figure 5

Directions of viewing coupling

from top of pump

MEASUREMENT TECHNIQUES

1. To ensure accuracy of indicator readings, always rotate

both coupling halves together so indicators contact the

same point on coupling half Y. This will eliminate any

measurement problems due to runout on coupling half

Y.

2. Take indicator measurements with driver hold down

bolts tightened. Loosen hold down bolts prior to

making alignment corrections.

3. Take care not to damage indicators when moving

driver during alignment corrections.

VRS IOM - 5/08

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A (Angular

Indicator), Figure 3, does not vary by more than 0.003 in

(0.076 mm) as measured at four points on the coupling

periphery 90 degrees apart at operating temperature. There

are two methods outlined below which are acceptable to

achieve alignment.

13

Page 20

METHOD 1 - DIAL INDICATOR METHOD

METHOD 1 - DIAL INDICATOR METHOD

For the following steps, refer to Figure 5.

1. Zero indicator A at position 1 of coupling half Y. Mark

this position on both flanges.

2. Rotate both flanges 180 degrees to position 3. Observe

needle and record reading.

3. Negative Reading - The coupling halves are further

apart at position 3 than position 1.

Positive Reading - The coupling halves are closer at

position 3 than position 1.

4. The angular alignment should not be a problem. If,

however, 0.003 in (0.076 mm) TIR or less is not

attainable, check the motor and motor mount for

perpendicularity to their respective centerlines.

5. Repeat steps 1 through 4 substituting position 2 for

position 1 and position 4 for position 3. Use the same

marks made on the coupling from position 1 and be

sure to turn the coupling halves together.

METHOD 2 - FEELER GAUGE METHOD

For the following steps refer to Figure 5.

1. Insert a feeler gauge at position 1 at the periphery of

the couplings. Mark this position on both flanges.

2. Record the largest gauge size which fits snugly

between the two flanges.

3. Rotate both flanges 180 degrees to position 3.

4. Insert a feeler gauge at position 3 at the periphery of

the couplings.

5. Record the largest gauge size which fits snugly

between the two flanges.

6. Calculate the difference between the readings at

positions 1 and 3. The difference should not be greater

than 0.003 in (0.076 mm). If, however, 0.003 in (0.076

mm) TIR or less is not attainable, check the motor and

motor mount for perpendicularity to their respective

centerlines.

7. Repeat steps 1 through 6 substituting position 2 for

position 1 and position 4 for position 3. Use the same

marks made on the coupling from position 1 and be

sure to turn the coupling halves together.

PARALLEL ALIGNMENT

The unit is in parallel alignment when indicator P (Parallel

Indicator, see Figure 4) does not vary by more than 0.003

in (0.076 mm) as measured at four points on the coupling

periphery 90 degrees apart at operating temperature. There

are two methods outlined below which are acceptable to

achieve alignment.

For the following steps, refer to Figure 5.

1. Zero indicator P at position 1 of coupling half Y. Mark

this position on both flanges.

2. Rotate both flanges 180 degrees to position 3. Observe

the needle and record the reading.

3. Negative Reading - The coupling half Y is shifted

toward position 1. If the value is greater than 0.003 in

(0.076 mm), shift the motor accordingly.

Positive Reading - The coupling half Y is shifted toward

position 3. If the value is greater than 0.003 in (0.076 mm),

shift the motor accordingly.

4. Repeat steps 1 through 3 until indicator P reads 0.003

in (0.076 mm) or less.

5. Once ideal alignment is reached, repeat steps 1 through

4 substituting position 2 for position 1 and position 4

for position 3.

METHOD 2 - STRAIGHT EDGE METHOD

For the following steps, refer to Figure 5.

1. Place a straight edge across the two coupling flanges at

position 1 and mark this position on both flanges.

2. Adjust the motor so that the straight edge rests evenly

on both flanges within 0.003 in (0.076 mm).

3. Rotate both flanges to position 2 and repeat steps 1 and

2.

4. The unit will be in parallel alignment when the straight

edge rests evenly within 0.003 in (0.076 mm) on the

coupling periphery at both positions along the

periphery.

NOTE: Care must be taken to have the straight edge

parallel to the axis of the shafts.

TIP: Since the coupling halves are disconnected, this would

be a good time to check the direction of motor rotation.

FACTORS THAT MAY AFFECT

ALIGNMENT

$

The unit should be checked periodically for alignment.

If the unit does not stay aligned after being properly

installed, it may be due to any of the following causes:

1. Non-rigid foundation

2. Foundation settling

3. Bearing wear

CAUTION

14 VRS IOM - 5/08

Page 21

4. Distortion due to piping loads/strain

5. Distortion of support due to an adjacent heat source

6. Structural changes due to variable loading or other

causes

7. Loose nuts/bolts on the pump and/or drive assembly

PIPING

GENERAL

Review the guidelines for piping in the ‘Hydraulic Institute

Standards’ prior to pump installation.

1. All piping must be supported independently of, and

line up naturally with, the pump flanges.

$

Never draw piping into place by forcing the flanged

connections of the pump. This may impose dangerous

strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely affect the

reliability of the pump.

2. Piping runs should be as short as possible to minimize

friction losses.

3. Arrangements should be made to keep the pump from

back spinning severely during shutdown. In situations

where this occurs, a non-slam check valve should be

installed.

$

Do not start the pump while the impeller is in reverse

rotation.

CAUTION

CAUTION

FINAL PIPING CHECK

After Connecting the Piping to Pump:

1. Turn the shaft several times by hand to confirm free

rotation.

2. Check alignment per the procedure outlined earlier. If

pipe strain is affecting alignment, it must be corrected

prior to startup.

3

VRS IOM - 5/08

15

Page 22

16 VRS IOM - 5/08

Page 23

OPERATION

PREPARATION FOR START-UP ............................17

Pump Support.....................................17

Bearing Lubrication .................................17

Shaft Rotation ....................................17

Correct Driver Rotation ...............................17

Priming ........................................17

START THE PUMP ....................................18

RUNNING PUMP......................................18

General Considerations................................18

Operating At Reduced Capacity ...........................18

Final Alignment ...................................18

PREPARATION FOR START-UP

4

PUMP SUPPORT

Before starting a newly installed pump, check the pump

supports and piping to be certain that they conform to the

specifications in the ‘Installation’ section of this manual.

BEARING LUBRICATION

The bearings must have adequate lubrication. The bearings

were properly filled with grease prior to shipment.

Regrease bearings if pump was disassembled. Refer to the

Maintenance of Bearings section.

SHAFT ROTATION

The pump shaft must turn without any binding or rubbing only the uniform frictional drag of the bearings should be

felt. If the pump does not turn freely by hand, check to

determine the cause of the binding.

CORRECT DRIVER ROTATION

$

Incorrect rotation could result in considerable damage

to the pump. Check the motor rotation when motor is

not connected to the pump shaft.

The direction of rotation of the driver must be checked

before it can be coupled to the pump. The correct direction

of rotation of the pump is indicated on the bearing frame.

Since the impeller is threaded on, reverse rotation could

cause the impeller to unscrew from the shaft.

CAUTION

! WARNING

s

Lock out driver power to prevent accidental start-up

when working on drive.

1. Lock out power to driver.

2. Disconnect coupling from the driver or the belts from

the drive. Make sure no parts are loose.

3. Unlock driver power.

4. Make sure everyone is clear of driver. Jog the driver

just long enough to determine the direction of rotation.

Rotation must correspond to the arrow on the pump.

5. Lockout power to driver and reinstall coupling or

belts.

6. Reinstall coupling or belt drive guard.

PRIMING

The liquid level must be above that shown on the

dimensional drawing supplied with the order.

VRS IOM - 5/08

17

Page 24

START THE PUMP

! WARNING

s

This unit must never be used without proper

installation of the safety guards for rotating parts.

1. Make sure the liquid level is at or above the minimum.

2. Slightly open the discharge valve.

3. Start driver.

RUNNING PUMP

GENERAL CONSIDERATIONS

Driver may overload if the pumpage specific gravity

(density) is greater than originally assumed or the rated

flow rate is exceeded.

Always operate the pump at or near the rated conditions to

prevent damage resulting from cavitation or recirculation.

New bearing housing seals may generate some heat until

broken in. Oil should be applied to them if heat becomes

excessive.

OPERATING AT REDUCED

CAPACITY

$

Immediately observe the discharge gauge after starting

pump. If discharge pressure is not quickly obtained,

stop the driver, check the liquid level and discharge

valve, and attempt to restart.

4. Slowly open the discharge valve.

2. Increased Radial Thrust - Stresses on shaft and

bearings.

3. Heat Build Up - Vaporization causing rotating parts to

score or seize or possible explosion.

CAUTION

FINAL ALIGNMENT

1. Run the pump under actual conditions for a sufficient

length of time to bring the pump and driver up to

operating temperature.

2. Check the alignment per alignment procedure outlined

earlier.

! WARNING

s

Do NOT operate pump below minimum rated flows or

with the discharge valve closed. These conditions can

quickly lead to pump failure and a possible explosion.

Damage caused by reduced flow operations includes:

1. Increased Vibration Levels - Affects bearings.

18 VRS IOM - 5/08

Page 25

PREVENTIVE MAINTENANCE

GENERAL COMMENTS .................................19

MAINTENANCE SCHEDULE ..............................19

Routine Maintenance .................................19

Routine Inspections..................................19

Quarterly Inspections .................................19

Yearly Inspections ..................................19

MAINTENANCE OF BEARINGS ............................20

MAINTENANCE OF SEALS ...............................20

MAINTENANCE OF DRIVE ...............................20

IMPELLER CLEARANCE SETTING ..........................21

PUMP WASHDOWN....................................21

TROUBLESHOOTING GUIDE ..............................21

GENERAL COMMENTS

A routine maintenance program can extend the life of your

pump. Well maintained equipment will last longer and

require fewer repairs. A maintenance record will help

identify the potential causes of problems.

MAINTENANCE SCHEDULE

Routine Maintenance

Bearing Lubrication

•

Vibration Analysis

•

Routine Inspections

Check for unusual noise, vibration and bearing

•

temperature

Inspect pump and piping for leaks

•

Check temperature of bearings

•

Observe discharge pressure

•

Quarterly Inspections

Check hold down bolts for tightness

•

Yearly Inspections

Check pump capacity, pressure, and power. If the

•

pump performance does not satisfy your process

requirements, the pump should be disassembled and

inspected. Worn parts should be replaced.

5

VRS IOM - 5/08

19

Page 26

MAINTENANCE OF BEARINGS

The bearings have been adequately greased prior to

shipment. Under normal operating conditions, add grease

monthly or after 500 operating hours, whichever occurs

first. Add approximately (4) pumps to the inboard fitting

and outboard fitting. Use a lithium based NLGI 2 grease to

match the type used when the pump was initially built.

$

Never mix greases of different consistency (NLGI 1 or

3 with NLGI 2) or different thickener soaps (sodium or

calcium with lithium). The consistency usually

becomes softer and will not provide adequate

lubrication to the bearings.

CAUTION

MAINTENANCE OF SEALS

When it becomes necessary to replace the bearing housing

seals, the housing and the bearings should be flushed clean

with a solvent and repacked with new grease. Overpacking

results in excessive bearing temperature.

NOTE: When regreasing there is a possibility of

impurities entering the bearing housing. The grease

container, the greasing device, and the fittings must be

clean.

Acceptable Greases:

Shell Alvania No. 2

Mobil Mobilux EP No. 2

Texaco Multifak No. 2

Sun Oil Co. Prestige No. 42

American Oil Co. Amolith Grease No. 2

MAINTENANCE OF DRIVE

Well designed and properly installed V-belt drives are

capable of running for years without maintenance. There

are a few points that should be checked periodically.

Sheave Alignment - Alignment must be maintained

•

for full power transmission, minimum vibration, and

long drive life.

Belt Installation - When installing new belts, shorten

•

the center distance between sheaves so that the belts

can be placed on the sheave without the use of force.

Never ‘roll’ or ‘pry’ the belts into place, as this could

damage the belt cords.

Check Belt Fit - Regardless of the belt section used,

•

the belt should never be allowed to bottom in the

groove. This will cause the belts to lose their wedging

action and allow slippage. Replace such sheaves or

belts.

Maintain Proper Belt Tension - Tension is essential

•

for long belt life. Improper tension could cause belt

fatigue and/or hot bearings. Methods of determining

proper belt tension can be obtained from the drive

manufacturer.

Use Belt Guards - Belt guards protect personnel from

•

danger and the drive from contamination. Inspect

periodically to assure that belts do not rub against

guard.

Keep Belts Clean - Dirt and grease reduce belt life.

•

Belt dressing affects performance only temporarily

and is never recommended. Maintaining a clean drive

is a better idea.

If any questions arise pertaining to the drive limitations,

consult the manufacturer.

20 VRS IOM - 5/08

Page 27

IMPELLER CLEARANCE SETTING

A change in pump performance may be noted over time by

a drop in head or flow or an increase in power required.

Performance can usually be restored by adjusting the

impeller clearance. Each application is different and hence

it is necessary to monitor the amount of wear over a certain

period of time in order to set up an adjustment schedule.

Other factors which may indicate that impeller adjustment

is required are:

High thrust bearing temperatures resulting from

•

uneven adjustment of impeller adjusting bolts

Noise and vibration resulting from the impeller

•

rubbing the suction liner

Adjust the impeller clearance with the pump in the vertical

position.

! WARNING

s

Lockout driver power to prevent accidental start-up.

1. Lockout power to driver.

2. Remove the coupling guard (direct drive) or belt guard

(belt drive).

3. “Break” the coupling (direct drive) or remove tension

from belts (belt drive).

NOTE: Lubricate the adjusting bolts and nuts for easy

turning.

4. Loosen the thrust housing adjusting bolt nuts (415A)

and locking capscrews (356B).

5. Turn thrust housing adjusting bolts (9956)

counterclockwise to lower the thrust housing (134A)

until the impeller (101) touches the suction liner

(600R).

6. Turn the thrust housing adjusting bolts (9956)

clockwise to raise the thrust housing (134A) 0.030 in

(0.76 mm), which is the recommended operating

clearance. This adjustment is best measured with a dial

indicator. Adjust each bolt slightly each time around so

that the thrust housing rises evenly and is not cocked

in the bearing frame (228). Make sure the rotating

assembly turns freely throughout the entire rotation.

7. Tighten the thrust housing adjusting bolt nuts (415A)

and locking capscrews (356B), carefully noting that

the dial indicator does not change during final

tightening.

8. Make sure the rotating assembly turns freely

throughout the entire rotation.

9. Align the coupling (direct drive) or sheaves (belt

drive) as outlined in the installation section.

10. Replace the coupling guard (direct drive) or belt guard

(belt drive).

5

PUMP WASHDOWN

The pump is designed to prevent liquid from entering the

bearing frame. Care should be taken, however, to avoid

spraying a high pressure stream directly at the bearing

frame seals.

TROUBLESHOOTING GUIDE

INSUFFICIENT CAPACITY

Pump not primed, check the sump liquid level

•

Speed too low

•

Total head higher than pump rating

•

Insufficient NPSH

•

Impeller passages partially blocked.

•

Wrong direction of rotation

•

Mechanical defects: impeller worn or damaged,

•

defective gasket causing leakage

INSUFFICIENT PRESSURE

Speed too low

•

Air in liquid

•

Wrong direction of rotation

•

Mechanical defects: impeller worn or damaged,

•

defective gasket causing leakage

VRS IOM - 5/08

21

Page 28

MOTOR OVERLOAD

Speed too high

•

Total head lower than pump rating resulting in

•

increased flow

Liquid being pumped has higher specific gravity than

•

that for which it is rated

Mechanical defects: bent shaft, worn bearings, worn

•

impeller or other wet end parts

Solids locked in and around impeller

•

Rubbing or binding of rotating elements

•

PUMP VIBRATION

Foundation not sufficiently rigid

•

Impeller partially blocked causing imbalance

•

Misalignment of thrust housing - housing cocked

•

Mechanical defects: bent shaft, worn bearings, worn

•

impeller

WATER HAMMER

Water hammer is a high pressure surge within a closed pipe

system, created by a rapid change in the flowrate. The most

common is the sudden opening or closing of a valve or

other flow control device. Rapid changes in flowrate can

also occur when there is a sudden change in pump speed.

Extensive damage to the pump and pipeline can result from

water hammer.

22 VRS IOM - 5/08

Page 29

DISASSEMBLY AND REASSEMBLY

PUMP DISASSEMBLY ..................................23

Disassembly of Wet End ...............................23

Disassembly of Power End ..............................24

INSPECTIONS .......................................24

Impeller........................................24

Suction/Gland Liners .................................24

Casing ........................................24

Shaft .........................................24

Column Pipe.....................................24

Bearings .......................................24

Seals, O-Rings, Gaskets ...............................24

REASSEMBLY .......................................25

Reassembly of Power End ..............................25

Reassembly of Wet End ...............................25

Reassembly of Drive .................................25

REFER TO FIGURES AT END OF MANUAL FOR DISASSEMBLY AND REASSEMBLY.

PUMP DISASSEMBLY

DISASSEMBLY OF WET END

! WARNING

s

Lockout driver power to prevent accidental startup.

1. Lockout power supply to motor.

2. Close discharge valve. Drain the pump.

! WARNING

s

The pump may handle hazardous and/or toxic fluids.

Hazardous fluids may be under pressure and may erupt

when pump is opened, particularly if pump is hot.

Allow pump to cool and open cautiously. Skin and eye

protection may be required. Precautions must be taken

to prevent injury or environmental damage. Always

know the contents of the pump prior to opening it.

Failure to do so can result in death, personal injury or

property or environmental damage.

3. Remove piping from pump.

4. Remove coupling guard (direct connect) or belt guard

and belts (belt drive). Remove motor.

5. Remove pump from sump and lay on horizontal

surface.

6. Wash down pump and inside column pipe and casing

with appropriate cleaner.

7. Remove motor mount and coupling (direct drive) or

sheave (belt drive) from the pump.

8. Remove strainer, and/or tailpipe from suction half

casing (100A), if supplied.

9. Remove the discharge pipe assembly (195) from

bearing frame (228) and casing (100A/D), if

applicable.

! WARNING

s

Suction casing (100A) must be supported before

removing tiebolts.

10. Remove the suction half casing (100A). The suction

liner (600R) will be attached to the casing.

11. Remove the suction liner (600R) from the suction half

casing (100A).

! WARNING

s

Do NOT apply heat to the hub or nose of the impeller

due to the danger of explosion.

12. Unscrew the impeller (101) from the shaft (122) by

clamping the shaft and turning the impeller in the

direction for a normal right hand thread (counterclockwise when viewing eye of impeller). After

removing impeller, wrap tape around shaft threads to

6

VRS IOM - 5/08

23

Page 30

avoid damage. Remove impeller washer (199).

13. Mark the orientation of the gland half casing (100D) to

the column pipe (192). Disassemble the gland half casing

from the column pipe by removing capscrews (371W).

The gland liner (600T) will be attached to the casing.

14. Remove the gland liner (600T) from the gland half

casing (100D).

15. Mark orientation of column pipe (192) to bearing

frame (228). Disassemble column pipe from bearing

frame by removing capscrews (371M).

DISASSEMBLY OF POWER END

1. Remove the inboard bearing deflector (123A) by

sliding it down the shaft.

2. Remove the inboard seal plate (119B) with O-ring

(412) and seal (333) from the bearing housing (228).

3. Remove thrust housing locking capscrews (356B).

4. Draw thrust housing (134A) and shaft (122) from

bearing frame (228).

5. Check inboard bearing (168C) to see if it is worn,

loose, or rough and noisy when rotated. Press the

inboard bearing (168C) off the shaft (122) if

replacement is required. It is recommended that a new

bearing be installed after pressing off old bearing,

regardless of condition. The thrust bearing must be

removed from the shaft to replace the inboard bearing

(see step 7).

6. Remove the outboard deflector (123) by sliding up the

shaft.

7. Remove the thrust bearing locking clip (361) from the

thrust housing (134A).

8. Slide thrust housing (134A) up the shaft to remove

from the thrust bearing (112C).

7. Check outboard thrust bearing (112C) to see if they are

worn, loose, or rough and noisy when rotated. Remove

the outboard bearing locknut (136) and lockwasher

(382). Press the outboard bearing (112C) off the shaft

if replacement is required. It is recommended that a

new bearing be installed after pressing off old bearing,

regardless of condition.

8. Check the condition of the inboard seal (333). Remove

the inboard seal from the inboard seal plate (119B) if

replacement is required. It is recommended that a new

seal be installed after pressing out old seal, regardless

of condition.

9. Check the condition of the outboard seal (332). Press

the outboard seal from the thrust housing (134A) if

replacement is required. It is recommended that a new

seal be installed after pressing out old seal, regardless

of condition.

INSPECTIONS

IMPELLER

Replace if excessive erosion, extreme wear, or vane

breakage is evident. Reduction in hydraulic performance

may be caused by excessive wear, especially along the

suction wear ring surface.

SUCTION/GLAND LINERS

Replace if excessive erosion or extreme wear is evident.

CASING

Replace if excessive erosion, corrosion, or extreme wear is

evident.

SHAFT

Check for runout [0.006 in (.015 mm) maximum] to ensure

that the shaft is not bent. Bearing seats and seal areas must

be smooth and free of scratches and grooves. Shaft threads

must be in good condition. Replace if necessary.

COLUMN PIPE

Replace if worn or excessively corroded.

BEARINGS

Replace if worn, loose, or rough and noisy when rotated.

SEALS, O-RINGS, GASKETS

Replace during reassembly.

24 VRS IOM - 5/08

Page 31

REASSEMBLY

REASSEMBLY OF POWER END

1. Clean shaft (122) thoroughly, checking for nicks or

worn areas.

2. Press the outboard seal (332) into the thrust housing

(134A), positioning the seal so that the lip points

upward when installed in the pump. Press the inboard

seal (333) into the inboard seal plate (119B),

positioning the seal so that the lip points downward

when installed in the pump. Lubricate both seals with a

thin coat of grease.

3. Heat the inboard bearing (168C) evenly using an oven,

bearing heater, or hot clean oil bath. The use of a torch

is not recommended. Heat the bearing to 230 degrees F

to 250 degrees F (110 degrees C to 121 degrees C).

Slide the bearing onto the shaft from the drive end

until the bearing shoulder is firmly against the shaft

shoulder. Hold in place until bearing cools and grips

the shaft.

4. Heat the outboard bearing (112C) evenly using an

oven, bearing heater, or hot clean oil bath. The use of a

torch is not recommended. Heat the bearing to 230

degrees F to 250 degrees F (110 degrees C to 121

degrees C). Slide the bearing onto the shaft until the

bearing shoulder is firmly against the shaft shoulder.

Hold in place until bearing cools and grips the shaft.

5. Position bearing lockwasher (382) and locknut (136)

against the bearing shoulder and tighten firmly. Bend

‘tang’ of lockwasher into locknut slot after the locknut

has been tightened.

6. Hand pack the inboard (168C) and outboard bearings

(112C) with recommended grease (see Maintenance

section). Mound a small amount of grease above the

bearing to ensure sufficient lubrication.

7. Insert thrust housing (134A) over the outboard bearing

(112C).

8. Insert bearing locking clip (361) in thrust housing

(134A).

9. Install O-ring (496A) on thrust housing (134A) and

lubricate.

10. Install outboard deflector (123) by sliding it down the

shaft until it is approximately 0.06 in (1.5 mm) from

the thrust housing (134A).

11. Insert thrust housing and shaft assembly into bearing

frame (228). Install thrust housing locking capscrews

(356B), thrust housing adjusting capscrews (9956) and

nuts (415A). Adjust all hardware so that the thrust

housing (134A) bottoms out in bearing frame (228).

12. Install O-ring (412) on inboard seal plate (119B). Slide

inboard seal plate and seal up shaft and mount to

bearing housing (228).

13. Install inboard deflector (123A) by sliding it up the

shaft until it is approximately 0.06 in (1.5 mm) from

the inboard seal plate (119B).

REASSEMBLY OF WET END

1. Slide column pipe (192) up shaft (122) and attach to

bearing frame (228) with capscrews (371M) using the

orientation marks made during disassembly.

2. Attach gland liner (600T) into gland half casing

(100D).

3. Attach gland half casing (100D) to column pipe (192)

using the orientation marks made during disassembly.

4. Remove protective tape from shaft (122) threads.

Install impeller washer (199) on shaft (122). Thread

the impeller (101) onto the shaft until it is snug against

the shaft washer (199). Hold the drive end of the shaft

and firmly tighten the impeller.

5. Move the impeller (101) by means of the thrust

housing adjusting capscrews (9956) toward the drive

end as far as possible.

6. Install the suction liner (600R) into the suction half

casing (100A).

7. Attach the suction half casing (100A) and liner to the

gland half casing (100D).

8. Adjust the impeller using the thrust housing adjusting

screws (9956) so that the impeller turns freely.

9. Assemble the discharge pipe assembly (195) to the

casing discharge (100A/D) and bearing frame, if

supplied.

10. Install strainer and/or tailpipe onto suction half casing

(100A), if supplied.

11. Install unit into sump, being careful not to damage the

strainer, if supplied.

12. Connect piping to pump following procedures in the

‘Installation’ section.

13. Use the impeller clearance setting procedure on page

18 to set proper impeller clearance.

REASSEMBLY OF DRIVE

1. Mount drive onto pump.

2. Align the coupling (direct drive) or sheaves (belt

drive) as outlined previously.

3. Replace the coupling guard (direct drive) or belt guard

(belt drive).

6

VRS IOM - 5/08

25

Page 32

26 VRS IOM - 5/08

Page 33

SPARE AND REPAIR PARTS

REPLACEMENT PARTS PROCEDURE ........................27

RECOMMENDED SPARE PARTS ............................27

REPLACEMENT PARTS PROCEDURE

To ensure against possible long and costly down time

periods, especially on critical services, it is advisable to

have spare parts on hand.

Repair orders will be handled with a minimum of delay if

the following directions are followed:

1. Give model number, size of pump, and serial number.

These can be obtained from the nameplate on the

pump.

RECOMMENDED SPARE PARTS

Light Duty - Random mildly abrasive particles

(1) Seal/Gasket Set

Medium Duty - Light slurries up to 1.2 SG with

moderately abrasive materials

(1) Impeller

(1) Gland Liner

(1) Suction Liner

(1) Seal/Gasket Set

(1) Set Bearings

2. Write plainly the name and part number of each part

required. These names and numbers should agree with

those on the bill of material.

3. Give the number of parts required.

4. Give complete shipping instructions.

Severe Duty - Key process equipment and/or heavy

slurries over 1.2 SG with high heads and highly abrasive

particles

(2) Impeller

(2) Gland Liner

(2) Suction Liner

(3) Seal/Gasket Set

(1) Spare Pump

7

Heavy Duty - Slurries over 1.2 SG with highly abrasive

materials

(1) Impeller

(1) Gland Liner

(1) Suction Liner

(1) Shaft/Bearing Assembly

(3) Seal/Gasket Set

VRS IOM - 5/08

27

Page 34

Figure 6

VRS Sectional

28 VRS IOM - 5/08

Page 35

Figure 7

VRS Wet End Assembly

7

VRS IOM - 5/08 29

Page 36

Figure 8

VRS Power End Assembly

30 VRS IOM - 5/08

Page 37

NOTES

7

VRS IOM - 5/08 31

Page 38

Page 39

Page 40

HOW TO ORDER PARTS

When ordering parts call

1-800-446-8537

or your local ITT Goulds Representative

EMERGENCY SERVICE

Emergency parts service is available

24 hours a day, 365 days/year

Call 1-800-446-8537

Visit our website at www.gouldspumps.com

Form No. IVRS Rev. 5/08

© copyright 2008 Goulds Pumps, Incorporated

a subsidiary of ITT Corporation.

Loading...

Loading...