Page 1

Installation, Operation, and Maintenance Instructions

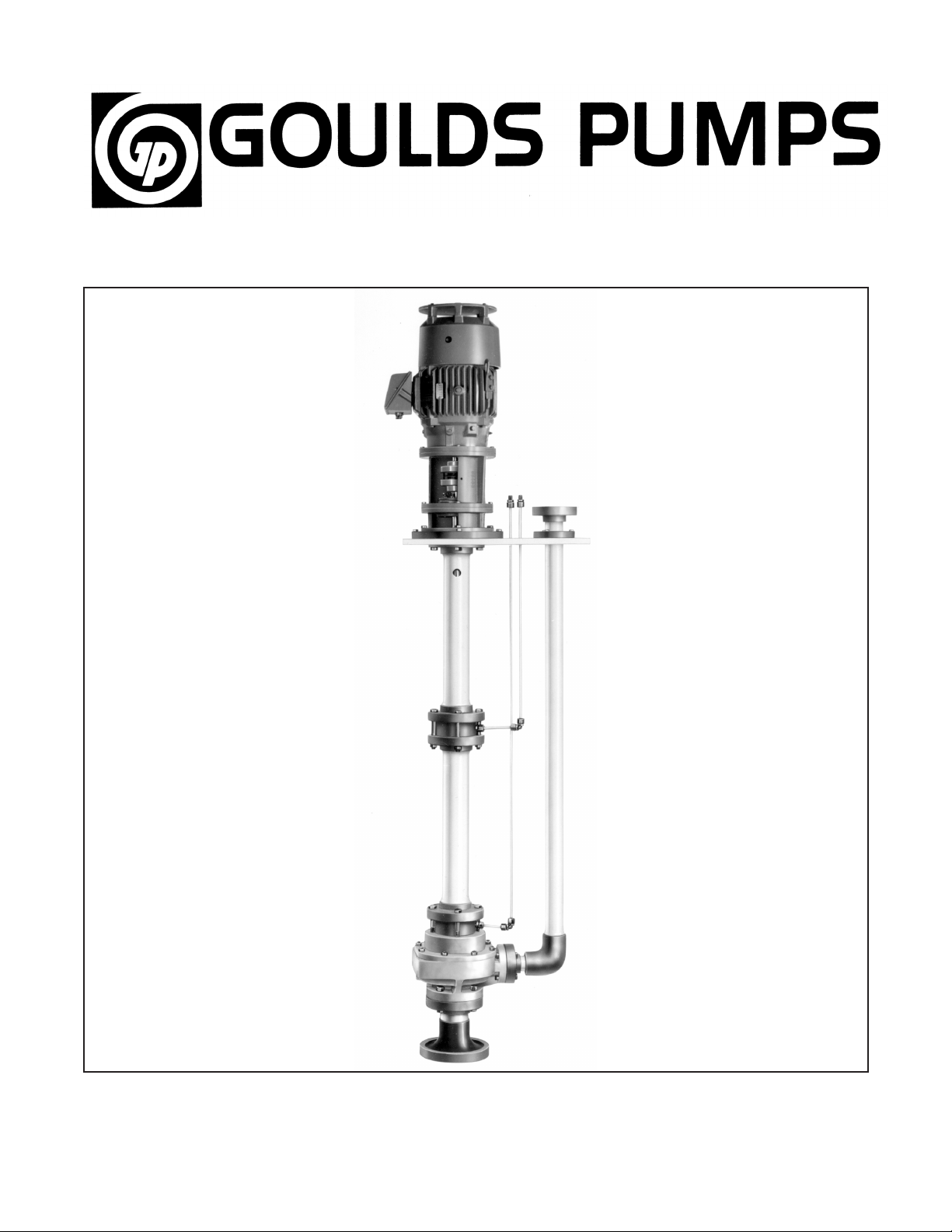

Model NM 3171

Page 2

Page 3

FOREWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the

Goulds Model NM 3171 Non-Metallic Vertical Process Pump. This manual covers the standard

product plus common options that are available. For special options, supplemental

instructions are supplied. This manual must be read and understood before installation

and start-up.

The design, materials, and workmanship incorporated in the construction of Goulds pumps

makes them capable of giving long, trouble-free service. The life and satisfactory service of

any mechanical unit, however, is enhanced and extended by correct application, proper

installation, periodic inspection, condition monitoring, and careful maintenance. This instruction

manual was prepared to assist operators in understanding the construction and the correct

methods of installing, operating, and maintaining these pumps.

Goulds shall not be liable for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this

manual.

Warranty is valid only when genuine Goulds parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty,

unless written approval is obtained in advance from Goulds Pumps.

Supervision by an authorized Goulds' representative is recommended to assure proper installation.

Additional manuals can be obtained by contacting your local Goulds representative or by

calling 1-800-446-8537.

THIS MANUAL EXPLAINS

n

Proper Installation

n

Start-up Procedures

n

Operation Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Trouble Shooting

n

Ordering Spare or Repair Parts

NM 3171 IOM 5/08 3

Page 4

Page 5

TABLE OF CONTENTS

PAGE SECTION

7 SAFETY 1

9 GENERAL INFORMATION 2

11 INSTALLATION 3

13 OPERATION 4

15 PREVENTIVE MAINTENANCE 5

17 DISASSEMBLY & REASSEMBLY 6

21 TROUBLESHOOTING 7

23 PRODUCT DESCRIPTION - SECTIONAL VIEW 8

25 ORDERING SPARE PARTS 9

27 APPENDIX 10

NM 3171 IOM 5/08 5

Page 6

Page 7

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and star t-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 8

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazard o us. An y press ure vessel can explode,

rupture, or discharge its contents if sufficiently ove r press u r i zed causi n g deat h, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 9

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example:

Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoi ded, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 10

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

General Precautions

NEVER use heat to disassemble pump due to risk of explosion from tapped liquid.

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to

trapped liquid.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump without safety devices installed.

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without

prime.

ALWAYS lock out power to the driver befo re per fo rming pump maintenance.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT

Goulds Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with shar p ed ges, especially

impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift

and support equipment can result in serious physical injury and/or equipment

damage. Lift equipment only at specifically identified lifting points or as

instructed in the current IOM. Current manuals are available at

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

Pumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)

must be rated, selected, and used for the entire load being lifted.

Alignment:

WARNING

Shaft alignment procedures must be followed to prevent catastrophic failure of

drive components or unintended contact of rotating parts. Follow coupling

manufacturer’s coupling installation and operation procedures.

S-4

Page 11

WARNING

CAUTION

General Precautions

Before beginning any alignment procedure, make sure driver power is locked out.

Failure to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flan ged con necti on s of t he pump.

This may impose dangerous strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the operation of the pump

resulting in physical injury and damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the

motor is properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat

generation, and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting

the clearance or not following any of the proper procedures can result in sparks,

unexpected heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set

screws loosened prior to setting impeller clearance. Failure to do so could result

in sparks, heat generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified

and must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury

will occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess

heat generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly

certified. Prior to start up, ensure all points of potential leakage of process fluid to

the work environment are closed.

Never operate the pump without liquid supplied to mechanical seal. Running a

mechanical seal dry, even for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the

coupling spacer is removed.

WARNING

WARNING

S-5

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or

discharge valve closed. These conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to pump failure and physical injury.

Page 12

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

General Precautions

Ensure pump is isolated from system and pressure is relieved before

disassembling pump, removing plu gs, ope ni n g vent or drain valves, or

disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to

avoid physical injury and/or equipment damage. Steel toed shoes must be worn at

all times.

The pump may handle hazardous and/or toxic fluids. Observe proper

decontamination procedures. Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical injury. Pumpage must be

handled and disposed of in conformance with applicable environmental

regulations.

Operator must be aware of pumpage and safety precautions to prevent physical

injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent

physical injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,

or 3107, there may be a risk of static electric discharge from plastic parts that are

not properly grounded. If pumped fluid is non-conductive, pump should be

drained and flushed with a conductive fluid under conditions that will not allow

for a spark to be released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion

due to trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause

physical injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can

cause physical injury.

S-6

Page 13

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds represe ntative before proceeding.

Current IOMs are available at

Pumps Sales representative.

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 14

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 15

GENERAL INFORMATION

PUMP DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Importance of Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Special Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Receiving Inspection - Shortages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preservation and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Handling Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PUMP DESCRIPTION

Goulds Model NM 3171 is a vertical centrifugal

submerged or wet pit type pump intended for

installation directly into a sump or vessel vented to

atmospheric pressure.

All pump parts in contact with the pumpage are

constructed of glass reinforced vinylester or

polyester resin, except for the shaft and hardware,

which are of an alloy selected for compatibility with

the pumpage.

The design of the NM 3171 incorporates one or

more non-metallic column (steady) bearings which

require a source of clean liquid for cooling and

lubrication.

GENERAL INFORMATION

IMPORTANCE OF INSTRUCTIONS

This instruction manual is intended to assist those

involved with the installation, operation and

maintenance of Goulds Model NM 3171 pump. It is

recommended that this manual be thoroughly

reviewed prior to installing or performing any work

on the pump or motor.

Study thoroughly and carefully follow the instructions

for installation and operation. Keep this instruction

manual available for reference.

Further information may be obtained by contacting

the Seneca Falls Operations at Goulds Pumps,

Seneca Falls, N.Y. 13148, or your nearest Goulds

sales office or representative.

PRECAUTIONS

s

! WARNING

Personal injuries will result if procedures

outlined in this manual are not followed.

1. Do not over tighten bolts and nuts. Tighten

according to Chart C-l (Appendix I)

2. Never rotate pump in the wrong direction.

Severe pump damage can be caused by wrong

rotation. Proper rotation direction is indicated on

the motor support (240).

3. Never force pump parts during disassembly or

assembly.

4. Avoid undue impacts or shocks to pump while

hanging.

NM 3171 IOM 5/08 9

Page 16

5. Do not put pipe strain or bending moments on

discharge pipe and flange (195C). Piping should

be independently supported and should line up

naturally with the discharge. Use properly

restrained expansion joints between pump and

piping.

6. Clean liquid must be applied to the column

bearings (213) at a rate of 0.25 - 0.50 GPM

(0.16 - 0.32 I/s)

7. Never operate pump without coupling guard

correctly installed.

8. Never operate pump beyond the rated

conditions to which the pump was supplied.

9. Never operate pump without safety devices

installed.

10. Lower ends of pumps must be braced in

turbulent sumps.

11. Always lock out power to the driver before

performing pump maintenance.

PRESERVATION AND STORAGE

Goulds' normal domestic storage preparation is

suitable for protecting the pump during shipment in

covered trucks. It also provides protection during

covered storage at the job site and for a short period

before installation and start-up.

Motor manufacturers should be contacted for their

recommendations on preservation and protection

procedures.

HANDLING TECHNIQUES

! WARNING

s

Pump and components are heavy. Failure to

properly lift and support equipment could

result in serious physical injury, or damage

to pumps. Steel toed shoes must be worn at

all times.

Care should be used in moving pumps. Slings

should be put under the mounting plate (189) to

properly support the unit.

SPECIAL WARNINGS

Goulds Pumps will not be liable for any damages or

delay caused by failure to comply with the provisions

of this instruction manual.

This pump is not to be operated at speeds, working

pressures, discharge pressures or temperatures

higher than, or used with liquids other than, that

stated in original order acknowledgement without

written permission of Goulds Pumps.

RECEIVING INSPECTION - SHORTAGES

Care should be taken when unloading pumps. If

shipment is not delivered in good order and in

accordance with the bill of lading, note the damages

or shortages on both receipt and freight bill. Make

any claims to the transportation company

promptly.

Instruction sheets on various components, as well

as the installation, operation and maintenance

instructions for the pump, are included in the

shipment.

Do not discard!

The best method of lifting unit is with parallel

straps attached to a horizontal bar.

10 NM 3171 IOM 5/08

Page 17

INSTALLATION

LOCATION OF UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PREPARATION FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . 11

INSTALLATION OF UNIT IN PIT. . . . . . . . . . . . . . . . . . . . . . . . 11

Assembly Of Motor To Motor Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connection Of Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Alignment Of Flexible Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

LOCATION OF UNIT

Vertical sump pumps are to be mounted directly in a

sump or tank, with proper support under the

polyester mounting plate (189). Floor space and

head room allotted to the unit must be sufficient for

removal from the sump or tank.

PREPARATION FOR INSTALLATION

Vertical units are shipped completely assembled

except for level controls and motors. Make sure all

bolts are securely tightened. Use a torque wrench

on all non-metallic joints. Bolt and nut torque values

should not exceed those shown in Chart C-l

(Appendix I).

Install level controls per the manufacturer's

recommendations included with the controls.

INSTALLATION OF UNIT IN PIT

Installation must be done with care to avoid damage

and insure proper operation.

1. Check clearance between the unit and pit. There

must be at least 1/2 inch (13 mm) clearance

between the sides of the pumping unit and any

portion of the pit. There should be 5.50 to 7.50

inches (140 to 190 mm) from the bottom of the

pump to the bottom of the pit. Check pump

dimension print for the distance pertaining to

your pump.

2. Guide the assembled pump carefully into pit so

that it does not strike the sides.

3. Once mounting plate (189) is supported on the

pit, shim under mounting plate where necessary

to level unit. Pump must hang vertically to avoid

placing a bending stress on the unit. Bolt

mounting plate to the supports on the pit.

4. Check for free turning. lf shaft (122) does not

turn freely, misadjustment of the discharge pipe

collar (242) may be placing a bending moment

on the column pipe assembly (192), causing the

shaft to bind or rub. lf that occurs, follow the

steps listed below.

a. Loosen set screws (222J). Gently raise or

lower discharge pipe assembly (195) while

rotating shaft (122) by hand in a clockwise

direction until shaft turns freely.

b. Tighten set screws (222J).

NM 3171 IOM 5/08 11

Page 18

ASSEMBLY OF MOTOR TO MOTOR

SUPPORT

If motor is shipped from Goulds' factory, both

coupling halves will be assembled on shafts in their

correct positions. If motor is shipped direct or

furnished by customer, the motor half coupling must

be fitted on motor shaft.

Place motor on motor support (240) and tighten hex

cap screws (370U) snugly.

ROTATION CHECK

Before coupling is connected, motor should be wired

and the direction of rotation checked. A rotation

arrow is located on the motor support (240).

Standard rotation for Model NM 3171 is clockwise

(CW) as viewed from the driver.

! CAUTION

s

Serious damage may result if pump is run in

the wrong direction.

CONNECTION OF PIPING

Connect discharge piping to discharge pipe flange

(195C) above mounting plate (189). This piping

should be independently supported, should align

naturally with the discharge flange, should be as

direct as possible and should have a minimum

number of fittings. A gate valve should be used for

flow control. There should be no strain on the piping,

and a properly restrained expansion joint must be

used.

s

! WARNING

Never draw piping into place by forcing at

the flange connections of the pump. This

may impose dangerous strains on the unit

and adversely affect the operation of the

pump resulting in physical injury and

damage to the equipment.

ALIGNMENT OF FLEXIBLE COUPLING

Check for coupling alignment by laying a straight

edge across both coupling rims at four points 90

degrees apart. When the straight edge rests evenly

at all four points, the coupling will be in correct

alignment. Tighten hex cap screws (370U).

12 NM 3171 IOM 5/08

Page 19

OPERATION

PREPARATION FOR OPERATION . . . . . . . . . . . . . . . . . . . . . . 13

Motor Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Pump Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Check For Free Turning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operating with Surge Conditions In Line . . . . . . . . . . . . . . . . . . . . . . . . . 14

Freezing Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Shutdown Practice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PREPARATION FOR OPERATION

MOTOR BEARINGS

Check and follow motor manufacture's lubrication

instructions.

PUMP BEARINGS

The upper (ball) bearing (112) is greased for life. No

additional lubrication is necessary.

Optional regreasable ball bearing is available upon

request. Grease is applied as standard from Goulds

Pumps. The bearing must be regreased periodically

through the grease fitting in the bearing housing.

The column bearings (213) are a sleeve type and

are made of Rulon, a corrosion resistant

non-metallic bearing material. The bearings must be

lubricated. If the pumpage is clean and suitable for

lubrication, a bypass off the discharge is possible. If

not, a connection above the mounting plate (189)

will be provided for bearing lubrication. A flow of

15-30 GPH (gallons per hour) (57-115 liters per

hour) of clean water is sufficient to lubricate the

bearing.

COUPLING

Assure that the coupling is properly lubricated if

required by the coupling manufacturer's instructions.

CHECK FOR FREE TURNING

Before pump is started, rotate shaft by hand to be

sure it is free. If pump cannot be turned by hand, or

binding or rubbing is noticed, refer to Installation of

Unit in Pit, Step 4 (page 11).

Install coupling guard securely before starting the

pump to prevent serious injury.

PRIMING

The pump must be full of liquid with specified

submergence head above centerline of impeller.

NM 3171 IOM 5/08 13

Page 20

OPERATION

! WARNING

s

Check motor rotation before coupling motor

to pump. Refer to Rotation Check (page 12)

for instructions.

! CAUTION

s

Serious damage may result if pump is run in

the wrong rotation.

START-UP PROCEDURE

1. Connect coupling, following instructions for the

particular make of coupling used. This data is

supplied separately, giving complete instructions

for connection, lubrication, alignment and

maintenance.

2. Check for free turning.

3. Install coupling guard.

! WARNING

s

Never operate a pump without coupling

guard properly installed. Personal injury will

occur if pump is run without coupling guard.

4. Before pump is started, the flushing flow

specified in Precautions, Step 6 (page 10)

should be started. Do not run the pump without

flush to the column bearings (213). (Internal for

clean liquids - external for dirty liquid).

OPERATING WITH SURGE CONDITIONS IN

LINE

If the pump is installed with a quick-acting valve in

the discharge line that could close when the pump is

running, dangerous pressure surges may be built up

that can cause damage to the pump or line. In

services of this kind, some cushioning arrangement

must be provided to protect the pumping equipment.

FREEZING CONDITIONS

If exposed to freezing conditions while the pump is

standing idle, liquid inside the pump must be

drained.

SHUTDOWN PRACTICE

When a check valve is installed in the discharge, the

pump can be shut off without closing any valves.

When no check valve is used, the discharge valve

must be closed before the pump is stopped to

prevent back flow through the pump.

! WARNING

s

When handling hazardous and/or toxic fluids,

proper personal protective equipment should

be worn. If pump is being drained,

precautions must be taken to prevent

physical injury. Pumpage must be handled

and disposed of in conformace with

applicable environmental regulation.

5. Starting: Pump is now ready to start. Start pump

with closed or slightly opened discharge valve.

Open immediately after starting.

OPERATIONAL CHECKS

Inspect pump carefully and frequently during the first

few hours of operation. Check motor for excessive

heating. Check motor for excessive vibration or

unusual noise. Do not run pump at greatly reduced

flow because all the motor power will go into heating

the liquid in the pump and damage may result. If this

condition exists over a long period, the temperature

of the liquid in the pump may increase until the

boiling point is reached. If this occurs, the rotating

parts are exposed to vapor with no lubrication, and

they may score or even seize to the stationary parts.

Continued operation under these conditions may

create an explosive hazard due to the confined

vapor under high pressure and temperature.

14 NM 3171 IOM 5/08

Page 21

PREVENTIVE MAINTENANCE

LUBRICATION

The ball bearing (112) supplied is greased for life.

No further lubrication is required. Column bearings

(213) must be lubricated by an integral pumpage

flush or clean source of external liquid flush.

Consult Goulds Pumps for appropriate option.

Follow motor and coupling manufacturers lubrication

instructions.

VIBRATION

It is good practice to periodically monitor vibration of

the pump. Normally, vibration level will be well below

accepted standards. Of equal importance is that the

vibration level not increase. If a problem with

vibration is encountered, refer to Trouble Shooting

(page 20).

NM 3171 IOM 5/08 15

Page 22

Page 23

DISASSEMBLY & REASSEMBLY

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inspection And Parts Replacement Guidelines . . . . . . . . . . . . . . . . . . . . . . 18

REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Impeller Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DISASSEMBLY

1. Lock out power supply to motor.

! WARNING

s

Lockout driver power ro prevent accidental

start up and physical injury.

2. Shut off valves controlling flow from pump.

3. Disconnect coupling.

4. Disconnect motor and remove from motor

support (240).

5. Remove coupling hub.

6. Remove motor support (240) from adapter (106)

by removing screws (371 S).

7. Disconnect discharge pipe at the discharge

flange (195C).

8. Dismantle flow controls (when furnished).

9. Loosen and remove mounting plate to pump

support structure screws or bolts.

10. Disconnect flush lines (190).

11. Lift pump from sump and if possible,

disassemble in vertical position. If not, lay

horizontally on proper supports.

SAVE ALL BOLTS, NUTS, SCREWS AND

MISCELLANEOUS HARDWARE.

THEY ARE OF ALLOY CONSTRUCTION FOR

CORROSION RESISTANCE.

12. Loosen pipe collar set screws (222J).

13. Remove casing/discharge pipe assembly

screws (371H).

14. Remove casing/discharge gasket (351A).

15. Remove casing/suction tail pipe assembly

screws (372A).

16. Remove suction tail pipe assembly (161) and

gasket (36OY).

17. Remove casing stud nuts (425).

18. Remove casing (100). It may be necessary to

GENTLY tap or pry casing loose from pump

cover (160).

19. Remove pump cover O-ring (4122).

20. Unscrew impeller (101) from shaft (122).

NOTE: Model NM 3171 impellers are threaded

onto the pump shaft and removal can be

difficult unless some means is used to hold

the shaft from turning.

s

! WARNING

Operator must be aware of pump and safety

precautions to prevent physical injury.

s

! WARNING

Pump components can be heavy. Proper

methods of lifting must be employed to avoid

physical injury and/or equipment damage.

Steel toed shoes must he worn at all times.

NM 3171 IOM 5/08 17

21. Remove impeller O-ring (412A).

22. Remove and discard anti-rotation pin (445A).

23. Disconnect any column bearing flush tubing.

24. Unscrew impeller adjustment bolts (370D) and

bearing end cover to bearing housing screws

(37OC).

25. Remove bearing end cover (109) and O-ring

(496).

Page 24

26. Remove bearing locknut (136) and bearing

lockwasher (382).

27. Pull ball (thrust) bearing (112) off shaft (122)

using suitable bearing puller and pulling on

bearing housing (134). DO NOT hammer on

pump shaft to remove bearing.

INSPECTION AND PARTS REPLACEMENT

GUIDELINES

Impeller (101) - Replace if impeller shows excessive

erosion, corrosion, extreme wear or vane breakage.

O-ring groove and impeller hub must be in good

condition. Check impeller balance if possible.

28. Slide pump shaft (122) out of column assembly

(192) from impeller end.

29. Unscrew column pipe assembly/pump cover

screws (371W).

30. Remove pump cover (180). Be sure shaft

column assembly (192) is supported properly.

31. Remove column bearing housing (213).

Note: Pump may be supplied with

intermediate column bearing housing (213),

Remove column/column screws (372B),

column pipe assemblies (192) and

intermediate column bearing housings (213)

individually.

32. Remove column pipe assembly/protector plate

screws (371Z).

33. Remove shaft column assembly (192).

Note: Protector plate (215) should not be

removed unless it is to be replaced. To

remove protector plate, unscrew protector

plate/mounting plate screws (317X). Remove

protector plate from mounting plate (189).

Shaft (122) - Check for runout (.005" MAX) to see

that the shaft has not been bent. Shaft surface and

threads must be in good condition. Replace if

necessary.

Casing (100) - Replace if casing shows excessive

erosion, corrosion or extreme wear.

Lip Seals - upper (332) and lower (333A) - Replace

if damaged.

Vapor Seal (215A) - Replace if damaged.

Column Bearing Assembiy (213) - Assure flush

passages are clean. Check clearance. Assembly

should be replaced if diametral clearance exceeds

0.062" (1.6mm).

Flush Tubing (190) - Make sure tubing is clear and

clean.

Ball Bearing (112) - Renew at each overhaul and

when damage is obvious (through vibration, etc.).

Note: Refer to back cover for information on

ordering spare parts.

18 NM 3171 IOM 5/08

Page 25

REASSEMBLY

This procedure covers reassembly of pumps after

complete disassembly. Make sure all Inspection and

Parts Replacements Guidelines above have been

followed.

All parts should be clean before assembly. This is

especially important for O-ring grooves, threads,

lock fits, and gasket surfaces. Any burrs should be

removed.

If access permits, it is recommended that the pump

be reassembled in vertical position. If necessary to

reassemble pump in horizontal position, be sure to

properly support shaft (122) and shaft column

assembly (192).

NOTE: Refer to Chart C-1 (Appendix I) for

recommended torque values.

1. Slide mounting plate (189) and adapter (108)

assembly on shaft (122) from motor end and

past ball (thrust) bearing (112) location.

2. Install vapor seal (215A).

3. Install new lower lip seal (333A) (if required) in

bearing housing (134).

13. Install impeller adjustment screws (370D) and

bearing end cover screws (370C).

14. Lubricate outside surface of bearing housing

(134).

15. Pull mounting plate (169) and adapter (106)

assembly over bearing housing (134). If

assembly becomes cocked, push apart and

realign. It may be necessary to use bearing end

cover screw (370C) to seat bearing housing in

adapter (106).

16. Slide first column pipe assembly (192) over

pump shaft (122) and fasten to protector plate

(215) using screws (371Z). Make sure vent hole

is toward protector plate.

17. Slide a column bearing assembly (213) against

the column pipe assembly (192) flange. Make

sure drilled flush opening in column bearing

assembly matches location of holes in mounting

plate (169).

18. Install additional column pipes (192) and column

bearing assemblies (213), if any, using screws

(3728).

4. Slide bearing housing (134) on shaft (122). Be

careful not to damage lip seal (333A).

5. Lubricate bearing seat on shaft (122) and slide

the ball bearing (112) as far as possible by

hand. Place pipe or driving sleeve over shaft

against inner race of bearing. Make sure bearing

is "square" on shaft. Tap or press evenly until

bearing is seated firmly against shaft shoulder.

Do not mar the shaft.

6. Place bearing lockwasher (382) on shaft (122).

7. Tighten bearing locknut (136) firmly on shaft

(122).

8. Bend "tang" of bearing lockwasher (382) into

slot in bearing locknut (136).

9. Pull bearing housing (134) over ball bearing

(112) until firmly seated against bearing.

10. Install new upper lip seal (332) (if required) in

bearing end cover (109).

11. Install bearing housing O-ring (496) in groove in

bearing housing (134).

12. Slide bearing end cover (109) over shaft (122)

and seat in bearing housing (134). Be careful

not to damage lip seal (332).

NOTE: All column bearings (213), except the

last, are to be installed with the bearing

retaining lip facing toward the casing (100).

The last, and in cases where there is only

one bearing assembly, install with bearing

retaining lip facing the motor end of the

pump.

19. Place pump cover (180) against last column

bearing (213).

20. Fasten pump cover (180) to column assembly

(192) using screws (371W).

21. Apply O-ring lube to pump cover O-ring (412Z).

22. Place O-ring in groove of pump cover (180).

23. Apply a small amount of O-ring lube to impeller

O-ring (412A).

24. Install O-ring (412A) in impeller (101).

25. Place new anti-rotation pin (445A) in hole in

shaft threads.

NOTE: Make sure shaft threads and impeller

insert threads are clear of dirt, grease and

oil. Scrube or wipe clean if necessary.

NM 3171 IOM 5/08 19

Page 26

26. Spray shaft (122) threads and impeller (101)

threads with Loctite Locquic Primer T or

equivalent. Allow 5 minutes for drying.

27. Coat entire threaded area of shaft (122) threads

with Loctite 242 or equivalent.

28. Evenly disperse three (3) drops of Loctite 242 or

equivalent on impeller (101) threads. Refer to

manufacturers literature for set and cure times.

33. Connect discharge pipe assembly (195) to

casing using screws (371H).

34. Tighten pipe collar set screws (222J). Make sure

no strain has been placed on the pump. Rotate

shaft (122) by hand to assure that no bending is

present.

35. Replace casing/suction tail pipe assembly

gasket (360Y).

29. Screw impeller (101) on shaft (122) assuring

impeller does not touch pump cover (180). If

impeller does hit, use adjusting screws (370D

and 370C) to correct. Firmly tighten impeller

using Shaft Key Wrench.

Model NM 3171 impellers are threaded onto the

pump shafts. Removal can be difficult unless some

means is used to hold the shaft from turning.

Figure 1 shows a "shaft key wrench" which is an

excellent tool for holding the shaft. It provides a

positive restraint and does not damage the shaft or

coupling hub as a pipe wrench could.

The impeller should be turned clockwise by hand,

raising the shaft key wrench off the table or floor.

The impeller should then be given a quick turn

counter-clockwise causing the wrench to impact the

table.

The shaft key wrench has Goulds Part Number

A01676, and customers can order through their local

Goulds Pumps sales office.

36. Align suction tail pipe assembly (161) with

casing (100) and fasten using screws (372A).

37. Reconnect flush tubing (190) to bearing housing

assembly (213).

38. Install motor support (240) on adapter (106)

using screws (371S).

39. Install coupling hub.

Refer to the Installation section for instruction on

installation. Particular attention should be directed

to instructions concerning alignment and rotation.

IMPELLER ADJUSTMENT

Model NM 3171 is designed so that the impeller

must be adjusted relative to the casing.

This procedure should be followed with pump

installed in the vertical position.

1. Disconnect coupling.

2. Loosen bolts (370D) evenly while slowly rotating

the shaft (122) clockwise until impeller contacts

pump casing (100).

3. Place and zero a dial indicator on top of shaft

(122).

Fig. 1

NOTE: NEVER USE HEAT TO ASSIST IN

IMPELLER REMOVAL! The application of

heat to the hub or nose area of the impeller

will not aid in removal and could cause the

hub area to fail.

30. Align casing studs (356A) with pump cover (180)

and fasten with nuts (425). Torque nuts (425) to

values shown in table C-l.

31. Check axial travel of the impeller (101) within the

casing (100) by using the procedure in Impeller

Adjustment (page 20).

32. Replace casing/discharge pipe assembly gasket

(351A).

4. Tighten evenly and alternately impeller

adjustment bolts (370D) until dial indicator reads

.015" (.38mm). This adjustment has raised the

impeller from contact with the casing (100) .015"

(.38mm) which is the normal clearance between

these two parts.

5. Tighten bearing end cover/bearing housing

screws (370C). Rotate shaft (122) to ensure no

binding or rubbing of parts occurs.

6. Install coupling guard.

20 NM 3171 IOM 5/08

Page 27

TROUBLESHOOTING

CAUSES AND CORRECTIVE MEASURES . . . . . . . . . . . . . . . . . . 21

Problem Possible Causes & Corrections

No liquid delivered, not enough liquid delivered or not enough pressure 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 15, 16, 17

Pump works a while and then quits 4, 5, 7, 8, 9, 17

Pump takes too much power 6, 10, 11, 12, 13, 14, 18, 19, 20, 22

Pump is noisy or vibrates 4, 12, 13, 14, 21, 22

1. Priming - Liquid level in sump not equal to or

greater than minimum submergence.

2. Speed too low - check whether motor wiring is

correct and receives full voltage.

3. System discharge head too high - check system

head, particularly friction losses.

4. Suction lift too high - check sump level.

5. Impeller or piping obstructed - check for

obstructions.

6. Wrong direction of rotation - check rotation.

7. Air pocket in casing increasing - increase level in

sump.

8. Float controls operating incorrectly - check

operation.

9. Entrained air or gases in liquid - consult factory.

10. Impeller clearance too great - check for proper

clearance.

11. Impeller damaged - inspect and replace as

required.

13. Shaft bent - straighten or replace as required.

14. Coupling or pump and driver misaligned - check

alignment and realign if required.

15. Impeller diameter too small - consult factory for

proper impeller diameter.

16. Improper pressure gauge location - check

correct position and discharge nozzle or pipe.

17. Pump cover O-ring damaged - check O-ring and

replace as required.

18. Speed too high - check motor winding voltage.

19. Head lower than rating; pumps too much liquid

-consult factory. Install throttle valve, cut

impeller.

20. Liquid heavier than anticipated - check specific

gravity and viscosity.

21. Cavitation - Consult factory. Increase NPSH

available.

22. Bearings worn out - inspect and replace as

required. Assure bearings have proper

lubrication.

12. Rotating parts bind - check internal wearing

parts for proper clearances.

NM 3171 IOM 5/08 21

Page 28

22 NM 3171 IOM 5/08

Page 29

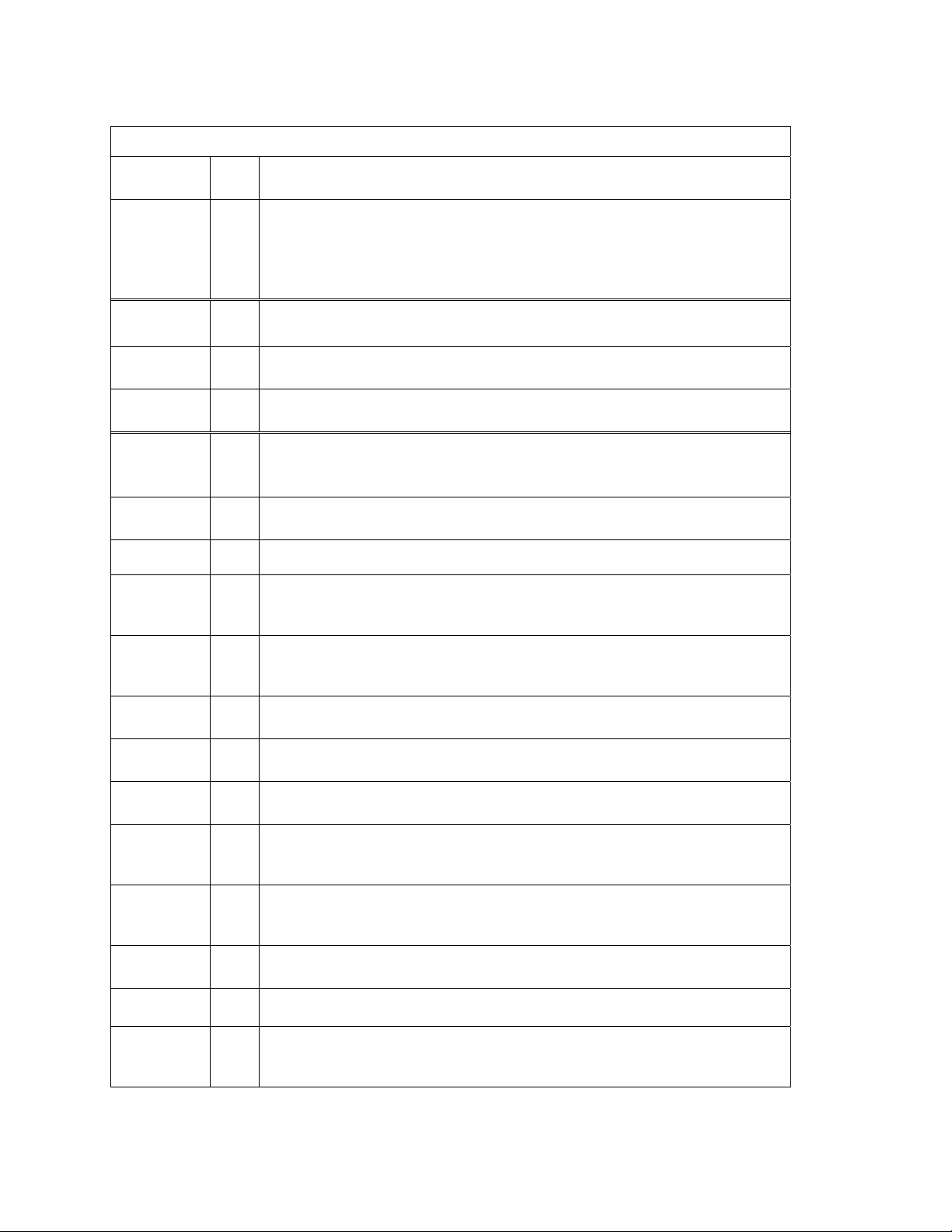

PARTS LIST AND MATERIALS OF CONSTRUCTION

Item

No.

100 1 Casing GMP-2000

101 1 Impeller with Insert GMP-2000/Hastelloy C

108 1 Adapter Cast Iron

109 1 Bearing End Cover Cast Iron

112 1* Ball Bearing Steel

113 1 Grease Relief Fitting (Optional) Steel

122 1 Shaft 316 SS (Optional - Various Alloys)

134 1 Bearing Housing Cast Iron

136 1* Bearing Locknut Steel

180 1 Pump Cover Polyester

181 1 Suction Tail Pipe Assembly Polyester

189 1 Mounting Plate Polyester

190 A 1-4 Flush Tubing Polypropylene

192 A 1-4 Column Pipe Assembly Vinyl Ester

193A 1 Grease Fitting (Optional) Steel

194 1 Suction Strainer Valox

195 1 Discharge Pipe Assembly Vinyl Ester

195C 1 Flange - Discharge Pipe Vinyl Ester

213 A 1-4 * Column Bearing Assembly Polyester / Rulon

215 1 Protector Plate Polyester

215A 1* Vapor Seal Teflon

222J 3 Set Screw - Pipe Collar / Discharge Assembly 304 SS

240 1 Motor Support Cast Iron

242 1 Pipe Collar Polyester

332 1* Lip Seal - Upper Steel / Buna

333A 1* Lip Seal - Lower Steel / Buna

351A 1* Gasket - Casing / Discharge Pipe Assembly Non-Asbestos

356A B 4-16 Stud - Casing / Pump Cover 316 SS (Optional - Various Alloys)

360Y 1* Gasket - Casing / Tail Pipe Assembly Non-Asbestos

370C 3 H-Cap Screw-Bearing, End Cover / Bearing Housing 304 SS

370D 3 H-Tap Bolt - Impeller Adjustment 304 SS

370U C 4-8 H-Cap Screw - Motor / Motor Support 304 SS

371H B 4-8 H-Cap Screw - Casing / Discharge Pipe Assembly 316 SS

371S 4 H-Cap Screw - Motor Support Adapter 304 SS

371W 4 H-Cap Screw - Column Pipe Assembly / Pump

371X 3 H-Cap Screw - Protector Plate / Meeting Plate 304 SS

371Y 4 H-Cap Screw - Adapter / Protector Plate 304 SS

371Z 4 H-Cap Screw - Column Pipe Assembly / Protector

372A B 4-8 H-Cap Screw - Casing / Suction Tailpipe Assembly 316 SS

372B A 0-12 H-Cap Screw - Column / Column 316 SS

372X 3 H-Cap Screw - Pipe Collar / Meeting Plate 304 SS

382 1* Bearing Lockwasher Steel

400 1 Key Coupling Steel

412A 1* O-Ring, Impeller Acid-Resistant Viton

412Z 1* O-Ring, Pump Cover Acid-Resistant Viton

415 3 Locknut - Impeller Adjustment 304 SS

425 B 4-16 Hex, Nut - Casing / Pump Cover Stud 316 SS

445A 1* Pin, Anti-Rotation Nylon

496A 1* O-Ring, Bearing Housing Buna

* Suggested replacement parts

A Quantity determined by pump setting

B Quantity determined by pump size

C Quantity determined by motor size

Qty Per

Pump

Part Name Material

316 SS

Cover

316 SS

Plate

NM 3171 IOM 5/08 23

Page 30

24 NM 3171 IOM 5/08

Page 31

ORDERING SPARE PARTS

SPARE PARTS

To insure against possible long and costly down

time periods, it is advisable to have spare parts on

hand.

The recommended spare parts for the NM 3171 are:

1. Impeller (101)

2. Shaft Assembly (122)

3. Ball Bearing (112)

4. Column Bearing Assembly (213)

5. Complete set of O-rings and gaskets

INSTRUCTIONS FOR ORDERING SPARE

PART S

Repair orders will be handled with a minimum of

delay if the following directions are allowed:

1. Give model number, size of pump, and serial

number. These can be obtained from the

nameplate.

2. Write plainly the names, part numbers and

materials of the parts required. The names and

numbers should agree with those on the

sectional view in Section VIII.

3. Give the number (quantity) of each part

required.

4. Give complete shipping instructions.

NM 3171 IOM 5/08 25

Page 32

Page 33

APPENDIX I

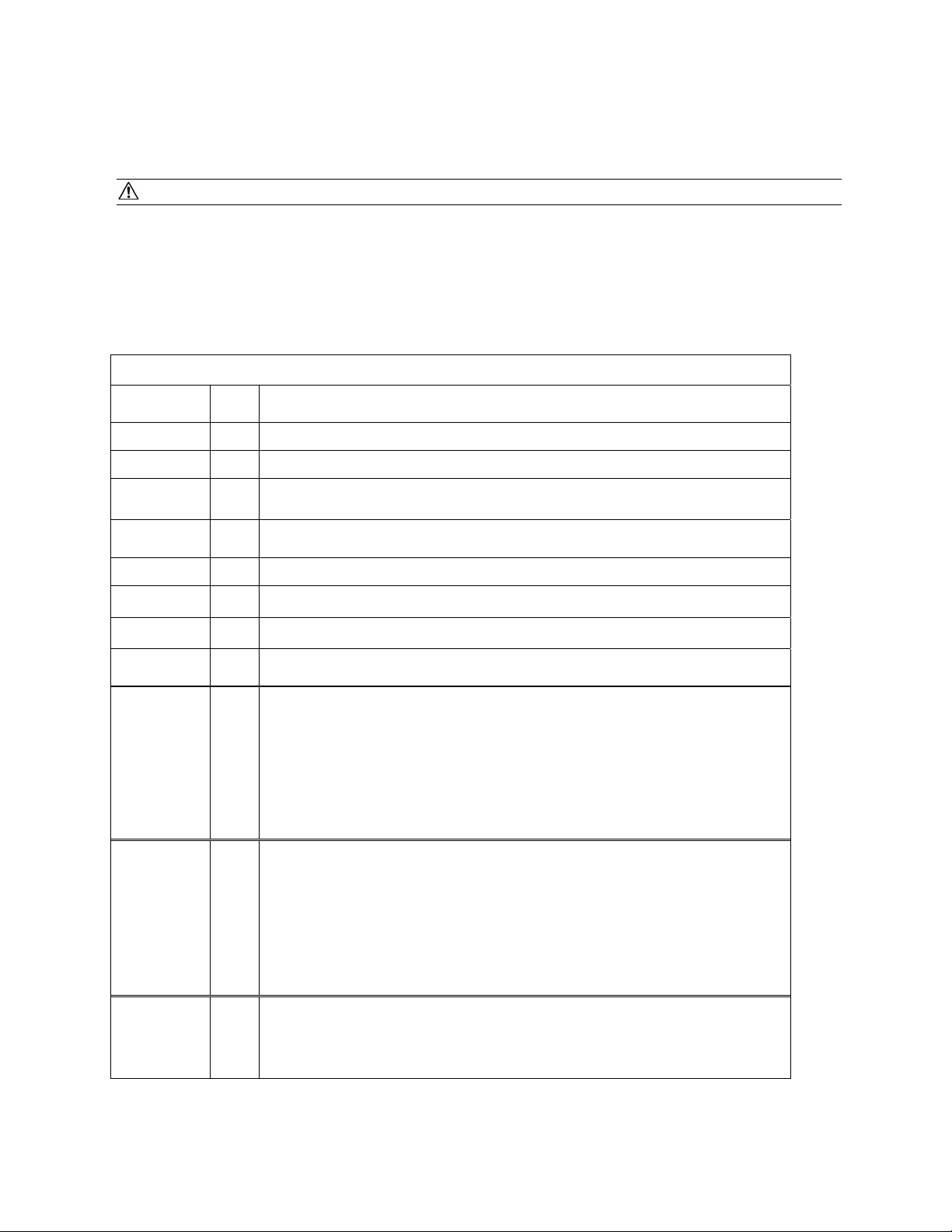

CHART C-1, RECOMMENDED TORQUE VALUES . . . . . . . . . . . . . . 27

Chart C-1

Recommended Torque Values

(All Values in ft-lb)

Description Item Number Size Recommended Torque Value

Casing Nuts - 6" ST & All MT 425

Casing Nuts - 8" ST Only 425 ½ - 13 40

Nozzle/Connections

1" and 1½" Flanges

Nozzle Connections

2" - 4" Flanges

Column/Pump Cover

Screw All

Protector/Mounting Plate

Screw All

Adapter/Protector Plate

Screw All

Ccolumn/Protector Plate

Screw All

Column Pipe Joint

Screw All

Pipe Collar/Mounting Plate

Screw All

371H ½ 30

371H

371W

371X ½ - 13 25

371Y ½ - 13 15

371Z

372B

372X ½ - 13 25

5

- 11 30

8

5

8

5

- 11

8

5

- 11

8

5

- 11

8

40

25

25

25

NM 3171 IOM 5/08 27

Page 34

Page 35

APPENDIX II

SUPPLEMENTAL INSTRUCTIONS FOR NM3171 MAINTENANCE . . . . . 29

SEALED BEARING DESIGN

This supplement addresses the grease

lubricated/sealed bearing design that uses the

pumpage to externally cool the bearing cavity. The

standard bearing configuration is product lubricated,

and is addressed in the IOM. The bearing housing

will be provided fully assembled. This will include

the bearing housing, bearing, lip seals and snap

rings.

Assembly steps to immediately follow the

attachment of the first column pipe assembly to the

protector plate. (Page 11 of the NM3171 IOM):

1. Squeeze the top lip seal of the bearing assembly

so that it will go over the pump shaft.

2. Slide the bearing assembly onto the shaft and

lock it into place on the lock collar of the column

shaft.

Note: Care must be taken to align the cooling

connections on the bearing housing with the

cooling piping. The same care must be taken

to align the grease connection with the

grease line. All fittings should line up with

the appropriate supply lines as originally

installed by the factory.

Note: it is important to ensure that all air is

out of grease lines and grease lines are

charged before pump startup.

3. Repeat steps 1-3 until all column shafts and

bearing assemblies are in place.

4. Grease the bearing with NLGI#2 Grade Lithium

12 Hydroxysterate EP Grease or equivalent

before assembling grease lines.

5. Assemble all grease lines, fittings and

connectors together but do not connect to

bearing housing.

6. Charge all grease lines from the grease cup

down to the connector of the bearing assembly.

7. Confirm that grease comes out of the male

connector of the bearing assembly, and then

connect to the bearing assembly.

8. Continue with instructions in IOM at point of

placing pump cover against last column bearing.

Note: Keep grease cup reservoir full at all

times.

NM 3171 IOM 5/08 29

Page 36

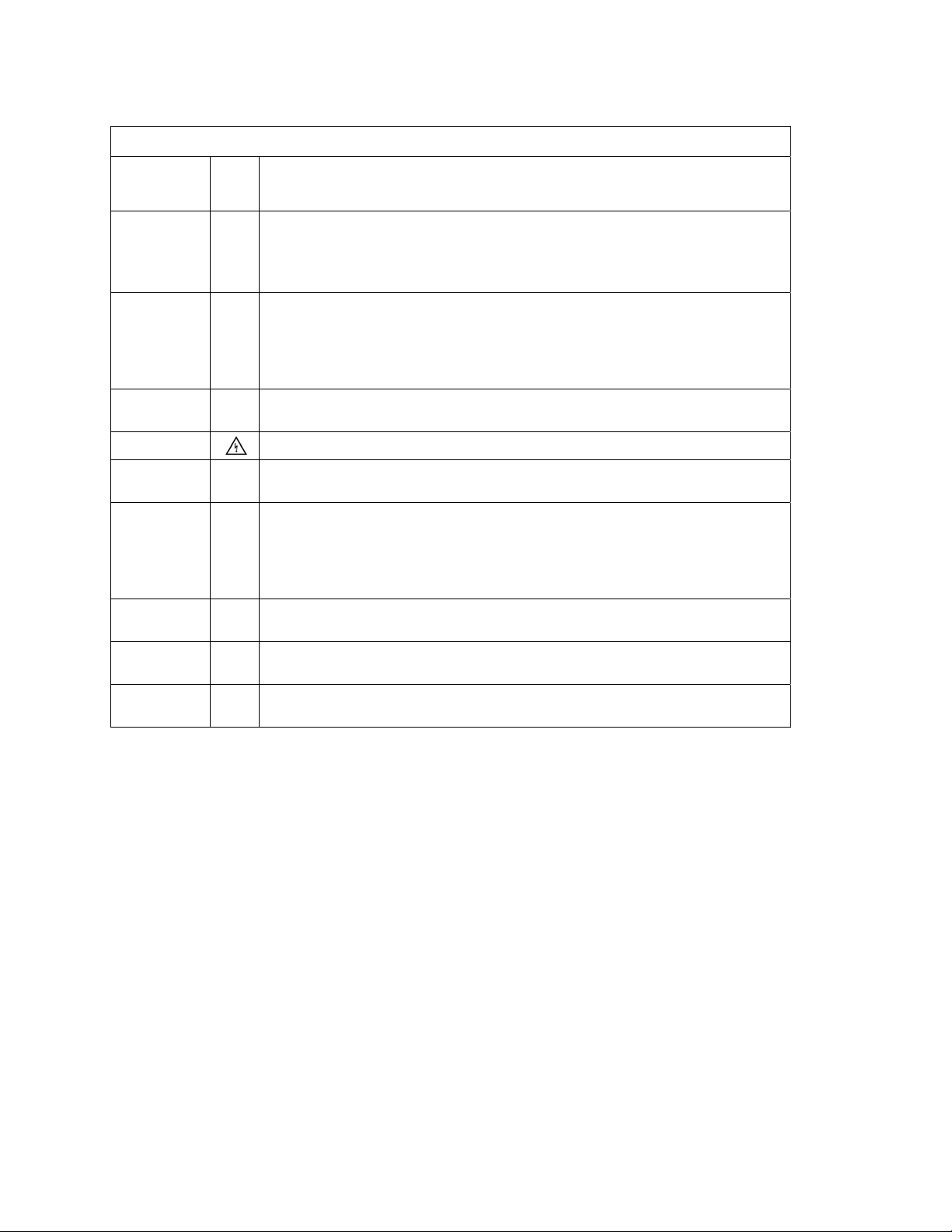

PARTS LIST AND MATERIALS OF CONSTRUCTION

30 NM 3171 IOM 5/08

Page 37

NM 3171 IOM 5/08 31

Page 38

Page 39

Page 40

HOW TO ORDER

When ordering parts call

1-800-446-8537

or your local Goulds Representative

EMERGENCY SERVICE

Emergency parts service is available

24 hours/day, 365 days/year...

Call 1-800-446-8537

For more information, call your nearest Goulds sales representative or visit our website at www.gouldspumps.com

© copyright 2002 Goulds Pumps, Incorporated,

Form No. I3171NM Rev. 5/08

a subsidiary of ITT Industries, Inc.

Loading...

Loading...