Goulds Pumps HYDROVAR Quick Start Manuals

HYDROVAR

Pump Control

Quick Start Guide

Startup of a Hydrovar drive or Packaged Hydrovar

Pump/Drive. Consult IM223 for recommended system design, including pump, valves, transducer, and

diaphragm tank. For additional applications, consult

IM223.

Must be installed by qualified personnel.

1. Align drive on 3 Ph/TEFC motor and attach to motor

using 4 clamps and screws provided. Remove cover.

2. Verify power is off before connecting to drive. Attach

power wires to pump mounted fused disconnect

(if packaged product) or from wall mounted fused

disconnect or breaker box. Use fast acting Class

T fuses. Route wires through cable gland, conduit

plate – large opening –and through cable gland nut.

3. Attach Power wires to drive: Attach ground wire to

ground screw. If 1 Ph, attach L and N to appropriately labeled terminals. If 3 Ph, attach wires to appropriate L1, L2, L3 terminals. See IOM for terminal

locations.

1 Ph 2, 3 HP 3 Ph 3, 5 HP 3 Ph 7.5, 10, 15 HP

(A) Power supply (B) Motor (C) Terminal block:

connections

- START/STOP

(D) RS-485 Interface (E) Status-Relays - SOLORUN

- User interface - RS-485 Interface

- Internal interface (F) Optional

Relay Card

4. Drive connection to motor: Route wires through

cable gland and other large conduit opening as

above. Connect wires to appropriate terminals. Use

crimp-on spades for sizes 2, 3, 5 HP. Terminate wires

at terminals U, V, W for sizes 7.5 HP and up.

*** Route the following low voltage wires

through small conduit glands and openings as

needed. ***

5. Attach transducer wires to terminals X3: 1-3; Shield,

White, Brown respectively.

6. Attach thermal overload switch to motor body at

conduit box screw, and terminate at the 2 terminals labeled X1 PTC. If not using Thermal overload

switch, place jumper between PTC terminals.

7. Provide Emergency stop switch, or jumper between

terminals X3: 7, 8.

8. Provide additional on/off switch or jumper between

terminals X3: 11, 12

9. If using multiple communicating drives, attach

RS485 wires to terminals X4: 4-6, (-, +, Shield respectively) on Master drives; X2: 1-3 on Basic drives.

Daisy chain communication wires starting at Master

drive to all additional drives.

10. Verify all connections are secure with no stray wires.

Attach ground wire from drive to cover and replace

cover. Note: Be sure cover sits securely on drive

without pinching any wires. Securely HAND TIGHTEN cover screws. Cover must be firmly attached for

buttons to function properly.

11. Connect power. The display should look as follows:

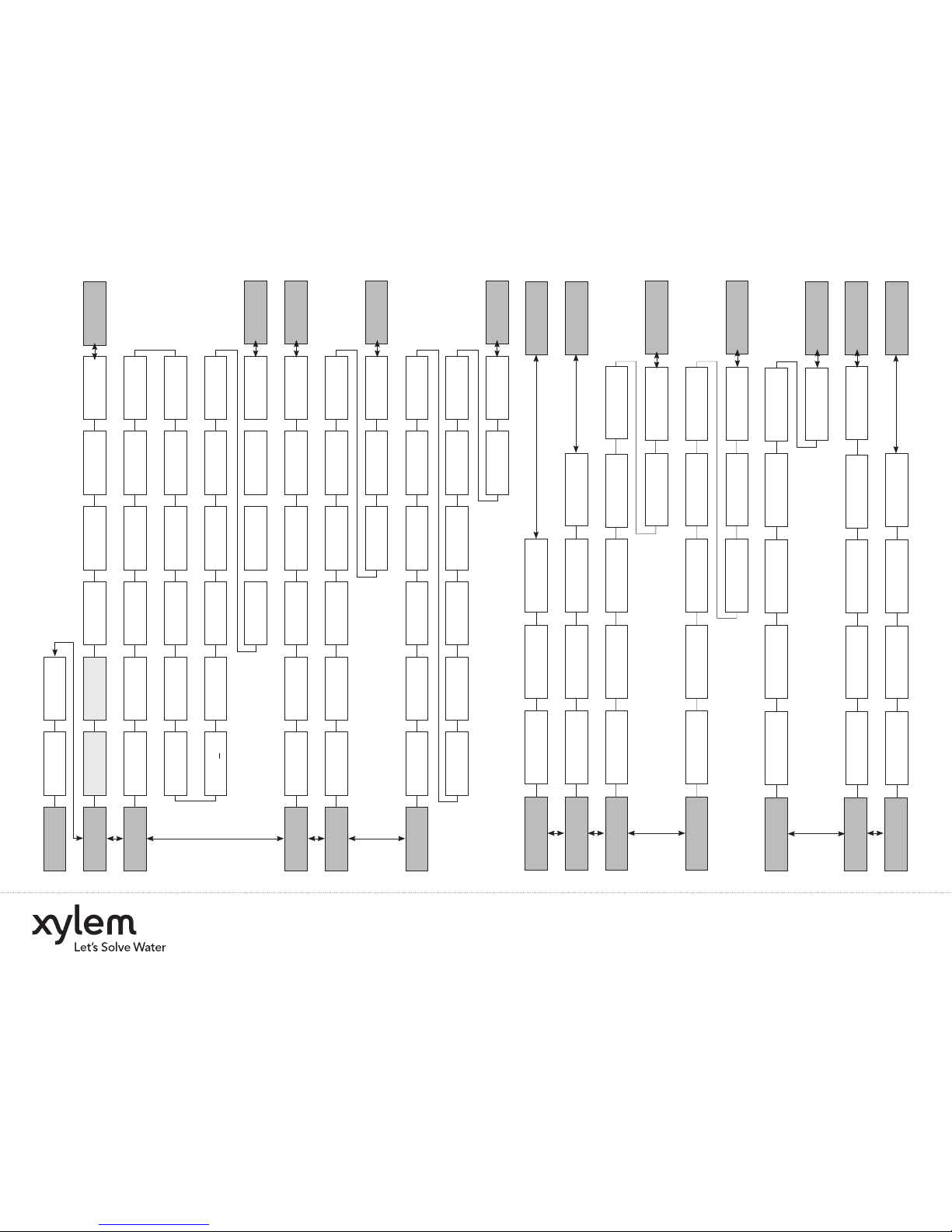

12. See attached flowchart for available programming

options to change.

13. Push Right arrow to next screen to change Setpoint.

Use Up/Down arrows to change setpoint, (Required

value).

14. Push left arrow once to get back to main screen.

Push left arrow again to get to Main menu. Use

Down arrow to scroll through menu options. To

change any parameter other than set point, you

must first enter a password. From main menu, scroll

down to Group 60, and push right arrow once to

parameter 61. Enter password using up arrow key,

(password = 66).

15. For multipump programming, change the highlighted parameters in the flowchart. Change: Parameter

105 to “Cascade Serial”; set the pump address to 1,

2, etc in parameter 106.

16. From main screen, press up arrow to start drive.

Check rotation on pump. Switch 2 of 3 line wires

from the drive at motor if reverse rotation.

XYLEM 0.0 Hz

STOP XXX.X PSI

QUICK START GUIDE

HYDROQSG

100 SUBMENU

BASIC SETTINGS

200 SUBMENU

CONF INVERTER

300 SUBMENU

REGULATION

400 SUBMENU

SENSOR

500 SUBMENU

SEQUENCE CNTR

100 SUBMENU

BASIC SETTINGS

60 SUBMENU

SETTINGS

200 SUBMENU

CONF INVERTER

300 SUBMENU

REGULATION

400 SUBMENU

SENSOR

500 SUBMENU

SEQUENCE CNTR

61 PASSWORD

0000

105 MODE

Controller

202 SOFTWARE

HV V01.3

205 MAX. UNITS

6

210 INVERTER

ALL

215 RAMP 1

4 sec

225 RAMP 3

70 sec

260 FMIN TIME

0 sec

265 BOOST

5 %

310 WINDOW

10 %

510 ACT.VAL.DEC

2 PSI

540 DROP FREQ

42.0 Hz

410 CONF SENSOR

Sensor 1

315 HYSTERESIS

80 %

515 ENABLE FREQ

48 Hz

545 OVERVALUE

disabled

415 SENSOR TYPE

analog I 4-20mA

320 REG. MODE

normal

520 ENABLE DLY

5 sec

550 OVERVAL DLY

0 sec

420 SENS. RANGE

300 PSI

325 FRQ. LIFT

30.0 Hz

525 SWITCH DLY

2 sec

555 SWITCH INTV

24 hours

425 SENS. CURVE

linear

330 LIFT AMOUNT

0.0 %

530 DISABLE FRQ

30.0 Hz

560 SYNCH.LIM.

0.0 Hz

565 SYNCH.WIN.

2 Hz

570 MSTPRIORITY

ON

430 SENS1 CAL 0

0 % = x,xx PSI

440 SENS2 CAL 0

0 % = x,xx PSI

435 SENS1 CAL X

0 % = xx,xx PSI

445 SENS2 CAL X

0 % = xx,xx PSI

285 SKIPFRQ CTR

0.0 Hz

270 KNEE FREQ.

60 Hz

286 SKIPFRQ RNG

60 Hz

275 POWER RED.

OFF

290 CURR. LIMIT

OFF

280 SEL.SW.FRQ.

Auto

291 CURR. LIMIT

100 %

230 RAMP 4

70 sec

235 RAMP FMIN A

2 sec

240 RAMP FMIN D

2 sec

245 MAX. FREQ

60 Hz

250 MIN. FREQ

20 Hz

220 RAMP 2

4 sec

203 SET VER INV

sel. 01 act. 01

106 PUMP ADDR

1

110 SET PASSW.

0066

115 LOCK FUNCT.

0066

120 DISP. CONTR.

75 %

125 DISP. BRIGHT

100 %

62 JOG Hz

50 PSI

305 JOG Hz

50 PSI

505 ACT.VAL.INC

5 PSI

535 DISABLE DLY

5 sec

405 DIMENS. UNIT

PSI

255 CONF. FMIN

F > 0

1000 SUBMENU

TESTRUN

800 SUBMENU

REQUIRED VALUES

700 SUBMENU

OUTPUTS

1000 SUBMENU

TESTRUN

1100 SUBMENU

SETUPS

1100 SUBMENU

SETUPS

605 MIN.THRESH.

disabled

705 ANALOG OUT1

Output frequency

1005 TESTRUN

100 hours

610 DELAY TIME

2 sec

1010 TESTRUN FREQ.

30 Hz

710 ANALOG OUT2

Actual value

810 C.REQ.VAL.2

OFF

1120 PASSWORD 2

0000

907 OFFS.INPUT

100

1210 BAUDRATE

9600

1215 FORMAT

RTU N81

830 ACTUAT.FRQ1

0.0 Hz

1220 PUMP ADDR

1

835 ACTUAT.FRQ2

0.0 Hz

805 C.REQ.VAL.1

digital

1110 FACTORY SET

USA

905 OFFS.INPUT

OFF

1205 ADDRESS

1

615 ERROR RESET

ON

1015 TESTR.BOOST

10 %

715 CONF REL 1

Running

815 SW REQ.VAL

Setpoint 1

1125 CLR ERRORS

ALL

910 LEVEL 1

0

915 LEVEL 2

100

1020 TESTR.TIME

5 sec

720 CONF REL 2

Errors

820 REQ.VAL.1

50 PSI

1130 CLR MOTORH.

ALL

912 OFFSET X1

0

917 OFFSET X2

100

1025 SEL.DEVICE

01

1030 TESTRUN MAN

Press > 3 sec

825 REQ.VAL.2

50 PSI

1135 CLR OPERAT.

Press > 3 sec

913 OFFSET Y1

0 PSI

918 OFFSET Y2

0 PSI

800 SUBMENU

REQUIRED VALUES

600 SUBMENU

ERRORS

600 SUBMENU

ERRORS

700 SUBMENU

OUTPUTS

1200 SUBMENU

RS485-INTERFACE

1200 SUBMENU

RS485-INTERFACE

900 SUBMENU

OFFSET

900 SUBMENU

OFFSET

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem, Inc. HYDROQSG July 2009

Xylem, Inc.

2881 East Bayard Street Ext., Suite A, Seneca Falls, NY 13148

Phone: (800) 453-6777 • Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Loading...

Loading...