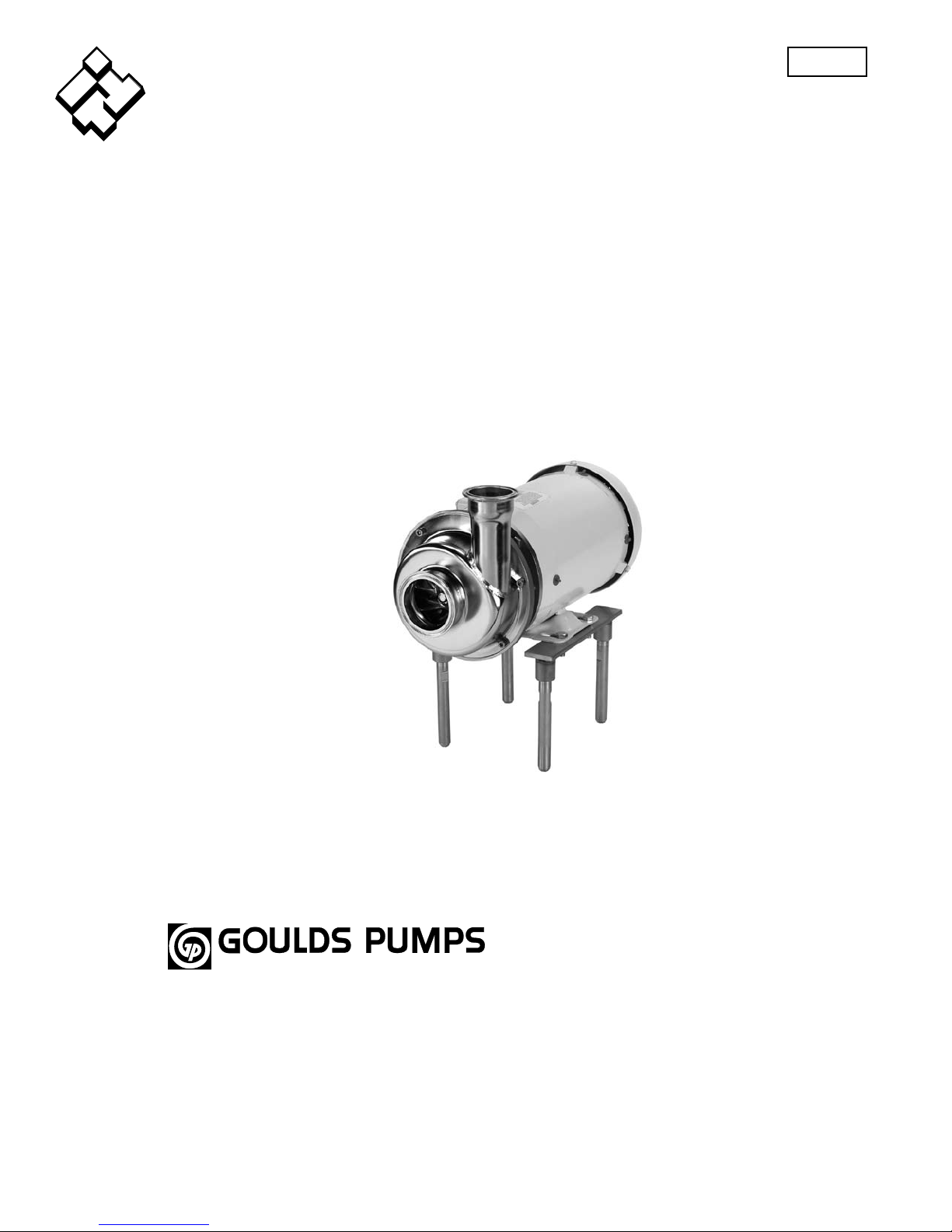

Goulds Pumps GSP Series Installation, Operation And Maintenance Instructions

ITT

Goulds Pumps

Models GSP

Installation, Operation and Maintenance Instructions

IM206

Commercial Water

Goulds Pumps is a brand of ITT Corporation.

www.goulds.com

Engineered for life

ITT

GOULDS PUMPS

Commercial Water

Table of Contents

Topic Page

Introduction and Safety .......................................................................................................................... 3

Transportation and Storage ..................................................................................................................... 5

Product Description................................................................................................................................6

Installation ............................................................................................................................................. 8

Commissioning, Startup, Operation and Shutdown .............................................................................. 13

Maintenance......................................................................................................................................... 15

Troubleshooting ...................................................................................................................................20

Parts Listing and Cross Sectional Drawings ........................................................................................... 24

Appendix.............................................................................................................................................. 25

Product code structure..........................................................................................................................25

Owners Information

Complete this information for your records.

Model number and serial number may be found

on the tag mounted to the pump casing.

Model Number _______________________________

Serial Number _________________________________

Dealer ______________________________________

Dealer phone number _______________________

Date of purchase ____________________________

Date of installation _________________________

2

ITT

GOULDS PUMPS

Commercial Water

I. Introduction and Safety

Introduction

Description

This manual provides instructions for the Installation, Operation and Maintenance of

the Goulds Model GSP pumps. This manual covers the standard product plus common

options that are available.

Requirement

This manual must be read and understood before installation and start-up. Goulds shall

not be liable for physical injury, damage or delays caused by a failure to observe the

instructions for installation, operation and maintenance contained in this manual.

Content

This instruction manual covers several different pump models that all have similar

power end configurations. Most assembly, disassembly and inspection procedures are

the same for all the pumps. However, where there are differences, they are called out

separately within the manual. The design, materials and workmanship incorporated

in the construction of Goulds pumps makes them capable of giving long, trouble free

service. The life and satisfactory service of any mechanical unit, however, is enhanced

and extended by correct application, proper installation, periodic inspection, condition

monitoring and careful maintenance. This instruction manual was prepared to assist

operators in understanding the construction and the correct methods of installing,

operating and maintaining these pumps.

Key Topics

Proper Installation

Start up Procedures

Operation Procedures

Routine Maintenance

Pump Overhaul

Trouble Shooting

Identifying spare or repair parts

3

Safety

It is extremely important that you read, understand, and follow the safety messages

and regulations carefully before handling an ITT product. They are published to help

prevent

• personal accidents and health problems

• damage to the product

• product malfunction

Observe all safety messages highlighted in other sections of this manual.

A pump is a pressure-containing device with rotating parts that can be dangerous.

Caution: You must observe the instructions for installation, operation, and

maintenance contained in this manual. Failure to do so could result in physical

injury, damage, or delays.

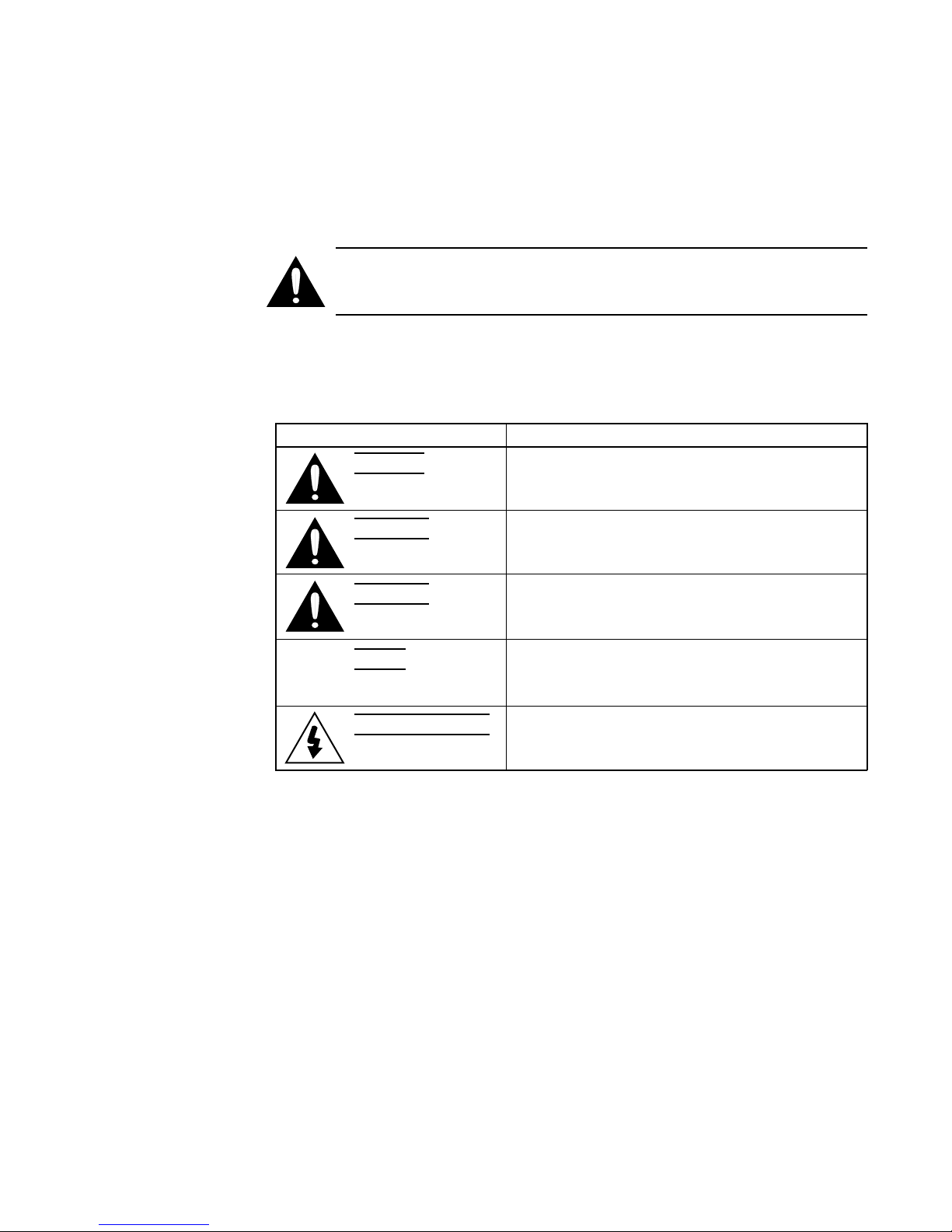

Safety message levels

Table 1: Definitions

Safety message level Indication

Danger: Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Warning: Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Caution: Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Note: Indicates a potential situation which, if not avoided,

may result in undesirable results or state. Indicates a

practice not related to personal injury.

Electrical Hazard: Indicates the possibility of electrical risks if

direction are not applied in a proper manner.

Environmental safety

Preventive measures for the working area

Always keep the pump station clean to avoid and/or discover emissions.

Recycling guidelines

Always recycle according to the guidelines listed below:

1. Follow local laws and regulations regarding recycling if the unit or parts are accepted

by an authorized recycling company.

2. If the first guideline is not applicable then return the unit or parts to the nearest

ITT representative.

Waste and emissions

Observe these safety regulations regarding waste and emissions:

• Dispose appropriately of all waste.

• Handle and dispose of the pumpage in compliance with applicable environmental

regulations.

• Clean-up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

4

Reference for electrical installation

For electrical installation recycling requirements, consult your local electric utility.

User health and safety

Safety equipment

Use safety equipment according to the company regulations. The following safety

equipment should be used within the working area depending on the fluid being

pumped:

• helmet

• safety goggles (with side shields)

• protective shoes

• protective gloves

• gas mask

• hearing protection

Note: The noise level of the product is lower than 70 dB. However,

the noise level of 70 dB may be exceeded in some installations and at

certain operating points on the performance curve. Make sure that

you understand the noise level requirements in the environment where

the pump is installed. Failure to do so may result in hearing loss or

violation of local laws.

The working area

Observe these regulations and warnings in the working area:

• Always keep the work area clean.

• Pay attention to the chemical and physical characteristics of the gas and vapors

present in hazardous areas.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc ash

hazards.

Product and product positioning requirements

Observe these requirements for the product and the product positioning:

• Never operate a pump unless safety devices are installed.

• Three-phase motors must have a properly sized starter with properly sized heaters

to provide overload and undervoltage protection. Single-phase motors have built-in

overload protectors.

• Never start a pump without the proper priming.

• Never run a pump below the minimum rated ow or with any suction or discharge

valve closed.

Electrical connections

Electrical connections must be made by authorized electricians in compliance with all

international, national, state, and local rules.

Observe the following regulations and warnings for electrical connections.

• Make sure that the product is isolated from the power supply and can not be

energized by mistake. This rule applies to the control circuit as well.

• Make sure that the thermal contacts are connected to a protection circuit according

to the product approvals, and that they are in use.

Observe the following regulations for grounding connections.

Table 2: Grounding

Grounding regulation Comment

All electric equipment must be grounded. This rule applies to pumps and mixers as

well as monitoring equipment.

5

Precautions before work

Observe the following safety precautions before working with or in connection with the

product:

• Provide a suitable barrier around the work area, for example a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that the equipment is properly insulated when operating at extreme

temperatures.

• Allow all system and pump components to cool before you handle them.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

property.

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Make sure that the product has been thoroughly cleaned.

• Make sure that there are no poisonous gases within the work area.

• Make sure that a rst-aid kit is close at hand.

• Disconnect and lock out power before servicing.

• Check the explosion risk before welding or using electric hand tools.

Precautions during work

Observe the following safety precautions when working with or in connection with the

product:

• Never work alone.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after disassembling the pump.

• Do not exceed the maximum working pressure of the pump.

• Do not open any vent or drain valves or remove any plugs while the system is

pressurized. Ensure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

• Always bear in mind the risk of

• electrical accidents

• burn injuries

Clean chemicals from the eyes

1. Forcibly hold the eyelids apart with the fingers.

2. Rinse the eyes for at least 15 minutes. Use an eyewash or running water.

3. Seek medical attention.

Clean chemicals from the body

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. If required, seek medical attention.

Product approval standards

Regular standards

All electrical ratings and performance of the motors comply with UL, CSA and NEMA

standards.

3-A® standards

The GSP is certified to 3-A® 02-10 sanitary food and beverage standards. The GSP

platform and legs are certified to 3-A® 88-00 standards.

6

Product warranty

Personnel requirements

All work on the product must be carried out by certified electricians and ITT

authorized mechanics.

ITT disclaims all responsibility for work done by untrained and unauthorized

personnel.

Modification and spare parts

Modifications or changes to the product/installation should only be carried out after

consulting with ITT. Original spare parts and accessories authorized by ITT are essential

for compliance. The use of other parts can invalidate any claims for warranty or

compensation and explosion-proof approvals.

Warranty claim

For warranty claim, contact your ITT Fluid Technology representative.

II. Transportation and Storage

Description

This section describes recommended methods for receiving, storing and handling the

pump prior to physical installation.

Receiving

The pump should be uncrated or unboxed when it is received so that it can be

completely inspected. Carefully check that everything is in good order. Make notes

of damaged or missing items on the receipt and freight bill. File any claims with the

transportation company as soon as possible.

Storage

Short Term: For storage of less than six months, the normal packaging procedures used

by Goulds Pumps are designed to protect the pump during shipping. After receipt, store

in a covered and dry location.

Long Term: For storage of more than six months, preservative treatment of bearings

and machined surfaces will be required. Rotate the pump and motor shaft several times

every three months. Refer to driver and coupling manufacturers for their long term

storage procedures. Store in a covered, dry location.

Handling

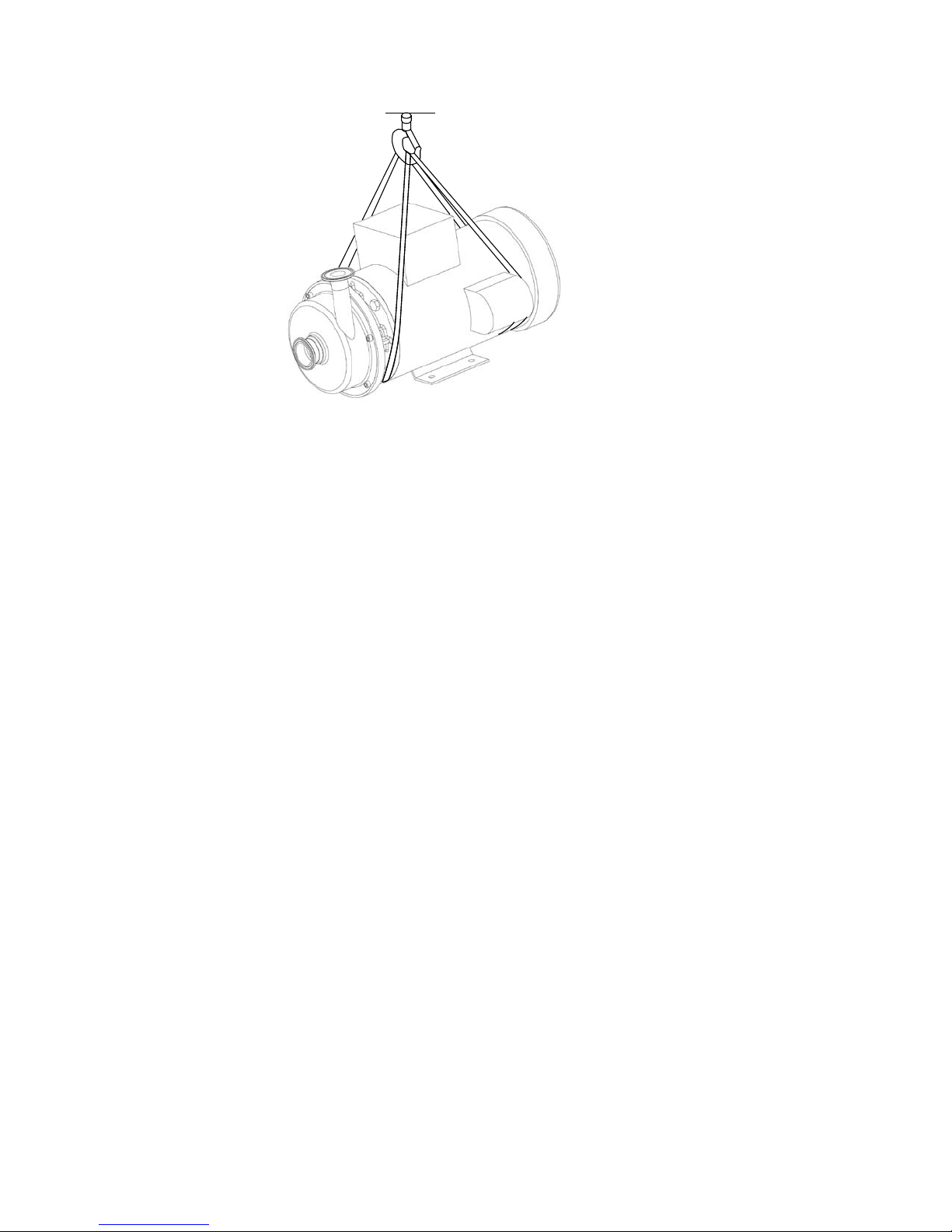

Warning: Pump and components are heavy. Failure to properly lift and support

equipment could result in serious physical injury or damage to pumps. Steel toed shoes

must be worn at all times.

7

Use care when moving pumps. Lifting equipment must be able to adequately support

the entire assembly. Hoist pump using a suitable sling under the motor adapter and

motor (Figure 1). For larger pumps, motor lifting rings may be used.

III. Product Description

Description

This section provides a general description of the Goulds Model GSP and key

engineering specifications.

Overview

The Goulds model GSP pumps are single stage, end suction, centrifugal pumps designed

to meet the rigorous standards of hygiene needed by the food and beverage industries.

Pumps are used in the food industry as process or clean in place pumps.

The GSP series meets 3A Sanitary Standards for Centrifugal and Positive Rotary Pumps,

Number 02-10 and 3A Sanitary Standard for Machine Leveling Feet and Supports,

Number 88-00 for both internal and external hygienic design. This enables operators

to insure the purity of their process and the cleanliness of their plant to meet both local

and national health and safety regulations. Not all products marked 3A meet these

design and clean-ability standards.

Mechanical seals are FDA approved and several versions of the pump have EHEDG

European sanitary certification.

Pump impellers are fully open, and either threaded or key driven and held in position

by an impeller bolt and o-ring. Impeller hubs are extended through the seal and

backplate eliminating the need for shaft sleeves.

Casings are full volute in design. 316 Stainless parts and welds are polished to

Ra<0.8 um.

Suction and discharge connections are Tri-clamp sanitary flange type.

Close-coupled units have NEMA standard JM motors with C-face mounting and key

driven shaft extension or for smaller pumps, NEMA standard 56J motors with threaded

shafts. Pumps are available with standard ODP or TEFC motors with shrouds and

pump stands or wash down enclosures. These are provided for hygienic cleaning of the

pump and its surroundings.

8

Engineering Data

Noise level

The noise generated by a pump depends on different factors. Most important are: power,

speed and brand name of the motor, whether there is cavitation or not, operating point

of the pump, and handling of small quantities of air. A guide value for the sound pressure

level measured in dB(A) at a distance of 3 feet from the pump with a 2 pole motor

operating at 60 Hz in ideal circumstances with cold water is 78 dB(A) for pumps up to 5

hp, 83 to 85 dB(A) for pumps with motors ranging from 7.5 to 50 hp. For pumps with 4

or 6 pole motors, the value can be decreased with +/- 8 dB(A).

Maximum Liquid Temperature:

250ºF (120ºC)

Note: Pump and piping should be protected from skin contact if temperature is less

than 10ºC or higher than 40ºC

Maximum Working Pressure (Fluid temperature dependant):

S1 – 125 PSIG (9 Bar); S2 – 150 PSIG (10.5 Bar)

Maximum Suction Pressure:

=125 PSIG/150 PSIG – Pump generated pressure (see performance curve)

Starts per hour:

20 evenly distributed with standard across the line start

Unlimited with soft starter or drive

Connections

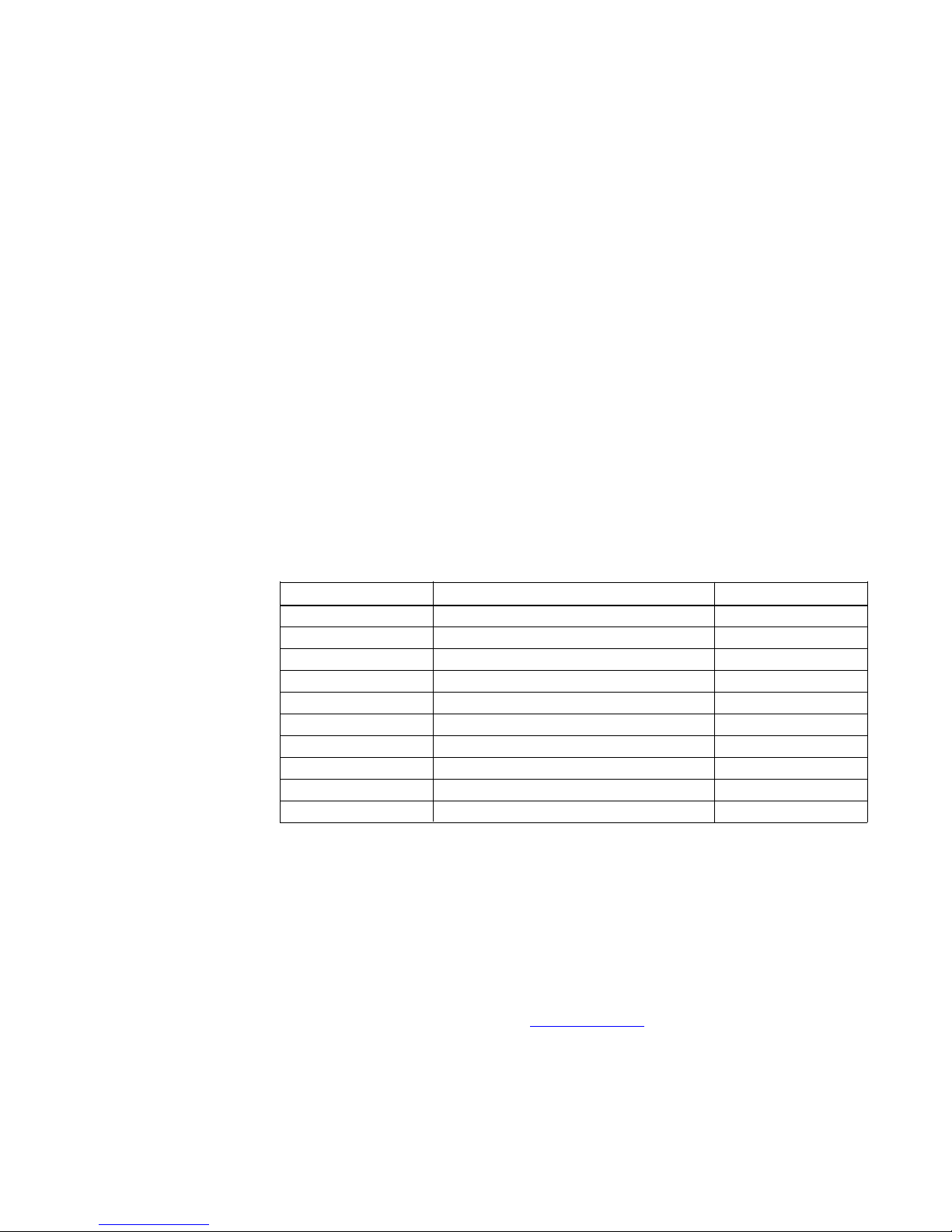

The following table shows the discharge and suction sizes in inches for each of the GSP

pumps. The Pump designation is the first three characters of the pump model number.

Pump Designation Fitting Size (discharge x Suction) Nominal Impeller

S1A 1 x 1.5 5

S1B 2 x 2.5 4

S2A 1.5 x 2 7

S2B 2 x 2.5 7

S2C 2.5 x 3 7

S2D 1.5 x 2 8

S2E 2 x 2.5 8

S2F 2 x 2.5 9

S2G 2.5 x 3 9

S2H 2 x 2.5 11

Name Plate

Model #

The various versions of the GSP are identified by a product code number on the pump

label. This number is also the catalog number for the pump. The meaning of each

digit in the product code number is shown in the Appendix. Not all combinations are

possible; consult your Goulds Pumps distributor for specic requirements.

Performance

Performance curves and dimension drawings for your Goulds model GSP may be found

in the selection program available on www.goulds.com. The correct performance curve

can be determined from the name plate model number as defined above. You will need

to know pump size, impeller trim and operating speed.

9

Loading...

Loading...