Page 1

1 CV#3171#IOM#05/11#

Installation, Operation and Maintenance Instructions

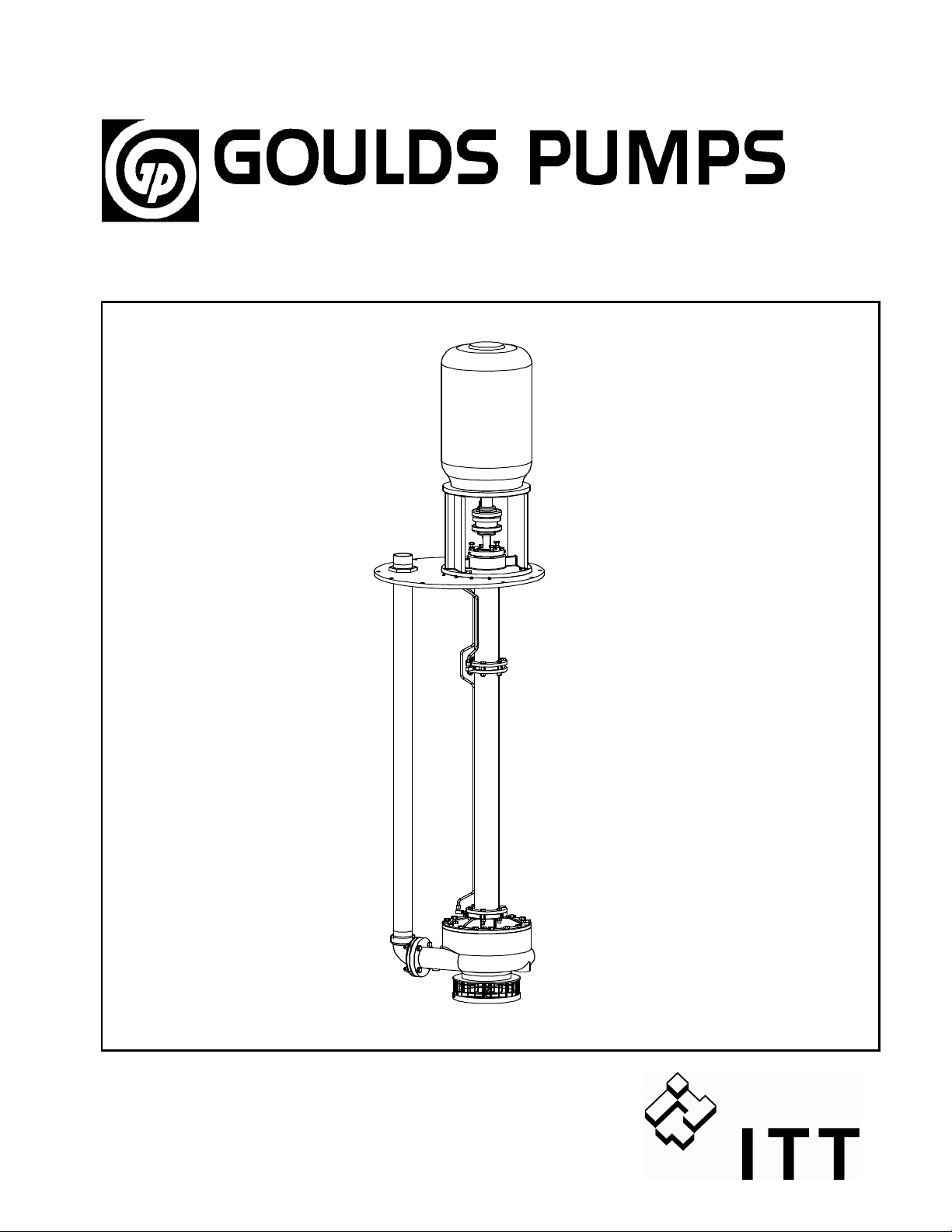

Model CV 3171 !

Page 2

2 CV#3171#IOM#05/11#

Pump Safety Tips

Safety Apparel:

• Insulated work gloves when handling hot

bearings or using a bearing heater

• Heavy work gloves when handling parts with

sharp edges, especially impellers

• Safety glasses (with side shields) for eye

protection, especially in machine shop areas

• Steel-toed shoes for foot protection when

handling parts, heavy tools, etc.

• Other personal protective equipment to protect

against hazard/toxic fluids

Coupling Guards:

• Never operate a pump without a coupling guard

properly installed

Flanged Connections:

• Never force piping to make a connection with a

pump

• Use only fasteners of the proper size and

material

• Ensure there are no missing fasteners

• Beware of corroded or loose fasteners.

Operation:

• Do not operate below minimum rated flow, or

with suction/discharge valves closed

• Do not open vent or drain valves, or remove

plugs while system is pressurized

Maintenance Safety:

• Always lockout power

• Ensure pump is isolated from system and

pressure is relieved before disassembling

pump, removing plugs, or disconnecting piping

• Use proper lifting and supporting equipment to

prevent serious injury

• Observe proper decontamination procedures

• Know and follow company safety regulations

Observe all cautions and warnings highlighted

in pump Installation, Operation and Maintenance

Instructions.

Page 3

CV#3171#IOM#05/11# 3

FORWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the

Goulds Model CV3171 Vertical Vortex (recessed impeller) as well as the low flow sizes. This

manual covers the standard product plus common options that are available. For special

options, supplemental instructions are supplied. This manual must be read and understood

before installation and start-up.

The design, materials and workmanship incorporated in the construction of a Goulds pump

makes them capable of giving long, trouble-free service. The life and satisfactory service of

any mechanical unit, however, is enhanced and extended by correct application, proper

installation, periodic inspection, condition monitoring and careful maintenance. This

instruction manual was prepared to assist operators in understanding the construction and the

correct methods of installing, operating, and maintaining these pumps.

#

ITT Goulds Pumps shall not be liable for physical injury, damage or delays caused by a

failure to observe the instructions for installation, operation, and maintenance

contained in this manual.

Warranty is valid only when genuine ITT Goulds parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty,

unless written approval is obtained in advance from ITT Goulds Pumps.

Supervision by an authorized ITT Goulds representative is recommended to assure proper

installation.

Additional manuals can be obtained by contacting your local ITT Goulds representative or by

calling 1-800-446-8537.

THIS MANUAL EXPLAINS

Proper Installation

Start-up Procedures

Operation Procedures

Routine Maintenance

Pump Overhaul

Troubleshooting

Order Spare or Repair Parts

Page 4

4 CV#3171#IOM#05/11#

When a pumping unit is installed in a potentially explosive atmosphere, the instructions after

the Ex symbol must be followed. Personal injury and/or equipment damage may occur if these

instructions are not followed. If there is any question regarding these requirements or if the

equipment is to be modified, please contact a Goulds representative before proceeding.

Explosion Prevention

In order to reduce the possibility of accidental explosions in atmospheres containing explosive

gasses and/or dust, the instructions under the ATEX symbol must be closely followed. ATEX

certification is a directive enforced in Europe for non-electrical and electrical equipment

installed in Europe. ATEX requirements are not restricted to Europe, and are useful guidelines

for equipment installed in any potentially explosive environment.

Special ATEX Considerations

All installation and operation instructions in this manual must be strictly adhered to. In

addition, care must be taken to ensure that the equipment is properly maintained. This

includes but is not limited to:

• monitoring the pump frame and liquid end temperature

• maintining proper bearing lubrication

• ensuring that the pump is operated in the intended hydraulic range

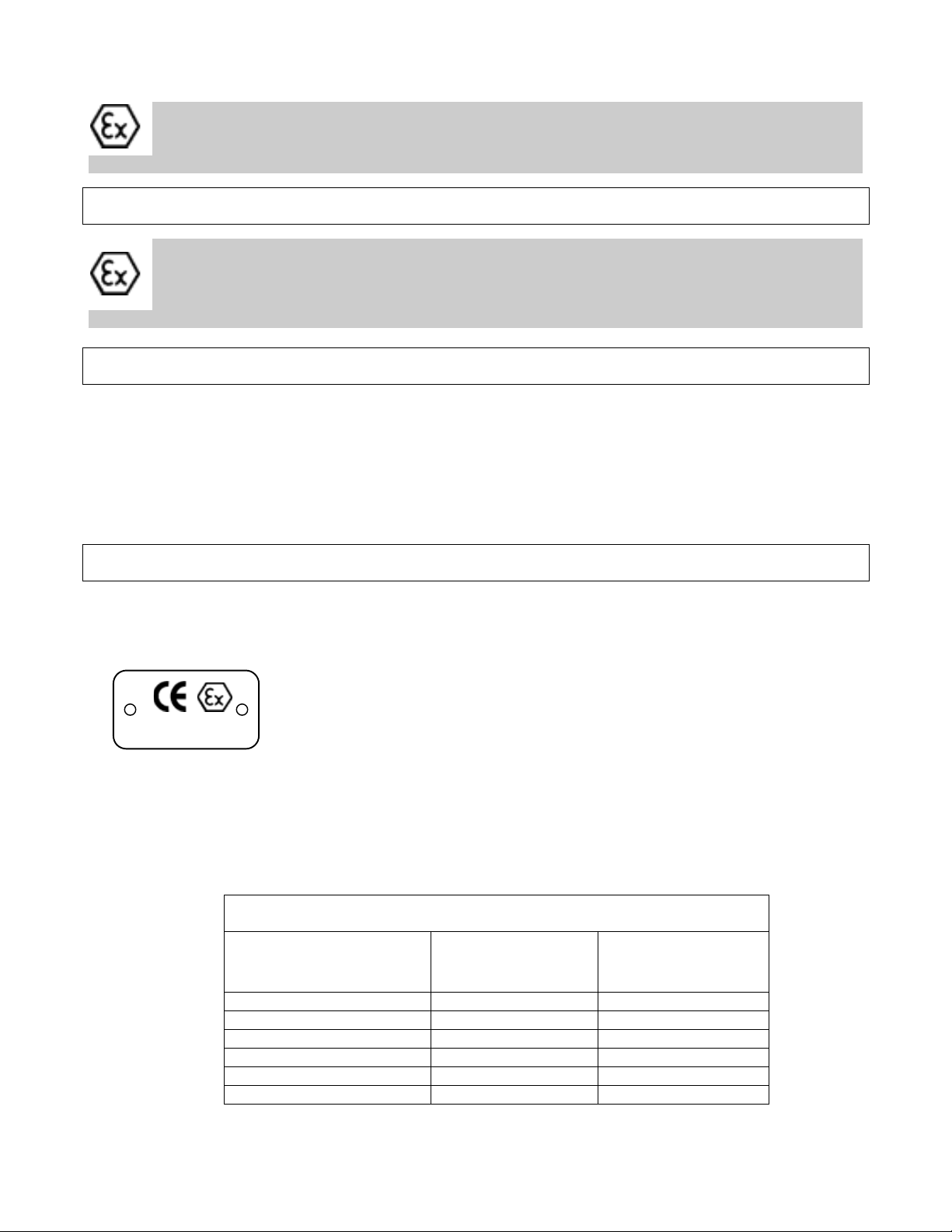

ATEX Identification

For a pumping unit (pump, seal, coupling, motor and pump accessories) to be certified for use

in an ATEX classified environment, the proper ATEX identification must be present. The

ATEX tag will be secured to the pump or the baseplate on which it is mounted. A typical tag

will look like this:

II 2 G/D X

The CE and the Ex designate the ATEX compliance. The code directly below these

symbols reads as follows:

II ------------ Group 2

2 ------------- Category 2

G/D ------------ Gas and Dust present

X ------------ Temperature class, can be T1 to T6 (see following table)

Maximum Process Temperature to Achieve Desired T rating

T Rating per EN 1127-1

Maximum Surface

Temperature

in Celsius

Maximum Process

Temperature

in Celsius!

T1

450

410

T2

300

260

T3

200

165

T4

135

100

T5

100

65

T6

85

50

Page 5

CV#3171#IOM#05/11# 5

The code classification marked on the equipment should be in accordance with the specified

area where the equipment will be installed. If it is not, please contact your ITT Goulds

representative before proceeding.

Intended Use

The ATEX conformance is only applicable when the pump unit is operated within its intended

use. All instructions within this manual must be followed at all times. Operating, installing or

maintaining the pump unit in any way that is not covered in this manual can cause serious

personal injury or damage to the equipment. This includes any modification to the equipment

or use of parts not provided by ITT Goulds. If there is any question regarding the intended

use of the equipment please contact an ITT Goulds representative before proceeding.

Page 6

6 CV#3171#IOM#05/11#

THIS PAGE INTENTIONALLY LEFT BLANK

Page 7

CV#3171#IOM#05/11# 7

TABLE OF CONTENTS

PAGE SECTION

9 SAFETY 1

11 GENERAL INFORMATION 2

15 INSTALLATION 3

21 OPERATION 4

25 PREVENTIVE MAINTENANCE 5

33 DISASSEMBLY AND REASSEMBLY 6

47 APPENDICIES 7

51 SPARE PARTS 8

Page 8

8 CV#3171#IOM#05/11#

THIS PAGE INTENTIONALLY LEFT BLANK

Page 9

CV#3171#IOM#05/11# 9

SAFETY

DEFINITIONS ........................................................................................................................... 7

GENERAL PRECAUTIONS ..................................................................................................... 7

DEFINITIONS

This pump has been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this

manual. A pump is a pressure containing device

with rotating parts that can be hazardous. Operators

and maintenance personnel must realize this and

follow safety measures. ITT Goulds Pumps shall not

be liable for physical injury, damage or delays

caused by a failure to observe the instructions in this

manual.

Throughout this manual the words WARNING,

CAUTION, and NOTE are used to indicate

procedures or situations which require special

operator attention:

WARNING

Operating procedure, practice, etc.

which, if not correctly followed, could

result in personal injury or loss of life.

CAUTION

Operating procedure, practice, etc.

which, if not followed could result in

damage or destruction of equipment.

NOTE: Operating procedure, condition, etc.

which is essential to observe.

EXAMPLES

WARNING

Pump shall never be operated without

coupling guard installed correctly.

CAUTION

Throttling flow from the suction side

may cause cavitation and pump

damage.

NOTE: Proper alignment is essential for long

pump life.

GENERAL PRECAUTIONS

Personal injury will result if procedures

outlined in this manual are not followed.

Never run pump below recommended minimum flow or

when dry.

Never apply heat to remove impeller. It may

explode due to trapped liquid.

Always lock out power to the

driver before performing

pump maintenance.

Never use heat to disassemble pump due to

risk of explosion from trapped liquid.

Never operate pump without safety

devices installed.

Never operate pump without coupling

guard correctly installed.

Never operate pump with

discharge valve closed.

Never operate pump beyond the rated

conditions to which the pump was

sold.

Never operate pump with

suction valve closed.

Never start pump without proper prime,

or proper liquid level in self priming

pumps.

Do not change conditions of service

without approval of an authorized

Goulds representative.

1!

Page 10

10 CV#3171#IOM#05/11#

Condition Monitoring

For additional safety precautions, and where noted in this manual, condition monitoring devices

should be used.

This includes, but is not limited to:

Pressure gauges

Flow meters

Level indicators

Motor load readings

Temperature detectors

Bearing monitors

Leak detectors

PumpSmart control system

For assistance in selecting the proper instrumentation and its use, please contact your ITT

Goulds representative.

Page 11

CV#3171#IOM#05/11# 11

GENERAL INFORMATION

PUMP DESCRIPTION ............................................................................................................9

NAMEPLATE INFORMATION..............................................................................................10

RECEIVING THE PUMP....................................................................................................... 11

Storage Requirements ...............................................................................................11

Handling .....................................................................................................................11

Uncrating/Deskidding .................................................................................................12

PUMP DESCRIPTION

The model CV3171 is a vertical vortex, recessed

open impeller pump that generates pressure head

by creating a vortex in the casing. Use of a

recessed impeller allows for solids, entrained air, or

shear sensitive liquid handling.

The model is based on 1 power end and 8 hydraulic

pump sizes:

2X2-8 2X2-10 3X3-10

2X3-13 3X4-13

LF 1x1.5-8 LF 1x2-10 LF 1.5x3-13

Casing: The casing of the CV3171 is concentric

volute and available with optional connections for

venting, flushing and solids clean out.

Impeller: The impeller of the CV3171 is fully open,

has curved vanes, and is threaded to the shaft. The

LF sizes have straight radial vanes and are

threaded to the shaft. The threads are sealed from

the pumpage by a Teflon O-ring.

Strainer: The strainer is a basket type with

openings sized to prevent the entrance of large

solids commonly ending up in open sumps.

Power End: The power end of this pump is

identical to the 3171 power end. It consists of the

motor, coupling, motor mount, support plate,

double-row ball thrust bearing, shaft, column pipe

header, steady bearings, and column pipe

extension.

Bearings: The thrust bearing is a grease or oil-mist

lubricated double row angular contact ball bearing.

It is shouldered and locked to the shaft and the

housing enabling it to carry all of the thrust loads

and some of the radial load. All fits are precision

machined to industry standards. The steady

bearings are press fit sleeve bearings. Fits are

designed for optimum life under all operating

conditions.

Seals: The standard CV3171 has three seals.

An upper labyrinth seal is used to exclude dirt

and water from the thrust bearing.

A lower grease seal is used below the thrust

bearing to contain the grease and exclude any

possible contamination.

A carbon Teflon casing collar is installed

immediately behind the impeller in the adapter

to minimize recirculation back to the sump,

thereby maximizing hydraulic efficiency.

Discharge Elbow: The discharge elbow is a short

radius elbow that provides compact size and

minimum profile.

Direction of Rotation: Clockwise (right hand) as

viewed from the driver, looking at the pump shaft.

Maximum Solids Size: For CV3171 pumps, the

max. solids size is 1.875 in. for 2” discharge and

2.875 in. for 3” discharge. Refer to the current

pump curve for maximum solids capabilities.

2!

Page 12

12 CV#3171#IOM#05/11#

Steady Bearings:

1. Carbon and Carbon Filled Teflon - These

bearings are chemically inert in most liquids

and can be used in liquids up to the

temperature limits of the pump. They should

not be used in liquids containing abrasive

solids. Clear flush from the support plate is

required.

2. Fluted Rubber or Viton - These bearings

consist of fluted rubber or Viton contained

within a metal shell. Clear water from an

outside source, 1 to 2 GPM, is required to each

bearing housing. They are ideally suited for

liquids containing abrasive solids but are limited

to 160°F temperature liquid. Corrosion resistant

shafting is required.

3. Metallic Bearing - Bronze steady bearings are

available and must be grease lubricated. Lack

of lubrication can lead to galling and eventual

seizing. It becomes extremely difficult to keep

enough grease in the housing when handling

hot liquids, caustic solutions or solvents.

Unless an adequate maintenance program

exists, it is recommended that a self-lubricating

bearing such as carbon be used in place of the

metallic bearing.

4. Sealed Bearings - Recommended for abrasive

liquids where no outside flush is available. The

carbon bearing is sealed within the housing by

two lip seals and filled by grease via pressure

lubricator located above the support plate. The

pressure cup must be kept full of grease. The

control screw on the pressure cup should be

wide open to start and then controlled by

usage.

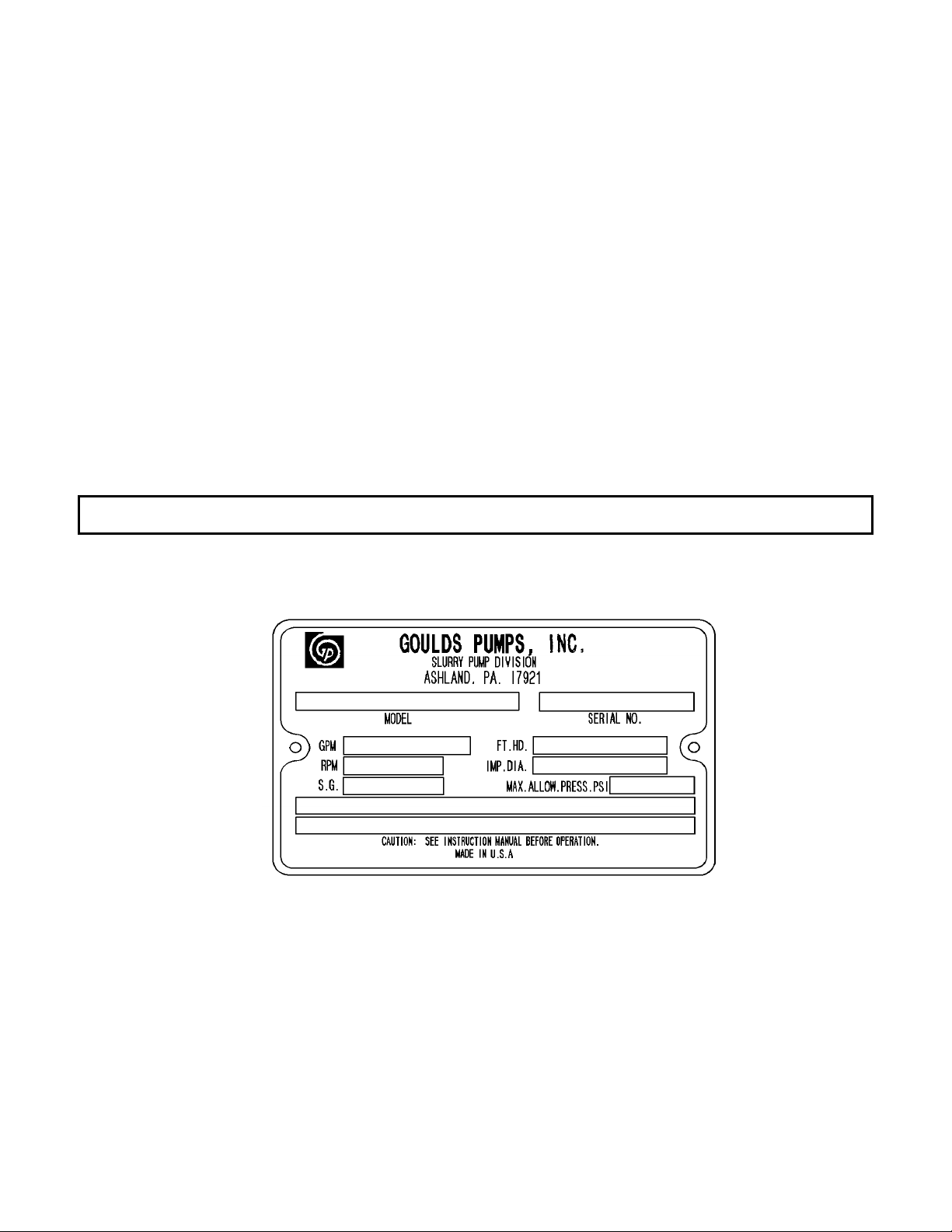

NAMEPLATE INFORMATION

Pump Nameplate – Every pump has a Goulds nameplate that provides information about the pump. The tag is

located on the motor support. When ordering spare parts you will need to identify pump model, size, serial

number, and the item number of required parts. Information can be found in this manual. Part numbers can also

be found on the Repair Data Sheet supplied with the original pump data package.

Figure#1#

Page 13

CV#3171#IOM#05/11# 13

RECEIVING THE PUMP

Inspect the pump as soon as it is received.

Carefully check that everything is in good order.

Make notes of damaged or missing items on the

receipt and freight bill. File any claims with the

transportation company as soon as possible.

STORAGE REQUIREMENTS

Short Term: (Less than 6 months) Goulds normal

packaging is via a skid. It is designed to protect

the pump during shipping only. Upon receipt,

store in a covered and dry location.

Long Term: (More than 6 months) Preservative

treatment of bearings and machined surfaces is

required. Rotate the shaft several times every

three months making sure that the shaft does not

stop in the same place as it may sag. Refer to

driver and coupling manufacturers for their

recommended long-term storage procedures.

Store in covered dry location.

NOTE: Long term storage treatment can be

purchased with the initial pump order.

HANDLING

WARNING

Pump and components are heavy. Failure to

properly lift and support equipment

could result in serious physical injury

or damage to pumps. Steel toe shoes

must be worn at all times.

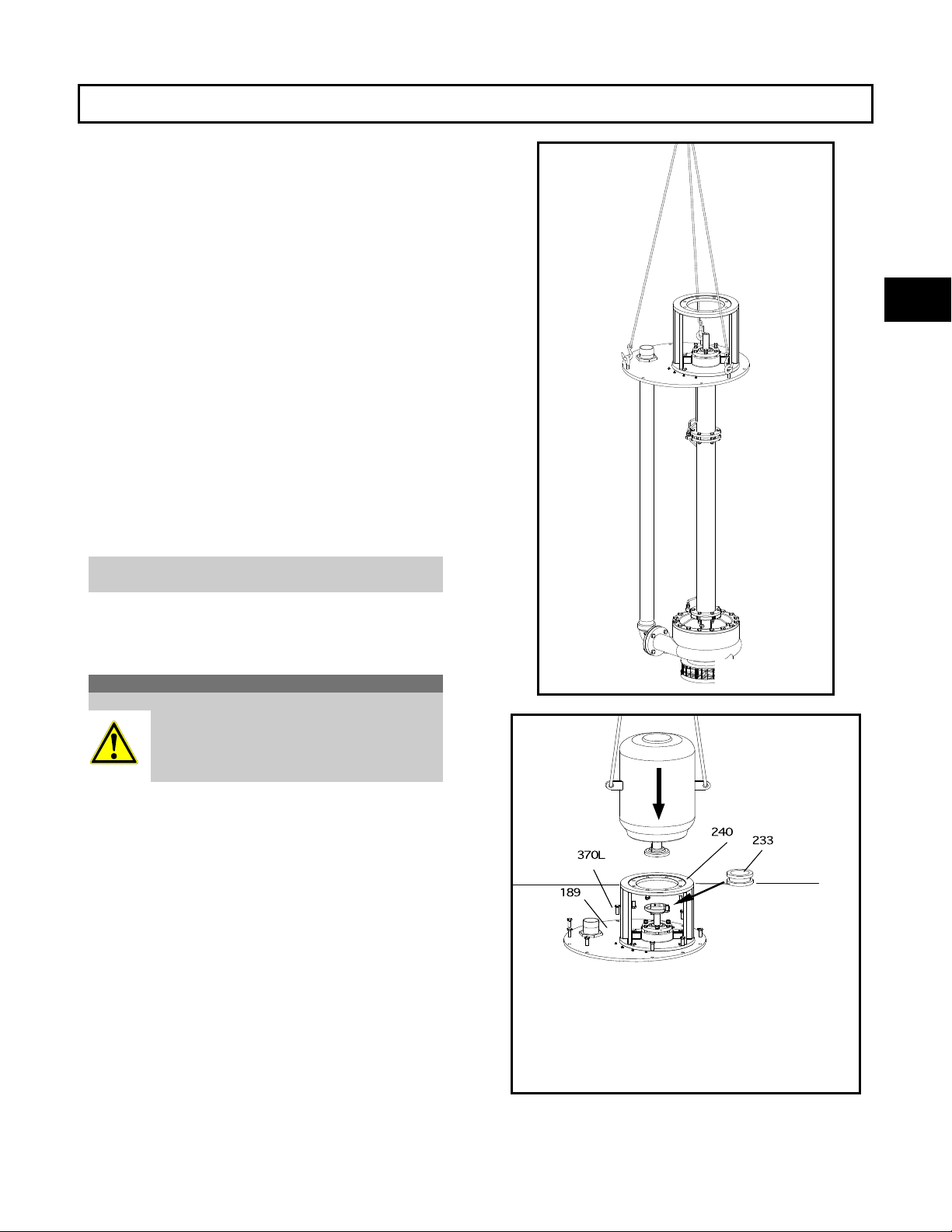

Use care when moving pumps. Lifting equipment

must be able to adequately support the entire

assembly. Position the pump where it can be

handled without dragging the casing on the ground

or moving the lifting equipment while the pump is

off the ground. Use the lifting lugs supplied with

the unit and suitable slings to lift the entire pump

to a vertical position (Figure 2). A tag line should

be attached to the casing end to prevent the pump

from swinging and possibly causing damage or

injury. Lower the unit into the sump. The motor

should then be hoisted into position using the

lifting lugs on the motor and a suitable sling

(Figure 3).

Figure#3#

Figure#2#

2!

Page 14

14 CV#3171#IOM#05/11#

UNCRATING/DESKIDDING

Care should be taken when uncrating or

deskidding pumps. If shipment is not delivered in

good order, and in accordance with the bill of

lading, note the damage or shortage on both the

receipt and freight bill.

Make any claims to the transportation company

promptly. Instruction sheets as well as the

instruction book for the pump are included in the

shipment.

CV 3171 Installation and Operation Checklist

COMPLETE

INITIAL

DESCRIPTION

SECTION NO.

Installation Manual Received and Read

ALL

Level Pit Opening

3

Level Support Plate

3

Check Motor Rotation ---CW ---CCW

3

Install Coupling

3

Rough Alignment Completed

3

Piping Installed and Alignment Rechecked

3

Flush or Grease Piping Connected

4

Impeller Clearance Set ______ Inch

4,5

Pump Shaft-Free Turning

4

Float Controls Understood

4

Bearing Types and Lubrication

4

Coupling Guard Installed

4

Discharge Valve Partially Open

4

Page 15

CV#3171#IOM#05/11# 15

INSTALLATION

INSPECTION ......................................................................................................................... 15

SITE/FOUNDATION .............................................................................................................. 16

WHEN PIT COVER IS USED................................................................................................. 16

NO PIT COVER...................................................................................................................... 17

IMPELLER CLEARANCE SETTING..................................................................................... 17

MOTOR INSTALLATION AND COUPLING ALIGNMENT ................................................... 17

PIPING ................................................................................................................................... 19

INSPECTION

Equipment that will operate in a

potentially explosive

environment must be installed

in accordance with the following

instructions.

All equipment being installed

must be properly grounded to

prevent unexpected static

electric discharge. If not, a static

electric discharge may occur when the

pump is drained and disassembled for

maintenance purposes.

Service temperature in an

ATEX classified environment

is limited by Table 1 in the

ATEX identification section.

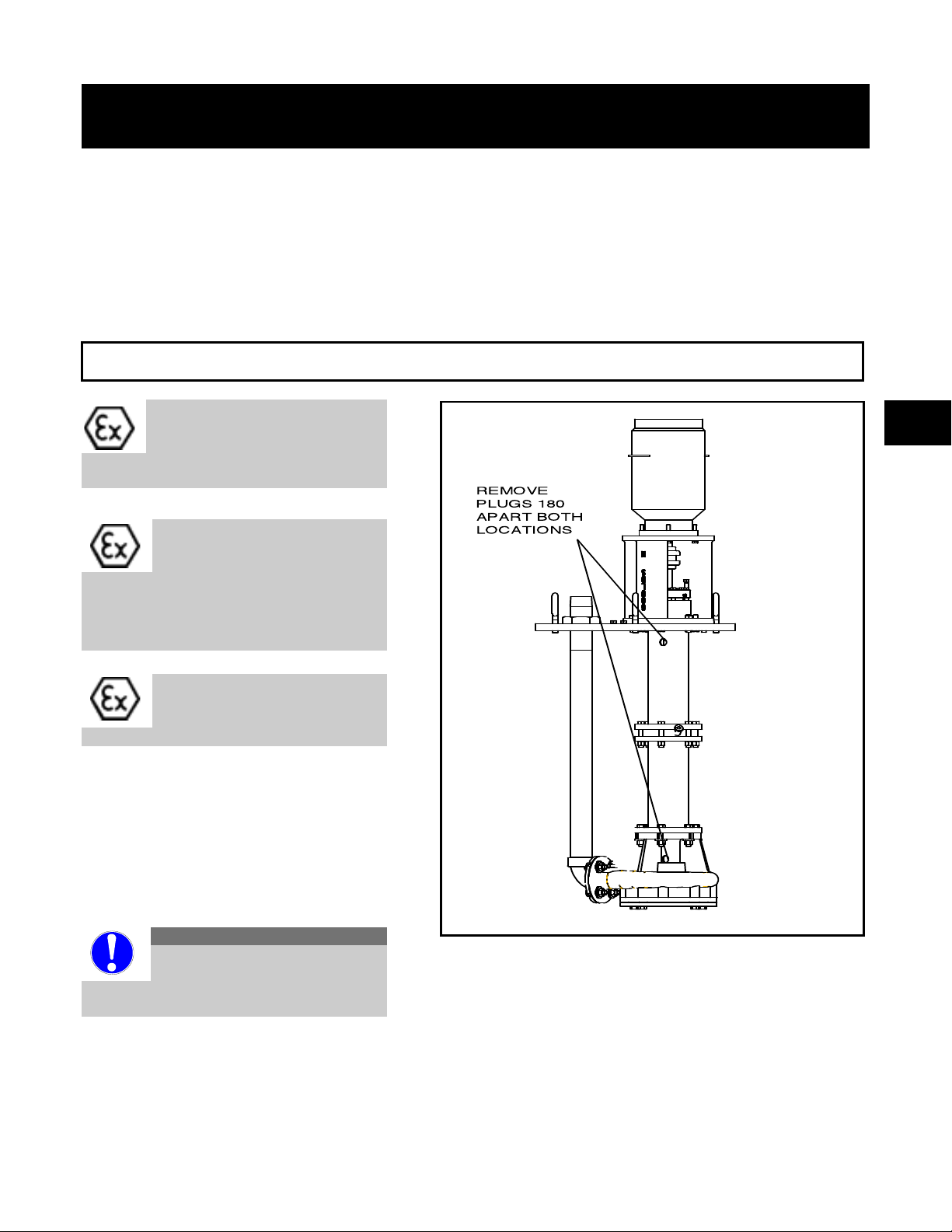

1. Remove all equipment from shipping

containers.

2. Completely clean the underside of the

support plate, and both sides of the

optional pit cover (if supplied).

3. Remove any grease from machined

surfaces if applicable.

CAUTION

Remove plastic shipping plugs

from the vent holes in the head

column and casing. Refer to Figure 4 for

locations.

3!

Figure#4#

Page 16

16 CV#3171#IOM#05/11#

SITE/FOUNDATION

The pump should be located where there is

adequate space for installation, operation,

maintenance, and inspection. Make sure there is

adequate overhead clearance for installing and

removing the pump. There should be at least 1/2”

clearance between the sides of the pump and

any portion of the pit.

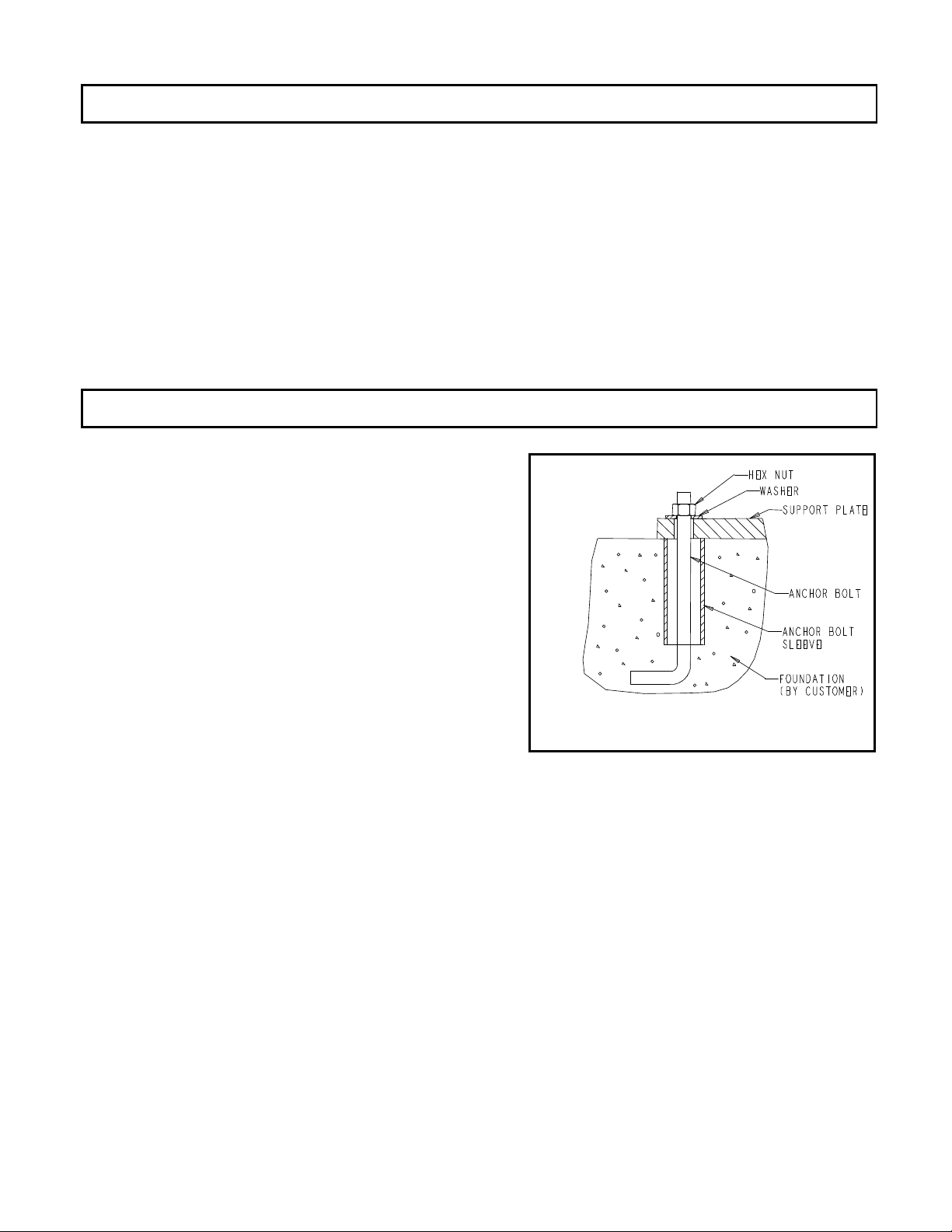

Vertical sump pumps are normally bolted to a

concrete sump or steel tank. The supporting

structure must provide a permanent rigid support

for the pumping unit(s) to eliminate any possible

vibration. Support plates and/or pit covers are not

normally grouted in place. The location and size

of the mounting bolt holes are shown on the

pump outline drawing provided with the pump

data package. If anchor bolts are to be poured

into the concrete, it is recommended that a

sleeve type as shown in Figure 5 be used to

allow for adjustment.

WHEN PIT COVER IS USED

If access to the bottom of the pit cover is not

possible during the installation process, the

pump (less motor), support plate and pit cover

must be assembled and installed as a unit.

1. The pit cover must be installed level to insure

that the pump remains plumb when installed.

2. Carefully lower pit cover foundation bolts.

3. Using as long a level as practical, level the

pit cover in all directions with shims or

wedges.

4. Hand tighten the anchor bolts, check the

level and re-shim if necessary.

5. Tighten all anchor bolts in a star pattern to

avoid distorting the support plate.

6. If access to the bottom side is possible,

carefully lower the pump and support plate

onto the pit cover.

7. Install all bolts finger tight.

8. Check level on support plate and shim if

necessary.

9. Tighten all bolts in a star pattern to avoid

distorting the support plate.

Vapor Proof Option

The vapor proof option includes machined,

gasketed fits between the support plate/pit cover

and the pit cover/foundation. These gaskets

must be installed to insure emissions

performance. The pit cover should be bolted to a

metal sole plate with a machined surface to

insure an airtight seal.

Figure#5#

Figure 5

Page 17

CV#3171#IOM#05/11# 17

NO PIT COVER

Standard Support Plates

1. Carefully lower the pump and support plate onto

the foundation bolts.

2. Level the support plate in all directions using

shims and wedges.

3. Hand tighten the anchor bolts, check the level

and re-shim if necessary.

4. Tighten all anchor bolts in a star pattern to avoid

distorting the support plate.

5. Assure that the support plate is level.

Vapor Proof Option

The support plate/foundation fit is a gasketed fit.

The support plate should be bolted to a metal sole

plate with a machined surface to insure an airtight

seal. Refer to Figure 6 for standard layout. A gasket

is supplied for installation between the two flanges

to insure an airtight fit.

Tank Flange Support Plates

1. Mating flange on the tank must be level. Very

minor adjustments can be made with gasket

material between the two flanges.

2. Install all bolts finger tight.

3. Tighten all bolts in a star pattern to avoid any

distortion of the support plate.

IMPELLER CLEARANCE SETTING

Adjust the impeller clearance setting. This

procedure is easiest to perform without the motor

and coupling installed. See Section 5, “Impeller

Clearance Setting” for proper procedure.

MOTOR INSTALLATION AND COUPLING ALIGNMENT

The Model CV3171 is designed for use with NEMA

Vertical C-face motors. P-Base motor adapters and

IEC motor adapters are available as options.

Installation

1. Install both coupling halves prior to mounting

the motor. Refer to the coupling manufacturers

instructions.

2. Using the lifting lugs on the motor, carefully

lower the motor onto the pump and align the

bolt holes.

3. Install motor bolts and finger tight.

4. Before the coupling is connected, the motor

must be wired and the direction of rotation

checked. A rotation arrow is located on the

motor support. Correct rotation for the pump is

CW looking down from the driver at the

impeller.

Checking Rotation

CAUTION

Serious damage may result if pump is

run in the wrong direction.

Figure#6#

3!

FOUNDATION#

GASKET#

189#

Page 18

18 CV#3171#IOM#05/11#

WARNING

Lock out power to prevent accidental

start-up and physical injury.

1. Lock out power to driver.

2. Make sure coupling hubs are securely

fastened to shafts.

3. Ensure all persons and material are clear of

pump.

4. Unlock driver power.

5. Bump motor and observe rotation. Correct if

required.

Alignment of Flexible Coupling

WARNING

Before beginning any alignment

procedure, make sure the driver power

is locked out. Failure to lockout driver

power will result in serious physical injury.

Alignment of the pump and motor is of extreme

importance for trouble-free mechanical operation.

Straight edge alignment by an experienced

installer proves adequate for most installations. For

disc couplings and applications where it is felt that

alignment to tighter tolerances is desirable, use

dial indicators. Standard dial indicator procedures

would apply.

Alignment procedures must be

followed to prevent unintended

contact of rotating parts. Follow

coupling manufacturer’s installation and

operation procedures.

When installing in a potentially

explosive environment, ensure that the

motor is properly certified.

The coupling used in an ATEX

classified environment must be

properly certified.

Straight Edge Alignment

1. Check for coupling alignment by laying a

straight edge across both coupling rims at four

points 90 degree apart.

2. Move motor until straight edge rests evenly at

each position. Repeat procedure until correct

alignment is achieved.

3. Install flexible sleeve between the hubs per the

manufacturer’s directions included with the

pump data package.

4. Tighten all motor bolts.

Coupling Guard

WARNING

Never operate a pump without

coupling guard properly installed.

Personal injury will occur if pump is

run without coupling guard.

1. Install coupling guard (See Figure 7) by

wrapping the expanded metal shield (501)

around the motor support and installing the two

guard springs (501L).

Figure#7#

Page 19

CV#3171#IOM#05/11# 19

PIPING

General

Guidelines for piping are given in the “Hydraulic

Institute Standards” available from: Hydraulic

Institute, 9 Sylvan Way, Parsippany, NJ, 070543802 and must be reviewed prior to pump

installation.

1. All piping must be supported independently of,

and line up naturally with, the pump discharge

pipe.

2. Piping runs should be as short as possible to

minimize friction losses.

3. DO NOT connect piping to pump until the

anchor bolts have been tightened.

4. Carefully clean all pipe parts, valves and fittings,

prior to assembly.

5. Isolation and check valves should be installed in

the discharge line. Locate the check valve

between the isolation valve and the pump in

order to permit inspection of the check valve.

The isolation valve is required for inspection of

the pump and flow regulation. The check valve

prevents pump damage due to reverse flow

through the pump when the driver is turned off.

6. Increasers, if used, should be installed between

the pump and check valve to minimize friction

losses through the check valve.

7. Cushioning devices should be used to protect

the pump from surges and water hammer if

quick closing valves are installed in the system.

Suction Piping - For Optional Dry Pit,

Outside Tank Mount, and Tailpipe

Applications ONLY

WARNING

NPSHA must always exceed

NPSHR as shown on Goulds

performance curve received with

order. Reference Hydraulic Institute standard for

NPSH and pipe friction values needed to

evaluate suction piping.

1. The general requirement for the pump is to

install an elbow at the pump. Long radius elbows

are recommended. If an elbow can be

eliminated or moved further from the suction, it

would be recommended to do this.

2. Suction piping should never be of a smaller

diameter than the pump suction.

3. Pump should never be throttled on the suction

side.

4. Separate suction lines are recommended when

more than one pump is operating from the same

source of supply.

5. Suction pipe must be free of air pockets.

6. Suction piping must slope upwards to the pump.

7. All joints must be airtight.

8. A means of priming the pump must be provided.

For outside tank mount and dry pit, this is

usually accomplished by allowing the fluid level

inside the tank/pit to rise above the casing level.

In tailpipe applications, the casing must be

submerged prior to starting the pump.

9. For outside tank mount and dry pit applications,

an isolation valve should be installed in the

suction line at least two pipe diameters from the

suction to permit closing the line for pump

inspection and maintenance. Isolation valve

must be kept fully open during operation.

10. The entrance to the suction pipe must be kept

adequately submerged below the free liquid

surface to prevent vortices and air entrainment.

Outside Tank Mount Only

The outside tank mount option has a column

assembly that allows the fluid coming through the

lower bushings to flow up through the column and

back through the connection at the top of the column

back to the tank. The pipe at the top of the pump

column must be connected back to the source tank

to prevent fluid from entering the thrust bearing.

3!

Page 20

20 CV#3171#IOM#05/11#

WARNING

Never draw piping into place by

forcing at the flanged

connections of the pump. This

may impose dangerous strains

on the unit and cause misalignment between

pump and driver. Pipe strain will adversely

effect the operation of the pump resulting in

physical injury and damage to the equipment.

CAUTION

Pump must never be throttled on

suction side.

Page 21

CV#3171#IOM#05/11# 21

OPERATION

PREPARATION FOR OPERATION.......................................................................................21

OPERATION...........................................................................................................................23

PREPARATION FOR OPERATION

The following options may be supplied with your

pump. Refer to the original data package to see

which options apply.

WARNING

Operation of the unit without proper

lubrication will cause bearing failure

and pump seizure.

External Bearing Flush

There are five 1/4” NPT pipe plugs on the standard

support plate for connection of up to five flush

lines. Pumps with five or more bearings will have

one for each bearing. Pumps with less than five

bearings will still have five plugs, but only the

required number will be connected to a bearing.

Remove the plugs from the holes that are

connected to flush lines. An external source of

clean water capable of delivering 1-2 GPM to

EACH bearing should be connected to the taps.

NOTE: The flush must be turned on PRIOR to

starting the pump and remain on until the pump

turns off.

Grease Lubricated Bearings

Bearings must be lubricated properly

in order to prevent excess heat

generation, sparks and premature

failure.

Grease lubricated bearings will have zerk fittings

installed for each bearing. Bearings are prelubricated at the factory. Unscrew the fittings and

confirm there is adequate grease in the line.

Replace the fitting and add grease if necessary.

Sealed Bearings

Sealed bearings have a lip seal installed above

and below the bearing to exclude grit from the

bearing (Figure 8). Sealed bearings use a spring

loaded grease cup to lubricate the bearings. The

bearings are pre-lubricated at the factory, but the

grease cups may ship in a separate box. The

grease cups should be filled with grease and

screwed into the taps that are connected to the

bearings.

NOTE: The control screw on the pressure cup

should be wide open to start and then

controlled by usage.

The cup should be refilled with fresh grease as

needed. Frequent inspection after startup is

recommended to check usage and establish the

best relubrication interval.

Packed Upper Stuffing Box

Packed stuffing boxes are not allowed

in an ATEX classified environment.

An upper stuffing box is installed for high

Figure 8

4!

Page 22

22 CV#3171#IOM#05/11#

temperatures and vapor proof construction. The

standard configuration is packed. Since no fluid is

in the column to lubricate the packing, the packing

is grease lubed. The packing is installed at the

factory prior to shipment. A screw type grease cup

is provided for the packed box. Fill the cup with

grease and give the cap several turns to force

grease into the packing. Fresh grease should be

installed on a regular basis to insure constant

lubrication for the packing. Frequent inspection

after startup is recommended to check usage and

establish the best relubrication interval.

Mechanical Seal Upper Stuffing Box

A mechanical seal is frequently supplied on upper

stuffing box applications. The seal is installed and

set at the factory. Cartridge seals will still have the

setting clips installed and should be removed.

Refer to the seal manufacturer’s guidelines for any

special requirements for the particular seal

provided.

The mechanical seal used in an ATEX

classified environment must be

properly certified.

The mechanical seal must always be

properly flushed. Failure to do so will

result in excess heat generation and

seal failure.

WARNING

Some seals require oil lubrication from

a bottle oiler, some are dry running,

and some may require external flush

plans. Do not allow the seal to run dry

unless it is specifically designed for dry

running.

Steam Jacketed Pumps

The steam jacket connections are located on the

support plate. Connect the steam in line to an

appropriate source of steam. The steam

out/condensate return connections should be

made as dictated by the installation requirements.

A suitable trap should be used.

Float Controls

A variety of float controls can be supplied by

Goulds. Refer to the float control installation

instructions provided with the controls for proper

installation procedure. Procedures for some of the

more common controls are provided in Appendix I.

Checking Rotation

Rotation should have been checked prior to

coupling alignment and installation. Refer to

previous section if this has not been done.

Check For Free Turning

Before pump is started, rotate the pump by hand to

be sure it turns freely and does not rub or bind.

Motor Bearing and Coupling

Check to be sure the motor bearings and coupling

are properly lubricated, if required. Refer to

manufacturers recommendations.

Check Impeller Clearance

Improper impeller adjustment could

cause contact between the rotating

and stationary parts, resulting in a

spark and heat generation.

WARNING

Check impeller clearance before

starting pump.

The pump efficiency is maintained when the proper

impeller clearance is set. The clearance is initially

set at the factory. The settings from the factory

could change due to piping attachment. Refer to

Section 5 for procedures on setting impeller

clearance.

Coupling Guard and Safety Devices

Insure coupling guard and any other safety devices

are properly installed.

Priming

Pumps that are not self-priming must

be fully primed at all times during

operation.

Never start the pump until it has been properly

primed. The pump casing should be fully

submerged prior to starting the pump.

CAUTION

Do not run the pump dry, as this may

damage the pump and/or steady

bearings.

Page 23

CV#3171#IOM#05/11# 23

For Dry Pit/Outside tank mount units:

1. Suction supply line must have adequate fluid

head to prime the pump.

2. Slowly open the suction valve.

Starting the Pump

1. Before the pump is started, the external

bearing flush (if specified) must be started.

2. Make sure the pump shaft is freely rotating.

3. Partially open the discharge valve.

4. Start driver.

5. Slowly open discharge valve until the desired

flow is obtained.

CAUTION

Observe pump for high vibration

levels, bearing temperature, and

excessive noise. If normal levels are

exceeded, shut down and resolve.

Immediately observe pressure gauges. If

discharge pressure is not quickly attained, stop

driver, check submergence level, and attempt to

restart.

Start Up Precautions

1. All equipment and personal safety-related

devices and controls must be installed and

operating properly.

2. To prevent premature pump faiure at initial

start up due to dirt or debris in the pipe

system, ensure the system has been

adequately cleaned and flushed.

3. Variable speed drivers should be brought

to rated speed as quickly as possible.

4. Variable speed drivers should not be

adjusted or checked for speed governor or

overspeed trip settings while coupled to the

pump at initial start up. If settings have not

been verified, uncouple the unit and refer to

driver manufacturer’s instructions for

assistance.

6. Pumpage tempartatures in excess of 200°F

will require warmup of pump prior to

operation. Circulate a small amount of

pumpage through the pump until the casing

temperature is within 100°F of the pumpage

temperature and evenly heated.

CAUTION

When starting pump,

immediately observe pressure

gauges. If discharge pressure

is not quickly attained, stop

driver, reprime, and attempt to restart.

OPERATION

General Considerations

CAUTION

Always vary capacity with

regulating valve in the

discharge line. Never throttle

flow from the suction side.

CAUTION

Driver may overload if the

pumpage specific gravity

(density) is greater than

originally assumed, or the rated flow rate is

exceeded.

CAUTION

Always operate the pump at or

near the rated conditions to

prevent damage resulting from

cavitation or recirculation.

4!

Page 24

24 CV#3171#IOM#05/11#

Operating At Reduced Capacity

WARNING

DO NOT operate pump below

minimum rated flows or with

discharge valve closed. These

conditions may create an explosive hazard due

to vaporization of pumpage and can quickly

lead to pump failure and physical injury.

A centrifugal pump should never be operated

continuously near shut-off or zero capacity, or with

the discharge valve closed. To do so may shorten

the life of the pump and greatly increase down time

and maintenance.

CAUTION

Damage occurs from:

1. Increased vibration levels - affects

bearings, stuffing box or seal chamber, and

mechanical seal.

2. Increased radial loads – Stresses on shaft

and bearings.

3. Heat buildup - Vaporization causing

rotating parts to score or seize.

4. Cavitation - Damage to internal surfaces of

pump.

CAUTION

Serious damage may result if

the pump is run in the wrong

direction.

CAUTION

Operation of the unit without

proper lubrication will cause

bearing failure, and pump

seizure.

Operating At Reduced Head

On motor driven pumps, when discharge head is

dropped below the rated point, the motor should be

watched for overloading. If this condition is likely

to persist, arrangements should be made to either

manually or automatically throttle the discharge

valve to build up head to prevent overloading.

Operating With Surge Conditions

If pump is installed with a quick closing valve in the

discharge line that closes when the pump is

running, dangerous pressure surges may be built

up that can cause damage to the pump or line.

In services of this kind, some cushioning

arrangement must be provided to protect the

pumping equipment.

Operating Under Freezing Conditions

Exposure to freezing conditions while pump is idle

could cause liquid to freeze and damage the pump.

Liquid inside pump should be drained.

Final Alignment/Clearance Check

1. Run the unit under actual operating conditions

for a sufficient length of time to bring the pump

and driver up to operating temperature.

2. Check alignment while unit is still hot per

alignment procedure.

3. Reinstall coupling guard.

The coupling guard used in an

ATEX classified environment

must be constructed from a

non-sparking material.

Page 25

CV#3171#IOM#05/11# 25

PREVENTIVE MAINTENANCE

GENERAL COMMENTS ...................................................................................................... 25

MAINTENANCE SCHEDULE............................................................................................... 25

MAINTENANCE OF BALL/STEADY BEARINGS ............................................................... 26

MAINTENANCE OF UPPER STUFFING BOX .................................................................... 27

IMPELLER CLEARANCE SETTING – CV 3171.................................................................. 28

IMPELLER CLEARANCE SETTING – LF Sizes

TROUBLESHOOTING ......................................................................................................... 31

GENERAL COMMENTS

A routine maintenance program can extend the life of your pump. Well-maintained

equipment will last longer and require fewer repairs. Accurate records should be kept

as they will identify trends and help pinpoint potential causes of problems.

MAINTENANCE SCHEDULE

ROUTINE MAINTENANCE

Bearing lubrication

Discharge pressure

Temperature monitoring

Vibration analysis

Seal monitoring (when applicable)

ROUTINE INSPECTIONS

Check for unusual noise, vibration and thrust

bearing temperatures

Check float controls for proper setting and

operation

Inspect pump and piping for leaks

Check grease for thrust bearing. Refer to

Table 1, Section 5 for lubrication intervals.

Grease steady bearings if applicable, adjust

grease cups if supplied

Check upper stuffing box leakage. Adjust or

replace packing if required (when applicable)

3 MONTH INSPECTIONS

Check anchor bolts for tightness

If pump has been idle, check carbon steel

shafts (if applicable) for rust and seizing by

rotating the shaft several turns. Replace if

required.

Ball (thrust) bearing grease should be changed

at least every 3 months or according to Table 1,

whichever occurs first. Change grease more

often if there are any adverse conditions which

may contaminate the grease. Grease should be

injected while turning the shaft until fresh

grease comes out.

• Check coupling alignment and realign if

required

ANNUAL INSPECTIONS

• Check pump capacity, pressure and power. If

pump performance does not satisfy your

process requirements, and process

requirements or the piping system has not

changed, pump should be disassembled,

inspected, and worn parts should be replaced. If

there is no sign of wear, a system inspection

should be done.

The Preventive Maintenance section

must be adhered to in order to keep the

applicable ATEX classification of the

equipment. Failure to follow these procedures

will void the ATEX classification for the

equipment.

Inspection intervals should be

shortened appropriately if the

pumpage is abrasive and/or corrosive,

or if the environment is classified as potentially

explosive.

5!

Page 26

26 CV#3171#IOM#05/11#

MAINTENANCE OF BALL/STEADY BEARINGS

BALL BEARINGS

The angular contact (thrust) bearing is prelubricated at the factory. Regrease the bearing

according to Table 1.

STEADY BEARINGS

Steady bearings requiring grease lubrication are

pre-lubricated at the factory. Most bearings are set

up to automatically dispense lubrication via grease

cups mounted on the support plate.

Metallic steady bearings are grease lubricated. It

becomes difficult to keep grease in the housings

when handling hot liquids, caustic solutions or

solvents. Lack of lubrication can cause galling and

eventual seizing.

Sealed bearings are grease lubricated but they

retain the grease due to their dual seals on top and

bottom. If pressure cups are used they must be

kept full of grease at all times.

If manual greasing is used, regrease according to

Table 1.

TABLE 1

LUBRICATING INTERVALS

IN OPERATING HOURS

SPEED

<1800

RPM

1800

RPM

3000

RPM

3600

RPM

GROUP

S/ST

2000

2000

1200

750

M/MT

2000

1800

800

450

L

2000

1200

N/A

N/A

REGREASE PROCEDURE BALL BEARING:

NOTE: When regreasing there is danger of

impurities entering the bearing shell. The

grease, the greasing device, and fittings must

be clean.

1. Wipe dirt from grease fittings.

2. Fill grease cavity through grease fitting (193B)

on bearing shell (134). Use recommended

grease and fill until fresh grease comes out of

the relief fitting (113) on the opposite side of the

bearing shell (See Figure 9).

3. Wipe excess grease from grease and relief

fittings.

4. Ensure relief port closes.

NOTE: The bearing temperature usually rises

after regreasing due to an excess supply of

grease. Temperature will return to normal after

the pump has run and purged the excess from

the bearings, usually two to four fours.

For most operating conditions a lithium complex

soap based grease of NLGI consistency No. 2 is

recommended. This grease is acceptable for

bearing temperatures of 5°F to 230°F (-15°C to

115°C). Bearing temperatures are generally about

20°F (18°C) higher than bearing housing outer

surface temperature.

CAUTION

Never mix greases of different

consistency (NLGI 1 or 3 with NLGI 2)

or different thickener. For example,

never mix a lithium based grease with a

polyurea based grease.

Figure#9#

Page 27

CV#3171#IOM#05 /11# 27#

The original grease from the factory is a lithium

based NLGI 2. Table 2 lists some various

manufacturers compatible greases.

Temperature extremes (either high or low) may

require a different grease.

NOTE: If it is necessary to change the grease

type or consistency, the bearing must be

removed and all the old grease eliminated from

the housing and bearing.

Bearings must be lubricated properly

in order to prevent excess heat

generation, sparks and premature

failure.

Throughout this section on bearing

lubrication, different pumpage

temperatures are listed. If the

equipment is ATEX certified and the listed

temperature exceeds the applicable value

shown in Table 1 under ATEX identification,

then that temperature is not valid. Should this

situation occur, please consult with your ITT

Goulds representative.

5!

TABLE 2

LUBRICATING GREASE REQUIREMENTS

Pumpage temperature

below 230°F (115° C)

NLGI Grade

2

Mobil

Mobilith AW2

Exxon

Unirex N2

Sunoco

Multipurpose EP

SKF

LGMT 2

Page 28

28 CV#3171#IOM#05/11#

IMPELLER CLEARANCE SETTING – CV 3171

Sizes: 2 x 2-8; 2 x 2-10; 3 x 3-10; 2 x 3-13; 3 x 4-13

WARNING

Lock out driver power to prevent

electric shock, accidental startup and

physical injury.

DIAL INDICATOR METHOD

1. Remove coupling guard.

2. Remove coupling if required

3. Set indicator so that indicator button contacts

either the shaft end or the face of the coupling

(Figure 10).

4. Loosen each locking bolt (370C) several turns.

5. Loosen jam nuts (415) on jack bolts (370D) and

turn bolts in several turns until impeller contacts

the adapter cover. Turn shaft to ensure contact

is made.

6. Set dial indicator at zero.

7. Alternately back off the jacking bolts (370D) and

tighten the locking bolts (370C) to move the

impeller away from the adapter cover until the

dial indicator shows that a .060” clearance has

been obtained.

8. Tighten all bolts and the jam nuts (415) evenly.

9. Check shaft for free turning.

10. Replace coupling.

11. Replace coupling guard.

FEELER GAUGE METHOD

1. Remove coupling guard.

2. Remove coupling if required.

3. Loosen each locking bolt (370C) several turns

(Figure 11).

4. Loosen jam nuts (415) on jack bolts (370D) and

turn bolts in several turns until impeller contacts

the adapter cover. Turn shaft to ensure contact

is made.

5. Turn in locking bolts (370C) until they are snug

against the shell. Loosen jack bolts (370D) until

a 0.060” feeler gauge can be inserted between

the underside of the locking bolt head (370C)

and the bearing shell (134).

6. Tighten locking bolts (370C) evenly until they

are tight against the bearing shell (134). Make

sure all bolts are tight. Tighten jam nuts (415).

7. Check the shaft for free rotation.

8. Replace coupling.

9. Replace coupling guard.

Both of the above methods set the impeller 0.060”

away from the adapter, giving the required clearance

for ambient temperatures. For high temperatures, it

is recommended that this procedure be repeated

after the pump reaches operating temperature.

Figure#10#

Figure#11#

Page 29

CV#3171#IOM#05/11# 29#

IMPELLER CLEARANCE SETTING – LF SIZES

LF 1 x 1.5-8; LF 1 x 2-10; LF 1.5 x 3-13

WARNING

Lock out driver power to prevent

electric shock, accidental startup and

physical injury.

DIAL INDICATOR METHOD

1. Remove coupling guard.

2. Remove coupling if required.

3. Set indicator so that indicator button contacts

either the shaft end or the face of the pump

coupling hub (Figure 12).

4. Loosen jam nuts (415) on jack bolts (370D).

Back off jack bolts several turns.

5. Turn all locking bolts (370C) in several turns

until impeller contacts the casing (100). Turn

shaft to insure contact has been made.

6. Set dial indicator at zero.

7. Loosen the locking bolts (370C) and tighten the

jacking bolts (370D) to move the impeller away

from the suction cover until the dial indicator

shows that a 0.015” clearance has been

obtained.

8. Tighten all bolts and the jam nuts (415) evenly.

9. Check the shaft for free rotation.

10. Replace coupling.

11. Replace coupling guard.

FEELER GAUGE METHOD

1. Remove coupling guard.

2. Remove coupling if required.

3. Loosen jam nuts (415) on jack bolts (370D).

Back off jack bolts several turns (Figure 13).

4. Turn all locking bolts (370C) in several turns

until impeller contacts the casing (100). Turn

shaft to insure contact has been made.

5. Loosen locking bolts (370C) until a 0.015” feeler

gauge can be inserted between the underside

of the bolt head and the bearing shell (134).

6. Tighten jack bolts (370D) evenly until the

bearing shell (134) is tight against the locking

bolts (370C). Make sure all bolts are tight.

Tighten jam nuts (415).

7. Check the shaft for free rotation.

8. Replace coupling.

9. Replace coupling guard.

Both of the above methods set the impeller 0.015”

away from the adapter, giving the required

clearance for ambient temperatures. For high

temperatures, it is recommended that this

Figure 12

Figure 13

5!

Page 30

30 CV#3171#IOM#05/11#

procedure be repeated after the pump reaches

operating temperature.

The impeller clearance setting

procedure must be followed.

Improperly setting the clearance or not

following any of the proper procedures can

result in sparks, unexpected heat generation

and equipment damage.

Page 31

CV#3171#IOM#05/11# 31

TROUBLESHOOTING

Problem

Probable Cause

Remedy

Pump not primed.

No liquid in pit. Fill pit above casing. On dry

pit units, casing and suction pipe must be

completely filled.

Discharge head too high.

Check total head, particularly friction loss.

Speed too low.

Check motor speed.

Wrong direction of rotation.

Check rotation.

Impeller, discharge pipe, strainer

completely plugged.

Remove obstructions or backflush.

Suction pipe problems (where

applicable)

Check suction lift, it may be too high. Line

may be plugged.

No liquid delivered.

Inadequate NPSH available.

Check NPSH available and required.

Impeller, discharge pipe, or strainer

partially plugged.

Remove obstructions or backflush.

Wrong direction of rotation

Check rotation.

Discharge head higher than

anticipated.

Check total head, particularly friction loss.

Worn or broken impeller.

Inspect and replace if necessary.

Suction pipe problems (where

applicable)

Check suction lift, it may be too high. Line

may be plugged.

Speed too low.

Check motor speed.

Air or gasses in liquid.

Increase submergence; rearrange piping to

prevent entrained air.

Pump not producing

rated flow or head.

Inadequate NPSH available.

Check NPSH available and required.

Float controls misadjusted.

Check float controls.

Air or gasses in liquid.

Increase submergence; rearrange piping to

prevent entrained air.

Strainer plugged.

Check sump for large items that the pump

may be picking up.

Pump starts then

stops running.

Air leak in suction line (where

applicable).

Repair leak.

Improper alignment.

Realign pump and driver.

Bearings run hot.

Improper lubrication.

Check lubricant for suitability and level.

Foundation not rigid.

Tighten hold down bolts; stiffen foundation.

Improper pump/driver alignment.

Align shafts.

Partially clogged impeller causing

unbalance.

Backflush pump to clean impeller.

Binding, loose, broken rotating parts.

Inspect and replace as required.

Bent shaft.

Straighten or replace.

Worn bearings.

Inspect and replace as required.

Discharge piping or suction piping not

anchored or properly supported.

Anchor and support per Hydraulic Institute

standards.

Pump is noisy or

vibrates.

Pump is cavitating.

Correct system problem.

Head lower than rating. Pump is

pumping too much liquid.

Install throttle valve or trim impeller.

Liquid heavier than expected.

Check specific gravity and viscosity.

Rotating parts binding.

Check internal wear parts for proper

clearances.

Motor requires

excessive power

Speed too high

Check motor.

5!

Page 32

32 CV#3171#IOM#05/11#

THIS PAGE INTENTIONALLY LEFT BLANK

Page 33

CV#3171#IOM#05/11# 33

DISASSEMBLY & REASSEMBLY

REQUIRED TOOLS................................................................................................................33

DISASSEMBLY ......................................................................................................................33

INSPECTIONS........................................................................................................................39

REASSEMBLY .......................................................................................................................41

SECTIONAL ..................................................................................................................... 45-46

REQUIRED TOOLS

• Wrenches

• Screwdriver

• Lifting Sling

• Rubber Mallet

• Induction Bearing Heater

• Bearing Puller

• Brass Drift Punch

• Snap-Ring Pliers

• Torque Wrench with Sockets

• Allen Wrenches

• Dial Indicator

• Micrometer

• Cleaning Agents

• Feeler Gauges

• Hydraulic Press

DISASSEMBLY

WARNING

Pump components can be heavy.

Proper methods of lifting must be

employed to avoid physical injury and

or equipment damage. Steel toed

shoes must be worn at all times.

WARNING

When handling hazardous and /

or toxic fluids, proper personal

protective equipment should be

worn. If pump is being drained, precautions

must be taken to prevent physical injury.

Pumpage must be handled and disposed of in

conformance with applicable environment

regulations.

NOTE: Before disassembling the pump for

overhaul, ensure all replacement parts are

available.

WARNING

Lock out power supply to driver motor

to prevent accidental start-up and

physical injury.

WARNING

Operator must be aware of pumpage and

safety precautions to prevent physical injury.

1. Shut all valves controlling flow to and from

pump.

2. Drain liquid from piping, flush pump if

necessary.

3. Disconnect all auxiliary piping.

4. Remove the coupling guard springs (501L)

then unwrap the coupling guard (501) from the

motor mount (240) (Figure 14).

5. Disconnect coupling.

6. Remove motor bolts (371) (Figure 15).

7. Place sling on motor lifting lugs and remove

motor.

8. Remove support plate anchor bolts.

9. Attach eyebolts to the support plate 120°

apart.

10. Dismantle flow controls from pump and pit

cover, if required (when furnished).

WARNING

Always use equipment adequate to lift

the pump. Follow the equipment

6!

Page 34

34 CV#3171#IOM#05/11#

manufacturer’s safe operating guidelines.

11. Using slings of suitable capacity, lift pump

from the sump (Figure 16). Refer to General

Information section for proper handling

procedure.

Figure#14#

Figure#15#

Figure#16#

Page 35

CV#3171#IOM#05/11# 35

12. Lay the pump horizontally on proper supports

where there is sufficient clearance to

disassemble the pump (Figure 17).

13. Remove the strainer (187) from the pump

(Figure 18).

14. Disassemble the discharge pipe (195) by

removing the upper nut (242) and elbow

fasteners (370H). Pull the discharge pipe from

the support plate and pump flange (Figure 19).

15. Remove all steady bearing flush tubing (190)

that is attached to the pump and steady

bearings.

16. Remove pump half-coupling hub (233) and

key.

Figure#18#

6!

Figure 17

Page 36

36 CV#3171#IOM#05/11#

17. Disassemble the pump casing (100) by

removing the casing to adapter bolts (370).

Leave the jacking bolts (418) in place. When

removing the casing, be careful not to mar the

inside casing walls (Figure 20).

WARNING

When removing impeller, wear heavy

work gloves to prevent cutting hands

on sharp edges of impeller vanes.

18. Remove the impeller (101) from the shaft (122).

One method is by using a locking bar to break

the thread grip on the impeller. Attach the

locking bar (locking bar detail can be found in

Figure 22) onto the power end of the pump

shaft. Quickly turn impeller counter clockwise as

viewed from the impeller end of the shaft (right

hand thread) impacting the locking bar handle

on the motor support. Repeat this process until

the impeller breaks free (Figure 21).

Figure#20#

Figure#21#

Figure#19#

Page 37

CV#3171#IOM#05/11# 37

19. Remove the impeller (101) and O-ring (412A)

(Figure 23).

20. Using a scribe, put a small mark on each of

the column pipes, steady bearings, adapter,

and motor support to match mark the pieces.

This will help in identifying and aligning during

re-assembly.

21. Loosen the bolts (370G) that hold the adapter

(108A) to the column pipe. Slide the adapter

from the shaft (122). If adapter is difficult to

remove, shaft end may be corroded. Remove

any rough spots or corrosion using an emery

cloth (Figure 24).

22. If your pump has no intermediate steady

bearings (only one column section), you will

not have any column extension (306) or

steady bearing housing (213). Go to step 24.

23. Starting at the casing end of the pump (Figure

25), remove column to steady bearing housing

bolts (372B) and remove column extensions

(306), steady bearing housings (213), and

deflectors (123) one at a time. While removing

column sections, support the shaft to prevent

bending. There is usually no need to remove

the head column (192) (Figure 26). Do not

remove steady bearings at this time. Refer to

the inspection procedures prior to removal.

Figure#22#

Figure#23#

Figure#24#

Figure#25#

6!

Page 38

38 CV#3171#IOM#05/11#

24. Remove locking bolts (370C) and slide

bearing shell (134) assembly with shaft out

through the motor support (240) (Figure 27).

CAUTION

Two people should handle any shaft

over 9 feet long as improper handling

can bend a shaft.

25. Remove labyrinth seal (332A). A screwdriver

is required to pry the seal from the bearing

shell (134) (Figure 28).

26. Remove bearing retaining ring (361A). Slide

bearing shell (134) off the bearing and shaft.

27. Remove locknut (136) and lockwasher (382).

28. Using a suitable bearing puller, remove

bearing (112).

NOTE: Save bearing for inspection.

29. Set the shaft on a table where it is adequately

supported.

30. There is usually no need to tear the pump

down any further unless parts are known to be

bad. Refer to Figure 29 if the motor adapter

must be removed.

Figure#26#

Figure#27#

Figure#29#

Figure#28#

Page 39

CV#3171#IOM#05/11# # # 39

INSPECTIONS

The pump parts must be inspected to the following

criteria before they are reassembled to insure the

pump will run properly. Any part not meeting the

required criteria should be replaced.

Casing and Adapter

1. The casing (100) and adapter (108A) should be

inspected for excessive wearing or pitting. They

should be replaced if they exceed:

A. Localized wear or grooving greater than

1/8” (3.2 mm) deep.

B. Pitting greater than 1/8” (3.2 mm) deep.

2. Inspect casing gasket seat surface for

irregularities.

3. Check ID of casing collar (155) per the

dimensions in Table 3. If ID is greater than

allowable, pry or pull the casing collar from its

seat on the backside of the adapter (Figure 30).

4. Check ID of the steady bearing (197) per the

dimensions in Table 3. If ID is greater than

allowable, remove the inner and outer retaining

rings (369) and seals (333H) (if applicable),

then press out the steady bearing (197) using a

small press.

5. Check bore of adapter (108A) per Table 3. If

bore is excessive, replace.

6. Inspect casing-to-column connection area for

any cracks or excessive corrosion damage.

Replace if any of these conditions exist.

Impeller

1. Inspect impeller (101) vanes for damage.

Replace if grooved deeper than 1/16” (1.6 mm)

or if worn evenly more than 1/32” (0.8 mm).

2. Inspect back pumpout vanes for damage.

Replace if worn more than 1/32” (0.8 mm).

3. Inspect leading and trailing edges of the vanes

for pitting, erosion, or corrosion damage.

Column Sections

1. Inspect column section(s) (306,192) for any

cracks or excessive corrosion damage. Replace

if any of these conditions exist.

Steady Bearing Housings

1. Check the ID of steady bearings (197) per the

dimensions in Table 3. If ID is greater than

allowable, remove the inner and outer retaining

rings (369) and seals (333H) (if applicable),

then press out the steady bearing (197) using a

small press.

2. Check bore of steady bearing housing (213) per

Table 3. If bore is excessive, replace.

Figure#31#

6!

Figure#30#

Page 40

40 CV#3171#IOM#05/11#

Table 3

Steady Bearing Tolerances

Bearing ID

(pressed in place)

Housing Bore

Running Clearance

(1/2 diametrical clearance)

Bearing

Material

S/ST

M/MT

L

S/ST

M/MT

L

S/ST

M/MT

L

Carbon

1.132/1.134

1.633/1.635

2.258/2.260

1.620/1.622

2.120/2.122

2.993/2.995

0.0055/0.0035

0.006/0.004

0.0065/0.004

Bronze

1.129/1.131

1.629/1.631

2.256/2.258

1.620/1.622

2.120/2.122

2.993/2.995

0.004/0.002

0.004/0.002

0.0055/0.003

Fluted

Elastomer

1.126/1.130

1.627/1.632

2.253/2.257

1.620/1.622

2.120/2.122

2.993/2.995

0.0035/0.0005

0.0045/0.001

0.005/0.004

Rulon

1.132/1.134

1.633/1.635

2.258/2.260

0.0055/0.0035

0.006/0.004

0.0065/0.004

S/ST

M/MT

L

S/ST

M/MT

L

S/ST

M/MT

L

Casing

Collar

1.183/1.190

1.678/1.685

2.299/2.306

1.811/1.813

2.243/2.245

3.243/3.245

0.0335/0.029

0.031/0.0265

0.029/0.0245

NOTE: Bearing ID prior to pressing into the housing will be slightly larger than ID after it is pressed in place.

Shaft

1. Check the thrust bearing fit. If it is outside the

tolerance in Table 4, replace the shaft (122)

(Figure 32).

Table 4

Thrust Bearing Fits

Group

Shaft OD

Shell ID

S/ST

0.9848/0.9844

2.4416/2.4409

M/MT

1.5755/1.5749

3.5442/3.5433

L

2.1660/2.1655

4.7253/4.7240

2. Check the steady bearing areas. If more than

0.002” of wear exists, replace the shaft.

3. Check the shaft straightness. If any of the

values exceed the values in Table 5, replace

the shaft.

Table 5

Shaft Runout Tolerances

Group

Coupling

End

Shaft Body

Impeller

End

All

0.002”

0.0005”/ft.

0.005”

Bearing Shell

1. Inspect bearing shell (134) bore per the

dimensions in Table 4 and replace if dimensions

exceed values.

2. Remove lower grease seal (133). It is always

recommended that the seal be replaced at

every overhaul.

3. Visually inspect for cracks and pits. Pay

particular attention to the snap ring groove.

Ball Bearing

Ball bearing (112) should be inspected for

contamination and damage. The condition of the

bearing will provide useful information on operating

conditions in the bearing shell. Lubricant condition

should be noted. Bearing damage should be

investigated to determine cause. If cause is not

normal wear, it should be corrected before the

pump is returned to service.

DO NOT REUSE BEARINGS.

Motor Support

Inspect motor support (240) for any cracks or

excessive corrosion damage. Replace if any of

these conditions exist.

Figure#32#

Page 41

CV#3171#IOM#05/11# 41

REASSEMBLY

Refer to Table 7 for torque values while reassembling pump.

Table 7

BOLT TORQUE TABLE

Location

Lubricated Threads

Dry Threads

Casing Bolts (370)

30 FT-LBS (40 Nm)

45 FT-LBS (60 Nm)

Column Pipe to

Adapter Bolts (370G)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Steady Bearing

Bolts (372B)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Column Pipe to

Motor Mount (370M)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Motor Mount to

Support Plate (370L)

30 FT-LBS (40 Nm)

45 FT-LBS (60 Nm)

Motor to

Motor Mount (371)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Strainer to Case (317N)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

ASSEMBLY OF MOTOR SUPPORT,

HEAD COLUMN, AND SUPPORT PLATE

1. If motor support disassembled, attach motor

support (240) to support plate (189) with bolts

(370L) (Figure 33).

2. Attach head column (192) to motor support with

bolts (370M). Vent holes should be closer to the

motor support.

OPTIONAL WITH STUFFING BOX

DESIGN

Refer to Figure 48, Appendix II.

1. Attach stuffing box (221) to support plate (189)

with bolts (370L).

2. Attach motor support (240) to stuffing box with

bolts (370J).

3. Attach head column (192) to stuffing box with

bolts (370M). Vent holes should be closer to the

motor support.

ASSEMBLY OF ROTATING ELEMENT

CAUTION

Shafts can be damaged by improper

handling. Extreme care should be taken

at all times. It is recommended that

shafts over 9 feet long be handled by two people

at all times to prevent possible bending.

1. Install retaining ring (369A) on shaft (122)

(Figure 34).

NOTE: S/ST groups do not use the 369A

retaining ring.

2. Install thrust bearing (112) on shaft (122).

Figure#33#

6!

Page 42

42 CV#3171#IOM#05/11#

NOTE: There are several methods for installing

bearings. The recommended method is to use

an induction heater that heats as well as

demagnetizes the bearing.

WARNING

Use insulated gloves when using a

bearing heater. Bearings will get hot

and can cause physical injury.

3. Install lockwasher (382) on shaft (122). Place

tang of lockwasher in keyway of shaft.

4. Thread locknut (136) onto shaft (122). Tighten

locknut until snug. Bend any tang of the

lockwasher into one of the slots on the locknut.

Tighten the locknut if necessary to align

lockwasher tab with a locknut slot.

5. Press grease seal (333) into bearing shell (134).

The seal is mounted with the lip out, facing

toward the pump casing.

6. Slide bearing shell onto pump end of shaft and

over the bearing.

7. Insert retaining ring (361A) in bearing shell

groove keeping flat side against bearing.

8. Slide labyrinth seal (332A) over coupling end of

shaft. Press into bearing shell unit to shoulder.

9. With the support plate in a vertical position,

slide the shaft horizontally through the motor

support. Support the shaft and column with

suitable stands (Figure 35).

10. Install hold down bolts (370C) and jacking bolts

(370D) with jam nuts (415).

ASSEMBLY OF COLUMN (WHEN

REQUIRED)

When intermediate steady bearings are required,

there will be additional column extensions (306) and

steady bearing housings (213) required.

1. Prepare the steady bearing housing

assembly(s) if required. Press in new steady

bearing. Install snap ring and seals on sealed

bearings (Figure 31). The seals are mounted

with the lips out, facing away from the steady

bearing.

NOTE: The steady bearing does not have to be

centered exactly nor do the holes in the bearing

have to line up with the holes in the housing.

There is a recessed area on the inside of the

housing (213) that allow lubricants to find the

opening in the bearing.

2. Slide steady bearing housing assembly (213)

onto the shaft. Seat housing against flange of

column pipe. Make sure that the drilled flush tap

matches the location of the holes in the support

plate.

3. Install column extension (306). Make sure

match marks scribed during disassembly line

up. Install bolts (372B).

4. Repeat steps 1-4 as necessary.

Figure#35#

Figure#34#

Page 43

CV#3171#IOM#05/11# 43

ASSEMBLE LIQUID END

1. Press casing collar (155) into adapter (108A)

using a suitable press.

2. Prepare the adapter (108A) if required. Press in

new steady bearing. Install snap ring and seals

on sealed bearings (Figure 30). The seals are

mounted with the lips out, facing away from the

steady bearing.

NOTE: The steady bearing does not have to be

centered exactly nor do the holes in the bearing

have to line up with the holes in the housing.

There is a recessed area on the inside of the

adapter (108A) that allows lubricants to find the

opening in the bearing.

3. Slide the adapter onto shaft. Seat adapter

flange against column flange. Make sure match

marks scribed during disassembly line up.

Install bolts (371G) (Figure 36).

4. Insert O-ring into impeller groove. A small

amount of grease can be used to hold the Oring in place. Install impeller on shaft and

tighten. If impeller rubs adapter during

tightening, adjust impeller at thrust housing

away from adapter. Ensure shaft rotates freely

after tightening the impeller (Figure 37).

5. Adjust impeller (101) towards adapter using

jacking bolts (370D) until impeller just touches

adapter (108A). Place casing gasket (351) on

seat in casing (100). Install casing against

adapter. Make sure match marks scribed during

disassembly line up. Install casing to adapter

bolts (370) and tighten. Back off jacking bolts

(370D) until shaft rotates freely (Figure 38).