Page 1

Installation, Operation and Maintenance Instructions

Page 2

TABLE OF CONTENTS

1.0 Introduction …………………………………………………………………… 2

2.0 Safety Considerations….…………………………………………………… 2

3.0 General Overview……………………………………………………………. 2

3.1 Warranty Statement……………….………………………………… 2

3.2 Application……………………….…………………………………… 2

3.3 Storage / Handling……………….………………………………….. 3

4.0 Installation…………………………………………………………………………………..… 4

4.1 General Description………………………………………………………………… 4

4.2 Motor Mounting System……………………………………………………………. 5

4.3 Foundation Mounted Baseplates …………………………………………..……. 5

4.4 Stilt Mounted Baseplates ………………………… ………………………………. 7

Appendix I. Corrosion Guide

Appendix II. Insert Installation Guide

Appendix III Recommended Fastener Torques

Appendix IV Alignment

Questions?

Please contact your local Goulds Pumps represent ati ve.

ChemBasePlus™ 02/15/02— 1/2002 Page 1 of 16

Page 3

SECTION 1. 0 INTRODUCTION

This Installation, Operation, and Maintenance

Instructions manual contains instructions and

guidelines for the installation of the Goulds

Pumps ChemBasePlus™ baseplate.

SECTION 2.0 – SAFETY CONSIDERATIONS

The Goulds ChemBasePlus™ baseplate has

been designed and packaged for safe handling

and installation. It is very important to review

the contents of this manual before removing

the baseplate from its shipping skid. Goulds

shall not be liable for physical injury, damage

caused by failure to observe the instructions

for installation and handling in this manual.

Please make special note of the following

general precautions as listed below:

1. Do not remove the ChemBasePlus™

from its shipping skid until you are

ready to lift it onto its foundation.

2. Do not subject the ChemBasePlus™

to rough handling or unnecessary

hammer shock.

3. Do not attempt to lift the

ChemBasePlus™ by any means other

than that which is described in this

manual.

It is extre me ly importa nt that th is entire

guideline be reviewed prior to installation

and handling of the baseplate. This is

important for both safety and reliability

purposes.

4. Do not hammer shock or use other

impact loading techniques to adjust

the positioning of the

ChemBasePlus™. Do not pry against

the motor mounting blocks when

moving the motor during shaft

alignment.

5. Do not tighten the anchor bolt nuts

until you have verified that the

ChemBasePlus™ is properly

supported.

6. Do not attempt to transport, handle or

install a ChemBasePlus™ when

ambient temperature is below -45° F.

7. Do not operate a pump installed on a

ChemBasePlus™ at process fluid

temperatures in excess of 290° F.

SECTION 3.0 - GENERAL OVERVIEW

3.1 WARRANTY STATEMENT

All due care is taken in producing the Goulds

line of baseplates and complimentary

accessory items. Goulds warrants to provide

equipment that meet Goulds’ standards and

specifications, but not to be suitable for any

particular application. No warranty is made in

regard to the use of the materials or finished

goods, in the Purchaser’s application. All

design co nsiderations and acce ptance of the

Goulds products for use in the Purchaser’s

applications are the Purchaser’s sole

responsibility. In no case will Goulds be

responsible for more than supplying

replacement products.

ChemBasePlus™ — 1/2002 Page 2 of 16

3.2 APPLICATION

The polymer composite material used in the

manufacture of the Goulds ChemBasePlus™

has been formulated for application in a broad

range of corrosive fluid handling services. This

material does not, however, offer universal

corrosion resistance. Goulds highly

recommends that the Corrosion Guide in

Appendix I be reviewed prior to specifying or

installing a ChemBasePlus™ baseplate.

The ChemBa sePlus™ is also suitable for

application in a wide range of fluid process

temperatures, specifically, -45° F to 290° F.

For temperature boundaries exceeding these

recommended limitations, please contact

Goulds for assistance in determining

acceptability of a specific application.

Page 4

3.3 STORAGE / HANDLING

Goulds’ normal packaging is designed to

protect the ChemBasePlus™ during shipment.

for safe, even lifting. Raise the

ChemBasePlus™ slightly off the pallet and

verify that it suspends reasonably level and

that the slings are not subject to slipping out of

! CAUTION !

position.

It is extremely important to observe proper

handling procedures during transport and

installation of the ChemBasePlus™. While the

polymer composite material is constructed of

inherently high strength materials, subjecting it

Be sure to keep hands and feet out from under

the baseplate during these steps to prevent

injury.

! WARNING !

to impact or bending loads through rough

handling or improper lifting or mounting may

result in irreparable damage to the baseplate

as well as potential damage to the mounted

equipment or put personnel at risk of injury

Leave the ChemBasePlus™ strapped to its

wooden shipping pallet until installation is

ready to occur. If the ChemBasePlus™ is

intended for indoor installation and comes with

carbon steel inserts, but is to be stored in an

outdoor location, cover the base completely

with some weather resistant material so as to

prevent rusting of the insert material.

! WARNING !

Do not stand the ChemBasePlus™ on end to

make more efficient use of storage space.

Severe personal injury or death as well as

possible permanent damage to the

ChemBasePlus™ may result should it tip over.

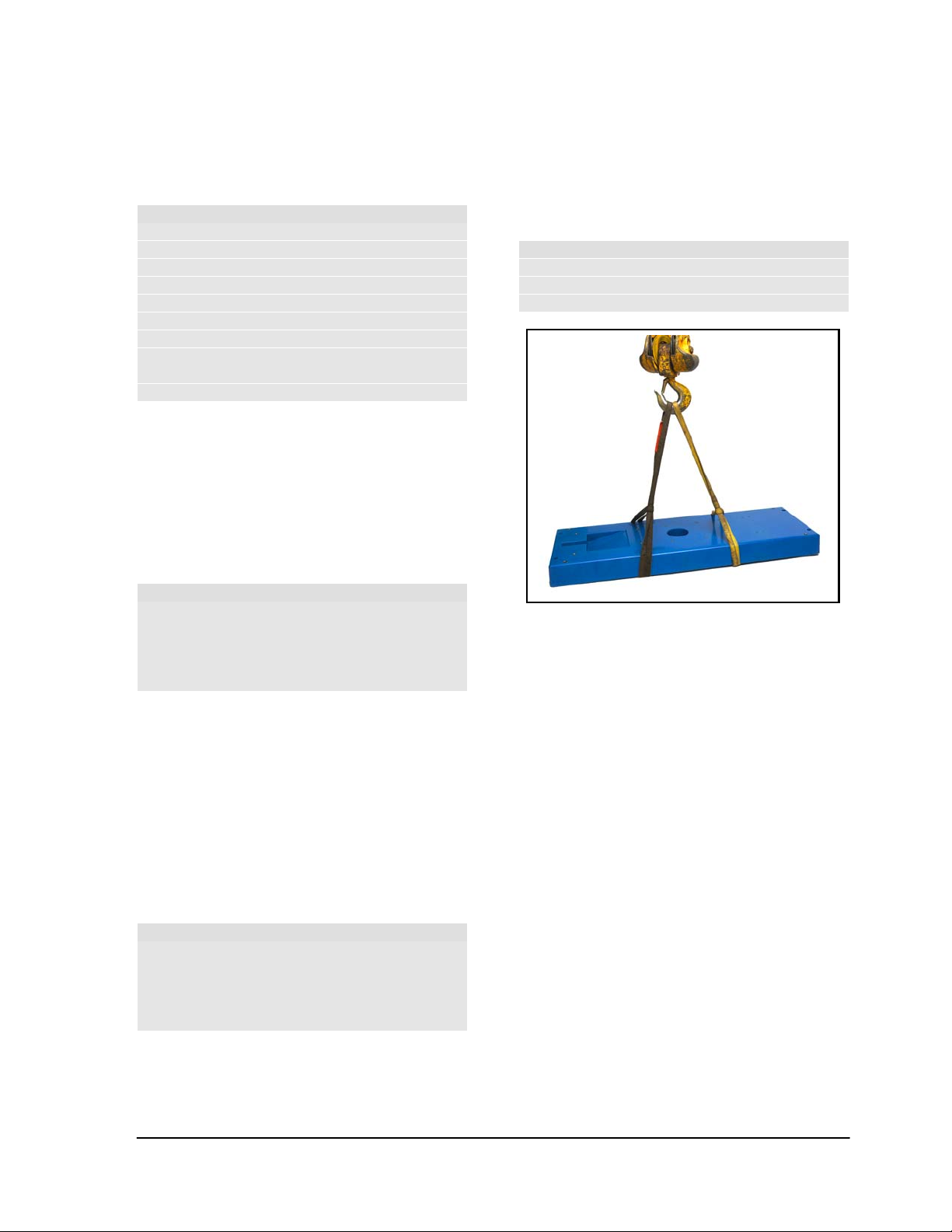

LIFTING

Lifting should be performed by trained

personnel only. Pumps and motors typically

have integral lifting eye bolts. These are

intended for use of the individual units only.

Do not use these features to lift a

ChemBasePlus™/ Pump and Motor Assembly.

ChemBasePLUS™ with no mounted equipment

Should the slinging appear unstable, set the

baseplate back down on the pallet and

reposition the slings for more stable condition.

After satisfactory slinging has been achieved,

the baseplate may be hoisted onto its

foundation. Slowly lower the baseplate over

the foundation using care to engage the

anchor bolts in the holes provided. Place

shims or wedges under the baseplate at a

minimum of four locations to allow for removal

of the slings

.

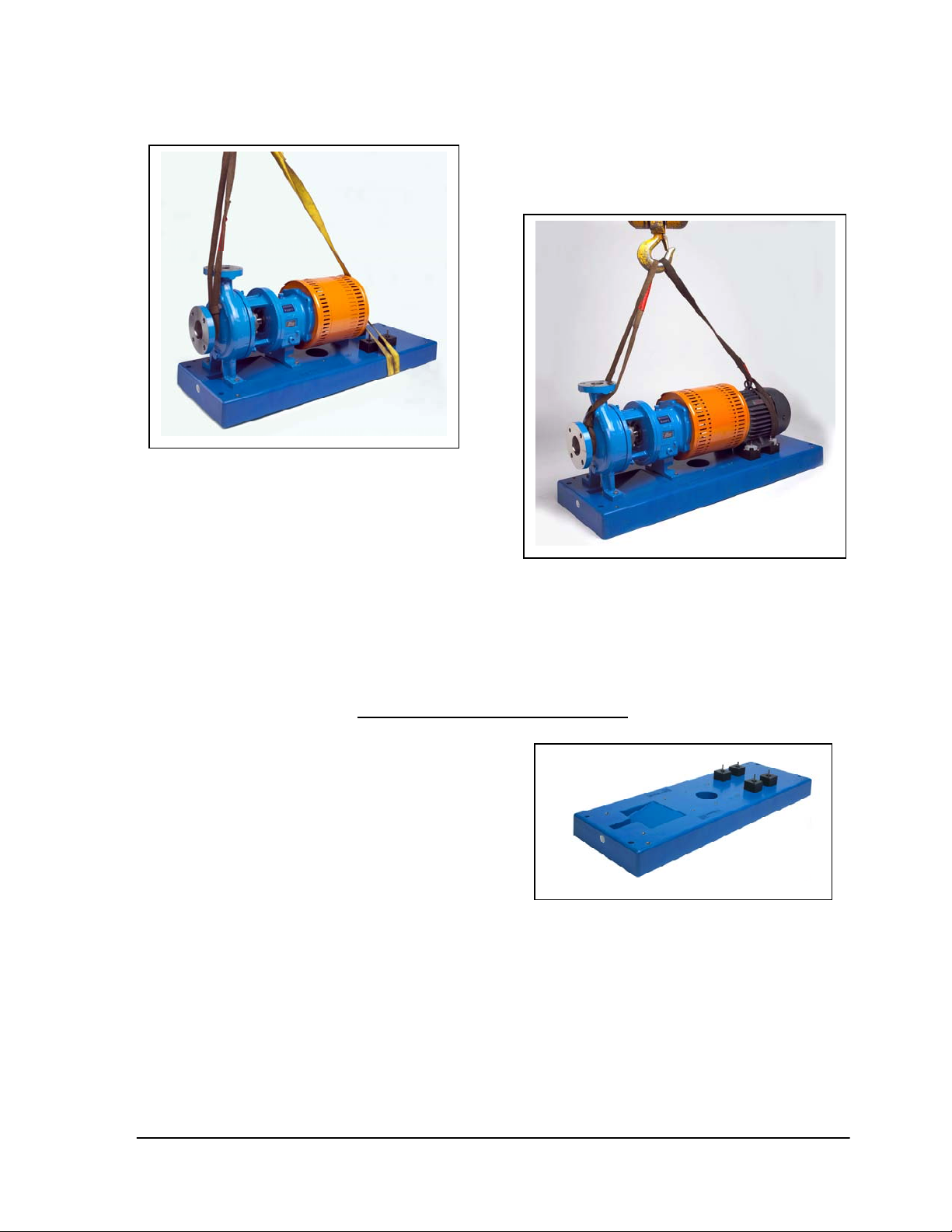

FIGURE 1

ChemBasePlus™

Baseplates With No Mounted Equipment

ChemBasePlus™

Baseplates With Installed Equipment:

! WARNING !

Do not install eye bolts in the

ChemBasePlus™ threaded inserts for the

purpose of lifting the baseplate. This practice

may induce excessive loading on the inserts,

which they were not designed to withstand.

Pump only installed:

Remove the straps that hold the

ChemBasePlus™ to the wooden pallet. Install

a sling around the pump suction nozzle using a

choker hitch pulled firmly tight. Install an

additional sling around the motor end of the

Remove th e s traps tha t s e c u r e th e

ChemBasePlus™ to the wooden pallet. Slip

ChemBasePlus™ using a basket hitch as

shown in Figure 2.

two slings underneath the baseplate between

the pallet cross members as shown in

Figure 1. Slings should be positioned to allow

ChemBasePlus™ — 1/2002 Page 3 of 16

Page 5

FIGURE 2 - Pump only Installed

Pump and mo tor installed:

Remove the straps that hold the

ChemBasePlus™ to the wooden pallet. Install

a sling around the pump suction nozzle and

around the outboard end of the motor frame

using choker hitches pulled firmly

tight as shown in Figure 3. The motor sling

should be positioned so the weight is not

carried through the motor fan housing.

FIGURE 3 - Pump and motor installed

SECTION 4.0 – INSTALLATION

4.1 GENERAL DESCRIPTION OF THE

ChemBasePlus™

The Goulds ChemBasePlus™ is a solid

polymer composite baseplate that is

manufactured to conform to ASME/ANSI

B73.1M-1991 and custom versions. The

Goulds ChemBasePlus™ has been designed

to provide a solid and rigid foundation under

the pump and its respective motor, whereby,

serving the purpose of maintaining sound

alignment between them.

The ChemBa sePlus™ has been made

available in two basic types:

• Foundation mounted (grouted in

design – Figure 4)

ChemBasePlus™ — 1/2002 Page 4 of 16

FIGURE 4 – Foundation Mounted

Page 6

• Stilt Mounted (free standing –

Figure 5)

FIGURE 5 – Stilt Mounted

The foundation -mounted style utilizes grout to

add rigidity to the structure. Because the

ChemBasePlus™ by nature offers excellent

rigidity, the Stilt-mounted style can be

employed without sacrificing on reliability

whatsoever. The Stilt-mounted base offers a

free-standing rigid foundation void of any

additional grouting needs.

Resin Aggregate Material utilized in

the construction of these baseplates.

3) To allow the end user to perform final

field alignment to their respective

tolerance standards.

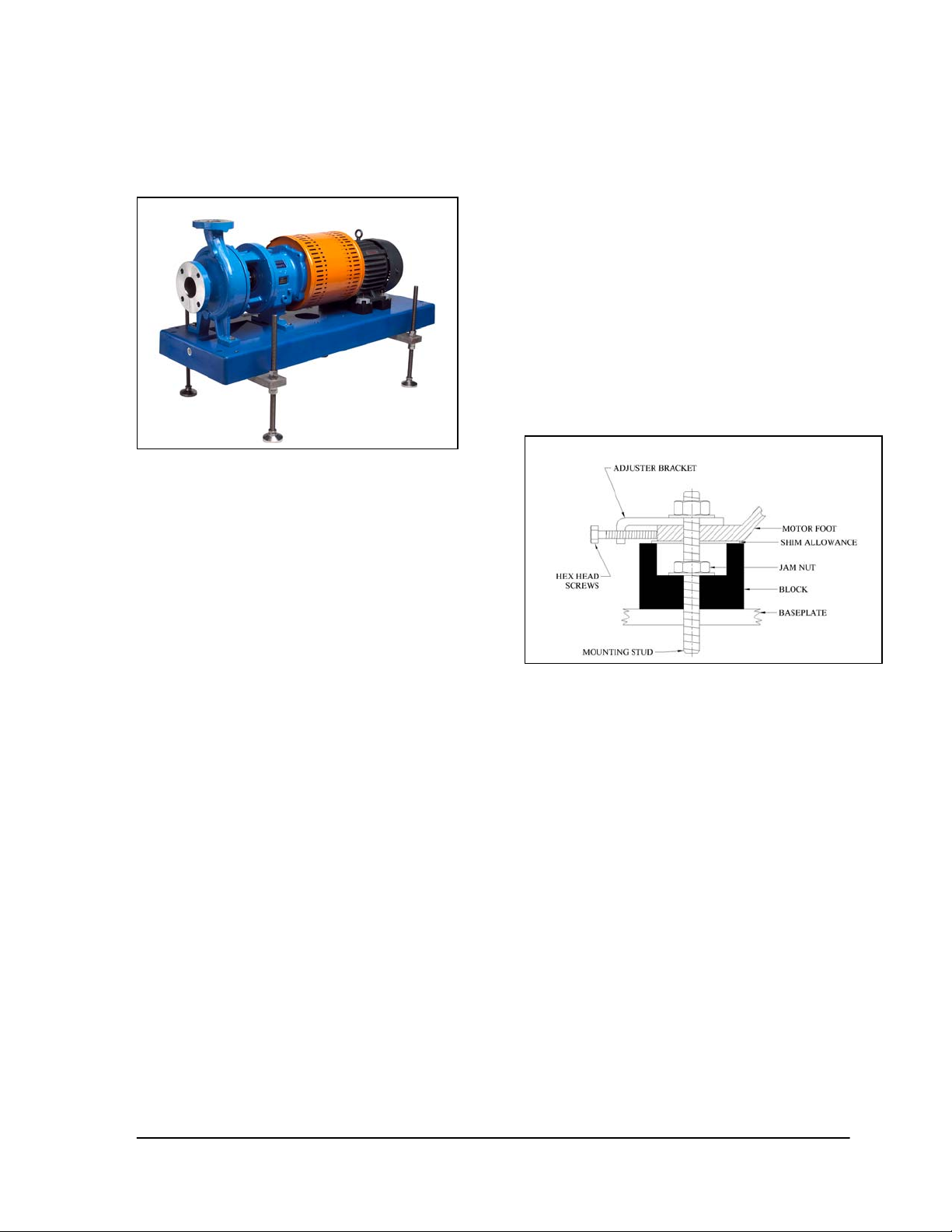

4.2 MOTOR MOUNTING SYSTEM

The Goulds ChemBasePlus™ utilizes as

standard the polymer block mounting system.

This system is comprised of corrosion resistant

polymer composite mounting blocks which

have surface flatness to .005”. Motor mounting

blocks incorporate a counterbore / jam nut

feature fo r s e c ure atta chment to th e

ChemBasePlus™

The ChemBa sePlus™ performs the proper

function of a reliable baseplate foundation for a

pump and motor. Those basic functions are as

follows:

1) To provide adequate rigidity to assure

the pump/motor assembly can be

shipped and installed without damage

and to withstand the operating loads of

the given assembly. The solid

structure of the ChemBasePlus™

offers superior dampening to vibration

associated with the rotating

pump/motor assembly.

2) To provide a flat mounting surface for

the pump and motor assembly. The

ChemBasePlus™ product is designed

to hold under a .005 inch flatness

specification (end-to-end). The

aforementioned flatness specifications

are measured across the diagonal

corners of the ba seplate to p surface.

These excellent flatness specifications

are achieved by the superior Epoxy

FIGURE 6

Optional Bi-Directional motor adjusters provide

both axial and transverse motor adjustment.

The top mounted adjusters assist with precise

shaft alignment when critical tolerances are

trying to be achieved as they do not disturb

indicator equipment.

4.3 FOUNDATON MOUNTED BASEPLATES

1) The baseplate should be positioned as

close to the liquid supply source as

possible. There should be an

adequate amount of space for

personnel to install, operate and

maintain the pump/motor assembly.

As mentioned above, the end result of

the grouted in baseplate should offer

excellent rigidity and dampen any

vibration associated with the operating

pump/motor assembly.

ChemBasePlus™ — 1/2002 Page 5 of 16

Page 7

2) Using the recommended slinging

procedures shown in Figures 2 and 3,

hoist the ChemBasePlus™ unit off its

shipping pallet.

6) Install the flat washers and nuts to the

anchor bolts and snug them down but

do not torque them at this point.

3) Lower the ChemBasePlus™ into

position over the foundation. Proceed

to engage the anchor bolts in the four

holes provided. As seen in Figure 7,

protective sleeves should be placed

over the anchor b olts to prevent grout

adhesion to the bolts.

FIGURE 7

4) The baseplate assembly should be

properly leveled. It is suggested to

utilize the pump suction and discharge

flanges as reference points for leveling

purposes. If the ChemBasePlus™ is

equipped with the recommended

optional leveling screw inserts, install

the leveling screws and thread them

far enough to provide the desired

grouting clearance underneath. Apply

wax to screws to allow for their

eventual removal.

5) If the ChemBasePlus™ is not

equipped with leveling screws, shim

under the baseplate to bring the

discharge flange into proper level.

Never stress the baseplate under any

condition to bring the assembly into

the desire d level. Hold off bo lting the

pump’s flanges until the baseplate is

completely installed. A proper

practice is to shim under all baseplate

anchor bolt locations. Apply wax to

shims to allow for their eventual

removal.

7) Alignment should now be done in

accordance with procedures identified

in Appendix IV.

8) The baseplate should now be properly

grouted. Grout the baseplate in

accordance with the grout

manufacturer’s recommended

procedures. Mask off areas not

intended to be grouted. Good

procedure is to utilize a non-shrinking

grout material. Pour or trowel the

grout into the desired area until the

proper level is reached. Immediately

wipe away any spills as this must be

done before the grout sets. Allow at

least two days for the grout to fully

cure.

9) Check for voids after the grout has

properly cured. Remove the forms

and withdraw the leveling screws or

shims used for leveling. Remove the

masking from all surfaces.

10) Fill the leveling screw holes (if

provided) with a flexible sealer.

11) Lubricate the anchor bolt threads and

tighten the nuts to the following torque

values: ½” bolt – 22 lb/ft or ¾” – 65

lb/ft.

12) Connect piping to the flanges of the

pump. Assure that no adv erse pipin g

loads are transmitted to the pump

flanges. Perform a final alignment

check for verification that there are no

significant piping loads.

13) Final alignment of the pump/motor

assembly should now be brought into

the tolerances as specified in

Appendix IV.

14) It is possible that a realignment may

be deemed necessary should the

temperature of the process conditions

cause suspect thermal expansion of

the piping.

ChemBasePlus™ — 1/2002 Page 6 of 16

Page 8

4.4 STILT MOUNTED BASEPLATES

As mentioned previously, the

ChemBasePlus™ is inherently rigid due to its

thickness of construction. The end result is a

baseplate that can be stilt mounted while not

sacrificing on reliability. The pump/motor

alignment techniques for Goulds’ Stilt Mounted

baseplates follow the same methodology of the

grouted in baseplates. The key difference

revolves around the way the baseplate is

leveled.

1) The stilt mounted baseplate is set on a

flat surface with no anchor bolts

needed.

2) The baseplate is leveled by using the

nut stilt adjuster kit. Refer to

Figures 8 and 9 for suggested

asse mbly instructions.

a) Elevate the baseplate assembly

above the floor to allow stilt

assembly.

b) Measure the approximate desired

height of the baseplate assembly

above the foundation.

c) Locate the bottom nuts above the

stilt threaded bolts to desired

height.

d) Insert the lock washer over the stilt

bolt.

e) Move the threaded stilt bolt up

through the holes in the bottom of

the baseplate and secure in place.

f) Attach the remaining lock washer

and nuts on to the threaded stilt

bolt. Fasten the nut on to the lock

washer.

g) Secure all four threaded stilts.

Now locate the baseplate

assembly over the flexible leveling

feet and tighten the feet to the

threaded stilts. Now lower the

entire assembly to the foundation.

h) Make final level and height

adjustments by simply loosening

the top nuts and turning the bottom

nuts to raise or lower the

baseplate assembly.

i) Finally, first tighten the top and

bottom nuts located on the

respective lock washers and then

tighten the other nuts to insure the

baseplate is properly locked in

place.

FIGURE 8

At this point, follow the steps as listed above

(Steps 12, 13, and 14) for grouted baseplates.

FIGURE 9

ChemBasePlus™ 02/15/02— 1/2002 Page 7 of 16

Page 9

APPENDIX I

Corrosion Guide

ChemBasePlus™ — 1/2002 Page 8 of 16

Page 10

Corrosion Guide, con’t.

ChemBasePlus™ — 1/2002 Page 9 of 16

Page 11

Corrosion Guide, con’t.

ChemBasePlus™ — 1/2002 Page 10 of 16

Page 12

APPENDIX II

Insert Guide

The following guide is to assist with the field

installation of inserts if there is a need to

replace a damaged thread or to install a new

insert into a custom location. In order to

achieve a successful installation the following

procedures are recommended:

! WARNING !

Field installation should only be performed by

qualified personnel using suitable drilling

equipment. Personnel should be sure to use a

face mask to prevent inhalation of silica dust

as the ChemBasePlus™ casting is penetrated

during drilling operations. If MSDS

specifications are required, contact your local

Goulds representative. Also, be sure to utilize

protective eyewear while performing any

drilling operation.

1. It is recommended to utilize a carbide tip

drill bit to perform drilling procedure.

Please refer to Table 1 for drill bit size

recommendation. We suggest providing

a hole diameter that will allow ample

space to install the insert yet still maintain

a snug fit as to not need too much filler

epoxy resin.

3. Drill the new hole (Figure 1) or drill ou t

the damaged insert taking care not to

enlarge or elongate the hole into which

the new insert will be installed. Remove

all dust and metal particles from the

drilled hole using compressed air.

FIGURE 1

Table 1

Hole Drill Size Recommendation

Insert Size Drill Size*

1 / 4 – 20 0.625 in.

5 / 16 – 18 0.625 in.

3 / 8 – 16 0.875 in.

1 / 2 – 13 1.000 in.

5 / 8 - 11 1.375 in.

*NOTE: Drill size list ed abov e is mi n imum —

increasing the hole diameter by an extra 0.125

inches may assist in allowing for any hole

location variances established by installer.

2. Drill approximately 1/8” (.125) lower then

the given length of the provided insert.

4. It is critical that perpendicularity in relation

to the surface of the ChemBas ePlus™ is

maintained. Goulds prescribes two basic

methods of insuring that the insert will

achieve proper perpendicularity and are as

follows:

a) Fabricate a template (i.e. constructed of

plywood or metal) based off the number

of inserts. The template should be

designed to locate the holes off a

reference point located on the respective

drawing of the given baseplate (please

contact your Goulds Pumps

representative if you are in need of a

particular drawing or consult factory).

Fasten the insert to a stud with a nut on

the top side of the template

ChemBasePlus™ — 1/2002 Page 11 of 16

Page 13

(Figure 2). Prior to placing the template /

insert assembly down on the baseplate as

seen in Figure 2, proceed to step 5 for

filling the hole with the proper amount of

epoxy resin.

FIGURE 2

b). With the pump assembly elevated above

the baseplate, fasten the insert to the

bottom of the motor hex bolt that is

intended to mount the pump/motor

assembly down to the baseplate. Do not

fully tighten the bolt at this time as some

slip is desired so as to insure that the

insert drops slightly below the surface of

the baseplate. Proceed to step 6.

FIGURE 3

6. Dispense the epoxy resin material into the

drilled hole as seen in Figure 3. Fill the

hole only a third of the way. Lower the

pump/motor assembly (if C-Flange motor

is being used) or motor down into the

epoxy filled holes (Figure 4). Check that

all inserts are centered accordingly and

allow the epoxy to harden. After the epoxy

resin has hardened, remove the motor

assembly and top off the holes accordingly

and wipe away any excess material so as

to keep the top surface clean.

5. Dispense epoxy resin material into the

drilled hole (Figure 3) following the

instructions provided – the two-part epoxy

can be mixed together to activate in the

hole. Make certain not to overfill the hole

as excess material may spill over on to the

top surface of the insert and down into the

threads. Goulds prescribes that you fill the

hole about half-way when utilizing a

template device. Now locate the template

arrangement down over the epoxy filled

holes and allow epoxy to harden. Top off

the hole accordingly after the template has

been removed and wipe away any excess

material so as to keep the top surface

clean.

The baseplate in now ready to be installed

FIGURE 4

or shipped, respectively. Do not exceed

the recommended fastener torques as

shown in Appendix III.

ChemBasePlus™ — 1/2002 Page 12 of 16

Page 14

APPENDIX III

Recommended Fastener Torques

FASTENER

FASTENER

STANDARD

S A E 3/8” 13

NOMINAL

SIZE

¼” 4

5/16” 8

½” 34

5/8” 66

¾” 118

RECOMMENDED

TORQUE

LB/FT

ChemBasePlus™ — 1/2002 Page 13 of 16

Page 15

APPENDIX IV

Alignment

SET UP

1. Mount two dial indicators on one of the

coupling halves (X) so they contact the

other coupling half (Y) (Fig. IV-1).

Vertical Correction (Top-to-Bottom)

1. Zero indicator A at top dead center (12

o’clock) of coupling half Y.

2. Check setting of indicators by rotating

coupling half X to ensure indicators stay in

contact with coupling half Y but do not

bottom out. Adjust indicators accordingly.

Fig. IV-1

MEASUREMENT

1. To ensure accuracy of indicator readings,

always rotate both coupling halves

together so indicators contact the same

point on coupling half Y. This will eliminate

any measurement problems due to runout

on coupling half Y.

2. Rotate indicators to bottom dead center (6

o’clock). Observe needle and record

reading.

3. Negative Reading - The coupling halves

are further apart at the bottom than at the

top. Correct by either raising the driver feet

at the shaft end (add shims) or lowering

the driver feet at the other end (remove

shims), (Fig. IV-2).

Positive Reading - The coupling halves

are closer at the bottom than at the top.

Correct by either lowering the driver feet at

the shaft end (remove shims) or raising the

driver feet at the other end (add shims).

Fig. IV-2

2. Take indicator measurements with driver

feet hold-down bolts tightened. Loosen

hold down bolts prior to making alignment

corrections.

3. Take care not to damage indicators when

moving driver during alignment corrections.

ANGU LAR AL IGNMENT

A unit is in angular alignment when indicator A

(Angular indicator) does not vary by more that

.002 in. (.05 mm) as measured at four points

90° apart.

4. Repeat steps 1-3 until indicator A reads

.002 in (.05 mm) or less.

Horizontal Correction (Side-to-Side)

1. Zero indicator A on left side of coupling

half Y, 90° from top dead center

(9 o’clock).

2. Rotate indicators through top dead center

to the right side, 180° from the start

(3 o’clock). Observe needle and record

reading.

ChemBasePlus™ — 1/2002 Page 14 of 16

Page 16

3) Negative Reading - The coupling halves

are further apart on the right side than the

left. Correct by either sliding the shaft end

of the driver to the left or the other end to

the right.

Positive Reading - The coupling halves

are closer together on the right side than

the left. Correct by either sliding the shaft

end of the driver to the right or the other

to the left (Fig. IV-3).

end

the indicator reading from each driver foot

(Fig. IV-4 ).

Fig. IV-4

NOTE: Equal amounts of shims must be

added to or removed from each driver foot.

Otherwise the vertical angular alignment will be

affected.

Fig. IV-3

4) Repeat steps 1 through 3 until indicator A

reads .002 in. (.05 mm) or less.

5) Re-check both horizontal and vertical

readings to ensure adjustment of one did

not disturb the other. Correct as

necessary.

PARALLEL ALIGNMENT

A unit is in parallel alignment when indicator P

(parallel indicator) does not vary by more than

.002 in. (.05 mm) as measured at four points

90° apart at operating temperature. Note the

preliminary vertical cold setting criteria, Table

1.

Vertical Correction (Top-to-Bottom)

1. Zero indicator P at top dead center of

coupling (12 o’clock) half Y (Fig. III-1).

2. Rotate indicator to bottom dead center (6

o’clock). Observe needle and record

reading.

3. Negative Reading - Coupling half X is

lower than coupling half Y. Correct by

removing shims of thickness equal to half

of the indicator reading under each driver

foot.

Positive Reading - Coupling half X is

higher than coupling half Y. Correct by

adding shims of thickness equal to half of

4. Repeat steps 1 through 3 until indicator P

reads within .002 in. (.05 mm) or less when

hot, or per Table 1 when cold.

Horizontal Correction (Side-to-Side)

1. Zero indicator P on the left side of coupling

half Y, 90° from top dead center

(9 o’clock).

2. Rotate indicators through top dead center

to the right side, 180° from the start

(3 o’clock). Observe needle and record

reading.

3. Negative Reading - Coupling half Y is to

the left of coupling half X. Correct by

sliding driver evenly in the appropriate

direction (Fig. IV-5).

Positive Reading - Coupling half Y is to

the right of coupling half X. Correct by

sliding driver evenly in the appropriate

direction.

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

4. Repeat steps 1 through 3 until indicator P

reads .002 in. (.05 mm) or less.

Fig. IV-5

5. Re-check both horizontal and vertical

readings to ensure adjustment of one did

not disturb the other. Correct as

necessary.

ChemBasePlus™ — 1/2002 Page 15 of 16

Page 17

COMPLETE ALIGNMENT

A unit is in complete alignment when both

indicators A (angular) and P (parallel) do not

vary by more than .002 in. (.05 mm) as

measured at four points 90° apart.

Vertical Correction (Top-to-Bottom)

1. Zero indicators A and P at top dead center

(12 o’clock) of coupling half Y.

2. Rotate indicator to bottom dead center

(6 o’clock). Observe the needles and

record the readings.

3. Make corrections as outlined previously.

Horizontal Correction (Side-to-Side)

1. Zero indicators A and P on the left side of

coupling half Y, 90° from top dead center

(9 o’clock).

2. Rotate indicators through top dead center

to the right side, 180° from the start

(3 o’clock). Observe the needle, measure

and record the reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal

readings to ensure adjustment of one did

not disturb the other. Correct as

necessary.

NOTE: With experience, the installer will

understand the interaction between angular

and parallel and will make corrections

appropriately.

ChemBasePlus™ — 1/2002 Page 16 of 16

Page 18

Form No. I-Chembase — 1/20 02

ge 14 of 15

© copyright 2002 Goulds Pumps, Inc.

a subsidiary of IT Industries, Inc.

Loading...

Loading...