Page 1

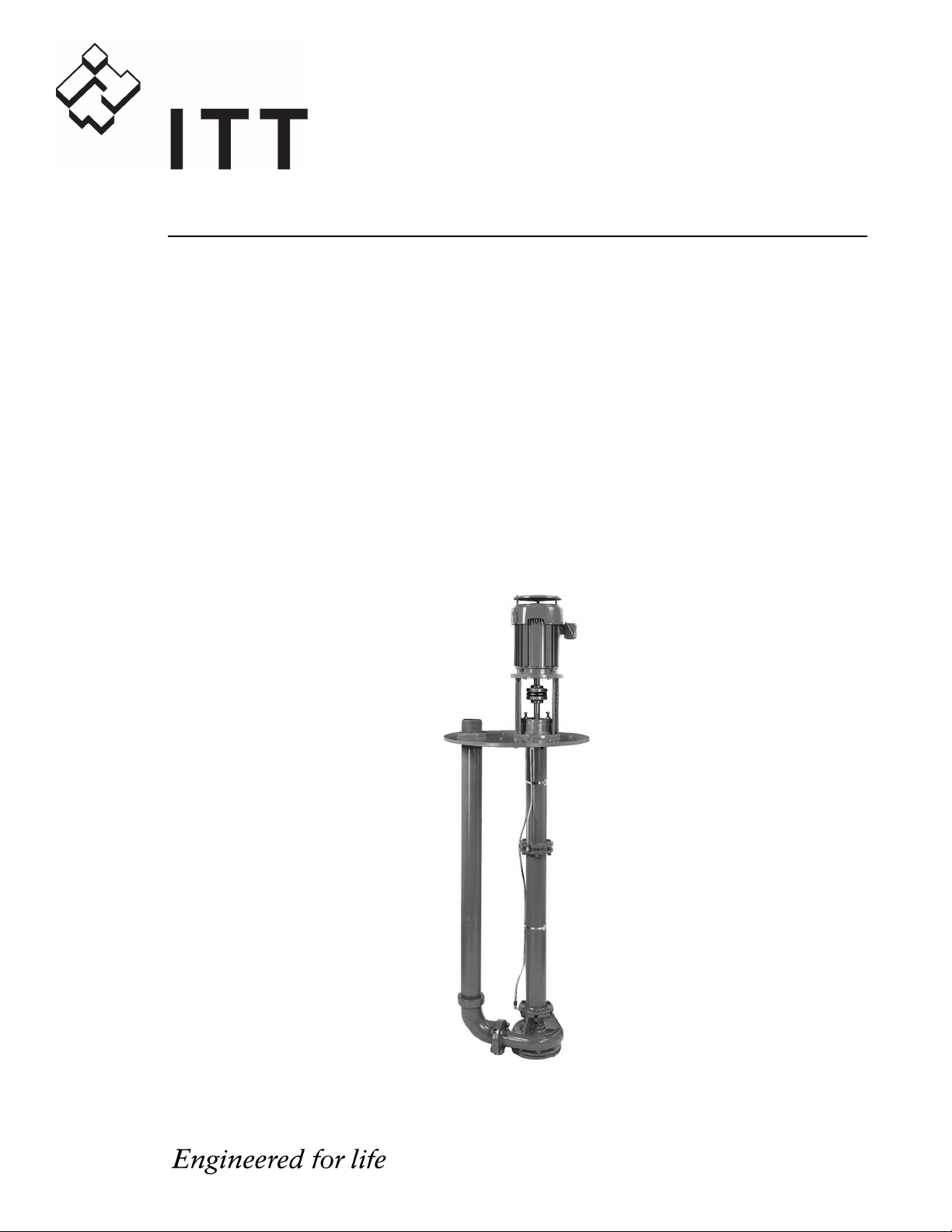

Goulds Pumps

Installation, Operation, and

Maintenance Manual

Model API 3171

Page 2

Page 3

Table of Contents

Introduction and Safety...................................................................................................................................................4

Introduction.......................................................................................................................................................................4

Safety...................................................................................................................................................................................4

Safety terminology and symbols..................................................................................................................................4

Environmental safety.....................................................................................................................................................5

User safety.......................................................................................................................................................................6

Ex-approved products...................................................................................................................................................7

Product warranty...............................................................................................................................................................8

Transportation and Storage............................................................................................................................................9

Inspect the delivery...........................................................................................................................................................9

Inspect the package........................................................................................................................................................9

Inspect the unit...............................................................................................................................................................9

Transportation guidelines.................................................................................................................................................9

Pump handling................................................................................................................................................................9

Lifting methods..............................................................................................................................................................9

Storage guidelines............................................................................................................................................................10

Pump storage requirements........................................................................................................................................10

Prepare the pump for long-term storage.................................................................................................................11

Table of Contents

Product Description........................................................................................................................................................12

General description.........................................................................................................................................................12

Enclosed lineshaft........................................................................................................................................................13

Nameplate information..................................................................................................................................................14

Permissible temperatures...............................................................................................................................................16

Installation.........................................................................................................................................................................17

Preinstallation...................................................................................................................................................................17

Inspect the pump.........................................................................................................................................................17

Pump location guidelines............................................................................................................................................18

Concrete foundation requirements...........................................................................................................................18

Support plate installation...............................................................................................................................................19

Install the support plate with a pit cover..................................................................................................................19

Install the support plate without a pit cover............................................................................................................19

Stuffing box installation.................................................................................................................................................20

Install the packed stuffing box...................................................................................................................................21

Install the pump, driver, and coupling.........................................................................................................................21

Motor installation and coupling alignment.................................................................................................................22

Install the motor...........................................................................................................................................................22

Alignment checks.........................................................................................................................................................22

Permitted indicator values for alignment checks....................................................................................................23

Align the coupling........................................................................................................................................................23

Float control installation................................................................................................................................................23

Install the Square D 9036 simplex and 9038 duplex float controls.....................................................................24

Piping checklists..............................................................................................................................................................26

General piping checklist..............................................................................................................................................26

Suction piping for optional dry pit, outside tank mount, and tailpipe applications..........................................27

Steam lines.....................................................................................................................................................................28

Final piping checklist...................................................................................................................................................28

Commissioning, Startup, Operation, and Shutdown............................................................................................29

Preparation for startup...................................................................................................................................................29

Model API 3171 Installation, Operation, and Maintenance Manual 1

Page 4

Table of Contents

Check the rotation...........................................................................................................................................................29

Thrust bearing lubrication.............................................................................................................................................30

Flush the steady bearings............................................................................................................................................30

Sealed bearings.............................................................................................................................................................30

Lubricate the sealed bearings with grease cups.......................................................................................................31

Shaft sealing with a mechanical seal.............................................................................................................................32

Shaft sealing with a stuffing box...................................................................................................................................33

Steam jacket pumps (molten sulfur construction).....................................................................................................33

Impeller-clearance setting..............................................................................................................................................33

Set the impeller clearance - dial indicator method .................................................................................................33

Set the impeller clearance - feeler gauge method ...................................................................................................34

Pump priming..................................................................................................................................................................35

Install the coupling guard...............................................................................................................................................35

Start the pump.................................................................................................................................................................36

Pump operation precautions.........................................................................................................................................37

Shut down the pump......................................................................................................................................................37

Make the final alignment of the pump and driver......................................................................................................38

Maintenance......................................................................................................................................................................39

Maintenance schedule.....................................................................................................................................................39

Bearing maintenance.......................................................................................................................................................39

Thrust bearings............................................................................................................................................................40

Lubricate the bearings after a shutdown period......................................................................................................40

Lubricating-grease requirements...............................................................................................................................40

Steady bearings.............................................................................................................................................................41

Shaft-seal maintenance...................................................................................................................................................41

Mechanical-seal maintenance.....................................................................................................................................41

Packed stuffing-box maintenance..............................................................................................................................42

Disassembly......................................................................................................................................................................42

Disassembly precautions.............................................................................................................................................42

Tools required...............................................................................................................................................................43

Drain the pump............................................................................................................................................................43

Remove the pump from the sump............................................................................................................................43

Remove the impeller....................................................................................................................................................45

Disassemble the column.............................................................................................................................................46

Preassembly inspections.................................................................................................................................................47

Replacement guidelines...............................................................................................................................................47

Shaft replacement guidelines......................................................................................................................................48

Bearings inspection......................................................................................................................................................48

Bearing fits and tolerances..........................................................................................................................................49

Reassembly.......................................................................................................................................................................49

Assemble the column and support plate..................................................................................................................49

Assemble the rotating element...................................................................................................................................50

Assemble the column..................................................................................................................................................51

Assemble the impeller, suction cover, and strainer.................................................................................................51

Troubleshooting...............................................................................................................................................................53

Operation troubleshooting............................................................................................................................................53

Assembly troubleshooting.............................................................................................................................................54

Parts Listings and Cross-Sectional Drawings.........................................................................................................55

Cross-sectional diagram.................................................................................................................................................55

Dimensional drawings....................................................................................................................................................56

Parts list.............................................................................................................................................................................57

Other Relevant Documentation or Manuals...........................................................................................................60

For additional documentation.......................................................................................................................................60

2 Model API 3171 Installation, Operation, and Maintenance Manual

Page 5

Table of Contents

Local ITT Contacts.........................................................................................................................................................61

Regional offices................................................................................................................................................................61

Model API 3171 Installation, Operation, and Maintenance Manual 3

Page 6

Introduction and Safety

Introduction and Safety

Introduction

Purpose of this manual

The purpose of this manual is to provide necessary information for:

• Installation

• Operation

• Maintenance

CAUTION:

Read this manual carefully before installing and using the product. Improper use of the product can cause

personal injury and damage to property, and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the location of the unit.

Safety

WARNING:

• The operator must be aware of safety precautions to prevent physical injury.

• Any pressure-containing device can explode, rupture, or discharge its contents if it is over-pressurized.

Take all necessary measures to avoid over-pressurization.

• Operating, installing, or maintaining the unit in any way that is not covered in this manual could cause

death, serious personal injury, or damage to the equipment. This includes any modification to the

equipment or use of parts not provided by ITT. If there is a question regarding the intended use of

the equipment, please contact an ITT representative before proceeding.

• This manual clearly identifies accepted methods for disassembling units. These methods must be

adhered to. Trapped liquid can rapidly expand and result in a violent explosion and injury. Never apply

heat to impellers, propellers, or their retaining devices to aid in their removal.

• Do not change the service application without the approval of an authorized ITT representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so could result in physical injury,

damage, or delays.

Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and regulations

carefully before handling the product. They are published to help prevent these hazards:

• Personal accidents and health problems

• Damage to the product

• Product malfunction

4 Model API 3171 Installation, Operation, and Maintenance Manual

Page 7

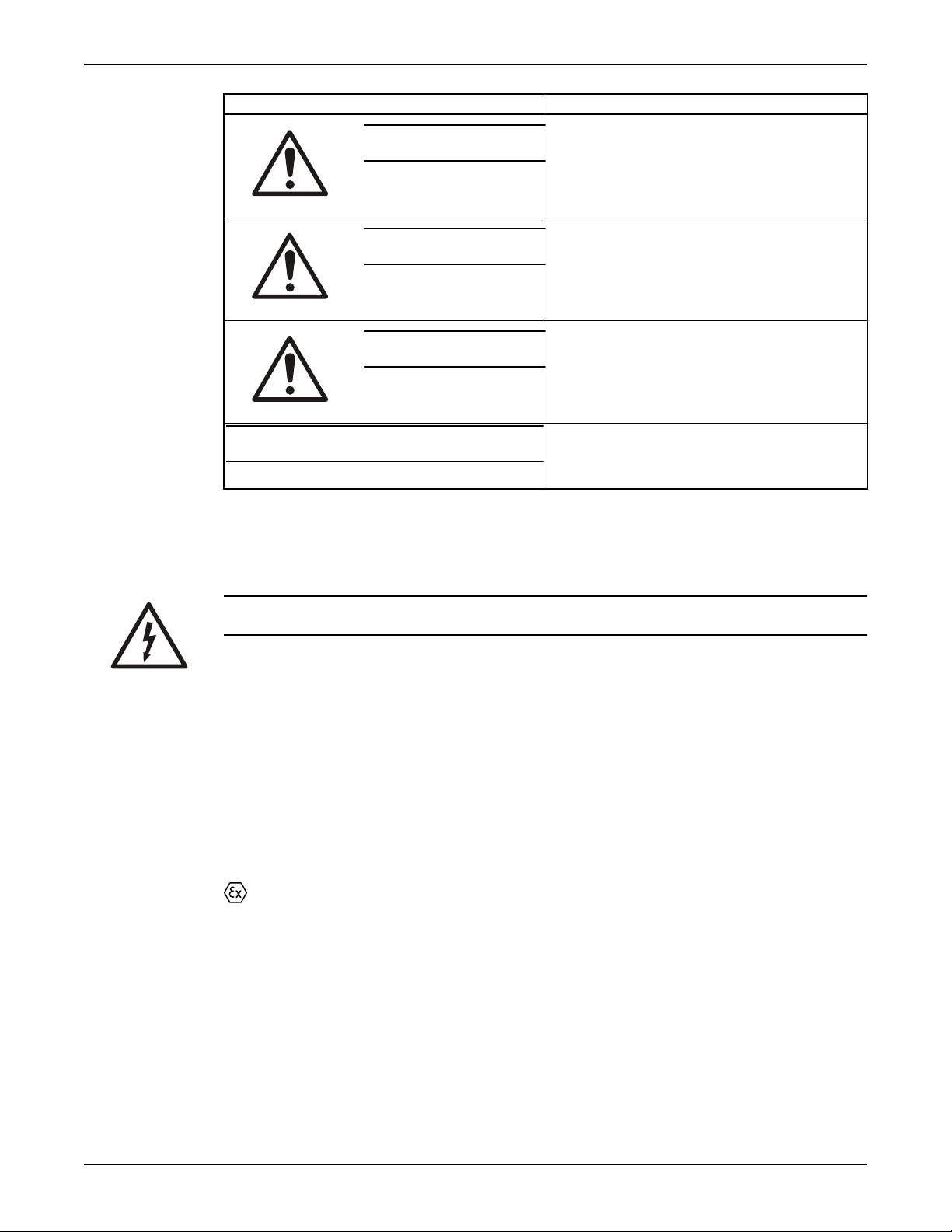

Hazard levels

Hazard level Indication

A hazardous situation which, if not avoided, will

DANGER:

WARNING:

CAUTION:

result in death or serious injury

A hazardous situation which, if not avoided, could

result in death or serious injury

A hazardous situation which, if not avoided, could

result in minor or moderate injury

Introduction and Safety

Hazard categories

The Ex symbol

NOTICE:

Hazard categories can either fall under hazard levels or let specific symbols replace the ordinary hazard

level symbols.

Electrical hazards are indicated by the following specific symbol:

Electrical Hazard:

These are examples of other categories that can occur. They fall under the ordinary hazard levels and may

use complementing symbols:

• Crush hazard

• Cutting hazard

• Arc flash hazard

The Ex symbol indicates safety regulations for Ex-approved products when used in atmospheres that are

potentially explosive or flammable.

• A potential situation which, if not avoided,

could result in undesirable conditions

• A practice not related to personal injury

Environmental safety

The work area

Always keep the station clean to avoid and/or discover emissions.

Waste and emissions regulations

Observe these safety regulations regarding waste and emissions:

• Appropriately dispose of all waste.

• Handle and dispose of the processed liquid in compliance with applicable environmental regulations.

• Clean up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

Model API 3171 Installation, Operation, and Maintenance Manual 5

Page 8

Introduction and Safety

Electrical installation

For electrical installation recycling requirements, consult your local electric utility.

Recycling guidelines

Always follow local laws and regulations regarding recycling.

User safety

General safety rules

These safety rules apply:

• Always keep the work area clean.

• Pay attention to the risks presented by gas and vapors in the work area.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc flash hazards.

• Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

Safety equipment

Use safety equipment according to the company regulations. Use this safety equipment within the work

area:

• Helmet

• Safety goggles, preferably with side shields

• Protective shoes

• Protective gloves

• Gas mask

• Hearing protection

• First-aid kit

• Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific information about safety

devices in other chapters of this manual.

Electrical connections

Electrical connections must be made by certified electricians in compliance with all international, national,

state, and local regulations. For more information about requirements, see sections dealing specifically with

electrical connections.

Precautions before work

Observe these safety precautions before you work with the product or are in connection with the product:

• Provide a suitable barrier around the work area, for example, a guard rail.

• Make sure that all safety guards are in place and secure.

• Allow all system and pump components to cool before you handle them.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage property.

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Make sure that the product is thoroughly clean.

• Make sure that there are no poisonous gases within the work area.

• Make sure that you have quick access to a first-aid kit.

• Disconnect and lock out power before servicing.

• Check the explosion risk before you weld or use electric hand tools.

Wash the skin and eyes

Do the following if chemicals or hazardous fluids have come into contact with your eyes or your skin:

6 Model API 3171 Installation, Operation, and Maintenance Manual

Page 9

Introduction and Safety

If you need to wash

your...

Eyes

Skin

Then...

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least one minute.

3. Seek medical attention, if required.

Ex-approved products

Follow these special handling instructions if you have an Ex-approved unit.

Personnel requirements

These are the personnel requirements for Ex-approved products in potentially explosive atmospheres:

• All work on the product must be carried out by certified electricians and ITT-authorized mechanics.

Special rules apply to installations in explosive atmospheres.

• All users must know about the risks of electric current and the chemical and physical characteristics of

the gas, the vapor, or both present in hazardous areas.

• Any maintenance for Ex-approved products must conform to international and national standards

(for example, IEC/EN 60079-17).

ITT disclaims all responsibility for work done by untrained and unauthorized personnel.

Product and product handling requirements

These are the product and product handling requirements for Ex-approved products in potentially

explosive atmospheres:

• Only use the product in accordance with the approved motor data.

• The Ex-approved product must never run dry during normal operation. Dry running during service

and inspection is only permitted outside the classified area.

• Before you start work on the product, make sure that the product and the control panel are isolated

from the power supply and the control circuit, so they cannot be energized.

• Do not open the product while it is energized or in an explosive gas atmosphere.

• Make sure that thermal contacts are connected to a protection circuit according to the approval

classification of the product, and that they are in use.

• Intrinsically safe circuits are normally required for the automatic level-control system by the level

regulator if mounted in zone 0.

• The yield stress of fasteners must be in accordance with the approval drawing and the product

specification.

• Do not modify the equipment without approval from an authorized ITT representative.

• Only use parts that are provided by an authorized ITT representative.

Description of ATEX

The ATEX directives are a specification enforced in Europe for electrical and non-electrical equipment

installed in Europe. ATEX deals with the control of potentially explosive atmospheres and the standards

of equipment and protective systems used within these atmospheres. The relevance of the ATEX

requirements is not limited to Europe. You can apply these guidelines to equipment installed in any

potentially explosive atmosphere.

Guidelines for compliance

Compliance is fulfilled only when you operate the unit within its intended use. Do not change the

conditions of the service without the approval of an ITT representative. When you install or maintain

explosion proof products, always comply with the directive and applicable standards (for example, IEC/

EN 60079–14).

Model API 3171 Installation, Operation, and Maintenance Manual 7

Page 10

Introduction and Safety

Product warranty

Coverage

ITT undertakes to remedy faults in products from ITT under these conditions:

• The faults are due to defects in design, materials, or workmanship.

• The faults are reported to an ITT representative within the warranty period.

• The product is used only under the conditions described in this manual.

• The monitoring equipment incorporated in the product is correctly connected and in use.

• All service and repair work is done by ITT-authorized personnel.

• Genuine ITT parts are used.

• Only Ex-approved spare parts and accessories authorized by ITT are used in Ex-approved products.

Limitations

The warranty does not cover faults caused by these situations:

• Deficient maintenance

• Improper installation

• Modifications or changes to the product and installation made without consulting ITT

• Incorrectly executed repair work

• Normal wear and tear

ITT assumes no liability for these situations:

• Bodily injuries

• Material damages

• Economic losses

Warranty claim

ITT products are high-quality products with expected reliable operation and long life. However, should the

need arise for a warranty claim, then contact your ITT representative.

8 Model API 3171 Installation, Operation, and Maintenance Manual

Page 11

Transportation and Storage

Inspect the delivery

Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the distributor.

Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact your sales representative if anything is out of order.

Transportation and Storage

Transportation guidelines

Pump handling

WARNING:

• Make sure that the pump cannot roll or fall over and injure people or damage property.

• These pumps might use carbon or ceramic silicon carbide components. Do not drop the pump or

subject it to shock loads as this can damage the internal ceramic components.

NOTICE: Use a forklift truck or an overhead crane with sufficient capacity to move the pallet with the

pump unit on top. Failure to do so can result in equipment damage.

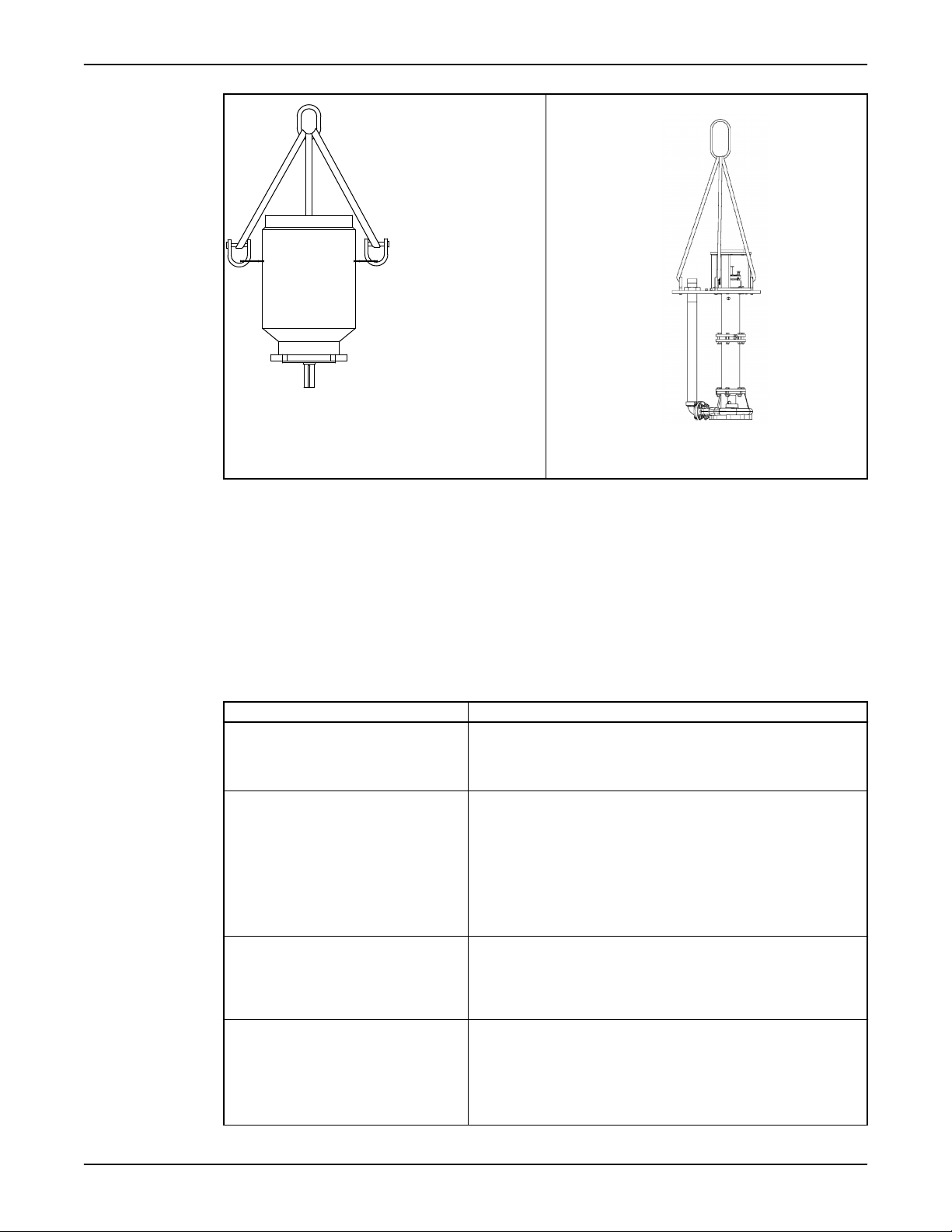

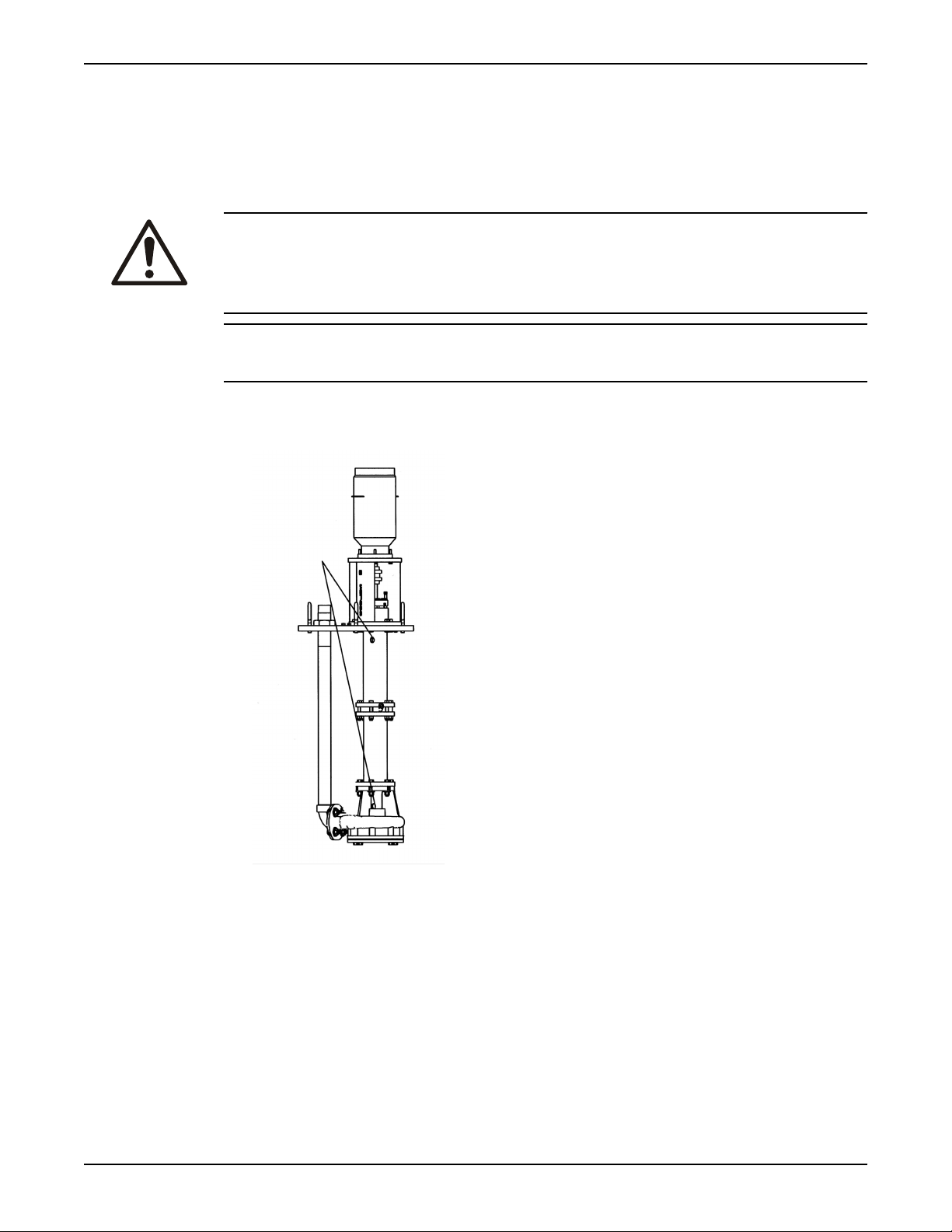

Lifting methods

WARNING:

• Assembled units and their components are heavy. Failure to properly lift and support this equipment

can result in serious physical injury and/or equipment damage. Lift equipment only at the specifically

identified lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected,

and used for the entire load being lifted.

• Crush hazard. The unit and the components can be heavy. Use proper lifting methods and wear steeltoed shoes at all times.

• Do not attach sling ropes to shaft ends.

Use the supplied lifting lugs and suitable slings in order to lift the entire pump to a vertical position and

lower the unit into the sump. Then use the lifting lugs on the motor and a suitable sling in order to hoist

the motor into position. Use a tag line attached to the casing end in order to prevent the pump from

swinging.

Model API 3171 Installation, Operation, and Maintenance Manual 9

Page 12

Transportation and Storage

Examples

Figure 1: Example of lifting motor properly with

lifting lugs

Figure 2: Example of lifting pump properly with

sling

Storage guidelines

Pump storage requirements

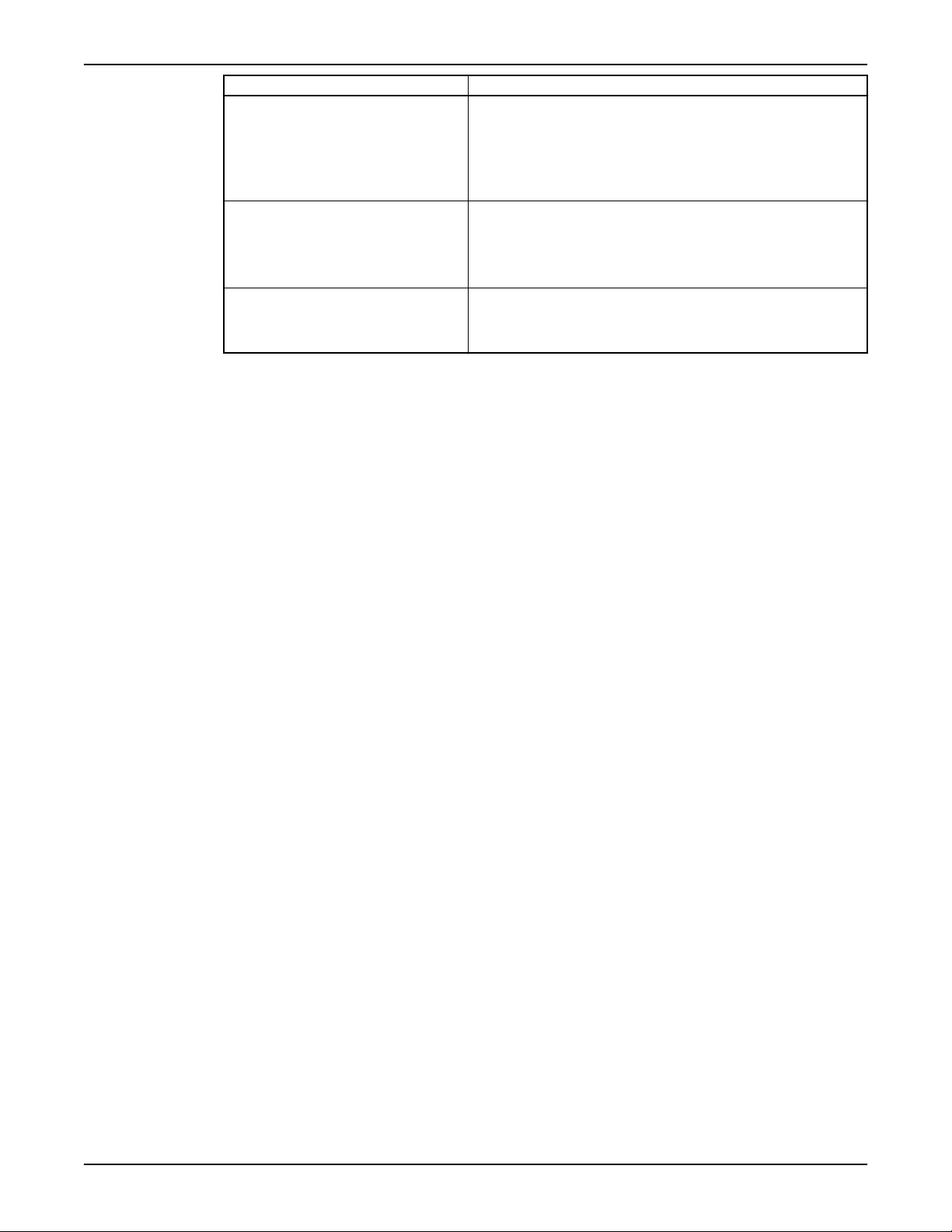

Requirements

Vertical pumps require proper preparation for storage and regular maintenance during storage. The pump

is considered in storage when it has been delivered to the job site and is awaiting installation.

For specific requirements for storing motors, gearheads, and engines, contact the equipment manufacturer.

Storage preparation

Condition Proper preparation

Indoor storage area (preferred)

Outdoor storage area (when indoor

storage is not available)

Placement of pumps and component

parts

Stacking of pumps or component parts

• Pave the area.

• Clean the area.

• Drain the area and keep it free from flooding.

• Observe all indoor storage requirements.

• Use weather-proof coverings such as flame-resistant sheeting

or tarpaulins.

• Place coverings in a manner that maximizes drainage and air

circulation.

• Tie coverings down in order to protect the pump from wind

damage.

• Place the pump on skids, pallets, or shoring higher than 6 in.

(15 cm) from the ground for good air circulation.

• Sort the parts in order to permit easy access for inspection

and/or maintenance without excessive handling.

• Make sure that racks, containers, or crates bear the full

weight of pumps or parts in order to prevent distortion.

• Keep identification markings readily visible.

• Immediately replace any cover you remove for internal

access.

10 Model API 3171 Installation, Operation, and Maintenance Manual

Page 13

Condition Proper preparation

Rotation of the pump and bowl

assembly shaft

Controlled storage facilities

Uncontrolled storage facilities that have

uneven temperatures, higher humidity,

and/or dusty conditions)

When pump is not in regular operation

If a pump has been installed, but is not in regular operation for an extended period of time, such as during

a seasonal shutdown, then operate it for at least 15 minutes every two weeks, if possible.

Prepare the pump for long-term storage

For storage periods over six months, you must follow the pump storage requirements and this procedure:

1. Inspect the lube-oil and seal-flush piping and either fill the piping with rust-preventative oil, or recoat

the piping periodically in order to prevent corrosion.

2. Place 10 lbs (4.5 kg) of moisture-absorbing desiccant or 5.0 lbs (2.3 kg) of vapor-phase inhibitor

crystals near the center of the pump.

3. If the pump is assembled, place an additional one pound (0.5 kg) in the discharge nozzle and securely

fasten the nozzle to the discharge elbow.

4. Install a moisture indicator near the perimeter of the pump.

5. Cover the pump with black polyethylene with a minimum thickness of 6.0 mil (0.15 mm), and seal it

with tape.

6. Provide a small ventilation hole approximately 0.5 in. (12.0 mm) in diameter.

7. Provide a roof or shed shelter in order to protect the pump from direct exposure to the elements.

Transportation and Storage

• Rotate the pump and bowl assembly shaft counterclockwise

once a month, at a minimum.

• Never leave the shaft in a previous position or in the extreme

raised or lowered lateral position.

• Make sure that the shaft rotates freely.

• Maintain an even temperature of 10°F (6°C) or higher above

the dew point.

• Keep the relative humidity to less than 50%.

• Make sure that there is little or no dust.

• Inspect the pump periodically to make sure that all

preservatives are intact.

• Seal all pipe threads and flanged pipe covers with tape.

Model API 3171 Installation, Operation, and Maintenance Manual 11

Page 14

Product Description

Product Description

General description

Product description

The Model API 3171 is a vertical submerged bearing sump and process pump that meets the requirements

of the 10th and 11th editions of API Standard 610 (ISO 13709).

This model is based on three bearing frames with 17 hydraulic sizes. The S/ST group has identical

bearings with a slightly different shaft on the impeller end for the S and ST. The M/MT group is identical

in all aspects for the power end. However, the liquid end of the MT is common with the S group except

that the MT is modified to accept a larger shaft. There are two MT sizes that are common with the S/ST

group.

This table shows the number of hydraulic sizes available for each drive-unit size group. Note that each

pump has a choice of two different discharge pipes which results in four combinations.

Drive-unit size group Number of hydraulic sizes

S/ST 9

M/MT 8

L 2

Casing

Impeller

Strainer

Discharge elbow

Column pipe

The casing has these features:

• A tangential discharge

• Is self-venting

• Has an integral bearing retainer

• Is precision-bored in order to ensure permanent alignment between the column casing, suction cover,

and bearing

The impeller is fully open, keyed to the shaft, and held in place by a self-locking capscrew in order to

ensure positive locking and prevent damage from reverse rotation. Impellers are spin-balanced (single

plane) to ISO G2.5. The impeller is provided with back vanes in order to reduce the axial thrust and

prevent the entrance of solids.

The impellers on this pump do not meet the dimensional requirements for dynamic balancing.

The flat plate strainer is designed to maximize draw-down in a given sump depth. Openings are sized to

prevent the entrance of large solids that are commonly found in open sumps.

The discharge elbow is designed to allow the pump to fit into the smallest possible opening. A threaded

connection to the discharge pipe allows the pipe to be changed without removing the pump from the

sump.

The column pipe has flanged connections that are machined in order to ensure true parallelism and to

maintain steady bearings concentric with the shaft.

Shaft

The standard design uses a one-piece shaft in order to ensure accurate alignment. The shaft is precisionground, polished, and straightened to keep vibration and deflection to a minimum. Standard bearing spans

keep the shaft well below first critical speed for all sizes.

12 Model API 3171 Installation, Operation, and Maintenance Manual

Page 15

Bearings

Seals

Motor support

Product Description

The thrust bearing is grease- or oil-mist-lubricated and consists of a pair of single-row, angular contact ball

bearings arranged back-to back. The bearing is shouldered and locked to the shaft and housing. This

enables the bearing to carry all of the thrust loads and some of the radial load. All fits are precisionmachined to industry standards. The steady bearings are press fit sleeve bearings. Fits are designed for

optimum life under all operating conditions.

This pump has three seals:

Seal type Description

Upper labyrinth seal This seal is used to exclude dirt and water from the thrust

bearing.

Lower labyrinth seal This seal is used below the thrust bearing in order to contain the

grease and exclude any possible contamination.

Carbon Teflon® casing collar This seal is installed immediately behind the impeller in the casing

in order to minimize recirculation back to the sump and

maximize hydraulic efficiency.

Motor supports are cast construction and precision-machined in order to maintain proper alignment

between the motor and pump shaft with minimal shimming. Motor supports are designed for vertical Cface motors as standard. P-base supports and IEC adapters are available upon request.

Direction of rotation

The shaft rotates clockwise when you look down on the pump shaft.

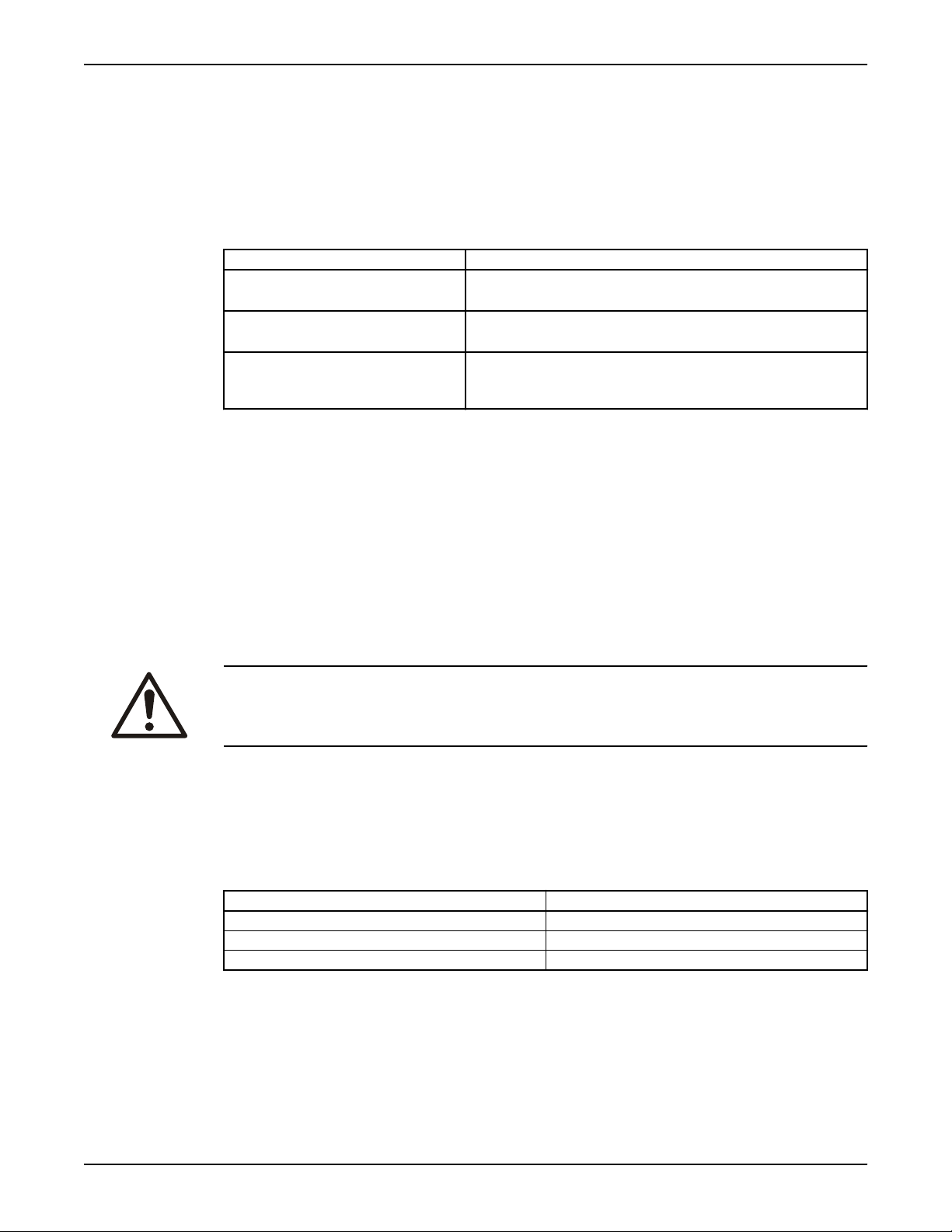

Enclosed lineshaft

The enclosed lineshaft design lends itself well for applications where abrasives are present in the pumped

fluid, or when a bearing lubricant other than the pumped fluid is required.

Lubrication system

CAUTION:

The fluid must run continuously to ensure flow out of the column at all times. If the flush stops, the fluid

in the sump can back up into the column. This contaminates the bearings.

The main feature of this modified design is a positive lubrication system for all bearings. This design

requires a minimum of lubrication fluid due to the bushing located at the bottom of the column adapter

housing directly above the impeller.

Acceptable leak rates

Leaks (flows) across the bushing for certain pressure differentials are shown in this table. Higher pressures

will result in higher leaks.

Pressure differential (PSI) Approximate leak rate (GPM)

3.0 0.33

5.0 0.44

7.5 0.60

Standard materials of construction

• Floating bushings are 18-8 stainless steel housing and spring with a glass-filled Teflon bushing.

• Flush tubing is steel.

Drawing

Positive flow must be maintained at all times.

Model API 3171 Installation, Operation, and Maintenance Manual 13

Page 16

2

1

Product Description

1. Flush Inlet connection 1/4 pressure = 3 PSI + "P" PSI

2. Maximum liquid level "P" PSI above suction

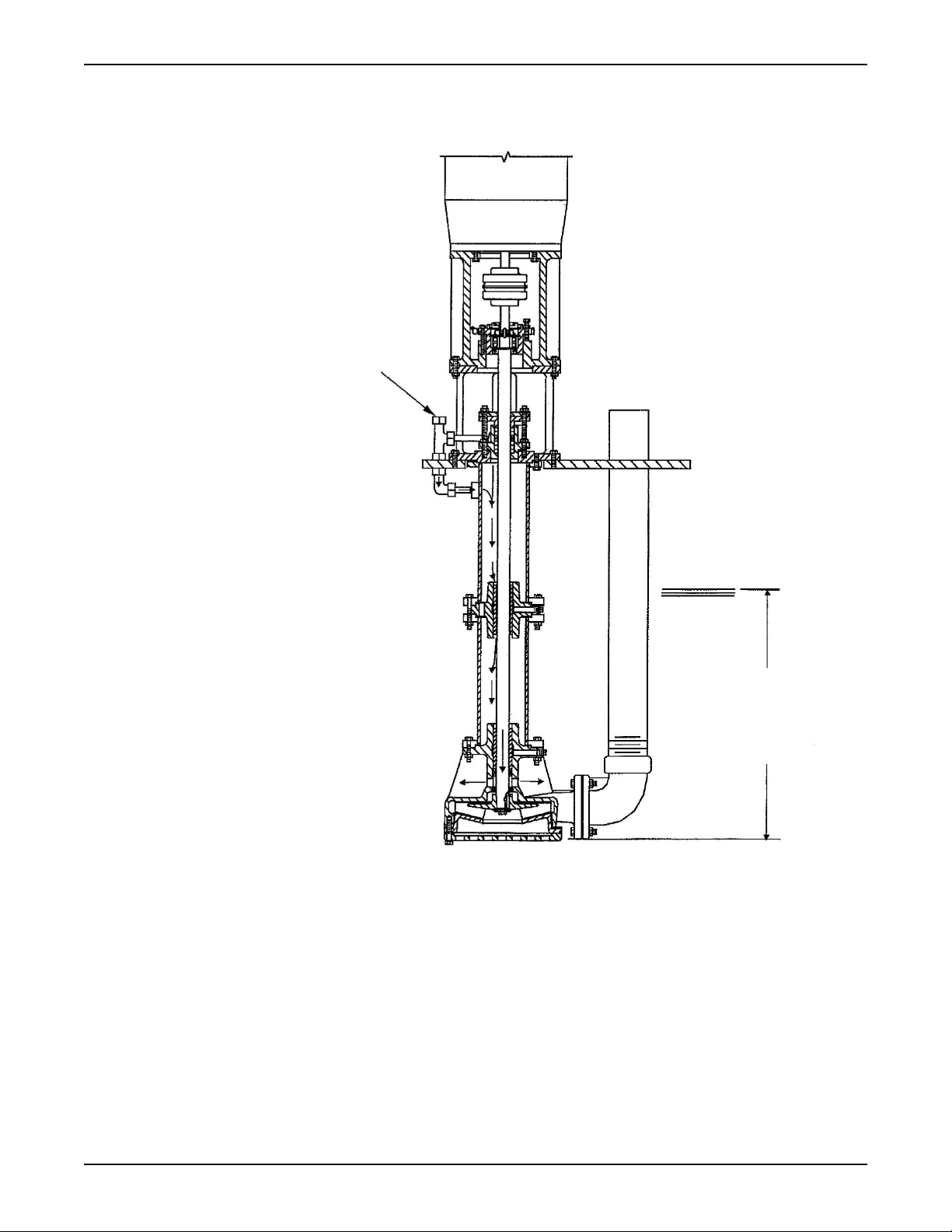

Nameplate information

Important information for ordering

Every pump has a nameplate that provides information about the pump. The nameplate is located on the

motor support.

14 Model API 3171 Installation, Operation, and Maintenance Manual

Page 17

When you order spare parts, identify this pump information:

• Model

• Size

• Serial number

• Item numbers of the required parts

Refer to the nameplate on the pump casing for most of the information. See Parts List for item numbers.

Nameplate on the pump casing using English units

Table 1: Explanation of nameplate on the pump casing

Nameplate field Explanation

IMPLR. DIA. Impeller diameter, in inches

MAX. DIA. Maximum impeller diameter, in inches

GPM Rated pump flow, in gallons per minute

FT HD Rated pump head, in feet

RPM Rated pump speed, revolutions per minute

MOD. Pump model

SIZE Size of the pump

STD. NO. ANSI standard designation

MAT L. CONST. Material of which the pump is constructed

SER. NO. Serial number of the pump

MAX DSGN PSI

Maximum pressure at 100ºF according to the pump design

@ 100F

Product Description

Nameplate on the pump casing using metric units

Table 2: Explanation of the nameplate on the pump casing

Nameplate field Explanation

IMPLR. DIA. Impeller diameter

MAX. DIA. Maximum impeller diameter

Model API 3171 Installation, Operation, and Maintenance Manual 15

Page 18

Product Description

ATEX nameplate

Nameplate field Explanation

M3/HR Rated pump flow, in cubic meters per hour

M HD Rated pump head, in meters

RPM Rated pump speed, in revolutions per minute

MOD. Pump model

SIZE Size of the pump

STD. NO. ANSI standard designation

MAT L. CONST Material of which the pump is constructed

SER. NO. Serial number of the pump

MAX. DSGN KG/CM3 @

20°C

Nameplate field Explanation

II Group 2

2 Category 2

G/D Pump can be used when gas and dust are present

T4 Temperature class

Kilograms per cubic centimeter at 20°C

NOTICE: Make sure that the code classifications on the pump are compatible with the specific

environment in which you plan to install the equipment. If they are not compatible, do not operate the

equipment and contact your ITT representative before you proceed.

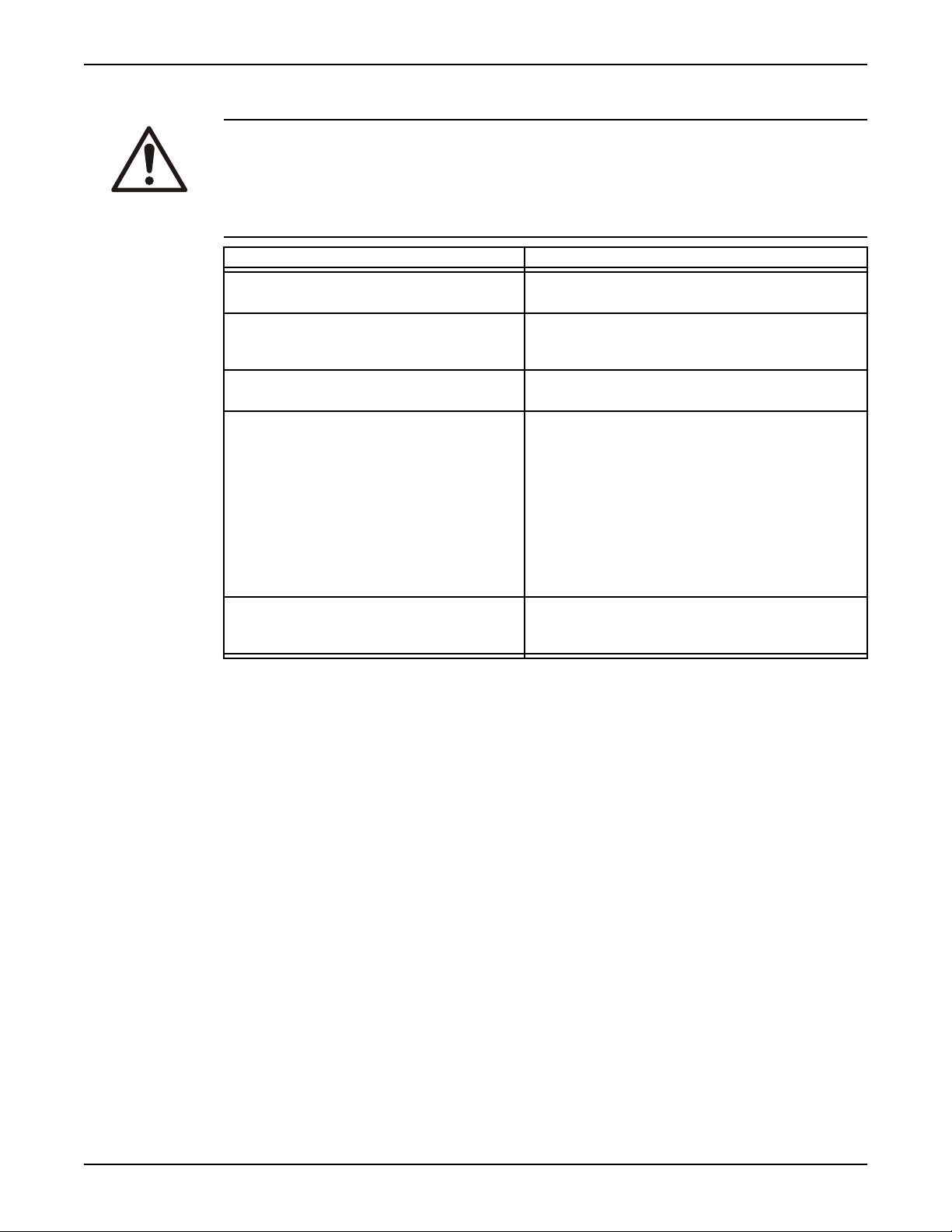

Permissible temperatures

Code Maximum permissible surface

temperature

T1 842°F (450°C) 700°F (372°C)

T2 572°F (300°C) 530°F (277°C)

T3 392°F (200°C) 350°F (177°C)

T4 275°F (135°C) 235°F (113°C)

T5 212°F (100°C) Option not available

T6 185°F (85°C) Option not available

NOTICE:

The code classification marked on the equipment must be in accordance with the specified area where you

plan to install the equipment. If it is not, contact your ITT representative before you proceed.

Maximum permissible liquid

temperature

16 Model API 3171 Installation, Operation, and Maintenance Manual

Page 19

Installation

A

Preinstallation

Precautions

WARNING:

• When installing in a potentially explosive environment, make sure that the motor is properly certified.

• You must earth (ground) all electrical equipment. This applies to the pump equipment, the driver, and

any monitoring equipment. Test the earth (ground) lead to verify that it is connected correctly.

NOTICE: Supervision by an authorized ITT representative is recommended to ensure proper installation.

Failure to do so may result in equipment damage or decreased performance.

Inspect the pump

1. Remove the plastic shipping plugs from the vent holes in the head column and the casing.

Installation

• "A" represents the location of the plugs

2. Remove all the equipment from the shipping containers.

Model API 3171 Installation, Operation, and Maintenance Manual 17

3. Completely clean the underside of the support plate and both sides of the optional pit cover, if

supplied.

4. Remove any grease from the machined surfaces.

Page 20

Installation

Pump location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this equipment can

result in serious physical injury and/or equipment damage. Lift equipment only at the specifically identified

lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected, and used for

the entire load being lifted.

Guideline Explanation/comment

Make sure that the space around the pump is

sufficient.

If you require lifting equipment such as a hoist

or tackle, make sure that there is enough space

above the pump.

Protect the unit from weather and water damage

due to rain, flooding, and freezing temperatures.

Do not install and operate the equipment in

closed systems unless the system is constructed

with properly-sized safety devices and control

devices.

Take into consideration the occurrence of

unwanted noise and vibration.

Concrete foundation requirements

Requirements

Make sure that you meet these requirements when you prepare the pump foundation:

• The foundation must be able to absorb any vibration.

• The foundation must be able to form a permanent and rigid support for the pumping unit.

• The foundation must be of adequate strength in order to support the complete weight of the pump

and driver, plus the weight of the liquid that passes through it.

• There should be at least 0.5 in.(12.7 mm) clearance between the sides of the pump and any portion of

the pit.

This facilitates ventilation, inspection, maintenance, and

service.

This makes it easier to properly use the lifting

equipment and safely remove and relocate the

components to a safe location.

This is applicable if nothing else is specified.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the

pump.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil

underneath.

Typical installation

A typical installation has these characteristics:

• Bolts with a pipe sleeve that is two and a half times the size of the bolt diameter embedded in the

concrete

• Properly sized

• Located in accordance with the dimensions given in the example drawing

• Enough space inside the pipe sleeves to allow the final position of the foundation bolts to align with

the holes in the sub-base flange

18 Model API 3171 Installation, Operation, and Maintenance Manual

Page 21

1

2

3

4

5

6

1. Hex nut

2. Washer

3. Support plate

4. 0.5 in. (12.5 mm) anchor bolt

5. Anchor bolt sleeve

6. Foundation (by customer)

Figure 3: Example of a typical installation

Installation

Support plate installation

Install the support plate with a pit cover

If access to the bottom of the pit cover is not possible during the installation process, you must assemble

and install the pump (without the motor), support plate, and pit cover as a unit. You must install the pit

cover perfectly level in order to make sure that the pump remains straight up and down when installed.

The vapor-proof option includes machined, gasketed fits between the support plate/pit cover and the pit

cover/foundation. You must install these gaskets in order to ensure emissions performance. Bolt the pit

cover to a metal sole plate with a machined surface in order to ensure an air tight seal.

1. Carefully lower the pit cover onto the foundation bolts.

2. Use as long a level as possible in order to level the pit cover in all directions with shims or wedges.

3. Hand tighten the anchor bolts. Check the level and re-shim if necessary.

4. Tighten all anchor bolts in a star pattern in order to avoid distorting the pit cover.

5. If access to the bottom side is possible, carefully lower the pump and support plate onto the pit cover.

6. Install all bolts and hand tighten.

7. Check the level on the support plate and re-shim if necessary.

8. Tighten all bolts in a star pattern in order to avoid distorting the support plate.

Install the support plate without a pit cover

1. Carefully lower the pump and support plate onto the foundation bolts.

2. Level the support plate in all directions using shims and wedges.

3. If you use the vapor-proof option, then perform one of these actions in order to make sure that you

have an air-tight seal:

Support plate

Action

type

Standard Insert the supplied gasket between the two flanges. Bolt the support plate to a

Tank flange Install the supplied gasket between the two flanges. Make sure that the mating

metal sole plate that has a machined surface.

flange on the tank is level. Use gasket material between the flanges in order to

make minor adjustments.

Model API 3171 Installation, Operation, and Maintenance Manual 19

Page 22

2

3

6

9

8

7

5

4

1

Installation

Figure 4: Layout for a standard support plate with the vapor-proof option

4. Hand tighten the anchor bolts. Check the level and re-shim if necessary.

5. Tighten all anchor bolts in a star pattern in order to avoid distorting the support plate.

Stuffing box installation

This pump is a sealless design. Therefore, when temperatures exceed 180°F (82°C), you must move the

thrust bearing away from the heat source in the pump by adding the upper stuffing box. Air can then

circulate around the bearing in order to keep it cool.

The upper stuffing box is also used to minimize vapor emissions when the pump handles controlled

substances.

1. Motor support

20 Model API 3171 Installation, Operation, and Maintenance Manual

2. Upper stuffing box

3. Gasket

4. Discharge pipe

5. Support plate

6. Gasket

7. 3 in. (76.2 mm) NPT female connection

8. Pit cover

9. Gasket

Page 23

Install the packed stuffing box

355

193I

494V

367B

106

221

107

353

355C

105

364A

190G

WARNING:

Packed stuffing boxes are not allowed in an ATEX-classified environment.

The stuffing box is packed at the factory. The packing is lubricated by a grease cup supplied with the

pump.

1. Fill the grease cup with any lithium-based #2 grease.

2. Install the grease cup on the tapped opening on the stuffing box.

3. Turn the cap on the grease cup several turns in order to inject the grease into the packing.

4. Hand-tighten the gland nuts.

Installation

105 Lantern ring 353 Gland stud

106 Packing set 355 Gland nuts

107 Gland 355C Insert nuts

190G Pipe nipple 364A Packed box insert

193I Grease cup 367B Insert gasket

221 Stuffing box support 494V Pipe elbow

Install the pump, driver, and coupling

1. Mount and fasten the pump on the baseplate. Use applicable bolts.

2. Mount the driver on the baseplate. Use applicable bolts and hand tighten.

3. Install the coupling.

See the installation instructions from the coupling manufacturer.

Model API 3171 Installation, Operation, and Maintenance Manual 21

Page 24

Installation

Motor installation and coupling alignment

WARNING:

• Follow shaft alignment procedures in order to prevent catastrophic failure of drive components or

unintended contact of rotating parts. Follow the coupling installation and operation procedures from

the coupling manufacturer.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.

NOTICE: Proper alignment is the responsibility of the installer and the user of the unit. Check the

alignment of frame-mounted units before you operate the unit. Failure to do so can result in equipment

damage or decreased performance.

Install the motor

Use NEMA Vertical C-face motors with this pump. P-base motor adapters and IEC motor adapters are

available as options.

1. Install both coupling halves before you mount the motor.

Refer to the instructions from the coupling manufacturer.

2. Use the lifting lugs on the motor in order to carefully lower the motor onto the pump.

Make sure to align the bolt holes.

3. Before you connect the coupling, wire the motor and check the direction of rotation.

The rotation arrow is on the motor support. The correct rotation is clockwise as you look down from

the drive at the impeller.

Alignment checks

When to perform alignment checks

You must perform alignment checks under these circumstances:

• The process temperature changes.

• The piping changes.

• The pump has been serviced.

Types of alignment checks

Type of check When it is used

Initial alignment (cold alignment)

check

Final alignment (hot alignment)

check

Initial alignment (cold alignment) checks

When Why

Before you grout the baseplate This ensures that alignment can be accomplished.

After you grout the baseplate This ensures that no changes have occurred during the grouting

After you connect the piping This ensures that pipe strains have not altered the alignment.

Prior to operation when the pump and the driver are at ambient

temperature.

After operation when the pump and the driver are at operating

temperature.

process.

22 Model API 3171 Installation, Operation, and Maintenance Manual

Page 25

Final alignment (hot alignment) checks

When Why

After the first run This ensures correct alignment when both the pump and the driver

are at operating temperature.

Periodically This follows the plant operating procedures.

Permitted indicator values for alignment checks

NOTICE: The specified permitted reading values are valid only at operating temperature. For cold

settings, other values are permitted. You must use the correct tolerances. Failure to do so can result in

misalignment and reduced pump reliability.

When dial indicators are used to check the final alignment, the pump and drive unit are correctly aligned

when these conditions are true:

• The total indicator runout is a maximum of 0.002 in. (0.05 mm) at operating temperature.

• The tolerance of the indicator is 0.0005 in./in. (0.0127 mm/mm) of indicator separation at operating

temperature.

Align the coupling

WARNING:

• Disconnect and lock out electrical power before installing or servicing the pump.

• When installing in a potentially explosive environment, make sure that the motor is properly certified.

• The coupling used in an ATEX classified environment must be properly certified.

Installation

Alignment of the pump and motor is of extreme importance for trouble-free mechanical operation.

Straight-edge alignment by an experienced installer is adequate for most installations. Use dial indicators

for disc couplings and applications where alignment to tighter tolerances is desirable. In these cases, use

standard dial indicator procedures.

1. Check for coupling alignment by using either the reverse dial indicator method or laser alignment

tools.

2. Move the motor until you achieve the correct alignment.

Refer to the coupling manufacturer literature for proper alignment criteria.

3. Install discs between the hubs per the manufacturer's directions included with the pump data package.

4. Tighten all motor bolts.

Float control installation

ITT supplies several different float controls. Refer to the float control installation instructions provided

with the controls for the proper installation procedure. This topic describes the Square D 9036 Simplex

and Square D 9038 Duplex float controls.

How float controls work

The on and off levels of the Square D 9036 simplex and the Square D 9038 duplex are controlled by

adjusting the collars (335). As the liquid level rises, the float rises to contact the upper collar and the

upward movement of the float rod causes the mechanical switch inside the control to close. This

completes the circuit to the starter. Operation continues until the liquid level drops low enough for the

float to contact the lower collar. This pulls the rod down, opening the switch and turning off the pump.

The only difference between the Square D 9036 simplex and the Square D 9038 duplex is in the operating

sequence. For the Square D 9038 duplex, the first pump starts as the water level rises. This allows the float

to contact the upper collar. When the water level drops down and shuts off the first pump, a lever arm

inside the control mechanically switches to the second pump and it comes on for the next cycle.

Model API 3171 Installation, Operation, and Maintenance Manual 23

Page 26

1

2

3

5

6

7

4

Installation

APEX high level alarm

If the first pump fails to keep up with demand, or not come on at all, then a continued rise in the level

turns both pumps on. Both pumps run until the low-water level is reached. If both pumps are unable to

keep up with the demand, then an optional high-water alarm switch can be supplied in the alternator to

close a switch if the water level rises past the second pumps on the level. This switch can be wired into a

customer-supplied alarm horn or light.

The APEX high level alarm is an independent device used to sense fluid level and close a switch that

activates a separate alarm. The switch is mounted on a pipe above the support plate. The pipe must extend

into the sump 4 to 6 in. (10 to 15 cm) below the required actuation point. As the liquid level rises in the

pipe, trapped air causes bellows inside the switch to inflate and trip a microswitch. The switch can then

activate a light, horn, relay, solenoid valve, or other electric device.

1. High water alarm

2. Reducing adapter, 0.5 in. x 1.0 in. (13.0 mm x 26.0 mm)

3. Nipple, 1.0 in. (26.0 mm)

4. Coupling, 1.0 in (26.0 mm)

5. Pit cover

6. Pipe, 1.0 in (26 mm), 8.0 in. (204 mm) shorter than the pump length

7. Cut the pipe 2.5 in. (64 mm) below the required switch actuation point

Magnetrol displacer-type liquid level switch

The Magnetrol displacer-type liquid level switch is closed by a magnetic seal inside a sealed tube. Switch

operation is controlled by the buoyancy of weighted displacers suspended on a spring. As liquid level rises,

the resulting change in buoyancy moves the spring upwards. The spring movement causes a magnetic

sleeve to attract a pivoted magnet, closing the actuating switch. Refer to installation guide supplied by the

manufacturer for proper installation and configuration.

Float ball switches

Float balls are individual switches that are used in multiple configurations to control the pump circuit. The

float balls are suspended in the sump to the desired control level. When the fluid level rises to the float

ball, the switch begins to float. The float is either anchored to a pipe or weighted. This allows the switch to

tilt when the fluid continues to rise. When the float tilts, a switch closes that you can use in order to turn

the pump on, activate a high-level alarm, or control any other electrical device.

Install the Square D 9036 simplex and 9038 duplex float controls

A single float and rod assembly is used with the 9036 float switch on a simplex unit or the 9038 duplex

alternator. Refer to the wiring diagram from the manufacturer for the correct wiring of the switch.

If a pit cover is supplied with the pump, the float switch support pipe (435) and the upper rod guide (337)

are installed by the factory. If the pit cover is supplied by others, you must locate, drill, and tap the holes

before you install the switch.

24 Model API 3171 Installation, Operation, and Maintenance Manual

Page 27

1

2

3

4

5

6

7

339

435

335

398

337

437

335

342

335

334

336

366

Installation

1. Diameter of the coverplate (A)

2. Radius (B)

3. CL of the pump

4. Radius of 7.0 in. (178.0 mm)

5. 1.25 in. (31.8 mm) NPT float switch NTG

column

6. 0.38 in. (9.5 mm) NPT for the float rod guide

7. 8 in. (203.0 mm) diameter of float (standard)

Figure 5: Location of the float, rod, and switch

Number Coverplate diameter (A) Radius (B)

1 22 in. (559 mm) 14.50 in. (368 mm)

2 26.50 in. (673 mm) 16.50 in. (419 mm)

3 31.00 in. (787 mm) 18.50 in. (470 mm)

1. Before you install the pump in the sump, attach the lower guide arm (366) and the float rod guide

(336) to the correct suction cover bolt (based on the layout).

2. Thread the float switch support pipe (435) and the upper rod guide (337) into the pit cover.

3. Attach the float switch bracket (398) to the float switch support pipe.

You can rotate the float switch around the center line of the pump on the radius (B).

4. Install the float rod (334), float (342), and collars (335).

You must maintain the radius (4) between the float switch column and the float.

Model API 3171 Installation, Operation, and Maintenance Manual 25

Page 28

Installation

Piping checklists

General piping checklist

Precautions

CAUTION:

• Never draw piping into place by using force at the flanged connections of the pump. This can impose

dangerous strains on the unit and cause misalignment between the pump and driver. Pipe strain

adversely affects the operation of the pump, which results in physical injury and damage to the

equipment.

• Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the

suction side. This action can result in decreased performance, unexpected heat generation, and

equipment damage.

Checklist

Check Explanation/comment Checked

Check that all piping is supported

independently of, and lined up

naturally with, the pump flange.

Keep the piping as short as

possible.

Check that only necessary fittings

are used.

Do not connect the piping to the

pump until:

• The grout for the baseplate or

sub-base becomes hard.

• The hold-down bolts for the

pump and the driver are

tightened.

Make sure that all the piping

joints and fittings are airtight.

If the pump handles corrosive

fluids, make sure that the piping

allows you to flush out the liquid

before you remove the pump.

If the pump handles liquids at

elevated temperatures, make sure

that the expansion loops and

joints are properly installed.

Make sure that all piping

components, valves and fittings,

and pump branches are clean

prior to assembly.

Make sure that the isolation and

check valves are installed in the

discharge line.

This helps to prevent:

• Strain on the pump

• Misalignment between the pump and the drive unit

• Wear on the pump bearings and the coupling

• Wear on the pump bearings, seal, and shafting

This helps to minimize friction losses.

This helps to minimize friction losses.

—

This prevents air from entering the piping system or

leaks that occur during operation.

—

This helps to prevent misalignment due to linear

expansion of the piping.

—

Locate the check valve between the isolation valve and

the pump. This will permit inspection of the check valve.

The isolation valve is required for regulation of flow, and

for inspection and maintenance of the pump. The check

valve prevents pump or seal damage due to reverse flow

through the pump when the driver is turned off.

26 Model API 3171 Installation, Operation, and Maintenance Manual

Page 29

Check Explanation/comment Checked

Use cushioning devices. This protects the pump from surges and water hammer

if quick-closing valves are installed in the system.

Alignment criteria for pump flanges

Type Criteria

Axial The flange gasket thickness is ±0.03 in. (0.8 mm).

Parallel Align the flange to be within 0.001 in./in. to 0.03 in./in. (0.025 mm/mm to 0.8 mm/mm) of

the flange diameter.

Concentric You can easily install the flange bolts by hand.

Suction piping for optional dry pit, outside tank mount, and tailpipe applications

Checklist

Check Explanation/comment Checked

Install an elbow at the pump. Whenever possible, perform these actions:

• Use long radius elbows.

• Move the elbow further from the suction.

• Eliminate unneeded elbows.

Installation

Make sure the suction piping is a larger

diameter than the pump suction.

Install separate suction lines when more

than one pump is operating from the same

source of supply.

Make sure that the suction piping contains

no air pockets.

Make sure that the suction piping slopes

upwards toward the pump.

Make sure that all joints are air tight. —

Provide a method to prime the pump. For outside tank mount and dry pit applications,

For outside tank mount and dry pit

applications, install an isolation valve in the

suction line at least two pipe diameters

from the suction.

Make sure that the entrance to the suction

pipe is kept adequately submerged below

the free liquid surface.

For an outside tank mount application,

make sure that a column assembly is

installed.

—

—

—

—

allow the fluid level inside the tank or pit to rise

above the casing level.

In tailpipe applications, submerge the casing

before you start the pump.

This allows the line to be closed for pump

inspection and maintenance. The isolation valve

must be kept fully open during operation.

This prevents vortices and air entrainment.

The column assembly allows the fluid that comes

through the lower bushings to flow up through the

column and back through the connection at the

top of the column back to the tank.

Connect the pipe at the top of the pump column

back to the source tank in order to prevent fluid

from entering the thrust bearing.

Model API 3171 Installation, Operation, and Maintenance Manual 27

Page 30

Installation

Steam lines

Checklist

Check Explanation/comment Checked

Before you install the pump,

become familiar with the location

of the steam lines.

Determine which method to use

in order to connect the steam

lines.

Before you install the pump,

check the fittings for leaks. Use

plant air or high pressure water.

Provide source of steam at 35 psi

and 300°F (149°C).

After the pump is brought to

temperature for the first time,

shut down the unit temporarily

and readjust the impeller

clearance.

There are three connections above the support plate:

• Two steam connections

• One condensate return connection.

The steam connections are connected to the tops of the

column and discharge jackets.

There are two methods you can use in order to connect

the steam lines:

• You can use both steam lines as input for steam

(preferred method).

• You can use one steam line as input for steam, while

the other steam line is used as a feed through to

additional pumps.

Only use this method if absolutely necessary, because

it is difficult to control the steam at subsequent

pumps.

The jackets are hydrotested by the factory at 100 psi

before shipment. However, the tube fittings can become

loose during transit.

If you use air to check for leaks, use a soap solution at

each joint in order to check for air bubbles.

Less than ideal conditions require higher pressure steam

in order to keep the correct temperature.

Refer to Impeller clearance setting in the Operations

chapter.

Final piping checklist

Check Explanation/comment Checked

Check that the shaft rotates smoothly. Rotate the shaft by hand. Make sure there is no

Re-check the alignment to make sure that

pipe strain has not caused any

misalignment.

rubbing that can lead to excess heat generation or

sparks.

If pipe strain exists, then correct the piping.

28 Model API 3171 Installation, Operation, and Maintenance Manual

Page 31

Commissioning, Startup, Operation, and Shutdown

Commissioning, Startup, Operation, and

Shutdown

Preparation for startup

WARNING:

• Failure to follow these precautions before you start the unit will lead to serious personal injury and

equipment failure.

• Do not operate the pump below the minimum rated flows or with the suction or discharge valves

closed. These conditions can create an explosive hazard due to vaporization of pumped fluid and can

quickly lead to pump failure and physical injury.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.

• Operating the pump in reverse rotation can result in the contact of metal parts, heat generation, and

breach of containment.

Precautions

NOTICE:

• Verify the driver settings before you start any pump.

• Make sure that the warm-up rate does not exceed 2.5°F (1.4°C) per minute.

You must follow these precautions before you start the pump:

• Flush and clean the system thoroughly to remove dirt or debris in the pipe system in order to prevent

premature failure at initial startup.

• Bring variable-speed drivers to the rated speed as quickly as possible.

• Run a new or rebuilt pump at a speed that provides enough flow to flush and cool the close-running

surfaces of the stuffing-box bushing.

• If temperatures of the pumped fluid will exceed 200°F (93°C), then warm up the pump prior to

operation. Circulate a small amount of fluid through the pump until the casing temperature is within

100°F (38°C) of the fluid temperature.

At initial startup, do not adjust the variable-speed drivers or check for speed governor or over-speed trip

settings while the variable-speed driver is coupled to the pump. If the settings have not been verified, then

uncouple the unit and refer to instructions supplied by the driver manufacturer.

Check the rotation

WARNING:

• Operating the pump in reverse rotation can result in the contact of metal parts, heat generation, and

breach of containment.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.

1. Lock out power to the driver.

2. Make sure that the coupling hubs are fastened securely to the shafts.

3. Make sure that the coupling spacer is removed.

The pump ships with the coupling spacer removed.

4. Unlock power to the driver.

Model API 3171 Installation, Operation, and Maintenance Manual 29

Page 32

Commissioning, Startup, Operation, and Shutdown

5. Make sure that everyone is clear, and then jog the driver long enough to determine that the direction

of rotation corresponds to the arrow on the bearing housing, or close-coupled frame.

6. Lock out power to the driver.

Thrust bearing lubrication

WARNING:

Make sure to properly lubricate the bearings. Failure to do so can result in excess heat generation, sparks,

and premature failure.

Grease lubrication

Grease-lubricated bearings have zerk fittings installed for each bearing. Bearings are pre-lubricated at the

factory. Unscrew the fittings and confirm there is grease in the line. Replace the fitting and add grease if

necessary.

Pure oil-mist lubrication

The inlet (IN), outlet (OUT), and drain (DRN) ports are stamped on the thrust housing. The DRN port is

located on the bottom of the thrust housing and is below the floorplate on pumps without a stuffing box.

Connect the oil mist system supply to the IN port of the thrust housing. The outlet for the thrust housing

can be connected to the OUT port or DRN port. The recommended oil for the oil mist is an ISO VG

100. See the table for recommended oil mist airflows. Follow the instructions from the oil mist system

supplier. The oil mist system must be interconnected with the pump so that the pump will shut down if

the mist system fails.

This data is based on an oil/air ratio of 0.4 cubic inch (0.22 ounce) per hour per cfm.

Table 3: Recommended oil mist airflows

Frame size Airflow in cfm (l/m)

S/ST 0.10 (2.83)

M/MT 0.16 (4.53)

L 0.22 (6.23)

Flush the steady bearings

There are five 1/4-in. NPT pipe plugs on the standard support plate that you use to connect the flush

lines. Each plug connects with each of the five bearings. Pumps with less than five bearings still have five

plugs, but only the required number are connected to bearings.

1. Remove the plugs from the holes that are connected to flush lines.

2. Connect an external source of clean water to the taps.

The water source must be able to deliver 1 to 2 GPM to each bearing.

3. Turn on the water in order to begin the flush.

Sealed bearings

Sealed bearings have a lip seal above and below the bearing in order to keep grit out of the bearing. Sealed

bearings use a spring-loaded grease cup for lubrication. The bearings are pre-lubricated at the factory, but

the grease cups ship in a separate box in order to prevent shipping damage. Fill the grease cups with grease

and screw the cups into the taps that are connected to the bearings. Refill the cups with fresh grease as

needed. Frequently inspect the grease cups after startup in order to check usage and establish the best

relubrication interval.

30 Model API 3171 Installation, Operation, and Maintenance Manual

Page 33

123

333H

333H

369

197

213

369

123 Deflector

1

2

3

4

197 Steady bearings

213 Housing, steady bearings

333H Lip seal

369 Retaining ring, steady bearing

Commissioning, Startup, Operation, and Shutdown

Lubricate the sealed bearings with grease cups

For models with grease-lubricated bearings, the spring-operated automatic grease cups are designed to

maintain constant lubrication of the intermediate pump bearings that are fixed to the vertical pump

housing. The center stem protrudes out of the housing when the cup is full and gradually moves down

into the housing as the grease is used. After the wing nut is threaded against the stem zerk fitting and the

bottom of the wing nut rests on the cap of the grease cup, then the grease reservoir is empty and you must

refill it.

1. Zerk fitting

2. Wing nut

3. Grease reservoir

4. Throttling screw

Model API 3171 Installation, Operation, and Maintenance Manual 31

Page 34

Commissioning, Startup, Operation, and Shutdown

Fill the housing