Page 1

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and start-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 2

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Any pressure vessel can explode,

rupture, or discharge its contents if sufficiently over pressurized causing death, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 3

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example: Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 4

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

General Precautions

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to

trapped liquid.

NEVER use heat to disassemble pump due to risk of explosion from tapped liquid.

NEVER operate pump without coupling guard correctly installed.

NEVER operate pump without safety devices installed.

NEVER run pump below recommended minimum flow when dry, or without

prime.

ALWAYS lock out power to the driver before performing pump maintenance.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT

Goulds Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with sharp edges, especially

impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift

and support equipment can result in serious physical injury and/or equipment

WARNING

WARNING

damage. Lift equipment only at specifically identified lifting points or as

instructed in the current IOM. Current manuals are available at

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

Pumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)

must be rated, selected, and used for the entire load being lifted.

Alignment:

Shaft alignment procedures must be followed to prevent catastrophic failure of

drive components or unintended contact of rotating parts. Follow coupling

manufacturer’s coupling installation and operation procedures.

S-4

Page 5

WARNING

CAUTION

General Precautions

Before beginning any alignment procedure, make sure driver power is locked out.

Failure to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flanged connections of the pump.

This may impose dangerous strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the operation of the pump

resulting in physical injury and damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the

motor is properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat

generation, and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting

the clearance or not following any of the proper procedures can result in sparks,

unexpected heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set

screws loosened prior to setting impeller clearance. Failure to do so could result

in sparks, heat generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified

and must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury

will occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess

heat generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly

certified. Prior to start up, ensure all points of potential leakage of process fluid to

the work environment are closed.

Never operate the pump without liquid supplied to mechanical seal. Running a

mechanical seal dry, even for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the

coupling spacer is removed.

WARNING

WARNING

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or

discharge valve closed. These conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to pump failure and physical injury.

S-5

Page 6

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

General Precautions

Ensure pump is isolated from system and pressure is relieved before

disassembling pump, removing plugs, opening vent or drain valves, or

disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to

avoid physical injury and/or equipment damage. Steel toed shoes must be worn at

all times.

The pump may handle hazardous and/or toxic fluids. Observe proper

decontamination procedures. Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical injury. Pumpage must be

handled and disposed of in conformance with applicable environmental

regulations.

Operator must be aware of pumpage and safety precautions to prevent physical

injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent

physical injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,

or 3107, there may be a risk of static electric discharge from plastic parts that are

not properly grounded. If pumped fluid is non-conductive, pump should be

drained and flushed with a conductive fluid under conditions that will not allow

for a spark to be released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion

due to trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause

physical injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can

cause physical injury.

S-6

Page 7

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds representative before proceeding.

Current IOMs are available at

Pumps Sales representative.

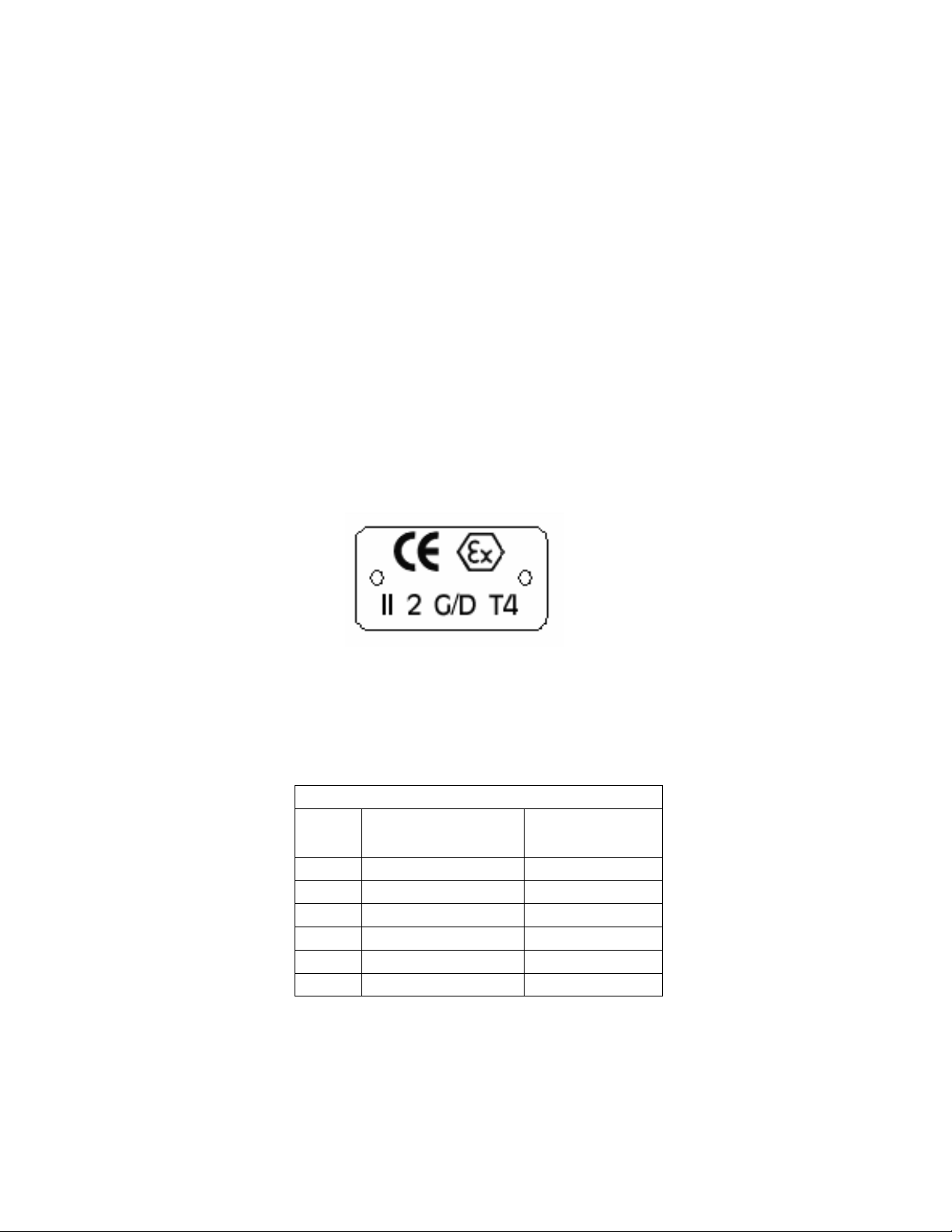

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

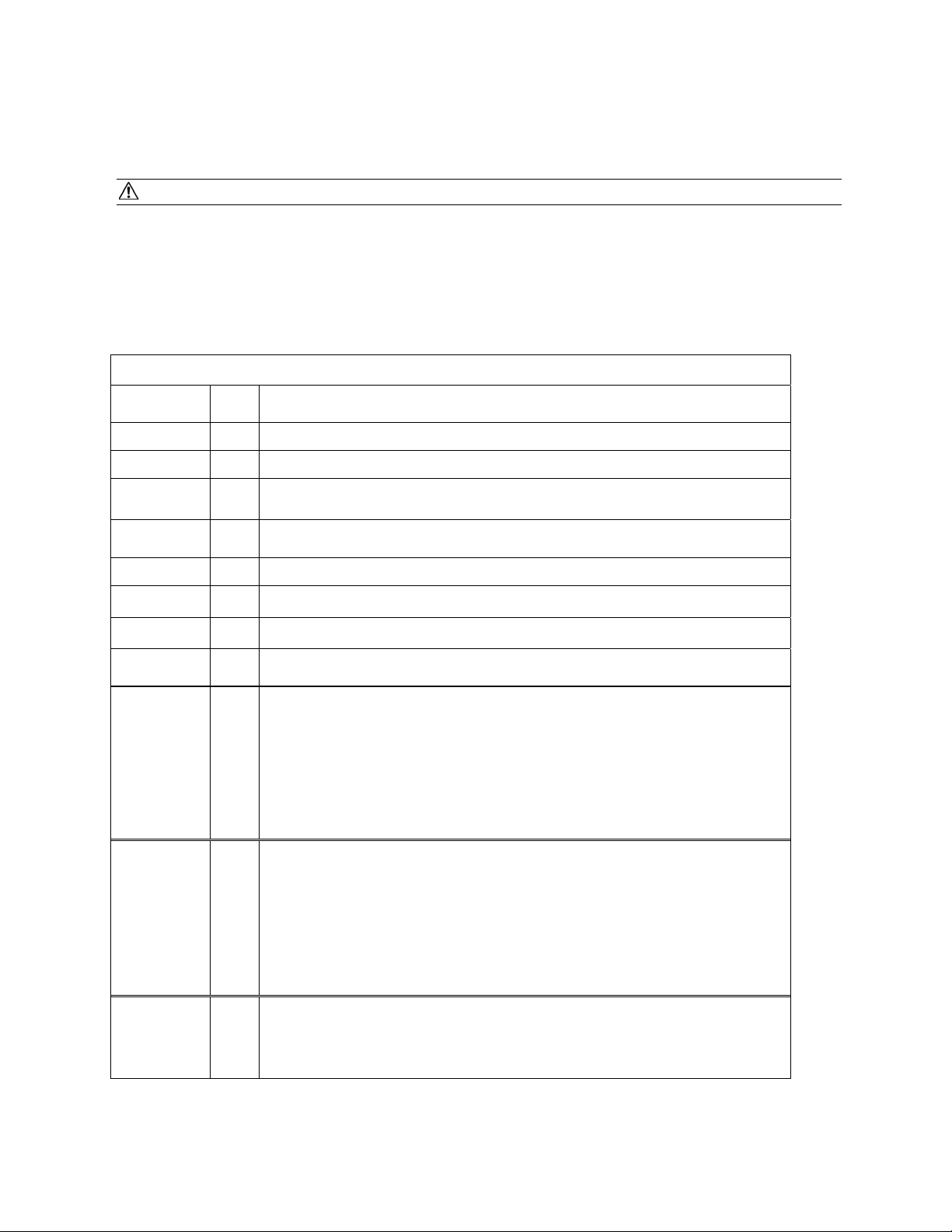

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 8

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 9

SPARE PARTS

RECOMMENDED SPARE PARTS . . . . . . . . . . . . . . . . . . . . 111

INTERCHANGEABILITY . . . . . . . . . . . . . . . . . . . . . . . . . 112

APPENDIX I Frame Lubrication Conversion . . . . . . . . . 119

APPENDIX II Installation Instructions for . . . . . . . . . . 123

ITT Goulds ANSI B15.1 Coupling Guards

APPENDIX III Alignment . . . . . . . . . . . . . . . . . . . . 127

APPENDIX IV Labyrinth Seal Installation Instructions . . . . 131

APPENDIX V C-Face Adapter Installation Instructions. . . . 133

APPENDIX VI 3198 Teflon® Sleeve Field Replacement . . . . 135

Procedure

APPENDIX VII-1 Double Row Angular Bearing . . . . . . . . . 137

Installation Instructions

APPENDIX VII-2 Duplex Angular Contact Bearing . . . . . . . . 139

Installation Instructions

APPENDIX VIII INPRO Labyrinth Oil Seal . . . . . . . . . . . . 141

Installation Instructions

When ordering spare parts, always state ITT Goulds Serial No. and indicate part name and

item number from relevant sectional drawing. It is imperative for service reliability to have a

sufficient stock of readily available spares.

RECOMMENDED SPARE PARTS

Impeller (101)

•

Shaft (122A)

•

Shaft Sleeve (126)

•

Outboard Bearing (112A)

•

Inboard Bearing (168A)

•

Casing Gasket (351)

•

Frame-to-Adapter Gasket (360D)

•

Bearing Housing Retaining Ring (361A)

•

Bearing Lockwasher (382)

•

Bearing Locknut (136)

•

Impeller O-Ring (412A)

•

Bearing Housing O-Ring (496)

•

Outboard Labyrinth Seal Rotary O-Ring (497F)

•

Outboard Labyrinth Seal Stationary O-Ring (497G)

•

Inboard Labyrinth Seal Rotary O-Ring (497H)

•

Inboard Labyrinth Seal Stationary O-Ring (497J)

•

Lantern Ring Half (105) (Packed Stuffing Box)

•

Stuffing Box Packing (106) (Packed Stuffing Box)

•

Packing Gland (107) (Packed Stuffing Box)

•

Impeller Gasket (428D) XLT-X & X17

•

7

ANSIFAM IOM - 5/08

111

Page 10

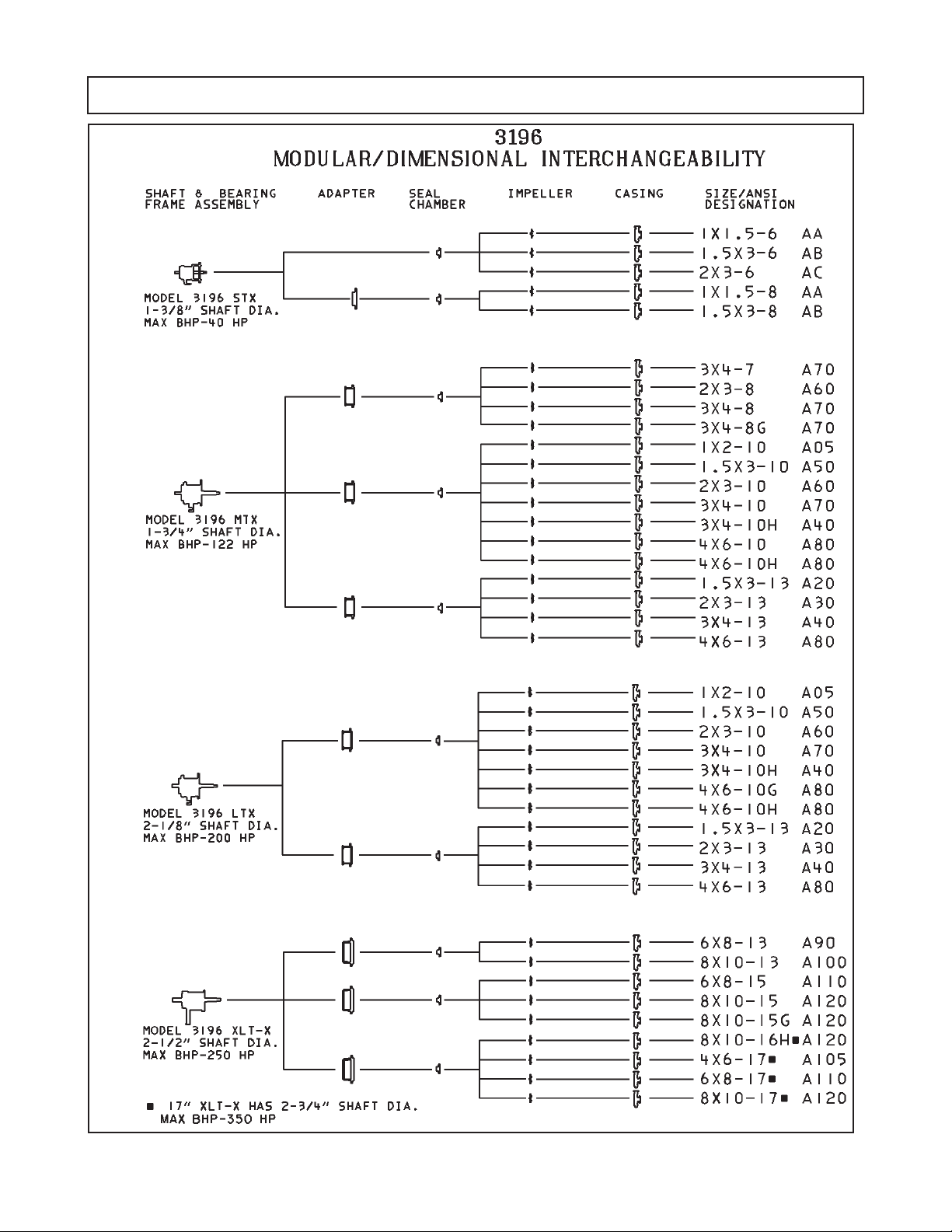

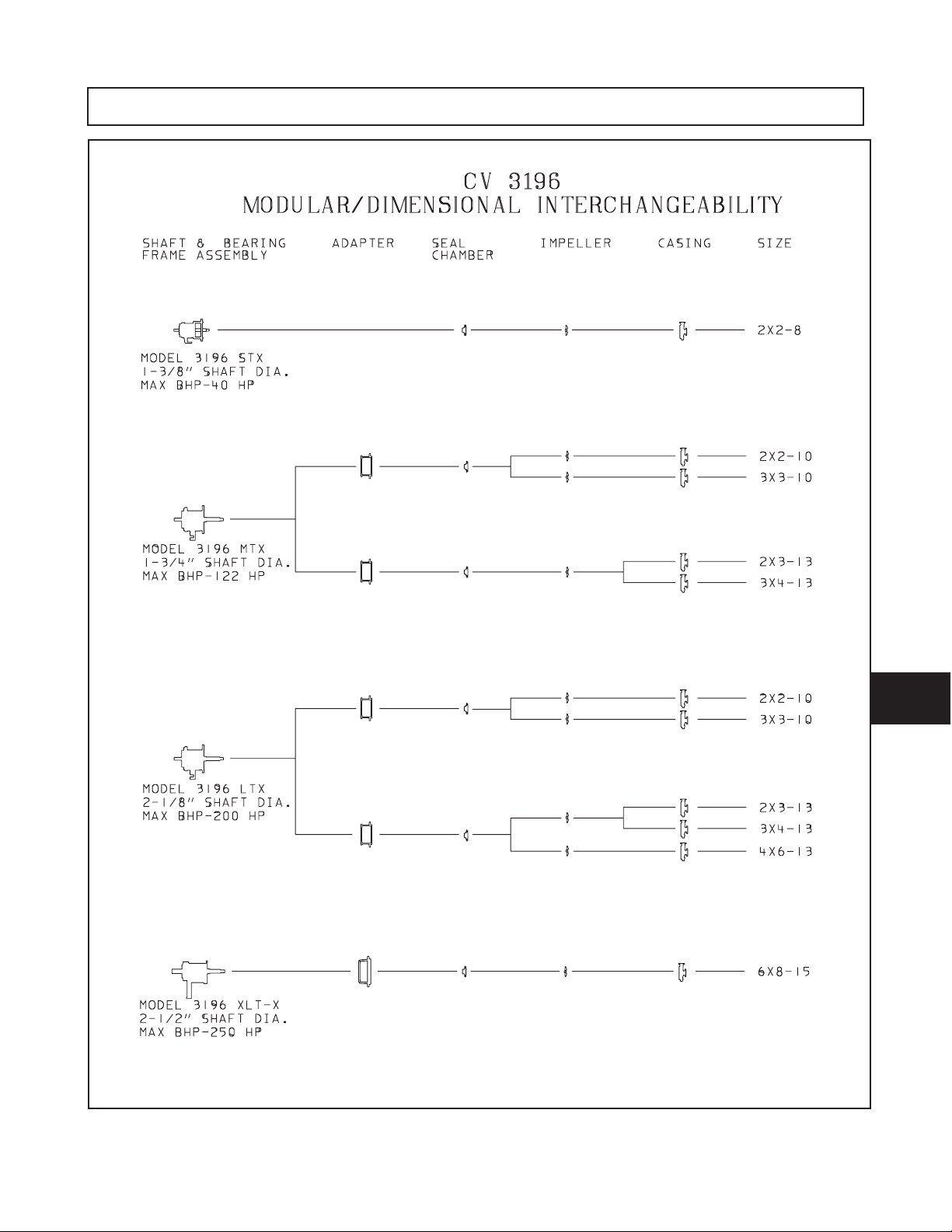

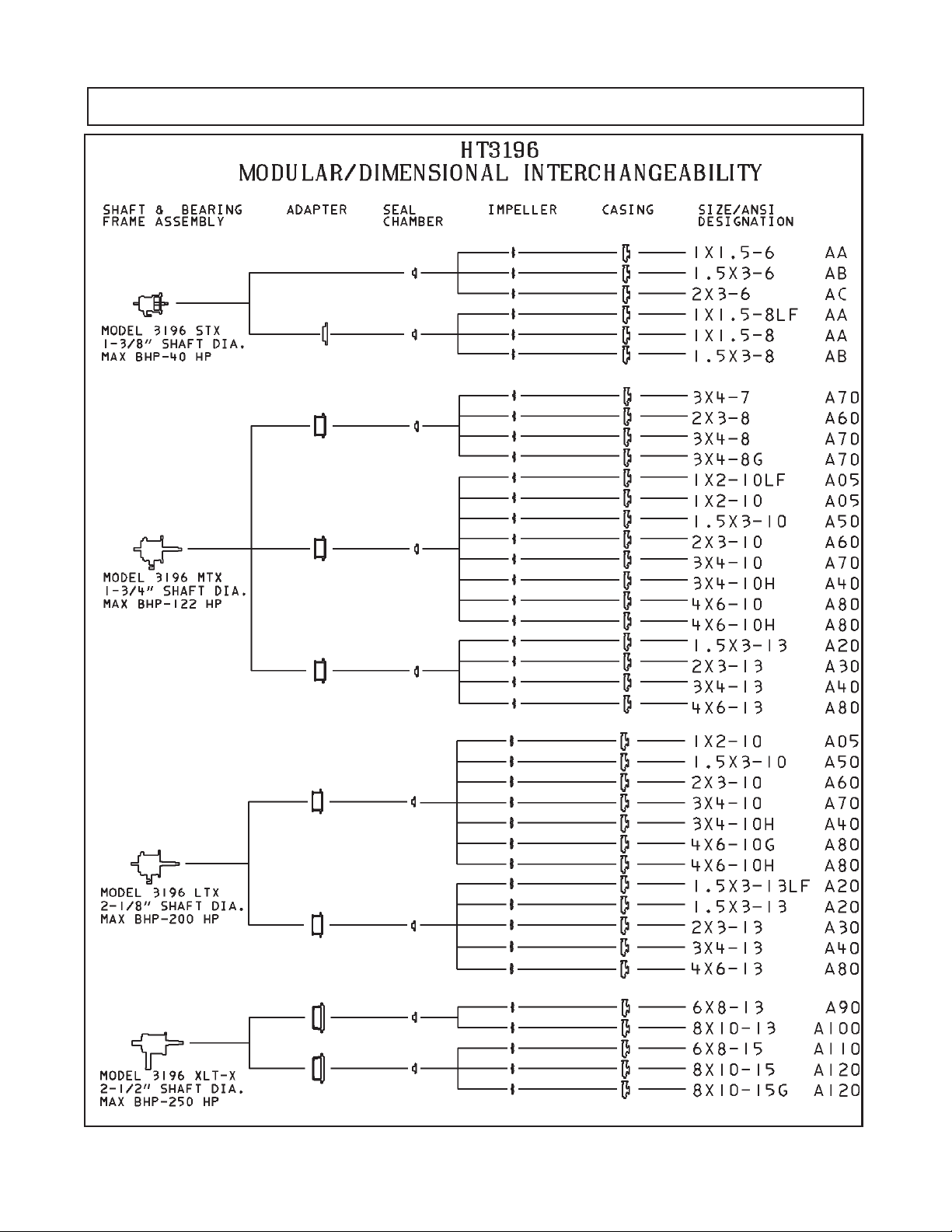

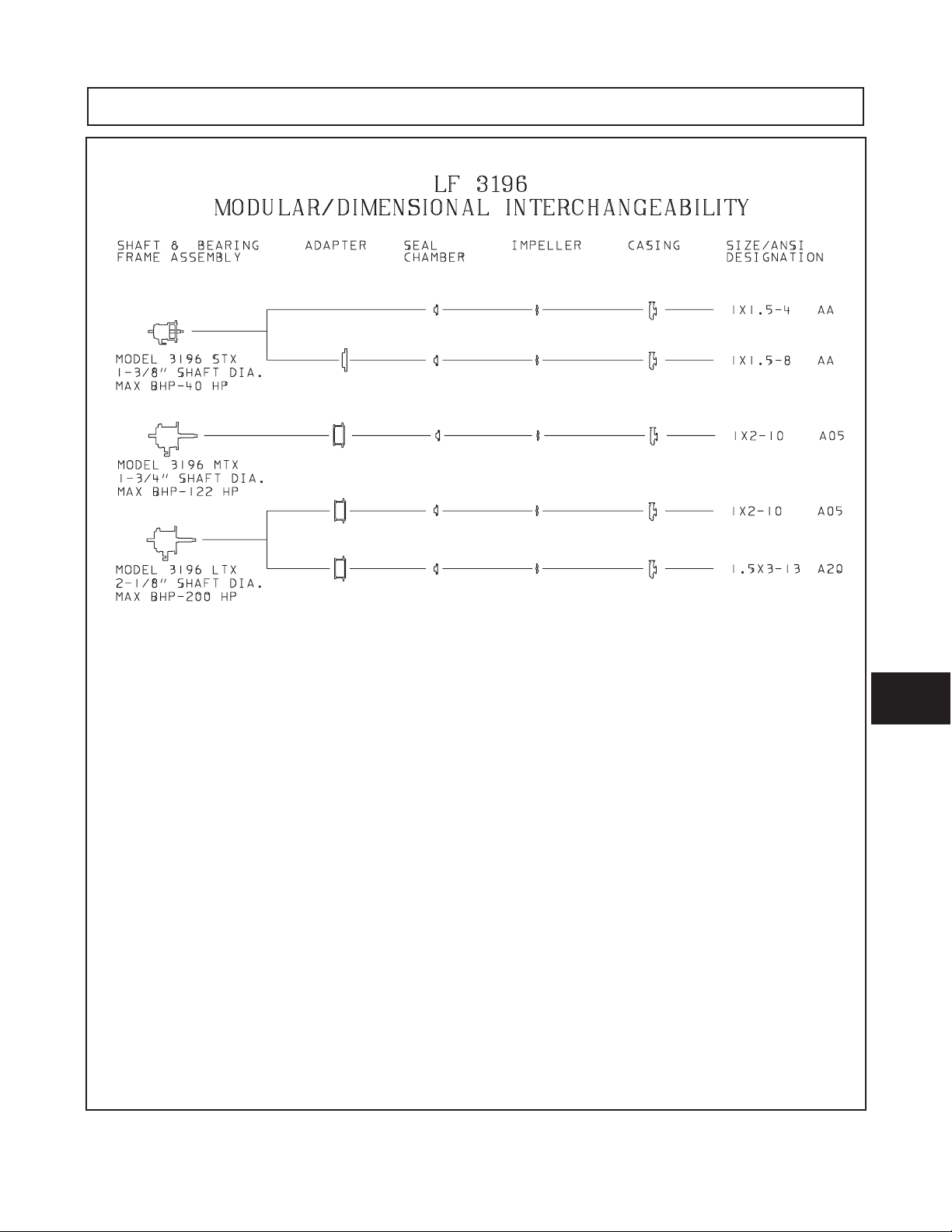

INTERCHANGEABILITY

112 ANSIFAM IOM - 5/08

Page 11

INTERCHANGEABILITY

7

ANSIFAM IOM - 5/08 113

Page 12

INTERCHANGEABILITY

114 ANSIFAM IOM - 5/08

Page 13

INTERCHANGEABILITY

7

ANSIFAM IOM - 5/08 115

Page 14

INTERCHANGEABILITY

116 ANSIFAM IOM - 5/08

Page 15

INTERCHANGEABILITY

7

ANSIFAM IOM - 5/08 117

Page 16

INTERCHANGEABILITY

118 ANSIFAM IOM - 5/08

Page 17

APPENDIX I

Frame Lubrication Conversion

Lubrication Conversion

Pumpage Temperature

below 350°F (177°C)

NLGI Consistency 2 3

Mobil Mobilux EP2 SCH32

Exxon Unirex N2 Unirex N3

Sunoco Multipurpose 2EP

SKF LGMT 2 LGMT 3

Pumpage Temperature

above 350°F (177°C)

Pumpage temperatures above 350°F (177°C) should

be lubricated by a high temperature grease. Mineral

oil greases should have oxidation stabilizers and a

consistency of NLGI 3.

NOTE: If it is necessary to change grease type

or consistency, the bearings must be removed

and the old grease removed.

!

l

Never mix greases of different consistency (NLGI

1 or 3 with NLGI 2) or different thickener soaps

(sodium or calcium with lithium). The consistency

usually becomes softer and will not provide

adequate lubrication to the bearings.

CAUTION

FRAME LUBRICATION CONVERSION

Conversion from Flood Oil to Pure Oil Mist

There are several ways to apply oil mist. ITT Goulds

has designed X-Series Power Ends to accept a

variety of oil mist configurations. The following

instructions are written for two popular systems in

use.

NOTE: Make sure that pipe threads are clean

and apply thread sealant to plugs & fittings.

NOTE: The LTX requires that the bearing

housing be changed when making the

conversion from flood oil to oil mist lubrication.

After the proper bearing housing has been

installed follow the instructions as they apply

to STX, MTX, XLT-X, X17.

A. Non-Vented Oil Mist System

1. Attach oil mist inlet to

outboard end of frame (plugged with 408H allen

head plug), and top, center of frame (plugged with

113A hex head plug).

2. Attach drain at bottom center of frame

hole (plugged with 408A magnetic drain plug).

1

" NPT connection at top,

4

3

" NPT

8

operation.

B. Vented Oil Mist System

1. Attach oil mist inlet connection to

connections at outboard and inboard ends of

frame.

2. Attach vent connection at

top center of frame.

3. Attach drain connection at

bottom center of frame (plugged with 408A

magnetic drain plug).

4. Follow oil mist generator manufacturer’s

instructions for oil mist volume adjustment and

operation.

l

!

Oil mist falls under Title III of the Clean Air Act

and must be controlled or the user will be

subject to penalty.

CAUTION

1

1

" NPT

4

" NPT hole located in

2

3

" NPT hole located at

8

8

3. Follow oil mist generator manufacturer’s

instructions for oil mist volume adjustment, and

ANSIFAM IOM - 5/08

119

Page 18

Conversion from Flood Oil to Regreaseable

NOTE: Make sure that pipe threads are clean

and apply thread sealant to plugs and fittings.

NOTE: LTX regreaseable power end requires a

changeout of the bearing housing and bearing

clamp ring. This housing provides a grease

path to the bearings.

1. Plug inboard oil return in bearing frame.

STX: Use epoxy, keep drilled hole clear.

MTX, LTX, XLT-X, X17: Use set screw, install

from adapter side, bottom in hole.

2. Plug outboard oil return slot in bearing housing,

keep through holes clear. (does not apply to LTX)

3. Replace both bearings with single shield type.

Refer to Assembly Section for installation

guidelines.(Ref. Bearing Chart Table 11)

4. Install grease fittings at top, inboard and top,

outboard

(plugged with 408H allen head plug).

5. Remove 2 (408H) Allen head plugs from bottom

side of frame prior to greasing bearings. Reinstall

hex head plugs (113) after bearings have been

greased.

1

" NPT connections in bearing frame

4

X-Series Conversion from Greased for Life

or Regreaseable to Oil Lubricated Bearings

NOTE: LTX bearing housing and clamp ring are

not interchangeable between oil and grease

lubrication.

1. Remove plug from oil return slot in the frame,

under the radial bearing.

STX: Remove epoxy from return slot.

MTX, LTX, XLT-X, X-17: Remove set screw

installed in the oil return hole.

2. Remove plug from oil return hole in the bearing

housing (134). For LTX only, housing (134) and

clamp ring (253B) require replacement. Contact

ITT Goulds for price and availability.

3. Replace both bearings with unshielded, oil lube

bearings. Refer to Assembly Section for

installation guidelines. (Ref. Bearing Chart,

Table 11).

4. Grease fittings should be removed to prevent

accidental greasing. Quantity of two (2) plugs

(408H) are required to replace the two (2) grease

fittings (193).

120 ANSIFAM IOM - 5/08

Page 19

Item No. Size Description Qty.

113 1/4"-18 NPT Ext. Hex/square Head Pipe Plug 2

113A 1/2"-14 NPT Ext. Hex/square Head Pipe Plug 1

193 1/4"-18 NPT Grease Fitting 2

228 ---- Bearing Frame 1

241 ---- Frame Foot 1

370F 1/2" Hex Cap Screw 2

408A 3/8"-18 NPT Ext. Square Head Pipe Plug (magnetic) 1

408J 1/4"-18 NPT Ext. Hex/square Head Pipe Plug 1

408L 1/2"-14 NPT Square Countersunk Headless Pipe Plug 1

408M 1" 11-1/2" NPT Square Countersunk Headless Pipe Plug 1

319 1" 11-1/2" NPT Sight Window 1

529 1/2" Light Helical Spring Lock Washer 2

MTX

Grease Lube

ANSIFAM IOM - 5/08 121

8

Page 20

122 ANSIFAM IOM - 5/08

Page 21

APPENDIX II

Installation Instructions for ITT Goulds

ANSI B15.1 Coupling Guards

The coupling guard used in an Atex

classified environment must be

constructed from a non-sparking material.

! WARNING

s

Before assembly or disassembly of the coupling

guard is performed the motor must be

de-energized, the motor controller/starter put in a

locked-out position and a caution tag placed at the

starter indicating the disconnect. Replace

coupling guard before resuming normal operation

of the pump. ITT Goulds Pumps assumes no

liability for avoiding this practice.

XLT-X Align the end plate (pump end) to the

pump bearing housing so that the large slots on

the end plate clear the bearing housing tap bolts

and the small slots are aligned to the impeller

adjusting bolts. Attach the end plate to the

bearing housing using the jam nuts on the

impeller adjusting bolts as shown in Fig. II-3.

After the end plate is attached to the bearing

housing, the impeller clearance must be checked

and reset as explained in Section V - Preventive

Maintenance.

NOTE: Coupling adjustments should be

completed before proceeding with coupling

guard assembly.

STX, MTX, LTX

Fig. II-1

Simplicity of design allows complete assembly of the

coupling guard, including the end plate (pump end), in

about fifteen minutes. If the end plate is already in place,

assembly can be accomplished in about five minutes.

Assembly:

NOTE: If end plate (pump end) is already

installed, make any necessary coupling

adjustments and then proceed to Step 2.

1. STX, MTX, LTX - Align end plate (pump end) to the

Bearing Frame. (No impeller adjustment required.)

ANSIFAM IOM - 5/08

XLT-X

Fig. II-2

Fig. II-3

123

8

Page 22

2. Spread bottom of coupling guard half (pump end)

slightly and place over pump end plate as shown

in Fig. II-4. The annular groove in the guard half

is located around the end plate (Fig. II-5).

501B

DRIVER

ANNULAR

GROOVE

234A

ANNULAR GROOVE

234A

501B

Fig. II-4

Fig. II-6

NUT

WASHER

4. Spread bottom of coupling guard half (driver end)

slightly and place over coupling guard half (pump

end) so that annular groove in coupling guard half

(driver end) faces the motor as shown in Fig. II-8.

BOLT

Fig. II-7

Fig. II-5

3. After the coupling guard half (pump end) is

located around the end plate, secure it with a bolt,

nut and two (2) washers through the round hole at

the front end of the guard half as shown in Fig.

II-6. Tighten securely (Fig. II-7).

ANNULAR

501B

GROOVE

DRIVER

Fig. II-8

124 ANSIFAM IOM - 5/08

Page 23

5. Place end plate (driver end) over motor shaft as

shown in Fig. II-9. Locate the end plate in the

annular groove at the rear of the coupling guard

half (driver end) and secure with a bolt, nut, and

two (2) washers through the round hole at the rear

of the guard half. Finger tighten only.

DRIVER

SLIDE TO FIT

DRIVER

6. Adjust length of coupling guard to completely

cover shafts and coupling as shown in Fig. II-10

by sliding coupling guard half (driver end) towards

motor. After adjusting guard length, secure with

bolt, nut and two (2) washers through the slotted

holes at the center of the guard and tighten.

Check all nuts on the guard assembly for

tightness.

! WARNING

s

Before assembly or disassembly of the

coupling guard is performed, the motor must

be de- energized, the motor controller/starter

put in a locked-out position and a caution tag

placed at the starter indicating the disconnect.

Replace coupling guard before resuming

normal operation if the pump. ITT Goulds

Pumps assumes no liability for avoiding this

practice.

234B

Fig. II-9

Fig. II-10

Disassembly

The coupling guard must be removed for certain

maintenance and adjustments to the pump, such as

adjustment of the coupling, impeller clearance

adjustment, etc. The coupling guard should be

replaced after maintenance is completed.

DO NOT resume normal pump operation with the

coupling guard removed.

NOTE: Refer to illustrations for assembly in

reverse order.

1. Remove nut, bolt, and washers from center

slotted hole in the coupling guard. Slide motor

end coupling guard half towards pump. Fig. II-10.

2. Remove nut, bolt, and washers from coupling

guard half (driver end), and remove end plate.

Fig. II-9.

3. Spread bottom of coupling guard half slightly and

lift off. Fig. II-8.

4. Remove remaining nut, bolt, and washers from

coupling guard half (pump end). Spread bottom

of coupling guard half slightly and lift off. Fig. II-4.

This completes disassembly of the coupling guard.

8

ANSIFAM IOM - 5/08

NOTE: It is not necessary to remove the end

plate (pump end) from the pump bearing

housing. The bearing housing tap bolts are

accessible without removing the end plate in

case maintenance of internal pump parts is

necessary. Before removing the pump bearing

housing, refer to Section 6 - Disassembly &

Reassembly.

125

Page 24

126 ANSIFAM IOM - 5/08

Page 25

APPENDIX III

Alignment

Alignment procedures must be followed to

prevent unintended contact of rotating

parts. Follow coupling manufacturer’s

coupling installation and operation

procedures.

SET UP

1. Mount two dial indicators on one of the coupling

halves (X) so they contact the other coupling half

(Y) (Fig. III-1).

2. Check setting of indicators by rotating coupling

half X to ensure indicators stay in contact with

coupling half Y but do not bottom out. Adjust

indicators accordingly.

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A

(Angular indicator) does not vary by more that .002 in.

(.05 mm) as measured at four points 90° apart.

Vertical Correction (Top-to-Bottom)

1. Zero indicator A at top dead center (12 o’clock) of

coupling half Y.

2. Rotate indicators to bottom dead center

(6 o’clock). Observe needle and record reading.

3. Negative Reading - The coupling halves are

further apart at the bottom than at the top. Correct

by either raising the driver feet at the shaft end

(add shims) or lowering the driver feet at the other

end (remove shims), (Fig. III-2).

Positive Reading - The coupling halves are

closer at the bottom than at the top. Correct by

either lowering the driver feet at the shaft end

(remove shims) or raising the driver feet at the

other end (add shims).

Fig. III-1

MEASUREMENT

1. To ensure accuracy of indicator readings, always

rotate both coupling halves together so indicators

contact the same point on coupling half Y. This

will eliminate any measurement problems due to

runout on coupling half Y.

2. Take indicator measurements with driver feet

hold-down bolts tightened. Loosen hold down

bolts prior to making alignment corrections.

3. Take care not to damage indicators when moving

driver during alignment corrections.

ANSIFAM IOM - 5/08

8

Fig. III-2

4. Repeat steps 1-3 until indicator A reads .002 in

(.05 mm) or less.

Horizontal Correction (Side-to-Side)

1. Zero indicator A on left side of coupling half Y, 90°

from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the

right side, 180° from the start (3 o’clock). Observe

needle and record reading.

3. Negative Reading - The coupling halves are

further apart on the right side than the left. Correct

by either sliding the shaft end of the driver to the

left or the other end to the right.

127

Page 26

3. Positive Reading - The coupling halves are

closer together on the right side than the left.

Correct by either sliding the shaft end of the driver

to the right or the other end to the left (Fig. III-3).

Fig. III-3

4. Repeat steps 1 through 3 until indicator A reads

.002 in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the

other. Correct as necessary.

PARALLEL ALIGNMENT

A unit is in parallel alignment when indicator P

(parallel indicator) does not vary by more than .002 in.

(.05 mm) as measured at four points 90° apart at

operating temperature. Note the preliminary vertical

cold setting criteria, Table 1.

Vertical Correction (Top-to-Bottom)

1. Zero indicator P at top dead center of coupling

(12 o’clock) half Y (Fig. III-1).

2. Rotate indicator to bottom dead center (6 o’clock).

Observe needle and record reading.

Fig. III-4

NOTE: Equal amounts of shims must be added

to or removed from each driver foot. Otherwise

the vertical angular alignment will be affected.

4. Repeat steps 1 through 3 until indicator P reads

within .002 in. (.05 mm) or less when hot, or per

Table 1 when cold.

Horizontal Correction (Side-to-Side)

1. Zero indicator P on the left side of coupling half Y,

90° from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the

right side, 180° from the start (3 o’clock). Observe

needle and record reading.

3. Negative Reading - Coupling half Y is to the left

of coupling half X. Correct by sliding driver evenly

in the appropriate direction (Fig. III-5).

Positive Reading - Coupling half Y is to the right

of coupling half X. Correct by sliding driver evenly

in the appropriate direction.

3. Negative Reading - Coupling half X is lower than

coupling half Y. Correct by removing shims of

thickness equal to half of the indicator reading

under each driver foot.

Positive Reading - Coupling half X is higher than

coupling half Y. Correct by adding shims of

thickness equal to half of the indicator reading

from each driver foot (Fig. III-4).

Fig. III-5

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

4. Repeat steps 1 through 3 until indicator P reads

.002 in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the

other. Correct as necessary.

128 ANSIFAM IOM - 5/08

Page 27

COMPLETE ALIGNMENT

A unit is in complete alignment when both indicators A

(angular) and P (parallel) do not vary by more than .002

in. (.05 mm) as measured at four points 90° apart.

Horizontal Correction (Side-to-Side)

1. Zero indicators A and P on the left side of

coupling half Y, 90° from top dead center (9

o’clock).

Vertical Correction (Top-to-Bottom)

1. Zero indicators A and P at top dead center

(12 o’clock) of coupling half Y.

2. Rotate indicator to bottom dead center (6 o’clock).

Observe the needles and record the readings.

3. Make corrections as outlined previously.

2. Rotate indicators through top dead center to the

right side, 180° from the start (3 o’clock). Observe

the needle, measure and record the reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal readings to

ensure adjustment of one did not disturb the

other. Correct as necessary.

NOTE: With experience, the installer will understand the interaction between angular and

parallel and will make corrections appropriately.

ANSIFAM IOM - 5/08

8

129

Page 28

130 ANSIFAM IOM - 5/08

Page 29

APPENDIX IV

Old JM Clipper CFT Design Labyrinth Seal Installation Instructions

Description of Operation

The labyrinth oil seal serves two functions. The first

being to exclude environmental contamination from

the power-end. This is accomplished with a series of

tight clearance fits between the stationary and rotor.

Any water that manages to enter the seal is

eliminated from the seal through a drain slot located

at the six o’clock position when installed.

On the oil side, a series of oil grooves are present to direct

any oil between the shaft and stationary back into the oil

sump through a drain slot at the six o’clock position.

®

O-rings are supplied as standard due to their

Viton

chemical resistance. The stationary uses an O-ring to fit

the labyrinth seal to the housing. The stator uses an

O-ring to fit the labyrinth to the housing. The rotor uses an

O-ring to seal along the shaft and to serve as the drive.

Installation Procedures

l

!

The ITT Goulds labyrinth oil seal is a one piece

assembly. Do not attempt to separate the rotor

and stator. Damage to the seal may result.

1. Assemble the power end per the instructions in

Section 6 - Disassembly & Reassembly.

l

!

The edges of the keyway can be sharp. Failure

to cover the keyway may result in a cut O-ring

and a damaged seal.

2. Wrap tape around the coupling end of the shaft to

cover the keyway.

CAUTION

CAUTION

3. Press the seal over the shaft into the thrust

bearing housing or thrust bearing end cover by

hand until the shoulder of the seal is seated

against the housing/cover.

NOTE: An O-ring lubricant is not required, but

can be used if desired. If used, be sure the

lubricant is compatible with the O-ring material

and plant standards.

4. For STX units: Press the seal over the shaft into

the bearing frame by hand until the shoulder of

the seal is seated against the frame.

For all other units: Once the frame adapter is

installed on the bearing frame, press the seal over

the shaft into the frame adapter by hand until the

shoulder of the seal is seated against the adapter.

NOTE: An O-ring lubricant is not required, but

can be used if desired. If used, be sure the

lubricant is compatible with the O-ring material

and plant standards.

NOTE: During start-up when the parts of the

labyrinth oil seal establish a voluntary running

clearance, a small amount of wear is experienced

as the parts are in contact. This wear produces a

carbon filled Teflon

diameter of the seal and at the drain slot. This is

the result of the two surfaces being smoothed,

similar to burnishing. A lubricant should not be

applied between the faces at installation. Once the

running clearance has been established, no further

wear is experienced and no decrease in seal

performance occurs as a result of the carbon/

®

Teflon

residue.

®

residue, visible at the outside

8

NOTE: The smooth surface of electrical tape

provides an excellent surface to slide the rotor

O-ring over.

ANSIFAM IOM - 5/08

131

Page 30

Labyrinth Oil Seal Conversion (After Oct. '03)

As of October 2003 ITT Goulds has standardized on

INPRO VBXX-D Brass Labyrinth Oil Seals over the

old JM Clipper CFT design. As a result of this

change, new part numbers have been assigned to the

old JM Clipper CFT design as follows:

Table IV-1

Labyrinth Oil Seal Conversion

Part Numbers

Old Part # New Part #

STX Frame (Outboard) D08717A01 D08717A44

STX Frame (Inboard) D08717A02 D08717A45

MTX (Outboard) D08717A03 D08717A46

MTX (Itboard) D08717A04 D08717A47

LTX (Outboard) D08717A05 D08717A48

LTX (Inboard) D08717A06 D08717A49

XLTX (Outboard) D08717A07 D08717A50

XLTX (Inboard) D08717A08 D08717A51

* 3198 MTX (Inboard) D08717A31 D08717A52

132 ANSIFAM IOM - 5/08

Page 31

APPENDIX V

C-Face Adapter Installation Instructions

Disassembly

1. Remove the motor by loosening the motor

mounting bolts (371). Refer to Table V-1 for the

number of bolts.

Table V-1

Number of Motor Bolts

Pump Frame Motor frame No. of Bolts

STX All 4

MTX

143-286 4

324-365 8

Fig. V-1

!

l

The motor may be heavy and should be

properly supported with a clean, uncorroded

eye bolt or a strap under both end bells.

NOTE: Use of a C-Face adapter will result in

one of the following configurations — a foot

mounted adapter with an overhung motor or an

unsupported adapter and a foot mounted motor.

2. Remove the C-Face adapter (340) from the pump

bearing frame (228A) by loosening the four bolts

(371N) attached to the bearing frame flange.

NOTE: Both coupling hubs do not need to be

removed.

CAUTION

Inspections

1. Visually inspect the C-face adapter (340) for

cracks. Check surfaces for rust, scale, or debris.

Remove all loose or foreign material (Fig. V-1).

2. Check for corrosion or pitting.

Reassembly

1. Mount both the pump and motor coupling hubs if

not already mounted.

2. Slide the C-Face adapter (340) over the pump

shaft (122) and mount against the pump bearing

frame (228A) flange using four bolts (371N).

Torque bolts to the values shown in Table V-2.

3. Mount the motor to the C-Face adapter (340)

using the four or eight motor bolts (371). Torque

bolts to the values shown in Table V-2.

Table V-2

Bolt Torque

Location Frame

C-face

adapter-to-

frame

C-face

adapter-to-

motor

STX

MTX

LTX

143TC-145TC

182TC-286TC

324TC-365TC

Lubricated

Threads

20 ft-lbs (27 N-m) 30 ft-lbs (40 Nm)

20 ft-lbs (27 N-m) 30 ft-lbs (40 Nm)

20 ft-lbs (27 N-m) 30 ft-lbs (40 Nm)

8 ft-lbs (11 N-m) 12 ft-lbs (16 Nm)

20 ft-lbs (27 N-m) 30 ft-lbs (40 Nm)

39 ft-lbs (53 N-m) 59 ft-lbs (80 Nm)

Dry

Threads

8

8

ANSIFAM IOM - 5/08 133

Page 32

Alignment

A shaft alignment is not required when using the C-Face

adapter. The rabbetted fits of the motor to the adapter

and the adapter to the bearing frame automatically

aligns the shaft to within the specified limits below.

The C-face motor adapter is intended for end users

who need fast pump installation. A C-face adapter

can attain a nominal alignment of 0.007 inches TIR.

However, due to the stack up of machining tolerances

of the various parts, the alignment can be as high as

0.015 inches TIR. Using a flexible, elastomer

coupling like a Rexnord ES or Wood's Sureflex will

provide acceptable pump and motor life under these

alignment conditions.

To achieve the best Mean Time Between Pump

Maintenance (MTBPM) requires shaft alignments of

less than 0.002 inches (0.05mm). End users who

require high pump and motor reliability are better

served by using a foot mounted motor on a precision

machined baseplate and performing a conventional

alignment.

134 ANSIFAM IOM - 5/08

Page 33

APPENDIX VI

3198 Teflon®Sleeve Field Replacement Procedure

The Model 3198 Teflon®sleeve is field replaceable,

provided a controlled oven capable of heating the

sleeve to 550° F (228° C) and a method of machining

the sleeve after installation on the shaft are available.

!

l

Do not heat the sleeve with an open flame.

Irreparable damage will occur to the sleeve.

For those users who do not have the above facilities,

shaft/sleeve sub-assemblies are available from ITT

Goulds.

1. Remove the old or damaged sleeve (126) from

the shaft (122). The sleeve may be cut

lengthwise with a sharp knife.

2. Thoroughly clean the shaft. Pay particular

attention to the knurled area of the shaft under the

sleeve.

NOTE: The replacement sleeve will not have

the same dimensions as the sleeve which was

removed until it is mounted on the shaft and

machined.

3. Heat the replacement sleeve in a controlled oven

at 550° F (288° C) for 40 minutes.

l

!

Do not heat the sleeve with an open flame —

irreparable damage will occur to the sleeve.

! WARNING

s

The oven and sleeve are hot. Use insulated gloves

to prevent burn injuries.

4. Remove the sleeve from the oven.

5. Slide the sleeve onto the shaft immediately after

removing it from the oven. Push the sleeve onto

the shaft until the sleeve bottoms out on the

shoulder of the shaft (Fig. VI-1). The hook end of

the sleeve will extend beyond the knurled portion

of the shaft.

CAUTION

CAUTION

6. As the sleeve cools, it will shrink in length. Apply

light pressure to keep the sleeve against the shaft

shoulder. Maintain pressure until the hook

portion of the sleeve seats itself against the

shoulder under the hook (Fig. V-2).

Fig. VI-2

!

l

Care must be taken not to damage the end of

the sleeve.

7. Allow the shaft and sleeve to cool completely.

8. Machine the Teflon

and finish shown in Table VI-1.

CAUTION

®

sleeve to the dimensions

Fig. VI-3

Table VI-1

3198 Teflon

®

Sleeve Diameter and Finish

Frame Sleeve OD Surface Finish

STX 1.375 / 1.373

MTX 1.750 / 1.748

9. Face off the sleeve shoulder even with and

parallel to the shaft shoulder (Fig. VI-4).

16 μ in.

16 μ in.

8

ANSIFAM IOM - 5/08

Fig. VI-4

Fig. VI-1

135

Page 34

136 ANSIFAM IOM - 5/08

Page 35

APPENDIX VII-1

Double Row Angular Contact Bearing Installation Instructions

1. Inspect the shaft (122) to ensure that it is clean,

dimensionally correct, and is free of nicks, burrs,

etc.

2. Lightly coat the bearing seating with a thin film of

oil.

3. Remove the bearing (112) from its packaging.

4. Wipe the preservative from the bearing (112) bore

and outer diameter.

5. Use an induction heater with a demagnetizing

cycle to heat bearing (112) to an inner ring

temperature of 230 °F (110 °C).

! WARNING

s

Wear insulated gloves when using a bearing

heater. Bearings will get hot and can cause

physical injury.

6. Position the bearing (112) on the shaft (122)

against the shoulder and snug the locknut (136)

against the bearing until it is cool. The locknut

prevents the bearing from moving away from the

shaft shoulder as it cools.

NOTE: Regreasable bearing has a single shield.

The outboard bearing is installed with shield

toward impeller.

7. Remove bearing locknut (136) after bearing (112)

has cooled.

8. Place lockwasher (382) on shaft (122). Place

tang of lockwasher in keyway of shaft.

9. Thread locknut (136) onto shaft (122). Tighten

locknut one-eighth (1/8) to one-quarter (1/4) turn

beyond snug. Bend any tang of lockwasher (382)

into a slot of locknut.

NOTE: Tighten locknut if necessary to align the

closest tab of lockwasher with slot on locknut,

but do not overtighten. See Table VII-1 for

maximum locknut torque.

Table VII-1

Maximum Bearing Locknut Torque

Torque

Group Bearing Size Locknut Size

STX 5306 N-06 20 (27)

MTX 5309 N-09 50 (68)

XLT-X, X17 5313 N-13 140 (190)

Ft-Lb (Nm)

Table VII-2

Maximum Bearing Locknut Torque

Maximum Torque

Group Bearing Size Locknut Size

STX 7306 N-06 20 (27)

MTX 7309 N-09 50 (68)

LTX 7310 N-10 70 (95)

XLT-X, X17 7313 N-13 140 (190)

ANSIFAM IOM - 5/08 137

Ft-Lb (N!m)

8

Page 36

138 ANSIFAM IOM - 5/08

Page 37

APPENDIX VII-2

Duplex Angular Contact Bearing Installation Instructions

1. Inspect the shaft (122) to ensure that it is clean,

dimensionally correct, and is free of nicks, burrs,

etc. (Fig. VII-1).

Fig. VII-1

2. Lightly coat the bearing seating with a thin film of oil.

3. Remove the bearings (112) from their packaging.

4. Wipe the preservative from the bearing (112) bore

and outer diameter.

7. Position the bearings (112) on the shaft (122)

against the shoulder and snug the locknut (136)

against the bearings until they are cool. The

locknut prevents the bearings from moving away

from the shaft shoulder as they cool. It is best to

rotate the outer bearing rings relative to each

other as they are placed on the shaft to assure

good alignment.

8. Remove bearing locknut (136) after bearings

(112) have cooled.

9. Place lockwasher (382) on shaft (122). Place

tang of lockwasher in keyway of shaft. (Fig. VII-2).

5. Use an induction heater with a demagnetizing

cycle to heat both bearings (112) to an inner ring

temperature of 230 °F (110 °C).

6. Place both bearings (112) on the shaft (122) with

the large outer races together (back to back).

l

! CAUTION

Duplex bearings are mounted back to back.

Make sure orientation of bearings is correct.

! WARNING

s

Wear insulated gloves when using a bearing

heater. Bearings will get hot and can cause

physical injury.

Fig. VII-2

10. Thread locknut (136) onto shaft (122). Tighten

locknut one-eighth (1/8) to one-quarter (1/4) turn

beyond snug. Bend any tang of lockwasher (382)

into a slot of locknut.

NOTE: Tighten locknut if necessary to align the

closest tab of lockwasher with slot on locknut,

but do not overtighten. Refer to Table VII-2 for

maximum locknut torque.

8

ANSIFAM IOM - 5/08 139

Page 38

140 ANSIFAM IOM - 5/08

Page 39

APPENDIX VIII

INPRO Labyrinth Oil Seal Installation Instructions

Description of Operation

The INRP VBXX-D®Labyrinth Oil Seal is specially

designed to protect pump bearings from lubrication

starvation as well as environmental contamination.

The bearing is made up of three basic parts: the rotor

(1), stator (2), and VBX

over the shaft and is held in place by an elastomeric

drive ring (4). The drive ring causes the rotor to turn

with the shaft and provides a positive, static seal

against the shaft. There is no metal-to-metal contact,

therefore, no friction or wear concerns.

®

Ring (3). The rotor (1) fits

Intallation Procedures

! CAUTION

l

The INPRO VBX is a one piece design. Do not

attempt to separate the rotor (1) from the stator

(2) prior to or during installation.

1. Assemble the power end per the instructions in

Section 6 - Disassembly and Reassembly.

l

! CAUTION

The edges of the keyway can be sharp. Failure

to cover the keyway with tape may result in a

cut o-ring and a damaged seal.

2. Wrap some electrical tape around the coupling

end of the shaft to cover the keyway.

NOTE: The smooth surface of the electrical

tape provides an excellent surface to slide the

rotor O-ring over.

3. Lightly lube the shaft and rotor drive ring (4) with

supplied lubricant.

NOTE: Lubricant will aid in the installation

process. If used, be sure the lubricant is

compatible with the O-ring material and plant

standards.

4. Use an arbor press to install the outboard INPRO

VBXX-D

port (6) at the 6 o'clock position. Press it only as far

as the beginning of the stator location ramp (9) and

avoid angular misalignment. There is nominal 0.002"

interference fit. Discard any residual material from

the stator gasket (5).

For STX Units

5. Press the inboard seal over the shaft into the

bearing frame as described in Step 4 above.

For All Other Units

5. Once the frame adapter is installed on the

bearing frame, press the inboard seal over the shaft

and into the adapter as descbied in Step 4 above.

®

into the bearing cover with the expulsion

8

ANSIFAM IOM - 5/08

Fig. VIII-1

141

Page 40

NOTES

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

142 ANSIFAM IOM - 5/08

Page 41

NOTES

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

ANSIFAM IOM - 5/08 143

Page 42

HOW TO ORDER

When ordering parts call

1-800-446-8537

or your local ITT Goulds Representative

EMERGENCY SERVICE

Emergency parts service is available

24 hours/day, 365 days/year . . .

Call 1-800-446-8537

Form No. IFAMILY Rev. 5/08

© copyright 2008 Goulds Pumps, Incorporated

a subsidiary of ITT Corporation

Loading...

Loading...