Page 1

Page 2

Pump Safety Tips

Safety Apparel:

• Insulated work gloves when handling hot bearings

or using a bearing heater

• Heavy work gloves when handling parts with sharp

edges, especially impellers

• Safety glasses (with side shields) for eye protection,

especially in machine shop areas

• Steel-toed shoes for foot protection when handling

parts, heavy tools, etc.

• Other personal protective equipment to protect

against hazard/toxic fluids

Coupling Guards:

• Never operate a pump without a V-belt guard

properly installed

Flanged Connections:

• Never force piping to make a connection with a

pump

• Use only fasteners of the proper size and material

• Ensure there are no missing fasteners

• Beware of corroded or loose fasteners

Operation:

• Do not operate below minimum rated flow, or with

discharge valves closed

• Do not open vent or drain valves, or remove plugs

while system is pressurized

Maintenance Safety:

• Always lockout power

• Ensure pump is isolated from system and pressure

is relieved before disassembling pump, removing

plugs, or disconnecting piping

• Use proper lifting and supporting equipment to

prevent serious injury

• Observe proper decontamination procedures

• Know and follow company safety regulations

• Never apply heat to remove impeller

• Observe all cautions and warnings highlighted in

pump instruction manual

Safety Definitions

These pumps have been designed for saf e and reliable operation when properly used and maintained in accordance

with instructions contained in this manual. A pum p is a pressure containing device with rotating parts that can be

hazardous. Operators and maintenance personnel must realize this and follow safety meas ures. Goulds pumps

shall not be liable for physical injury, damage or delays caused by a failure to observe the instructions in this manual.

The following symbols are used to denote special attention:

Electrical Hazard. Particular care must be taken when electrical power source to the equipment is

energized.

Warning. O perating procedure, prac tice etc which, if not c orrect ly followed, could result in personal injury or

loss of life

Caution. Operating procedure, practice etc which if not followed could result in dam age or destruction of

equipment

ATEX. If equipment is to be installed in a potentially explosive atmosphere and these procedures are not

followed, personal injury or equipment damage from an explosion may

Page 3

FOREWORD

When pumping unit is installed in a potentially explosive atmosphere, the instructions after the Ex symbol

please contact a Goulds representative before proceeding.

This manual provides instructions for the Installation, operation, and maintenance of the

Goulds Axial Flow (AF) pump model. This manual covers the standard product. For special

options, supplemental instructions are supplied. This manual must be read and understood

before installation and start-up.

The design, materials and workmanship incorporated in the construction of Goulds pumps

makes them capable of giving long, trouble-free service. The life and satisfactory service of any

mechanical unit, however, is enhanced and extended by correct application, proper installation,

periodic inspection, condition monitoring and careful maintenance. This instruction manual was

prepared to assist operators in understanding the construction and the correct methods of

installing, operating, and maintaining these pumps.

Goulds shall not be liable for physical injury, damage or delays caused by a failure to

observe the instructions for Installation, Operation, and Maintenance contained i n thi s

manual.

Warranty is valid only when genuine Goulds parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty,

unless written approval is obtained in advance from Goulds Pumps, Inc.

Supervision by an authorized Goulds representative is recommended to assure proper

installation.

Additional manuals can be obtained by contacting your local Goulds representative or by

calling 1-800-446-8537.

THIS MANUAL EXPLAINS

Proper Installation

Start-up Procedures

Operation Procedures

Routine Maintenance

Pump Overhaul

Trouble shooting

Order Spare or Repair Parts

must be followed. Personal injury and/or equipment damage may occur if these instructions are not

followed. If there is any question regarding these requirements or if the equipment is to be modified,

AF (42-66) IOM 3

Page 4

4

General Precautions

potentially explosive environment.

Never apply heat to remove impeller. It may explode due to trapped

liquid

Never use heat to disassemble pump due to risk of explosion from

trapped liquid

Never operate pump without coupling guard correctly installed

Never operate pump beyond the rated conditions to which the pump was

sold

Never start pump without proper prime, or proper liquid level in self

priming pumps

Never run pump below recommended minimum flow or when dry

Always lock out power to the driver before performing pump maintenance

Never operate pump without safety devices installed

Never operate pump with discharge valve closed

Never operate pump with suction valve closed

Do not change conditions of service without approval of an authorized

Goulds representative

Explosion Prevention

In order to reduce the possibility of accidental explosions in atmospheres containing explosive gasses

and/or dust, the instructions under the ATEX symbol must be closely followed. ATEX certification is a

directive enforced in Europe for non-electrical and electrical equipment installed in Europe. ATEX

requirements are not restricted to Europe, and are useful guidelines for equipment installed in any

Special ATEX considera ti ons

All installation and operation instructions in this manual must be strictly adhered to. In addition, care must be taken to

ensure that the equipment is properly maintained. This includes but is not limited to:

1. monitoring the pump frame and liquid end temperature

2. maintining proper bearing lubrication

3. ensuring that the pump is operated in the intended hydraulic range

AF (42-66) IOM

Page 5

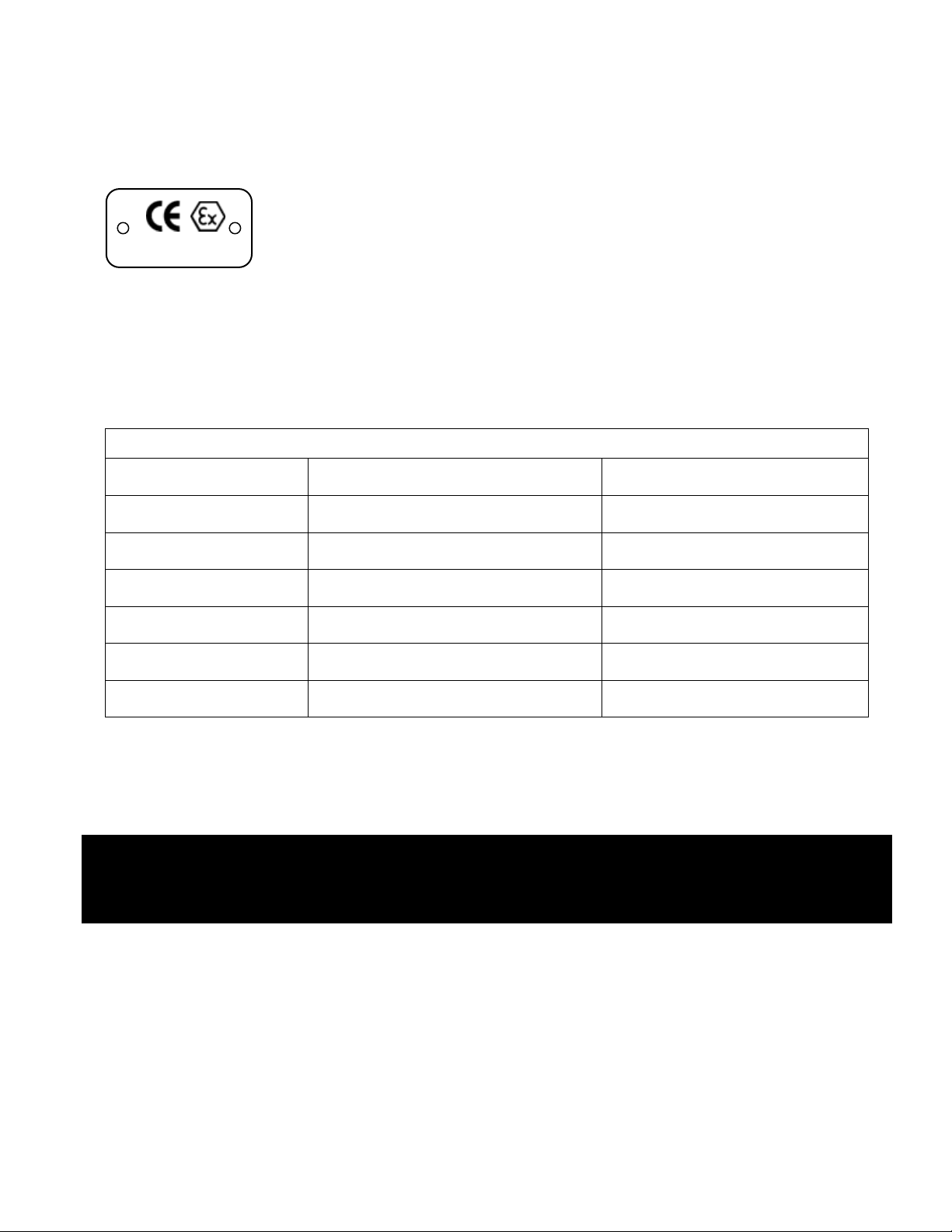

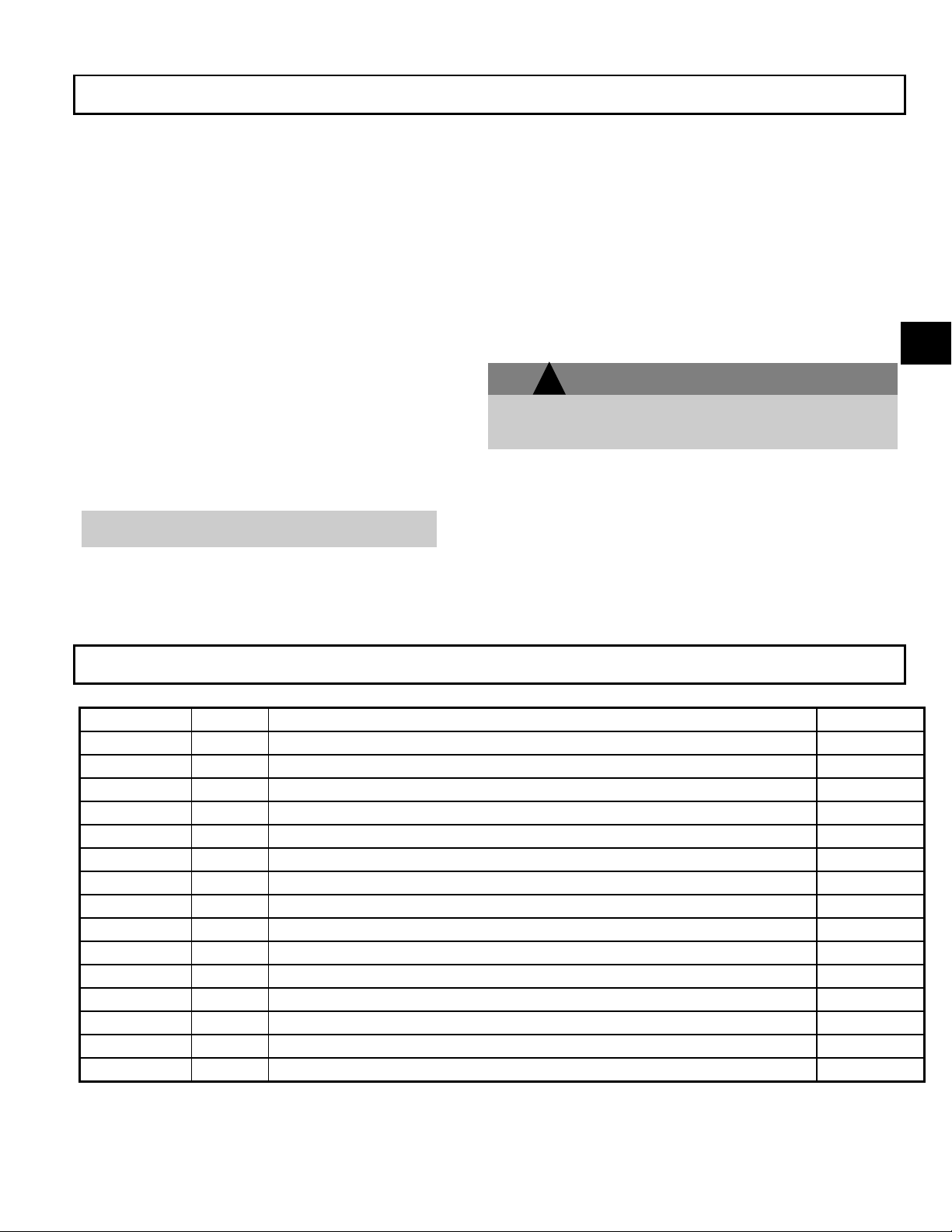

ATEX Identification

Temperature in Celsius

Temperature in Celsius

T1

T3

T4

T5

For a pumping unit (pump, seal, coupling, motor and pump accessories) to be certified for use in an ATEX classified

environment, the proper ATEX identification must be present. The ATEX tag will be secured to the pump or the

baseplate on which it is mounted. A typical tag will look like this:

II 2 G/D X

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II ------------ Group 2

2 ------------- Category 2

G/D ------------ Gas and Dust present

X ------------ Temperature class, can be T1 to T6 (see following table)

Maximum Process Temperature to achieve desired T rating

T Rating per EN 1127-1 Maximum Surface

450 410

T2

300 260

200 165

135 100

100 65

Maximum Process

T6

The code classification marked on the equipment should be in accordance with the specified area where the

equipment will be installed. If it is not, please contact your ITT/Goulds representative before proceeding.

85 50

Intended Use

The ATEX conformance is only applicable when the pump unit is operated within its intended use. All instructions

within this manual must be followed at all times. Operating, installing or maintaining the pump unit in any way that is

not covered in this manual can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT/Goulds. If there is any question regarding the

intended use of the equipment please contact an ITT/Goulds representative before proceeding.

AF (42-66) IOM 5

Page 6

6

THIS PAGE

INTENTIONALLY

LEFT BLANK

AF (42-66) IOM

Page 7

7

TABLE OF CONTENTS

Page

9

11

15

31

39

45

SAFETY

GENERAL INFORMATION

INSTALLATION

OPERATION

PREVENTATIVE MAINTENANCE

DISASSEMBLY & RE-ASSEMBLY

3

4

5

6

Section

1

2

49

61

AF (42-66) IOM

SPARE PARTS

APPENDIX 1

7

8

Page 8

8

THIS PAGE

INTENTIONALLY

LEFT BLANK

AF (42-66) IOM

Page 9

SAFETY

1

! ! !

!

!

DEFINITIONS ................................................................................................... 9

GENERAL PRECAUTIONS.............................................................................. 9

DEFINITIONS

Axial flow pumps are pressure-containing devices with

rotating parts that can be hazardous. It has been

designed for safe and reliable operation when properly

used and maintained in accordance with instructions

contained in this manual. It is not to be operated at

speeds, working pressures, discharge pressures, or

temperatures higher than, nor used with liquids other

than stated in the original order acknowledgement,

without written permission of ITT Industries, Gould’s

Pumps, Inc. Operators and maintenance personnel

must realize this and follow safety measures. ITT

Industries, Gould’s Pumps, Inc. shall not be liable for

physical injury, damage or delays caused by a failure to

observe the instructions in this manual.

Throughout this manual, the words Warning, Caution,

and Note are used to indicate procedures or situations

which require special operator attention:

WARNING

Warning is used to indicate the presence of a

hazard which can cause severe personal injury,

death or substantial property damage if the warning

is ignored.

CAUTION

Caution is used to indica te the presence of a hazard

which will or can cause minor personal injury or

property damage if the warning is ignored.

NOTE: Operating procedure, condition, etc. that is

essential to observe.

EXAMPLES

WARNING

Pump shall never be operated without V-belt or

coupling guard installed correctly.

CAUTION

Obstructions to flow or pipe fowling may cause

cavitation and pump damage.

NOTE: Proper alignment is essential for long pump

life.

GENERAL PRECAUTIONS

WARNING

Personal injury will result if procedures outli n ed in

this manual are not followed.

• Never apply heat to remove the impeller. It may

explode due to trapped liquid.

• Never use heat to disassemble pump due to risk of

explosion from trapped liquid.

• Never operate pump without V-belt or coupling

guard correctly installed.

• Never operate pump beyond the rated conditions

to which the pump was sold.

• Never start pump without proper prime (sufficient

liquid in pump casing).

• Never run the pump < 75% or > 115% of the Best

Efficiency Point (B.E.P.), AF pumps are unstable in

these regions.

• Always lock out power to the driver before

performing maintenance.

• Never operate pump without safety devices

installed.

• Never operate pump with suction valve closed.

• Never operate pump with discharge valve closed.

• Do not change conditions of service without

approval of an authorized Gould’s representative

AF (42-66) IOM 9

Page 10

THIS PAGE

INTENTIONALLY

LEFT BLANK

AF (42-66) IOM

10

Page 11

2

GENERAL INFORMATION

GENERAL .................................................................................................... 11

PUMP DESCRIPTION .................................................................................. 11

NAME PLATE INFORMATION .................................................................... 12

RECEIVING THE PUMP .............................................................................. 13

INSTALLATION AND OPERATION CHECKLIST ........................................ 13

GENERAL

This instruction manual is intended to assist those

involved with the installation, operation and

maintenance of Gould’s pumps. It is recommended

that this manual be thoroughly reviewed prior to

installing or performing any work on the pump or

motor.

The design, material and workmanship incorporated

into the construction of Gould’s pumps makes them

capable of giving long, trouble-free service. The life

and satisfactory service of any mechanical unit,

however, are enhanced and extended by periodic

inspection and careful maintenance. Keep this

instruction manual handy for reference. Further

information can be obtained by contacting Gould’s

Pumps, Ashland Operations, East Centre St., Ashland,

PA 17921 or your local representative.

Gould’s Pumps will not be liable for any damages or

delay caused by failure to comply with the provisions of

this instruction manual. This pump is not to be

operated at speeds, working pressures, discharge

pressures, or temperatures, nor used on liquids other

than stated in the original order acknowledgment

without written permission of Gould’s Pumps.

PUMP DESCRIPTION

The AF pump generates flow by the thrust or lift

action of the rotating axial vanes of the impeller. It

provides high flow rates and low heads which are

ideal for re-circulation, evaporator, and generator

cooling systems. The AF utilizes an elbow to direct

the flow through the suction and out the discharge

end of the pump. The pump accommodates top or

end suction configurations using either the LMR or

LM bearing arrangement. The LMR is for top

suction and the LM is for end suction.

Arrangements are as follows:

Power Inboard Outboard

End Bearing Bearing

LMR Spherical roller Spherical thrust/spacer/Spherical

roller

LM Spherical roller Spherical roller/spacer/Spherical

thrust

Elbow – AF elbows are fabricated with 150# flat

face suction and discharge flanges. They come

with fabricated feet for mounting to a sub-base or

without feet to be mounted directly in the piping.

The elbows have a built in stuffing box and a rear

flange for mounting the power end to the elbow.

There are also adjusting lugs for aligning the shaft

to the stuffing box.

Casing – The AF comes with a casing or spool piece to

simplify impeller installation and alignment. The casing

bolts to the elbow and shrouds the impeller. It has a gasket

or o-ring seal between it and the elbow. Adjusting lugs on

the elbow center the casing relative to the impeller.

Power End - The power end is made up of the bearing

housing, bearings, locknuts, lock washers, labyrinth oil

seals, shaft, shaft sleeve (w/packing), oil slinger, keys,

shaft, and shaft washer.

Stuffing Box – The stuffing box is integral with the elbow

and provides a mounting surface for a mechanical seal or

cylindrical bore with flush ports and gland face for packing.

The standard packed box includes (5) rings of packing and

(2) lantern rings to seal the shaft area. (2) flush ports are

provided for lubrication. The innermost flush port is used

with process flow and the outermost port for water flush. A

special alternate packing arrangement is available that

includes a throat bushing and additional ring of packing

near the gland (see the attached addendum). A gland is

used for packing adjustment.

AF (42-66) IOM 11

Page 12

Shaft Sleeve – If packing is specified, a

replaceable wear sleeve is provided with the power

end. The sleeve is keyed to prevent rotation. The

stuffing box can also be modified to accept a

mechanical seal if required.

Impeller - The impeller is cast with (4) fixed vanes

at 0 or +5 degrees, CW or CCW rotation, and top

or end suction. The impeller bore is stepped for

easy assembly to the shaft. It is held in place with

a key, shaft washer, and bolts. It has a cover plate

and o-rings to prevent corrosion and allow for easy

impeller replacement. The impeller is dynamically

balanced (two plane) per ISO 1940 to a quality

grade G-16.

Shaft – The shaft is cantilevered into the elbow to

eliminate the need for internal bearings. It is sized

for minimal deflection, high critical speed, and

extreme corrosion resistance. The shafts are

stepped for easy assembly with the impeller. The

shaft comes with a replaceable sleeve when used

with stuffing boxes.

Bearings - The inboard radial bearing absorbs shaft radial

loads and aligns the pump shaft. It is a spherical roller

bearing. The outboard thrust bearing absorbs impeller

thrust loads and comes as either back-to-back angular

contacts or a single taper roller bearing, depending on

pump size. Lubrication is by flood oil or grease, depending

on customer requirements.

Oil-Cooling (Optional ) – An oil-cooling coil is available on

all sizes, it is installed in the bottom of the bearing housing

and circulates water to cool the oil bath. Generally, it is

used when process temperatures cause excessive heat

build up in the bearing housing and/or bearings.

Configurations and Drives – The 42”, 1200mm, 54”, 60”,

and 66”pumps are usually gear driven and come on a

subbase as standard. They can also be pipe mounted with

a drive shaft to a motor on a separate subbase.

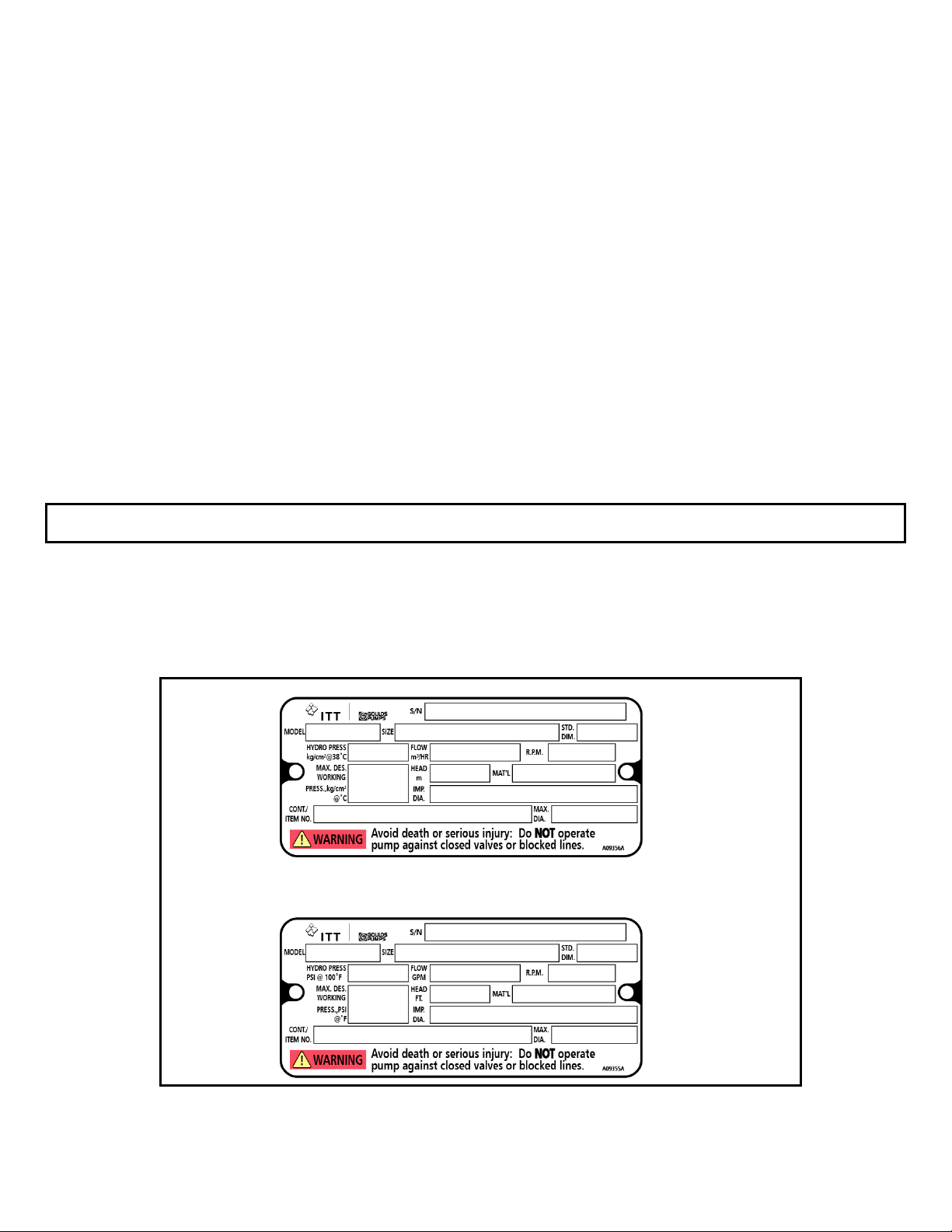

NAMEPLATE INFORMATION

Every Gould’s pump has a nameplate that provides

information about the pump, including hydraulic

characteristics. The nameplate for the AF is located on the

bearing housing. Note the format of the pump size:

Discharge X Suction - Impeller Diameter in inches or

millimeters (Example 42” X 42”-42” or 1200mm X

1200mm-1200mm, see Fig. 1). When ordering spare

parts you will need to identify pump model, size, serial

number, and the item number of required parts.

Information can be found in this manual.

12 AF (42-66) IOM

Page 13

COMPLETE

INITIAL

DESCRIPTION

PAGE NO.

Manual read and understood

1~54

Level foundation

15

Level subbase

16

Check motor rotation ---CW _____ ---CCW _____

28

Component rough alignment complete

21~26

V-belt tension and alignment per drive mfgr.

21,22

Coupling alignment per cplg mfgr.

22

Piping installed and alignment rechecked

19, 20

Mech. seal adjusted per mfgr.

Mfgrs Mnl

Seal flush lines connected

41

Impeller alignment and clearance set ______ Inch/Side

27

Pump shaft-free turning

30

Bearing lubrication

30, 38

V-belt or coupling guards installed

9, 22,30

Motor electrical connections

Mfgrs Man’l

2

!

RECEIVING THE PUMP

Inspect the pump as soon as it is received.

Carefully check that everything is in good order.

Make notes of damaged or missing items on the

receipt and freight bill. File any claims with the

transportation company as soon as possible.

STORAGE REQUIREMENTS

Short Term: (Less than 6 months) Gould’s normal

packaging is via a skid. It is designed to protect

the pump during shipping only. Upon receipt, store

in a covered and dry location.

Long Term: (More than 6 months) Gould’s longterm packaging via crating. Preservative treatment

of bearings and machined surfaces is required.

Rotate the shaft several times every 3 months.

Refer to drive manufacturer's instruction manual

for their long-term storage procedures. Store in a

covered dry location

Note: Long-term storage treatment can be

purchased with initial p u mp order.

UNCRATING/DE-SKIDDING

Care should be taken when uncrating or de-skidding

pumps. If shipment is not delivered in proper order, and in

accordance with the bill of lading, note the damage or

shortage on both the receipt and freight bill. Make any

claims to the transportation company promptly. Instruction

books and sheets are included in the shipment - DO NOT

DISCARD.

LIFTING THE PUMP/SUB-BASE

WARNING

Pump and components are heavy. Failure to properly

lift and support equipment could result in serious

physical injury or damage to pumps.

Use care when moving pumps. Lifting equipment must be

able to adequately support the entire assembly. Lift

assembled unit by the lifting holes found in the sub-base.

If the motor, sheaves, and guard are in place, be sure that

the lifting cable or chain clears these components. If

necessary remove the guard or use a spreader bar to

prevent damage. In case the motor ships separate use the

eyebolts or lifting lugs found on the motor to hoist it into

place on the sub-base.

INSTALLATION AND OPERATION CHECKLIST

AF (42-66) IOM 13

Page 14

THIS PAGE

INTENTIONALLY

LEFT BLANK

14 AF (42-66) IOM

Page 15

Equipment that will operate in a potentially

accordance with the following instructions.

All equipment being installed must be

maintenance purposes.

3

INSTALLATION

PREPARATION FOR INSTALLATION ........................................................ 15

LOCATION/FOUNDATION .......................................................................... 15

SUB-BASE LEVELING ................................................................................ 16

CONNECTION OF PIPI NG .......................................................................... 19

PIPE HUNG INSTALLATION ....................................................................... 21

DRIVE ALIGNMENT PROCEDURES .......................................................... 22

IMPELLER ALIGNMENT ............................................................................. 27

ROTATION CHECK ..................................................................................... 29

PREPARATION FOR INSTALLATION

AF units are usually shipped completely assembled.

Check all bolts and nuts on the entire unit and make

sure they are securely tightened. If necessary, install

and adjust drive components per manufacturer’s

recommendations

explosive environment must be installed in

properly grounded to prevent unexpected

static electric discharge. If not, a static

electric discharge may occur when the pump

is drained and disassembled for

AF pump shall be located in a clean, dry area free from

flooding. The area should provide adequate space for

operation, maintenance, inspection and repair,

considering complete disassembly and handling of

equipment. The pump should have a supply of clean

liquid for packing or mechanical seal lubrication. The

pump should be positioned to provide the most efficient

pipeline system.

The AF pumps covered by these instructions may be

designed to hang in the piping system, furnished with

spring loaded sub-base bolts, or have a sub-base

designed to be anchor bolted and grouted to the

foundation.

The foundation must be substantial enough to absorb

any vibration and form a permanent, rigid support for the

pumping unit to the degree that there shall not be any

adverse movement or settling over a long period of time.

Foundations for anchor bolted and grouted sub-bases

are typically concrete with anchor bolts cast in to secure

the pump.

LOCATION/FOUNDATION

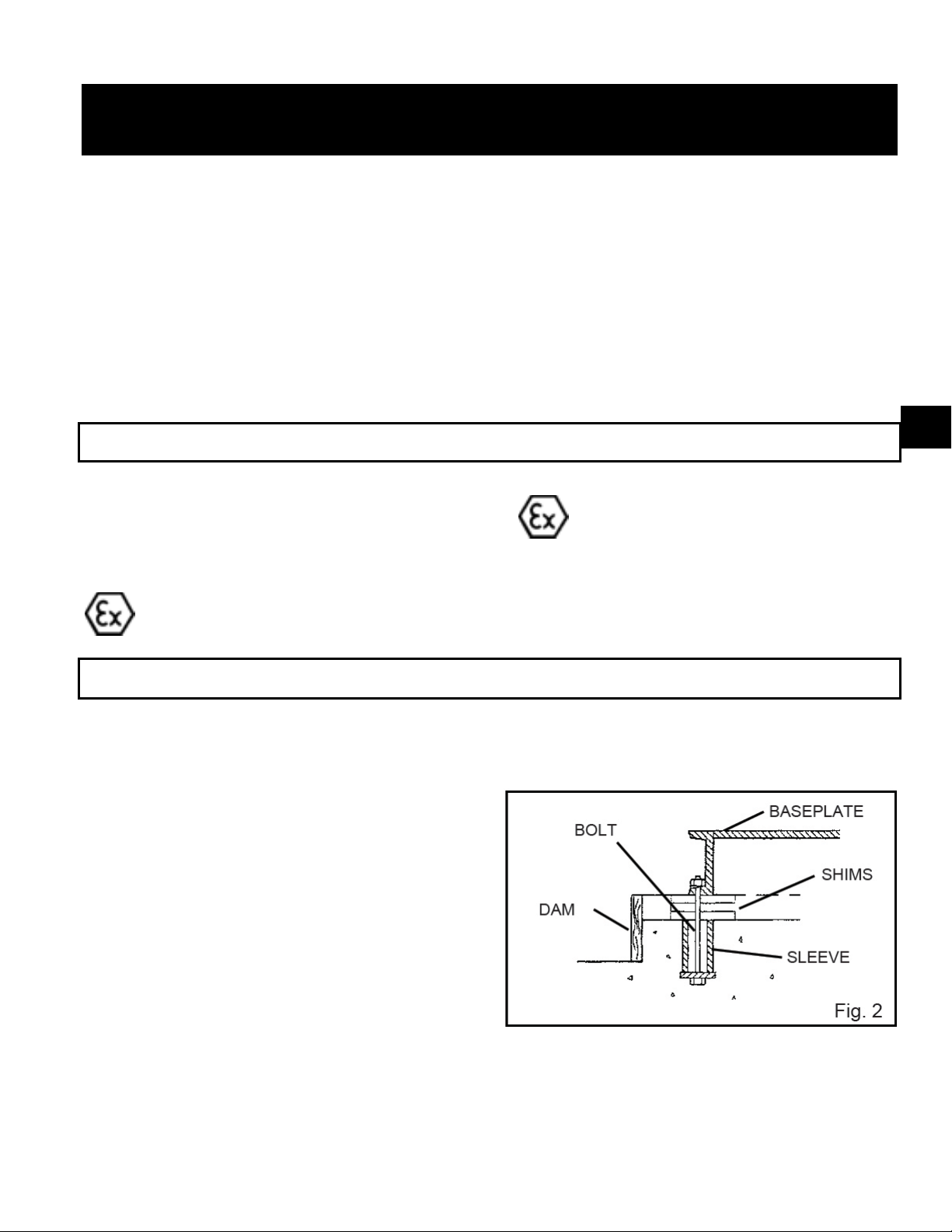

The most commonly used foundation bolts are the

sleeve-type (Fig 2 and J type Fig. 3)

AF (42-66) IOM 15

Page 16

SHIMS OR WEDGES

SHIMS OR WEDGES

Both designs permit movement for final bolt

adjustment. Anchor bolts should be located in the

concrete by a template dimensioned from the pump

installation drawing. The top of the sleeve-type bolt

should be temporarily sealed with waste material to

prevent concrete from entering during the concrete

pouring operation. Foundation bolts are located

according to the bolt hole dimensions shown on the

installation drawing. Bolt size is based on hole size,

they should be 1/8” to ¼” under the sub-base hole size.

For information on spring mounted sub-bases, see the

following section under spring mounted bases.

SUB-BASE LEVELING

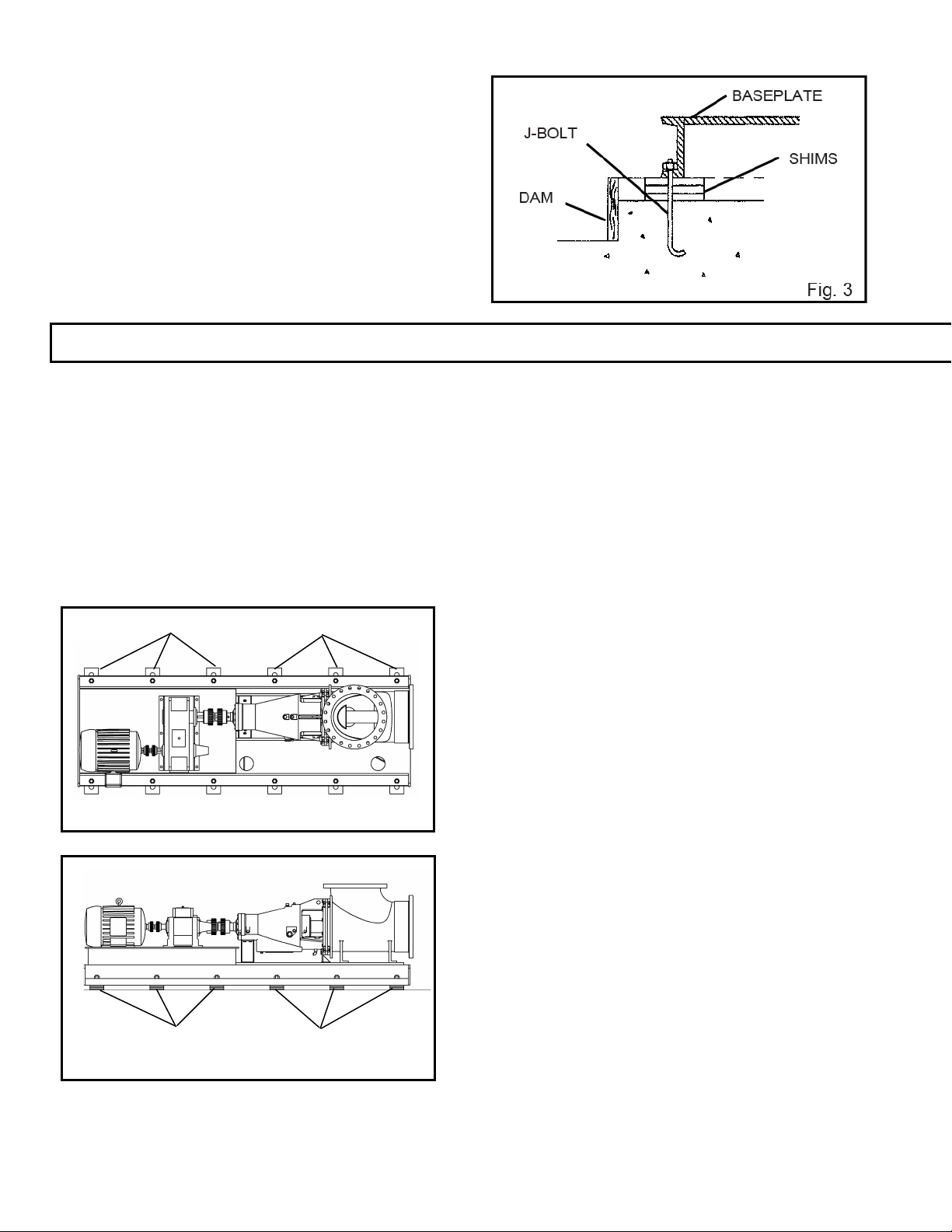

GROUTED BASE

When the unit is received with the pump and driver

mounted to the sub-base, it should be placed on the

foundation and the coupling halves or V-belts

disconnected (Fig. 4). The coupling should not be

reconnected until all realignment operations have been

completed. A recommended coupling alignment

procedure is included in the following sections.

Fig. 4

Fig. 5

1. The sub-base should be supported on rectangular

metal blocks or on metal wedges having a slight

taper. There should be support blocks or wedges

on both sides of each foundation bolt. A gap of

about 3/4" to 1-1/2' should be allowed between the

sub-base and the foundation for grouting (Fig. 5).

2. Adjust the metal supports or wedges until the

shafts of the pump and driver and sub-base are

level. Check the coupling faces, as well as the

suction and discharge flanges of the pump, for

horizontal and vertical position by means of a level.

Check also for any internal rubbing in the pump.

Correct, if necessary, by adjusting the supports or

wedges under the sub-base as required. In most

cases, factory alignment will be regained by

shimming under the sub-base alone. Provisions

must be made to support the discharge piping

independently from the pump to prevent excessive

loads and maintain pump-driver alignment.

3. The sub-base should be level to within .125 in. (3

mm) over the length of the base and .0875 in. (1.5

mm) over the width of the base. Bases anchored

with conventional foundation bolts use shims on

both sides of the anchor bolts to level the base.

The bolts which secure the pump sub-base to the

foundation should be 1/8” – 1/4” less in diameter

than the holes in the sub-base (hole size is shown

on the certified installation drawing).

4. Clean outside areas of sub-base that will contact

grout. Do not use oil-based cleaners because

grout will not bond to it. Refer to grout

manufacturer's instructions.

5. Build a dam around foundation and thoroughly wet

the foundation (Fig. 6).

16 AF (42-66) IOM

Page 17

Fig. 10

SPRING

POCKETS

Fig. 8

BOLT

BASEPLATE

GROU

DAM

GROUT

FOUNDATION

Fig. 6

BOLT

BASEPLATE

DAM

GROUT

FOUNDATION

Fig. 7

3

SPRING MOUNTED BASE

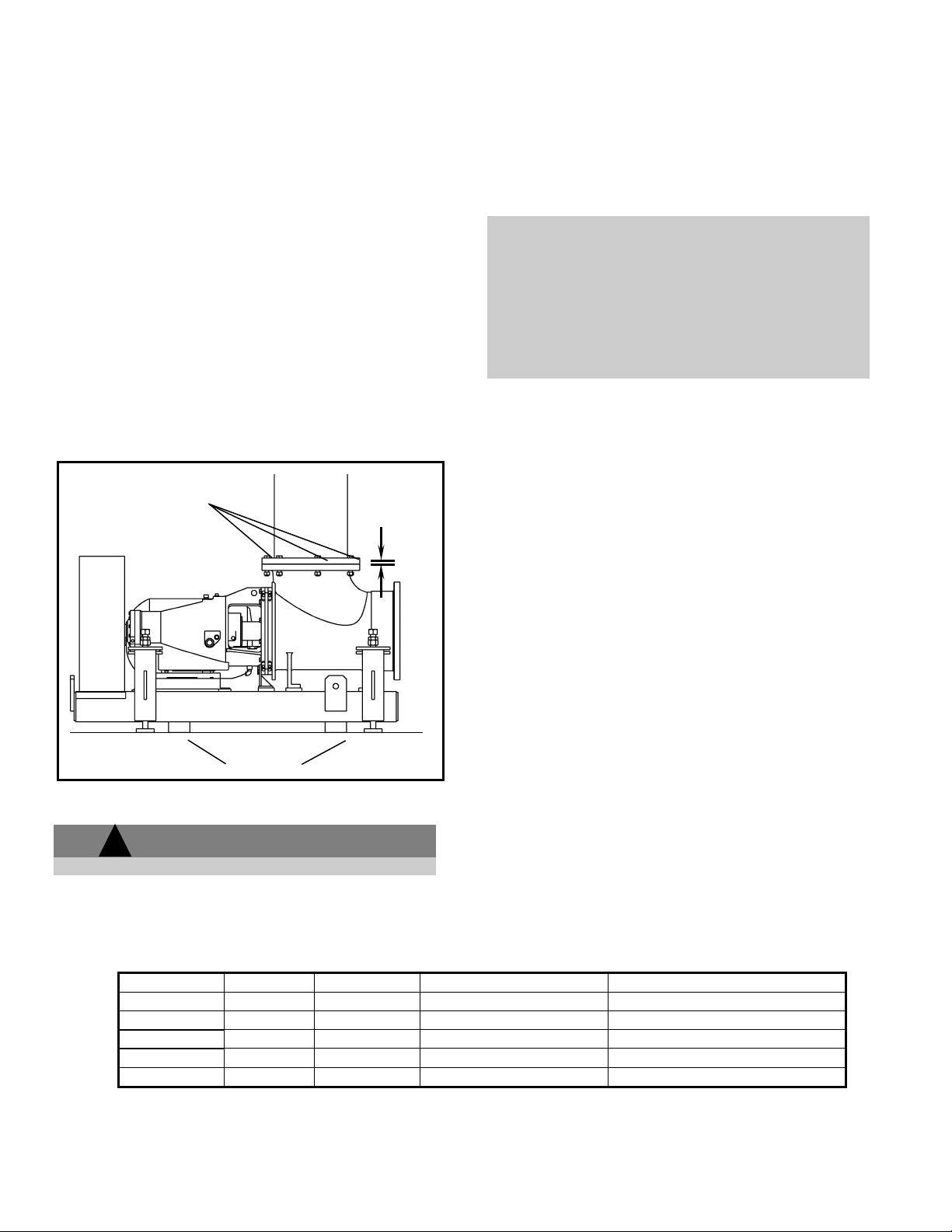

Fig. 8 shows a V-belt driven AF pump on a spring

mounted sub-base. Sub-bases supported by spring

pockets assure that the pump remains level,

regardless of vertical movement due to thermal pipe

expansion during operation.

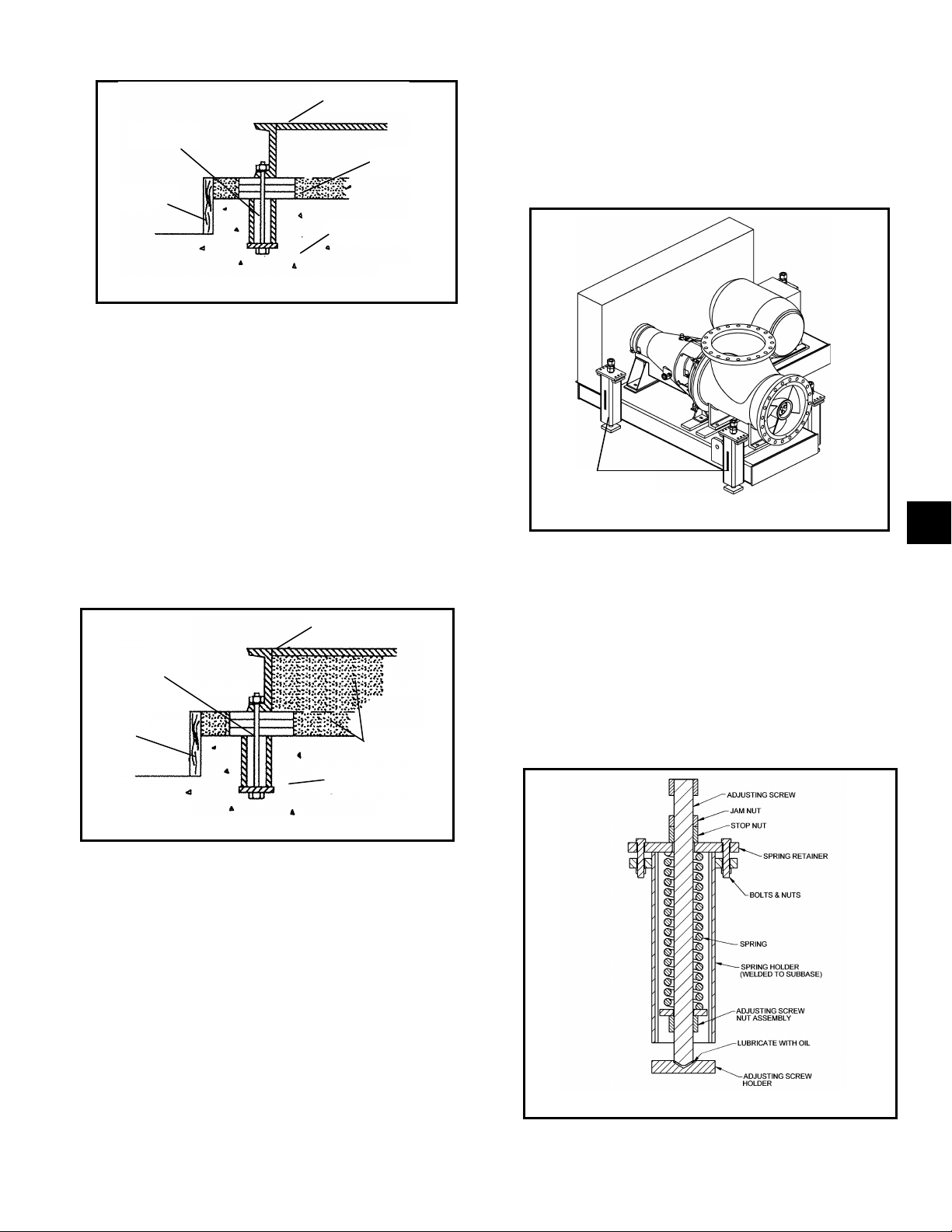

6. Pour grout through the grout holes in the sub-base,

up to level of dam. Remove air bubbles from grout

as it is poured by puddling, using a vibrator, or

pumping the grout into place. Non-shrink grout is

recommended.

7. Allow grout to set.

8. Fill remainder of sub-base with grout. Remove air

as before (Fig. 7)

9. Allow grout to set at least 48 hours.

10. Tighten foundation bolts.

Fig. 8

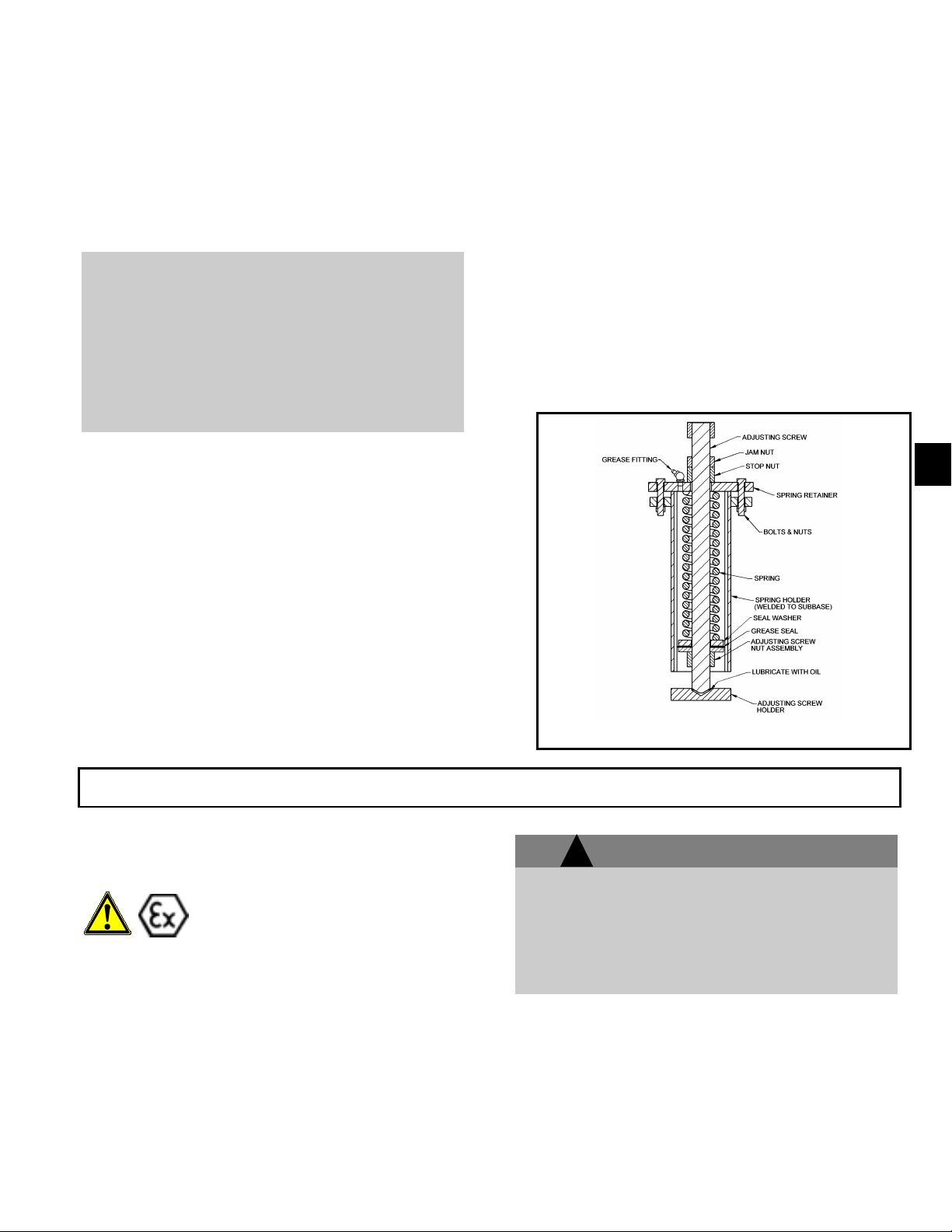

The following is a brief description of the spring pocket

components and their function (see Fig. 9). The

adjusting screw is used to compress or relax the

spring. Turning the screw causes the adjusting screw

nut assembly to move vertically and change the

amount of force the spring exerts against the spring

retainer, which is fastened to the sub-base. The stop

nut is to limit the vertical up motion of the sub-base in

case part of the load is removed from the pump unit

AF (42-66) IOM 17

Fig. 9

Fig. 9

Page 18

1/16”

FLANGE

BOLTS

BLOCKS

Spring Size

Wire Size

Spring Rate

Adjusting Screw Size

Load Change per Full Turn

1

.812”

1140 #/in.

1-1/2”-6 UNC

190 #

2

.750”

760 #/in.

1-1/2”-6 UNC

127 #

3

.532”

560 #/in.

1-1/2”-6 UNC

93 #

4

1.00”

1000 #/in.

2”-4-1/2 UNC

222 #

5

.375”

133 #/in.

¾”-10 UNC

13 #

Table 1

!

when the system is cold. The jam nut keeps the stop

nut from turning during normal operation when the subbase has been pushed down from the thermal

expansion. The adjusting screw holder is a bearing

surface for the end of the adjusting screw and serves

to hold the end of the screw in a fixed location.

The adjusting screw was lubricated at the factory but

should be re-lubricated with heavy protective grease

during the pump installation. The springs and other

parts should be coated with an agent to protect the

surface from corrosion, and a heavy lubricant should

be applied to the adjusting screw holder pocket.

The following steps are used to set the springs and

level the sub-base:

1. Place blocks under the sub-base, near each spring

holder, and position the sub-base level on the blocks.

A small gap (approx. 1/16" or 1.6 mm) should exist

between the flange of the vertical pipe and the pump

elbow with the gasket in place (Fig. 10).

allow the required horizontal motion without having the

adjusting screw nut assembly hit the walls of the spring

holder. Make sure there is sufficient clearance

between the adjusting screw holder and the bottom of

the sub-base for vertical thermal expansion, this

clearance is usually shown on the pump installation

drawing.

NOTE: Each spring carries a share of the unit load

but generally do not carry equal loads. Each

holder has a small "window” to check the spring

coil spacing, which is an indication of the relative

load on the spring. The ins tallation drawing may

indicate the approximate number of turns required

for each spring loca tion, especially if the unit uses

more than (4) springs. If necessary refer to table 1

for spring rate information.

4. Turn the adjusting screws until the bottom of the

sub-base just clears each block. Next adjust each

screw evenly until the pump flange and gasket are less

than 1/32” (0.8 mm) away from the pipe flange.

Careful adjustment is necessary to keep the pump

level and obtain better weight distribution on the

springs. After the springs have been loaded and

adjusted, the base should be off the support blocks

and level.

5. Check the alignment of the impeller and the pump

elbow. If necessary, correct the alignment by adjusting

the springs or by using shims.

NOTE: If the flange gap is over 1/32” (0.8 mm), turn

the adjusting screws a uniform amount to close the

gap. For a gap of 1/32” (0.8 mm) or less, omit this

step.

Fig. 10

2. Install several flange bolts to help maintain

alignment of the flanges.

6. Tighten the vertical pipe flange bolts, recheck the

alignment and connect the horizontal pipe flange to the

elbow. The pump unit should be level and there

should not be any rubbing of the impeller in the elbow

when the shaft is turned by hand.

WARNING

Do not tighten bolts.

3. Position the adjusting screw holders, while the

adjusting screw end is seated in the hole, in the

direction of the horizontal thermal expansion. This will

18 AF (42-66) IOM

Page 19

Never draw piping into place by

damage to the equipment.

3

!

7. Run each stop nut down to make light contact with

the spring retainer. Lock in place by turning the

jam nut down tight against the stop nut.

8. Inspect each spring holder to check the gap

between the coils of the spring. There must be

enough total gap to accommodate the downward

thermal expansion of the system without having

them compressed solid.

NOTE: Pumps with oil lubrication should be

checked for oil level while thermal expansion is

taking place. It may be necessary to add oil to the

bearing housing to provide the proper oil level to

the higher bearing. A line parallel with the subbase deck through the pr o p er oil level line will

show the correct level at the highest end of the

bearing housing. A hori zontal line back from that

point will establish the proper level mark on the

sight gauge.

The system should be operated at normal temperature

before the adjusting screw holders are grouted in

place. Some customers operate their units with the

adjusting screw holders ungrouted.

If it becomes necessary to remove a spring assembly

from a spring pocket, for safety the following steps

should be strictly adhered to:

1. Make sure the spring is relaxed. If the spring

cannot be relaxed with the adjusting screw, the safest

method is to pry off the Plexiglas cover and cut the

coils using a torch.

2. Remove the bolts or cap screws, which fasten

the spring retainer to the holder and lift out the entire

assembly.

3. When the pump is connected to the system and

a spring is removed, there should be support under the

sub-base near the spring location until the spring has

been replaced and adjusted. Distortion of the subbase will affect the pump alignment, and the weight of

the components is more likely to cause distortion when

the pump is connected to the rigid pipe system.

4. If a spring is replaced while the system is hot,

the stop nut should not be set until the system is cold.

The springs must be allowed to push the base back to

its cold position.

An optional grease filled spring pocket is shown in

figure 11. The difference between the standard pocket

and the grease filled pocket is the addition of a grease

fitting and grease seal. Adjustment and setting of the

grease filled pocket are identical.

Fig. 11

GENERAL

forcing at the flanged connections of

the pump. This may impose

dangerous strains on the unit and

cause misalignment between pump

and driver. Pipe strain will adversely

effect the operation of the pump

resulting in physical injury and

Guidelines for piping are given in the “Hydraulic

Institutes Standards” available from: Hydraulic

Institute, 30200 Detroit Road, Cleveland OH 441451967 and must be reviewed prior to pump installation.

AF (42-66) IOM 19

CONNECTION OF PIPI NG

WARNING

Never draw piping into place by forcing at the

flanged connections of the pump. This may

impose dangerous strains on the unit and cause

misalignment between the pu m p and driver. Pipe

strain will adversely affect the operation of the

pump resulting in physical injury and damage to

the equipment.

1. All piping must be supported independently of, and

line up with the pump flanges.

2. Piping runs should be as short as possible to

minimize friction losses

Page 20

!

3. DO NOT connect piping to the pump until the

pump and driver hold-down bolts have been

tightened.

4. It is suggested that expansion loops or joints be

properly installed in suction and /or discharge lines

when handling liquids at elevated temperatures, so

linear expansion of piping will not draw pump out

of alignment.

5. The piping should be arranged to allow pump

flushing prior to removal of the unit on services

handling corrosive liquids.

6. Carefully clean all pipe parts, valves and fittings,

and pump branches prior to assembly.

SUCTION AND DISCHARGE P IPING

WARNING

NPSHA must always exceed NPSHR as shown on

Goulds performance curves received with order.

(Reference Hydraulic Institute for NPSH and pipe

friction values needed to evaluate suction piping

Properly installed suction piping is a necessity for

trouble-free pump operation. Suction piping should be

flushed BEFORE connection to the pump.

1. Use of elbows close to the pump suction flange

should be avoided. There should be a minimum of

2 pipe diameters of straight pipe between the

elbow and suction inlet. Where used, elbows

should be long radius.

2. Use suction pipe one or two sizes larger than the

pump suction, with a reducer at the suction flange.

Suction piping should never be of smaller diameter

than the pump suction.

3. To prevent suction cavitation, horizontal reducers

should be eccentric with the sloping side down and

concentric for vertical applications.

5. Pump must never be throttled on suction side.

7. Separate suction lines are recommended when

more than one pump is operating from the same

source of supply.

Suction lift conditions

1. Suction pipe must be free from air pockets.

2. Suction piping must slope upwards to pump.

3. All joints must be airtight.

Suction head/Flooded suction conditions

1. An isolation valve should be installed in the suction

line at least two pipe diameters from the suction to

permit closing of the line for pump inspection and

maintenance.

2. Keep suction pipe free from air pockets.

3. Piping should be level or slope gradually

downward from the source of supply.

4. No portion of the piping should extend below pump

suction flange.

5. The size of entrance from supply should be one or

two sizes larger than the suction pipe.

6. The suction pipe must be adequately submerged

below the liquid surface to prevent vortices and air

entrainment at the supply.

Discharge piping

1. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump, this will permit inspection

of the check valve. The isolation valve is required

for priming, regulation of flow, and for inspection

and maintenance of pump. The check valve

prevents pump or seal damage due to reverse flow

through the pump when the driver is turned off.

2. Increasers, if used, should be placed between

pump and check valves.

3. Cushioning devices should be used to protect the

pump from surges and water hammer if quickclosing valves are installed in system.

Final Piping Check

1. Rotate shaft several times by hand to be sure that

there is no binding and all parts are free.

2. Check alignment, per the impeller alignment

procedure outlined on pg. 28 to determine

absence of pipe strain. If pipe strain exists, correct

the piping.

20 AF (42-66) IOM

Page 21

Foundation

Pipe

Shaft

Level Sub-base

be Parallel

be Parallel

level .005”/ft

3

PIPE HUNG INSTALLATION

LOCATION OF UNIT

The pump should be located in a clean, dry area free

from flooding. The area should provide adequate

space for maintenance and repair, considering

complete disassembly and handling of equipment.

The unit should be positioned to provide the most

efficient pipeline system.

PIPING

Short, direct suction and discharge pipelines having a

minimum of elbows and fittings will result in the least

amount of pipe friction. Excessive friction losses will

result in insufficient capacity and cavitation. Future

access to the pump impeller and shaft will require

removal of a section of discharge pipe (spool piece).

NOTE: The horizontal pipe flange must be parallel

with the pump flange before the bolts are

tightened. If the flanges are not parallel, forcing

them parallel by tightening the bolts may put

excessive strain on the pump.

INSTALLATION OF PUMP IN PIPELINE

1. Connect the pump top flange to the vertical

pipe and tighten flange bolts. Level pump

within .005” (0.42 mm)/Meter.

2. Check the impeller clearance in the casing so

that it is reasonably well centered using the

criteria that the minimum gap at the vane.

3. O.D. is at least 50% of the maximum gap (see

the impeller alignment worksheet, pg. 28 for

instructions)

4. Connect the casing flange to the spool piece

and tighten the flange bolts.

INSTALLATION OF THE DRIVER

Install the driver (motor and reduction gear on a

separate sub-base) as indicated on the installation

drawing for the pump. The universal joint drive shaft

requires the gear and pump shafts be parallel within 1

degree but off-set as indicated on the drawing. The

optimal universal joint life is obtained with off-set shaft

angles of 1 to 3 degrees.

Level the driver base relative to the pump, in

accordance with the proceeding paragraph using

leveling wedges adjacent to the anchor bolts. Partially

tighten the anchor bolt nuts and check the shaft

alignment between the motor and reduction gear. If the

alignment is reasonably satisfactory, grout the base in

place.

After the grout has hardened, tighten the anchor bolt

nuts. Check and correct the motor shaft alignment. We

recommend the actual shaft misalignment for the

flexible couplings be considerably less than the

maximum allowed by the coupling manufacturer for

long coupling life and reduced vibration levels.

CONNECTION TO PUMP DRI VER

The pipe hung pump is connected to the driver via a

drive shaft and universal joints at each end. Follow the

drive shaft installation instructions and the angle limits

per the pump installation drawing. An extendable guard

is provided for the drive shaft and should be used any

time the pump driver is rotating.

AF (42-66) IOM 21

Motor

Extendable

Guard

Reduction

Gear

Flanges must

Drive

Shaft Offset

+/- 1 to 3 deg.

Vertical

Spool Piece

Flanges must

Pump must be

Horizontal

Pipe

Fig. 11A

Page 22

injury.

Fig. 12

!

DRIVE ALIGNMENT PROCEDURES

Alignment procedures must be followed to

prevent unintended contact of rotating parts.

Follow coupling manufacturer’s installation and

operation procedures.

WARNING

Before beginning any alignment procedure, make

sure driver power is locked out. Failure to lock out

driver power will result in serious physical injury.

Lock out driver power to prevent electric

shock, accidental start-up and physical

The AF pump comes with two drive variations, V-belt

and gear driven. Accurate alignment of both systems

is essential to long pump life and reduced pump

problems.

The points at which alignment are checked and

adjusted are:

• Initial Alignment is done prior to operation

when the pump and the driver are at ambient

temperature.

• Final Ali g n ment is done after operation when

the pump and driver are at operating temperature.

Alignment is achieved by adding or removing shims

from under the feet of the driver and gearbox and

shifting equipment horizontally by adjusting bolts as

needed.

NOTE: Proper alignment is the responsibility of

the installer and user of the unit.

Trouble free operation can be accomplished by

following these procedures.

Initial Alignment (Cold Alignment)

• Before Grouting Sub-base - To ensure alignment

can be attained. After Grouting Sub-base - To

ensure no changes have occurred during the mounting

process.

• After Spring Setting – To ensure no changes

have occurred during the leveling process.

After Connecting Piping - To ensure pipe strains

have not altered alignment. If changes have occurred,

alter piping to remove pipe strains on pump flanges.

• Final Ali g n ment (Hot Alignment)

• After First Run - To obtain correct alignment

when both pump and driver are at operating

22 AF (42-66) IOM

temperature. Thereafter, alignment should be

checked periodically in accordance with plant

operating procedures.

NOTE: Alignment check must be made if process

temperature changes , piping changes, and or

pump service is performed.

V-BELT DRIVE (SHEAVES)

Well designed and properly installed V-belt drives are

capable of running for years. AF pumps come in

several different belt drive configurations i.e. side by

side, overhead, underslung or “Z” mount. Installation

and alignment procedures are similar for all

configurations. Remove the guard or guards by

referring to the assembly/disassembly instructions.

There are a few items that should be checked during

installation and alignment.

Sheave Alignment - Alignment must be maintained

for full power transmission, minimum vibration, and

long drive life. A dial indicator can be used to check

runout on the periphery and face of each sheave. A

straight edge can be used to check parallel and

angular alignment of the pump and drive sheaves, see

Fig. 12.

Belt Installation - When installing new belts, shorten

center distance between sheaves so that belts can be

placed on the sheave without the use of force. Never

'roll' or "Pry" the belts into place, as this could damage

the belt cords.

Page 23

!

3

1. Check Belt Fit - Regardless of the belt section

used, the belt should never be allowed to bottom

in the groove. This will cause the belts to lose

their wedging action and slippage can occur.

Sheaves or belts that permit such a condition to

occur should be changed.

2. Maintain Proper Belt Tension - Proper tension

is essential for long belt life. Improper tension

could cause belt fatigue and/or hot bearings.

3. Impeller Alignment after Belt Tensioning – If

the impeller was aligned prior to belt tensioning a

check should be made to determine that it is still

centered. An off center impeller may rub and

cause unnecessary pump damage. Belt Tension

will usually cause impeller misalignment opposite

the motor. Be sure to align or re-align in

accordance with the Impeller Alignment section

page 26.

The general method of tensioning belts is given

below, and should satisfy most drive requirements.

General Method:

STEP 1. Reduce the center distance so that the belts

may be placed over the sheaves and in the grooves

without forcing them over the sides of the grooves.

Arrange the belts so that both belt spans have a

proximately the same sag between the sheaves.

Apply tension to the belts by increasing the center

distance until the belts are snug, see Fig. 13.

Fig. 13

WARNING

Do not operate the pump without the proper drive

guard in place. Failure to observe this warning

could result in perso n al injury to operating

personnel

STEP 2. Operate the drive a few minutes to seat the

belts in the sheave grooves. Observe the operation of

the drive under its highest load condition (usually

starting). A Slight bowing of the slack side of the drive

indicates proper tension. If the slack side remains

taut during the peak load, the drive is too tight.

Excessive bowing or slippage indicates insufficient

tension. If the belts squeal as the motor begins

operation or at some subsequent peak load, they are

not tight enough to deliver the torque demanded by the

drive machine. The drive should be stopped and the

belts tightened.

STEP 3. Check the tension on a new drive frequently

during the first day by observing the slack side span.

After a few days of operation the belts will seat

themselves in the sheave grooves and it may become

necessary to readjust so that the drive again shows a

slight bow in the slack side.

Other methods of determining proper belt tension can

be obtained from the drive manufacturer.

5. Use Belt Guards - Belt guards protect personnel

from danger and the drive from contamination.

Inspect periodically to assure that belts do not rub

against guard.

6. Keep Belts Clean - Dirt and grease reduce belt life.

An occasional wiping with a dry cloth to remove any

build-up of a foreign material can extend the life of

the belt. Should oil or grease splatter onto the

belts, clean with soap and water.

Belt dressing affects performance only temporarily and

is never recommended. Maintaining a clean drive is a

better practice.

If any questions arise pertaining to the drive limitations,

consult the manufacturer.

GEAR DRIVE (COUPLINGS)

The coupling used in an ATEX classified

environment must be properly certified.

Remove the guard or guards by referring to the

assembly/disassembly instructions. Disconnect

motor/gearbox and the pump/gearbox coupling halves

before proceeding with the alignment. First, align the

pump/gearbox coupling then the motor/gearbox

coupling. Check both coupling connections for parallel

and angular alignment by either the Dial Indicator or

Straight-Edge Method outlined below.

Good alignment is achieved when the dial indicator

readings, for both parallel and angular misalignment,

are .003" (.076mm) Total Indicated Reading (T.I.R.) or

less when the pump and driver are at operating

temperature (Final Alignment). Fig. 14 describes what

to look for.

AF (42-66) IOM 23

Page 24

Fig. 14

1. Mount two dial indicators off one half of the

coupling (X) so they contact the other coupling half (Y)

(Fig. 15).

Fig. 15

2. Check setting of indicators by rotating coupling

half (X) to ensure indicators stay in contact with

coupling half (Y) but do not bottom out. Adjust

indicators accordingly.

MEASUREMENT

3. To ensure accuracy of indicator readings, always

rotate both coupling halves together so indicators

contact the same point on coupling half (Y). This will

eliminate any measurement problems due to runout

on coupling half (Y).

4. Take indicator measurements with hold-down bolts

tightened. Loosen hold down bolts prior to making

alignment corrections.

5. Take care not to damage indicators when moving

driver during alignment corrections.

Keep this instruction manual handy for reference.

Further information can be obtained by contacting

Goulds Pumps, 240 Fall St., Seneca Falls, New York

13148 or your local representative.

ALIGNMENT PROCEDURE

On gear driven AF pumps angular and parallel

misalignment are corrected in the vertical direction by

means of shims under the motor or gearbox mounting

feet, and in the horizontal direction by adjusting bolts

that slide the motor or gearbox in the proper direction.

After each adjustment, it is necessary to recheck the

alignment of the coupling halves. Adjustment in one

direction may disturb adjustments already made in

another direction. It should not be necessary to adjust

the pump in any way.

ANGULAR ALIGNMENT

Couplings are in angular alignment when indicator “A“

(Angular Indicator), Fig 15, does not vary by more than

.003” (.076mm) as measured at four points on the

coupling periphery 90° apart at operating temperature.

Outlined below are two acceptable methods to achieve

the desired alignment.

METHOD 1 - Dial Indicator Method

For steps 1 through 5 refer to Fig. 16 on the following

page.

1. Zero indicator “A” at position 1 of coupling half (Y).

Mark this position on both flanges.

2. Rotate both flanges 180° to position 3. Observe

needle and record reading.

3. Negative Reading - The coupling halves are

further apart at position 3 than position 1.

Positive Reading - The coupling halves are closer

at position 3 than position 1.

24 AF (42-66) IOM

Page 25

3

Directions for viewing coupling

View from front end of pump

Fig. 16

4. Correct any misalignment by shimming the under

the motor or gearbox feet to attain the proper

alignment.

When using positions 2 and 4 in steps 1-3, correct

any misalignment by sliding the motor back and forth

to attain the proper alignment.

5. Repeat steps 1-4 substituting position 2 for

position 1 and position 4 for position 3. Use the

same marks made on the coupling from position 1

and be sure to turn the coupling halves together.

METHOD 2 - Feeler Gauge Method

For the following steps refer to Fig. 16.

1. Insert a feeler gauge at position 1 at the periphery

of the couplings. Mark this position on both

flanges.

2. Record the largest gauge size that fits snugly

between the two flanges.

3. Rotate both flanges to position 3 - 180°.

4. Insert a feeler gauge at the periphery of the

couplings at position 3

5. Record the largest gauge size that fits snugly

between the two flanges.

6. Calculate the difference between the readings at

positions 1 and 3. The difference should not be

greater than .003" (.076mm).

7. Correct any misalignment by shimming under the

motor or gearbox feet to attain the proper

alignment.

When using positions 2 and 4 in steps 1 - 6, correct

any misalignment by sliding the motor or gearbox

back and forth to attain the proper alignment.

8. Repeat steps 1-6 substituting positions 2 and 4 for

position 1 and 3 respectively. Use the same marks

made on the coupling from position 1 and be sure

to turn the coupling halves together.

Parallel Alignment

The unit is in parallel alignment when indicator “P”

(Parallel Indicator) does not vary by more than .003”

(.076mm) as measured at four points on the coupling

periphery 90' apart at operating temperature. There are

two methods outlined below that are acceptable to

achieve the desired alignment.

NOTE: Equal amounts of shims must be added to

or removed from eac h d river foot. Otherwise the

vertical angular alignment will be affected.

METHOD I - Dial Indicator Method

For the following steps, refer to Fig. 16.

1. Zero the indicator “P” at position 1 of coupling half

(Y). Mark this position on both flanges.

2. Rotate both flanges 180° to position 3. Observe

needle and record reading.

3. Negative Reading - Coupling half (Y) is shifted

toward position 1.

If the value is greater than .003” (.076mm), correct the

misalignment by evenly (at equal amounts on both

sides) shimming the motor higher.

When using positions 2 and 4 in steps 1 - 2, correct any

misalignment by sliding the motor evenly toward

position 2.

Positive Reading - Coupling half (Y) is shifted

toward position 3.

If the value is greater than .003" (.076mm), correct the

misalignment by evenly (at equal amounts on both

sides) shimming the motor or gearbox lower.

When using positions 2 and 4 in steps 1 - 2, correct any

misalignment by sliding the motor or gearbox evenly

toward position 4.

4. Repeat steps 1-3 until indicator “P” reads .003"

(.076mm) or less.

AF (42-66) IOM 25

Page 26

5. Once the ideal alignment is reached, repeat steps

1-4 substituting position 2 for position 1 and

position 4 for position 3.

METHOD 2 - Straight-Edge Method

For the following steps refer to Fig. 16.

1. Place a straight edge across the two coupling

flanges at position 1 and mark the spot on both

flanges.

2. Adjust the motor or gearbox so that the straightedge rests evenly on both flanges (within .003"

.076mm).

3. Rotate both flanges 90° to positions 2 and repeat

steps one and two.

4. The unit will be in parallel alignment when the

straight edge rests evenly (within .003” .076mm)

on the coupling periphery at both positions along

the periphery.

NOTE: Care must be taken to h ave the straight

edge parallel to the axis of the shafts

Complete Alignment

A unit is in complete alignment when both indicators

“A” (angular) and “P” (parallel) do not vary by more

than .003” (.076 mm) as measured at four points 90°

apart.

Vertical Correction (Top-to-Bottom)

1. Zero indicators “A” and “P” at top dead center (12

o'clock) of coupling half (Y).

2. Rotate indicator to bottom dead center (6 o'clock).

Observe the needles and record the readings.

3. Make corrections as outlined previously.

Horizontal Correction (Side-to-Side)

1. Zero indicators “A” and “P” on the left side of

coupling half (Y), 90° from top dead center (9

o'clock).

2. Rotate indicators through, top dead center to the

right side, 180° from the start (3 o'clock), Observe

the needle, measure and record the reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal readings to

ensure adjustment of one did not disturb the

other. Correct as necessary.

Factors that may disturb alignment

The unit should be checked periodically for alignment.

If the unit does not stay in line after being properly

installed, the following are possible causes:

1. Settling or spring of the foundation.

2. Wear of bearings.

3. Pipe strains distorting or shifting the machine.

4. Shifting of the sub-base due to heat created from

an adjacent heat source.

5. Shifting of the building structure due to variable

loading or other causes.

6. Loose nuts or bolts on the pump or driver

assembly.

NOTE: With experience, the installer will

understand the interaction between angular and

parallel and will make corrections appropriately.

26 AF (42-66) IOM

Page 27

Improper impeller adjustment could cause

generation.

The impeller clearance setting procedure

heat generation and equipment damage.

3

IMPELLER ALIGNMENT

GENERAL

contact between the rotating and stationary

parts, resulting in a spark and heat

must be followed. Improperly setting the

clearance or not following any of the proper

procedures can result in sparks, unexpected

The AF impeller has been aligned at the factory but

should be checked prior to pump operation. The

impeller requires several thousandths of and inch of

clearance to prevent rubbing due to the action of

hydraulic forces when the pump is operating. Many

corrosion-resistant alloys will gall and build up if

rubbing occurs, therefore, pumps using these alloys

need to be free from any rubbing.

Turn the shaft by hand, if the impeller rubs the inside of

the casing it must be realigned. The following steps

are used to align the impeller.

Note: Impeller rubbing is often caused by pipe

strain or belt tension. Pipe strain must be

eliminated prior to impeller alignment. The

impeller should aligned after proper belt

tensioning.

Clearance measurement - The alignment worksheet

on page 27 is used to align the impeller of the AF

pump. The measurement procedure is as follows:

Make sure the cap screws fastening the casing to the

elbow are tight, so an accurate measurement of the

impeller clearances can be made prior to adjustment.

Mark each blade 1, 2, 3 and 4 and then align the

impeller blades as shown on the impeller alignment

worksheet (approx. 2, 4, 8, and 10 o’clock)

Rotate the shaft and measure the gap between each

blade and the casing at all four clock positions

indicated on the worksheet. The value of interest is

the largest value of feeler gage thickness that will slide

easily the whole length of the vane tip.

Add the measurements for all positions together and

divide by the number of measurements. This will give

the average measurement.

Divide the average measurement by 2. This will give

the minimum clearance.

If any blade has a clearance in any position smaller

than the calculated minimum clearance the prop is not

sufficiently centered and should be adjusted.

Impeller Alignment

1. Loosen the bolts that attach the casing to the

elbow.

2. Use the adjusting bolts attached to the elbow to

adjust the impeller clearance. The adjusting bolts

are used to raise and lower the casing and shift the

casing left to right relative to the impeller.

3. Move the casing relative to the impeller until the

impeller is centered. At this point it is

recommended that the Impeller Alignment

Worksheet (on the following page) be filled out and

filed with the pump maintenance records for future

reference.

4. Tighten the bolts between the casing and the

elbow and re-check the clearance to be sure the

adjustments have centered the impeller. If the

impeller is centered the casing may be taper

pinned to the elbow to maintain alignment.

AF (42-66) IOM 27

Page 28

(1.16 mm )

(0.58 mm )

28 AF (42-66) IOM

Page 29

When installing in a potentially explosive

properly certified.

3

ROTATION CHECK

Before the V-belts or couplings are installed, the

motor should be wired and the direction of rotation

checked. A rotation arrow is located on the

bearing housing (134C).

Serious damage could occur if the pump is run the

wrong direction.

environment, ensure that the motor is

AF (42-66) IOM 29

Page 30

THIS PAGE

INTENTIONALLY

LEFT BLANK

30 AF (42-66) IOM

Page 31

When installing in a potentially explosive

properly certified.

The coupling guard used in an ATEX

from a non-sparking material.

4

!

!

OPERATION

PREPARATION FOR OPERATION ............................................................. 31

STARTING THE PUMP ............................................................................... 35

OPERATION ................................................................................................ 36

SHUTDOWN ................................................................................................ 37

FINAL ALIGNMENT .................................................................................... 38

PREPARATION FOR OPERATION

CHECKING ROTATIO N

environment, ensure that the motor is

Damage occurs

from:

1. Increased vibration levels-affects bearings, stuffing

box or seal chamber and mechanical seal

2. Increased radial loads Stresses on shaft and

bearings

3. Heat build up-Vaporization causing rotating parts to

score or seize

4. Cavitation-Damage to internal surfaces of pump

CAUTION

Serious damage may result if pump is run in the

wrong direction.

WARNING

Lock out power to prevent accidental start-up and

physical injury.

Serious damage may result if the pump is

run in the wrong direction.

A check must be made to be sure motor rotation

coincides with the pump rotation direction. Depending

on your pump arrangement (V-belt or

gear-drive) use one of the following methods to check

motor rotation.

Direct Connect

1. Lock out power to the driver.

2. Remove the pump coupling guard.

3. Make sure the coupling halves are securely

fastened to shafts.

4. Unlock driver power.

5. Make sure everyone is clear. Jog the driver just

long enough to determine direction of rotation of

the output shaft of the gearbox. Rotation must

correspond to an arrow on bearing housing.

6. Lock out power to driver.

7. Replace the pump coupling guard.

classified environment must be constructed

V-BELT

1. Lock out power to the driver.

2. Remove the V-belt guard.

3. Make sure the sheaves are securely fastened to

shafts.

AF (42-66) IOM 31

Page 32

Bearings must be lubricated properly in

sparks and premature failure.

AXIAL FLOW PUMP

APPROX. OIL VOLUME

Pump Size

Quarts

Liters

42” / 1200mm / 54”

74

70.5

60” / 66”

62

59

Table 2

4. Unlock driver power.

5. Make sure everyone is clear. Jog the driver just

long enough to determine direction of rotation.

Rotation must correspond to an arrow on bearing

housing.

6. Lock out power to driver.

7. Replace the V-belt guard.

CHECK IMPELLER CLEA RANCE

Check impeller clearance before installing the pump.

The impeller mus t not rub when the shaft is turned by

hand, therefore it is recommended that the Impeller

Alignment Worksheet (shown on pg. 27) is filled out

and filed with the pump m aintenance records f or future

reference.

CHECK FOR FREE TURNING

Before the pump is started, rotate the pump by hand to

be sure it turns freely, and does not rub or bind.

BEARINGS

The bearing assembly uses spherical roller bearings to

carry the radial load, and a spherical roller thrust

bearing to carry the axial thrust load from the impeller.

The bearing housing has a horizontal split along the

centerline for ease of assembly and inspection.

Approximate values only. Always fill using sight glass to verify level. Oil level should be at t he center of the sight glass. See comments in this sec tion.

LUBRICATION

The bearing uses oil bath lubrication. Oil lubricated

bearing assemblies are shipped without oil. Oil must be

added to the bearing housing before starting. Remove

the bearing housing breather (113A) and add oil until oil

level is at the center of the sight glass. If the unit has

an external oil lube system, fill the bearing housing and

the reservoir to satisfy the system requirements.

Replace the breather. Table 2.shows the oil volume

required.

order to prevent excess heat generation,

Run the pump for 1 minute to fill the oil galleys and in

and around each bearing. Check the sight glass and

add oil accordingly. Monitor the oil level indicator for

the first 24 hours of operation and maintain fill level.

OIL TYPE

Use an industrial quality lubrication oil such as Mobil

DTE series, Exxon Teresstic, or similar of ISO VG68.

ISO VG46 may be used in ambient temperatures

below 40F.

In any case the operating temperature viscosity must

be a minimum of 150SSU.

An oil with a higher viscosity than required will

increase the bearing operating temperature because

of the extra viscous drag, but never to the point where

the viscosity becomes lower than required from the

increased heat generation. It is therefore better for the

bearings to have an oil that is too heavy rather than

too light.

Change the oil after the first 200 hours of operation.

For normal operating conditions, change the oil at

least four (4) times a year. If the bearing assembly is

exposed to dirty or moist conditions, the oil should be

changed more often.

OIL LEVEL CONTROL

If the level of oil in the bearing housing (134C) is too

high, excessive heat may be generated due to

churning. If the level is too low, excessive heat may be

generated due to inadequate lubrication. A liquid level

switch connected to the oil sump can be used to warn

of a dangerous oil level condition.

Observe the oil level requirements shown on the

assembly drawing furnished with the pump. If

excessive heat is experienced within these levels,

consult the factory. Be sure that the shaft centerline is

horizontal through the bearing housing

NORMAL BEARING TEMPERATURE

The running temperature for a bearing assembly

depends on many factors such as speed, bearing

loads, lubrication, ambient air temperatures, and

condition of bearings. Temperatures higher than the

human hand can tolerate are very satisfactory for

good bearing operation and should not cause any

alarm.

For a given speed and loading, the bearing housing

temperature will stabilize at some temperature, usually

32 AF (42-66) IOM

Page 33

PACKING RINGS

CORRECT

INCORRECT

4

below 200°F., which will be the normal temperature for

temperature, without any change in speed or loading

can mean a lubrication difficulty or the approach of

bearing failure.

INSTALLING A BEARING

Long bearing life is dependent on careful handling of

the bearing when it is out of the housing and during the

installation procedure. Dirt and rough handling are

prime enemies of precision bearings. Bearings should

be pressed, not “hammered” into place. If heat is used

to facilitate the installation, a hot oil bath is the best

method.

THRUST BEARING ORIENTATION

Fig. 20 at the end of this section shows the axial thrust

bearing (112C) in the outboard location. This is used

for top suction pumps.

End suction pumps have the flow and axial thrust in

the opposite direction. Therefore, the complete thrust

bearing assembly is reoriented in the opposite

direction. This does not change the basic disassembly

procedure, other than the sequence of installing the

thrust bearing assembly components on the shaft.

The illustration shows the thrust bearing (112C)

mounted on a sleeve (196). For the other bearing

orientation, the bearing is mounted on an extension of

the spacer (443), eliminating the separate sleeve.

SHAFT SEALING

A packed stuffing box or mechanical seal is used to

seal the AF pump shaft. Both methods are described

below.

PACKED STUFFING BOX

The original equipment packing is a suitable grade for

the service intended. To pack the standard stuffing

box use the following procedure: For the special (6)

ring packing arrangement see the appendix 1.

1. Stuffing box and shaft sleeve must be clean and

free of grit.

2. Form packing over shaft or mandrel of same

diameter. Carefully cut to packing length. Discard

rings cut too short.

3. Pre-form each ring by coiling 1 -1 /2 turns.

the installation.

4. To install packing rings, do not pull straight.

Expand the coil as a coil spring, see Fig 17 for the

correct and incorrect method of installing packing.

Fig. 17

Expand the first coil as shown and insert into stuffing

box. Tamp packing to stuffing box shoulder firmly with

the gland. Note, where the cut is positioned.

5. Install the first lantern ring into the stuffing box.

6. Install the second and third coil as required by

7. Install the second lantern ring into stuffing box,

8. Install the third and fourth coil as required by

9. After packing and lantern rings are properly

10. Turn lubricant supply on, start pump, and adjust

11. Periodic maintenance is absolutely required for all

Packed stuffing boxes are not allowed in an

ATEX classified environment.

Failure to property locate the lantern ring with the

flush port will result in insufficient packing

lubrication.

sectional drawing, staggering the cut 90° to 120°.

carefully noting its proper position on the sectional

drawing.

sectional drawing, staggering the cut 90° to 120°.

installed, insert gland into stuffing box. Tighten

gland nuts finger tight only. The shaft should turn

freely.

the gland as described in Section III-E Stuffing Box

Adjustment.

packed pumps. Normal shaft run-out should be

under .005” to avoid pounding of stuffing box

packing. With excessive shaft run-out, shaft

straightening or replacement is necessary.

AF (42-66) IOM 33

Page 34

The mechanical seal used in an ATEX

certified.

The mechanical seal must always be properly

heat generation and seal failure.

!

GLAND ADJUSTMENT

Adjust the stuffing box if packing is used. When the

pump is first started, there should be considerable

leakage by the gland to cool the packing. Gradually

tighten the gland nuts on flat at a time while observing

the leakage and stuffing box temperature. Packing

requires time to “run-in” and extra coolant (leakage)

while it is being “run-in”. If the leakage is reduced too

quickly, the packing will overheat and may be destroyed.

The shaft sleeve may also be damaged.

LEAKAGE

Normal leakage for a properly adjusted box,

depending on shaft size and speed, varies

from a few drops a second to a small trickle

out of the gland.

MECHANICAL SEAL

classified environment must be properly

through the seal gland. Clear, grit-free liquid is

necessary. Goulds Pumps strongly recommends the

stocking of replacement sealing elements.

WARNING

Do not make shaft adjustments on mechanical seal

installations without consulting seal instructions and the

pump assembly drawing. Damage to the mechanical

seal may result.

Dynamic seals are not allowed in an ATEX

classified environment.

flushed. Failure to do so will result in excess

Most mechanical seals are installed and adjusted at the

factory. A common seal type used on the AF pump is

the cartridge type. Cartridge seals are preset at the seal

manufacturer’s facility and require no field settings. Due

to size and design, some installed mechanical seals are

supplied with holding clips. These clips keep the sealing

faces apart to avoid damage during transport. The clips

must be removed before the shaft is to be rotated.

Pumps with retained seal faces will be specifically

marked and instructions from the seal manufacturer for

clip removal will be provided.

If the seal has been installed in the pump at the Goulds

factory, these clips have already been removed. For

other types of mechanical seals, refer to the seal

manufacturer’s instructions for installation and setting.

Mechanical seals have a stationary and a rotating

sealing face. Commonly, these sealing rings are of

carbon and ceramic material, brittle in nature, and easily

damaged. As the sealing rings seat with the operation of

the pump, a compatible wear pattern develops between

the mating surfaces.

To disassemble the mechanical seal after the wear

pattern is established would necessitate the replacement

of the rotating element and stationary sealing elements.

Do not replace only one component.

To insure the life and sealing characteristics of the

mechanical seal, lubricating liquid must be circulated

34 AF (42-66) IOM

Page 35

When starting pump, immediately observe

.

4

!

!

STARTING THE PUMP

PRIMING PUMP

Pumps that are not self-priming must be fully

primed at all times during operation.

Start up Precautions

1. All equipment and personal safety related devices

and controls must be installed and operating properly.

2. To prevent premature pump failure at initial start