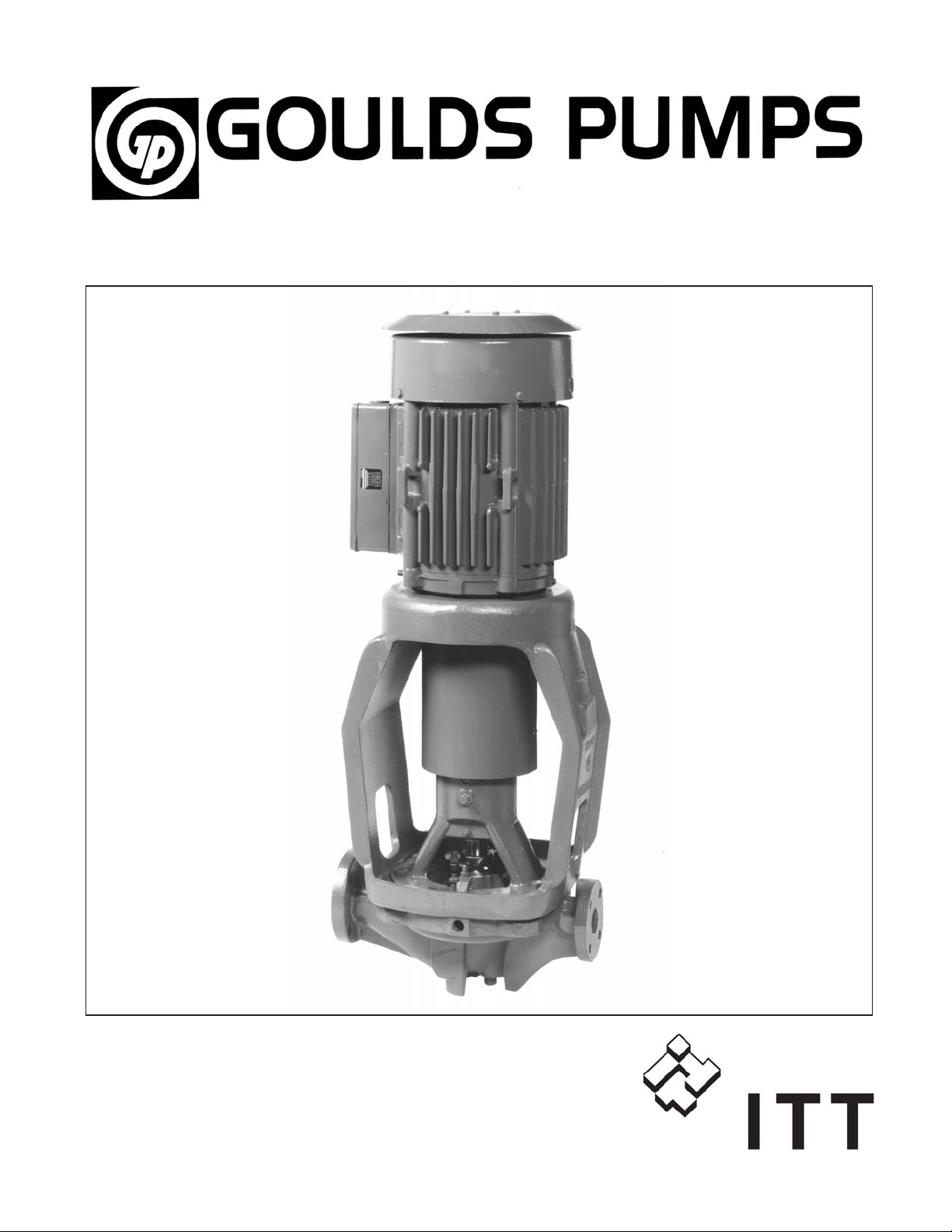

Page 1

Installation, Operation and Maintenance Instructions

Model 3996

Page 2

FOREWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Model 3996 pump. This manual covers

the standard product plus common options that are available. For special options, supplemental instructions are supplied. This manual

must be read and understood before installation and start-up.

The design, materials, and workmanship incorporated in the construction of Goulds pumps makes them capable of giving trouble-free

service. The life and satisfactory service of any mechanical unit, however, is enhanced and extended by correct application, proper

installation, periodic inspection, condition monitoring and careful maintenance. This instruction manual was prepared to assist operators in

understanding the construction and the correct methods of installing, operating, and maintaining these pumps.

Goulds shall not be liable for physical injury, damage or delays caused by a failure to observe the instructions for Installation,

Operation, and Maintenance contained in this manual.

Warranty is valid only when genuine Goulds parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval is obtained in advance

from Goulds Pumps.

Supervision by an authorized Goulds representative is recommended to assure proper installation.

Additional manuals can be obtained by contacting your local Goulds representative or by calling 1-800-446-8537.

THIS MANUAL EXPLAINS

Proper Installation

n

Start-up Procedures

n

Operation Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Trouble Shooting

n

Ordering Spare or Repair Parts

n

3996 IOM 9/2010 5

Page 3

TABLE OF CONTENTS

9 SAFETY

13 GENERAL INFORMATION

17 INSTALLATION

21 OPERATION

27 PREVENTATIVE MAINTENANCE

33 DISASSEMBLY/REASSEMBLY

1

2

3

4

5

6

45 TROUBLESHOOTING

7

3996 IOM 9/2010 7

Page 4

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

www.gouldspumps.com/literature_ioms.html or by contacting

These manuals must be read and understood before installation and star t-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

S-1

Page 5

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazard o us. An y press ure vessel can explode,

rupture, or discharge its contents if sufficiently ove r press u r i zed causi n g deat h, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 6

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example:

Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoi ded, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 7

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

General Precautions

NEVER APPLY HEAT TO REMOVE IMPELLER. The use of heat may cause an

explosion due to trapped fluid, resulting in severe physical injury and property damage.

NEVER use heat to disassemble pump due to risk of explosion from trapped liquid.

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without prime.

ALWAYS lock out power to the driver befo re per fo rming pump maintenance.

NEVER operate pump without safety devices installed.

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT Goulds

Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts wit h shar p ed ges, especi al l y im pel l ers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift and

support equipment can result in serious physical injury and/or equipment d amage. Lif t

equipment only at specifically identified lifting points or as instructed in the current IOM.

Current manuals are available at

from your local ITT Goulds Pumps sales representative. Note: Lifting devices (eyebolts,

slings, spreaders, etc.) must be rated, selected, and used for the entire load being lifted.

www.gouldspumps.com/literature_ioms.html or

S-4

Page 8

WARNING

WARNING

CAUTION

General Precautions

Alignment:

Shaft alignment procedures must be followed to prevent catastrophic failure of drive

components or unintended contact of rotating parts. Follow coupling manufacturer’s

coupling installation and operation procedures.

Before beginning any alignment procedure, make sure driver power is locked out. Failure

to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flanged connections of the pump. This may

impose dangerous strains on the unit and cause misalignment between pump and driver.

Pipe strain will adversely effect the operation of the pump resulting in physical injury and

damage to the equipment.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the motor is

properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat generation,

and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting the

clearance or not following any of the proper procedures can result in sparks, unexpected

heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set screws

loosened prior to setting impeller clearance. Failure to do so could result in sparks, heat

generation, and mechanical seal damage.

The coupling used in an ATEX classified environment must be properly certified and

must be constructed from a non-sparking material.

WARNING

WARNING

CAUTION

S-5

Never operate a pump without coupling guard properly installed. Personal injury will

occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess heat

generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly certified.

Prior to start up, ensure all points of potential leakage of process fluid to the work

environment are closed.

Page 9

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

General Precautions

Never operate the pump without liquid supplied to mechanical seal. Running a mechanical

seal dry, even for a few seconds, can cause seal damage and must be avoided. Physical

injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the coupling

spacer is removed.

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or discharge

valve closed. These conditions may create an explosive hazard due to vaporization of

pumpage and can quickly lead to pump failure and physical injury.

Ensure pump is isolated from system and pressure is relieved before disassembling pump,

removing plugs, opening vent or drain valves, or disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to avoid

physical injury and/or equipment damage. Steel toed shoes must be worn at all times.

The pump may handle hazardous and/or toxic fluids. Observe proper decontamination

procedures. Proper personal protective equipment should be worn. Precautions must be

taken to prevent physical injury. Pumpage must be handled and disposed of in

conformance with applicable environmental regulations.

Operator must be aware of pumpage and safety precautions to prevent physical injury.

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent physical

injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550, or

3107, there may be a risk of static electric discharge from plastic parts that are not

properly grounded. If pumped fluid is non-conductive, pump should be drained and

flushed with a conductive fluid under conditions that will not allow for a spark to be

released to the atmosphere.

Wear heavy work gloves when handling impellers as sharp edges may cause physical

injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can cause

physical injury.

S-6

Page 10

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds represe ntative before proceeding.

Current IOMs are available at

Pumps Sales representative.

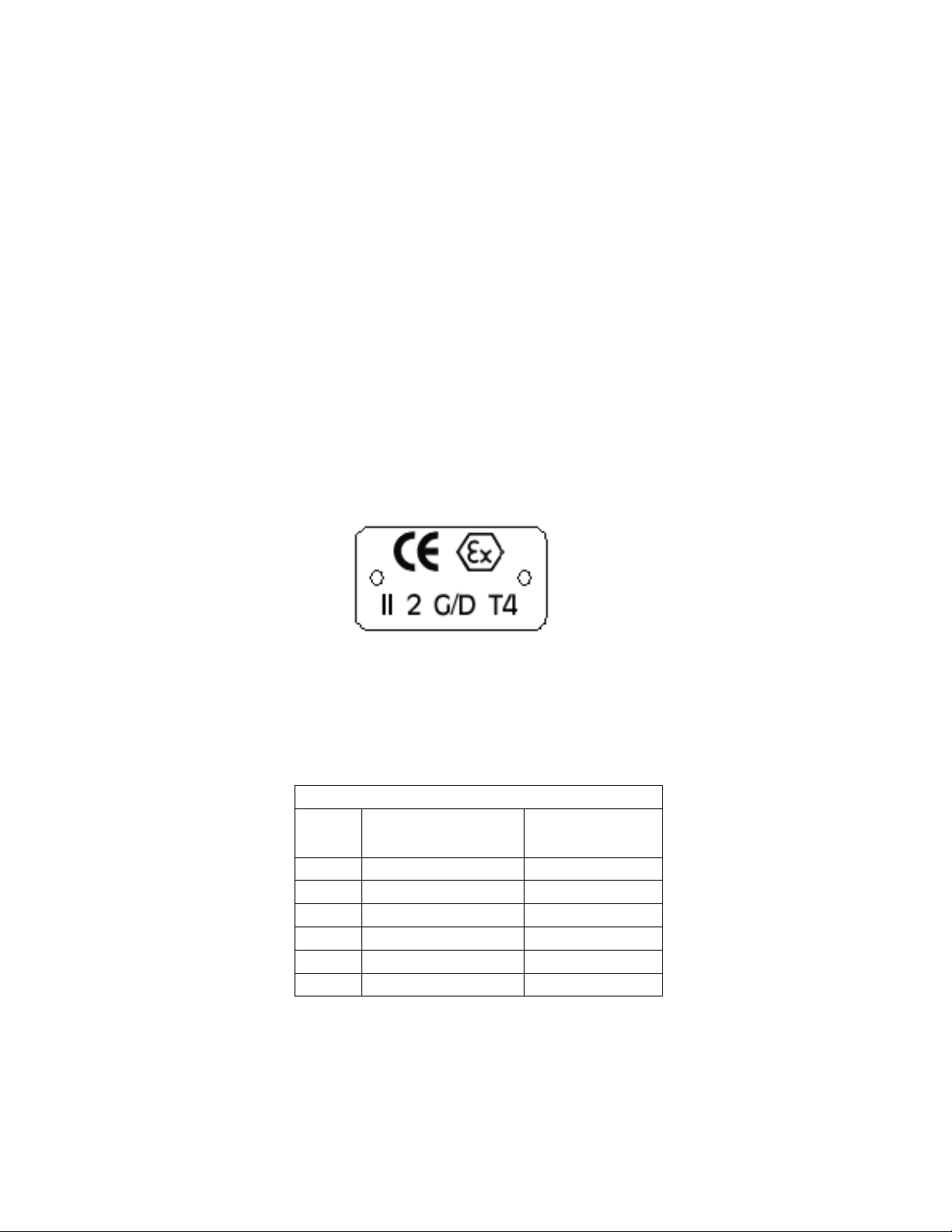

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

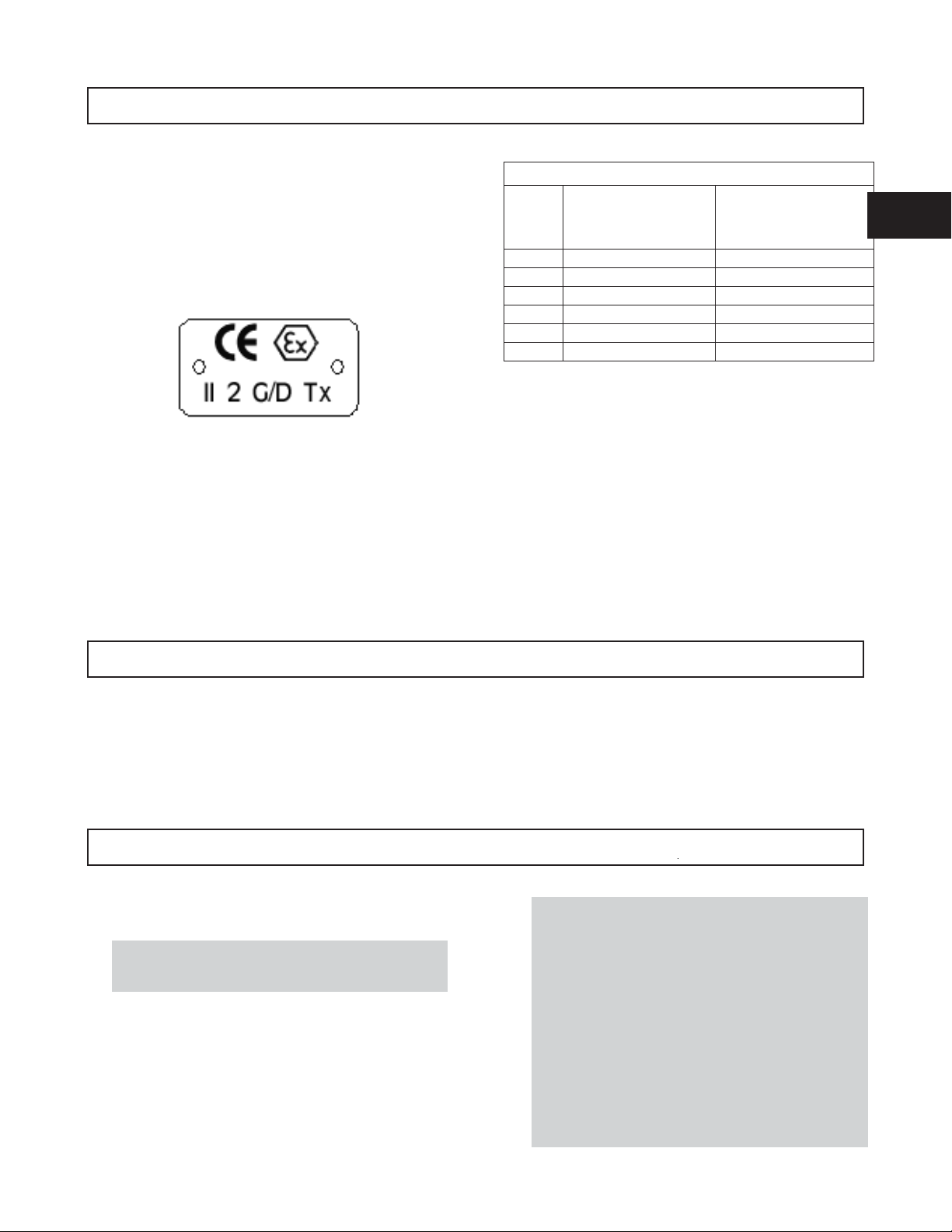

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 11

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 12

8 3996 IOM 9/2010

Page 13

SAFETY

DEFINITIONS......................................9

GENERAL PRECAUTIONS .............................10

EXPLOSION PREVENTION .............................10

SPECIAL ATEX CONSIDERATIONS........................10

ATEX IDENTIFICATION ..............................11

INTENDED USE ....................................11

CONDITION MONITORING ............................11

DEFINITIONS

1

These pumps have been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this manual. A

pump is a pressure containing device with rotating parts

that can be hazardous. Operators and maintenance

personnel must realize this and follow safety measures.

ITT Industries Goulds Pumps shall not be liable for

physical injury, damage or delays caused by a failure to

observe the instructions in this manual.

Throughout this manual the words WARNING,

CAUTION, ELECTRICAL, ATEX, and NOTE are

used to indicate procedures or situations which require

special operator attention:

! WARNING

s

Operating procedure, practice, etc. which, if not

correctly followed, could result in personal injury or

loss of life.

$

Operating procedure, practice, etc. which, if not

followed, could result in damage or destruction of

equipment.

CAUTION

EXAMPLES

! WARNING

s

Pump shall never be operated without coupling guard

installed correctly.

! CAUTION

$

Throttling flow from the suction side may cause

cavitation and pump damage.

Improper impeller adjustment could cause contact

!

between the rotating and stationary parts, resulting

in a spark and heat generation.

! WARNING

s

Lock out driver power to prevent electric shock,

accidental start-up and physical injury.

NOTE: Proper alignment is essential for long pump

life.

If equipment is to be installed in a potentially

!

explosive atmosphere and these procedures are not

followed, personal injury or equipment damage

from an explosion may result.

Particular care must be taken when the electrical

"

power source to the equipment is energized.

NOTE: Operating procedure, condition, etc. which is

essential to observe.

! WARNING

s

Particular care must be taken when the electrical

power source to the equipment is energized.

3996 IOM 9/2010 9

Page 14

GENERAL PRECAUTIONS

! WARNING

s

Personal injuries will result if procedures outlined in

this manual are not followed.

NEVER apply heat to remove impeller, It

may explode to due trapped liquid.

C

NEVER use heat to disassemble pump due to

risk of explosion from trapped liquid.

C

NEVER operate pump without coupling

AC

AD

guard correctly installed.

NEVER operate pump beyond the rated

conditions to which the pump was sold.

NEVER start pump without proper prime.

AD

EXPLOSION PREVENTION

AC

B

C

C

AC

AD

AC

NEVER run pump below recommended

minimum flow or when dry.

ALWAYS lock out power to the driver before

performing pump maintenance.

NEVER operate pump without safety devices

installed.

NEVER operate pump with discharge valve

closed.

NEVER operate pump with suction valve

closed.

DO NOT change conditions of service

without approval of an authorized Goulds

representative.

In order to reduce the possibility of accidental explosions in atmospheres containing explosive gasses and/or dust,

!

the instructions under the ATEX symbol must be closely followed. ATEX certification is a directive enforced in

Europe for non-electrical and electrical equipment installed in Europe. ATEX requirements are not restricted to

Europe. They are useful guidelines for equipment installed in any potentially explosive environment.

When pumping unit is installed in a potentially explosive atmosphere, the instructions after the Ex symbol must be

!

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there is any

question regarding these requirements or if the equipment is to be modified, please contact a Goulds representative

before proceeding.

SPECIAL ATEX CONSIDERATIONS

All installation and operation instructions in this manual

must be strictly adhered to. In addition, care must be

taken to ensure that the equipment is properly maintained.

This includes but is not limited to:

1. Monitoring the pump frame and liquid end

temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended

hydraulic range.

10 3996 IOM 9/2010

Page 15

ATEX IDENTIFICATION

For a pumping unit (pump, seal, coupling, motor and

pump accessories) to be certified for use in an ATEX

classified environment, the proper ATEX identification

must be present.

The ATEX tag will be secured to the pump or the

baseplate on which it is mounted. A typical tag will look

like this:

The CE and the EX designate the ATEX compliance.

The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T"x" =

Temperature class, can be T1 to T6

(see Table 1)

Table 1

Code Max permissible

surface temperature

o

F(oC)

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

The code classification marked on the equipment should

be in accordance with the specified area where the

equipment will be installed. If it is not, please contact

your ITT/Goulds representative before proceeding.

Max permissible

liquid temperature

oF(o

C)

1

INTENDED USEE

The ATEX conformance is only applicable when the

pump unit is operated within its intended use. All

instructions within this manual must be followed at all

times. Operating, installing or maintaining the pump unit

in any way that is not covered in this manual can cause

serious personal injury or damage to the equipment.

CONDITION MONITORINGG

For assistance in selecting the proper instrumentation and

its use, please contact your ITT/Goulds representative.

When installing in a potentially explosive

!

environment, ensure that the motor is properly

certified.

This includes any modification to the equipment or use of

parts not provided by ITT/Goulds. If there is any

question regarding the intended use of the equipment

please contact an ITT/Goulds representative before

proceeding.

For additional safety precautions, and where noted

!

in this manual, condition monitoring devices

should be used. This includes, but is not limited

to:

·

Pressure gauges

·

Flow meters

·

Level indicators

·

Motor load readings

·

Temperature detectors

·

Bearing monitors

·

Leak detectors

·

PumpSmart control system

3996 IOM 9/2010 11

Page 16

12 3996 IOM 9/2010

Page 17

GENERAL INFORMATION

INTRODUCTION ...................................13

Importance of Instructions ..............................13

Receiving Inspection.................................13

Preservation and Storage ..............................13

Handling Techniques ................................13

RECEIVING THE PUMP ...............................14

NAMEPLATE INFORMATION ...........................15

INTRODUCTION

2

This instruction manual is intended to assist those

involved with the installation, operation, and maintenance

of Goulds Model 3996 pumps. It is recommended that

this manual be thoroughly reviewed prior to installing or

performing any work on the pump or motor.

IMPORTANCE OF INSTRUCTIONS

The design, material and workmanship incorporated in

the construction of Goulds pumps makes them capable of

giving long, trouble-free service. The life and satisfactory

service of any mechanical unit, however, is enhanced and

extended by correct application, proper installation,

periodic inspection and careful maintenance. This

instruction manual was prepared to assist operators in

understanding the construction and correct methods of

installing, operating and maintaining these pumps.

Study thoroughly the following sections and carefully

follow the instructions for installation and operation.

Keep this instruction manual handy for reference. Further

information can be obtained by contacting the

Engineering Application Division, Goulds Pumps, Inc.,

Seneca Falls, New York 13148, or your local branch

office.

! WARNING

s

Goulds Pumps will not be liable for any damages or

delay caused by failure to comply with the provisions

of this instruction manual. This pump is not to be

operated at speeds, working pressures, discharge

pressures or temperatures higher than, nor used with

liquids other than stated in the original order

acknowledgement without written permission of

Goulds Pumps.

RECEIVING INSPECTION

Care should be taken when unloading pumps. If shipment

is not delivered in good order and in accordance with the

Bill-of-Lading, note the damage or shortage on both

receipt and freight bill. MAKE ANY CLAIMS TO THE

TRANSPORTATION COMPANY PROMPTLY.

Instruction sheets on various components as well as the

Installation, Operation and Maintenance (IOM) Manual

for the pump are included in the shipment. DO NOT

DISCARD!

PRESERVATION AND STORAGE

Goulds' normal domestic storage preparation is suitable

for protecting the pump during shipment in covered

trucks. It also provides protection during covered storage

at the jobsite, and for a short period between installation

and start-up.

If the pump is to be idle and exposed to the elements for

an extended period, either before or after installation,

special precautions are required. One approach is to

provide special preservatives and wrapping before

shipment. However, after installation, the protective

wrappings will have been removed. Therefore,

application of preservatives after installation is considered

a good practice. Information about various long-term

preservation and storage options available can be obtained

from your local Goulds representative.

The driver, coupling, and mechanical seal manufacturers

should be contacted for their recommendations on

preservations and protection procedures.

HANDLING TECHNIQUES

Care should be used in moving pumps. Where required

by size of units, slings should be put under both pump and

motor, as shown in Figures 1, 2, and 3 on the next page.

3996 IOM 9/2010 13

Page 18

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Carefully

check that everything is in good order. Make notes of

damaged or missing items on the receipt and freight bill.

File any claims with the transportation company as soon

as possible.

STORAGE REQUIREMENTS

Short Term (Less than 6 months)

Goulds normal packaging procedure is designed to

protect pump during shipping. Upon receipt, store in a

covered and dry location.

Long Term (More than 6 months)

Preservative treatment of bearings and machined surfaces

will be required. Rotate shaft several times every 3

months. Refer to driver and coupling manufacturers for

their long term storage procedures. Store in a covered

and dry location.

NOTE: Long term storage treatment may be

purchased with initial pump order.

HANDLING

! WARNING

s

Pump and components are heavy. Failure to properly

lift and support equipment could result in serious

physical injury, or damage to pumps.

Units with drivers mounted are moved with slings under

the pump casing and driver (Figs. 2 and 3).

Fig. 2

Or with hooks through the holes in the frame mounted

support or with slings through the large openings in the

casing mounted support.

Use care when moving pumps. Lifting equipment must be

able to adequately support the entire assembly. Hoist bare

pump using suitable hooks through the holes in the frame

mounted support or suitable slings through the large

openings in the casing mounted support (Fig. 1).

Fig. 1

Fig. 3

! WARNING

s

Units with drivers mounted can be top heavy. Driver

weight could cause the assembled unit to overturn

and could result in serious physical injury, or damage

to pumps.

14 3996 IOM 9/2010

Page 19

NAMEPLATE INFORMATION

Every pump has two Goulds nameplates that provide

information about the pump. The tags are located on the

casing and bearing frame.

Description Fig. No. Example

Pump Casing Tag - provides information

about the pump’s hydraulic

characteristics. Note the format of the

pump size: Discharge x Suction - Nominal

maximum Impeller Diameter in inches.

(Example: 2x3-8)

(Figs.4&5).

Fig. 4

English

Fig. 5

Metric

When ordering spare parts, you will need to identify

pump model, size, serial number, and the item number of

required parts. Information can be taken from the pump

casing tag. Item numbers can be found in this manual.

2

Bearing Frame Tag - provides

information on the lubrication system used

(Fig. 6).

ATEX Tag - If applicable, your pump

unit may have the following ATEX tag

affixed to the pump and/or baseplate. See

the Safety section for a description of the

symbols and codes

(Fig. 7).

3996 IOM 9/2010 15

Fig. 6

Fig. 7

Page 20

16 3996 IOM 9/2010

Page 21

INSTALLATION

SITE/FOUNDATION .................................17

Location .......................................17

Foundation and Baseplate ..............................17

PIPING .........................................17

ALIGNMENT .....................................19

When pumping unit is installed in a potentially explosive atmosphere, the instructions after the Ex symbol must be

!

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there is any

question regarding these requirements or if the equipment is to be modified, please contact a Goulds representative

before proceeding.

SITE/FOUNDATION

LOCATION

Pumping unit should be placed as close as practical to the

source of supply. Floor space and head room allotted to

the unit must be sufficient for inspection and

maintenance. Be sure to allow for crane or hoist service.

All equipment being installed must be properly

!

grounded to prevent unexpected static electric

discharge.

PIPING

Guidelines for piping are given in the “Hydraulic Institute

Standards,” available from:

Hydraulic Institute

30200 Detroit Road

Cleveland, OH 44145-1967

and must be reviewed prior to pump installation.

! WARNING

A

s

Never draw piping into place by forcing at the

flanged connections of the pump. This may impose

dangerous strains on the unit and cause misalignment between pump and driver. Pipe strain will

adversely affect the operation of the pump resulting

in physical injury and damage to the equipment.

1. Piping runs should be as short as possible to

minimize friction losses.

2. It is suggested that expansion loops be properly

designed and installed in suction and/or discharge

lines when handling liquids at elevated temperatures,

so thermal expansion of piping will not draw pump

out of alignment.

FOUNDATION AND BASEPLATE

Model 3996 In-Line pumps are designed to be mounted

directly in, and supported by the piping. No supports

under the pump are required. Pipe supports should be

located close to the pump and be designed to support the

weight of the complete unit (pump and motor).

3. The piping should be arranged to allow pump

flushing prior to removal of the unit on services

handling hazardous liquids.

4. Carefully clean all pipe parts, valves and fittings, and

pump branches prior to assembly.

5. All piping must be supported independently of, and

line up naturally with, the pump flanges. Table 2

shows piping flange alignment criteria.

Table 2

Piping Flange Alignment

Type Criteria

Axial

Parallel

Concentric

6. Bottom of casing should be supported by a solid

foundation or casing feet should be used.

Flange gasket thickness ± 0.8 mm (.03 in.).

0.001 mm/mm (.001 in./in.) of flange

diameter to a maximum of 0.8 mm (.03 in.).

Flange bolts should easily install by hand.

3

3996 IOM 9/2010 17

Page 22

SUCTION PIPING

!

s

A

NPSHAmust always exceed NPSHRas shown on

Goulds performance curves received with order.

(Reference Hydraulic Institute for NPSH and pipe

friction values needed to evaluate suction piping).

CAUTION

Suction Head/Flooded Suction Conditions

1. An isolation valve should be installed in the suction

line at least two (2) pipe diameters from the pump

suction to permit closing of the line for pump

inspection and maintenance.

2. Keep suction pipe free from air pockets.

$

A

Pump must never be throttled from suction side.

Properly designed and installed suction piping is a

necessity for trouble-free pump operation. Suction piping

should be flushed BEFORE connection to the pump.

1. Use of elbows close to the pump suction flange

should be avoided. There should be a minimum of

two (2) pipe diameters of straight pipe [five (5) pipe

diameters is preferred] between the elbow and

suction inlet. Where used, elbows should be long

radius.

2. Use suction pipe one (1) or two (2) sizes larger than

the pump suction, with a reducer at the suction

flange. Suction piping should never be of smaller

diameter than the pump suction.

3. Reducers, if used, should be eccentric and located at

the pump suction flange with sloping side down.

4. A suction screen should be installed prior to initial

start-up and when suction system has been opened

for work. The screen should be of the cone type with

a net area equal to at least three (3) times the cross

sectional area of the suction pipe. The mesh of the

screen should be sized to prevent particles larger than

1.6 mm (1/16 in.) from entering the pump and should

be installed in a spool piece to allow removal for

cleaning. The screen should remain in the system

until periodic inspection shows system is clean.

5. Separate suction lines are recommended when more

than one pump is operating from the same source of

supply.

Suction Lift Conditions

1. Suction pipe must be free from air pockets.

2. Suction piping must slope upwards to pump.

CAUTION

3. Piping should be level or slope gradually downward

from the source of supply.

4. No portion of the piping should extend below pump

suction flange.

5. The size of entrance from supply should be one (1) or

two (2) sizes larger than the suction pipe.

6. The suction pipe must be adequately submerged

below the liquid surface to prevent vortices and air

entrainment at the supply.

DISCHARGE PIPING

Properly designed and installed discharge piping is a

necessity for trouble-free pump operation. Discharge

piping should be flushed BEFORE connection to

the pump.

1. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump; this will permit inspection

of the check valve. The isolation valve is required

for priming, regulation of flow, and for inspection

and maintenance of pump. The check valve prevents

pump or seal damage due to reverse flow through the

pump when the driver is turned off.

2. Increasers, if used, should be placed between pump

and check valves.

3. Cushioning devices should be used to protect the

pump from surges and water hammer if quick-closing

valves are installed in system.

BYPASS PIPING

Systems that require operation at reduced flows for

prolonged periods should be provided with a bypass line

connected from the discharge side (before any valves) to

the source of suction.

3. All joints must be air tight.

4. A means of priming the pump must be provided.

A minimum flow orifice can be sized and installed in

bypass line to preclude bypassing excessive flows.

Consult nearest sales office or factory for assistance in

sizing orifice.

An automatic recirculation control valve and/or solenoid

operated valve should be considered if a constant bypass

(i.e. orifice) is not possible.

18 3996 IOM 9/2010

Page 23

AUXILIARY PIPING

Auxiliary piping may be required for seal chamber cover

cooling, mechanical seal flush or other special features

supplied with the pump. Consult pump data sheet for

specific auxiliary piping recommendations.

If seal chamber cover cooling is required, follow guidelines

listed below.

1. Flows of 4 l/min. (1 GPM) will generally satisfy

cooling requirements.

2. Cooling water pressure should not exceed

2

7.0 kg/cm

(100 psig).

ALIGNMENT

FINAL PIPING CHECK

After connecting the piping to pump:

1. Rotate shaft several times by hand to be sure that

there is no binding and all parts are free.

2. Check alignment, per alignment criteria outlined

previously, to determine if pipe strain has affected

alignment. If pipe strain exists, correct piping.

Alignment between pump and motor is built in by use of

machined lock fit between the C-face motor and motor

support. No further alignment is normally required.

There is one exception to this. The Model 3196

horizontal ANSI pump bearing frame can be used in the

Model 3996. This frame may be used in emergencies or

when it is desired to minimize inventory. The Model

3196 frame will not give built-in alignment, and normal

alignment procedures must be performed. The Model

3196 frame can be identified by the foot and cooling

jacket on the side.

SHAFT ALIGNMENT

Many users now require a 0.002" T.I.R. alignment to gain

a greater mean time between failure (MTBF). All 3996’s

that have been shipped after 1/9/90 have been aligned at

the factory to .002" T.I.R.

Assembly procedures have been developed to align the

pump shaft and the driver shaft to .002" T.I.R. Each

pump is assembled using a torque range of +

recommended torque value of the bolts. If .002" T.I.R.

alignment is required by the customer, a final alignment

must be done in the field.

10% of the

3. Move shaft assembly (shaft, housing, and impeller)

away from casing angle face, by adjusting the

bearing housing. A 1/4 turn of bearing housing jack

bolts is sufficient to ensure the impeller does not ride

on the casing angle face. Proper indication cannot be

done with the impeller touching the angle face.

4. Tighten motor hold down bolts in a criss cross

pattern to the recommended torque.

(Refer to the torque values listed in Table 3.)

5. Tighten the motor support bolts in a criss cross

pattern to 90% of the recommended torque value of

the bolts. For example, if the recommended torque

value for the bolts is 60 ft.-lbs., tighten bolts to 54

ft.-lbs.

6. Tighten casing bolts in a criss cross pattern to 90% of

the recommended torque value.

7. Attach a dial indicator to the driver shaft and mark

the pump shaft so the indicator always contacts the

same location on the pump shaft.

8. Rotate both shafts in the same direction and record

the indicator readings every 90° degrees (4 places).

3

The following is the procedure that has been developed

for the use in the field and on our assembly floor to obtain

0.002" shaft to shaft alignment.

3996 Shaft Alignment Procedure

1. Inspect all machined fits for signs of contamination

or damage. All fits must be clean. If the pump is

new this step is not necessary.

2. Loosen all motor, motorsupport, and casing bolts, but

do not remove.

NOTE: Make sure jack bolts on the casing are

backed off.

3996 IOM 9/2010 19

9. Incrementally increase the torque value and begin to

tighten the necessary bolts to bring the shafts into

alignment. Do no exceed 110% of the recommended

torque values. After each series of tightening, repeat

Step #5 until the desired alignment is achieved.

NOTE: Indicate off the hub to the motor lock I.D., in

the motor support, when supplying the pump less

motor.

10. Reset the clearance between the impeller and casing

angle face to .008 (.015 if using the high temperature

option). Ensure the bearing housing jack bolts are

secured.

Page 24

NOTE: Tighten coupling bolts and hub set screw

onto shaft. Torquing of these components is not done

at the factory, yet is required at the site. Please

reference the coupling manufacturers instructions for

correct torque levels.

Table 3

Fastener Size and Recommended

Torque Values

Fastener

Standard

SAE

1

Torque values shown for SAE fasteners are based on

dry threads at 75% of proof load for ASTM307

Grades A and B (SAE Grade 1) fasteners.

For lubricated, plated, or PFTE-coated threads, use

75% of torque values shown.

Fastner

Nominal Size

5

16

3

8

7

16

1

2

5

8

3

4

7

8

1 228

Recommended

Torque

6

10

18

27

53

94

152

1

lb.-ft.

20 3996 IOM 9/2010

Page 25

OPERATION

PREPERATION FOR STARTUP ..........................21

Checklist .......................................21

STARTING PUMP...................................25

OPERATION ......................................25

SHUTDOWN ......................................26

FINAL ALIGNMENT .................................26

PREPARATION FOR STARTUP

CHECKLIST

When installing in a potentially explosive

!

environment, ensure that the motor is properly

certified.

1. Checking Rotation

$

Serious damage may result if pump is run in the

wrong rotation.

a. Lock out power to driver.

! WARNING

s

Lock out driver power to prevent accidental start-up

and physical injury.

b. Make sure coupling hubs are securely fastened to

the shafts and the coupling spacer has been

removed.

NOTE: Pump is shipped with coupling spacer

removed.

c. Unlock driver power.

d. Make sure everyone is clear. Jog driver just long

enough to determine the direction of rotation.

Rotation must correspond to arrow on bearing

housing.

CAUTION

See Preventive Maintenance section for lubrication

recommendations.

Pure Oil Mist Lubrication

Pure oil mist is an optional feature for the Model 3996.

Follow oil mist generator manufacturer’s instructions.

The inlet and outlet connections are located on the side of

the bearing frame.

See Preventive Maintenance section for lubrication

recommendations and connection locations.

! WARNING

s

Operation of the unit without proper lubrication will

cause bearing failure and pump seizure.

3. Alignment - As described in the Alignment section,

alignment is normally built-in and need not be

rechecked.

4. Stuffing Box - Pumps are shipped without packing,

lantern ring or split gland installed. These are

included with the box of fittings shipped with the

pump and must be installed before start-up.

Packed stuffing boxes are not allowed in an ATEX

!

classified environment.

4

e. Lock out power to driver.

2. Lubrication

Bearings must be lubricated properly in order to

!

prevent excess heat generation, sparks and

premature failure.

Grease Lubrication

Greased lubricated ball bearings are standard on the

Model 3996 units.

The bearings are greased at the factory.

3996 IOM 9/2010 21

The mechanical seal used in an ATEX classified

!

environment must be properly certified.

a. Packing - Stuffing box packing, lantern ring and

gland are in the box of fittings supplied with the

pump. Install 3 rings of packing, the two piece

lantern ring (notched sides facing), 2 more rings

of packing and the gland. Twist rings sideways

instead of straight out when putting them on the

shaft to avoid damaging them. Seat each ring

firmly as it is installed, and stagger the joints

90°. Gland should be drawn up only finger tight.

Page 26

Packing must not run dry. If the pumped liquid

is clean, gland leakage of 40-60 drops per minute

is satisfactory. If the liquid is dirty, connect a

clean liquid flush to the lantern ring connection

to keep solids out of the packing.

Occasionally, the stuffing box is below

atmospheric pressure (suction under vacuum,

etc.). Under these conditions, supply sealing

liquid through a line from the discharge of the

pump to the lantern ring connection. Leakage

from the box can be piped away through the ½

inch drain connection in the casing.

b. Mechanical Seals - When mechanical seals are

supplied, they are installed in the pump.

Mechanical seals must not run dry, or in

abrasives. Connect recirculation, flush and/or

cooling flows as required, following instructions

on the seal print supplied for the order.

5. Stuffing Box Lubrication/Cooling - Check to be

sure that any required auxiliary piping is installed and

functioning. If cooling and/or flushing from an

outside source is being used, establish these flows.

6. Check Impeller Clearance -

Table 4

Impeller Clearances

Cold Temperature Clearances for Various

Service Temperatures

3996

Service

Temperature

From -20 to

150°F (-29 to

66°C)

Up to 175°F

(79°C)

Up to 200°F

(93°C)

Up to 250°F

(121°C)

Up to 300°F

(149°C)

Up to 350°F

(177°C)

ST MT

inches mm inches mm

0.005 0.13 0.008 0.20

0.005 0.13 0.008 0.20

0.005 0.13 0.008 0.20

0.006 0.16 0.009 0.23

0.007 0.19 0.010 0.26

0.009 0.22 0.012 0.29

The impeller clearance setting procedure must be

!

followed. Improperly setting the clearance or not

following any of the proper procedures can result

in sparks, unexpected heat generation and

equipment damage.

Prior to starting the pump, the impeller clearance

must be checked. The pump efficiency is maintained

when the proper impeller clearance is set. The

optimum hydraulic performance is attained by setting

the impeller front clearance at the factory to

predetermined limits which are consistent with

service conditions.

The maximum impeller setting should not be set

more than .005 inch (0.13) above values in Table 4 or

significant performance degredation will result.

Service temperature in an ATEX classified

!

environment is limited to the area classification

specified on the ATEX tag affixed to the pump

(reference Table 1 in the Safety section for ATEX

classifications).

Also, for pumpage temperatures above 200° F (93°

C) the cold (ambient) setting must be increased per

Table 4. This is necessary to prevent the impeller

from contacting the casing due to differential

expansion from the higher operating temperatures.

Up to 400°F

(204°C)

Up to 450°F

(232°C)

Up to 500°F

(260°C)

7. Couple Pump and Driver

! WARNING

s

Lock out driver power to prevent accidental rotation

and physical injury.

0.01 0.25 0.013 0.32

0.011 0.28 0.014 0.35

0.012 0.30 0.015 0.38

Fig. 8

22 3996 IOM 9/2010

Page 27

The coupling used in an ATEX classified

!

environment must be properly certified.

a. Install and lubricate coupling per manufacturer’s

instructions.

Fig. 9

! WARNING

s

Never operate a pump without coupling guard

properly installed. Refer to Appendix II for coupling

guard installation instructions. Personal injury will

occur if pump is run without coupling guard.

8. Priming - Never start the pump until it has been

properly primed. Several different methods of priming

can be used, depending upon type of installation and

service involved.

Pumps must be fully primed at all times during

!

operation.

Suction Supply Above Pump

1. Slowly open the suction valve (Fig. 8).

2. Open air vents on the suction and discharge piping,

casing, seal chamber, and seal piping, if provided, until all

air is vented and only liquid flows out.

3. Close the vents.

Suction Supply Below Pump

A foot valve and outside source of liquid may be used to

prime the pump. Outside source of liquid can come from

a priming pump, pressurized discharge line, or other

supply (Fig. 9 and 10).

Fig. 10

b. Install coupling guard. Refer to Coupling Guard

Installation and Disassembly Section Appendix

II.

1. Close discharge valve and open air vents in suction

and discharge piping, casing, seal chamber and seal

piping, if provided.

2. Open valve in outside supply line until all air is

vented and only liquid flows out.

! WARNING

s

When handling hazardous and/or toxic fluids, proper

personal protective equipment is required. If pump is

being drained, precautions must be taken to prevent

physical injury. Pumpage must be handled and

disposed of in conformance with applicable

regulations.

3. Close the vents and then the outside supply line.

Other Methods of Priming Pump

Priming by ejector.

·

Priming by automatic priming pump.

·

4

The coupling guard used in an ATEX classified

!

environment must be constructed from a

non-sparking material.

3996 IOM 9/2010 23

Page 28

START-UP PRECAUTIONS

1. All equipment and personal safety related devices and

controls must be installed and operating properly.

2. To prevent premature pump failure at initial start-up

due to dirt or debris in the pipe system, ensure the

pump can be run continuously at full speed and flow

for 2 to 3 hours.

3. Variable speed drivers should be brought to rated

speed as quickly as possible.

4. Variable speed drivers should not be adjusted or

checked for speed governor or overspeed trip settings

while coupled to the pump at initial start-up. If

settings have not been verified, uncouple the unit and

refer to driver manufacturer’s instructions for

assistance.

5. Pumpage temperatures in excess of 93° C (200° F) will

require warm-up of pump prior to operation. Circulate a

small amount of pumpage through the pump until the

casing temperature is within 38° C (100° F) of the

pumpage temperature and evenly heated.

NOTE: Warm-up rate should not exceed 1.4° C

(2.5° F) per minute.

24 3996 IOM 9/2010

Page 29

STARTING PUMP

1. Make sure suction valve and any recirculation or

cooling lines are open.

2. Fully close or partially open discharge valve as

dictated by system conditions.

3. Start Driver.

!

$

A

Immediately observe pressure gauges. If discharge

pressure is not quickly attained - stop driver, reprime

and attempt to restart.

CAUTION

OPERATION

GENERAL CONSIDERATIONS

! CAUTION

$

A

Always vary capacity with regulating valve in the

discharge line. NEVER throttle flow from the suction

side.

! CAUTION

$

A

Driver may overload if the pumpage specific gravity

(density) is greater than originally assumed, or the

rated flow rate is exceeded.

4. Slowly open discharge valve until the desired flow

is obtained.

!

$

A

Observe pump for vibration levels, bearing

temperature and excessive noise. If normal levels are

exceeded, shut down and resolve.

CAUTION

OPERATING AT REDUCED

CAPACITY

! WARNING

s

DO NOT operate pump below minimum rated flows

or with suction and/or discharge valve closed. These

conditions may create an explosive hazard due to

vaporization of pumpage and can quickly lead to

pump failure and physical injury.

! CAUTION

$

A

Damage occurs from:

4

! CAUTION

$

A

Always operate the pump at or near the rated

conditions to prevent damage resulting from

cavitation or recirculation.

1. Increased vibration levels - Affects bearings,

stuffing box or seal chamber, and mechanical seal.

2. Increased radial loads - Stresses on shaft and

bearings.

3. Heat build up - Vaporization causing rotating parts to

score or seize.

4. Cavitation - Damage to internal surfaces of pump.

OPERATING UNDER FREEZING

CONDITIONS

Exposure to freezing conditions, while pump is idle,

could cause liquid to freeze and damage the pump.

Liquid inside pump should be drained. Liquid inside

cooling coils, if supplied, should also be drained.

3996 IOM 9/2010 25

Page 30

SHUTDOWN

1. Slowly close discharge valve.

2. Shut down and lock driver to prevent accidental

rotation.

FINAL ALIGNMENT

Alignment procedures must be followed to prevent

!

unintended contact of rotating parts. Follow

coupling manufacturer's coupling installation and

operation procedures.

1. Run the unit under actual operating conditions for a

sufficient length of time to bring the pump and driver

and associated system up to operating temperature.

! WARNING

s

When handling hazardous and/or toxic fluids, proper

personal protective equipment should be worn. If

pump is being drained, precautions must be taken to

prevent physical injury. Pumpage must be handled

and disposed of in conformance with applicable

environmental regulations.

2. Remove coupling guard. Refer to coupling guard

installation and disassembly instructions in Appendix

II.

3. Check alignment while unit is still hot per alignment

procedure in the Installation Section.

4. Reinstall coupling guard.

26 3996 IOM 9/2010

Page 31

PREVENTIVE MAINTENANCE

GENERAL COMMENTS ...............................27

MAINTENANCE SCHEDULE ............................27

LUBRICATION ....................................28

MAINTENANCE OF BEARINGS ..........................28

IMPELLER CLEARANCE SETTING........................31

VIBRATION ......................................32

GENERAL COMMENTS

A routine maintenance program can extend the life of your pump. Well maintained equipment

will last longer and require fewer repairs. You should keep maintenance records, this will help

pinpoint potential causes of problems.

The preventive maintenance section must be adhered to in order to keep the applicable ATEX classification of the

!

equipment. Failure to follow these procedures will void the ATEX classification for the equipment.

MAINTENANCE SCHEDULE

ROUTINE MAINTENANCE

Bearing lubrication

·

Seal monitoring

·

Vibration analysis

·

Discharge pressure

·

Temperature monitoring

·

ROUTINE INSPECTIONS

Check level and condition of oil through sight glass

·

on bearing frame.

Check for unusual noise, vibration and bearing

·

temperatures.

Inspect pump and piping for leaks.

·

Check seal chamber/stuffing box leakage.

·

Mechanical Seal: Should be no leakage.

Packing: Excessive leakage requires adjust

ment or possible packing replacement. Re

fer to Section 4 - Operation for packing

gland adjustment.

3 MONTH INSPECTIONS

Check the foundation and the hold-down bolts for

·

tightness.

5

If the pump has been left idle, check the packing.

·

Replace if required.

Oil should be changed at least every 3 months (2000

·

hours) or more often if there are any adverse

atmospheric conditions or other conditions which

might contaminate or break down the oil. If it is

cloudy or contaminated as seen by inspection

through the sight glass, it should be changed

immediately.

Check the shaft alignment. Realign if required.

·

ANNUAL INSPECTIONS

Check the pump capacity, pressure and power. If

·

pump performance does not satisfy your process

requirements, and the process requirements have not

changed, the pump should be disassembled,

-

-

inspected, and worn parts should be replaced.

Otherwise, a system inspection should be done.

INSPECTION INTERVALS

Inspection intervals should be shortened appropriately if

the pumpage is abrasive and/or corrosive,

or if the environment is classified as potentially

!

explosive.

3996 IOM 9/2010 27

Page 32

LUBRICATION

Pump bearings are normally grease lubricated and are

lubricated at the factory. Regrease at approximately 3-6

month intervals, until grease comes out the oil caps which

MAINTENANCE OF BEARINGS

Do not insulate bearing housings as this can result

!

in excess heat generation, sparks, and premature

failure.

Service temperature in an ATEX classified environ-

!

ment is limited to the area classification specified on

the ATEX tag affixed to the pump (reference Table 1

in the Safety section for ATEX classifications).

GREASE LUBRICATED BEARINGS

Grease lubricated bearings are pre-lubricated at the

factory. Regrease bearings every 2000 operating hours

or 3 months, whichever occurs first.

Regrease Procedure

NOTE: When regreasing there is danger of

impurities entering the bearing housing. The grease

container, the greasing device, and fittings must be

clean.

1. Wipe dirt from both grease fittings (Fig. 11).

2. Remove two grease relief plugs from side of frame

opposite grease fittings.

3. Fill both grease cavities through grease fittings with

recommended grease until fresh grease comes out of

the relief holes. Reinstall grease relief plugs until

immediately prior to starting pump.

serve as grease relief fittings. Use a sodium or lithium

base grease, NLGI #2 consistency. Follow motor and

coupling manufacturer's lubrication instructions.

NOTE: The bearing temperature usually rises after

regreasing due to an excess supply of grease. Temperatures will return to normal after pump has run and

purged the excess from the bearings, usually two to

four hours. Grease relief plugs should be removed

during this period, and replaced when temperature

has stabilized.

For most operating conditions a lithium based mineral oil

grease of NLGI consistency number 2 is recommended.

This grease is acceptable for bearing temperatures of

-15°C to 110°C (5°F ro 230°F).

Bearing temperatures are generally about 20°F (18°C)

higher than bearing housing outer surface temperature.

Some acceptable greases are:

NLGI Consistency 2

Exxon Unirex N2

Mobil Mobilux EP2

Sunoco Multipurpose EP

SKF LGMT 2

! CAUTION

$

Never mix greases of different consistency (NLGI 1

or 3 with NLGI 2) or different thickener. For

example, never mix a lithium base grease with a

polyurea base grease.

NOTE: If it is necessary to change grease type or

consistency, the pump must be disassembled and the

old grease removed from the bearings.

Fig. 11

28 3996 IOM 9/2010

Page 33

PURE OIL MIST LUBRICATED

BEARINGS (OPTIONAL)

! WARNING

s

Pumps are shipped without oil. Oil mist lubricated

bearings must be lubricated at the job site.

Some acceptable oils are:

Exxon Teresstic EP68

Mobil

Mobil DTE 26 300 SSU

@ 40°C (100°F)

1. Follow oil mist system supplier’s instructions.

2. Connect oil mist supply lines to upper and center

tapped connection.

3. Connect drain line to bottom tapped connection

(Fig. 12).

Oil mist lubrication is required above pumpage

temperature of 232°C (450° F), but may be used at lower

temperatures.

A high quality turbine oil with rust and oxidation

inhibitors should be used. For the majority of operational

conditions, bearing temperatures will run between 50°C

(120°F) and 82°C (180°F). In this range, an oil of ISO

viscosity grade 68 at 40°C (100°F) is recommended. If

bearing temperatures exceed 82°C (180°F), use ISO

viscosity grade 100.

Sunoco Sunvis 968

Royal Purpal

SYNFILM ISO VG 68

Synthetic Lube

Fig. 12

5

STUFFING BOX

PACKED STUFFING BOX

Periodically inspect stuffing box to see that there is

sufficient leakage to lubricate the packing and maintain a

cool box. Never draw up packing so that the stuffing box

heats, as this will cause damage to both packing and

sleeve. Draw up gland nuts slowly and evenly and only

when pump is running.

MAINTENANCE OF SHAFT SEALS

The mechanical seal used in an ATEX classified

!

environment must be properly certified.

The mechanical seal must be properly flushed.

!

Failure to do so will result in excess heat

generation and seal failure.

MECHANICAL SEALS

When mechanical seals are furnished, a manufacturer’s

reference drawing is supplied with the data package. This

After pump has been in operation for some time and the

packing has been completely “run-in”, at least 40 to 60

drops per minute of the liquid should be allowed to trickle

from the stuffing box at all times for cooling and

lubricating the packing and shaft sleeve.

drawing should be kept for future use when performing

maintenance and adjusting the seal. The seal drawing will

also specify required flush liquid and attachment points.

The seal and all flush piping must be checked and

installed as needed prior to starting the pump.

The life of a mechanical seal depends on various factors

such as cleanliness of the liquid handled and its

lubricating properties. Due to the diversity of operating

conditions it is, however, not possible to give definite

indications as to its life.

3996 IOM 9/2010 29

Page 34

! WARNING

s

Never operate the pump without liquid supplied to

mechanical seal. Running a mechanical seal dry,

even for a few seconds, can cause seal damage and

must be avoided. Physical injury can occur if

mechanical seal fails.

PACKED STUFFING BOX

Packed stuffing boxes are not allowed in an ATEX

!

classified environment.

Packing operation can be inspected without shutting

down or disassembling the pump. During normal

operation the packing should leak approximately one drop

per minute. If the drip rate is higher or lower than one

drop per minute then an adjustment of the gland may be

required. To slow down the leakage rate, the two gland

bolts should be tightened evenly one-quarter (¼) turn

each until the desired leakage rate is obtained. NEVER

over-tighten packing to the point where less than one drop

per minute is observed. Overtightening can cause

excessive wear and power consumption during operation.

If the packing cannot be tightened to obtain less than two

drops per minute, then the packing may need to be

replaced and the packing installation procedures under

Operation should be followed.

Dynamic Seal with Packing

Fig. 13

Static Seal - A static seal is used to prevent leakage when

the pump is shut down. This is either a lip seal,

elastomeric face seal, or graphite packing. The lip and

elastomeric face seal require no maintenance other than

replacement when leakage becomes excessive. The

packing should be installed as stuffing box packing. It is a

special type designed to run dry, so it does not require an

external flush.

! CAUTION

$

Never attempt to replace packing until the driver is

properly locked out and the coupling spacer is

removed.

DYNAMIC SEAL

Dynamic seals are not allowed in an ATEX

!

classified environment.

Dynamic Seal Components

Repeller - The dynamic repeller effectively prevents

leakage of pumpage through the stuffing box when the

pump is operating under published acceptable conditions.

Dynamic seal parts do not wear substantially to affect

operation unless the service is particularly abrasive or

corrosive. Refer to Disassembly and Reassembly Section

for maintenance, disassembly, and repair.

Dynamic Seal with Chekseal™

Fig. 14

30 3996 IOM 9/2010

Page 35

IMPELLER CLEARANCE SETTING

The impeller clearance setting procedure must be

!

followed. Improperly setting the clearance or not

following any of the proper procedures can result

in sparks, unexpected heat generation and

equipment damage.

! WARNING

s

Lock out driver power to prevent accidental startup

and physical injury.

(about one flat at a time) backing the bearing housing

(134A) away from the bearing frame until the

indicator shows the proper clearance per Table 3.

8. Evenly tighten locking bolts (370C), then jack bolts

(370D) keeping indicator reading at proper setting.

9. Check shaft for free turning.

10. Replace coupling guard.

A change in pump performance may be noted over time

by a drop in head or flow or an increase in power

required. Performance can usually be renewed by

adjusting the impeller clearance. Two techniques are

given to set the impeller clearance, the dial indicator

method and the feeler gauge method.

DIAL INDICATOR METHOD

1. Remove coupling guard.

2. Remove coupling.

3. Set indicator so that button contacts either the shaft

end or against face of coupling (Fig. 38).

4. Loosen jam nuts (423) on jack bolts (370D) and back

bolts out about two turns.

5. Tighten each locking bolt (370C) evenly, drawing the

bearing housing (134A) towards the bearing frame

(228) until impeller contacts the casing. Turn the

shaft to ensure contact is made.

FEELER GAUGE METHOD

1. Remove coupling guard.

2. Loosen jam nuts (423) on jack bolts (370D) and back

bolts out about two turns (Fig. 16).

3. Tighten locking bolts (370C) evenly, drawing

bearing housing (134A) towards frame (228) until

impeller contacts the casing. Turn shaft to ensure

contact is made.

4. Using a feeler gauge, set the gap between the

three locking bolts (370C) and bearing housing

(134A) per impeller clearances in Table 1.

5. Evenly back out bearing housing (134A) using the

three jack bolts (370D) until it contacts the locking

bolts (370C). Evenly tighten jam nuts (423B).

6. Check shaft for free turning.

7. Replace coupling guard.

5

Dial Indicator Method

6. Set indicator to zero and back locking bolt (370C)

out about one turn.

7. Thread jack bolts (370D) in until they evenly contact

the bearing frame. Tighten the jack bolts evenly

3996 IOM 9/2010 31

Fig. 15

Fig. 16

Page 36

VIBRATION

It is good practice to periodically monitor vibration of the

pump. Normally, vibration level will be well below

accepted standards. Of equal

importance is that the vibration level not increase. If a

problem with vibration is encountered, refer to Trouble

Shooting.

32 3996 IOM 9/2010

Page 37

DISASSEMBLY AND REASSEMBLY

REQUIRED TOOLS ..................................33

DISASSEMBLY ....................................33

INSPECTION AND REPLACEMENT........................35

REASSEMBLY.....................................36

ADDITIONAL DETAILS ...............................37

Engineering Data Construction Details .......................38

SECTIONAL VIEWS .................................40

HIGH PRESSURE CAPABILITY ..........................43

REQUIRED TOOLS

·

Wrenches

·

Screwdriver

·

Lifting Sling

·

Rubber Mallet

·

Induction Bearing Heater

·

Bearing Puller

·

Brass Drift Punch

·

Snap-Ring Pliers

·

Torque Wrench with Sockets

·

Allen Wrenches

·

Dial Indicator

·

Micrometer

DISASSEMBLY

The Model 3996 is designed to permit the complete

pullout assembly to be removed without disturbing the

casing or motor. The sectional drawing, parts list and

construction details should be used in conjunction with

the disassembly instructions.

! WARNING

s

Pump components can be heavy. Proper methods of

lifting must be employed to avoid physical injury

and/or equipment damage. Steel toed shoes must be

worn at all times.

·

Cleaning Agents

·

Feeler Gauges

·

Hydraulic Press

·

Leveling Blocks

! WARNING

s

Lock out power supply to driver motor to prevent

accidental startup and physical injury.

2. Shut off all valves controlling flow to and from

pump.

! WARNING

s

Operator must be aware of pumpage and safety

precautions to prevent physical injury.

6

! WARNING

s

The pump may handle hazardous and/or toxic fluids.

Proper personal protective equipment should be

worn. Precautions must be taken to prevent physical

injury. Pumpage must be handled and disposed of in

conformance with applicable environmental

regulations.

NOTE: Before disassembling the pump for overhaul,

ensure all replacement parts are available.

1. Lock out motor

3996 IOM 9/2010 33

3. Drain liquid from piping, flush pump if necessary.

4. Remove auxiliary piping.

5. Unbolt and remove spacer member of coupling.

6. Remove the bolts (370) that hold the frame (228) to

the casing. Jacking bolts (418) are provided to assist

disassembly. Tighten the bolts evenly, a flat at a

time, to jack assembly from casing.

7. Remove casing gasket (351).

Page 38

8. Unscrew impeller (101) from shaft (122). The

threads are right-hand. Prevent the shaft turning by

using a wrench on coupling “flats”. Do not lose or

damage the O-ring (412A) which seals between the

impeller (101) and shaft (122) or shaft sleeve (126).

9. On units with mechanical seal (383).

a. Inside single or double seal – remove gland

stud nuts (355) and carefully slide gland (250)

off studs. Do not damage seal faces.

b. Outside seal – loosen set screws which position

rotary portion of seal and slide seal toward

bearing frame (228). Remove gland stud nuts

(355) and carefully slide gland (250) off studs.

Do not damage seal faces.

10. Remove stud nuts (370H) which hold stuffing box

cover (184) from frame. Do not allow stuffing box to

contact shaft (122), sleeve (126), shaft threads or any

mechanical seal parts. Slide sleeve (126), if any, off

shaft (122).

11. On units with mechanical seal, loosen set screws

which position rotary portion of seal to shaft (122)

and carefully slide seal and gland (250) assembly off

shaft. On units which have a shaft sleeve, (126), it is

not necessary to remove rotary portion of seal from

the sleeve unless replacement of seal is required.

12. Slide deflector (123) off shaft (122).

13. Scribe shaft (122) at coupling hub for proper

positioning of hub during reassembly and remove

hub.

14. Remove bearing housing bolts (370C). Impeller

adjustment bolts (370D) with jam nuts can be used to

assist in the removal of the shaft (122) and bearing

assembly from the bearing frame (228).

15. Slide complete shaft assembly from bearing frame.

This will include the shaft (122), both bearings (112

and 168), and bearing housing (134). Do not lose or

damage O-ring (496). Do not damage inboard grease

seal (333).

16. Pull inboard bearing (168).

17. Remove bearing retaining ring (361A) and slide

bearing housing off ball bearing. Do not damage

bearing housing grease seal (332).

18. Straighten “tang” in lockwasher (382) and remove

bearing locknut (136) and lockwasher. Pull ball

bearing (112).

19. On units with stuffing box packing, remove packing

(106) and lantern ring (105) from stuffing box cover

(184).

34 3996 IOM 9/2010

Page 39

INSPECTION AND REPLACEMENT

1. Impeller (101) – Replace if impeller shows excessive

erosion (especially on ejector vanes on back side of

impeller), corrosion, extreme wear or vane breakage.

O-ring groove and impeller hub must be in good

condition. Check impeller balance.

2. Shaft (122) – Check for runout to see that shaft has

not been bent. On pumps without shaft sleeves, shaft

surface in stuffing box area must be smooth and free

of grooves. Bearing seats and oil seal areas must be

smooth and free of scratches or grooves. Shaft