Page 1

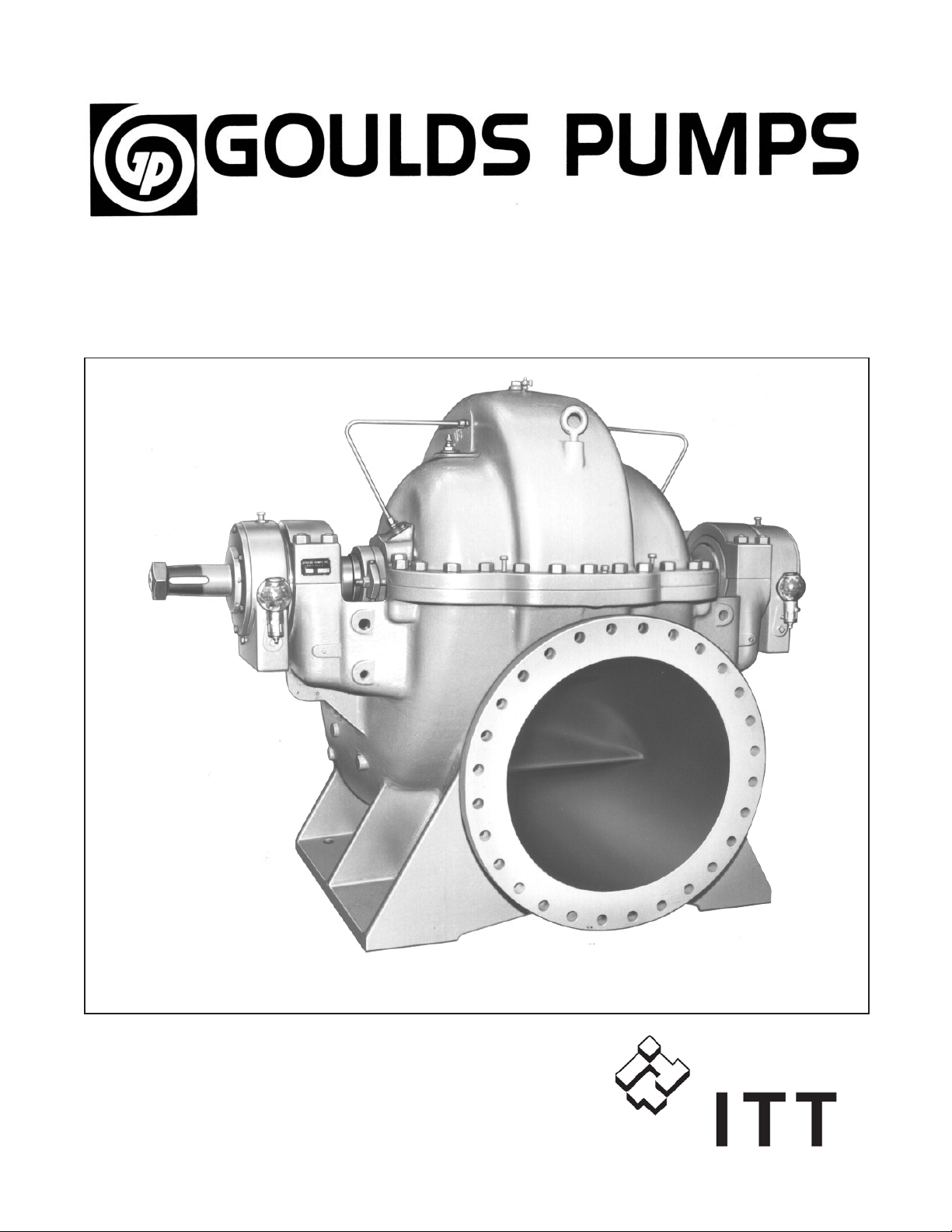

Installation, Operation and Maintenance Instructions

Model 3420

Page 2

2 3420 IOM 8/09

Page 3

FOREWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Model 3420/25 Single

Stage Double Suction Pump*. This manual covers the standard product plus common options that are available. For special

options, supplemental instructions are supplied. This manual must be read and understood before installation and start-up.

The design, materials, and workmanship incorporated in the construction of Goulds pumps makes them capable of giving

trouble-free service. The life and satisfactory service of any mechanical unit, however, is enhanced and extended by correct

application, proper installation, periodic inspection, condition monitoring and careful maintenance. This instruction manual

was prepared to assist operators in understanding the construction and the correct methods of installing, operating, and

maintaining these pumps.

ITT - Goulds Pumps shall not be liable for physical injury, damage or delays caused by a failure to observe the

instructions for Installation, Operation, and Maintenance contained in this manual.

When pumping unit is installed in a potentially explosive atmosphere, the instructions after the

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there is any

question regarding these requirements or if the equipment is to be modified, please contact a Goulds representative

before proceeding.

Warranty is valid only when genuine ITT - Goulds Pumps parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval is obtained

in advance from ITT - Goulds Pumps.

Supervision by an authorized ITT - Goulds Pumps representative is recommended to assure proper installation.

Additional manuals can be obtained by contacting your local ITT - Goulds Pumps representative or by calling

1-800-446-8537.

* The 3420 is an all English dimension unit and the 3425 is a hard metric design.

A symbol must be

THIS MANUAL EXPLAINS

Proper Installation

n

Start-up Procedures

n

Operation Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Trouble Shooting

n

Ordering Spare or Repair Parts

n

3420 IOM 8/09 3

Page 4

4 3420 IOM 8/09

Page 5

TABLE OF CONTENTS

PAGE SECTION

7 SAFETY

11 GENERAL INFORMATION

15 INSTALLATION

25 OPERATION

37 PREVENTIVE MAINTENANCE

43 DISASSEMBLY & REASSEMBLY

1

2

3

4

5

6

77 SPARE AND REPAIR PARTS

99 APPENDIX

7

8

3420 IOM 8/09 5

Page 6

Page 7

Industrial Process Pump Safety Manual

IMPORTANT SAFETY NOTICE

To: Our Valued Customers

User safety is a major focus in the design of our products. Following the precautions outlined in this

manual will minimize your risk of injury.

ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and

operated.

Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user

responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all

times during product life. Understanding and adhering to these safety warnings is mandatory to ensure

personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone,

however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate

safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is

the responsibility of all individuals involved in the installation, operation, and maintenance of industrial

equipment.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines

outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual.

Current manuals are available at

your nearest Goulds Pumps sales representative.

These manuals must be read and understood before installation and start-up.

For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at

www.gouldspumps.com.

www.gouldspumps.com/literature_ioms.html or by contacting

S-1

Page 8

SAFETY WARNINGS

Specific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Any pressure vessel can explode,

rupture, or discharge its contents if sufficiently over pressurized causing death, personal injury, property

damage, and/or damage to the environment. All necessary measures must be taken to ensure over

pressurization does not occur.

WARNING

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases.

Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and

result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is

avoided.

WARNING

The pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump

and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but

are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.

WARNING

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers

and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly

expand and result in a violent explosion and injury.

ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the

current IOM available at www.gouldspumps.com/literature.

S-2

Page 9

SAFETY

DEFINITIONS

Throughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate

where special operator attention is required.

Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with

your equipment.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Example: Pump shall never be operated without coupling guard installed correctly.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Example: Throttling flow from the suction side may cause cavitation and pump damage.

ELECTRICAL HAZARD

Indicates the possibility of electrical risks if directions are not followed.

Example: Lock out driver power to prevent electric shock, accidental start-up, and physical injury.

When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be

followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there

is any question regarding these requirements or if the equipment is to be modified, please contact an ITT

Goulds Pumps representative before proceeding.

Example:

parts, resulting in a spark and heat generation.

Improper impeller adjustment could cause contact between the rotating and stationary

S-3

Page 10

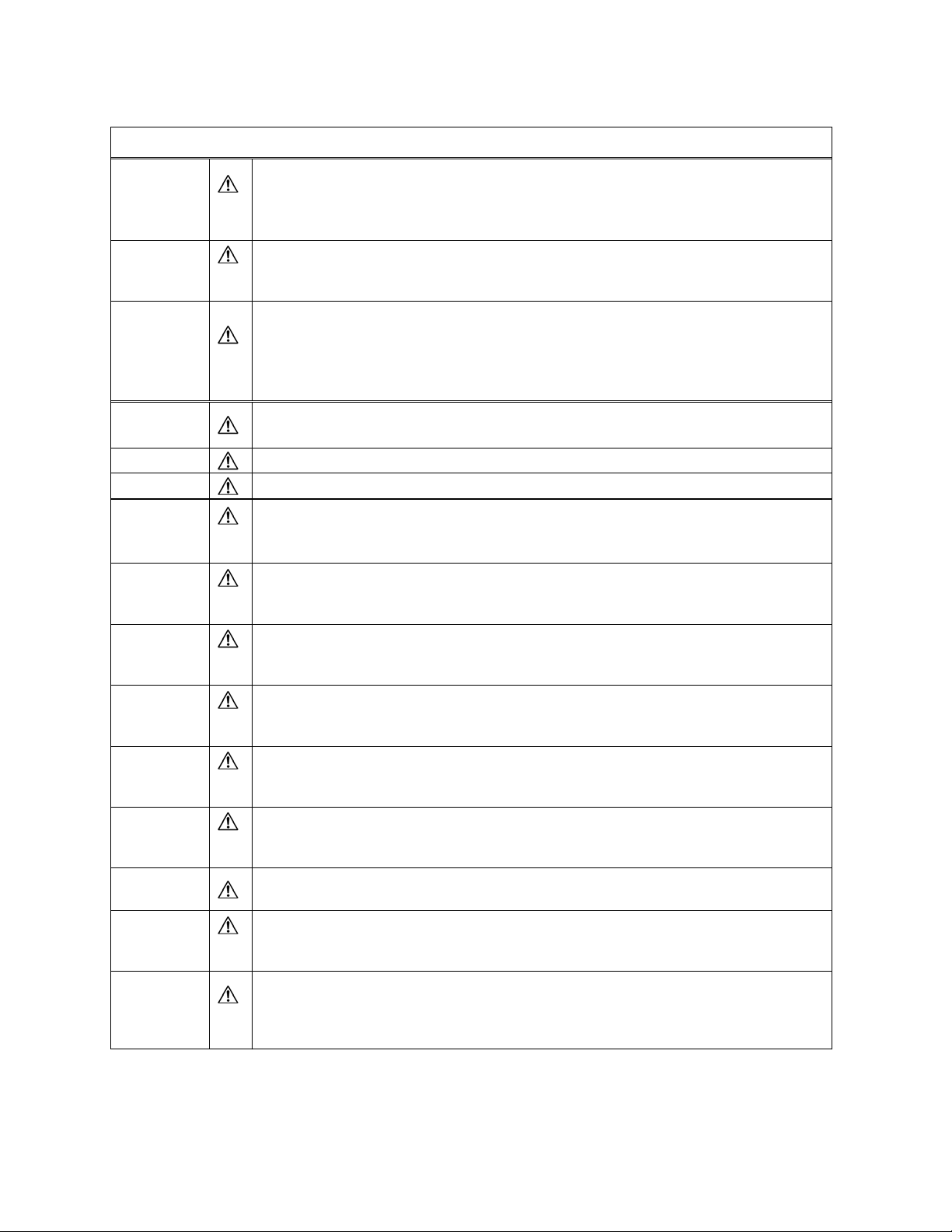

GENERAL PRECAUTIONS

WARNING

A pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the

pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators and

maintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures

outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury,

damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your

equipment.

General Precautions

WARNING

WARNING

NEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to trapped

liquid.

NEVER use heat to disassemble pump due to risk of explosion from trapped liquid.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

NEVER operate pump without coupling guard correctly installed.

NEVER run pump below recommended minimum flow when dry, or without prime.

ALWAYS lock out power to the driver before performing pump maintenance.

NEVER operate pump without safety devices installed.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change service application without approval of an authorized ITT Goulds

Pumps representative.

Safety Apparel:

Insulated work gloves when handling hot bearings or using bearing heater

Heavy work gloves when handling parts with sharp edges, especially impellers

Safety glasses (with side shields) for eye protection

Steel-toed shoes for foot protection when handling parts, heavy tools, etc.

Other personal protective equipment to protect against hazardous/toxic fluids

Receiving:

Assembled pumping units and their components are heavy. Failure to properly lift and

support equipment can result in serious physical injury and/or equipment damage. Lift

WARNING

equipment only at specifically identified lifting points or as instructed in the current IOM.

Current manuals are available at

from your local ITT Goulds Pumps sales representative. Note: Lifting devices (eyebolts,

slings, spreaders, etc.) must be rated, selected, and used for the entire load being lifted.

www.gouldspumps.com/literature_ioms.html or

S-4

Page 11

WARNING

General Precautions

Alignment:

Shaft alignment procedures must be followed to prevent catastrophic failure of drive

components or unintended contact of rotating parts. Follow coupling manufacturer’s

coupling installation and operation procedures.

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Before beginning any alignment procedure, make sure driver power is locked out. Failure

to lock out driver power will result in serious physical injury.

Piping:

Never draw piping into place by forcing at the flanged connections of the pump. This may

impose dangerous strains on the unit and cause misalignment between pump and driver.

Pipe strain will adversely effect the operation of the pump resulting in physical injury and

damage to the equipment.

Flanged Connections:

Use only fasteners of the proper size and material.

Replace all corroded fasteners.

Ensure all fasteners are properly tightened and there are no missing fasteners.

Startup and Operation:

When installing in a potentially explosive environment, please ensure that the motor is

properly certified.

Operating pump in reverse rotation may result in contact of metal parts, heat generation,

and breach of containment.

Lock out driver power to prevent accidental start-up and physical injury.

The impeller clearance setting procedure must be followed. Improperly setting the

clearance or not following any of the proper procedures can result in sparks, unexpected

heat generation and equipment damage.

If using a cartridge mechanical seal, the centering clips must be installed and set screws

loosened prior to setting impeller clearance. Failure to do so could result in sparks, heat

generation, and mechanical seal damage.

WARNING

WARNING

WARNING

CAUTION

The coupling used in an ATEX classified environment must be properly certified and

must be constructed from a non-sparking material.

Never operate a pump without coupling guard properly installed. Personal injury will

occur if pump is run without coupling guard.

Make sure to properly lubricate the bearings. Failure to do so may result in excess heat

generation, sparks, and / or premature failure.

The mechanical seal used in an ATEX classified environment must be properly certified.

Prior to start up, ensure all points of potential leakage of process fluid to the work

environment are closed.

S-5

Page 12

CAUTION

WARNING

General Precautions

Never operate the pump without liquid supplied to mechanical seal. Running a mechanical

seal dry, even for a few seconds, can cause seal damage and must be avoided. Physical

injury can occur if mechanical seal fails.

Never attempt to replace packing until the driver is properly locked out and the coupling

spacer is removed.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

Dynamic seals are not allowed in an ATEX classified environment.

DO NOT operate pump below minimum rated flows or with suction and/or discharge

valve closed. These conditions may create an explosive hazard due to vaporization of

pumpage and can quickly lead to pump failure and physical injury.

Ensure pump is isolated from system and pressure is relieved before disassembling pump,

removing plugs, opening vent or drain valves, or disconnecting piping.

Shutdown, Disassembly, and Reassembly:

Pump components can be heavy. Proper methods of lifting must be employed to avoid

physical injury and/or equipment damage. Steel toed shoes must be worn at all times.

The pump may handle hazardous and/or toxic fluids. Observe proper decontamination

procedures. Proper personal protective equipment should be worn. Precautions must be

taken to prevent physical injury. Pumpage must be handled and disposed of in

conformance with applicable environmental regulations.

Operator must be aware of pumpage and safety precautions to prevent physical injury.

Lock out driver power to prevent accidental startup and physical injury.

Allow all system and pump components to cool before handling them to prevent physical

injury.

If pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550, or

3107, there may be a risk of static electric discharge from plastic parts that are not

properly grounded. If pumped fluid is non-conductive, pump should be drained and

flushed with a conductive fluid under conditions that will not allow for a spark to be

released to the atmosphere.

Never apply heat to remove an impeller. The use of heat may cause an explosion due to

trapped fluid, resulting in severe physical injury and property damage.

Wear heavy work gloves when handling impellers as sharp edges may cause physical

injury.

Wear insulated gloves when using a bearing heater. Bearings will get hot and can cause

physical injury.

S-6

Page 13

ATEX CONSIDERATIONS and INTENDED USE

Special care must be taken in potentially explosive environments to ensure that the equipment is properly

maintained. This includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended hydraulic range.

The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating,

installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and

Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any

modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question

regarding the intended use of the equipment, please contact an ITT Goulds representative before proceeding.

Current IOMs are available at

Pumps Sales representative.

All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified

environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. A

typical tag would look like this:

www.gouldspumps.com/literature_ioms.html or from your local ITT Goulds

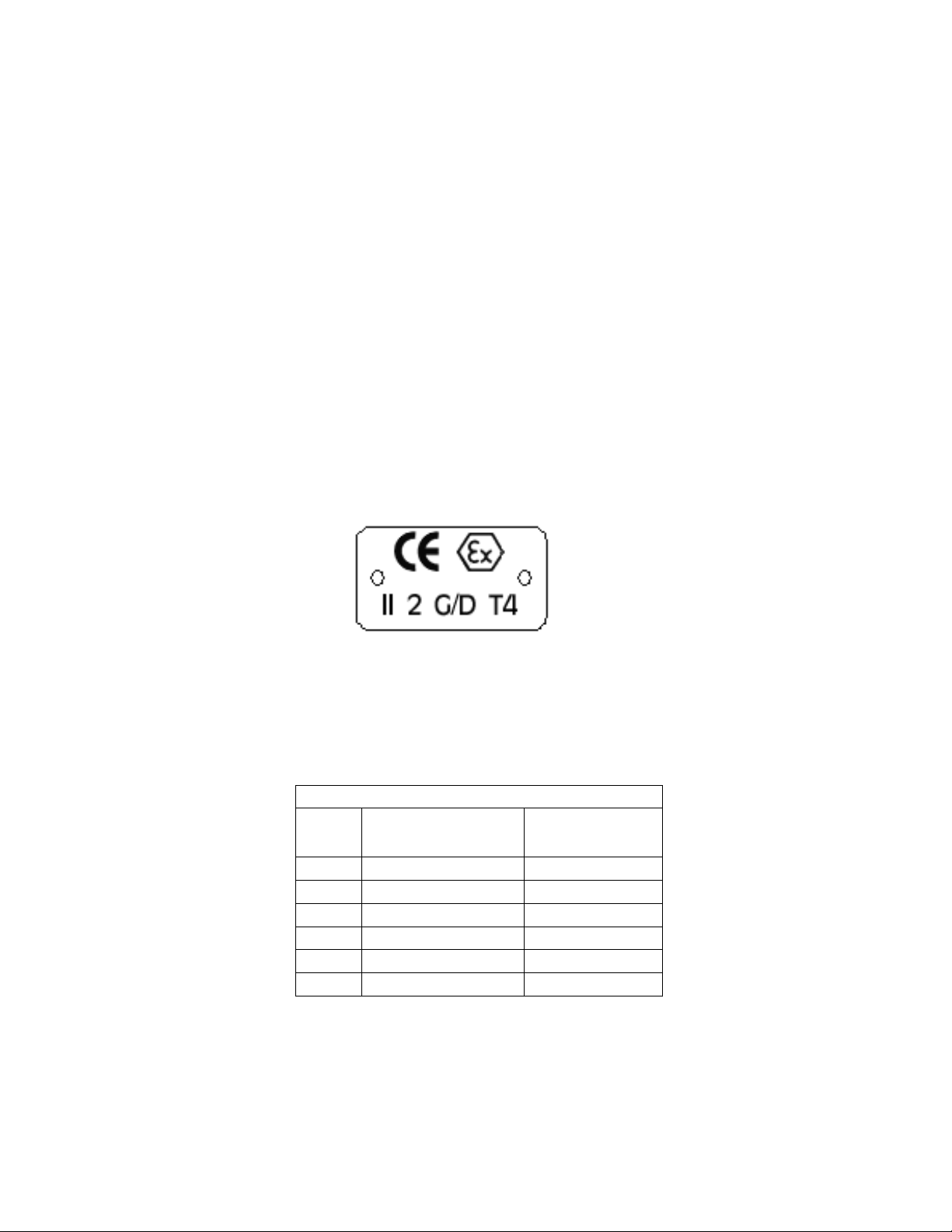

The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 = Temperature class, can be T1 to T6 (see Table 1)

Table 1

Max permissible

surface temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

o

F (oC)

The code classification marked on the equipment must be in accordance with the specified area where the

equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales

representative before proceeding.

Max permissible

liquid temperature

o

F (oC)

S-7

Page 14

PARTS

The use of genuine Goulds parts will provide the safest and

most reliable operation of your pump. ITT Goulds Pumps ISO

certification and quality control procedures ensure the parts are

manufactured to the highest quality and safety levels.

Please contact your local Goulds representative for details on

genuine Goulds parts.

S-8

Page 15

GENERAL INFORMATION

PUMP DESCRIPTION ................................11

NAMEPLATE INFORMATION ...........................13

RECEIVING THE PUMP ...............................14

PUMP DESCRIPTION

The model is based on 8 bearing configurations and 15 hydraulic sizes. Groupings are as follows:

Group Description Sizes

SX

MX

M

M

(modified)

—

L

LDS

XL

XXL

Ball radial and duplex ball thrust bearings. Flood oil lube with constant level oiler optional grease

lube. Bearing housings bolt to the casing. Goulds non-metallic labyrinth seals.

Ball radial and duplex ball thrust bearings. Flood oil lube with constant level oiler optional grease

lube. Bearing housings bolt to the casing. Goulds non-metallic labyrinth seals.

Ball radial and duplex ball thrust bearings. Ring oil lube with constant level oiler optional grease

lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs and nuts.

Goulds metallic labyrinth seals.

Same as M group except the shaft is longer to accommodate a wider pump.

Ball radial and duplex ball thrust bearings. Ring oil lube with constant level oiler, optional grease

lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs and nuts.

Goulds metallic labyrinth seals.

Double row roller bearings, both thrust and radial. Ring oil lube with constant level oiler, optional

grease lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs

and nuts. Goulds metallic labyrinth seals.

Double row roller bearings, both thrust and radial. Ring oil lube with constant level oiler, optional

grease lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs

and nuts. Goulds metallic labyrinth seals.

Double row roller bearings, both thrust and radial. Ring oil lube with constant level oiler, optional

grease lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs

and nuts. Goulds metallic labyrinth seals.

Double row roller bearings, both thrust and radial. Ring oil lube with constant level oiler, optional

grease lube. Bearing housing secured with tongue and groove fits and a bearing cap with studs

and nuts. Goulds metallic labyrinth seals.

12 x 14-15

16 x 18-17H

18 x 20-20

16 x 18-30

18 x 20-30

20 x 24-24

20 x 24-30

20 x 24-28

18 x 20-24

24 x 30-32

30 x 30-31

30 x 30-38

30 x 36-42

20x30-42

36x42-52

1

The model 3420 is a horizontal between bearings, enclosed

impeller double suction centrifugal pump.

Casing - The casing is horizontally split. The upper and

lower halves are held together with studs and nuts and/or

capscrews. Flanged suction and discharge connections are

located in the lower half of the casing and conform to ANSI

16.1/16.5 class 125/150. The casing is supported by

integrally cast feet. Separate bearing housings are attached

directly to machined fits in each end of the casing with

capscrews or machined fits secured with bearing caps and

studs and nuts. All sizes have dual volute casings to reduce

radial loads on the shaft. The casings are standard with two

jacking screws, two lifting lugs for the upper half, two

tapered dowel pins for alignment, and a .030 or .016 in. (.75

or .41 mm) non-asbestos parting gasket. The upper half is

3420 IOM 8/09 7

provided with a vent connection, a priming connection, and

one or two stuffing box seal ring connections. The lower half

is provided with two drain connections, suction and

discharge gauge connections, and stuffing box overflow

connections.

Impeller - The impeller is an enclosed, double suction design

providing axial hydraulic balance. All exterior surfaces are

fully machined. The impeller receives a one or two plane spin

balance as standard. The impeller is keyed to the shaft and

held in place using shaft sleeves and sleeve nuts.

Wear Rings - Casing and impeller wear rings are supplied as

standard to maintain proper running clearances and to

minimize leakage between the suction and discharge

chambers in the casing. Each casing ring is held in place with

Page 16

a machined hook lock. The impeller rings are held in place

using axial set screws.

Shaft - The shaft is a heavy duty design that minimizes

deflection and vibration. The shaft deflection is a maximum

of .002 in (.051 mm) at the stuffing box face under the worst

operating conditions. The shaft is completely dry with O-ring

seals between the impeller and shaft sleeves and the shaft

sleeves and the sleeve nuts. The standard shaft is AISI 4340

steel with an option for 316 stainless steel.

Shaft Sleeves - Shaft sleeves are standard on all pumps. They

are keyed to the shaft at the impeller and held in place using

sleeve nuts. The sleeve nuts tighten against rotation and are

secured in place with set screws.

Stuffing Box - Non-asbestos packing is standard. The

stuffing box contains a Teflon™ split lantern ring and

renewable stuffing box throat bushings. Tapped openings are

provided for water sealing from either the pump casing or an

outside source. Bypass piping is optional. Two-piece

machined split glands are standard on all packed pumps.

Mechanical Seals - Mechanical seals can be supplied as a

non-standard option. Most seal designs fit in the standard

stuffing box. Goulds does not have its own design gland, so

the gland must be supplied by the seal manufacturer.

Bearings - There are many different bearing configurations

that are offered on the 3420. Specific configurations are

dependent on pump size and group and purchased setup.

Grease lubricated ball, grease lubricated roller, flood oil

lubricated ball, ring oil lubricated ball, and ring oil lubricated

roller bearings are used on various sizes. Oil lubrication is

standard with grease optional. The bearing housings are

sealed with machined labyrinth seals or lip seals.

Baseplates - Fabricated steel bases are standard with a drip

collection chamber and a tapped drain connection. The base

is designed to be grouted and has grout and vent holes.

Soleplates for the pump only or motor only are offered as an

option.

8 3420 IOM 8/09

Page 17

NAMEPLATE INFORMATION

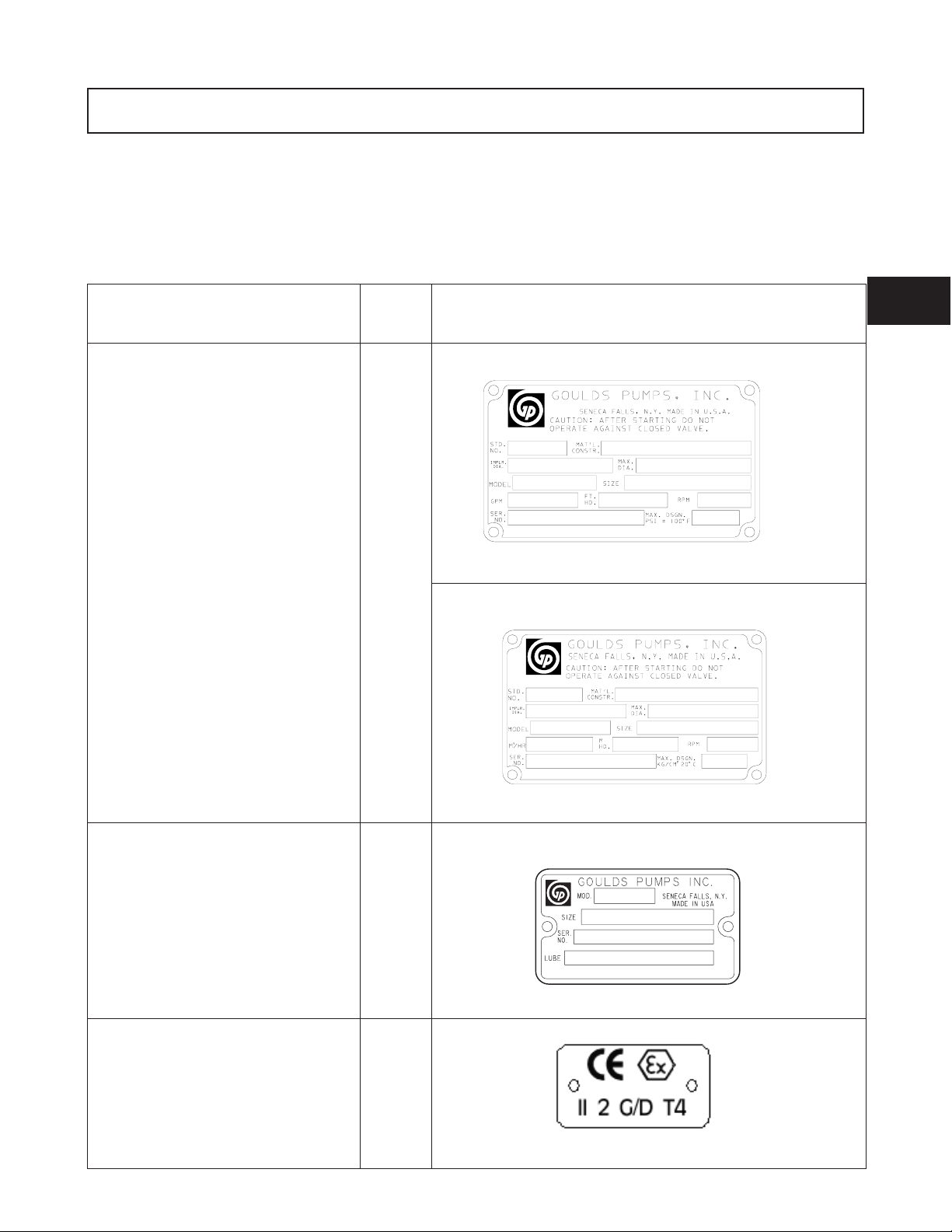

Every pump has two or three Goulds nameplates that provide

information about the pump. The tags are located on the

upper half and lower half of the casing.

Description Fig. No. Example

Pump Casing Tag - provides information

about the pump’s hydraulic

characteristics. Note the format of the

pump size: Discharge x Suction - Nominal

maximum Impeller Diameter in inches.

(Example: 2x3-8)

(Figs.1&2).

Fig. 1

English

When ordering parts, you will need to identify the pump

model, size, serial number, and the item number of the

required parts. Information can be taken from the pump

casing tags. Item numbers can be found later on in this

manual.

1

Bearing Frame Tag - provides

information on the lubrication system used

(Fig. 3).

ATEX Tag - If applicable, your pump

unit may have the following ATEX tag

affixed to the pump and/or baseplate. See

the Safety section for a description of the

symbols and codes

(Fig. 4).

Fig. 2

Metric

Fig. 3

Fig. 4

3420 IOM 8/09 9

Page 18

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Carefully check

that everything is in good order. Make notes of damaged or

missing items on the receipt and freight bill. File any claims

with the transportation company as soon as possible.

Storage Requirements

Short Term: (Less than 6 months): Goulds normal

packaging procedure is designed to protect the pump during

shipping. Upon receipt, store in a covered and dry location.

Long Term: (More than 6 months): Preservative treatment of

bearings and machined surfaces will be required. Rotate shaft

several times every three months. Refer to driver and

coupling manufacturers for their long term storage

procedures. Store in a covered dry location.

Note: Long term storage treatment can be purchased

with the initial pump order.

HANDLING

! WARNING

s

Pump and components are heavy. Failure to properly lift

and support the equipment could result in serious

physical injury, or damage to the pump(s). Steel-toed

shoes must be worn at all times.

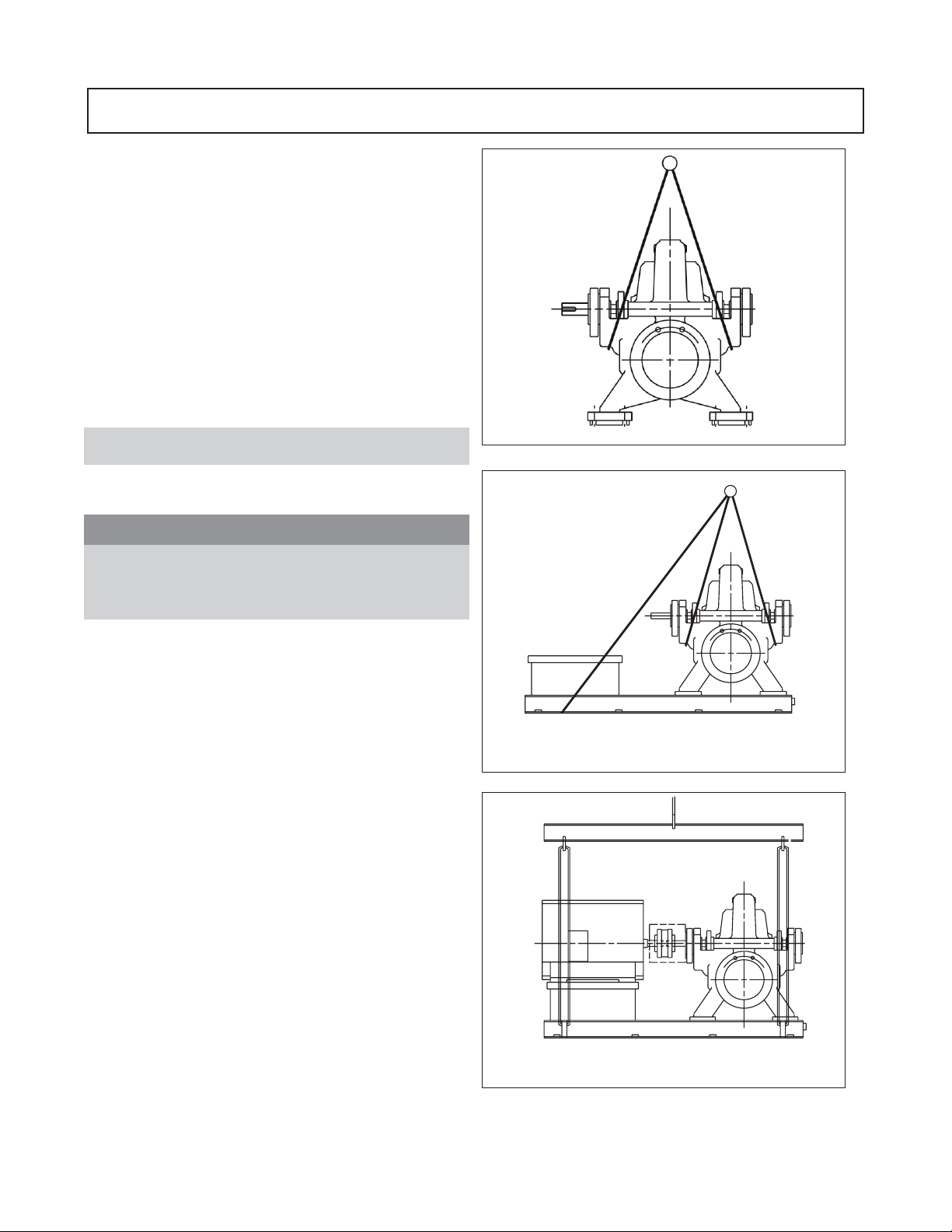

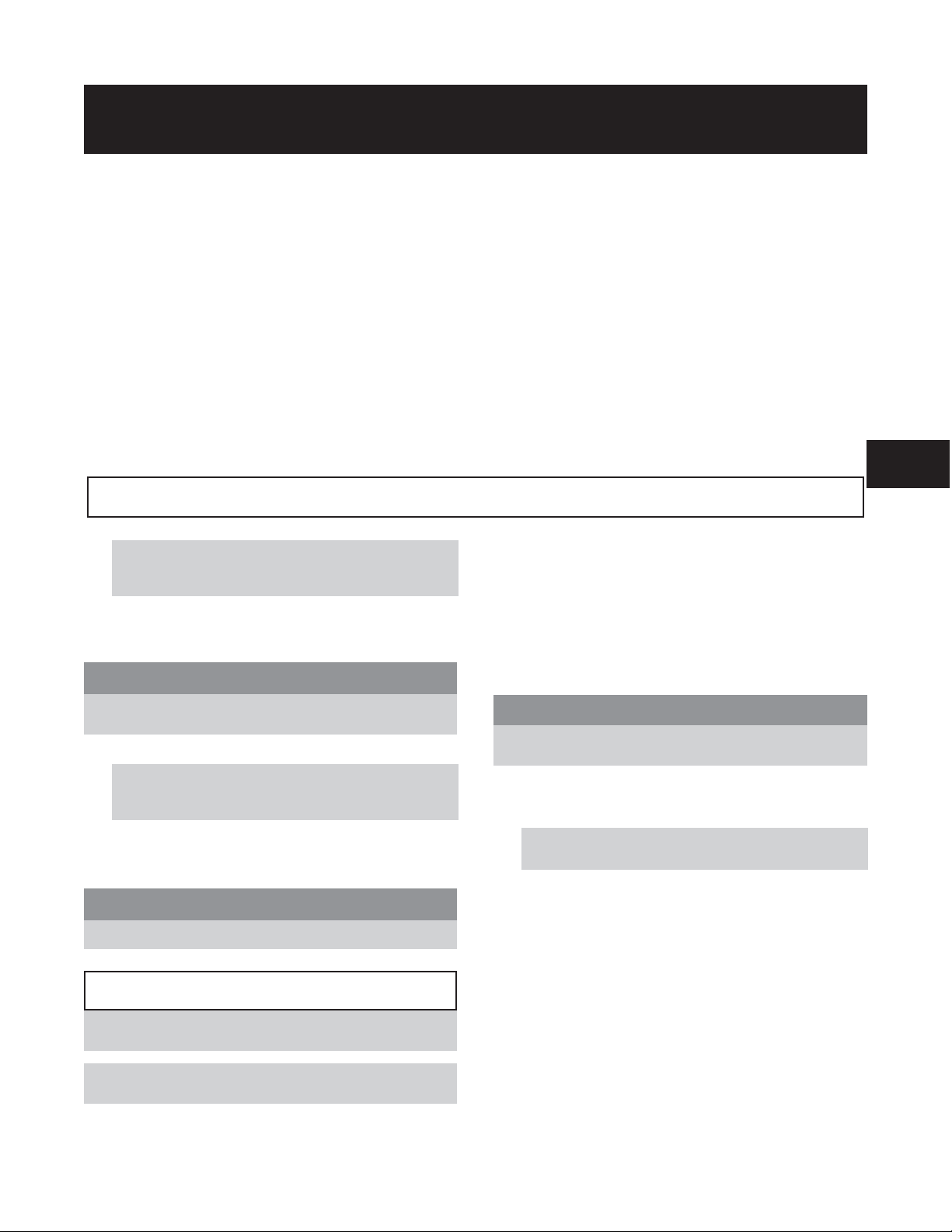

Fig. 3A

Use care when moving pumps. Lifting equipment must be

able to adequately support the entire assembly. Hoist a bare

pump or a pump and soleplate unit using a suitable sling,

under the two bearing housings (Fig. 3A). Baseplate mounted

units without motors are moved by supporting the pump with

a sling under the two bearing housings and a sling under the

motor end of the baseplate (Fig. 3B). Baseplate mounted

units with motors are moved with slings attached to the

baseplate lifting lugs. The use of a spreader bar is required so

that the pump is not damaged (Fig 3C).

Fig. 3B

Fig. 3C

10 3420 IOM 8/09

Page 19

INSTALLATION

SITE/FOUNDATION................................15

BASEPLATE INSTALLATION PROCEDURE .................16

LEVEL BASEPLATE ...............................16

ALIGNMENT AND ALIGNMENT PROCEDURE ...............18

Alignment Check ................................18

Alignment Criteria ...............................18

SetUp......................................19

Measurement ..................................19

Angular Alignment ...............................19

Parallel Alignment ...............................20

Complete Alignment ..............................20

Alignment Trouble Shooting ..........................21

GROUT BASEPLATE ...............................21

Alignment Check ................................21

PIPING........................................21

General .....................................21

Suction Piping .................................22

Discharge Piping ................................22

Final Piping Check ...............................23

3

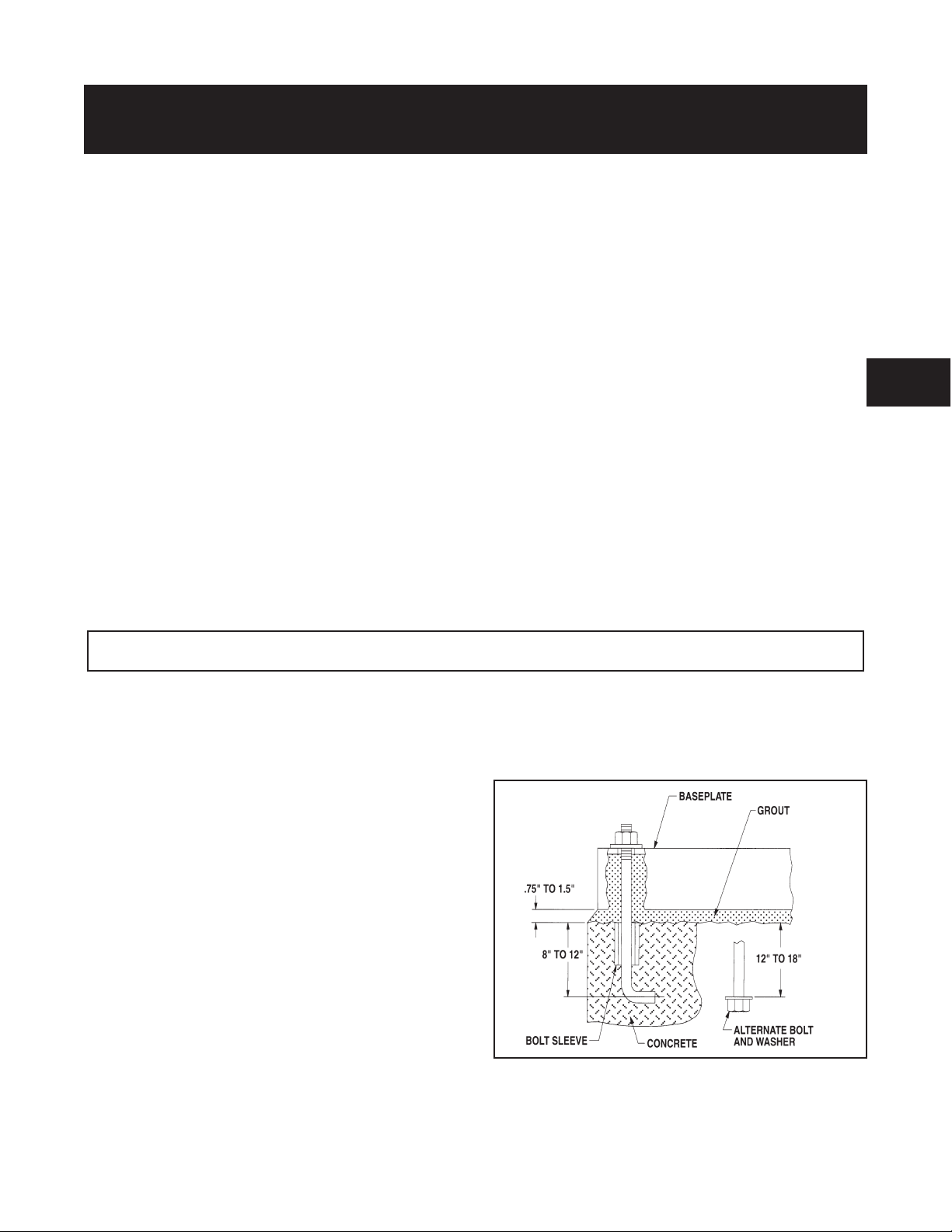

FOUNDATION

The foundation must be substantial enough to absorb

vibration. (Hydraulic Institute Standards recommends the

foundation weigh at least five [5] times the weight of the

pump unit.) It must form a permanent and rigid support for the

baseplate. This is important in maintaining the alignment of a

flexibly coupled unit.

Foundation bolts of the proper size should be embedded in the

concrete to a depth of eight (8) to twelve (12) inches and

locked with either a hook around a reinforcing bar or

alternatively, a nut and washer at the bottom. The bolts should

have a sleeve around them at least six (6) times the bolt

diameter in length and at least two (2) bolt sizes larger in I.D.

If a nut and washer are used for locking, the washer should

have an O.D. two (2) sizes larger than the sleeve. Foundation

bolts should be sized .125" less than the anchor bolt holes in

the base.

The foundation should be poured to within .75" - 1.5" of

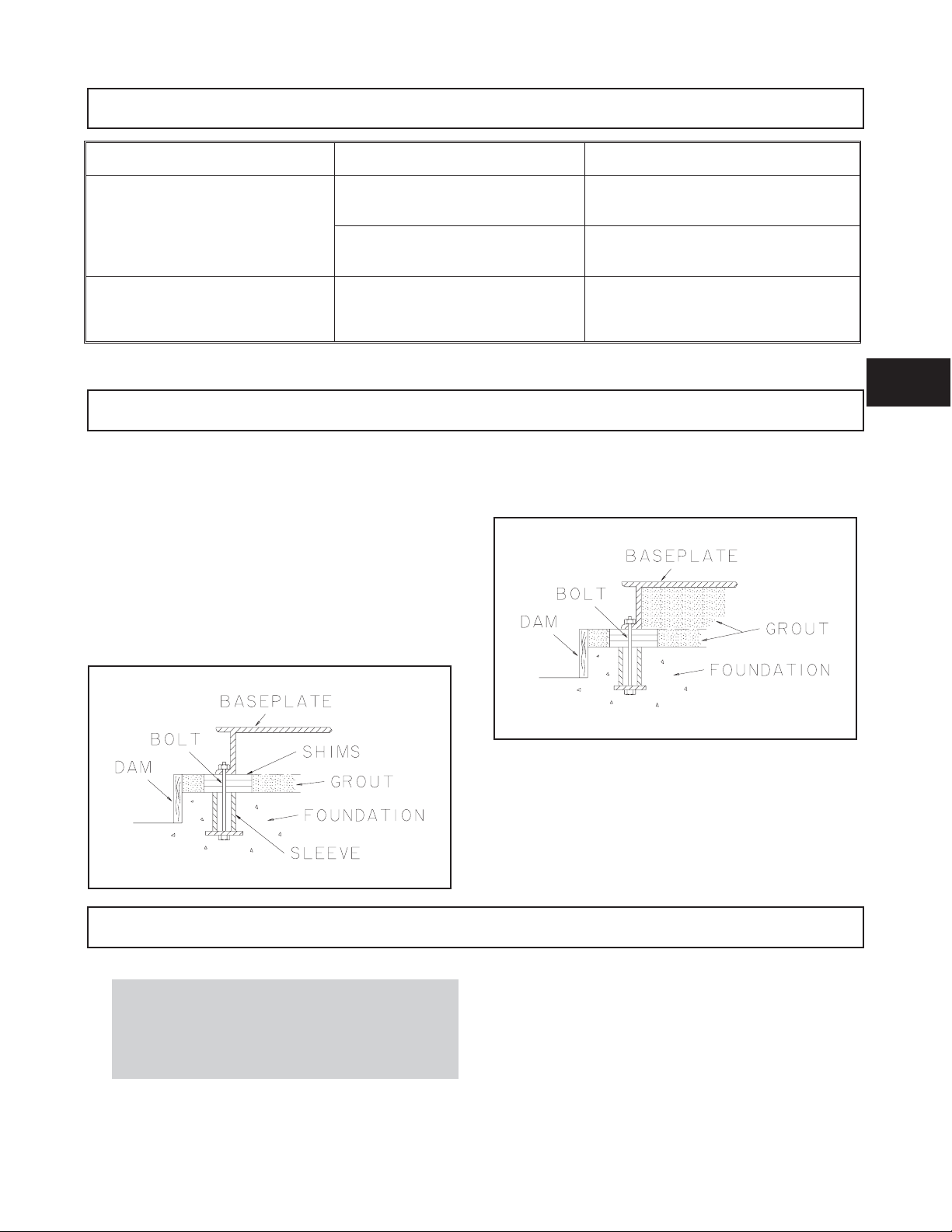

the finished height. (See Fig. 4) Freshly poured foundations

should be allowed to cure for several days before the unit is

set in place and grouted.

Fig. 4

3420 IOM 08/09 15

Page 20

BASEPLATE INSTALLATION PROCEDURE

Industry standard procedures and/or the following

procedure should be followed prior to grouting the

baseplate. The procedure assumes the installer has a basic

knowledge of baseplate and foundation design and

installation methods.

BASEPLATE PREPARATION

1. Inspect all surfaces of the baseplate that will contact

the grout for contamination (rust, oil, grime, etc.)

2. Thoroughly clean all surfaces of the baseplate that will

contact the grout with a cleaner that will not leave any

residue.

NOTE: It may be necessary to sandblast the contact

surfaces and coat with a primer compatible with the

grout. If sandblasting is necessary, remove all the

equipment prior to sandblasting.

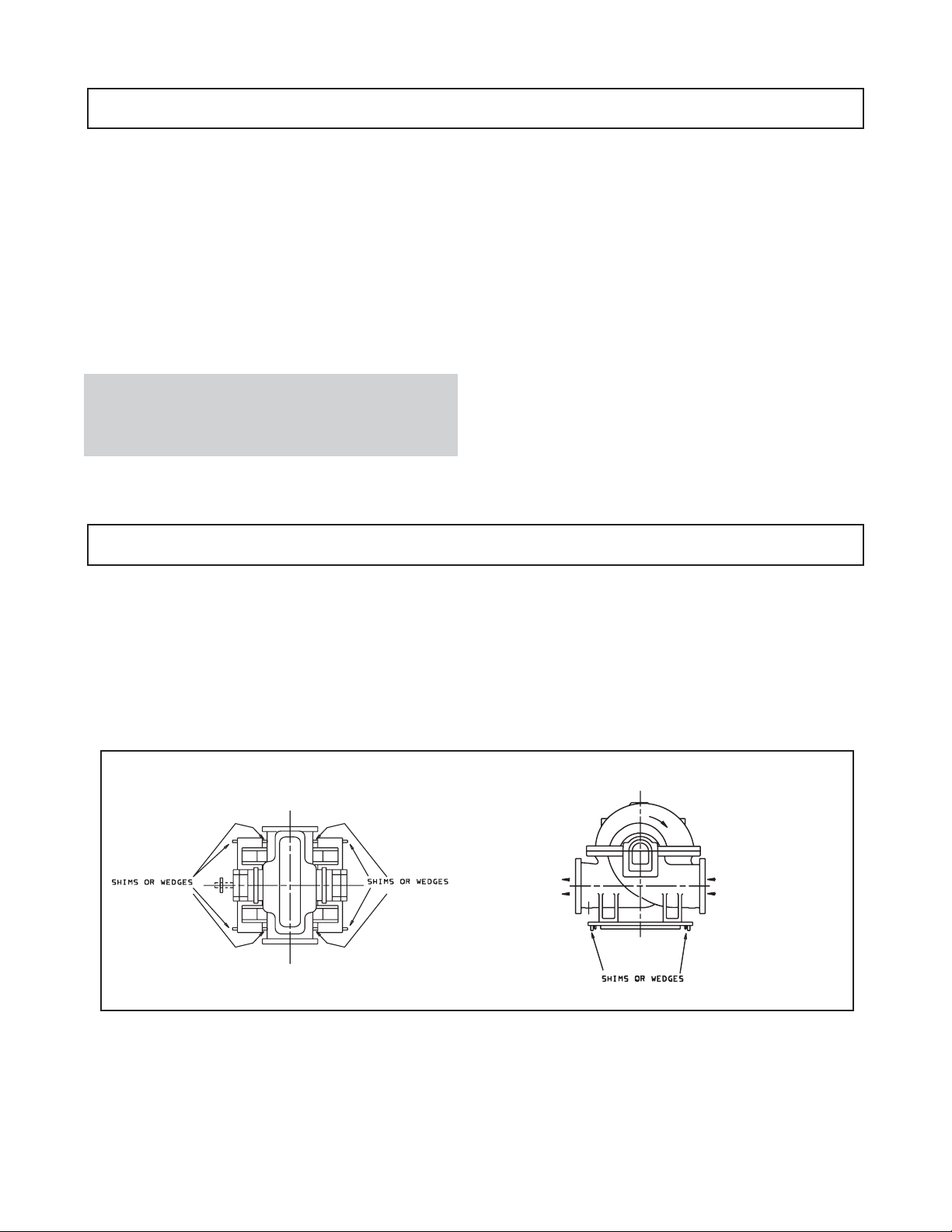

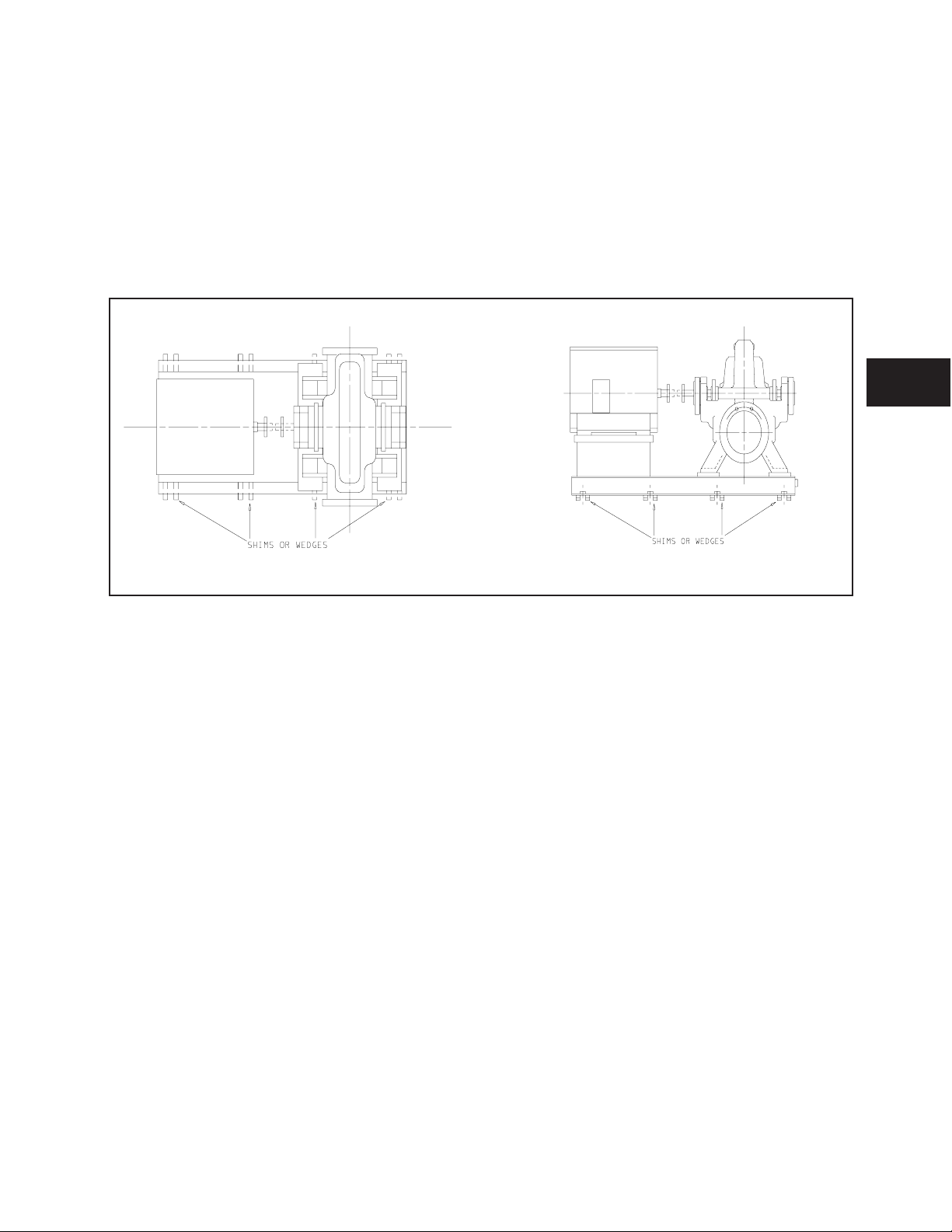

LEVEL BASEPLATE

1. Place two sets of wedges or shims on the foundation,

one set on each side of every foundation bolt. The

wedges should extend .75 in. (20 mm) to 1.5 in. (40

mm) above the foundation to allow for adequate

grouting. This will provide even support for the

baseplate once it is grouted.

3. Inspect all machined surfaces for burrs, rust, paint, or

any other type of contamination. If necessary, use a

honing stone to remove any burrs.

FOUNDATION PREPARATION

1. Chip the top of the foundation .50-1.0 in. (13-25 mm)

to remove porous or low strength concrete. If using a

pneumatic hammer, assure that it is not contaminating

the surface with oil, moisture, etc.

2. Remove water and/or debris from the foundation bolt

holes/sleeves. If sleeve type bolts are being used, fill

the sleeves with stuffing material and seal to prevent

grout from entering.

3. Coat the exposed portion of the anchor bolts with a

non-bonding compound to prevent grout from

adhering to the anchor bolts.

4. If recommended by the grout manufacturer, coat the

foundation surface with a compatible primer.

2. Remove water and/or debris from anchor bolt

holes/sleeves prior to grouting. If sleeve type bolts are

being used, fill the sleeves with rags to prevent grout

from entering.

Fig. 6

16 3420 IOM 08/09

Page 21

3. Carefully lower the baseplate onto the foundation

bolts.

4. Level the baseplate to within .125 in. (3.2 mm) over

the length of the baseplate and to within .088 in. (1.5

mm) over the width of the baseplate by adjusting the

wedges. If the baseplate has vertical leveling screws,

use the screws to level the base.

5. Hand tighten the foundation bolts.

3

Fig. 7

3420 IOM 08/09 17

Page 22

ALIGNMENT AND ALIGNMENT PROCEDURE

Alignment procedures must be followed to prevent

!

unintended contact of rotating parts. Follow

coupling manufacturer’s installation and operation

procedures.

! WARNING

s

Before beginning any alignment procedure, make sure

driver power is locked out. Failure to lock out driver

power may result in serious physical injury.

To remove guard, refer to coupling guard assembly/

disassembly instructions.

The points at which alignment is checked and adjusted are:

Initial Alignment is done prior to operation when the

•

pump and the driver are at ambient temperature.

Final Alignment is done after operation when the

•

pump and driver are at operating temperature.

Alignment is achieved by adding or removing shims from

under the feet of the driver and shifting equipment

horizontally as needed.

Final Alignment (Hot Alignment)

After First Run - To obtain correct alignment when

•

both pump and driver are at operating temperature.

Thereafter, alignment should be checked periodically

in accordance with plant operating procedures.

NOTE: Alignment check must be made if process

temperature changes, piping changes and or pump

service is performed.

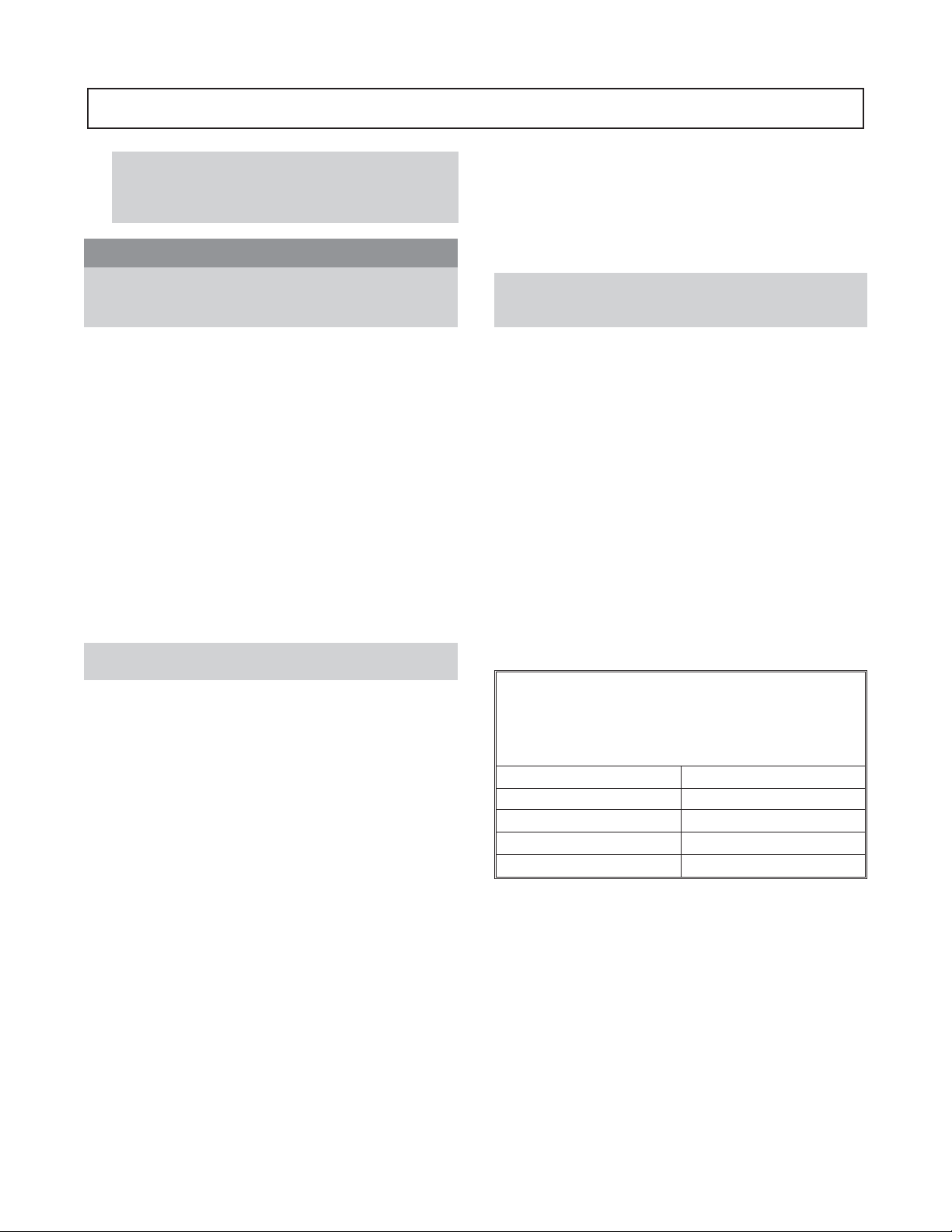

ALIGNMENT CRITERIA

Good alignment is achieved when the dial indicator

readings as specified in the alignment procedure are .002

in. (.05 mm) Total Indicated Reading (T.I.R.) or less when

the pump and driver are at operating temperature (Final

Alignment).

During the installation phase, however, it is necessary to

set the parallel alignment in the vertical direction to a

different criteria due to differences in expansion rates of

the pump and driver. Table 1 shows recommended

preliminary (cold) settings for electric motor driven pumps

based on different pumpage temperatures. Driver

manufacturers should be consulted for recommended cold

settings for other types of drivers (steam turbines, engines,

etc.)

NOTE: Proper alignment is the responsibility of the

installer and user of the unit.

Accurate alignment of the equipment must be attained.

Trouble-free operation can be accomplished by following

these procedures.

ALIGNMENT CHECKS

Initial Alignment (Cold Alignment)

Before Grouting Baseplate - To ensure alignment can

•

be obtained.

After Grouting Baseplate - To ensure no changes have

•

occurred during grouting process.

After Connecting Piping - To ensure pipe strains have

•

not altered alignment. If changes have occurred, alter

piping to remove pipe strains on pump flanges.

Table 1

Cold Setting of Parallel

Vertical Alignment

Pumpage Temperature Set Driver Shaft

ambient N/A

100°F

200°F

300°F

.000" - .002" HIGH

.002” - .004” HIGH

.004” - .006” HIGH

18 3420 IOM 08/09

Page 23

SET UP

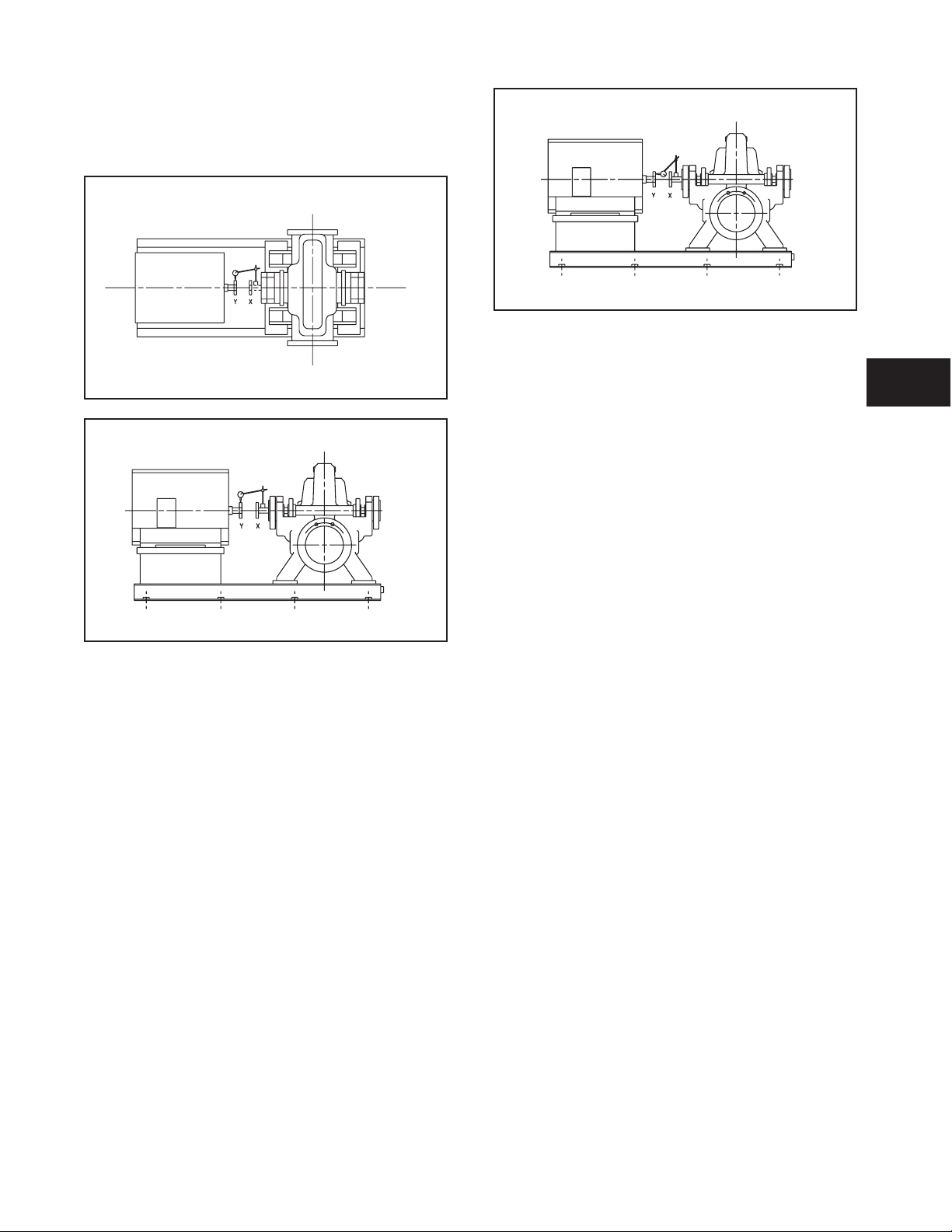

1. Mount two dial indicators on the pump coupling half

(X) so they contact the other coupling half (Y) (Figs.

8 & 9).

Fig. 8

Fig. 10

Vertical Correction (Top-to-Bottom)

1. Zero indicator A at top dead center (12 o‘clock) of

coupling half Y.

2. Rotate indicators to bottom dead center (6 o‘clock).

Observe needle and record reading.

3. Negative Reading - The coupling halves are further

apart at the bottom than at the top. Correct by either

raising the driver feet at the shaft end (add shims) or

lowering the driver feet at the other end (remove

shims).

3

Fig. 9

2. Check setting of indicators by rotating coupling half

X to ensure indicators stay in contact with coupling

half Y but do not bottom out. Adjust indicators

accordingly.

MEASUREMENT

1. To ensure accuracy of indicator readings, always

rotate both coupling halves together so indicators

contact the same point on coupling half Y. This will

eliminate any measurement problems due to runout on

coupling half Y.

2. Take indicator measurements with driver feet

hold-down bolts tightened. Loosen hold down bolts

prior to making alignment corrections.

3. Take care not to damage indicators when moving

driver during alignment corrections.

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A (Angular

indicator) does not vary by more that .002 in. (.05 mm) as

measured at four points 90° apart (Fig. 10).

Positive Reading - The coupling halves are closer at

the bottom than at the top. Correct by either lowering

the driver feet at the shaft end (remove shims) or

raising the driver feet at the other end (add shims).

4. Repeat steps 1-3 until indicator A reads .002 in (.05

mm) or less.

Horizontal Correction (Side-to-Side)

1. Zero indicator A on left side of coupling half Y, 90°

from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start (3 o’clock). Observe needle

and record reading.

3. Negative Reading - The coupling halves are further

apart on the right side than the left. Correct by either

sliding the shaft end of the driver to the left or the

other end to the right.

Positive Reading - The coupling halves are closer

together on the right side than the left. Correct by

either sliding the shaft end of the driver to the right or

the other end to the left.

4. Repeat steps 1 through 3 until indicator A reads .002

in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

3420 IOM 08/09 19

Page 24

PARALLELALIGNMENT

A unit is in parallel alignment when indicator P (parallel

indicator) does not vary by more than .002 in. (.05 mm) as

measured at four points 90° apart at operating temperature.

Note the preliminary vertical cold setting criteria, Table 1.

Vertical Correction (Top-to-Bottom)

1. Zero indicator P at top dead center of coupling (12

o’clock) half Y.

2. Rotate indicator to bottom dead center (6 o‘clock).

Observe needle and record reading.

3. Negative Reading - Coupling half X is lower than

coupling half Y. Correct by removing shims of

thickness equal to half of the indicator reading under

each driver foot.

Positive Reading - Coupling half X is higher than

coupling half Y. Correct by adding shims of thickness

equal to half of the indicator reading from each driver

foot.

NOTE: Equal amounts of shims must be added to or

removed from each driver foot. Otherwise the vertical

angular alignment will be affected.

4. Repeat steps 1 through 3 until indicator P reads within

.002 in. (.05 mm) or less when hot, or per Table 1

when cold.

Horizontal Correction (Side-to-Side)

1. Zero indicator P on the left side of coupling half Y,

90° from top dead center (9 o‘clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start (3 o‘clock). Observe needle

and record reading.

3. Negative Reading - Coupling half Y is to the left of

coupling half X. Correct by sliding driver evenly in

the appropriate direction.

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

4. Repeat steps 1 through 3 until indicator P reads .002

in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

COMPLETE ALIGNMENT

A unit is in complete alignment when both indicators A

(angular) and P (parallel) do not vary by more than .002 in.

(.05 mm) as measured at four points 90 apart.

Vertical Correction (Top-to-Bottom)

1. Zero indicators A and P at top dead center (12

o'clock) of coupling half Y.

2. Rotate indicator to bottom dead center (6 o'clock).

Observe the needles and record the readings.

3. Make corrections as outlined previously.

Horizontal Correction (Side-to-Side)

1. Zero indicators A and P on the left side of coupling

half Y, 90° from top dead center (9 o'clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start (3 o‘clock). Observe the

needle, measure and record the reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

NOTE: With experience, the installer will understand

the interaction between angular and parallel and will

make corrections appropriately.

Positive Reading - Coupling half Y is to the right of

coupling half X. Correct by sliding driver evenly in

the appropriate direction.

20 3420 IOM 08/09

Page 25

ALIGNMENT TROUBLESHOOTING

Problem Probable Cause Remedy

Driver feet bolt bound.

Cannot obtain horizontal (Side-to-Side)

alignment, angular or parallel

Cannot obtain vertical (Top-to-Bottom)

alignment, angular or parallel

Baseplate not leveled properly, probably

Baseplate not leveled properly,

probably bowed.

GROUT BASEPLATE

1. Clean areas of baseplate that will contact grout. Do

not use oil-based cleaners because grout will not bond

to it. Refer to grout manufacturers instructions.

2. Build dam around foundation. Thoroughly wet

foundation (Fig. 11).

3. Pour grout through grout hole in baseplate, up to level

of dam. Remove air bubbles from grout as it is poured

by puddling, using a vibrator, or pumping the grout

into place. Non-shrink grout is recommended.

twisted.

Loosen pump hold-down bolts and slide

pump and driver until horizontal alignment is

achieved.

Determine which corner(s) of the baseplate

are high or low and remove or add shims at

the appropriate corner(s) and realign.

Determine if center of baseplate should be

raised or lowered and correct by evenly add

ing or removing shims at the center of the

baseplate.

4. Allow grout to set.

5. Fill remainder of baseplate with grout. Remove air as

before (Fig. 12).

-

3

Flange loads from the piping system, including

!

those from thermal expansion of the piping, must

not exceed the limits of the pump. Casing

deformation can result in contact with rotating parts

and result in excess heat generation, sparks and

premature failure.

Fig. 11

Fig. 12

6. Allow grout to set at least 48 hours.

7. Tighten foundation bolts.

ALIGNMENT CHECK

Re-check alignment before continuing, using methods

previously described.

PIPING

GENERAL

Guidelines for piping are given in the “Hydraulic Institute

Standards” available from: Hydraulic Institute, 30200

Detroit Road, Cleveland, OH 44145-1967 and must be

reviewed prior to pump installation.

3420 IOM 08/09 21

Page 26

A

! WARNING

s

Never draw piping into place by forcing at the flanged

connections of the pump. This may impose dangerous

strains on the unit and cause misalignment between

pump and driver. Pipe strain will adversely effect the

operation of the pump resulting in physical injury and

damage to the equipment.

1. All piping must be supported independently of, and

line up naturally with, the pump flanges.

2. Piping runs should be as short as possible to minimize

friction losses.

3. DO NOT connect piping to pump until grout has

hardened and pump and driver hold-down bolts have

been tightened.

4. It is suggested that expansion loops or joints be

properly installed in suction and/or discharge lines

when handling liquids at elevated temperatures, so

linear expansion of piping will not draw pump out of

alignment.

! WARNING

s

All expansion joints should be properly supported,

anchored, and restrained. Failure to do so may result

in serious physical injury if the expansion joint fails.

5. The piping should be arranged to allow pump flushing

prior to removal of the unit on services handling

corrosive liquids.

6. Carefully clean all pipe parts, valves and fittings, and

pump branches prior to assembly.

straight pipe between the elbow and the pump suction

flange.

3. Use suction pipe one or two sizes larger than the

pump suction, with a reducer at the suction flange.

Suction piping should never be of smaller diameter

than the pump suction.

4. Reducers, if used, should be eccentric, at the pump

suction flange, with sloping side down.

5. Pump must never be throttled on suction side.

6. Suction strainers, when used, must have a net “free

area” of at least three times the suction pipe area.

7. Separate suction lines are recommended when more

than one pump is operating from the same source of

supply.

Suction Lift Conditions

1. Suction pipe must be free from air pockets.

2. Suction piping must slope upwards to pump.

3. All joints must be air tight.

4. A means of priming the pump must be provided, such

as a foot valve.

Suction Head/Flooded Suction Conditions

1. An isolation valve should be installed in the suction

line at least two pipe diameters from the suction to

permit closing of the line for pump inspection and

maintenance.

2. Keep suction pipe free from air pockets.

3. Piping should be level or slope gradually downward

from the source of supply.

SUCTION PIPING

! WARNING

s

NPSHAmust always exceed NPSHRas shown on Goulds

performance curves received with order. Reference

Hydraulic Institute for NPSH and pipe friction values

needed to evaluate suction piping.

Properly installed suction piping is a necessity for

trouble-free pump operation. Suction piping should be

flushed BEFORE connection to the pump.

1. Use of elbows close to the pump suction flange should

be avoided. There should be a minimum of two pipe

diameters of straight pipe between the elbow and

suction inlet. Where used, elbows should be long

radius.

2. If an elbow must be used at the suction flange, it must

be in the vertical position only. If an elbow must be

used in other than a vertical position, it is permissable

only by providing a minimum of two diameters of

4. No portion of the piping should extend below pump

suction flange.

5. The size of entrance from supply should be one or two

sizes larger than the suction pipe.

6. The suction pipe must be adequately submerged

below the liquid surface to prevent vortices and air

entrainment at the supply.

DISCHARGE PIPING

1. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump, this will permit inspection

of the check valve. The isolation valve is required for

priming, regulation of flow, and for inspection and

maintenance of pump. The check valve prevents

pump or seal damage due to reverse flow through the

pump when the driver is turned off.

2. Increasers, if used, should be placed between pump

and check valves.

22 3420 IOM 08/09

Page 27

3. Cushioning devices should be used to protect the

pump from surges and water hammer if quick- closing

valves are installed in system.

FINAL PIPING CHECK

After connecting the piping to pump:

1. Rotate shaft several times by hand to be sure that

there is no binding and all parts are free.

2. Check alignment, per the alignment procedure

outlined previously to determine absence of pipe

strain. If pipe strain exists, correct piping.

3

3420 IOM 08/09 23

Page 28

24 3420 IOM 08/09

Page 29

OPERATION

PREPARATION FOR START-UP ..........................25

Check Rotation ...................................25

Couple Pump and Driver ..............................25

Lubricating Bearings ................................26

Shaft Sealing ....................................27

Priming Pump ...................................29

STARTING PUMP ...................................31

OPERATION ......................................31

General Considerations...............................31

Operating at Reduced Capacity ..........................31

Operating Under Freezing Conditions .......................32

SHUTDOWN ......................................32

FINAL ALIGNMENT .................................32

PREPARATION FOR START-UP

When installing in a potentially explosive

!

environment, ensure that the motor is properly

certified.

4

4. Make sure everyone is clear. Jog driver just long

enough to determine the direction of rotation. The

rotation must correspond to the arrow on the pump

casing.

CHECK ROTATION

1. Lock out power to the driver.

! WARNING

s

Lock out driver power to prevent accidental start-up

and physical injury.

All equipment being installed must be properly

!

grounded to prevent unexpected static electric

discharge.

2. Make sure the coupling hubs are securely fastened to

the shafts.

! WARNING

s

Do not jog a coupled pump.

$

Serious injury may result if pump is run in the wrong

direction.

CAUTION

5. Lock out the power to the driver.

COUPLE PUMP & DRIVER

! WARNING

s

Lock out driver power to prevent accidental rotation

and physical injury.

1. Install and lubricate the coupling per the

manufacturer’s instructions.

The coupling used in an ATEX classified

!

environment must be properly certified.

NOTE: Pump is shipped with the coupling hubs

disconnected.

3. Unlock driver power.

3420 IOM 8/09 25

Page 30

2. Install the coupling guard (Fig. 13). Refer to the

Coupling Guard Installation and Disassembly Section

(Appendix I).

The coupling guard used in an ATEX classified

!

environment must be constructed from a

non-sparking material.

! WARNING

s

Never operate a pump without the coupling guard

installed. Personal injury will occur if the pump is run

without the coupling guard.

Leakage of process liquid may result in creating an

!

explosive atmosphere. Ensure the materials of the

pump casing, impeller, shaft, sleeves, gaskets and

seals are compatible with the process liquid.

A build up of gases within the pump, sealing system

!

and or process piping system may result in an

explosive environment within the pump or process

piping system. Ensure process piping system, pump

and sealing system are properly vented prior to

operation.

LUBRICATING BEARINGS

Bearings must be lubricated properly in order to

!

prevent excess heat generation, sparks and

premature failure.

Cooling systems such as those for bearing

!

lubrication, mechanical seal systems, etc, where

provided, must be operating properly to prevent

excess heat generation, sparks and premature

failure.

Rotate shaft by hand to ensure it rotates smoothly

!

and there is no rubbing which could lead to excess

heat generation and or sparks.

Ensure that pump and systems are free of foreign

!

objects before operating and that objects cannot

enter the pump during operation. Foreign objects in

the pumpage or piping system can cause blockage of

flow which can result in excess heat generation,

sparks and premature failure.

Fig. 13

$

Pumps are shipped without oil.

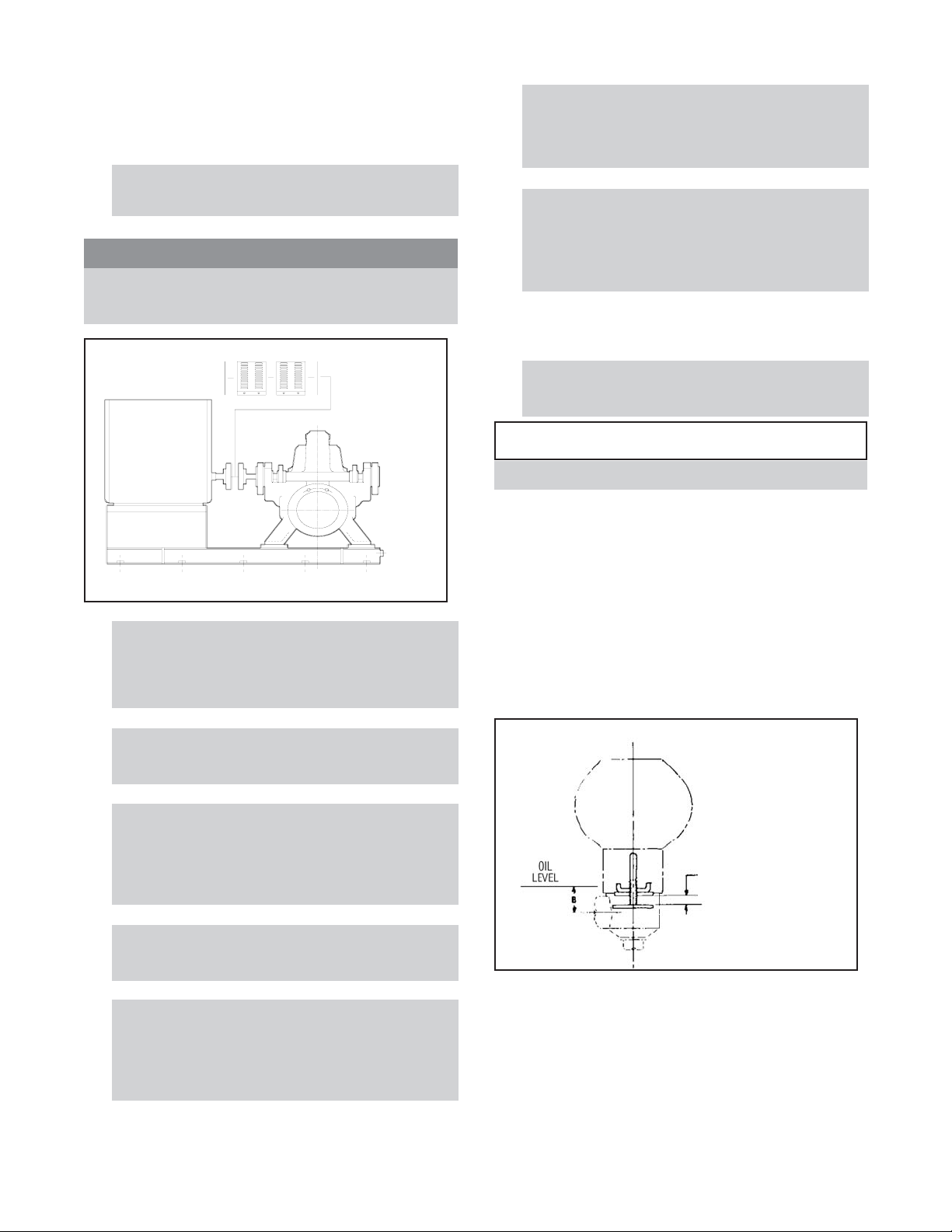

Oil Lubrication: Oil lubricated pumps are not lubricated at

the factory. Constant level oilers are supplied with oil

lubricated pumps. The oiler can be found in the box of

fittings that accompanied the pump during shipment. The

oiler was adjusted to maintain the proper oil level before

leaving the factory. The adjustment should be checked in

case the setting was disturbed during shipment. See Figure

14. The correct dimensions for A and B are given in Table

2. Fill the bearing housing with oil using the oil bottle.

Continue to refill the oil bottle until oil stops draining from

the oiler into the housing. See Table 4 for recommended

oil.

CAUTION

Instructions

1. Remove adjustment

assembly from oiler.

2. Adjust bars to dim. "A".

3. Lock in position.

4. Replace adjust. assem. in

oiler

A

Do not insulate bearing housings as this can result

!

in excess heat generation, sparks and premature

failure.

Check for magnetism on the pump shaft and

!

degauss the shaft if there is any detectable

magnetism. Magnetism will attract ferritic objects to

the impeller, seal and bearings which can result in

excess heat generation, sparks and premature

failure.

Pure/Purge Oil Mist: For pure oil mist, connect the oil

mist system according to the manufacturer's

recommendations. For purge oil mist, connect the oil mist

system per the manufacturers instructions. Fill the pump

with oil as detailed for oil lubrication above. In both cases,

refer to the pump dimensional drawing for the location of

the oil mist connections to the bearing housings. See Table

2 for oil bottle settings and Table 4 for recommended oil.

Fig. 14

26 3420 IOM 8/09

Page 31

Group Sizes

Table 2

Oil Settings - Inches (mm)

Flood Oil Ball / Ring Oil Ball / Ring Oil Roller

Oiler Size “A” in (mm) “B” in (mm)

SX

MX 18 x 20-20

M

M

Modified

- 18 x 20-24

L 24 x 30-32

LDS

XL

XXL 36x42-52

12 x 14-15

16 x 18-17H

16 x 18-30

18 x 20-30

20 x 24-24

20 x 24-30

20 x 24-28

30 x 30-31

30 x 30-38

30 x 36-42

20x30-42

Grease Lubrication: Pumps are shipped with grease

installed, sufficient for 2,000 hours operation. It is

recommended that additional or replacement lubrication be

added after every 2,000 hours or at three month intervals.

The lubricant should be renewed in the housings at least

once each year. See Table 5 (p. 35) for recommended

greases.

If the pump is put into operation after a prolonged

shut-down, flush out the bearing housings with a light oil

to remove any contaminants. During flushing, rotate the

shaft slowly by hand. Finally, flush the bearing housing

with the proper lubricating oil to ensure oil quality after

cleaning.

#3

4 OZ.

#3

4 OZ.

#10

16 OZ.

#10

16 OZ.

#10

16 OZ.

#10

16 OZ.

#10

16 OZ.

#10

16 OZ.

#10

16 OZ.

27/32 (21.4) 3/4 (19)

27/32 (21.4) 3/4 (19)

9/16 (14.3) 1/2 (12.7)

27/32 (21.4) 3/4 (19)

27/32 (21.4) 3/4 (19)

7/8 (22.2) 13/16 (20.6)

9/16 (14.3) 1/2 (12.7)

9/16 (14.3) 1/2 (12.7)

3/8 (9.7) 7/16 (11.1)

the box of fittings shipped with the pump and must be

installed before start-up.

Installation of Packing:

1. Carefully clean the stuffing box bore.

2. Twist the packing just enough to get it around the

shaft (Fig 15).

4

! WARNING

s

Operation of the unit without proper lubrication will

cause bearing failure and pump seizure.

SHAFT SEALING

Packed stuffing boxes are not allowed in an ATEX

!

classified environment.

Packed Stuffing Box: Pumps are shipped without packing,

lantern ring, or split gland installed. These are included in

3420 IOM 8/09 27

3. Insert packing, staggering the joints in each ring by

90° degrees.

Fig. 15

Page 32

4. Use a wooden split bushing to properly seat the first

two rings of packing. See Fig 16.

Fig. 16

5. The stuffing box arrangement in order of installation

is: two packing rings, lantern ring, then three packing

rings. See Fig. 17.

pressure for clean pumpages. For an abrasive pumpage, the

2

flush water pressure should be 30-50 psi (2.1-3.5 kg/cm

)

above the suction pressure.

NOTE: A product flush can be used if a clean

pumpage exists.

NOTE: Most packing requires lubrication. Failure to

lubricate the packing may shorten the life of the

packing and the pump.

Fig. 17

$

CAUTION

Follow instructions to ensure the lantern ring is

located at the flushing connection. Otherwise, no

flush will be obtained.

6. Install the gland halves. Bolt the gland halves together

and mount on gland studs. Tighten gland nuts.

Connection of Sealing Liquid: If the stuffing box pressure

is above atmospheric pressure and the pumpage is clean,

normal gland leakage of 40-60 drops per minute is usually

sufficient to lubricate and cool the packing. Sealing liquid

then, is not required.

An external sealing liquid is required when:

1. Abrasive particles in the pumpage could score the

shaft sleeve.

2. Stuffing box pressure is below atmospheric pressure

due to the pump running with suction lift or when the

suction source is under a vacuum. Under these

conditions, packing will not be cooled and lubricated

and air will be drawn into the pump.

If an outside source of clean compatible liquid is required,

the pressure should be 15 psi (1.0 kg/cm

2

) above the suction

28 3420 IOM 8/09

Page 33

PRIMING THE PUMP

Never start the pump until it has been properly primed.

Several different methods of priming can be used,

depending on the type of installation and service involved.

Suction Supply Below Pump

A. Priming with a Foot Valve - With the pump installed on

a suction lift and with a foot valve at the end of the suction

line, priming can be done any of the following three ways:

Pumps must be fully primed at all times during

!

operation.

! WARNING

s

If the pump is run dry, rotating parts within the pump

may seize to non-moving parts. This may result in

serious physical injury.

Suction Supply Above Pump

When the pump is installed as shown in Fig. 18, the pump

will prime itself.

Fig. 18

Outside Supply (Fig. 19)

4

Fig. 19

1. Close the discharge valve.

2. Remove the vent plugs or open the vent valves on the

top of the pump and the two suction lobes.

1. Close the discharge valve.

2. Open the suction valve.

3. Remove the vent plugs or open the vent valves on the

top of the pump and the two suction lobes until all air

is expelled and fluid flows through the openings.

4. Replace the vent plugs or close the vent valves.

5. Start the pump and open the discharge valve.

The pump will continue to be primed for any future

starting. This method is the simplest and, particularly for

automatic operation, the safest. A float switch in the

suction reservoir can be arranged to stop the pump, should

the liquid supply fall below minimum levels.

3. Open the valve in the priming supply line. Fill the

pump until all air is expelled and fluid flows through

the vents.

4. Replace the vent plugs or close the vent valves and

close the valve in the priming supply line.

5. Start the pump and open the discharge valve.

The pump will continue to be primed for any future

starting.

3420 IOM 8/09 29

Page 34

Priming with a Separate Hand or Manually Controlled

Priming Pump (Fig. 20)

Fig. 20

1. Close the discharge valve.

2. Open the valve in the priming line.

Priming by Bypassing Around the Discharge Check

Valve (Fig. 21)

NOTE: This method can only be used when there is

liquid under some pressure in the discharge line. The

original prime must be effected from some outside

source.

Fig. 21

3. Exhaust the air from the pump and the suction piping

until water flows from the priming pump.

4. Close the valve in the priming line.

5. Shutoff the priming pump.

6. Start the pump and open the discharge valve.

1. Close the discharge valve.

2. Remove the vent plugs or open the vent valves on the

top of the pump and the two suction lobes.

3. Open the valve in the check valve bypass line.

4. Exhaust the air from the pump and the suction piping

until water flows from vent connections.

5. Replace the vent plugs or close the vent valves and

close the valve in the bypass line.

6. Start the pump and open the discharge valve.

30 3420 IOM 8/09

Page 35

Priming with an Ejector (Fig. 22)

1. Close the discharge valve.

On suction lift applications, an ejector (operated by steam,

compressed air, or pressurized water) connected to the top

of the casing (priming or vent connection) can be used to

remove air from the casing and suction line, thus priming

the pump.

Fig. 22

STARTING PUMP

1. Make sure the suction valve and any recirculation or

cooling lines are open.

2. Open the ejector supply valve in the steam, air, or

water line, valve “E”.

3. Open the priming isolation valve, “S”.

4. Once the unit is primed, close the priming isolation

valve, “S”.

5. Close the ejector supply valve, “E”.

6. Start the pump and open the discharge valve.

4

4. Slowly open the discharge valve until the desired flow

is obtained.

2. Fully close or partially open the discharge valve as

dictated by system conditions.

3. Start the driver.

$

Immediately observe the pressure gauges. If the

discharge pressure is not quickly attained, stop the

driver, reprime, and attempt to restart.

CAUTION

OPERATION

GENERAL CONSIDERATIONS

Always vary the capacity by regulating the discharge valve.

NEVER throttle the flow from the suction side.

The driver may overload if the pumpage specific gravity

(fluid density) is greater than originally stated or if the flow

rate is exceeded.

Always operate the pump at or near the rated conditions to

prevent damage resulting from cavitation or recirculation.

$

Observe the pump for vibration levels, bearing

temperature, and excessive noise. If normal levels are

exceeded, shut down the pump and troubleshoot the

problem.

CAUTION

OPERATING AT REDUCED CAPACITY

! WARNING

s

DO NOT operate the pump below the minimum rated

flow or with the suction and/or discharge valves closed.

These conditions may create an explosive hazard due to

vaporization of the pumpage. This can quickly lead to

pump failure and physical injury. Refer to Appendix II

for the pump's minimum flow.

Damage occurs from:

1. Increased vibration levels - This affects the bearings,

stuffing box, and mechanical seal (if supplied).

3420 IOM 8/09 31

Page 36

2. Increased radial loads - Increases stress on the shaft

and increases loads on the bearings.

3. Heat build up - Vaporization of the pumpage may

cause the rotating parts to score or seize.

4. Cavitation - Damages the internal surfaces of the

pump.

SHUTDOWN

OPERATING UNDER FREEZING

CONDITIONS

Exposure to freezing conditions, while the pump is idle,

could cause the liquid to freeze and damage the pump.

Liquid inside the pump should be drained. Liquid inside

cooling coils, if supplied, should also be drained.

1. Slowly close the discharge valve.

2. Shut down and lock out the driver to prevent

accidental rotation.

! WARNING

s

Lock out driver power to prevent accidental rotation

and physical injury.

FINAL ALIGNMENT

1. Run the unit under actual operating conditions for a

sufficient length of time to bring the pump and driver

up to the normal operating temperature.

! WARNING

s

When handling hazardous and/or toxic fluids, proper

personal protective equipment should be worn. If the

pump is being drained, precautions must be taken to

prevent physical injury. The pumpage must be handled

and disposed of in conformance with the applicable

environmental regulations.

2. Check the alignment while the unit is at the normal

operating temperature per the alignment procedure in

Section 3.

3. Reinstall the coupling guard. Refer to the coupling

guard instructions in Appendix I.

32 3420 IOM 8/09

Page 37

PREVENTIVE MAINTENANCE

GENERAL COMMENTS ...............................33

MAINTENANCE SCHEDULE ............................33

MAINTENANCE OF BEARINGS ..........................34

Oil Lubricated Bearings ..............................34

Grease Lubricated Bearings ............................35

Bearing Removal ..................................36

MAINTENANCE OF SHAFT SEALS ........................37

Mechanical Seals ..................................37

Packed Stuffing Box ................................37

TROUBLE SHOOTING ................................38

GENERAL COMMENTS

A routine maintenance program can extend the life of your pump. Well maintained equipment

will last longer and require fewer repairs. You should keep maintenance records. This will help pinpoint

potential causes of problems.

The preventive maintenance section must be adhered to in order to keep the applicable ATEX classification of the

!

equipment. Failure to follow these procedures will void the ATEX classification for the equipment.

MAINTENANCE SCHEDULE

INSPECTION INTERVALS

Inspection intervals should be shortened appropriately if

the pumpage is abrasive and/or corrosive,

or if the environment is classified as potentially

!

explosive.

ROUTINE MAINTENANCE

Bearing lubrication

•

Seal Monitoring

•

Vibration Analysis

•

Discharge Pressure Monitoring

•

ROUTINE INSPECTIONS

Check the level and the condition of the oil

•

Check for unusual noise, vibration, and bearing

•

temperatures

Inspect the pump and piping for leaks

•

Check the seal chamber/stuffing box leakage

•

Mechanical Seal - There should be no leakage.

•

Packing - Excessive leakage requires adjustment

•

or possible packing replacement. Refer to sec

tion 4: Operation, for packing gland adjustment.

-

5

Temperature Monitoring

•

3420 IOM 8/09 33

Page 38

THREE MONTH INSPECTIONS

Check foundation and hold-down bolts for tightness.

•

If the pump has been left idle, check the packing.

•

Replace, if required.

Oil should be changed every three months (2,000 hrs)

•

or more often if there are any adverse atmospheric

conditions or other conditions that may contaminate

or break-down the oil. Change the oil whenever it

appears cloudy or contaminated.

MAINTENANCE OF BEARINGS

Bearings must be lubricated properly in order to

!

prevent excess heat generation, sparks and

premature failure.

OIL LUBRICATED BEARINGS

! WARNING

s

Pumps are shipped without oil. Oil lubricated bearings

must be lubricated at the jobsite.

Change the oil after 200 hours for new bearings.

Thereafter, change the oil every 2,000 hours or three

months, whichever comes first.

Check the shaft alignment. Re-align if required.

•

ANNUAL INSPECTIONS

Check the pump capacity, pressure, and power. If the

•

pump performance does not satisfy your process

requirements and your process requirements have not

changed, the pump should be disassembled,

inspected, and the worn parts replaced. Otherwise, a

system inspection should be done.

Ring oil or flood oil lubricated anti-friction bearings are

standard on all model 3420 pumps. Oil lubricated pumps

are supplied with oilers which maintain a constant oil level

in the bearing housings. Each oiler should be installed and

the pump lubricated as follows:

1. Check the oiler adjustment prior to installing the oiler,

refer to Table 2 for the proper oiler setting.

2. Install one oiler in each bearing housing.

$

Do not fill the bearing housings with oil through any

connection other than the oiler connection. This can

result in an improper oil level which may shorten the

life of the bearings and cause damage to the pump.

!CAUTION

Bearing

Arrangement

Flood Oil Ball Bearing

Ring Oil Ball Bearing

Ring Oil Roller Bearing

Table 3

Bearings and Oil Requirements

Oil Volume Required

Group Sizes

Bearing Size

(per each housing)

Thrust Radial mL pints

SX

MX 18 x 20-20 7316 6316

M

M (modified) 20 x 24-28 7321 6321 1350 2.85

-

L 24 x 30-32 22226 1700 3.60

LDS

XL

XXL 36x42-52 22240 4350 9.2

12 x 14-15

16 x 18-17H radial = 580 radial = 1.23

16 x 18-30

18 x 20-30

20 x 24-24

20 x 24-30

18 x 20-24 7318 6318 620 1.32

30 x 30-31

30 x 30-38

30 x 36-42

20x30-42

7313 6313

7321 6321 1170 2.47

22228 1720 3.64

22230 1350 2.85

thrust = 850 thrust = 1.80

thrust = 1350 thrust = 2.85

radial 857 radial = 1.81

34 3420 IOM 8/09

Page 39

3. Fill each oiler bottle with oil and replace the oiler

bottle in its housing. The oil will drain into the

bearing housing. Several refills will be required. Oil

will be at the proper level in the housings when oil

remains in the bottle. Do not fill the bearing housings

with oil through any other bearing housing

connection. Refer to Table 2 (p. 27) for setting and

Table 3 for volume.

A high quality turbine oil with rust and oxidation inhibitors

should be used. For the majority of operational conditions,

bearing temperatures will run between 120°F (50° C) and

180° F (82° C). In this range, an oil of ISO viscosity grade

68 at 100° F (40° C) is recommended. If bearing

temperatures exceed 180° F (82° C) use ISO viscosity

grade 100. See Table 4 for oil requirements.

Some acceptable lubricants are:

Table 4

Lube Oil Requirements

Exxon Teresstic EP 68

Mobil DTE 26 300 SSU

Mobil

Sunoco Sunvis 968

Royal Purple

o

@ 100

F (38oC)

SYNFILM ISO VG 68

Synthetic Lubricant

For most operating conditions, a lithium based mineral oil

grease of NGLI consistency No. 2 is recommended. This

grease is acceptable for bearing temperatures of 5° Fto

230° F (-15° Cto110° C). Bearing temperatures are

generally 20° F (18° C) higher than the bearing housing

outer surface temperature. See Table 5 for acceptable

greases.

Table 5

Lubricating Grease Requirements

NGLI consistency 2

Mobil Mobilux EP2

Exxon Unirex N2

Sunoco Multipurpose EP

SKF LGMT 2

$

Never mix greases of different consistency (1 or 3 with

NGLI 2) or different thickener. For example, never

mix a lithium based grease with a polyurea based

grease.

NOTE: If it is necessary to change the grease type or

consistency, the bearings must be removed and the old

grease removed.

!CAUTION

5

GREASE LUBRICATED BEARINGS

Grease lubricated bearings are lubricated at the

factory. Regrease the bearings every 2,000 operating hours

or every three months, whichever comes first.

NOTE: When regreasing, there is a danger of

impurities entering the bearing housing. The grease

container, the greasing device, and the fittings must be

clean.

To grease the bearings:

1. Remove relief plugs on the bearing end covers.

2. Insert grease through the grease fittings while the

shaft is rotating, until grease appears through the

relief plug holes.

3. Operate the unit for approximately 30 minutes with

the relief holes open to prevent overgreasing. After 30

minutes, replace the relief plugs.

NOTE: The bearing temperatures usually rise after

regreaseing due to an excess supply of grease.

Temperatures will return to normal after the pump has

run and purged the excess grease from the bearings.

This usually takes two to four hours.

3420 IOM 8/09 35

Page 40

BEARING REMOVAL

Ball Bearings

A puller, such as the one shown in Figures 23 and 24,

should be used. The puller bar must be square with the end

of the shaft at all times in order to keep even pressure on

the outer circumference of the bearing. The puller screw

should be tightened steadily to enable the bearing to slide

smoothly off the shaft. Do not damage the end of the shaft.

Fig. 23

Fig. 25

Fig. 26

Fig. 24

On the SX/MX units, the bearing housings slide off the

bearings and the puller, such as the one shown in Figures

25 and 26, should be used. This type of puller applies force

directly against the bearing itself. The puller bar must be

square with the end of the shaft at all times and the puller

screw should be tightened steadily to enable the bearings to

slide smoothly off the shaft. Do not damage the end of the

shaft.

Roller Bearings

1. Screw the adapter sleeve removal nut (furnished in the

box of fittings which accompanied the pump) onto the

adapter sleeves (item 521). Tightening the nut will

"jack" the sleeves out from under the inner race of the

bearings.

Fig. 27

2. Slide the adapter sleeves and bearings off of the shaft

and protect them from contamination. Unscrew the

adapter removal nut and store it for future use.

36 3420 IOM 8/09

Page 41

MAINTENANCE OF SHAFT SEALS

MECHANICAL SEALS

When mechanical seals are furnished, a manufacturers

reference drawing is supplied with the data package. This

drawing should be kept for future use when performing

maintenance and adjusting the seal. The seal drawing will

also specify required flush liquid and tapped connections.

The seal and all the flush piping must be checked and

installed as needed, prior to starting the pump.

The mechanical seal must have an appropriate seal

!

flush system. Failure to do so will result in excess

heat generation and seal failure.

Leakage of process liquid may result in creating an

!

explosive atmosphere. Follow all pump and seal

assembly procedures.

The life of a mechanical seal depends on various factors

such as cleanliness of the liquid handled and its lubricating

properties. Due to the diversity of the operating conditions

it is, however, not possible to give definite indications as to

its life.

! WARNING

s

Never operate the pump without liquid supplied to the

mechanical seal. Running a mechanical seal dry, even

for a few seconds, can cause seal damage and must be

avoided. Physical injury can occur if the mechanical

seal fails.

The mechanical seal used in an ATEX classified

!